Industrial 3d printer reviews

The Complete Industrial 3D Printer Buyer's Guide 2022

Industrial 3D printers are increasingly replacing injection molding and other processes like CNC milling as the go-to option for small production runs and rapid prototyping. 3D printers can create incredibly detailed and intricate parts as well as full-size models, making them perfect for prototypes and high-quality part production.

- Note: you may instead be looking for our ranking of the most valuable 3D printing companies.

How much does an industrial 3D printer cost?

Industrial 3D printer price really depends on the quality and type of 3D printer you’re using, and what you’re planning to produce or prototype.

There are resin 3D printers such as the Formlabs 3 that sell for $3,499 that can print industrial quality pieces in sectors such as dentistry, education, medical, and jewelry, and other printers such as the Ultimaker S3 and S5, Makerbot Method, Intamsys Funmat HT, and others that cover the prosumer 3D printer market.

Beyond this, there are machines costing between $10,000 to $100,000, such as FDM 3D printers like the BigRep Studio, and Markforged’s Metal X metal 3D printer, and premium industrial 3D printers such as those sold by EOS, Carbon 3D and Desktop Metal that can cost hundreds of thousands of dollars.

We have recommended lower-end industrial 3D printers starting from the $3,000-$6,000 range, as well as higher-priced commercial machines.

How to decide which industrial 3D printer to buy?

There are several factors to consider, most notably:

- Size: consider both the industrial 3D printer’s size in terms of build volume (maximum size of parts you can print), and the total area the printer encompasses. You may not have the space to store the printer, or need the extra build volume.

- 3D printing technology: there are a range of technologies within 3D printing, which we explain in our free 3D printing eBook. Do you prioritize cheap part printing, or extremely detailed surface quality? These will determine which technology you need, and therefore which industrial 3D printer to buy.

- Materials to print: are you looking to 3D print polymers like PLA, ABS or Nylon? If so, you have options between FDM (all 3), or SLS (Nylon). If you’re looking to 3D print metal materials such as aluminum or titanium, you’ll have to buy a DMLS, EBM, Binder Jetting or other type of metal 3D printer.

- Speed: some types of 3D printers print much faster than others, even within the same technology. DLP 3D printing is typically faster than SLA, and delta 3D printers are almost always faster than Cartesians.

- Does it require a trained operator: expensive, complex and high-quality industrial 3D printers often require a skilled operator to ensure the printing process goes smoothly and the correct temperatures are maintained. This adds to costs but may be necessary for your prototyping, and is something to keep in mind.

- Resolution: different 3D printers have different levels of accuracy, precision and resolution.

Resin 3D printers are more accurate than FDM 3D printers, and material jetting printers have some of the highest resolutions of any industrial 3D printer available on the market today.

Resin 3D printers are more accurate than FDM 3D printers, and material jetting printers have some of the highest resolutions of any industrial 3D printer available on the market today. - Ability to print full color: some 3D printing technologies are limited to a single color based on the metal / polymer powder, filament or resin, whereas some can print in full color such as Binder Jetting and Multi Jet Fusion.

The best industrial 3D printers we recommend

Based on our advice and criteria, here are some of the industrial 3D printers we recommend. Where possible we have provided options that are affordable to small and medium-sized businesses that do not run into the hundreds of thousands of dollars.

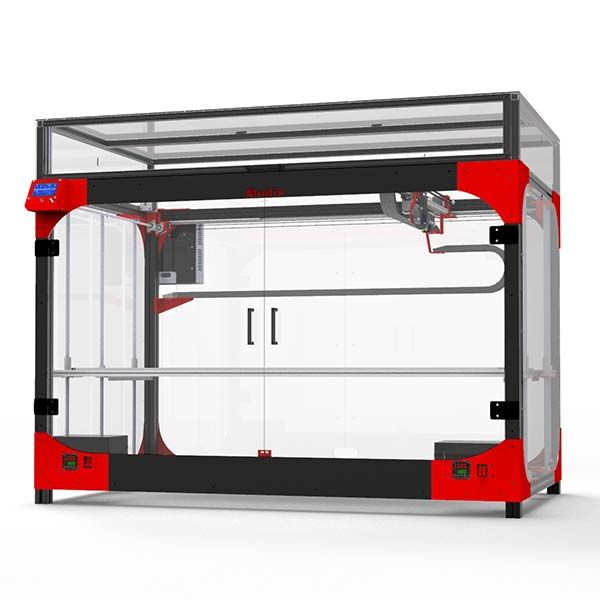

Raise3D Pro2 Plus — Great affordable yet large industrial 3D printer

- Build volume: 305 x 305 x 605 mm

- Price: $5,999 — Available on Dynamism Store here / Available at Matterhackers here

Raise3D offer both the Pro2 and the Pro2 Plus as industrial FDM 3D printers offering fantastic reliability, accuracy and versatility – with the Pro2 Plus offering a larger 605 mm Z-axis for tall parts compared with the Pro2’s 300mm.

The printer can print with 100-micron resolution, has an industrial build plate to prevent part warping, and a fully enclosed chamber to keep printing conditions consistent. The dual extruder allows for multi-material printing, such as for supports or for any rapid prototyping that requires two different colors.

The 7-inch touchscreen features a very ergonomic UI and provides useful on-screen visualizations during printing. Moreover, if you do have any problems Raise3D has US-based tech support to provide solutions.

The maximum temperature of 300C creates a lot of opportunities for filament printing; the Raise3D Pro2 Plus can print not only standard 3D printer filaments like ABS, PLA, PETG, Nylon, but also carbon fiber infused, metal-filled, and glass-infused filaments. You can connect wirelessly using IdeaMaker – Raise3D’s 3D slicer software – to control and monitor printing remotely.

Ultimaker S5 & S5 Pro Bundle

- Industrial 3D printer build volume: 330 x 240 x 300 mm

- Price: $5,499 for the S5, $9,000 for S5 Pro Bundle — Available on Dynamism Store here / Available on Matterhackers here

- Weight: 20.

6kg

6kg

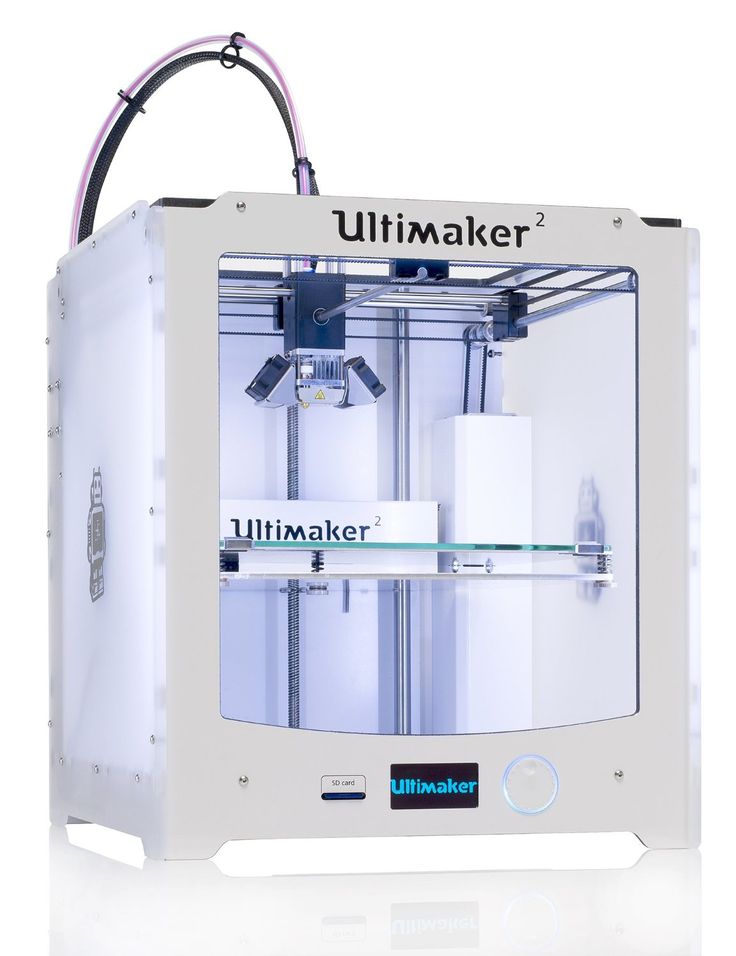

Ultimaker staked their claim as kings of the prosumer 3D printer market with the Ultimaker 3, winning awards and reaching new heights of success. The S5 was a step up into a higher price bracket, featuring a number of key upgrades and even better print quality.

Costing $5,499, the Ultimaker S5 moves up into the industrial FDM 3D printer price range, but that gets you up to 20-micron layer resolution. Incredibly accurate and intricate prototypes and parts can be printed to test functionality and shape, with partners including VW, Siemens, L’Oreal and Ford clearly seeing benefits to their production by using Ultimaker 3D printers. It can even print high-strength glass and carbon fiber filaments, with the latter especially having key applications in strong prototype and part production.

The 4.7-inch touchscreen is easy to use and has won design awards, and you can print with Ultimaker filaments or any third party 2.85mm filament — the S5 features an open filament system. Some architects have used the Ultimaker combined with a Palette to create multi-color architectural model prototypes.

Some architects have used the Ultimaker combined with a Palette to create multi-color architectural model prototypes.

Ultimaker also sells the Ultimaker S5 Pro Bundle, featuring an S5 as well as an Air Manager that goes on top of the printer that captures 95% of ultra-fine particles, and a Material Station that goes underneath the printer. The Material Station can hold up to six filament spools and can automatically switch between each one dependent on what material or color you need to use.

This allows for far more scalable and continuous printing — Ultimaker sells it as a 24/7 productivity feature. The S5 Pro Bundle costs around $9,000, and is one of the most highly regarded industrial FDM 3D printers around.The Ultimaker S5 Pro Bundle with the Air Manager on top, and Material Handler underneath.

Formlabs Form 3 — best affordable industrial resin 3D printer

- Build volume: 145 x 145 x 185 mm

- Price: $3,499 — Available on Dynamism Store here

- Weight: 17.

5kg

5kg

The Form 2 was already a mainstay in dental 3D printing, medical device printing and in 3D printed jewelry, and the Form 3 expands on this further with several key upgrades.

It uses Low Force Stereolithography (LFS) to provide extremely high quality, precise (up to 25-micron XY resolution), and crisp surface finish prints that are clear and accurate. And for those looking for a resin 3D printer with a larger build volume, Formlabs also sell the Form 3L, featuring a far larger 335 x 200 x 300 mm build volume.

No FDM 3D printer will be able to match the smooth surface area of a Formlabs resin print, making the Form 3 ideal for really precise prototypes – Formlabs show an example of 3D printed glasses on their site – as well as for intricate pieces like jewelry and dental parts, or custom pieces like hearing aids.

Intamsys Funmat HT Enhanced — entry-level industrial PEEK 3D printer

- Price: $7,499 — Available on Matterhackers here

- Build volume: 260 x 260 x 260 mm

The Intamsys Funmat HT has two interchangeable hot ends depending on whether you want to print standard filaments like PLA and ABS, or industrial 3D printer filaments like PEEK and ULTEM. This makes it versatile not just as an industrial or abrasive filament 3D printer, but also as an accurate 3D printer for more standard filaments for everyday rapid prototyping.

This makes it versatile not just as an industrial or abrasive filament 3D printer, but also as an accurate 3D printer for more standard filaments for everyday rapid prototyping.

Read more: the best PEEK 3D printers

With a 50-micron minimum layer thickness, small businesses and industrial clients will have no problem printing accurate PEEK, Nylon, or other material parts. The Intamsys Funmat HT offers a great alternative to using 3D printing services to 3D print PEEK and other industrial filaments, costing around $6,000, far less than previous industrial PEEK 3D printers.

The Funmat HT’s low price and effectiveness has seen it used to 3D print aerospace, automotive, engineering, and medical sector parts. It is also used in general R&D, and overall is considered a great 3D printer, offering industrial 3D printing on a smaller scale and the 3D printing of the toughest filaments around, at far more affordable prices.

Sinterit Lisa — Entry-level industrial 3D printer using SLS

- Build volume: 110 x 150 x 150 mm (For TPU)

- 90 x 130 x 130 mm (for Nylon/PA)

- Price: €7,999

- Weight: 41kg

The Sinterit Lisa is one of the lowest cost industrial SLS 3D printers around, bringing all the main advantages of selective laser sintering but without the price tag. Made in Poland, every machine passes a “precisely designed calibration and testing procedure” according to Sinterit.

Made in Poland, every machine passes a “precisely designed calibration and testing procedure” according to Sinterit.

The main advantage of SLS 3D printing is that you don’t need to print supports, saving time and money on powder. You can also print multiple parts concurrently in the build platform, and so is perfect for businesses printing multiple parts at once, or printing many similar parts that are slightly different to test which prototype is best. The Sinterit Lisa can perform all these functions with ease with its 0.05mm X and Y axis accuracy, and up to 0.075mm Z-axis precision.

Sinterit have designed their own dedicated software, and sell accessories including the Sandblaster as well as specialized SLS powder materials. You can control and print via the Sinterit Lisa’s 4-inch touchscreen, as well as by WiFi or USB.

Desktop Metal Fiber — Most affordable industrial metal 3D printing machine

- Price: Requires a Quote — Available at Dynamism here

- Build volume: 310 x 240 x 270 mm

Desktop Metal, now a public company and who recently acquired EnvisionTEC in a $300m deal, offer one of the most affordable ways to get into industrial metal 3D printing. The Desktop Metal Fiber System can print PEKK, PEEK, or Nylon with continuous carbon fibers or fiberglass to greatly improve part strength.

The Desktop Metal Fiber System can print PEKK, PEEK, or Nylon with continuous carbon fibers or fiberglass to greatly improve part strength.

The Fiber System is still an industrial 3D printing machine, but is far lower priced than previous metal printers. It combines FDM-style filaments with metal, using their new Micro Automated Fiber Placement technology with continuous carbon fibers. Rather than purchasing it outright, Desktop Metal offer leasing options with a yearly subscription, saving smaller businesses upfront costs and making it easier to get started.

Read more: metal 3D printer buyer’s guide

The Fiber mixes these already tough materials like PEEK with carbon fibers, creating astonishing strong — yet lighter than aluminum — parts that can withstand up to 250C temperatures. For a metal 3D printer the build area is also not bad, especially considering the low price compared with most industrial DMLS 3D printers.

Markforged Metal X — Accessible industrial 3D printing metal

- Price: $100,00

- Build volume: 300 x 220 x 180 mm

Markforged’s Metal X 3D printer is one of the most accessible ways to 3D print metal, a very viable alternative when compared with possibly spending hundreds of thousands of dollars on a DMLS or EBM 3D printer.

Using Markforged’s bound powder filament technique, you can print with materials like copper, inconel, A2 and D2 tool steel, and 17-4 PH stainless steel. The Metal X combines FDM-style filament printing with metal, not too dissimilarly to how Desktop Metal have. This makes for a more accessible way to 3D print metal, either for in-house part production and prototyping, or as a service creating reasonable-sized metal parts.

Why use an industrial 3D printer?

Industrial 3D printers are used for rapid prototyping in tandem with 3D CAD software for product design (although occasionally CNC machines are used instead).

3D printers can quickly print small-scale versions of final products to test the design or functionality, with any mistakes able to be instantly changed by editing the 3D model and re-printing the next iteration for testing. Rapid prototyping is frequently used in the aerospace, automotive, and medical sectors.

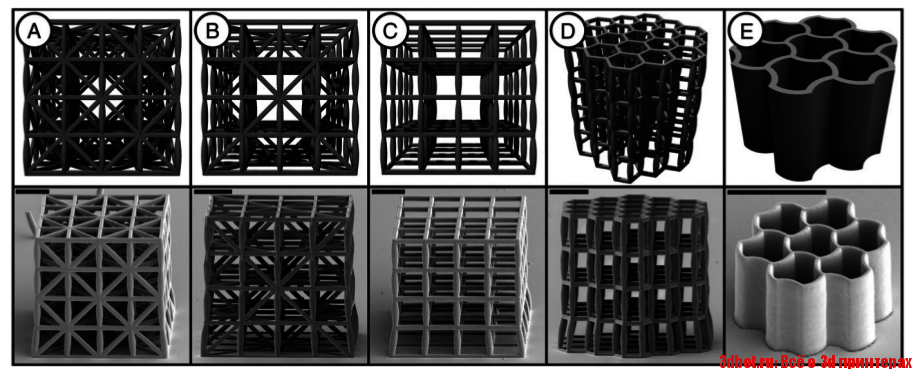

Since 3D printing is a form of additive manufacturing, there is no waste from removed materials such as with CNC machines. This makes industrial 3D printing very valuable in industries where saving on expensive materials is important, such as metal 3D printing. 3D printers can also create parts with differing infill percentages, leading to lighter yet still very strong metal parts — extremely valuable in the automotive and aerospace sectors where cutting weight can noticeably increase profit margins.

This makes industrial 3D printing very valuable in industries where saving on expensive materials is important, such as metal 3D printing. 3D printers can also create parts with differing infill percentages, leading to lighter yet still very strong metal parts — extremely valuable in the automotive and aerospace sectors where cutting weight can noticeably increase profit margins.

Some other articles you may be interested in:

- The best commercial 3D printers

- The best 3D printers for small business

- Large format resin 3D printers buyer’s guide

mix of features, performance, and price

What is the best professional desktop 3D printer?

There are so many different 3D printers on the market today that it can be a real challenge to choose one. When every penny of your quarterly budget counts, you want to make sure your professional 3D printer is adapted to your needs. Material compatibility, build size, ease of use, workflow, software, and many more elements come into play.

To help you cut through the clutter, we made a shortlist of some of the best professional 3D printers available this year. These benchtop and desktop FFF (fused filament fabrication) 3D printers for professionals offer a great combination of features, performance, and reliability, and come from well-established brands. They are ideal tools for rapid prototyping and iterative design processes, and are also suitable for low-volume production series. Keep in mind, though, that while part quality does depend on your printer’s performance, it also greatly relies on your choice of materials.

Towards the end of this article, we also provide a brief buying guide where you can learn more about different 3D printer specifications such as printing temperatures, layer thickness, dual extrusion, and more.

Best benchtop 3D printers for professionals in 2022: our selection

The table below recaps our selection of some of the best professional 3D printing options for office use. Our goal is to provide a quick, visual overview of the market; there are of course numerous other factors to take into account (material compatibility, certifications, customer service, software, etc.) before making the right choice.

Our goal is to provide a quick, visual overview of the market; there are of course numerous other factors to take into account (material compatibility, certifications, customer service, software, etc.) before making the right choice.

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Prusa Research | Original Prusa i3 MK3S This product has been reviewed by our team. | 250 × 210 × 210 mm9.84 × 8.27 × 8.27 in | Czech Republic | $ 9991 015 €886 £148,907 ¥ | Buy |

| BCN3D Technologies | Sigma D25 | 420 × 300 × 200 mm16.54 × 11.81 × 7.87 in | Spain | $ 3,9953 495 €3,544 £595,479 ¥ | Quote |

| Ultimaker | Ultimaker S5 | 330 × 240 × 300 mm12. 99 × 9.45 × 11.81 in 99 × 9.45 × 11.81 in | Netherlands | $ 5,9955 495 €5,318 £893,591 ¥ | Quote |

| MakerBot | Method X | 190 × 190 × 196 mm7.48 × 7.48 × 7.72 in | United States | $ 6,4996 606 €5,765 £968,715 ¥ | Quote |

| Raise3D This brand is a certified partner from our network. | Pro3 Plus This product has been reviewed by our team. | 300 × 300 × 605 mm11.81 × 11.81 × 23.82 in | United States | $ 7,2496 249 €6,430 £1,080,507 ¥ | Quote |

| Markforged | Onyx Pro | 320 × 132 × 154 mm12.6 × 5.2 × 6.06 in | United States | $ 9,60010 000 €8,516 £1,430,938 ¥ | Quote |

| Stratasys | F120 | 254 × 254 × 254 mm10 × 10 × 10 in | United States | $ 12,00011 000 €10,644 £1,788,672 ¥ | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Build volume | Extruder temp. | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|---|

| Prusa Research | Original Prusa i3 MK3S This product has been reviewed by our team. | 250 × 210 × 210 mm9.84 × 8.27 × 8.27 in | 11.03 L | 300°C | Czech Republic | $ 9991 015 €886 £148,907 ¥ | Buy on Prusa |

| BCN3D Technologies | Sigma D25 | 420 × 300 × 200 mm16.54 × 11.81 × 7.87 in | 25.2 L | 300°C | Spain | $ 3,9953 495 €3,544 £595,479 ¥ | Get a quote |

| Ultimaker | Ultimaker S5 | 330 × 240 × 300 mm12.99 × 9.45 × 11.81 in | 23.76 L | 280°C | Netherlands | $ 5,9955 495 €5,318 £893,591 ¥ | Get a quote |

| MakerBot | Method X | 190 × 190 × 196 mm7. 48 × 7.48 × 7.72 in 48 × 7.48 × 7.72 in | 7.08 L | 260°C | United States | $ 6,4996 606 €5,765 £968,715 ¥ | Get a quote |

| Raise3D This brand is a certified partner from our network. | Pro3 Plus This product has been reviewed by our team. | 300 × 300 × 605 mm11.81 × 11.81 × 23.82 in | 54.45 L | 300°C | United States | $ 7,2496 249 €6,430 £1,080,507 ¥ | Get a quote |

| Markforged | Onyx Pro | 320 × 132 × 154 mm12.6 × 5.2 × 6.06 in | 6.5 L | – | United States | $ 9,60010 000 €8,516 £1,430,938 ¥ | Get a quote |

| Stratasys | F120 | 254 × 254 × 254 mm10 × 10 × 10 in | 16.39 L | – | United States | $ 12,00011 000 €10,644 £1,788,672 ¥ | Get a quote |

Overview of the best professional 3D printers in 2022

In this section, we give some more context and information about each pro 3D printer from our selection.

The Prusa Research Original Prusa i3 MK3S+ is a desktop 3D printer manufactured by Prusa Research, based in the Czech Republic. Prusa Research is a well-known brand created by Josef Prusa, inventor of the open-source Prusa i3 3D printer design.

Prusa 3D printers are highly reliable machines and can produce excellent parts right out of the box. Priced just under $1,000, the MK3S+ offers a very good price-to-performance ratio. With its open chassis and customizable “everything”, it’s a great option for those that like to get manual. Professionals who are looking for easy and low-maintenance operation may want to look at options in a higher price range.

Full review: Original Prusa i3 MK3S review

Buy on Prusa Add to comparison

The BCN3D Sigma D25 is a large desktop 3D printer for office use made by BCN3D Technologies. BCN3D, or BCN3D Technologies, is based in Spain and is one of the desktop 3D printer market leaders. They produce high-quality 3D printers for professionals, the Sigma being their flagship series.

The Sigma D25 pro 3D printer offers a relatively big build volume and boasts BCN3D’s IDEX technology. This means that there are two separate print heads that can both move independently to either print two identical objects at the same time or print in mirror mode.

Contact manufacturer Get a quote Add to comparison

The Ultimaker S5 is a professional desktop 3D printer made by Ultimaker, a manufacturer based in the Netherlands. Users may control their S5 from a distance thanks to the Ultimaker App and a Wi-Fi connection. There is also an onboard camera to monitor 3D prints from a distance. Furthermore, to maximize production efficiency, it is possible to group multiple S5 3D printers together with Cura Connect.

Today, the Ultimaker S5 is often referred to as the best professional 3D printer, especially when equipped with the Pro Bundle. The Pro Bundle includes a “material station” where up to 6 spools of filament can be loaded and automatically managed (auto-switch, humidity control, etc. ), and an “air manager” that closes up the build area and filters particles.

), and an “air manager” that closes up the build area and filters particles.

Contact manufacturer Get a quote Add to comparison

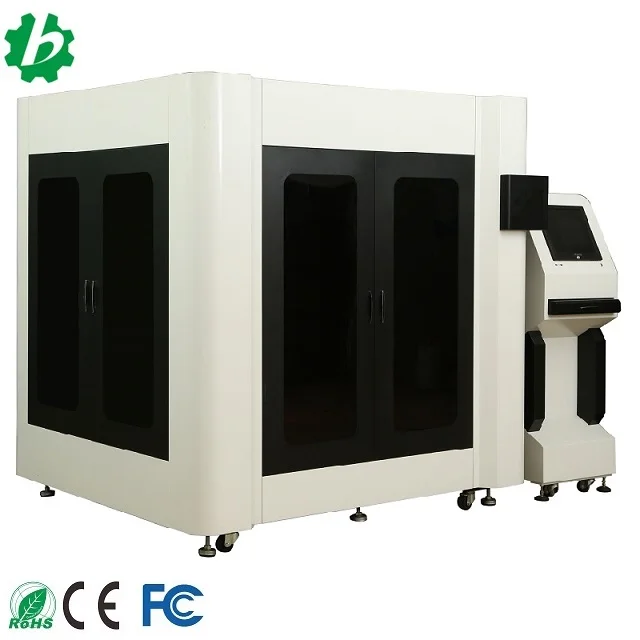

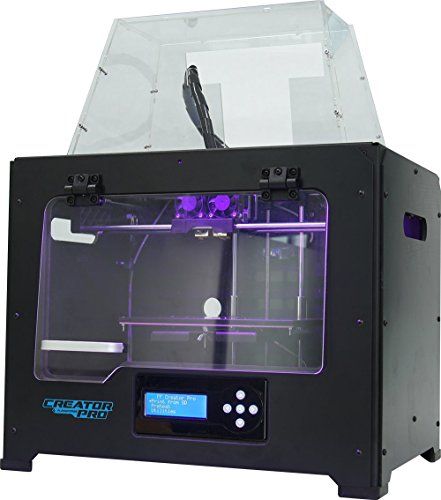

The Method X is a professional benchtop 3D printer produced by MakerBot (a Stratasys-owned brand). It was designed to 3D print ABS filament reliably and efficiently, thanks to a number of features– including a 100°C heated build chamber– than enable comprehensive environmental control.

Makerbot’s Method X is equipped with a 5-inch touchscreen with real-time feedback and status on print jobs, and offers automatic calibration. This pro 3D printer also boasts “SmartAssist Material Loading”, for fast and easy filament changing. Users can log in to the manufacturer’s proprietary CloudPrint software to monitor prints remotely at any time.

Contact manufacturer Get a quote Add to comparison

The Markforged Onyx Pro is a professional desktop 3D printer made by Markforged, a manufacturer based in Somerville, Massachusetts (USA). With its dual printhead, the Onyx Pro reinforces plastic parts with a continuous strand of fiberglass.

The main available materials for the Onyx Pro are Onyx (a carbon fiber filled nylon) and Precise PLA. Markforged advertises parts up to ten times stronger than non-reinforced plastic ones.

The MarkForged Onyx Pro is delivered with Markforged’s browser-based Eiger software, powerful and easy to use. Eiger allows precise control over the 3D printing process.

Contact manufacturer Get a quote Add to comparison

The Raise3D Pro3 Plus is a professional, industrial-grade 3D printer made by Raise3D, an ISO9001:2015 and ISO14001-certified manufacturer based in the US (California). Raise3D also has offices in the Netherlands (Rotterdam) and in China (Shanghai).

This 3D printer for office environments is a true workhorse, capable of printing for hours without any hiccups. It does an impressive job with complex overhangs and features an intuitive, user-friendly workflow. The printer comes with an air filtration system, an onboard camera, and a dual extruder. Its control software is also available as a smartphone app for convenient remote monitoring.

Raise3D’s Pro3 series also includes the Pro3, featuring a smaller build volume. Both printers are a follow-up to the Pro2 Series.

Full review: Raise3D Pro3 Plus review

Contact manufacturer Get a quote Add to comparison

Stratasys is the Apple of the 3D printing industry. Their 3D printers, including the F120, are reliable machines with industrial-grade components and printing quality. However, Stratasys 3D printers generally only work with Stratasys materials and hardware. At the moment, less than a handful of filaments are available for the Stratasys F120.

The F120 is one of the most affordable FDM printers from Stratasys and is destined to be a desktop workhorse for professionals. Stratasys emphasizes on the printer’s ease of use, durability, and industrial quality.

Contact manufacturer Get a quote Add to comparison

Professional 3D printer buying guide

There are several features and specifications to take into account when choosing the best professional 3D printer for your needs.

Technology

For this professional desktop 3D printer selection, we focused on FFF (fused filament fabrication) 3D printers. They are ideal for creating both prototypes and end-use parts.

For professionals in dental or jewelry industries where high precision and detail are required, resin 3D printers are more adapted, with SLA, DLP, or LCD-based technologies.

There are also desktop SLS 3D printers (powder 3D printers), PEEK 3D printers, continuous fiber 3D printers, and more for advanced applications. Explore these topics with all of our other 3D printer guides.

Build plate or print bed

A heated print bed is mandatory for users that need to 3D print with ABS and other more demanding materials. The heat helps prevent warping and offers better first-layer adhesion.

While today’s 3D printers almost always feature heated build plates, they don’t all reach the same temperatures. It is best to know which thermoplastics you will be printing and to choose your desktop 3D printer accordingly.

It is best to know which thermoplastics you will be printing and to choose your desktop 3D printer accordingly.

Some professional 3D printers have interchangeable build trays to help speed up the workflow, enabling users to quickly launch new prints while the previous build plate cools down. On higher-end 3D printers, there can even be vacuum systems for instant part release from the print bed.

Print head

PLA and ABS can be considered the most common and basic 3D printing materials in general. Professionals, however, often need to print more complex materials, such as Nylon, Polycarbonate, PETG, ASA, or other engineering-grade polymers.

They don’t all have the same melting or glass transition temperature and therefore have to be 3D printed at different temperatures. For example, PLA can be extruded at around 200°C, PC at around 260°C, and some high-performance materials like PEEK or PEKK need the extruder to reach at least 450°C.

Popular professional filaments also include plastics filled with carbon fiber or glass fiber for increased strength and resistance. These materials are abrasive and require tough nozzles; many professional printers are already compatible with these composites, but it’s important to make sure beforehand.

Some 3D printers are compatible with multiple types of nozzles with varying diameters, and even paste-type print heads exist to 3D print clay.

Automatic calibration

Most professional 3D printer systems are equipped with automatic calibration features to make the process as plug-n-play as possible. It’s important to recalibrate a 3D printer from time to time to ensure consistent print quality.

There are two main types of calibration:

- Print bed leveling (making sure the print bed is perfectly parallel to the nozzle, and not tilted)

- Nozzle offset (determining the right gap between the nozzle and the print bed)

Most 3D printers for professionals feature a probe attached to the print head to automate these processes instead of users having to use a piece of paper or business card.

Some 3D printers also have NFC readers to automatically adjust their temperature settings according to the detected material (so long as the spool is chipped, too).

Dual extrusion and independent dual extrusion (IDEX)

A dual extruder enables users to 3D print with two different colors or materials simultaneously, including soluble support material for complex objects.

If there are two separate print heads, the system is referred to as IDEX (independent dual extruder). BCN3D Technologies was one of the first manufacturers to offer this feature a few years back.

In addition to being able to 3D print two materials at a time, independent dual extrusion offers different 3D printing possibilities:

- Duplication mode: 3D prints two identical objects at the same time.

- Mirror mode: to 3D print an object twice as fast as with just one extruder, each nozzle completes one-half of the object.

Onboard camera

Some 3D printers are equipped with an onboard camera that monitors prints remotely or saves time-lapse videos. This feature can be useful if the printer must be left unattended for long periods of time. We found it to be quite practical when we launched a long print for our Pro3 Plus review.

With the right 3D software, onboard cameras can help with quality control. Quality control can also be done during post-processing workflows with a metrology 3D scanner.

Minimum layer thickness

3D print quality is intricately linked to layer thickness, a.k.a. layer height or Z resolution. It’s the minimum height of each successive layer that forms the 3D printed object. The thinner the layers, the less they are distinguishable and the smoother the object will be (similar to the ratio of pixels in an image).

Thinner layers also mean that more layers are required to complete the object, which translates into more 3D print time. Layer thickness can be adjusted depending on if you need a quick print (thicker) or a high-resolution print (thinner).

Layer thickness can be adjusted depending on if you need a quick print (thicker) or a high-resolution print (thinner).

The typical minimum layer thickness for mid-range FFF 3D printers is 100 microns or 0.1 millimeters, but it can go down to 0.01 mm in some cases.

A simple representation of layer height. Source: Primantes3DBuild volume

The build volume is the maximum size that your prints can be. If you need a bigger volume than what the 3D printers in this guide provide, you may be interested in these selections:

- L: Large volume 3D printers

- XL: Large format 3D printers

- XXL: Large scale 3D printers

Now, there are even large-sized resin 3D printers for those that need both volume and finer surface quality.

Closed frame

Many variables can interfere with 3D print quality, such as temperature changes and room drafts. Hence, 3D printers with an enclosed build chamber tend to provide better quality prints, in addition to reducing noise, odors, and– with a HEPA filter– harmful particle emissions.

A closed frame is almost mandatory when 3D printing with basically anything other than PLA. Today it is quite rare to see a professional 3D printer without an enclosure.

FAQ

Are 3D printers safe?

With basic precaution, 3D printers are relatively safe to use, although there has been some concern over harmful particle emissions from the melted filament. It’s best to use closed 3D printers with filters and to use 3D printers in well-ventilated areas. Users should also be careful not to burn themselves on a hot build plate or extruder; some 3D printers feature door safety sensors to lock the printer while it is printing.

Can 3D printers print metal? What 3D printers can print metal?

Yes, some FFF 3D printers are able to print metal-filled filaments. This is called metal FFF. Once the part has been 3D printed, however, it must undergo two processes called debinding and sintering. Other types of 3D printers (much more expensive and industrial-grade) are able to 3D print metal powder using various metal 3D printing technologies like L-PBF (laser powder bed fusion) or metal binder jetting, among others.

Other types of 3D printers (much more expensive and industrial-grade) are able to 3D print metal powder using various metal 3D printing technologies like L-PBF (laser powder bed fusion) or metal binder jetting, among others.

What is the best 3D printer for jewelry?

For jewelry, resin 3D printers are more adapted than FFF 3D printers. They use SLA, DLP, or LCD-based technologies to produce objects with fine details and smooth surfaces.

Can 3D printers print in color?

Yes, some 3D printers can print in color. They are called full-color 3D printers and often use powder-based technologies. Systems that mix CMYK filaments exist, but cannot reproduce photorealistic colors like powder-based 3D printers.

Overview of industrial 3D printers of popular brands

Industrial 3D printers have become popular because of the possibilities they offer. The equipment allows to produce customized products at the stage of product modeling. Users can improve existing CAD models or design entirely new shapes. All this leads to a reduction in the cost of products and prototypes. The market offers a diverse range of devices. The most iconic models are described below.

The equipment allows to produce customized products at the stage of product modeling. Users can improve existing CAD models or design entirely new shapes. All this leads to a reduction in the cost of products and prototypes. The market offers a diverse range of devices. The most iconic models are described below.

Overview of industrial 3D printers

3D Systems

The American company 3D Systems is at the forefront in all areas of 3D printing. Brand technology helps to significantly reduce the time for design, prototyping, mass production. Most frequently purchased models:

• The DMP Flex 350 3D Printer can print a variety of alloys with high precision. The next generation of equipment is characterized by high performance and accurate reproduction of the digital model. The machine works on DMLS technology and is able to operate around the clock. The technique is equipped with the option of rational use of raw materials, the work is automated at each stage of printing. Unused powder is reused, reducing the cost of the final project. Embedded software controls the entire production cycle, from parameter setting to material quantification and waste disposal. Finished products are characterized by low weight, strength, it is possible to print specimens with a dense structure, identical in properties to cast ones.

Unused powder is reused, reducing the cost of the final project. Embedded software controls the entire production cycle, from parameter setting to material quantification and waste disposal. Finished products are characterized by low weight, strength, it is possible to print specimens with a dense structure, identical in properties to cast ones.

Photo: 3DSystems

Features:

| Country | US |

| Applications | foundry industry, automotive industry, medicine, jewelry industry, automotive industry, medicine, jewelry industry |

| Housing color | gray |

| Construction area | 275x275x420 mm (including build platform) |

| Layer thickness | 30 µm; 60 µm |

| Platform | metal |

| Print material | metal |

| Print Technology | DMP |

| Warranty | 12 months |

| Minimum element size | 100 µm |

| Minimum wall thickness | 150 µm |

• The DMP Factory 350 3D printer has incorporated the advantages of the previous model, supplementing the list of advantages with an automatic powder circulation module. The car is supplied with an option of cleaning of a working platform at the closed chamber. The upgraded laminar airflow system of the printable area allows you to create models of higher quality. The user interface is equipped with a touch screen that simplifies interaction. The use of DMLS-technology and modern powders of the LaserForm series ensures high speed and increased productivity. The model is optimal for commercial use.

The car is supplied with an option of cleaning of a working platform at the closed chamber. The upgraded laminar airflow system of the printable area allows you to create models of higher quality. The user interface is equipped with a touch screen that simplifies interaction. The use of DMLS-technology and modern powders of the LaserForm series ensures high speed and increased productivity. The model is optimal for commercial use.

Photo: 3DSystems

Features:

| Country | US |

| Applications | aviation and space, automotive industry, foundry industry, mechanical engineering, medicine, jewelry industry, automotive industry, foundry industry, mechanical engineering, medicine, jewelry industry |

| Housing color | gray |

| Construction area | 275x275x420 mm (including build platform) |

| Layer thickness | 30 µm; 60 µm |

| Print material | metal |

| Print Technology | DMP |

| Warranty | 12 months |

| Minimum element size | 100 µm |

| Minimum wall thickness | 150 µm |

• The DMP Factory 500 3D printer is a machine optimized for industrial scale. The equipment is a scalable design consisting of several special modules. An integrated metal production system provides a controlled environment for building objects, enabling continuous operation. The right combination of modules can help optimize an existing factory line or start a new product line. The 3DXpert software allows you to grow large seamless elements.

The equipment is a scalable design consisting of several special modules. An integrated metal production system provides a controlled environment for building objects, enabling continuous operation. The right combination of modules can help optimize an existing factory line or start a new product line. The 3DXpert software allows you to grow large seamless elements.

Photo: 3DSystems

Features:

| Country | US |

| Applications | foundry industry, jewelry industry, mechanical engineering, medicine, metal industry, mechanical engineering, medicine |

| Housing color | white-grey |

| Dimensions | 3010x2290x2820 mm |

| Construction area | 500x500x500 mm (including build platform) |

| Layer thickness | 30 µm; 60 µm; 90 µm |

| Layer thickness | metal |

| Platform | metal |

| Print Technology | DMP |

| Operating system | Windows 10 Pro, 64 bit |

| Warranty | 12 months |

| Minimum element size | 100 µm |

| Number of lasers | 3 |

| Laser Power | 500 W |

| Laser wavelength | 1070 µm |

• The ProX 800 3D Printer sets the standard for performance and fine detail. The equipment operates according to SLA technology, focused on the construction of one large part or a series of small products in a full cycle. The technical ability allows the production of samples with a smooth surface that exactly matches the 3D digital model. Additional advantages of the device are the ability to select the necessary material, a clear workflow, saving on waste.

The equipment operates according to SLA technology, focused on the construction of one large part or a series of small products in a full cycle. The technical ability allows the production of samples with a smooth surface that exactly matches the 3D digital model. Additional advantages of the device are the ability to select the necessary material, a clear workflow, saving on waste.

Photo: 3DSystems

Features:

| Country | US |

| Application area | architecture, foundry industry, interior design, foundry industry, education, dentistry, foundry industry, interior design, foundry industry, education, dentistry |

| Housing color | gray |

| Communication interface | LANs, IEEE 802.3 using TCP/IP and NFS, USB |

| Dimensions | 1370x1600x2260 mm |

| Construction area | 650x750x550 mm (including build platform) |

| Layer thickness | 125 µm |

| Platform | mesh |

| Print media | photopolymer |

| Print Technology | SLA |

| Operating system | Windows 10 |

| Warranty | 12 months |

| Minimum element size | 125 µm |

| Maximum weight of model | 75 kg |

| Maximum resolution | 4000 DPI |

3DCeram

The French brand 3DCeram offers services and equipment for 3D printing of original ceramic products. For development work, serial production of samples of complex geometry, the following machines are used:

For development work, serial production of samples of complex geometry, the following machines are used:

• 3D printer CERAMAKER 100 is a brand development aimed at additive manufacturing of ceramic products. This modification is actively used in the chemical and aviation industries, the medical field, jewelry, watchmaking. The equipment operates on the principle of layer-by-layer curing by a laser installation of a special composition of ceramic powder and photopolymer. The latter is a binder and is burned out after the alignment of the object is completed.

Photo: 3DCeram

Features:

| Country | France |

| Applications | aviation and space, automotive, nuclear industry, interior design, railway, mechanical engineering, medicine, dentistry, shipbuilding |

| Dimensions | 1000x1500x1900 mm |

| Construction area | 100x100x100 mm |

| Layer thickness | 50 µm |

| Material | ceramics |

| Print Technology | SLA |

| Warranty | 12 months |

• The CERAMAKER 900 3D printer reproduces objects with a surface roughness of less than 2 µm. Mechanical post-processing of the product is available at every stage of production. The open architecture of the device allows you to customize the work with the necessary materials, and the adjustable size of the platform makes it possible to line up parts of various sizes. Production is carried out without preliminary creation of a form. Evenly distributed UV power over the entire area of the working platform ensures shrinkage is predictable.

Mechanical post-processing of the product is available at every stage of production. The open architecture of the device allows you to customize the work with the necessary materials, and the adjustable size of the platform makes it possible to line up parts of various sizes. Production is carried out without preliminary creation of a form. Evenly distributed UV power over the entire area of the working platform ensures shrinkage is predictable.

Photo: 3DCeram

Features:

| Country | France |

| Applications | foundry industry, jewelry industry, medicine, mechanical engineering, dentistry |

| Dimensions | 1060x2250x2040 mm |

| Construction area | 300x300x100 mm |

| Layer thickness | 35 µm |

| Print material | ceramics |

| Print Technology | SLA |

| Warranty | 12 months |

• The CERAMAKER C3600 ULTIMATE 3D printer is a large scale production equipment. The device is aimed at the production of massive products or large batches of products. The device is compatible with materials that are distinguished by chemical, corrosion resistance, as well as formulations used in dentistry. The industrial unit operates according to the stereolithography method, adopting unassisted printing technology.

The device is aimed at the production of massive products or large batches of products. The device is compatible with materials that are distinguished by chemical, corrosion resistance, as well as formulations used in dentistry. The industrial unit operates according to the stereolithography method, adopting unassisted printing technology.

Photo: 3DCeram

Features:

| Country | France |

| Industries of application | foundry industry, jewelry industry, medicine, mechanical engineering |

| Dimensions | 2100x1800x2500 mm |

| Construction area | 600x600x300 mm |

| Layer thickness | 25 to 125 µm |

| Print material | ceramics |

| Print Technology | SLA |

| Warranty | 12 months |

| Number of lasers | 4 UV lasers |

| Laser wavelength | 405 nm |

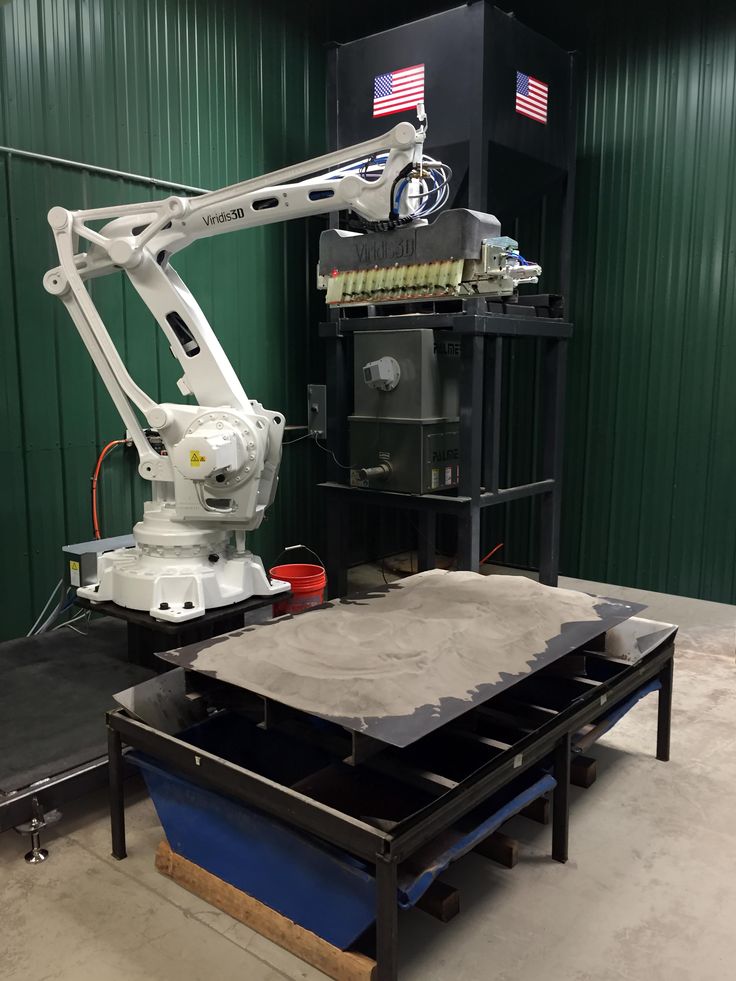

VoxeiJet

The German company VoxeiJet produces 3D machines for the production of sand molds and cores. The company has developed its own line of polymeric materials, and also produces a diverse range - from small-format research devices to large-sized industrial units. Most famous models:

The company has developed its own line of polymeric materials, and also produces a diverse range - from small-format research devices to large-sized industrial units. Most famous models:

• The VoxelJet VX 200 HSS 3D printer is a compact system based on polymer powder sintering technology. The equipment is used for research purposes and to create new resources for the HSS process. An open system makes it possible to control the settings of print modes and parameters of temperature, layer thickness.

Photo: VoxelJet

Features:

| Country | Germany |

| Application area | interior design, aviation and space, automotive, prototyping |

| Construction area | 290x140x180 mm |

| Layer thickness | > 80 micron |

| Print material | polyamide |

| Print Technology | BJ |

• The VoxelJet VX 1000 HSS 3D printer works with polymers. The high-performance system stands out with a capacious build chamber and high print speeds. The machine is useful for large-scale production of plastic parts that are comparable in quality to samples created by injection molding. The equipment is easily integrated into the existing factory line and adapted to the existing production. Material recycling technology reduces the cost of finished products.

The high-performance system stands out with a capacious build chamber and high print speeds. The machine is useful for large-scale production of plastic parts that are comparable in quality to samples created by injection molding. The equipment is easily integrated into the existing factory line and adapted to the existing production. Material recycling technology reduces the cost of finished products.

Photo: VoxelJet

Features:

| Country | Germany |

| Applications | prototyping, mechanical engineering, interior design |

| Construction area | 1000x540 mm |

| Print material | polyamide, nylon |

| Print technology | BJ |

• The VoxelJet VX 4000 3D printer is a 3D sand mold printing system. The printer is capable of producing large items or a series of small items in a single cycle. The device operates in automatic mode, which guarantees the continuity of the manufacturing process. The car provides fast release of products of the set quality. The capacious space of the construction area allows you to print custom objects with exact compliance with the configuration and plus sizes at high resolution. The technique is in demand in mechanical engineering and the aerospace sector. Finished molds and cores can be immediately used for metal casting.

The device operates in automatic mode, which guarantees the continuity of the manufacturing process. The car provides fast release of products of the set quality. The capacious space of the construction area allows you to print custom objects with exact compliance with the configuration and plus sizes at high resolution. The technique is in demand in mechanical engineering and the aerospace sector. Finished molds and cores can be immediately used for metal casting.

Photo: VoxelJet

Features:

| Country | Germany |

| Dimensions | 20000x7800x4000 mm |

| Construction area | 4000x2000x1000 mm |

| Layer thickness | 300 micron |

| Print material | sand |

| Print Technology | BJ |

| Maximum resolution | 600 dpi |

Inss Tek

The Korean company Inss Tek has focused on working with alloys. DMT 3D printing technology has found its way into various industries. The most popular models working with metals:

DMT 3D printing technology has found its way into various industries. The most popular models working with metals:

• The MX-Lab 3D printer is designed for the manufacture of functional devices, remodeling, reconstruction and restoration work, special coatings. The device uses DMT technology, which provides the necessary mechanical characteristics of the finished product, a unique density, the finest microstructure. Entry-level DMT machine with 3-axis laser system is suitable for material properties study, prototyping, alloy development. 9Feature:

| Country | South Korea |

| Applications | aviation and space, metallurgical industry, mechanical engineering, foundry industry |

| Dimensions | 700x700x860mm; 200 kg |

| Construction area | 150x150x150 mm |

| Layer thickness | 150 micron |

| Print material | metal |

| Print Technology | DMP |

| Operating system | Windows 7 |

• InssTek MX-600 3D Printer - The machine is configured to produce small objects with specified mechanical characteristics. Using this technique, you can repair various devices, modernize mechanisms, and create industrial alloys. The technique is able to quickly convert a complex CAD model into a finished part, which is in demand in medicine, electronics, defense and manufacturing industries. The advanced CVM powder feeding system operates at a stable, adjustable speed.

Using this technique, you can repair various devices, modernize mechanisms, and create industrial alloys. The technique is able to quickly convert a complex CAD model into a finished part, which is in demand in medicine, electronics, defense and manufacturing industries. The advanced CVM powder feeding system operates at a stable, adjustable speed.

Photo: InssTek

Features:

| Country | South Korea |

| Applications | foundry industry, metallurgical industry |

| Dimensions | 2000x2900x2550mm; 6.5 t |

| Construction area | 450x600x380 mm |

| Layer thickness | 250 micron |

| Print material | metal |

| Print Technology | DMT |

| Operating system | Windows 7 |

• The InssTek MX-Grande 3D Printer is an industrial system designed for producing large objects. The equipment adopts gravity feeding method or direct powder delivery method with gas. The capabilities of the device are used in the nuclear and oil industries, metallurgy, and shipbuilding.

The equipment adopts gravity feeding method or direct powder delivery method with gas. The capabilities of the device are used in the nuclear and oil industries, metallurgy, and shipbuilding.

Photo: InssTek

Features:

| Country | South Korea |

| Applications | automotive industry, nuclear industry, foundry industry, mechanical engineering, metallurgical industry, oil and gas industry, shipbuilding |

| Construction area | 4000x1000x1000 mm |

| Layer thickness | 750 micron |

| Print material | metal |

| Print Technology | DMT |

| Operating system | Windows 7 |

Conclusion

Large-scale manufacturing giants actively use additive technologies, while developed countries open large research centers and develop state programs. Industrial printers become more affordable every year, pay off faster. All this significantly affects the production process, making it efficient, environmentally friendly and profitable.

Industrial printers become more affordable every year, pay off faster. All this significantly affects the production process, making it efficient, environmentally friendly and profitable.

Source

Tags:

Industrial 3D printers, 3D Systems company, DMP Flex 350 3D printer, DMP Factory 350 3D printer, DMLS technology, 3DCeram brand, CERAMAKER 100 3D printer, CERAMATE3AKER3AKER60 3D printer VoxeiJet, 3D printer VoxelJet VX 200 HSS, Inss Tek

Other materials:

- Zortrax 3D Printed Sports Helmet for Cats

- QIDI TECH S-Box 3D Printer - Reliable Heavyweight!

- 3D Scanner Review: RangeVision PRO5M, Shining 3D PRO HD, Calibry, KSCAN20, Shining 3D HX

- Go!SCAN SPARK vs HandySCAN SILVER/BLACK: which scanner is right for you?

- Printing with nylon (Nylon) on a 3D printer technology features

Attention!

We accept news, articles or press releases

with links and images. [email protected]

[email protected]

Category "Reviews" - a community of owners of 3D printers 3DToday

Reviews of 3D printers and consumables for them, as well as 3D scanners and programs.

Reviews

0

Subscribe to the author

Subscribe

Don't want

Foreword

While sitting with friends and playing board games, the idea arose to replace simple figurines with more interesting and atmospheric ones, as they say, to please the eye. There were no suitable figures for sale, but here are 3D models - in bulk, print as much as you like, but there is nothing to print on ... And now, after long days of watching videos, reading various reviews and studying the market, the choice fell on Anycubic photon m3, about which and will be discussed further.

Appearance...

Read more

Reviews

one

Subscribe to the author

Subscribe

Don't want

So, for half a year I own a Prusa i3 mk3s Bear Upgrade printer. The whole bearish upgrade is to replace the frame with an aluminum profile and use other parts. Doing an upgrade with the original printer, as for me, makes no sense. I built the printer from scratch, and this version came out a little cheaper.

Briefly about the filling: EinsyRambo 1.2b board with TMC2130 drivers. Prusa steppers from aliexpress (except for Z-axis motors they are noun). You can put any suitable dimensions. The z-axis motors do not...

Read more

Reviews

four

Subscribe to the author

Subscribe

Don't want

Here I will try to review not the printer out of the box and first impressions, but what this particular model is interesting for after a long operation and what can be expected from it without any modifications in the design. Are you a 3d person? Perfectionist? Do you have ideas for using a 3D printer for commercial purposes, or can you draw not only a "square" and a "stick" in an editor convenient for you? Don't waste your time reading this article. And if you once indulged in standard at school ...

Are you a 3d person? Perfectionist? Do you have ideas for using a 3D printer for commercial purposes, or can you draw not only a "square" and a "stick" in an editor convenient for you? Don't waste your time reading this article. And if you once indulged in standard at school ...

Read more

Reviews

24

Subscribe to the author

Subscribe

Don't want

I present a review of a self-made FDM printer of my own design, similar to one of the classic delta kinematics. Made in a passive closed chamber, equipped with a "direct" extruder.

Necessity pushed to assemble the printer. my work printer (BIQU MAGICIAN's small home delta) has fallen into disrepair and needs a major overhaul. I have already been assembling my first home-made printer for about 4 years, and it is still not ready, but I need to print. The project presented in the review ...

The project presented in the review ...

Read more

Reviews

2

Subscribe to the author

Subscribe

Don't want

Good afternoon, dear beginners and experienced people! Yesterday a new worker from China called flying bear ghost 6 came to me. configuration, it is rich enough for the printer, you don’t need to buy anything to start working. The printer is small 377x365x349, perfect for home use, 250 * 210 * 210 print area is completely enough for the fun of a home designer. externally assembled very carefully, wires do not stick out from anywhere,...

Read more

Reviews

2

Subscribe to the author

Subscribe

Don't want

Dreambot 3D printers are reliable high performance devices for professional use. In this article, we will look at the features of Dreambot large-format 3D printers for printing with photopolymer resins and plastics.About the company

In this article, we will look at the features of Dreambot large-format 3D printers for printing with photopolymer resins and plastics.About the company

Shenzhen Dreambot 3D Technology Co., Ltd is a Chinese high-tech enterprise specialized in the production of industrial 3D printers and large format equipment. The company was founded in 2008 and was first engaged in the production of...

Read more

Reviews

one

Subscribe to the author

Subscribe

Don't want

Hello, Friends! 3DTool is with you!

The difficult situation in the 3D printing market makes it necessary to select equipment for purchase more carefully, especially when it comes to analogues of devices subject to trade sanctions or discontinued for one reason or another. Speaking of stereolithographic (SLA) 3D printing, we most often remember the unpretentious and high-quality printing Formlabs Form. But what if these devices are no longer available in our market? It's time to look...

But what if these devices are no longer available in our market? It's time to look...

Read more

D!al Up

Loading

10/17/2022

4392

Reviews

37

Subscribe to the author

Subscribe

Don't want

Hello everyone. The photo in the header is for those who start talking about the frivolity of my project. I myself know)

So, I collected all kinds of different circuit printers, but somehow my hands did not reach the delta. From the experience of reworking the finished delta, there is a Frankenstein, the former Anycubic Kossel in the world, which came out surprisingly well in terms of print quality and accuracy. Of course, after long dances with a tambourine. Here he is, handsome.

If anyone pays attention to the extra engine in the os. ..

..

Read more

Reviews

four

Subscribe to the author

Subscribe

Don't want

Good day to all.

Immediately to all readers who want to ask the question: "What does 3d printing have to do with it?". The answer is towards the end of the article. And this is not a banal "because this company produces printers"). Good reading.

In this article, as it has already become clear, we will focus on the Flying Bear Laserman laser engraver. Engraver, from a company well known for making good, quality 3d printers that many people love. I am the owner of Flying Bear Reborn, for which I am...

Read more

Reviews

5

Subscribe to author

Subscribe

Don't want

This year, Raise3D released the MetalFuse metal 3D printing system, consisting of a Forge1 3D printer, a D200-E catalytic resin removal station, and an S200-C vacuum furnace.