Essential dynamics 3d printer

DT60 Industrial 3D Printer | Dynamical 3D

DT60 Industrial 3D Printer | Dynamical 3DSkip to content

INDUSTRIAL 3D PRINTER LARGE PRINT VOLUME AFFORDABLE TECHNOLOGY 4 PRINTING MODES PROFESSIONAL TOOLLeader in technical solutions for industrial processes.

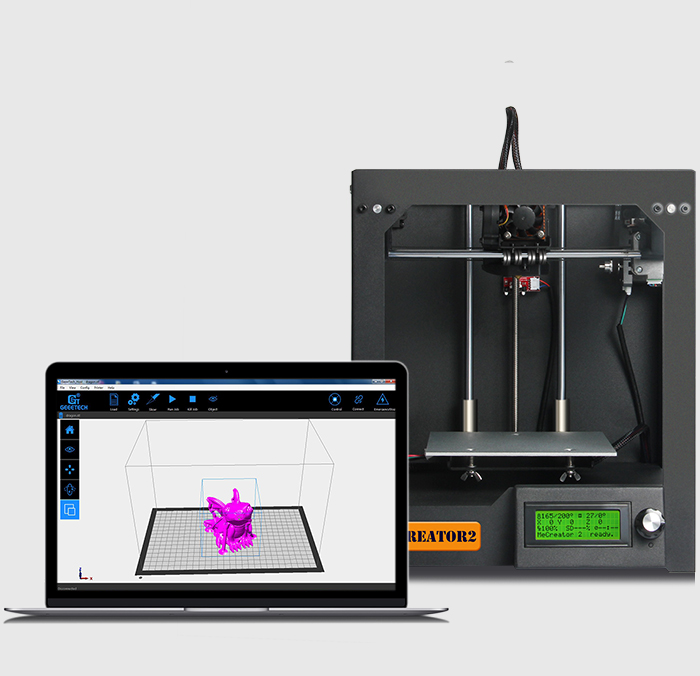

DT60 is an innovative, versatile and powerful 3D printer that represents the advance of FFF technology. Some features that will boost the concept of productive processes.

Technical Characteristics

| Print volume 600 x 450 x 450 mm |

| Printer size 1265 x 780 x 1725 mm |

| Precision Z axis: 1,25 microns |

| Precision XY axis: 7,5 microns |

| Max. extruder temperature 500ºC |

| Max. bed temperature 120 ºC |

| Nozzle diameter 0,6 mm |

| Other available diameters 0,2 / 0,4 / 0,8 / 1 / 1,2 mm |

| Double filament load |

| Heated filament feeder |

| Jam detection |

| End of filament detection |

| Printing recovery system |

| Liquid refrigeration |

| Double tempered glass |

| Base fixed by vacuum |

| Great printing speed |

| Positioning controlled by encoder |

| Double independent extruder |

| 4 printing modes : SINGLE, DUAL, TWIN, REFLEX |

| 220 – 240 V, 50-60 Hz |

| Maximum consumption 3 kW/h |

| 7” LCD touch screen |

| Remote monitoring |

| Conectivity: ethernet, USB |

| UPS Accomodation |

| MMS System – Modular maintenance system |

We have all these materials characterized and ready to print with Simplify 3D profiles

Frequently Asked QuestionsCan I print a 3rd party material?

We recommend to use our own Dynamical Materials because we test them and characterized them in simplify3D profiles, but you can create your own profiles for new 3rd party materials.

How can I manage the 4 printing modes?

We have Simplify3D profiles for print with 2 extruders in 4 different modes. You only need to select the desired profile and start to print.

Can I print PEEK with the DT60 industrial 3D printer?

The nozzle reach the temperature but it won’t print properly due to the chamber temperature. We have the HT45 3D printer to print the most difficult to print materials like PEEK or PEI.

Go to Top

This website uses cookies to improve your experience. We'll assume you're ok with this, but you can opt-out if you wish.AcceptReject Read More

3D Printing Service that Meets Your Needs - Rapid Prototyping

3D Printing Service that Meets Your Needs - Rapid Prototyping | Dynamical 3DSkip to content

ENGINEERING SERVICE

INDUSTRIAL 3D DESIGN

ARTISTIC 3D DESIGN

3D SCANNING

3D PRINTING

POSTPROCESSING

ENGINEERING SERVICE

If you were looking for a company to develop and industrialize your project (automatic machines, appliances, tools, Industry 4. 0, etc …), you have found it.

0, etc …), you have found it.

Dynamical 3D offers our clients the opportunity to reduce the development time of a new product and improve innovation cycles by using the most innovative 3D scanning and software methods, as well as highly qualified personnel with the most extended 3D design software in the market.

Dynamical 3D offers multiple customized solutions:

Comprehensive design: Our technical office will shape your product. We provide experience to optimize aesthetics, facilitate its manufacture and improve the performance of the final product.

Redesign: Obtaining 3D files of a product of which we have no plans.

Discontinued spare parts: There is old machinery on the market in perfect conditions of use of which spare parts are no longer manufactured because the manufacturer has been extinguished or simply because it has been discontinued. Reverse engineering reduces many hours of work and is essential to obtain these spare parts.

We offer solutions taking into account the entire process of creating a product

DESIGN AND ENGINEERING

PRODUCTION

We offer design solutions in a variety of applications: from simple designs to complex assemblies.

INDUSTRIAL 3D DESIGN

Dynamical 3D throughout its large experience in the additive manufacturing environment is able to offer the best service using the most advanced software for industrial design and which allow us to make everything real. Thanks to our vast experience we are specialist in different processes involved on the 3d Printing environment:

- Modelling

- Complex surfaces

- Assembly

- Sheet metal design

- Fluid conducting engineering

Ask us if you want to make real a design from an idea or improve the existing design

ARTISTIC 3D DESIGN

Other of the services offered by Dynamical 3D is 3D modelling, artistic rendering and the preparation to 3D print it. Conceptual 3D design specially focused on idea contests, movies, advertising, etc. Dynamical 3D is a company formed by a high experienced team in the decoration and artistic field.

Conceptual 3D design specially focused on idea contests, movies, advertising, etc. Dynamical 3D is a company formed by a high experienced team in the decoration and artistic field.

- Artistic 3D Design oriented to 3D printing

- Museums and heritage conservation

- Publicity and window dressing

- Trophies

- Cinema elements

- Interior dressing

3D SCANNING

Dynamical 3D offers scanning services in order to complete an integral service on the 3D environment. The inspection of industrial parts, replacement of discontinued parts when spare parts are not available or the creation of architectural models and heritage, are some of these applications.

We have different types of scanner depending on the piece to be digitized (size, material, interior / exterior, resolution or precision). With Dynamical 3D, the customer can count on a department of metrology and reverse engineering equipped with the latest technologies.

The main fields we cover are:

- Geometric and dimensional analysis

- Calibration and certification of tools

- Inspection of first series articles

- Inspection during the manufacturing process.

- Contactless inspection

- Art and heritage

Our engineering service offers:

- 3D scanning for replicas

- Virtual backups of artistic works

- Modification of 3d files

- Extensions and reductions

- Model symmetry

- Preparation of 3D printing files

3D PRINT

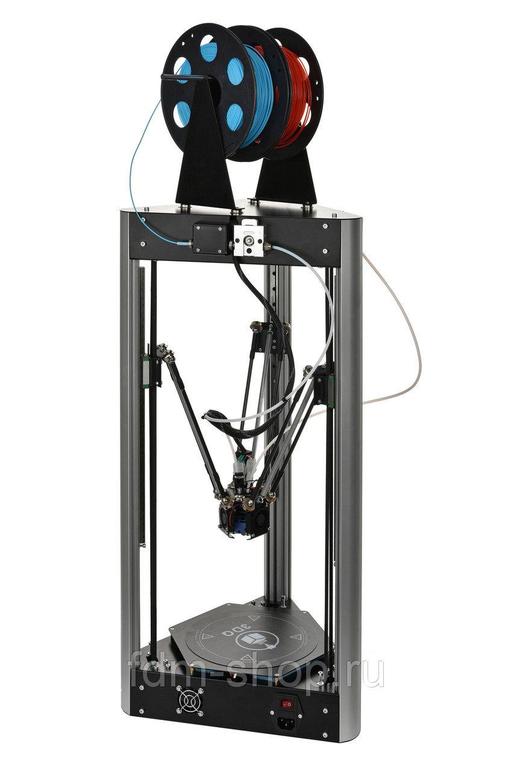

Dynamical 3D is a large format 3D printer manufacturer, an advantage that our 3D printing service takes advantage of, since we have a print farm where we can make prototypes, short runs and medium runs using FFF technology (Fused Filament Fabrication).

In addition to our own printers, we offer different printing technologies, being able to choose the most appropriate in each case.

We work with a wide range of technical materials, to meet the demands of each piece.

Fast and functional prototypes, custom parts, short and medium series manufacturing. Any project that requires 3D printing can be done.

Wind tunnel prototype

Wind tunnel prototype

Aeration nozzle 3 outputs

PEEK CARBON gear

PEEK CARBON gear

PA12 Laser Sintered Polyamide

PEKK fixture

Functional parts printing

Dynamical 3D is the first Production Partner in SpainCarbon® is revolutionizing manufacturing. Companies from Adidas to Ford are making possible impossible products every day. Whether it’s a new product or the improvement of an existing one, Carbon® brings you closer to the market faster than ever.

With our patented Digital Light SynthesisTM (DLSTM) technology, only Carbon® is capable of delivering end-use parts with industrial materials and an optimal surface finish. Make a piece or a million, the only limit is your imagination.

Make a piece or a million, the only limit is your imagination.

In our experience we have worked with several industrial sectors and we can recommend the most appropriate materials for your application, having many of them as demanding certifications as the FDA for dental and medical materials.

One of our main fields of activity is the automotive sector for which we have EPX82 material, resistant to all kinds of fluids, salt fog, and specially formulated to comply with specific automotive certifications.

We have made 3D prints in different technologies (FFF, DLS, SLS, …) for all kinds of industrial sectors: food, automotive, electronics, steel, aeronautics, petrochemicals, consumer objects. From the prototype to the final production, we are able to print in many applications.

POSTPROCESSINGThese types of treatments give a different and quality touch that goes beyond the possibilities offered by 3D printing technology, thus seeking greater customization giving a personal finish to the final piece.

It must be taken into account that some of the treatments we offer are, to a greater or lesser extent, a removal of material in the piece, something that can affect the dimensional quality of the piece, so it is important to choose the right one. In Dynamical 3D we have the experience that will help you choose the one that best suits your needs.

Chrome plated

Hydropainting

Polished

Painted

Acetone steam

Go to Top

This website uses cookies to improve your experience. We'll assume you're ok with this, but you can opt-out if you wish.AcceptReject Read More

3d printers. 2012 Achievement Review / Habr

Molecules and planes, weapons and blood vessels, prosthetics and integrated circuits, food and buildings, a cure for cancer, an ear, a beak and a rocket engine, all this was printed in 2012 on 3d printers.

This article is a partial translation of 3D Printing in 2012: Year In Review.

Pictures (70 pieces) are clickable - a reference to the source.

January

3D Systems completes acquisition of Z Corp and Vidar for $135.5 million in cash.

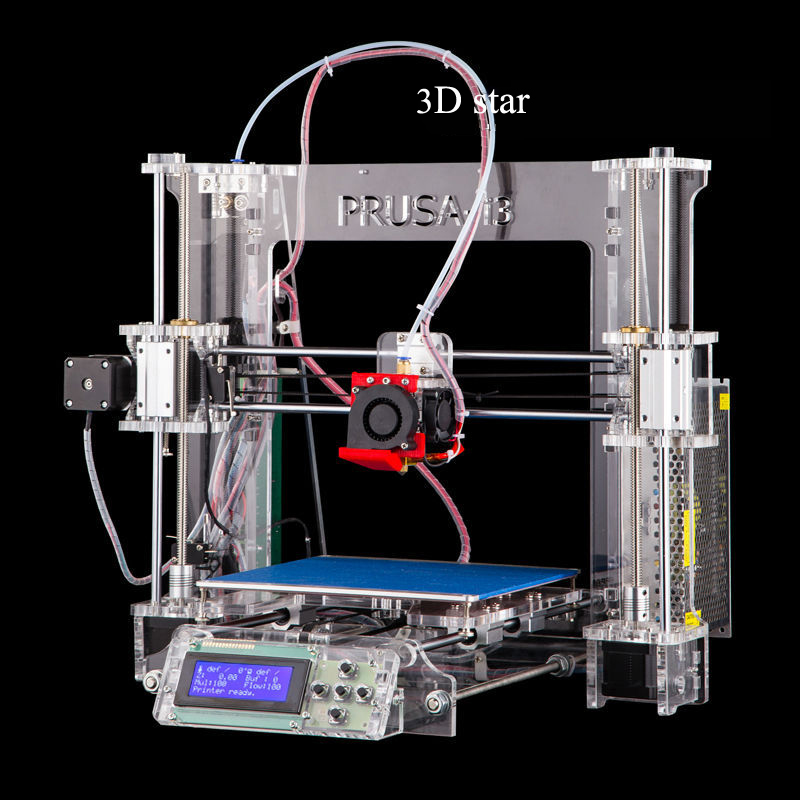

Makerbot announces the Replicator.

“3D Systems announces Cube 3D at CES2012.

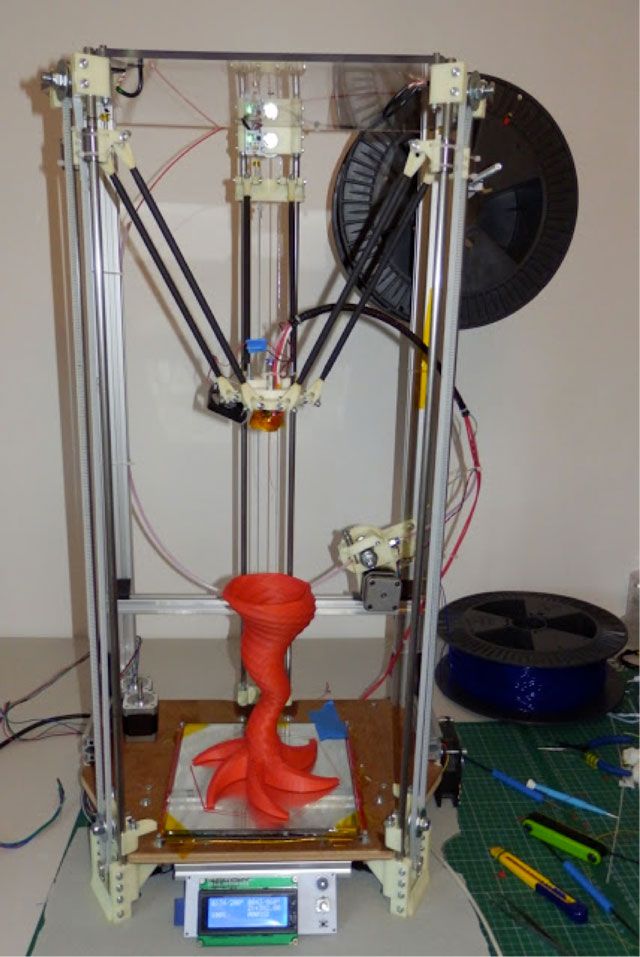

Essential Dynamics introduced the 3d food printer to the public and announced that they are accepting orders for such printers.

Pirate Bay has opened a new section with 3d models for free download and printing on 3d printers.

Factory on wheels.

For a whole month, Alex Hornstein and Bilal Ghalib traveled across America with four 3D printers in the trunk. They started the Pocket Factory project (pocket factory) with the aim of developing and selling goods made on cheap 3d printers.

February

Fifteen-year-old Laura played a 3D printed violin on CNN.

This is one of three violins of this type, but only this one is fully stringed. Laura, a student at South West Music School, made her premiere performance on the CNN news channel. This amazing performance perfectly illustrates the potential of 3D printing, which can be used to recreate almost anything.

Laura, a student at South West Music School, made her premiere performance on the CNN news channel. This amazing performance perfectly illustrates the potential of 3D printing, which can be used to recreate almost anything.

An 83 year old woman received a 3D printed prosthesis.

Belgian and German scientists have successfully implanted a 3D printed lower jaw.

Scientists have created a dinosaur robot using a 3d printer.

For the first time in 150 years, paleontologists are able to test hypotheses about how dinosaurs and other prehistoric animals moved and interacted with their environment.

3d printed human tissue for drug testing.

A San Diego "bioprinting" company has used 3D bioprinting to create a variety of body tissues from human cells.

The world's largest museum will go digital thanks to 3d scanners and 3d printers.

The world's largest museum and research institute, the Smithsonian, has created a reproduction of the statue of Thomas Jefferson using a high-tech scanner and 3D printer.

March

General Electric Co invests in manual labor labs for ordinary people.

General Electric Co launched the GE Garages project, manufacturing craft centers equipped with laser cutters, 3d printers, injection molds. Visitors will be able to learn the basics of prototyping and the manufacturing process.

Sensation: High-speed 3d printer with nano-precision.

The Vienna University of Technology has announced a major breakthrough in 3D printing technology: it is now possible to print 3D objects in incredible detail using "two-photon lithography".

7000 pieces 3d printed for The Pirates! In an Adventure with Scientists!

April

The MIT team used nano-robots to reproduce rough 3d objects.

MIT developers at Distributed Robotics Laboratory (DRL) have demonstrated "smart sand", nano-format robots equipped with the simplest processors.

Stratasys and Objet have agreed to the merger. The total cost is 1.4 billion dollars.

The total cost is 1.4 billion dollars.

Man vs 3d printer.

The battle between a human and a 3d printer: create an object with your own hands or draw on a computer and print it on a 3d printer?

Hobbyists 3D print circuit boards.

May

Fujitsu has proposed a technology that reduces design time by 90%.

The US government has launched a $60 million education and research program - a new 3d printing institute.

Printing spare parts for military equipment - F-35 Joint Strike Fighter.

Smart bandage.

University of Illinois researchers have developed a wound healing bandage.

DreamVendor is an interactive 3D printing station at Virginia Tech.

Students can now print prototypes of their projects. The station works like any other vending machine on the street.

DARPA creates new technologies through crowdsourcing.

The Defense Advanced Research Projects Agency (DARPA) announced a $3. 5 million investment in TechShop as part of DARPA's new Adaptive Vehicle Make to "create a factory for rapid design and reconfiguration of manufacturing capabilities to support the production of a wide range of military vehicles."

5 million investment in TechShop as part of DARPA's new Adaptive Vehicle Make to "create a factory for rapid design and reconfiguration of manufacturing capabilities to support the production of a wide range of military vehicles."

June

The world's first 3D printed floating humanoid robot.

Researchers at the Tokyo Institute of Technology have developed a robot that can mimic a swimmer's movements to measure water resistance. This robot is named

SWUMANOID (Swimming Humanoid) is the first robot designed exclusively for swimming.

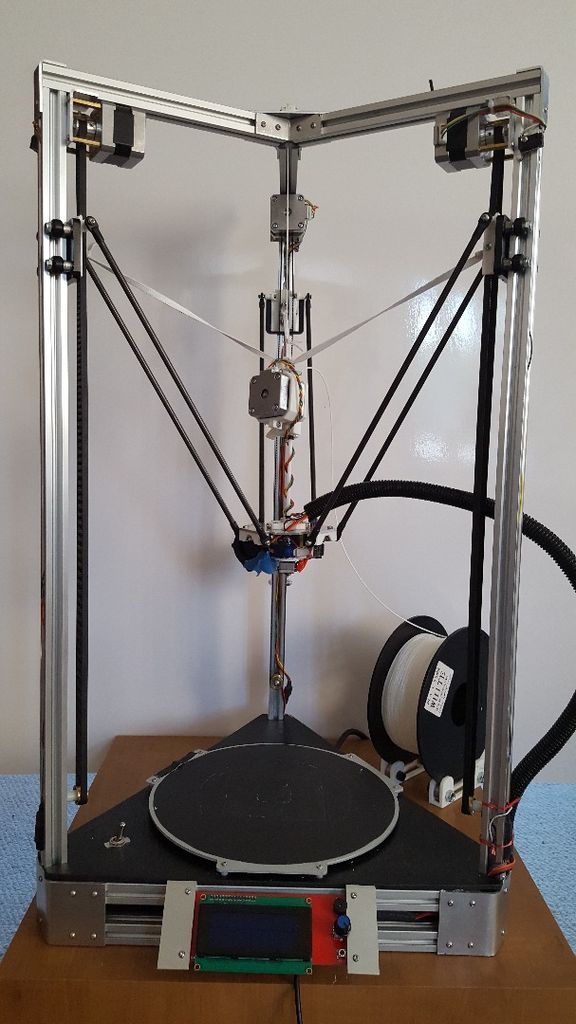

The first 3d printer assembled by children.

The School in Geldermalsen,NL gave the kids challenging projects to teach them how to handle challenges. One of the tasks was to build an Open Source 3D printer.

Startup Shapeways raised $6.2 million in funding.

Users upload files via the Internet, and the company prints them on 3d printers from various materials. By June 2012, Shapeways had printed and sold over a million items.

By June 2012, Shapeways had printed and sold over a million items.

Record: Objet broke the barrier of 100 materials.

Objet has expanded its range of materials to 107, including 39 new "digital materials" for Objet Connex Multi-Material 3D Printing Systems

"Molecule Printing".

Personal medicine has appeared using a 3D molecular printer.

Lee Cronin, professor of chemistry at the University of Glasgow, used a 3D printer to create reagents directly in a 3D reaction matrix to initiate chemical reactions.

Researchers have developed a 3d printer to print 3d silicon micro- and nanostructures.

Researchers from KTH Microsystem Technology have demonstrated a new technology for 3D printing silicon micro- and nanostructures.

July

Penn researchers have created a vascular network in living tissue using a RepRap 3D printer and sugar.

Thus, the problem of creating a 3d structure of blood vessels was solved.

Researchers have created a new method for producing 3d aluminum composite parts.

Researchers at the University of Exeter in the UK have developed a Selective Laser Melting process to produce 3d aluminum composite parts from inexpensive metal powder.

Chinese scientists used a 3D printer to print an ear.

Dr. Yang and his team used a 3D scanner to scan a patient's ear and sent the data to a 3D printer. An hour later, the work was completed.

Airbus is working on an airplane concept built using a giant 3D printer.

The aircraft is planned to be built by 2050.

3D printing will help create the fastest car in the world.

The first 3D printed AR-15 weapon successfully passed test firing.

The creator and tester, a user with the pseudonym "HaveBlue", posted the part in the public domain on Thingiverse.

August

3D printing gave two-year-old Emma "Magic Hands".

Two-year-old Emma was born with a serious illness. The researchers used a Stratasys Dimension 3D Printer to print the plastic prototype WREX that Emma now wears at home, in prep, and during treatment.

An Israeli student built the world's largest ceramic 3D printer.

Russia is building the world's largest network of FabLabs.

America's national symbol, the bald eagle, has its beak printed.

Thiel Foundation announces meat 3D printing technology grant.

Together with Breakout Labs, they plan to apply the latest fabric developments to an edible meat prototype that can be a humane and sustainable source of animal protein for consumers around the world.

The Wiki Weapon Project raises funds through crowdfunding to develop open source 3D printed weapons.

A group of young volunteers, engineers and designers from Arkansas and Texas are using 3D printing on an unprecedented project. A group called Defense Distributed is developing a plastic civilian self-defense system, the Wiki Weapon.

“The first 3D printed racing car reached 140 km/h.

Acceleration from 0 to 100 km / h - in 4 seconds.

A giant laser 3D printer has transformed local manufacturing.

This printer is able to create complex shapes from titanium, nickel, steel, chrome, etc. The printer is about the size of a small wagon.

September

For the first time, 3D printed wheelchairs were used at the Paralympic Games.

8 players (4 men and 4 women) played basketball at the UK Summer Paralympics.

Wheelchairs have been created taking into account the individual parameters of the players.

Inventor Kai Parthy has developed a fiber for RepRap that can print wood.

LAYWOO-D3 fiber is a wood-polymer composite containing recycled wood and harmless plastic.

Recreated an ancient sea creature.

American scientists and German specialists have recreated the mollusk "Protobalanus spinicoronatus" that lived 390 million years ago.

Nanoengineers are able to print three-dimensional microstructures in seconds.

Lab-made leather goods will be on sale in the next 5 years.

According to the forecast of the bioprinting company Modern Meadow, in the next five years, leather products: bags, belts, boots, etc., created in laboratories, will be sold in supermarkets. The market is valued at $2.5 trillion.

Formlabs announces the Form 1 "consumer" 3d printer.

Funding was raised through KickStarter. The initial request was 100,000 dollars, and 3 million were raised.

October

Trying to protect things from being copied.

Shapeways opens the world's largest 3D printing factory.

The company plans to return production to New York with the help of the “Factory of the Future”.

The British government is investing 7 million euros in 3D printing technology.

Science Minister David Willetts: “We believe the new investment will help UK companies take the necessary step to create new markets and gain a competitive edge. ”

”

3d printed rocket engine.

How often do you think about printing your own rocket engine?

November

Printed by Aston Martin for James Bond.

The world's first 3d photo booth was opened in Japan.

Liver printed from stem cells.

Scottish scientists create liver tissue.

LulzBot: a 3d printer will be sent to Mars.

3D Systems is suing Formlabs and Kickstarter.

The University of Warwick has created an inexpensive conductive plastic.

Now the creation of sensors will be available to all owners of 3d printers.

December

Rifle with printed spare part broke after 6 shots.

Drag-and-Drop DNA: This 3D printer prints a cure for cancer.

Researchers at Parabon NanoLabs have begun evaluating a drug against the deadly glioblastoma brain tumor.

US congressman urges extension of gun 3D printing ban.

The main danger, according to the congressman, is that these weapons cannot be detected by a metal detector.

The first 3d shop in the Netherlands is opened.

The first 3D printing shop in the Netherlands where the customer can come and talk to the staff.

The first Protoshop 3d store is opened in France.

"Our customers are mostly from academia, design or technical design bureaus," says the store manager.

Bioprinting software.

Organovo, a creator and manufacturer of 3D printed human tissue, is working with researchers at Autodesk to develop 3D bioprinting software.

Top 100 3d printing sites in 2012.

Home 3D Food Printers

The possibilities of a 3D printer are almost endless. With its help, prostheses, weapons, vehicles and other very useful and technological objects are created. According to most films, our future is scary and wonderful at the same time. What will we see? What do we do? What will we eat? Since microwave radiation has been emitted to many of us, we have been constantly inventing new ways of cooking. Now that the world has learned about 3D printing, it is natural that this technology will be used for cooking and make this process easy, or at least more fancy. If you believe the Star Trek movie, then 3D printing will be the only way to cook food in 2,000 years.

Now that the world has learned about 3D printing, it is natural that this technology will be used for cooking and make this process easy, or at least more fancy. If you believe the Star Trek movie, then 3D printing will be the only way to cook food in 2,000 years.

Recently, we could not imagine the existence of luminous sneakers with auto-lacing, as from "Back to the Future", and today we have the opportunity to try food from the printer. Just yesterday we learned how to print on disks and photocopied our body parts, and now we are ready to eat technological cuisine.

Modern technologies have made human life much more pleasant, comfortable and easier. Now you can spend more time with your family, have a good time and just have a hobby. You can print any dish, the main thing is to calculate the proportions and add the necessary ingredients. In fact, this is the same printer in which many printed diplomas, only instead of ink it uses food ingredients.

Restaurants that only cook with 3D printers already exist! Food Ink opened in London. The owners are sure that the technology helps to save food and not produce unnecessary meals. The menu includes "Flying Caviar", "Caesar's Flowers of Life", "Mystery Shrimp" for $330.

The owners are sure that the technology helps to save food and not produce unnecessary meals. The menu includes "Flying Caviar", "Caesar's Flowers of Life", "Mystery Shrimp" for $330.

3D food printing is one of the most desirable applications for 3D printers.

In early 2012, Essential Dynamics announced the world's first 3D food printer Imagine Machine. The printer went on sale in 2012 at a price of $3,000. The second generation of food 3D printers is now available on the manufacturer's website for a price of $3795.

A unique novelty - the Foodini device is a real breakthrough in the market of electronics and home appliances. A 3D printer prints not text or objects, but real food.

There are no analogs to such a device in the world yet, so its price is very high. The printer is equipped with Android system and connected to WI-FI. The display size is 7 inches. The device allows you to download various recipes from the Internet and view them.

A food printer costs about a thousand US dollars. The smart machine is able to print pizza, pastry and bakery products. It is also possible to print complex dishes: ravioli with various fillings, for example.

The smart machine is able to print pizza, pastry and bakery products. It is also possible to print complex dishes: ravioli with various fillings, for example.

How does the machine work? All the ingredients necessary for preparing the dish are placed in special containers that will be used in the food printing process. You don't need cartridges as such. Foodini prints various dishes, but you also have to participate in the printing process. Now the developers of the model are raising funds for the full-fledged production of such machines. It takes around $100,000 to get started, and nearly half of that has already been raised.

What is the main difference between Foodini and Imagine Machine

The former is essentially a household appliance for cooking using 3D technology, and the latter uses food products in the design of the print material. There are also a number of differences in the complex systems, software and user interface.

Potential buyers of such a device are always busy people, catering companies, restaurants and confectionery cafes The developers are sure that their products will be in demand: now the layman will spend less personal time preparing complex dishes.

Moreover, cleaning the kitchen after cooking will take a minimum of time. The development of unique recipes is carried out by chefs who have several top culinary awards.

The main idea that inspired the creators of the Foodini food printer is a healthy lifestyle and adherence to the principles of proper nutrition.

Homemade food, which is prepared from natural products, affects health much better than the daily absorption of fast food and semi-finished products of dubious quality. The task of such a printer is to facilitate the process of preparing dishes such as dumplings, pizza, shaped cookies, and the like. The printer will extrude the dough onto the moving platform.

The printing technology used by Foodini is FDM, that is, materials are superimposed in layers. The liquid material is placed in five capsules, each of which can contain a different material, and it can be squeezed out with different intensity and temperature. Mass for printing can be prepared using a mixer or blender.

After printing, the dish can be heat-treated: pizza will only need to be placed in the oven, after sprinkling with grated cheese, or dumplings, which will only need to be thrown into water and boiled. The touch screen will help you understand the printing process, which will demonstrate all the capabilities of the printer in full, as well as provide recipes for dishes that you can cook using a unique machine.

Chocolate Printer

Food is printed in layers by baking or cooling. Modern food printing allows you to work in the following areas: print with sugar syrup, print with chocolate, print pancakes or ice cream, print cheese and pasta. It is worth noting that you can print chocolates, but you will have to melt the chocolate for them yourself.

What are the models of food printers?

Digital Chocolatier : as the name suggests, the main ingredient of the capsules will be melted chocolate. It has the form of a carousel platform, with containers. The platform cools the layers of chocolate and forms a three-dimensional image or candy.

The platform cools the layers of chocolate and forms a three-dimensional image or candy.

Layer-by-layer printing with chocolate is complicated by the fact that liquid hot chocolate hardens slowly, and the figure must go through several stages of coating with melted chocolate mass. Such a car costs about 3,000 English pounds. It is called the miracle of technology Chock Edge Creator V1 .

Cornucopia : Prints dishes with multiple ingredients. The platform can both cool and warm dishes - that is, there is no need for additional preparation of printed food. The same applies to the tubes through which the mass flows.

Digital Fabricator : you put nutrients into the extruder and the mixer shapes them according to the recipe.

Cornell : Any liquid or semi-liquid product can be used. The basis is a culinary syringe.

ChefJet . Creates sweets by mixing powdered natural food coloring, alcohol and water. Printers of this type will be excellent helpers for professional bakers, confectioners and those who often work with shapes and inscriptions made of various types of chocolate. To make it easier to work with a complex apparatus, the creators have built in the recipe book The Digital Cookbook. Such a machine will be able to print chocolate sweets with the taste and smell of vanilla, mint, apples or cherries. The starting price of such a printer is about 5 thousand dollars. Advanced Model ChefJet Pro creates colorful sweets with combined flavors. The price of the device is 10 thousand dollars. The apps work on both Android and iOS systems. The user selects a recipe on the touch panel, and the printer will tell you which crushed ingredients to load into which capsule. Food printer specifications: Print area dimensions: 25.0 cm W x 16.5 cm D x 12.0 cm H. Weight: just over 10 kilograms. Touchpad: 7 inches running OC Android. Internet connection support: Wi-Fi module. Rotary glass platform: diameter 26 cm.

Printers of this type will be excellent helpers for professional bakers, confectioners and those who often work with shapes and inscriptions made of various types of chocolate. To make it easier to work with a complex apparatus, the creators have built in the recipe book The Digital Cookbook. Such a machine will be able to print chocolate sweets with the taste and smell of vanilla, mint, apples or cherries. The starting price of such a printer is about 5 thousand dollars. Advanced Model ChefJet Pro creates colorful sweets with combined flavors. The price of the device is 10 thousand dollars. The apps work on both Android and iOS systems. The user selects a recipe on the touch panel, and the printer will tell you which crushed ingredients to load into which capsule. Food printer specifications: Print area dimensions: 25.0 cm W x 16.5 cm D x 12.0 cm H. Weight: just over 10 kilograms. Touchpad: 7 inches running OC Android. Internet connection support: Wi-Fi module. Rotary glass platform: diameter 26 cm. Capsules: 5 capsules with different fillings can be placed in the printer at the same time. The printer uses only one capsule at a time. Capsules are automatically replaced. The material from which the capsule is made is at the choice of the consumer. It can be steel or safe and high temperature resistant plastic. The capacity of the capsule is a little over one hundred milligrams. The total capacity of 5 capsules is 615 ml.

Capsules: 5 capsules with different fillings can be placed in the printer at the same time. The printer uses only one capsule at a time. Capsules are automatically replaced. The material from which the capsule is made is at the choice of the consumer. It can be steel or safe and high temperature resistant plastic. The capacity of the capsule is a little over one hundred milligrams. The total capacity of 5 capsules is 615 ml.

The British have developed a device that prints raspberries for breakfast for children The author of the development, Vaiva Klnikite, says that natural raspberry juice, calcium, which helps strengthen bones, and sodium alginate solution, which forms a thin film of gelatin, are used in the process. thanks to which the product is formed faster and easier.

Printed raspberries look a bit like red caviar. To taste, a healthy breakfast really resembles raspberry marmalade and smells exactly like this berry. With the help of natural food dyes, you can change the color and taste of the finished product. The creators admit that in the process of testing the device, they once received a square blue berry that had the taste and smell of a banana.

The creators admit that in the process of testing the device, they once received a square blue berry that had the taste and smell of a banana.

The goal of the developers is to expand the boundaries of human touch. The printer is similar to the replicator machine that appears repeatedly in one of the popular TV shows. Also, a team of scientists involved in the development of devices for cooking healthy food, are struggling with the problem of cancer and diabetes.

As part of the project, a team of scientists is working on an analysis of the diet of the average citizen, and is looking for ways to make food and the cooking process the most useful and simple. Scientists are sure that each of us individually lacks nutrients and trace elements. A “nutrition dossier” will be developed for each person.

The prospect is very encouraging - the company plans to create a scanner that will analyze the general condition of the body and suggest which foods are best included in the diet. The microwave ovens familiar to all of us are gradually, right before our eyes, becoming a thing of the past.

The microwave ovens familiar to all of us are gradually, right before our eyes, becoming a thing of the past.

Barilla, the maker of the highest quality Italian pasta, recently announced that it plans to equip its chain of restaurants with a 3D printer over the next few years.

What is the essence of the innovation? A guest, a visitor to an establishment, makes an order, and the food is prepared literally within a couple of minutes.

The project will be prepared in cooperation with TNO Eindhoven. Kjeld Van Bommel, project curator for TNO, confirmed that they have been working with Barilla for two years to bring the idea to fruition.

Several printers have already started working in catering establishments, and work is underway to improve the taste of the produced pasta and the technical characteristics of the device.

Barilla is one of the world's leading pasta producers. By using 3D printing technologies in the production process, they have become even more popular and are absolutely confident that 3D printing will soon become mainstream.

The main thing in such technological processes is the high speed of cooking. The undoubted advantage of such printing of food products is that the paste can be given absolutely any shape - the widest field for creativity opens up Van Bommel, one of the immediate project managers, says: “Modern technologies have significantly expanded the possibilities of design art and embody the most daring individual wishes of the customer .” So, a person can please a loved one by ordering pasta in the form of a bouquet of roses in a restaurant.

At the moment, such models as "Rosa Pasta", the author of which was the designer from France Lori Tupin, have gained particular popularity. Pasta is made in the form of a flower, which opens during the cooking process. Danilo Spiga and Louis Fraguardo developed the Vortipa concept, which resembles a tartlet. "Lune" was invented by the Italian Alessandro Carbine. In this case, the craters will need to be filled with traditional tomato sauce.

3D printing technologies are already being used to create parts for various mechanisms, bridges and even entire houses. But the technology seems to have much more potential, and it could be used in the food industry. At least that's what scientists at the Hebrew University of Jerusalem think, who created the first 3D food printer capable of printing food.

But the technology seems to have much more potential, and it could be used in the food industry. At least that's what scientists at the Hebrew University of Jerusalem think, who created the first 3D food printer capable of printing food.

According to the inventors Odeda Shoseyov and Ido Braslavsky, the manufacturing process of such printers is not that difficult, and it may take no more than 5 years to enter the mass market. Their 3D food printer uses nanocellulose, proteins, fats and carbohydrates as raw materials. Right now, the printer can only print dough, but the researchers say their printer is capable of more.

Scientists have been studying nanocellulose for several years and came to the conclusion that the enzymes of the digestive tract easily digest this substance, and nanocellulose itself does not cause any adverse reactions. In the future, experts will mix nanocellulose not only with nutrients, but also with vitamins, trace elements and antioxidants. Under the influence of temperature from the printer's laser, the nanocellulose binds the ingredients. At the same time, laser processing allows you to give the printed dish a more “traditional” look.

At the same time, laser processing allows you to give the printed dish a more “traditional” look.

According to the inventors themselves, their development is quite promising. In addition to its use in cooking, it will help those who adhere to a strict diet - diabetics, vegetarians, professional athletes, allergy sufferers, and so on. In general, all those to whom the presence of certain substances in food can be harmful to health.

During the Experimental Biology 2018 conference, South Korean scientists presented a very unusual development, which in the future claims to be an integral part of the household equipment of an apartment.

3D printing technologies have either already occupied certain niches, or will occupy them in the coming years. There are a lot of applications for the technology - from the construction of space stations and lunar bases, to the printing of human organs, however, the development of a group of scientists from South Korea is a little more mundane. We are talking about 3D printing of food.

We are talking about 3D printing of food.

The device is capable of reproducing the physical properties of food products, and most importantly, their nanoscale texture. To work, the printer uses powder ingredients obtained by grinding nutrients, primarily proteins and carbohydrates, at a temperature of -100 degrees Celsius. Then the resulting powder under the influence of water, high pressure and temperature turns into a porous film.

The advantages of the device can hardly be overestimated. Firstly, it allows you to print food according to individual preferences, including taking into account the peculiarities of the metabolism of a particular person. According to scientists, the device even allows you to regulate the speed of digestion, which means the ability to create the most healthy food. Secondly, the device will seriously reduce the cost of food delivery, as well as their storage, which can solve the problem of hunger for many people, especially given the forecasts of scientists who predict the growth of the world's population to 10 billion people in 2050.