3D printed apartment building cost

Constructing the World’s First 3D Printed Apartment Building

Keep up with us!

Learn more about BIM, VR & AR.

Sign up for our newsletter below

Click outside the box to close

Exciting innovations in 3D printing is starting to change the way business is done in all sorts of industries – from medical devices to auto parts and even fashion. Engineers have been looking to 3D printing to revolutionize construction materials and techniques for several years now. A Chinese company, WinSun, has even recently completed its first 3D-printed apartment building – a five-story, 11,840-square-foot villa at Suzhou Industrial Park.

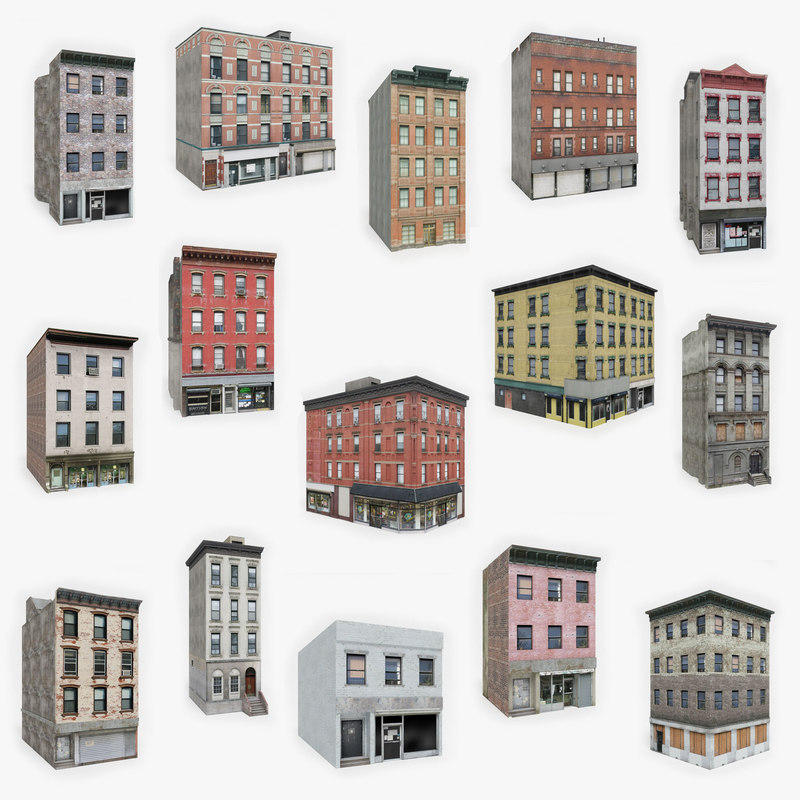

The WinSun 3D Apartment Building

A 3D printing inventor, Ma Yihe, developed the printer that created this building, and the printer stands 20 feet high by 33 feet wide by 132 feet long in size. According to CNET, the company assembles structures onsite, with steel reinforcements and insulation to comply with official building standards. The printer uses a CAD design as a template and prints the walls hollow with an internal zigzag pattern to leave room for insulation and for reinforcement.

Strength of 3D-Printed Materials

Many people entrenched in the traditional construction industry are concerned about the strength and stability of 3D-printed materials. However, site testing has shown that some types of 3D printed materials are actually better suited to extreme weather and environmental conditions. For example, curved walls can withstand earthquakes better than standard straight walls, and even straight 3D printed walls typically fare better than most traditionally-built walls today.

Budget-Friendly Designs

Although 3D printers can potentially make many different shapes and sizes, engineers on a budget are sticking to basic designs that get the job done at a minimal cost.

“Architects are crazy about those exotic designs, but they are expensive to do,” said Berok Khoshnevis, a University of Southern California engineering professor and director of the Center for Rapid Automated Fabrication Technologies. “To the printer, the task is not harder or easier.” Using CAD/CAM, the architect can make structures that are as swervy, complicated, and structurally sound as any structure in history.

“To the printer, the task is not harder or easier.” Using CAD/CAM, the architect can make structures that are as swervy, complicated, and structurally sound as any structure in history.

Speed and Efficiency

Another perk to 3D building is the speed and efficiency with which construction could soon be completed. If building materials can be printed and organized in advance, then the actual construction time would be greatly reduced. For example, Kohshnevis says that he’s developed a process that can build a 2,500-square-foot home within a mere 20 hours. Most residential and commercial consumers don’t need this extreme level of building speed; however, this type of process could certainly be useful in emergency situations and natural disaster sites.

Overall Cost Savings

Although 3D printing is still a fairly expensive option for the construction industry, at least in terms of upfront investment, there are a few long-term benefits to consider. With these promises of speed and efficiency, the cost of labor would be greatly reduced and very few materials would go to waste.

With these promises of speed and efficiency, the cost of labor would be greatly reduced and very few materials would go to waste.

In WinSun’s apartment building, for example, the 3D printing process saved between 30 to 60 percent of construction waste, decreased production time by 50 to 70 percent, and reduced labor costs by 50 to 80 percent. Construction of the total apartment building cost just $161,000.

Photo credit: Youtube, and Creative Tools via Flickr

Autodesk University

September 27-29, 2022 Autodesk University Get the chance to learn from and network with business leaders who are advancing the fields of architecture, engineering, construction, design, manufacturing, and media and …

BIM Services – What is it and why is it valuable?

What is BIM Services? Building Information Modeling (BIM) software has gained popularity over the past several years as the new standard for the design, documentation, and execution of construction projects. …

…

Accelerating AEC Innovation in a Post-COVID World

About The Event https://community.shadow.vc/events/danielle-dy-buncio-event/ Over the last few months, we’ve witnessed the global pandemic change the way people live, work, and interact with each other. It has forced the acceleration …

Enabling Automation in The Built Environment

Enabling Automation in the Built Environment The building and construction industry is primed for automation. The automatic manufacturing of the “stuff” of a building – the parts and pieces that …

How VIATechnik is Promoting Mass Timber Construction with BIM

The world’s population is booming. According to the United Nations Department of Economic and Social Affairs, urban areas will welcome 2.5 billion new residents by 2050. In addition to requiring …

The cost of 3D printed houses in 2021

3D printed houses bring the benefits of additive manufacturing to the construction space. The material costs incurred by construction 3D printing are usually an order of a magnitude less when compared to conventional methods. This is while we take into account the fact that 3D printing concrete tends to be more expensive than normal construction concrete.

This is while we take into account the fact that 3D printing concrete tends to be more expensive than normal construction concrete.

As for labor costs, they drop down basically to the daily wages of at most two or three operators. And that too is for a much shorter length of time as the 3D printed house would be ready for finishing and furnishing in days instead of months.

The cost to build an average sized 3-bedroom house with conventional building methods is from $250,000 to $320,000. Building the same home with 3D printing technology would cost from 20 percent to 40 percent less to build. So that same 3-bedroom house would presumably cost between $140,000 to $240,000 to build with 3D printing technology.

It should be noted at this point, that most construction 3D printers will not build, or 3D print the foundations, nor would the construction 3D printer be of any cost-saving benefit when it comes to roofing the house.

All those things: the roof, the windows, the doors, electrical wiring, paint and finishing – all of these costs remain the same as with a conventional house, as all this fall outside the scope of what a construction 3D printer is capable of.

University of Nantes researchers designed and constructed a full-size single-family house via construction 3D printer in France at a cost of $232,000 in 2018. Which was twenty percent less than what a similar sized building would have cost to construct via conventional means.

Haus.me – the business that sells the PassivDom highly insulated prefabricated houses, charges $210,000 for a ready to move in luxury 3D printed smart house that is entirely self-sufficient and filled to the brim with smart features.

Zillow listed 3-bedroom 2 baths 3D printed house with 1,900 square feet, asking price of 299,999The Dubai Future Foundation office that was 3D printed off-site by Winsun cost $140,000 at the time for the entire structure. With the fit and finish of this luxury office, a hundred and forty thousand dollars is quite a bargain seeing as how by using construction 3D printing technology, the government estimates that it saved almost 50% on the total (assembly, electrical, and technical) labor costs.

All three of the above are examples of luxury or large-sized 3D printed houses that cost a sizably less amount than what an equivalent construction done via conventional methods would cost.

On the other end of the scale are the small size houses that have been making headlines and have successfully been 3D printed at a fraction of conventional costs.

COBOD’s construction 3D printing services provide an online project cost calculator based on various factors such as the square meter area of all the walls, labor cost and number of operators, and the cost per unit of 3D printing concrete.

The cost of construction comes out to be around $15,000 for a small sized house (single bedroom). $20,000-25,000 for a medium sized house (two bedroom). And around $50,000 for a large sized 4 bedrooms house.

Compare this with the fact that building one’s own house can cost anywhere between $95 to $150 per square foot and it quickly becomes clear that even construction 3D printing services have a lot to offer in terms of cost savings.

On the extreme end of affordable housing of course, stand ICON and WASP’s efforts.

ICON and New Story’s 500 sq. Foot houses 3D printed on-site in El Salvador cost around $4,000-5,000 per house.

And WASP’s earthen house village made with their construction 3D printer. The average raw material cost per house came out to only 48 euros per house.

While costs are often the most quoted benefits of shifting to construction 3D printers. The time scale benefits are one of the most staggering numbers.

As a matter of fact, most 3D construction projects never need more than a month to 3D print even the most complex designs.

The Future Foundation Office of Dubai took a total of 3 months to go from idea to operational office.

Europe’s first 3D printed office, The BOD, only took 22 days on their first attempt, and this was reduced to just 3 days when COBOD reperformed the construction 3D printing of the building as a test 2 years later.

And of course, ICON’s 500 sq. foot houses take only a day each to go from nothing to a completely finished and ready-to-move-in house.

The mere thought of constructing an entire house in a single day is nothing short of amazing.

Compare this with conventional construction, and it is normal to expect ANY house to take at least several months to be ready to move in.

As it stands, consumers in most cases would be unable to commission a 3D printed house construction directly. The printers themselves are expensive investments for any local construction company. 3D construction printer generally starts at $39,000 for the small basic models, to the upwards of $100,000 for the larger models.

Apart of from the cost of equipment and materials, there’s another major hurdle in purchasing a 3D printed house depending on where you are located. Only a handful of construction permit have been handed out for 3D printed houses, in special experimental cases, in select areas.

The mass of 3D printed houses is currently being developed in more technologically primitive areas. However, for anyone interested, a good place to start would be to contact the large-size local construction companies first. And then, as option B, contact the construction 3D printer makers themselves.

One exception of course, is Haus.me. The luxury prefabricated home maker readily sells its houses conveniently online via both monthly installments plans as well as outright cash purchases.

PassivDom’s self-sustainable 3D printed house. Available from haus.me. Photo curtesy of PassivDomOthers such as COBOD (www.cobod.com) provide construction 3D printing services, albeit in limited areas of Europe.

Another potential website to check out is www.weprinthouses.com. However, they are currently only taking requests and not orders. Additionally, at a cost of $100 per square foot for the construction alone, there is not much of a cost saving benefit transferred to the customers.

The company based out of Austin Texas has been awarded the first commercial permit to build a 3D printed house that can appraised and sold in the U.S. The construction project has been given the code name the Genesis. Construction begins February of 2020.

See our post, when will 3D printed houses finally become available where we look at the viability of 3D printed houses, plus when and where 3D printed houses will be commercially available to begin with.

Tags: 3D printing3D printing housesHouse

How much does a 3D printed house cost?

3DPrintStory News How much does a 3D printed house cost?

Every new innovation comes to market with a price. For example, large concrete 3D printers had a fairly high price when they first launched. But as with most technology, prices are falling as new, better, and more affordable products are developed. New innovative concrete mixtures also contribute to lower prices.

But as with most technology, prices are falling as new, better, and more affordable products are developed. New innovative concrete mixtures also contribute to lower prices.

Since there are a number of 3D printed building projects around the world, it is impossible to give an exact price for a 3D printed house. Instead, we'll take a look at some of the most recent and promising projects and their prices.

However, in general, jumping ahead a bit, you will see that a 3D printed house can cost as little as $10,000, sometimes less. Let's take a look!

Example 1. House Apis Cor

One rather promising project from Russia. Apis Cor is a Russian company that specializes in the development of a mobile 3D construction printer capable of printing entire buildings on the spot.

Apis Cor built a 410 square foot home to showcase the potential and capabilities of its mobile 3D construction printer. The 3D-printed house cost the company about $10,150 - an incredibly low amount for building a house.

Here is a more detailed list of costs, according to the company's website:

- Foundation: $277

- Walls: $1624

- Floor and roof: $2434

- Wiring: $242

- Windows and doors: 3

- Exterior: $831

- Interior (including stretch ceiling): $1,178.

The company even decorated the house both inside and out. The outside of the house is painted, but inside there is a refrigerator, a large-screen TV, a sofa and other furniture. True, furniture is clearly not included in the price. Apis Cor just wanted to showcase what a finished home could look like.

Example 2. Is ICON a home for less than $4,000?

Look at the picture above. This house was 3D printed by Texas-based ICON.

ICON specializes in low cost building solutions, so their main project is a 3D printed house.

In partnership with the non-profit organization New Story, ICON plans to build an entire block of these affordable 3D printed houses in El Salvador. The goal is to provide housing for people who, unfortunately, do not yet have adequate housing conditions.

The goal is to provide housing for people who, unfortunately, do not yet have adequate housing conditions.

A prototype 3D printed house cost about $10,000, but the company says it can bring that down to $4,000, which is amazing and impressive news. The approximate assembly time for such a house from ICON is approximately 24 hours.

Example 3 Winsum - 10 houses in one day

Winsun from Shanghai became famous in 2014 by reaching the 3D printing milestone of 10 houses in just one day!

Winsun used large concrete 3D printers, 10 meters wide and 6.6 meters high. The company said that each 3D printed house costs $4,800, which is surprisingly low for 2014!

Although Winsun's 3D houses are not so exquisite, they have generated a lot of public interest. This project has definitely contributed to the increase in the number of houses made with 3D printers and the development of 3D printers themselves for their production.

Winsun is also known for producing one of the most advanced 3D printed buildings to date, which we will discuss in the next section. ..

..

Example 4 Office Building in Dubai in the world, printed on a 3D printer. What it is? Beautiful and futuristic office building in Dubai.

The entire 3D printing process took Winsun only 17 days. Up to this point, we have mentioned fairly cheap 3D printed houses, but this building was clearly more expensive - around $140,000. However, compared to what it would have cost had it not been 3D printed, the final price is impressively low.

Conclusions

As we mentioned above, it is difficult to give an exact price for 3D printing at home, since the price depends on the size and complexity of the design.

But keep in mind that these days you can 3D print a house for as little as $4,000. This price covers the frame of the house (base, walls, roof) and, in some cases, wiring.

As you may have noticed, the cost of an office building in Dubai is quite high compared to cheaper and smaller 3D printed houses. For high-tech concrete 3D printed projects, expect construction costs to be around $100,000, which is actually quite low compared to the cost of building the same building using traditional building techniques.

Over time, more and more companies will implement 3D printing of buildings. This, coupled with advances in technology, is sure to drive prices down and quality up.

How are the 3D printed houses?

The idea of 3D printed houses has been around for a long time. In this article, you will learn about the first projects of 3D printed houses, brought to reality.

Let's face it, 3D printed houses are still quite the off-kilter trend. Although construction 3D printing has been in development for several years, it is only recently that some “real” projects have seen the light of day. We are still far from technology replacing traditional building methods. But with each new project, the technology is becoming more and more popular.

This is partly due to the many benefits of 3D construction printing. For example, the cost of a 3D printed house can be much lower than an equivalent house built in the traditional way. In addition, the cost of construction is also much less.

To interim fix the first results, this article will focus on some "first" 3-D projects. These buildings will always remain important to the construction 3D printing industry as they set the stage for future advances in the field.

Germany's first 3D printed house

Germany is a country often associated with cutting-edge engineering, so let's start our list with the world's first 3D printed house in Germany.

The house itself is located in Beckum, a city that is part of North Rhine-Westphalia, next to the Netherlands and Belgium. And that's important because it's the first 3D printed house to be fully certified to the national government's building codes. The implications of such an achievement are expected to pave the way for many other 3D printing construction projects in Germany as well as the rest of Europe.

The project is the result of a collaboration between Peri, a German construction company, and COBOD, a Danish firm that specializes in construction 3D printing technology. Peri is a large corporation operating not only in Germany, but throughout the EU. They have many products, including scaffolding and formwork solutions, that every construction site needs.

Peri is a large corporation operating not only in Germany, but throughout the EU. They have many products, including scaffolding and formwork solutions, that every construction site needs.

Peri followed the construction 3D printing business for many years before acquiring a stake in COBOD in 2018 to further develop the technology. Both parties started building the house in Beckum just two years after the acquisition of the stake.

COBOD BOD2 Modular Concrete 3D Printer was used for a printing process that took just over 100 hours.

First privately owned 3D printed house in the US

There have been several 3D printed houses built in the US, but this is the first officially owned home, according to CNN. Alquist 3D has partnered with Habitat for Humanity Peninsula and Greater Williamsburg to design, develop and build the home.

From a distance, you might think that this is an ordinary house. However, as you get closer, the layered concrete structure of the walls reveals the building's secret: it's made using 3D printing.

Surprisingly, the concrete structure of this 1,200-square-foot home was completed in about 12 hours, significantly faster than traditional construction methods would have allowed.

April Springfield reportedly bought the house and will live there with her son and dog. She purchased the house through the Habitat for Humanity housing program. Given that the goal of the non-profit organization is to make a positive impact on the global housing crisis, it makes sense to use 3D printing to create homes that can be offered at very affordable prices, thereby making many people's dreams of owning their own home come true.

The first five-story 3D printed house

This project, made by the Chinese company WinSun, is a real record holder. It is a 3D printed five-story apartment building with a height of 10 meters, making it the tallest 3D printed building.

The building is located in Suzhou Industrial Park in Jiangsu Province in east China. It stands next to a mansion that was also built by WinSun using a concrete 3D printer.

It stands next to a mansion that was also built by WinSun using a concrete 3D printer.

Looking at WinSun designs, you can't help but notice that they look like they weren't even 3D printed. Typically 3D printed structures are gray in color and clearly show layer lines. But WinSun loves to add some color and make the walls smoother, making their projects more like the buildings we're used to. Although it is not stated how they do it, we assume that the workers manually level the walls.

First 3D printed biodegradable house

Most 3D printed buildings are made from some sort of concrete mix. But this project is different. With the aim of creating housing solutions with virtually no environmental impact, the Italian company WASP 3D printed the Gaia house using soil and agricultural waste.

To create the perfect blend of wall materials, WASP partnered with Ricehouse, a company that specializes in natural and agricultural building materials such as clay and rice.

The house is called Gaia because the soil is used as a binder in the walls. In fact, 25% of the mixture contains local soil as well as 10% hydraulic lime, 25% rice husks and 40% crushed rice straw (a by-product of rice production at harvest).

In addition to the mix of materials, innovations are also reflected in the design of the walls themselves. A special corrugated structure was used to provide ventilation on warm days as well as insulation during cold periods, virtually eliminating the need for air conditioning.

The Gaia house is indeed a small building with an area of about 215 sq. m. ft. However, the wall printing only took 10 days, and the estimated materials cost is just under $1,000.

AirBnB's first 3D printed house

There are many different types of accommodations on AirBnB, but what about a 3D printed house?

The so-called Fibonacci House is the first 3D printed house to be booked through AirBnB. Given that it is located in rural British Columbia, this is a wonderful and exciting place to stay.

Given that it is located in rural British Columbia, this is a wonderful and exciting place to stay.

Although it may seem small, the house has a lot to offer. In fact, the internal area is approximately 375 square meters. feet, which is enough to accommodate up to four people.

The house's concrete walls were designed and printed by Dutch 3D printing firm Twente. 20 concrete parts were produced off site in just 11 days from material provided by Laticrete. The parts were later delivered and assembled at their current location.

So how much does a visit cost you? It's hard to tell if you're visiting AirBnB as there are no available places, but in 2021 Designboom said it was $133 per night.

The first floating 3D printed house

Prvok is not only the first 3D printed house in the Czech Republic, but also the first floating 3D printed house in the world, as it stands on a pontoon.

Scoolpt, a construction 3D printing startup, is responsible for this project, which took just 22 hours to 3D print the concrete structure of a houseboat.

Approximately 465 sq. feet of living space divided into a bathroom, bedroom and living room with kitchen. And while weight isn't usually discussed in the context of houses, given that this one stands on water, it's interesting to note that Prvok weighs 43 tons, according to its creators.

Since the house is separated from the ground, it has a built-in recirculating shower and tanks for drinking and service water. All things considered, the house should last at least 100 years.

Europe's first occupied 3D printed house

Even in the last few years, 3D printed houses have mostly been showcases designed to demonstrate the possibilities of the technology. Most have no record of anyone actually driving into them. That changed back in 2017 when the couple moved into a 3D printed house located in Nantes, France, making the Yhnova house the first of its kind to be inhabited in Europe.

The house was created as part of a project between the University of Nantes and the Nantes Laboratory of Digital Sciences. And besides the main claim to fame, a very interesting aspect of the project is the specific technique used in its construction, which came from BatiPrint3D. Instead of 3D printing a concrete structure, the manipulator created wall shells from polyurethane, a material used for insulation. Later, these membranes were filled with concrete.

And besides the main claim to fame, a very interesting aspect of the project is the specific technique used in its construction, which came from BatiPrint3D. Instead of 3D printing a concrete structure, the manipulator created wall shells from polyurethane, a material used for insulation. Later, these membranes were filled with concrete.

In total, it took 54 hours to complete the 3D printing phase of the construction process. However, it took a little over 4 months to complete the construction. This was mainly due to the fact that the roof, doors, windows and installations were made using conventional means. But it doesn't help that the Yhnova isn't all that small, with about 1,025 feet of interior space.

India's first 3D printed house

India's first ever 3D printed house was built back in 2020. The project was carried out by a construction 3D printing startup called Tvasta, which was founded by graduates from the Indian Institute of Technology in Madras. In fact, the campus of the institute in Chennai was chosen as the site for construction.

In fact, the campus of the institute in Chennai was chosen as the site for construction.

The significance of this project lies in its impact on the housing crisis worldwide and in India in particular. The ability to build such a structure in a matter of days and for a minimal fraction of the cost of a standard equivalent home demonstrates the possibility of greatly reducing the country's housing crisis.

The internal area is 600 sq. m. feet, which is distributed in a simple layout with one bedroom and a combined kitchen and living room.

The concrete structure of the house was 3D printed off site and the pieces were later transported and assembled on campus. The foundation, meanwhile, was built using the conventional method of pouring concrete into the ground.

Africa's first 3D printed house

Back in 2019In 2018, construction began on Africa's first 3D printed house by Spanish firm Be More 3D in the Moroccan city of Ben Guerir. The project was born out of the group's participation in Solar Decathlon Africa, an event that requires members to design and build homes powered only by the sun.

The project was born out of the group's participation in Solar Decathlon Africa, an event that requires members to design and build homes powered only by the sun.

For their application, Be More 3D made a 345 sq. feet, which was printed in about 12 hours. This feat earned them first place and the title of Most Innovative Startup.

Be More 3D didn't stop at Africa, later creating Spain's first 3D printing house and also developing its own concrete 3D printer in partnership with several corporations working in the automation and materials industries.

First 3D printed house in the US

Last on our list is the first 3D printed house for sale in the US.

This concrete house was printed on site by SQ4D, a company specializing in the development of robotic building systems. The building was constructed using the Arcs concrete extrusion system and the printed structure comes with a 50-year warranty.

Behind the traditional exterior lies a large living space of 1407 sq.