3D printed teeth braces

A College Student Has 3D-Printed His Own Braces For Less Than $60 : ScienceAlert

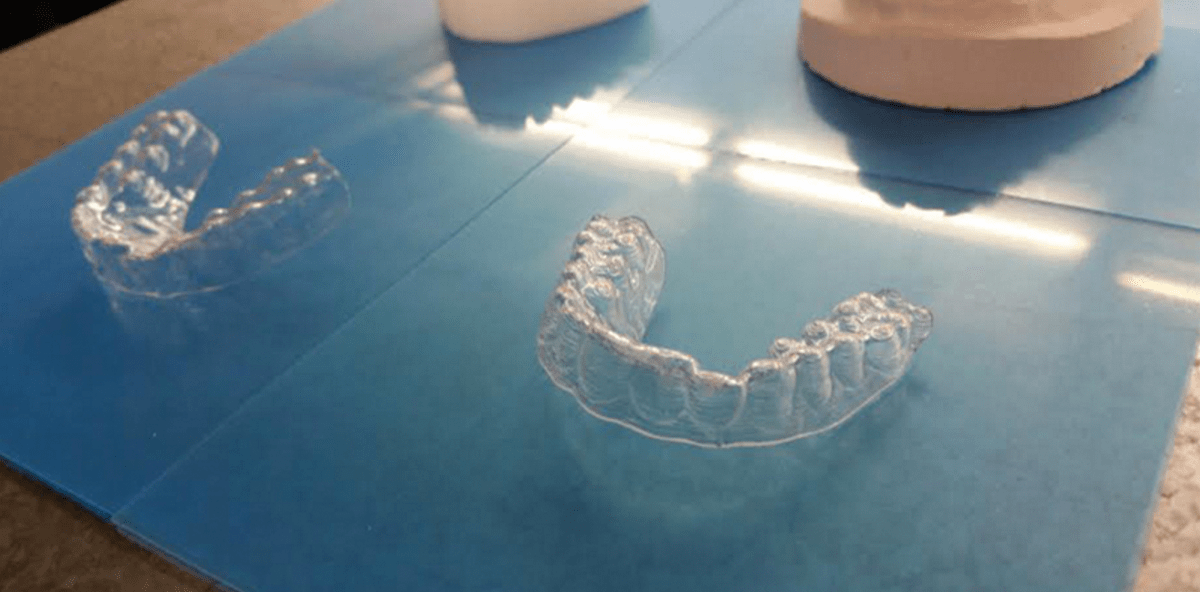

The finished product. Image: Amos Dudley

A digital design student in New Jersey went viral over the weekend after 3D-printing his very own set of clear, orthodontic aligners - just like the ones that sell for thousands of dollars - all for less than US$60.

Twenty-three-year-old Amos Dudley had braces as a kid, but failed to maintain them, so was left with a crooked smile that he hated. As a poor college student, he couldn't afford more orthodontist work… but he did have access to state-of-the-art digital fabrication tools at university, so he decided to create his own aligner and see if he could fix his teeth himself. From the photos at least, it seems to be working.

You can see below his before and after images, showing 16 weeks of progress:

Amos Dudley

Dudley was inspired after researching brand name aligners and spotting the tell-tale 3D-printed layer striations in some of the up-close images. He'd seen those same striations in his own university creations.

"What is to stop someone, who has access to a 3D printer, from making their own orthodontic aligners?" writes Dudley on his blog. "Turns out, not much!"

After a lot of research into the proper orthodontic process, Dudley started by taking a mould of his teeth using alginate powder and then filled it with liquid PermaStone to set it. He then scanned the cast, and used software to digitally model the progression of his teeth towards his ultimate goal.

Amos Dudley

That's a lot trickier than it sounds - Dudley first needed to separate the teeth into different objects and plan out a route for them to travel so that they moved but didn't intersect with each other.

"Then it was just a matter of animating them into their correct positions," he writes. "I measured the total distance of travel, and divided it by the maximum recommended distance a tooth can travel per aligner. Each frame of animation was baked into a new STL model. "

"

Amos Dudley

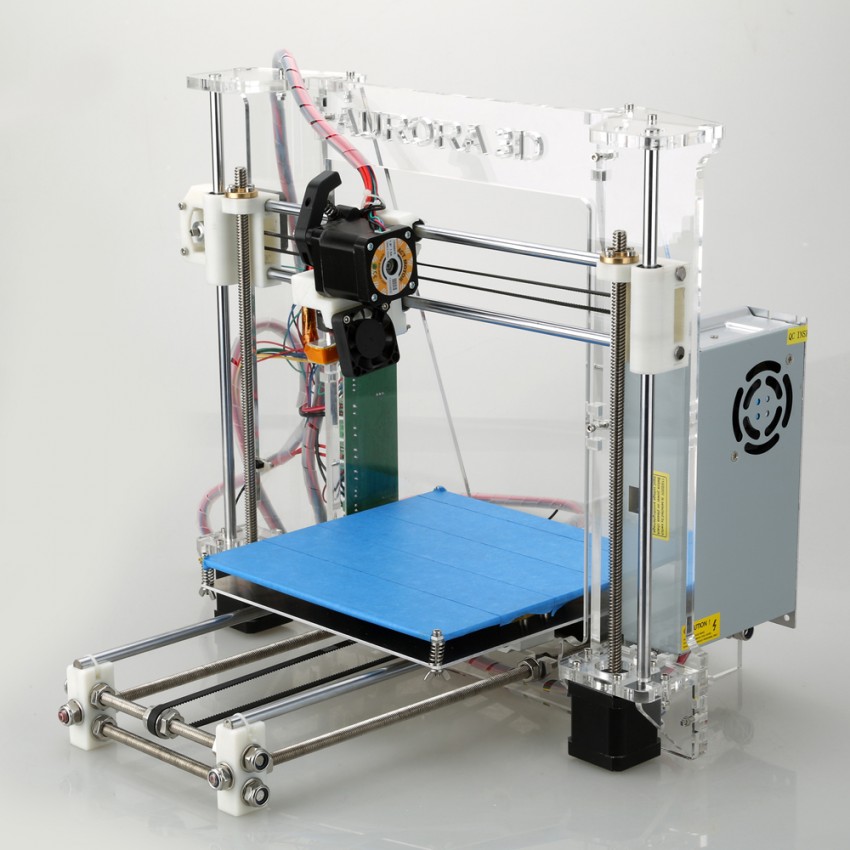

Using a Stratasys Dimension 1200es 3D printer from the New Jersey Institute of Technology, Dudley printed out each of the 12 models, and with a vacuum form machine, created plastic aligners over the top, using special dentist plastic he bought on eBay.

That part's important, because you can't actually print the aligners themselves, just the teeth they're modelled on - not only would 3D-printed aligners be uncomfortable, but the plastic is porous and would end up growing bacteria in your mouth. "These have to sit in the mouth without breaking down or releasing toxic chemicals, so the quality of the plastic is important," Dudley explains.

He's already been wearing the aligners day and night - only taking them out to eat - for 16 weeks, and wants to continue using them.

"As far as I know, I'm the first person to have tried DIY-ing plastic aligners. They're much more comfortable than braces, and fit my teeth quite well. I was pleased to find, when I put the first one on, that it only seemed to put any noticeable pressure on the teeth that I planned to move - a success!" he writes. "Most importantly, I feel like I can freely smile again."

"Most importantly, I feel like I can freely smile again."

Amos Dudley via CNN Money

But while Dudley thinks his own experiment was a success, he doesn't recommend anyone else print their own aligners - and he's not going to start doing it for others any time soon.

And that's a good thing, because while the idea works in theory, there's a reason it takes around 10 years of training to become an orthodontist.

"I'm impressed with the way [he] was able to use the scanning and printing technology that he had available to engineer and produce his own aligners but a little frightened that he would actually use them to treat himself without a professional assessment of the health and function of the teeth," practising orthodontist Brent Larson, who teaches at the University of Minnesota, told Sophie Kleeman over at Gizmodo.

"In fact, when looking at the images of the DIYer's teeth, there are specific areas of tooth wear visible that indicate unbalanced function and possible nighttime grinding. "

"

And he's right to be worried - there have been some terrifying examples of DIY dentistry in the past.

"This isn't like home remodelling where if you get into trouble you can always call in a professional later," said Larson. "Damage could result in loss of the supporting tooth root, gum recession, or, in the worst case, loss of teeth."

But while no one's recommending you start doing your own orthodontics at home, Dudley's experiment - and the interest in it - has highlighted the fact that people are "frustrated with the state of the orthodontic appliance industry," he told BuzzFeed. "There's not enough competition, and prices are very high."

Hopefully this will put more pressure on trained, industry professionals to come up with safer and more affordable options for everyone. And isn't that what disruptive technology is all about?

How to 3D Print Plastic Braces for $60

US Markets Loading... H M S In the news

Chevron iconIt indicates an expandable section or menu, or sometimes previous / next navigation options. HOMEPAGE Save Article IconA bookmarkShare iconAn curved arrow pointing right.

HOMEPAGE Save Article IconA bookmarkShare iconAn curved arrow pointing right.Download the app

Amos DudleyAn undergraduate at New Jersey Institute of Technology made his own plastic braces using a 3D printer, $60 of materials, and a healthy dose of ingenuity — and they actually worked.

Amos Dudley had braces in middle school, but he didn't wear a retainer like he was supposed to, so his teeth slowly shifted back.

He didn't want to shell out thousands of dollars for a whole new round of braces, so the digital-design major decided to make his own.

On his blog, Dudley wrote that he was an unlikely combination of two things: He was broke, but had access to a high-quality 3D printer through his university. He took full advantage of this.

The process wasn't exactly easy. He had to research orthodontic procedures and plot the route of his successive braces, so his teeth would move in the right way. But once that was done, all it took was fabricating a series of models out of relatively inexpensive plastic, and then following through on wearing them.

And it was worth it for Dudley, whose smile turned out looking remarkable.

Here is the process he went through:

Dudley ran across a photo from a "name brand clear-alignment treatment" and noticed that the plastic looked like it had the layer striations from a 3D print. So what was to stop him from 3D-printing his own, he thought.

Amos DudleyFirst he took a mold of his teeth with alginate powder.

"These molds are very precise, and capture an amazing amount of detail," he writes. "There were some bubbles in the mold," but they wouldn't matter for the aligner. Amos Dudley

"These molds are very precise, and capture an amazing amount of detail," he writes. "There were some bubbles in the mold," but they wouldn't matter for the aligner. Amos Dudley Making this casting was simple, he says. "I put the mold upside down in a yogurt container, and then filled it with liquid Permastone," he writes. "When it came out, I simply broke off the top to reveal the casting, and used a razor blade to smooth out the surrounding area."

Amos DudleyNow he had a better sense of what was going on with his teeth.

You can tell specifically that the LI-r (right lateral incisor) juts out. Amos Dudley

You can tell specifically that the LI-r (right lateral incisor) juts out. Amos Dudley The laser scanning was reasonably painless, he says, though he describes the NextEngine software interface as "awful." "The dimensions of the scan seemed to correspond very closely to the dimensions I measured on the physical model with calipers," he writes. He also says creating the animation, which would show the path his teeth would take through different iterations of the braces, wasn't particularly difficult either.

Amos Dudley"Here’s where it started to get very exciting," he writes.

The 3D printing of the molds. Amos Dudley

The 3D printing of the molds. Amos Dudley An up-close view of the 3D-printed mold.

Amos DudleyThese are the "steps" all 3D-printed out. "Labeling the pieces is critical," he advises. "They look virtually identical."

Amos DudleyAfter the final versions of the braces came out of a vacuum-form machine, Dudley sanded down the edges so they wouldn’t irritate his gums.

Amos Dudley

Amos Dudley But did they work? Here was his smile before.

Amos DudleyAnd after about four months.

Amos DudleyIf you want a more in-depth look at the process, check out Dudley's blog. (Just don't ask him to print any braces for you.)

(Just don't ask him to print any braces for you.)

Read next

LoadingSomething is loading.Thanks for signing up!

Access your favorite topics in a personalized feed while you're on the go.

Features 3D Printing3D printed teeth kill bacteria - Medicine

3D printed teeth kill bacteria - Medicine | Trends on json. tv

tv - Main

- Trends

- The medicine

- 3D printed teeth kill bacteria

2 November 2015 07:36

19213

The creation of spare parts for various parts of the human body has long been the norm for medicine in general and is called prosthetics. But 3D printing brings new opportunities to this industry and has huge potential, as it is focused on each person individually, and does not allow all people to choose from some standard.

Dental implants are also on this list. Scientists at the University of Groningen in the Netherlands have printed teeth that have a 99 percent chance of killing bacteria in the mouth. That is, harmful microorganisms do not accumulate on such teeth at all, and such a process as caries or a banal smell from the mouth in the morning is impossible. Such teeth are only exposed to mechanical stress and can wear out over time, like any material object.

Such teeth are only exposed to mechanical stress and can wear out over time, like any material object.

Scientists have also developed braces that fight bacteria and fungus using antimicrobial resin. This design is installed on the teeth until the fight against inflammatory processes is necessary without or together with the use of antibiotics.

To create an antibacterial resin, researchers combined antibacterial ammonium salts with standard dental resins. The resulting mixture is cured with ultraviolet light and placed inside a 3D printer to print samples, including replacement teeth.

A positive charge on the ammonium salt gives a resin that kills bacteria, while a negative one fights inflammation that is already occurring in the human mouth.

To test the antibacterial resin, the researchers used a mixture of saliva and bacteria that cause cavities, as well as streptococcus and other pathogens. All of them were destroyed in 99 percent of the cases on the samples. The designed material for teeth, therefore, can kill bacteria on contact, but is not harmful to human cells.

The designed material for teeth, therefore, can kill bacteria on contact, but is not harmful to human cells.

The scientific work was published in the journal Advanced Functional Materials.

Author: Stepan Mazur

Original photo: gizmag

Source: http://www.gizmag.com/3d-printer-teeth-kill-bacteria/40161/

- > Review: Samsung Galaxy C9 Pro

- > LG G6 vs Moto G5 Plus: flagship and budget phone in the Android world

- > Swatch creates its own operating system for smartwatches

- > Windows 10 will make some updates out of the plan

- > BLU launches budget $180 Android smartphone with Full HD and 4GB RAM

{ "prev":"/ict_news_read/smartfony-s-windows-10-i-pk--20151102073337", "prev_topic": "Windows 10 smartphones and PCs will work better together from 2016", "next": "/ict_news_read/naydiid-selskoe-hozyaystvo-20200213045732", "next_topic":"Find iD" " }

IBT Resin - fast and easy bracket placement

Formlabs is pleased to introduce IBT Resin, a resin designed to print an indirect adhesive bonding matrix to make orthodontic bracket placement easier. In addition to rapid model building resins such as Draft Resin, Formlabs now offers a comprehensive range of 3D printing materials that save time, money and labor for professional orthodontists.

In addition to rapid model building resins such as Draft Resin, Formlabs now offers a comprehensive range of 3D printing materials that save time, money and labor for professional orthodontists.

3D printing continues to prove its worth in orthodontics

Digital technology began to change orthodontics over a decade ago. With the widespread use of 3D printing to produce clear aligners, the industry has ushered in an era of mass-produced, affordable, custom-fitted products, allowing professionals to deliver healthcare services faster and easier, and improving the comfort of professionals and patients.

Aligners continue to gain popularity with patients, with so-called "invisible braces" appealing to adults and young adults alike. In the meantime, technology is allowing professionals to create their own aligners, making the treatment available to more patients. However, clear aligners remain clinically limited, and traditional orthodontic brackets are still indicated and preferred in many cases.

3D printed indirect bonding matrices are now available to reduce the labor and cost of bracket placement.

Save time and money on bracket placement

Indirect Adhesive Matrices are a custom made product that fits your individual teeth exactly and allows you to place multiple brackets at once. Since preparation and precise placement can be provided virtually in advance, the length of time a patient spends in the dentist's chair can be cut in half, thereby saving the orthodontist's valuable time.

Compared to other 3D matrix printing resins, Formlabs IBT Resin has optimum tensile strength, transparency and flexibility. Products printed from this polymer are easier to use in the dental office. They save practitioners time and money.

What makes Formlabs photopolymer different?

- Enhanced color for clearer visualization of brackets against teeth.

- Manufacture of end products without taste, odor and sticking.

- The minimum amount of material required to create supporting structures.

- No need for final polymerization using glycerol or nitrogen.

What are its advantages over other brands?

- Convenient use in the dental office with fewer errors.

- Comfortable conditions for patients.

- Reduce waste and reduce post-processing activities.

- Simple and convenient post-processing.

This polymer is a Class I material. It has been rigorously tested by Formlabs and industry experts. Beta testers of the material liked its accuracy, printability, and ease of use in the dental office.

Lisa Alvetro, an orthodontist at a private clinic in Sydney, Ohio, USA, tested the polymer before it was released.

“Clinically, indirect adhesive luting matrices printed with Formlabs IBT Resin have demonstrated accuracy and ease of insertion and removal” , she noted.

Dr. Alvetro has found that digital workflows such as 3D printing allow her to outsource much of her day-to-day work to highly skilled employees such as Patricia Mitchell, the digital workflow specialist used in their orthodontic clinic.

“With years of experience printing indirect bonding dies, I have found that Formlabs IBT Resin can easily create accurate models using PreForm software. I really like that IBT Resin has almost no smell. The printed matrices for indirect adhesive luting are easily removed from the work platform and their post-processing procedure is very simple. IBT Resin printing left a very positive impression!” - Patricia Mitchell, Digital Workflow Specialist, Alvetro Orthodontics

How to use IBT Resin

Working with IBT Resin is easy if your orthodontic practice or lab is already using digital instruments.

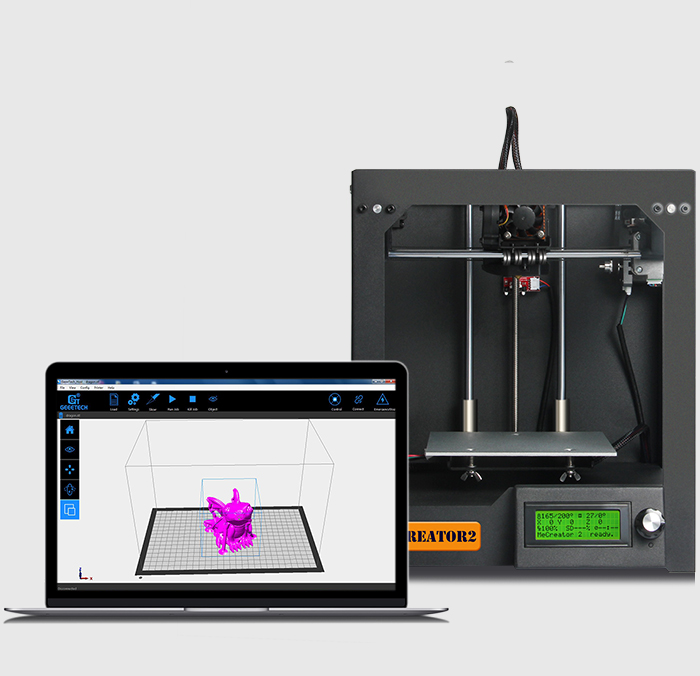

With intraoral scanning and a digital treatment plan, an orthodontist, technician or assistant can create a 3D matrix model in just a few minutes using any of the various orthodontic design software. The resulting STL file can be directly imported into the easy-to-use PreForm software and prepared for 3D printing.

3D printing a model on a Formlabs SLA 3D printer is an automated process.