3D drawings to print

Download paid and free 3D printer models related to Art・Cults

« My genius would be nothing without Cults. » L. Da Vinci

Download Cults' 3D masterpieces and unleash the artist that lies dormant within you. Get all the latest art related free STL models: fan art, sculpture, low poly, animals and so many more!

Caracol-Bichikids

Free

Cat and Butterflies wall art kitty butterfly wall decor

CA$1.68

Cat and Butterflies wall art kitty butterfly wall decor

CA$1.68

kitty with flowers wall art cat with butterflies wall decor

CA$1.68

Liveman Red Falcon

CA$13.48

POKEMON

CA$1.10

Funko Clicker - The Last Of Us

CA$3. 60

Rosaria - Genshin Impact

CA$5.60

Spartan key ring

Free

The Prisoner

Free

Harry Potter Logo!

CA$1.80

Gumball Watterson - The Amazing World of Gumball

CA$2.61

TRex head sculpture

CA$7.20

King Diamond Custom

CA$5.04

nordic viking wall art viking wall decor

CA$1.68

Tyrannosaurus (T-rex) realistic skull

CA$27.37 -20% CA$21.90

See all 3D models

Cali Cat Ornament

Free

Steven Universe Pumpkin

Free

Reloj bean

Free

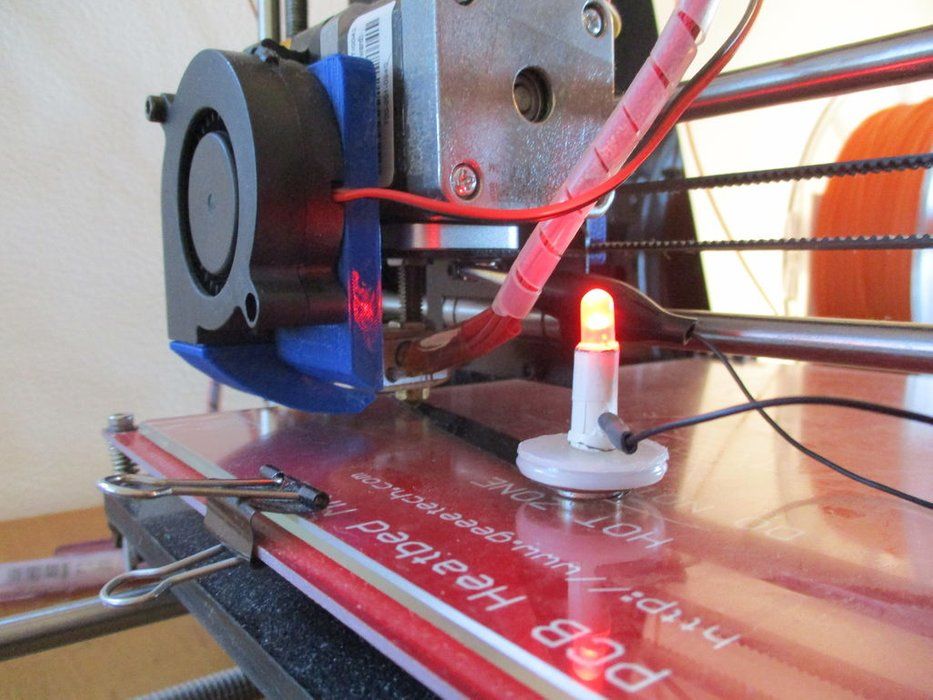

Night Light Pouncer (Easy print no support)

CA$2. 16

16

Messi World Cup

Free

Cant get this outa my head - That Dress - BY SPARX

CA$3.68

Cleo goes to the beach...

CA$8.64

Miniature 3D Printed Krampus Mask

Free

Izuku Midoriya (Deku)

CA$0.87

Octopus

CA$11.53

WiCat

Free

Predator Mask

Free

HULK 1/12 articulated action figure

CA$14.41

NFL DENVER BRONCOS

CA$8.80

Darth Vader Melted Mask

Free

DRAGON I

Free

💰 Best selling 3D files of the Art category

Blue Dragon / Glaucus Atlanticus ("The real life pokemon")

CA$2. 02

02

POKEMON - VALENTINE EEVEE (EASY PRINT NO SUPPORT)

CA$2.25

Baby Crystalwing Dragon, Cinderwing3D, Articulating Flexi Wiggle Pet, Print in Place, Fantasy

CA$5.39

Cute Flexi Print-in-Place Sloth

CA$3.98

Adorable Articulated Axolotl, Print-In-Place Body, Snap-Fit Head, Cute Flexi

CA$4.69

Cute Flexi Print-in-Place T-Rex Dinosaur

CA$3.98

Stitch Love (Easy print no support)

CA$2.16

Cute Flexi Print-in-Place Kitten

CA$3.98

Cute Flexi Print-in-Place Circus Elephant

CA$3.98

Rattlesnake articulated toy, print-in-place body, snap-fit head, cute-flexi

CA$5. 32

32

Cute Flexi Print-in-Place Frog

CA$2.63

Flexi PRINT-IN-PLACE Hand

CA$2.63

Flexi Print-in-Place kangaroo and Joey

CA$3.98

Biting dragon

CA$4.32

Flexi Print-in-Place Imperial Dragon

CA$5.32

Cute Flexi Print-in-Place Fox

CA$3.37

⬇️ Most downloaded free STL files in the Art category

Pen and Pencil Holder

Free

Baby Groot

Free

Satisfying hexagons

Free

Flexi Print-in-Place Fokobot 2.0 ( robot )

Free

Stitch [Lilo and Stitch]

Free

Virgin Mary

Free

BEARD SKULL COLLECTION - Nº1

Free

harry potter hogwarts hogwarts hogwarts

Free

Charmander(Pokemon)

Free

Raven with Skulls

Free

batman redesign

Free

Han Solo Bust

Free

Deadpool bust (Remastered Supportless Edition) (fan art)

Free

Dean the Dino

Free

Golum bust, from Lord Of The Rings

Free

Stan Lee Memorial

Free

See all 3D models

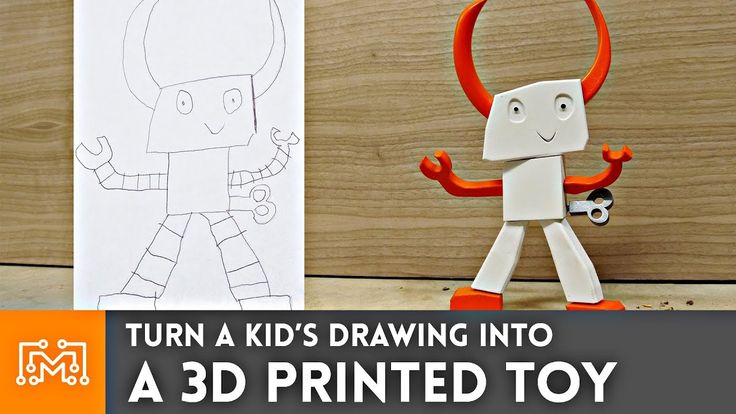

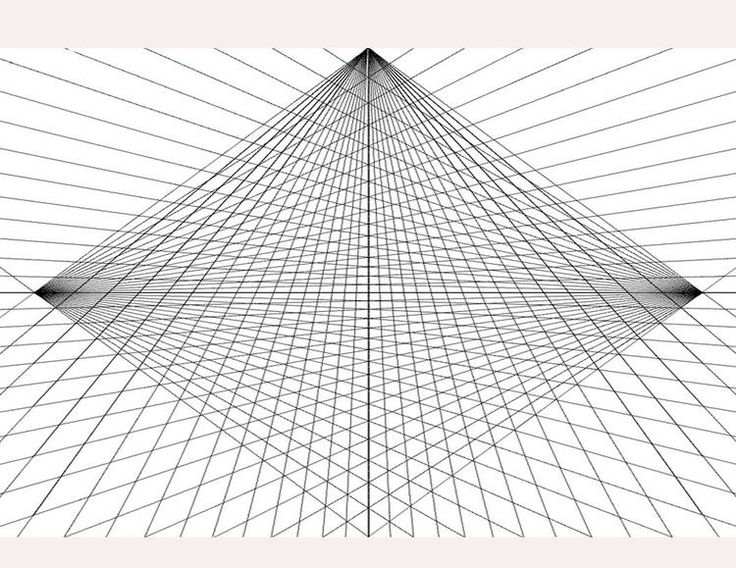

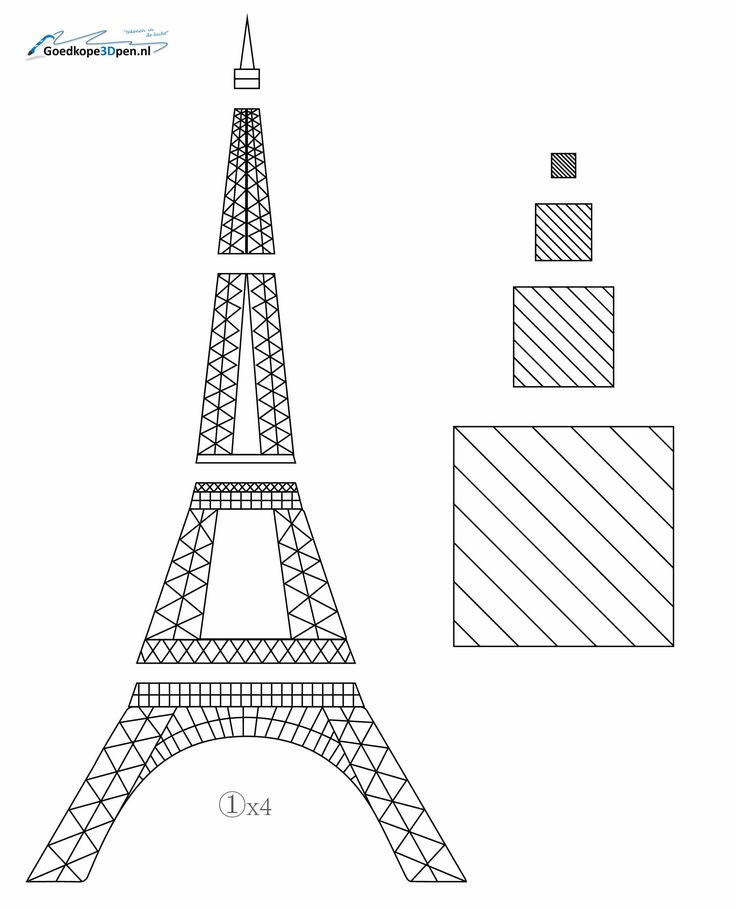

How to Turn a 2D Sketch into a 3D Printed Part in 3 Easy Steps

Do you have a concept sketch that you want to turn into a 3D Printed part? Read this guide to learn how to turn a simple 2D sketch, drawing, or image file into a 3D Printed part.

Learn how to turn your simple sketches into 3D Model files and 3D Printed parts.

If you can make a simple drawing, then you can make a 3D Printed part.

Getting from your sketch to a final 3D Printed part requires just one step in between: creating a 3D Model in STL file format. See this blog post to learn a little more about what 3D Model is, and why you need one in order to start 3D Printing.

This guide will walk you through how to transform your 2D sketch into a 3D Model file in STL format, and then how to use the Hollywood 3D Printing instant 3D Printing quoting tools to order your 3D Prints online.

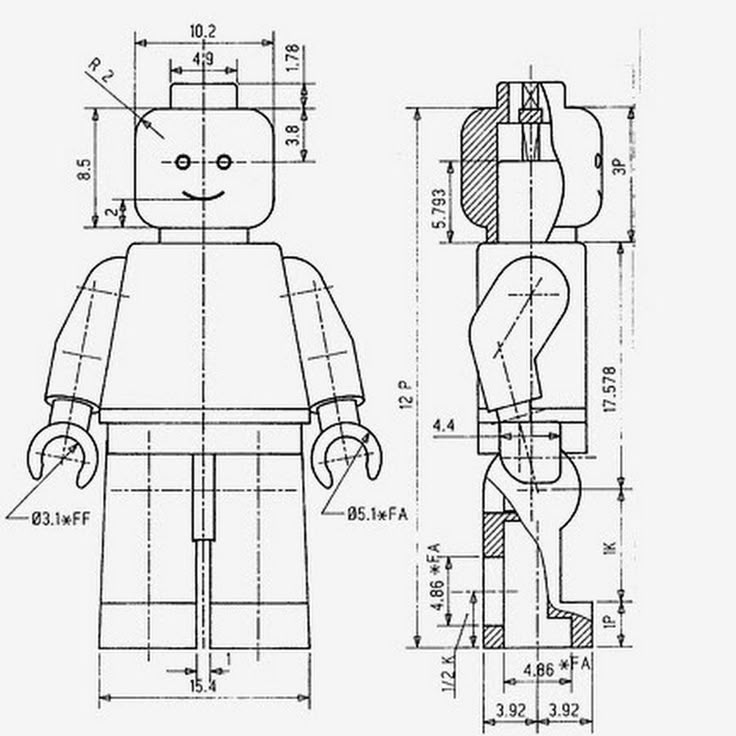

Step 1: Make your Sketch with Dimensions

In this guide, we'll focus on turning this simple 2D outline of an anchor into a 3D Printed part. This shape outline will be copied 1-to-1 in a 3D CAD program, and then assigned a thickness to turn it into a three-dimensional model.

Your drawing should have a basic outline of your part, with any important dimensions included.

While this is a relatively basic task compared to the complex design geometry that 3D Printing is able to reproduce, it's nevertheless a foundational concept in 3D Design. Understanding how to turn a simple sketch outline into a 3D Model is the first step towards creating more detailed 3D shapes.

There are two things you want to make sure you have here: a sketch trace, and any dimensions that are important to your final part.

Sketch Trace: This is the outline of the part you'll be creating. This can be drawn free-hand; lines don't have to be perfectly straight, and you don't need to be good at drawing circles. Luckily, the design tools covered in the next step of this article will take care of this perfection for you.

Dimensions: Define the overall size of the item you'll be creating. For a 2D shape, this can be only one dimension such as the overall height or width -- but if you have other areas where hole sizes or widths are important, you can call these out as well. For this anchor piece, we'll be focusing on only the overall height dimension to start. Then, when we're done creating our 3D Model, we can use a software measurement tool to check against the other dimensions written on the sketch.

For this anchor piece, we'll be focusing on only the overall height dimension to start. Then, when we're done creating our 3D Model, we can use a software measurement tool to check against the other dimensions written on the sketch.

Once you have your sketch ready, just take a picture of it -- or scan it to an image file -- and then you're ready to start creating your 3D Model design.

Step 2: Creating a 3D Model from Your Sketch

If you're new to the world of 3D Design software, creating a 3D Model from scratch may sound like a daunting task. While it's true that the 3D Design process can be a very in-depth process requiring skill and experience, you'll see here that the process of creating a 3D Model from a simple 2D sketch is quite simple.

The first thing you'll need is a 3D Design program. We recommend Autodesk Fusion 360 because it's free to start and easy for beginners, but it is also an incredibly powerful platform that will allow you to create just about anything you can imagine as you become more experienced in using the software.

While it might be more comfortable to use a more basic lighweight design tool, you'll thank yourself later for starting out with Fusion 360. Let's jump right in!

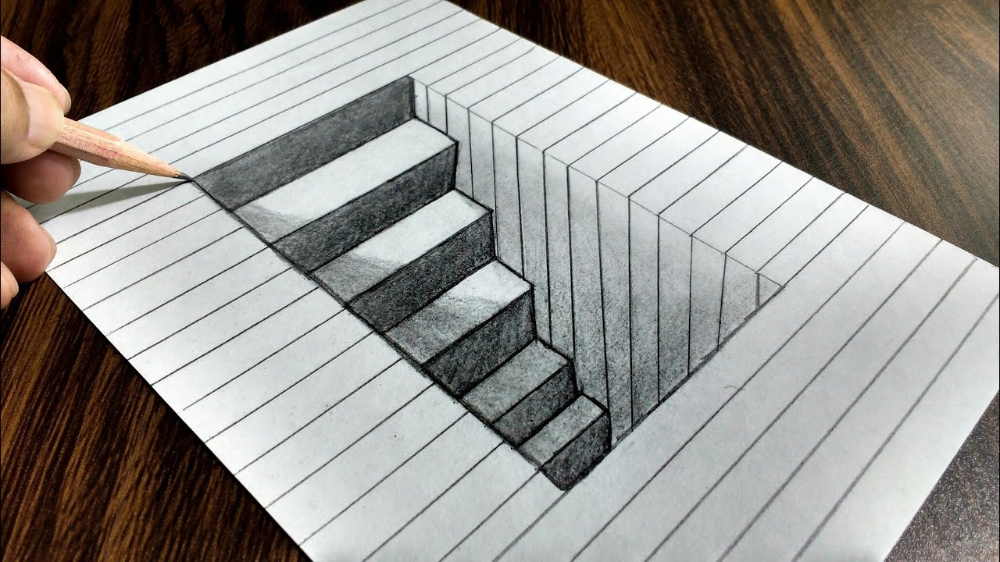

Draw a line defining your object height: When you launch Fusion 360, you'll have a new design open and ready. Press the "L" key to draw a line. This will first prompt you to select a sketch plane, so click any of the three options. We'll use the horizontal plane for a nice top-down view. Click anywhere to place your first point, and then as you go to place your second point, you'll see a text box appear. Type your height dimension into this box, and hit Enter to draw the line.

Congratulations! Now you have a line that matches the height of the anchor in the drawing. When you add your sketch image in the next step, you'll have a visual aid to help you scale the image to match this height dimension.

Import your sketch image: While still in Sketch mode, click Insert -> Canvas from the top tool menu, and select the image from your computer.

This will import your sketch into your CAD software, and then you can use the placement and sizing tools to get your image to be the same height as the height line you drew in the previous step.

When you've got your trace lined up with your height line, click OK to exit the canvas import menu. Now you're ready to trace over your sketch and create a flat profile of your shape in this 3D CAD software.

Trace the image: To trace this image, we'll use the Circle tool, Line tool, and Fit-Point Spline tool. We start off with the Circle tool, and place the center points in the middle of the round areas, and draw the circles out until they overlap with the drawing.

Use the line tool to trace over the straight areas of the drawing, and the Fit-Point Spline tool to place points along the areas of the drawing which have curvature. The Fit-Point Spline tool will create a curve which traces along the points you place one-by-one.

Since this is an object with symmetry along the vertical axis, meaning that it looks the same on the left half as it does on the right half, then we can save ourselves some time by mirroring the sketch across a vertical axis. Once you trace the left half of the drawing, you can use the Mirror tool to create that sketch geometry flipped over on the right axis.

Once you trace the left half of the drawing, you can use the Mirror tool to create that sketch geometry flipped over on the right axis.

After selecting and mirroring the left-half geometry we traced manually using the Circle, Line, and Fit-Point Spline tools, we now have a full trace of our drawing. Now it's time to create a solid three-dimensional object from this sketch geometry, using the Extrude tool.

Extrude the sketch geometry: Select the Extrude tool, and click all of the closed sketch faces that you want to give a thickness to, and type in the thickness you want them to be. We want this part to be 10mm thick, so we type in 10mm into the Extrude tool box after selecting the sketch faces, and this gives us our final 3D Model of our anchor.

Now you have completed the process of creating a 3D Model file from your sketch. We just need to save it off in the right format for 3D Printing.

Saving as an STL file: From the Bodies section in the model tree on the left of the design area, right-click the model body, and select Save as STL. Name your file, and click Save. Now you're ready to 3D Print this STL file.

Name your file, and click Save. Now you're ready to 3D Print this STL file.

Step 3: 3D Printing Your STL File

The hardest part is over -- once you have your STL file, getting a 3D Print is simple.

When you create a user account at Hollywood 3D Printing, you get 10% off your first online 3D Printing order. You also get free access to a suite of helpful online 3D tools.

On sign-in to your Hollywood 3D Printing user account, you're directed to a blank new quote which is ready for uploading your 3D Model files in STL, OBJ, STEP, or IGES file format. This is where we're going to be uploading the STL file created in the previous step of this guide.

When you sign in to your user account, you're directed to a blank New Quote. This is where you can upload 3D Model files and get an automatic 3D Printing quote and order parts online.

To order a 3D Print of your 3D Model file, just drag+drop your STL file over the upload icon in this window, and it will appear as a new Line Item in your automatic online 3D Printing quote.

Once your 3D Model appears as a new line item in this 3D Printing quote, you can click the "Generate Price" button. This step is where our online 3D software analyzes your 3D Model file, and determines the size of your part, how long it takes to 3D Print, and the volume of material required by the part. Based on this information, you will see a quoted price to 3D Print your 3D Model.

After adding a 3D Model file to your automatic quote, you will see a "Generate Price" button appear. Click this button, and our online 3D software will analyze your 3D Model file and generate a 3D Printing price.

Along with this pricing information will be the dimensional size of your 3D Model. If the default choice for the 3D Model dimension units is not right, you can change your units by clicking "mm", "cm", or "in" in the Set Units section, and you will see your dimensions update.

In addition to changing the dimension units, you can select your build material option, and change the quantity of your order if you're looking for more just one part.

Upon generating a price, your 3D Printing quote will include a thumbnail image of your part, and a link to view your 3D Model in the online 3D viewer software.

From here, you are ready to proceed to checkout, and your 3D Printed part will ship to you within a matter of days.

Thanks for reading this guide! If you got this far, hopefully you now understand how to go from a simple 2D sketch to a finished 3D Printed part. We look forward to becoming your trusted 3D Printing partner.

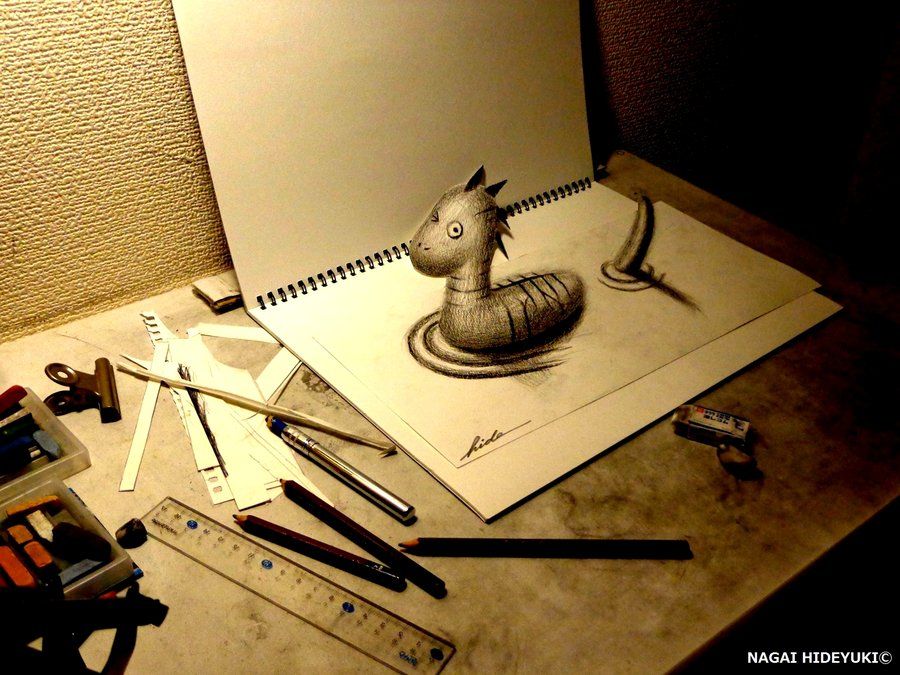

Get Inspired

Browse through hundreds of examples of our 3D printing, 3D design, and custom fabricated builds.

China 3d pattern wall paper printing machine Manufacturers

CMYKW Vertical 3D Wall Printing Machine Price

HAE Vertical Wall Printer quickly paints murals up to 12 feet high, unlimited width on any wall - indoor, outdoor, any surface, up to 2880 dpi, 850 square feet per hour with the best 3D images and murals HAE wall painting machine is equipped with an ultrasonic sensor that detects the texture of the wall and can automatically adjust the machine to paint any graphics and/or photos with 3D effects.

Compared to an artist's physical painting, automatic wall 3D printing is surprisingly efficient and cost-effective.

Wall 3D Printing Equipment Working Video

Wall 3D Printing Equipment Specification

| Model | YC-UV30 Wheel wall printing machine |

| machine control | 10" Touch Screen Industrial PC or LED control panel |

| Computer RAMs | RAM 4G; Solid State Disk 128G + Normal Hard Disk 500G |

| Printing head | 1pcs Epson Piezoelectric nozzle DX7 |

| machine size | 45(w) x 40(d) x 255(h)cm |

| Printing size | 200CM height, Printing width is no limit |

| ink | UV ink |

| color | CMYKW 5 color, 80ml ink tank |

| suitable | Brick wall, painted wall, wall paper, canvas, Wood, galss, cemaric tile etc. |

| Printing resolution | 360x720dpi, 720x720dpi, 720x1080dpi, 720x1440dpi, 720x2880dpi |

| Motor | Servo Motor |

| digital transfer | fiber cable |

| Processor | Altera |

| power supply | 90-246VAC, 47-63HZ |

| power consumption | no-load 20W, normal 100W, maxi 120W |

| noise | Ready mode<20dBA, Printing<72dBA |

| Operate | -21°C-60°C(59°F-95°F)10%-70% |

| Storage | -21°C-60°C(-5°F-140°F)10%-70% |

| driving program | Windows 7, Windows 10 |

| speed | 2pass:10 sqaure meters per hour |

| 4pass:6 square meters per hour | |

| 8pass: 3.5 sqauremeters per hour | |

16pass: 1. 5 square meters per hour 5 square meters per hour | |

| language | English,Chinese |

| Machine Weight , Dimensions | 40kg, 45x 40x 255cm, machine folded height is 145cm |

| Packing Weight | 116kg, 165x80x65cm |

Wall Print USA Applicatioin

Packing & Shipping:

Delivery Time: 3-5 working days after payment

Packing: Standard export PP box.

Delivery method: by sea, by air, by train

FQA:

Q1- How many different types of machines do you have now?

A: For ink, there is CMYK ink synthesis machine and CMYKW UV ink machine.

For machine type, there are wheel wall printer and ground wall printer for choice.

For machine nozzles, there are 1 nozzle, 2 nozzles and 4 nozzles for choice.

Q2- What size the machine can print

A: The vertical machine can print photos of any width, the printing height of the standard wall printing machine is 2m, the operator can easily do the photo joint for each photo joint

Q3- What software does he use?

A: The software belongs to Wuhan HAE, it can run on Windows XP, Windows 7, Windows 8 and Windows 10.

Q4- What surface can your machine print on?

A: inside or outside your building, on wood, metal, glass, brick, paper, drywall, canvas, etc.

Q5- How to transport?

A: by sea or by air

Q6- How to support me if I don't know how to use it?

A: We can support customers via skype, apps and mobile devices 24 hours a day.

Printing on glass, UV printing, 3d printing

Nizhny Novgorod, st. Malaya Yamskaya 63

Tel.: +7 (831) 214-42-84

Mon.-Fri. 09:00-18:00

Order

Photo printed glass

Some users wonder if the printed image reduces the transparency of the glass. Of course, this option is possible. But we adjust the transparency of the picture with the amount of paint However, sometimes this is exactly what is required. For example, photo printing is suitable for interior doors or partitions. You can install glass in a living room or studio apartment to visually zone the space.

The glass is easy to install, takes up almost no space and looks great. Therefore, in the interior it will be more appropriate than partitions made of other materials, such as drywall. Reducing transparency in this case is an advantage. Each zone is isolated, creating a feeling of comfort, intimacy. You can enhance the effect with frosted glass. However, this option is not suitable for a balcony door or panoramic glazing. So that the pattern does not block access to the light, the pattern is applied only with a thin contour. This allows you to simultaneously decorate the glass and maintain light transmission.

Photo printing is a versatile option that allows you to create original stained glass windows for any purpose. We will help you choose the option based on your wishes. Our company has extensive experience in printing on glass. We use any image. Features of the technology allow you to accurately transfer even complex drawings. High detailing and full-color printing will allow you to admire the drawing as a real painting.

We will select the printing option based on the technical requirements. For example, for furniture: countertops, cabinets, etc. - opaque glass and continuous printing are recommended. For glazing windows and balcony doors - contour printing. We will make sure that the environment is beautiful and comfortable.

Dimensions

The maximum print size: 1602 x 3100 mm

Maximum resolution: up to 1440 dpi

Application

Glass partitions

windows

order

Ultraviolet printing

000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000

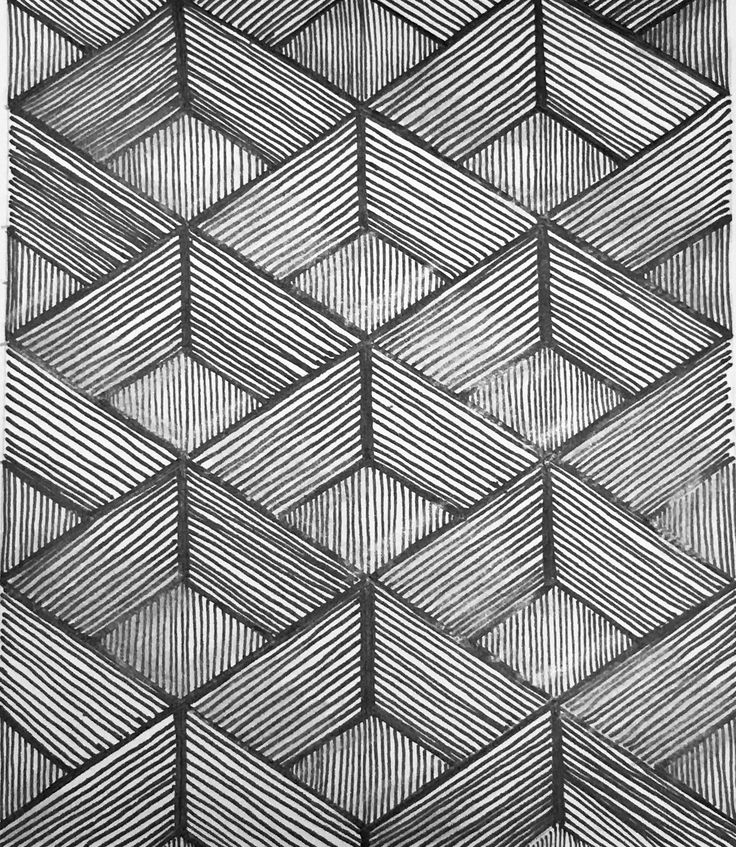

000 Mirrors have long been a popular interior decoration. They look aesthetically pleasing and neat on their own, but there is a way to make them even more interesting and attractive. UV printing allows you to recreate absolutely any pattern or photograph on glass. The image is clear and bright, it does not fade or deteriorate during operation, so it will take a long time to decorate the room. There are no restrictions on the type of picture: an abstract pattern, a highly realistic landscape or still life, even a photo from a personal archive - you can decorate the surface with various images. There are two versions.

There are no restrictions on the type of picture: an abstract pattern, a highly realistic landscape or still life, even a photo from a personal archive - you can decorate the surface with various images. There are two versions. - Glass decoration with UV printing: over it is applied a layer of special paints that harden under ultraviolet rays. The method is suitable for reproducing any picture, pattern, even natural texture. For example, natural marble.

- Drawing under a special film or in a triplex that protects it. The image can be applied to the glass in such a way that it is convex or, conversely, smooth and invisible. The pattern is combined with both transparent glass and frosted glass. Any sketch and wishes of the client can be realized.

UV printing on glass is recommended for those who want to add a touch of flair to their environment. Standard partitions, mirrors, countertops look ascetic and rather boring. Drawing on the surface will improve the appearance, make the product more vivid, interesting.