3D delta printers

7 Best Delta 3D Printers 2022 in Every Price Range

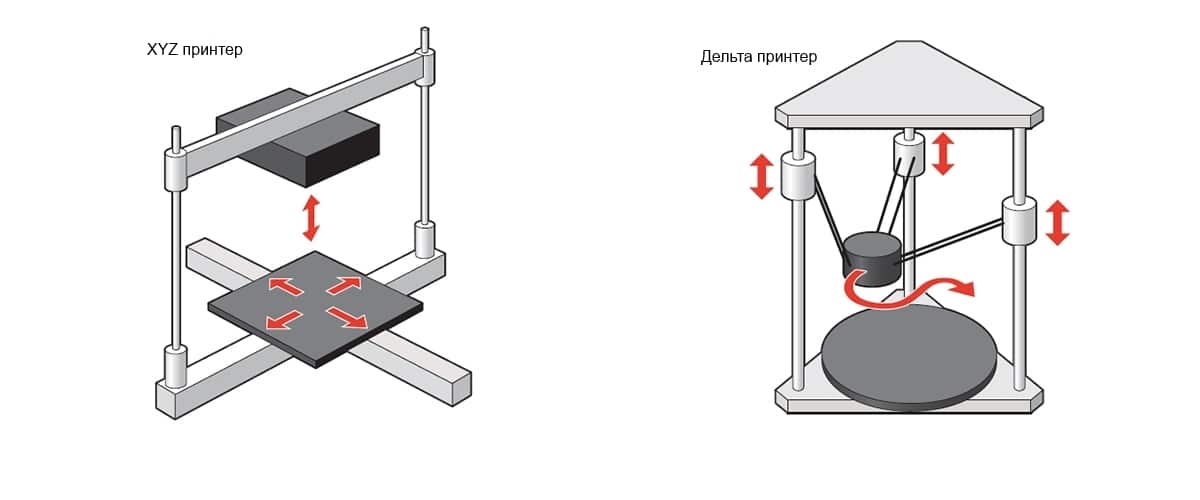

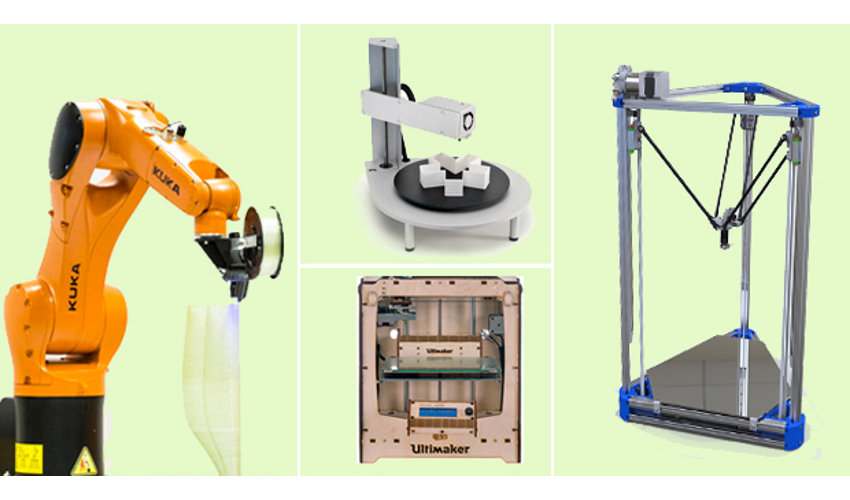

Named after the delta robots which inspired the RepRap Rostock and Kossel 3D printers, there are a number of small yet key differences between a delta 3D printer and a standard Cartesian FDM 3D printer.

Tall and extremely fast, we explain everything you need to know about delta 3D printers, and the best delta printers we recommend in every price range.

The Best Delta 3D printers and where to buy them

| Name | Max Build Volume (mm) | Speed (mm/s) | Price | Where to buy for best price |

|---|---|---|---|---|

| Monoprice Mini Delta | 110 x 110 x 120 | 150 mm/s | $179 | Amazon here |

| FLSUN Q5 | 200 x 200 x 200 | 150-300 mm/s | $260 | Amazon here |

| He3D K280 Delta | 280 x 280 x 600 | 150 mm/s | $320 | Amazon here |

| FLSUN QQ-S | 255 x 255 x 360 | 300 mm/s | $379 | Amazon here |

| Frankensbox FX-800 | 150 x 150 x 175 | 150 mm/s | $299 | Amazon here |

| Monoprice Delta Pro | 270 x 270 x 300 | 150 mm/s | $699 | Amazon here |

| WASP Delta 2040 PRO Turbo | 200 x 200 x 400 | 500-600 mm/s | $3,400 | Amazon here |

What is a Delta 3D Printer? How does Delta 3D Printing work?

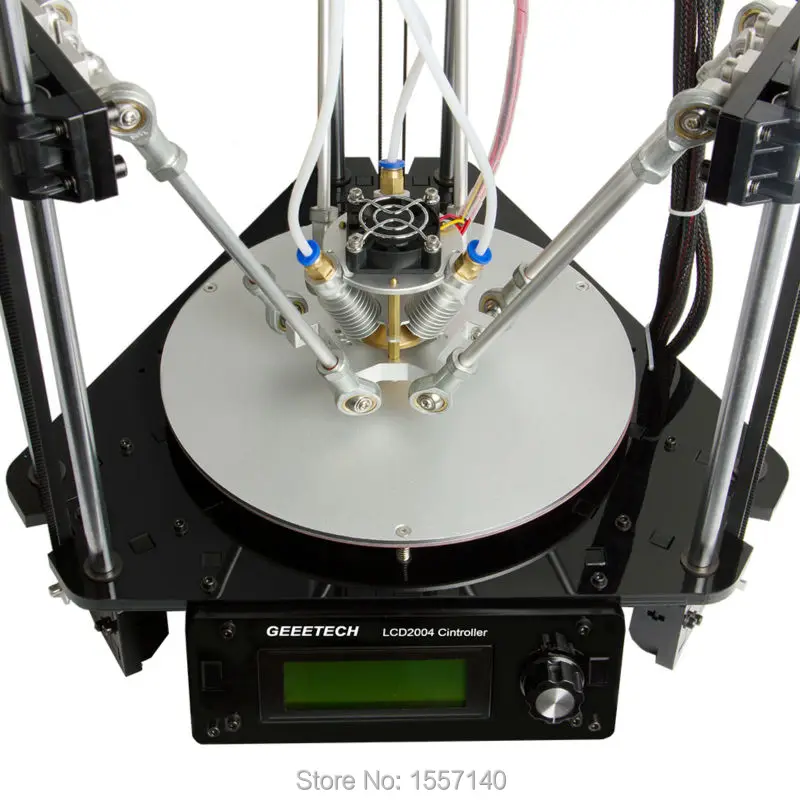

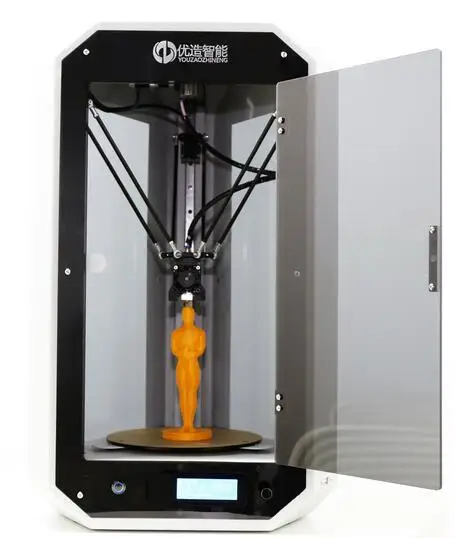

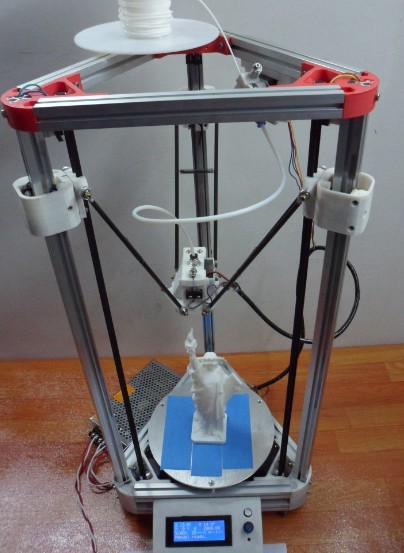

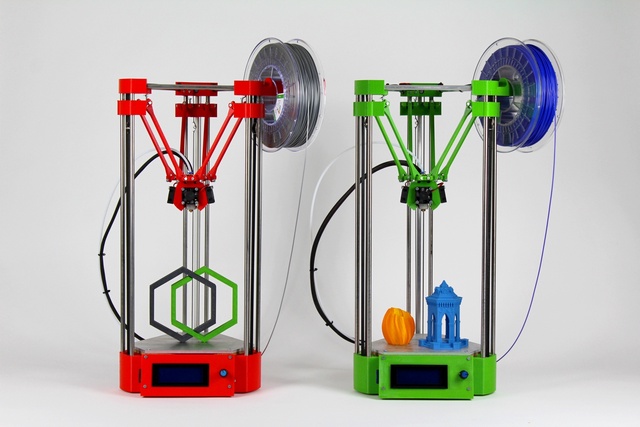

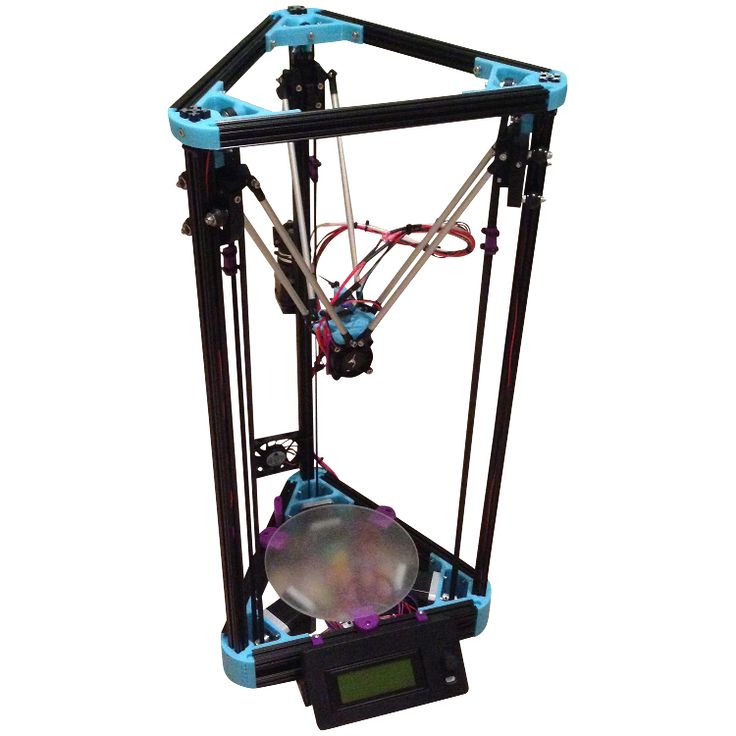

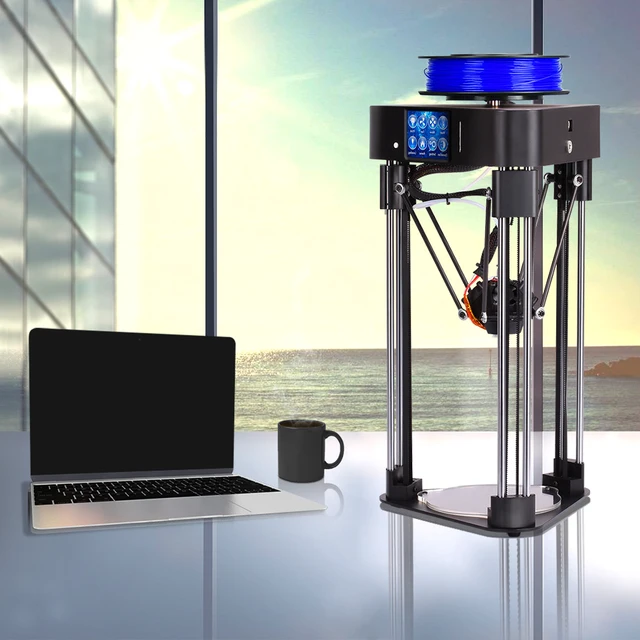

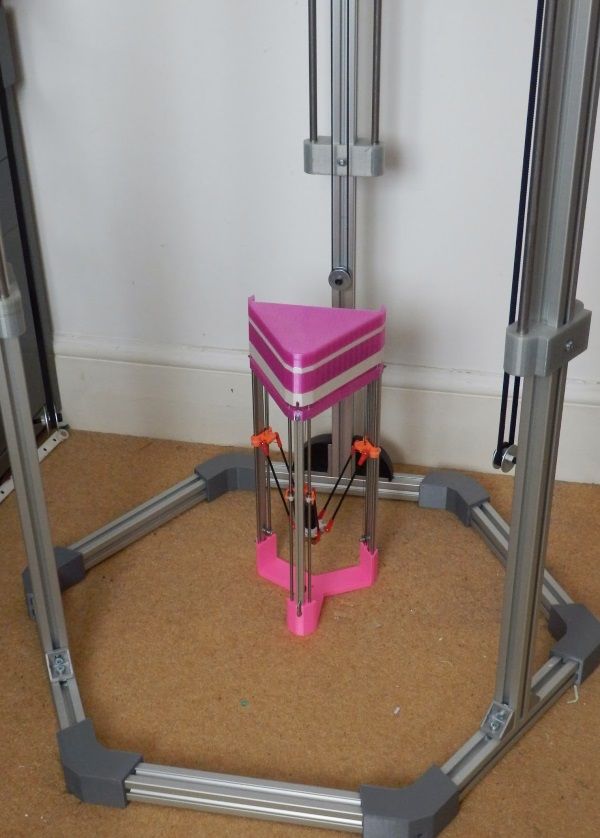

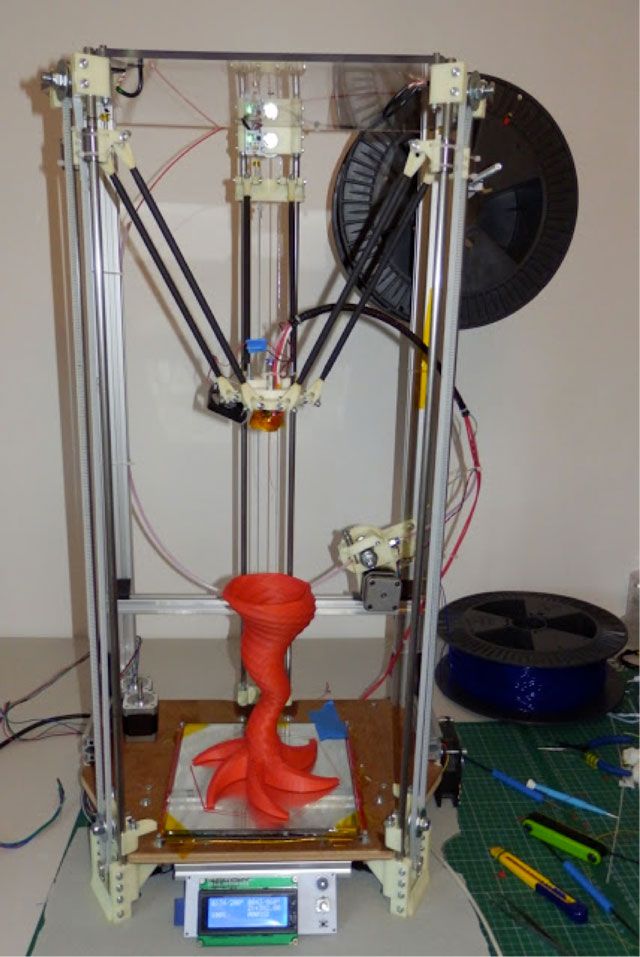

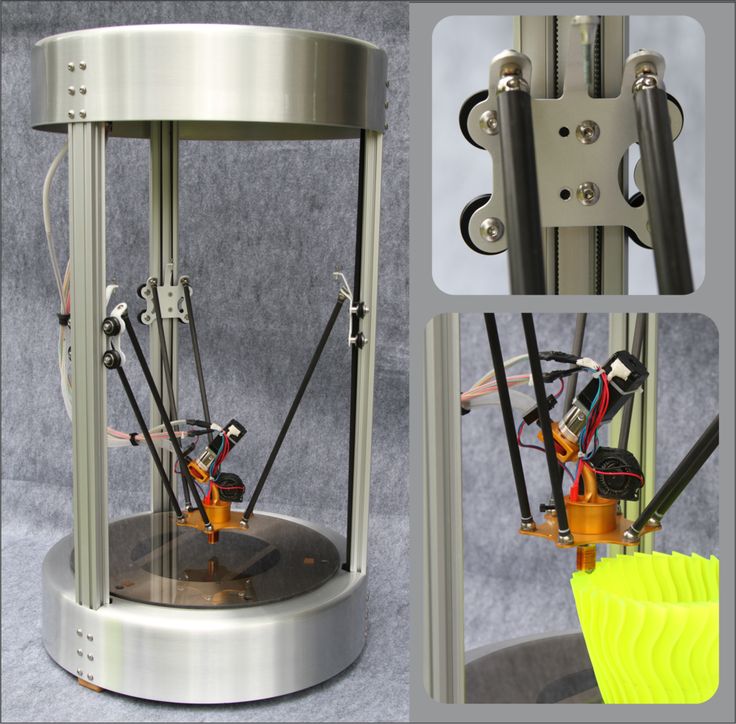

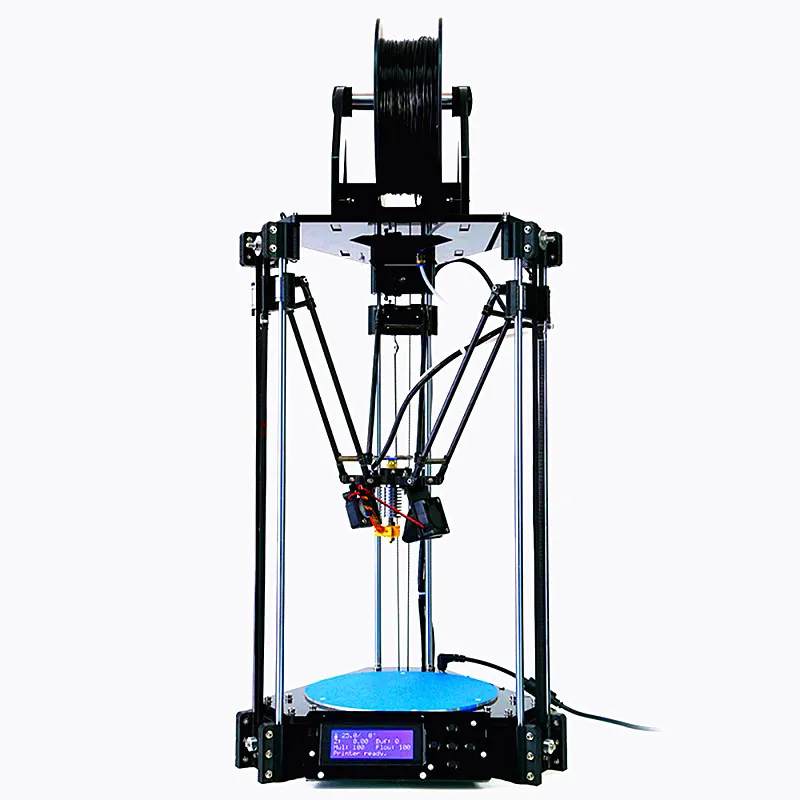

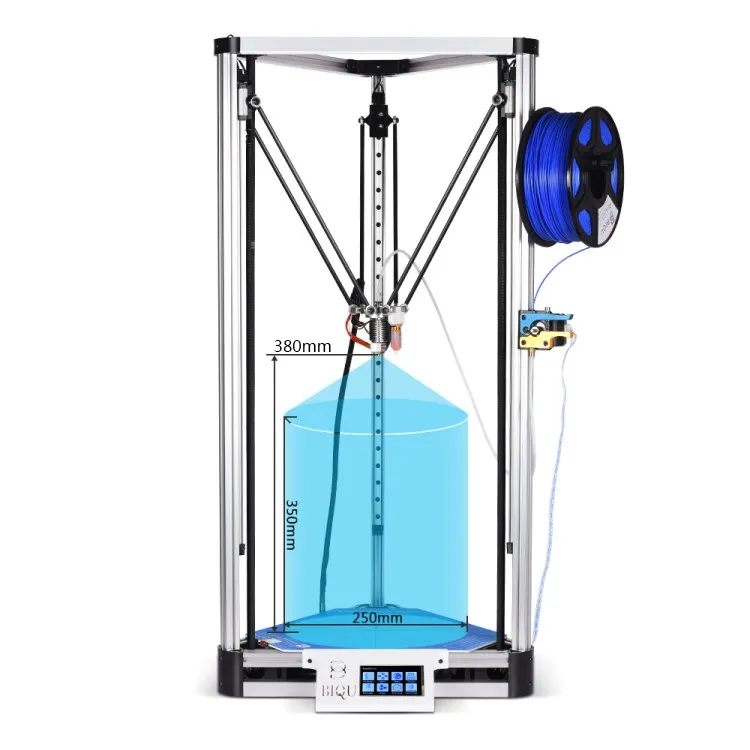

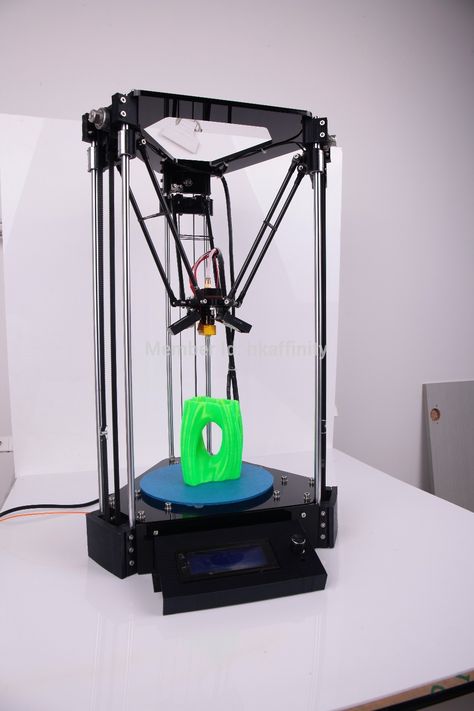

Delta 3D printers are tall and thin; they can easily be told apart from standard Cartesianprinters from their cylindrical build. They use Bowden extruders, and usually have round rather than square print beds, which do not move.

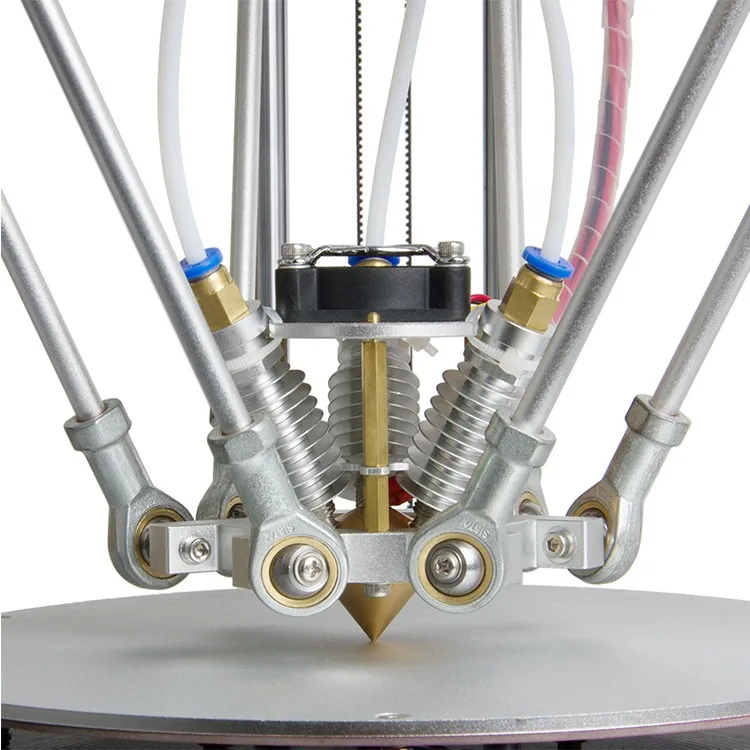

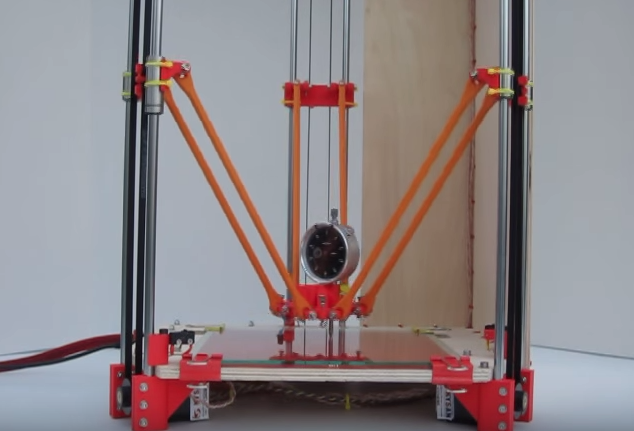

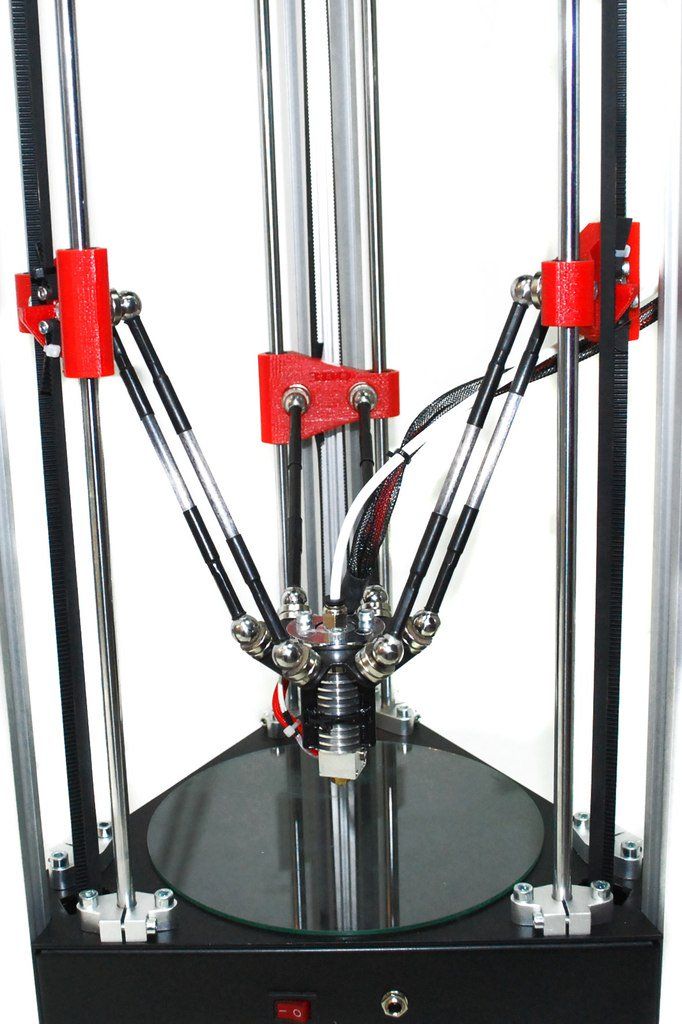

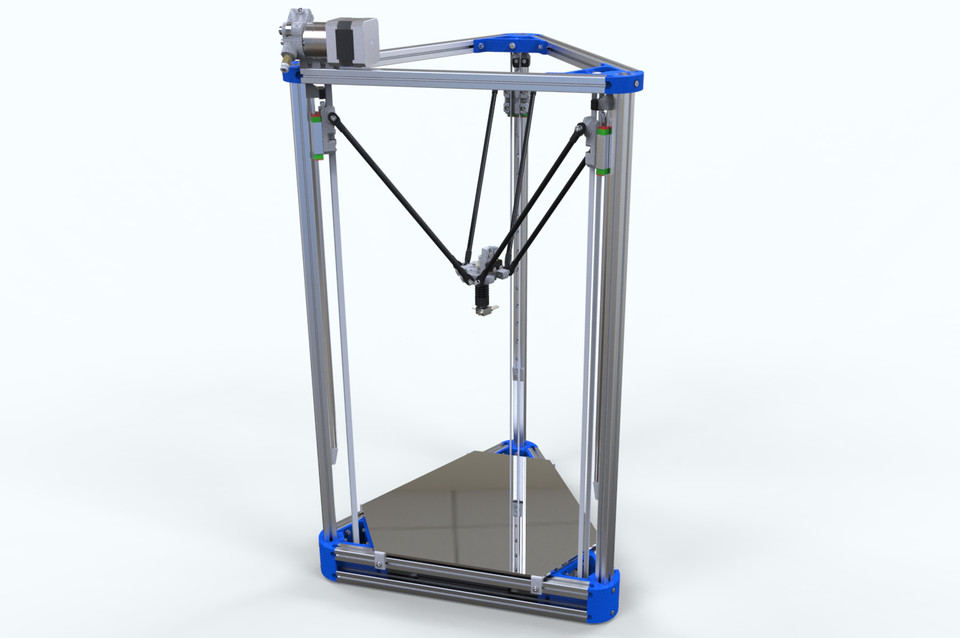

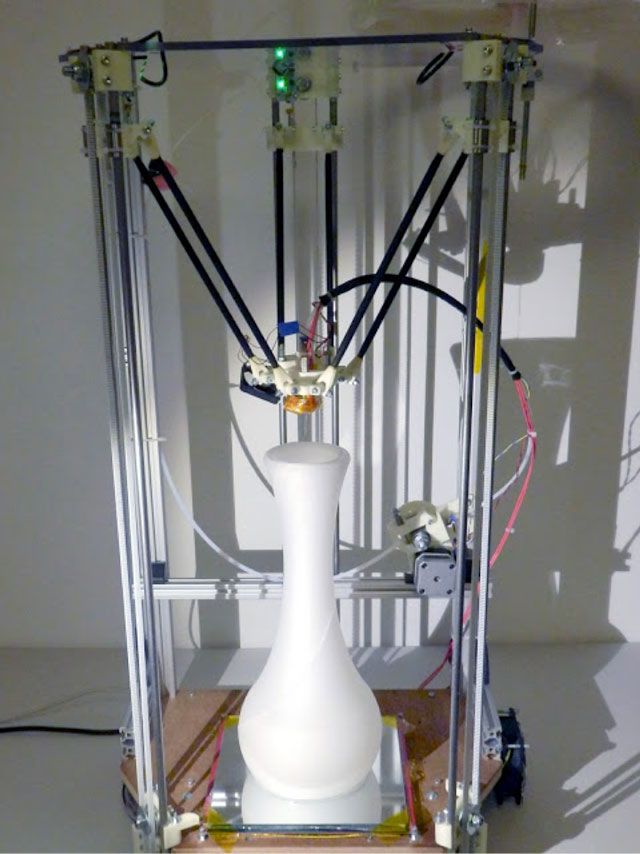

Instead, the extruder above the print bed moves using 3 arms attached to individual posts located every 120 degrees to form a triangle. Though each individual arm can only move up and down on each post, by moving each of these delta arms individually using trigonometric functions the extruder can reach any part of the print bed and move in any direction.

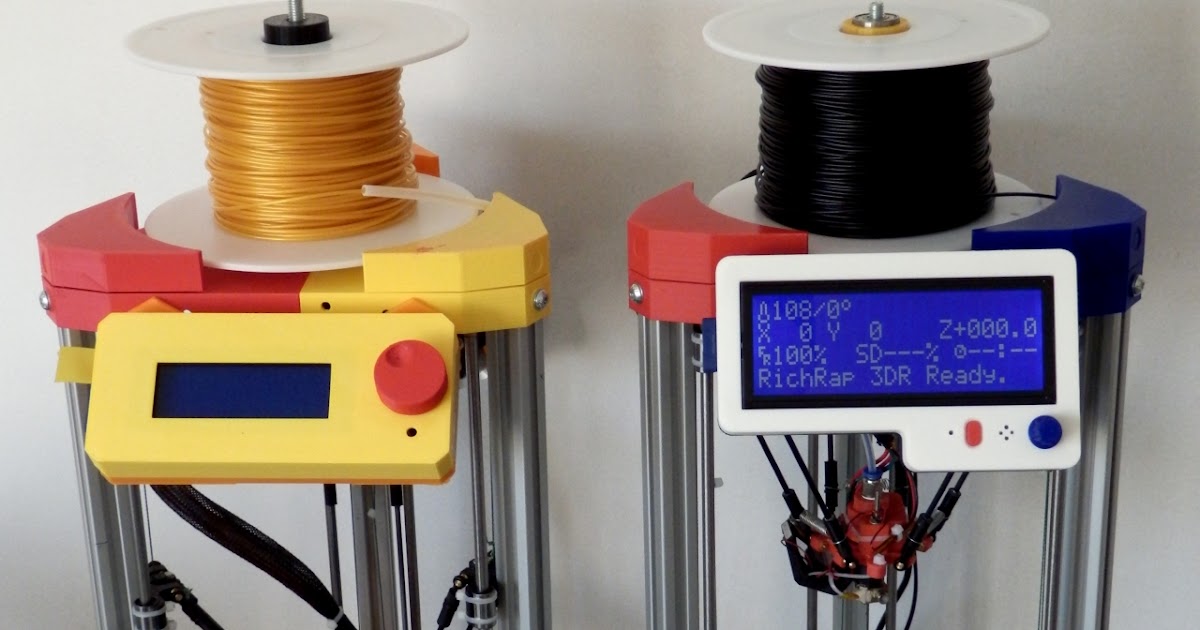

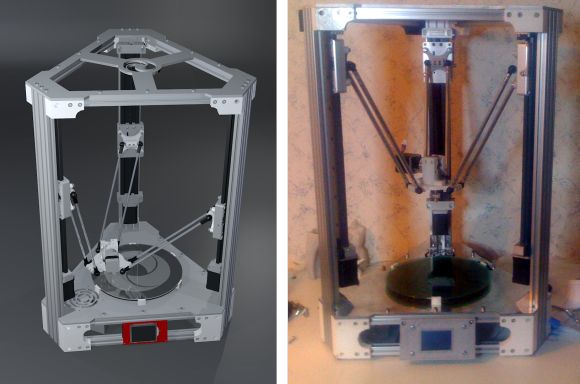

Delta robots like this design inspired the first delta 3D printers.Delta 3D printers are known for their speed. Everything about them is built to be fast — the motors and extruders are fixed around the top and sides of the printer, and the print head is as light as possible to minimize drag and retain accuracy at such high speeds. It is not unusual for a good delta printer to print at 300mm/s, whereas most Cartesian printers average around 60mm/s. They’re a joy to watch at such high speeds and make large prints far more bearable.

How much does a Delta 3D printer cost?

Cheap Delta 3D printers can start at just a couple of hundred dollars, with cost savings if you’re willing to build the printer yourself. The lowest price printer we recommend is under $200.

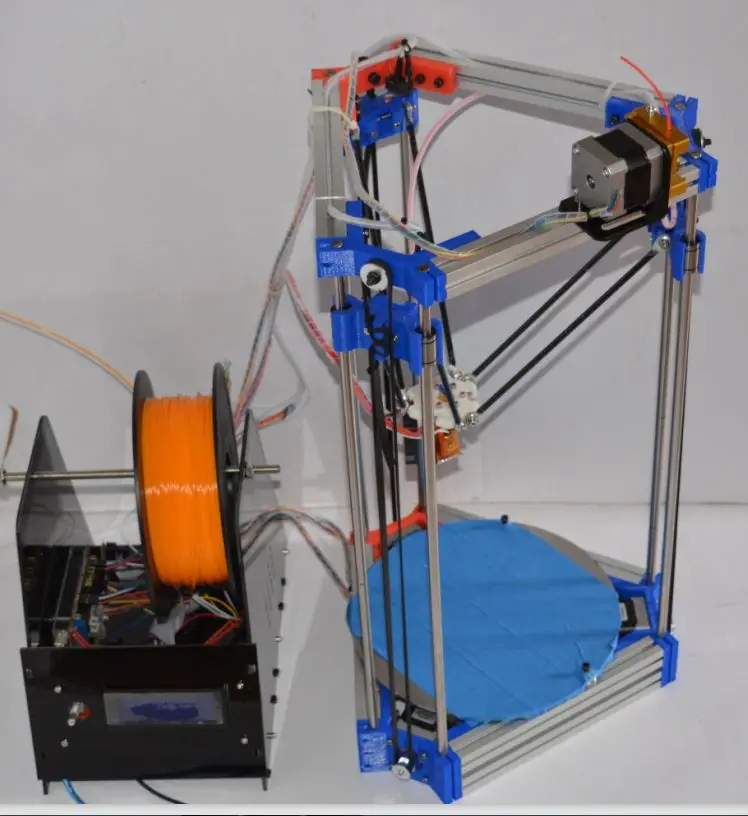

For a delta 3D printer that prints faster, more accurately and more reliably, you can spend a few hundred dollars up to a few thousand depending on your preferences.The 3 arms on a delta 3D printer can be seen here. They influence the movement of these very accurate 3D printers.

Delta 3D Printer Pros and Cons & Comparison vs Cartesian 3D Printers

Advantages of a delta 3D printer

- Extremely fast — even the cheapest delta 3D printer is twice as fast as most Cartesian printers. Cartesian printers are heavier and risk printing inaccurately by ‘overshooting’ the STL file dimensions if they try to print too fast, resulting from the momentum required to move the heavier printer parts.

- Large build volume 3D printing — delta printers can usually print very tall structures.

- Hypnotic print style — the speed and style of a delta print makes it almost a hypnotic experience. Not a technical advantage, but an aesthetic one.

Disadvantages of a delta 3D printer

- Smaller community of users — there are less users of delta printers so those facing problems may have more difficulty finding solutions. There are however facebook groups and forums for specific delta 3D printer owners to share information and help each other.

- Higher learning curve — many DIY delta 3D printers can take many hours to assemble and require previous electronics or 3D printing experience. Delta printers are generally known for being more for experts than beginners. We have however listed pre-assembled delta 3D printers in our ranking as well for those less confident in their DIY skills.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Learn more

Best Delta 3D Printer

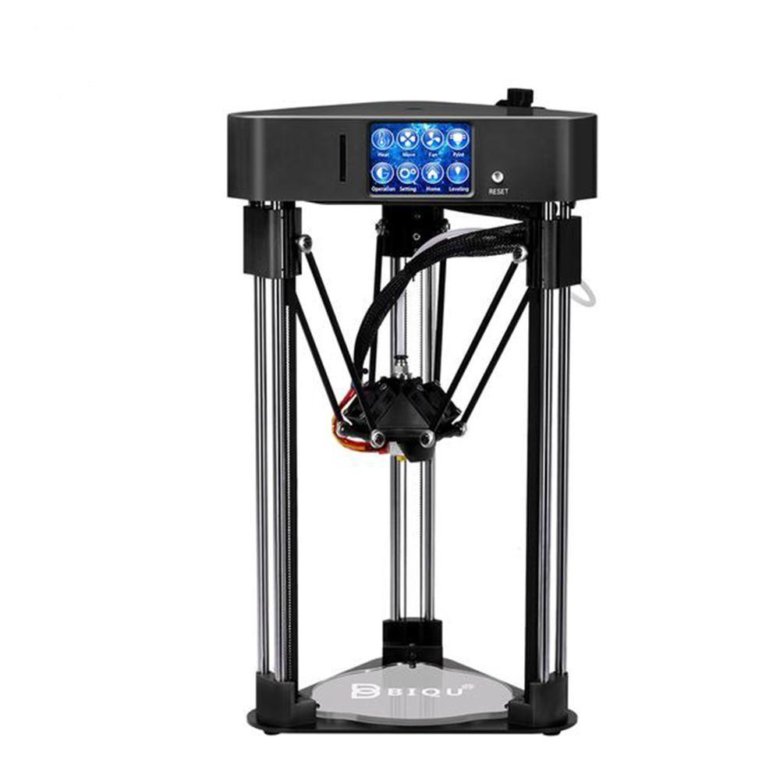

1. Monoprice Mini Delta

- Delta 3D printer price: $179 — Available on Amazon here

- Maximum print volume: 110 x 110 x 120 mm

- Speed: up to 150 mm/s

- Weight: 1.8kg

Monoprice make some of the best budget 3D printers around, with the Monoprice Mini Delta no exception. Despite the low price, the Mini Delta features a solid steel and aluminium frame to retain stability and durability. Additionally, the heated bed means you can print ABS and PLA — though beginners to 3D printing will probably most enjoy the fact that the Mini Delta comes fully assembled and doesn’t require any DIY skill.

Incredibly, the Monoprice Mini Delta can print at 50 micron layer resolutions, fantastic for such a low price printer. The printer calibrates itself you don’t need to, and you can print remotely via WiFi, as well as by USB or SD card.

However, the print speed isn’t as fast as some delta 3D printers in higher price ranges. Though the 150 mm/s speed is still far faster than most FDM 3D printers, for a delta printer this is still mediocre. It is easy to use, comes assembled, and compatible with Cura or Repetier-Host 3D slicers, so for a cheap delta 3D printer it’s a great choice.

Though the 150 mm/s speed is still far faster than most FDM 3D printers, for a delta printer this is still mediocre. It is easy to use, comes assembled, and compatible with Cura or Repetier-Host 3D slicers, so for a cheap delta 3D printer it’s a great choice.

2. FLSUN Q5

- Price: $260 — Available on Amazon here

- Maximum print area: 200 x 200 x 200 mm

- Speed: up to 300mm/s (recommended around 150mm/s)

- Weight: 6.5kg

The lower price version of the highly rated FLSUN QQ-S, the FLSUN Q5 is one of the best delta 3D printers around. It still features a solid metal structure for stability, still has the easy-to-use touchscreen, and can still print up to 300mm/s.

One of the key differences between the QQ-S (apart from being $100 cheaper) is the smaller print volume: 200 x 200 x 200 mm. This is still large enough for most prints, but those looking for a large 3D printer may prefer the QQ-S or another delta 3D printer we recommend. It’s easy to assemble, prints almost all the standard FDM filaments, and has a power resume function that can save you so much stress in the event of a power outage.

It’s not quite as accurate as some of the printers on this list, but for a low cost 3D printer that can print quickly and with reasonable accuracy, it’s a great choice.

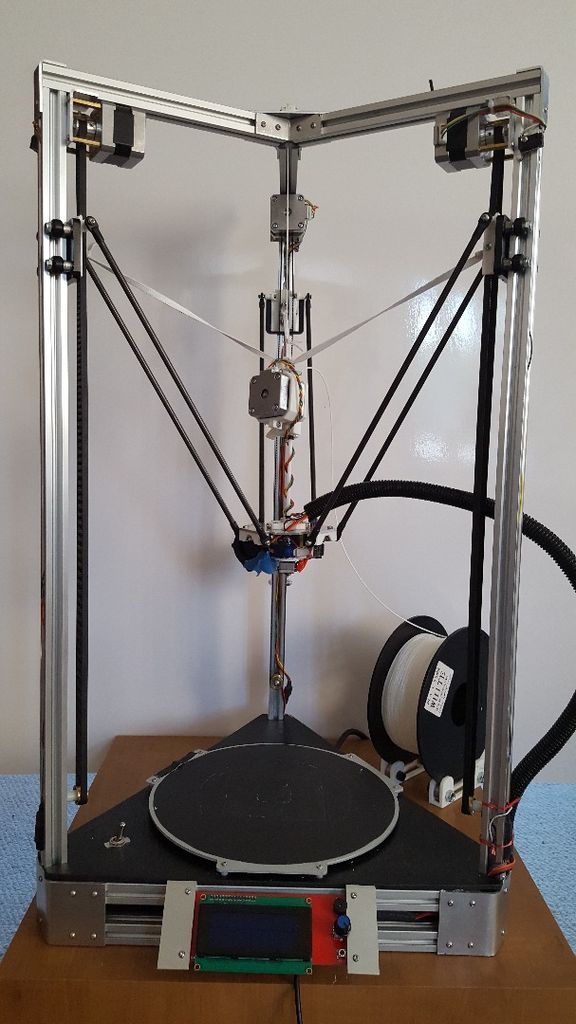

3. He3D K280 Delta — Huge delta 3D printer

- Price: $329 — Available on Amazon here

- Maximum build area: 280 x 280 x 600 mm

- Delta 3D printer print speed: 150 mm/s

- Weight: 10.5kg

The He3D K280 Delta is a truly massive 3D printer. You’ll need to assemble it yourself, but when you have, this beast prints taller parts than almost any other 3D printer in the world.

The frame is made of solid aluminium and steel, and prints a wide variety of filaments including Wood filaments, Nylon, TPU, HIPS, Flexible PLA as well as standard PLA and ABS. It’s compatible with Repetier-Host and like the Monoprice Mini Delta can print with a very impressive minimum 50-micron layer resolution. Like the Mini Delta you can also print over WiFi, or with a USB or SD card.

The reason you get so much printing volume for such a low price is that you do need to build it yourself. Some Amazon reviewers have highlighted difficulties with some of the screws during the build process, but fairly simple fixes have been found. There is an active Facebook group for the K280 Delta if you do run into problems, which you can find here.

Some Amazon reviewers have highlighted difficulties with some of the screws during the build process, but fairly simple fixes have been found. There is an active Facebook group for the K280 Delta if you do run into problems, which you can find here.

If you’re a beginner or not as confident with your making skills, go for the FLSUN QQ-S (or Mini Delta if you want to save money), but if you’ve got the skills you can reap the print size benefits with the He3D K280 Delta. Oh, and they also make a really neat 3D scanner.

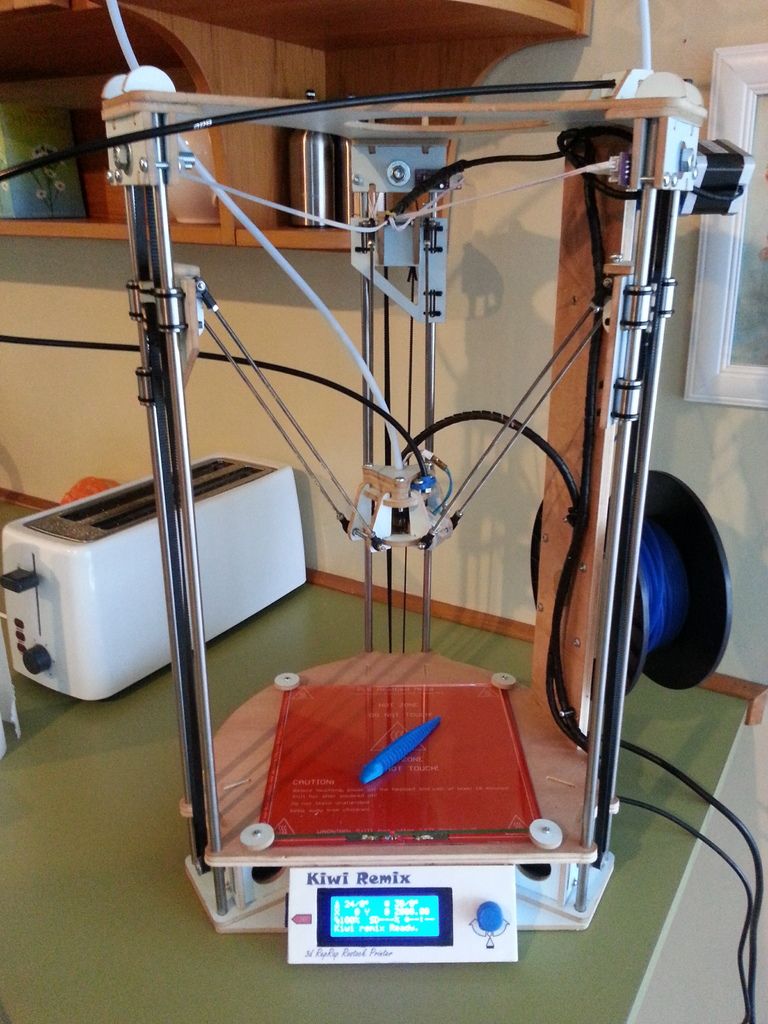

4. FLSUN QQ-S

- Delta 3D printer cost: $379 — Available on Amazon here

- Max print volume: 255 x 255 x 360 mm

- Speed: up to 300 mm/s

- Weight: 12.5kg

We recommend the FLSUN QQ-S highly as one of the best budget delta 3D printers around. It comes 90% assembled (the last few steps take around 20 mins to complete), comes with a 3.2 inch touchscreen, and can level itself.

- We were lucky enough to be sent a FLSUN QQ-S to test and review.

Check out our FLSUN QQ-S review!

Check out our FLSUN QQ-S review!

Influenced by the RepRap Kossel and in true delta 3D printer style, the FLSUN QQ-S has both a large printing area and fantastic print speed, able to print up to 300 mm/s. It can print PLA, ABS, HIPS, PVA, wood-filled filaments, and its heavy metal frame keeps the printer stable during printing.

Another feature that improves your 3D printing experience is the lattice platform bed, designed to make it as simple as possible to remove prints after printing has finished, as well as maintain temperatures to reduce warping. And it does all this while remaining under 50dB, one of the quietest 3D printers around! It’s very highly rated as one of the best 3D printers in its price range.

5. Frankensbox FX-800 — Best Delta 3D printer for Beginners

- Delta 3D printer price: $299 — Available on Amazon here

- Max print volume: 150 x 150 x 175 mm

- Speed: up to 150 mm/s

- Weight: 10kg

The Frankensbox FX-800 is a compact delta printer, printing smaller sizes than the FLSUN QQ-S Delta and also able to print at noises under 50 dB.

Like the FLSUN QQ-S it comes assembled — fully, rather than 90% — and is designed for those who value convenience. It’s the perfect delta 3D printer for those that want to just plug it in, set up the 3D printer software, and run it straight away. The FX-800 can print with resolutions of up to 100 microns, features one button leveling, and can print remotely via WiFi, SD card or USB stick.

With a max speed of 150 mm/s, it isn’t as fast as the FLSUN QQ-S, but sells itself on convenience. You get a 1-year warranty with your purchase so you’re insured against any problems, and if you have any issues with your FX-800, Frankensbox have US-based customer support to help you find a solution.

6. Monoprice Delta Pro

- Price: $699 — Available on Amazon here

- Maximum print area: 270 x 270 x 300 mm

- Speed: up to 150mm/s

The premium and upgraded version of the cheaper Mini Delta, the Delta Pro has a much larger build area, can auto level, and features full metal parts for stable printing unaffected by vibrations.

It comes with all the features you’d expect: a sensor for detecting when filament is low to avoid ruining prints; and a glass print bed for good adhesion and easy print removal.

The Delta Pro is compatible with all common filaments, like PLA, ABS, PETG and wood filaments, as well as tougher filaments like Nylon, and metal-filled materials. It’s accurate, with up to 50-micron layer resolutions, and prints up to 150mm/s.

Overall, it’s one of the best delta 3D printers under $1,000.

7. WASP 2040 PRO Turbo — Fastest Delta 3D printer in the world!

- Price: $3,400 — Available on Amazon here

- Max print volume: 200 x 200 x 400 mm

- Speed: up to 500-600 mm/s

- Weight: 25kg

Italian 3D printer company WASP not only make great delta 3D printers but have also made great contributions to 3D printed houses. They claim that the WASP 2040 Pro Turbo is the fastest 3D printer in the world, with a maximum print speed of 600mm/s, 10x the speed of some Cartesian printers! It’s popular with busy makers who value the speed, and small businesses looking to make fast plastic prototypes.

Everything is optimized for speed, but that doesn’t mean anything is sacrificed. The WASP 2040 PRO can still print with great accuracy — up to 50 microns — and with good stability from the strong aluminium frame for crisp looking finished prints. It can also fully calibrate itself with its auto calibration system.

Quality of life features include the ability to resume at the exact point on the exact layer where printing was paused or stopped — for example in the event of a power outage. This is an underrated benefit; we all have a horror story of a 40 hour print that was ruined because a random circumstance caused a print error with just a few hours to go, having to start all over again. But not with the WASP. The filament detector also informs you and stops printing when you run out so that prints never fail.

The WASP 2040 PRO Turbo can print a variety of 3D printer filaments, including PLA, PETG, ABS, PA, Carbon, and can be upgraded if you buy the clay extruder add-on for 3D printing clay. You can use the WASP with Cura, Slic3r or Simplify3D for slicing, and know that the printer is fast, effective and reliable. Undoubtedly one of the best delta 3D printers around, it just becomes a question of money as the WASP is noticeably more pricey than some lower priced delta printers we recommend.

You can use the WASP with Cura, Slic3r or Simplify3D for slicing, and know that the printer is fast, effective and reliable. Undoubtedly one of the best delta 3D printers around, it just becomes a question of money as the WASP is noticeably more pricey than some lower priced delta printers we recommend.

The 7 Best Delta 3D Printers for Rapid 3D Printing – Clever Creations

Delta 3D printers are best known for their large print heights and fast 3D printing speeds. They are a great choice if you want to quickly 3D print architectural designs, prototypes, or large-scale models. Alternatively, if you only have limited space available, the small footprint of a Delta 3D printer can be a big advantage.

Some Delta 3D printers are small and cheap, whereas others come with loads of features and a high price tag. If you’ve never worked with one before, it can be tricky to decide which model is best for your needs.

To help you choose, we’ve compared some of the best Delta 3D printers currently available. We will also explain what you should look for when choosing a Delta 3D printer.

We will also explain what you should look for when choosing a Delta 3D printer.

| Best Delta 3D Printer | Summary | Build Volume | Max Speed | Price (~) | Best Offer |

|---|---|---|---|---|---|

| FLSUN SR Super Racer | Best overall | ø260 x 330 mm | 200 mm/s | $499 | Amazon |

| WASP 2040 PRO | Best high-end | ø200 x 400 mm | 500 mm/s | $3200 | MatterHackers |

| Monoprice Mini Delta V2 | Best on a budget | ø110 x 120mm | 170 mm/s | $179 | Amazon |

| FLSUN Q5 | Best value | ø200 x 200 mm | 120 mm/s | $252 | Geekbuying |

| FLSUN QQ-S-PRO | Best large Delta | ø255 x 365 mm | 120 mm/s | $399 | Amazon |

| HE3D K280 | Best Delta 3D printer kit | ø280 x 600 mm | 300 mm/s | $329 | Amazon |

| Silhouette Alta Plus | Best Delta 3D printer for kids | Ø124 x 130 mm | 80 mm/s | $269 | Amazon |

What is a Delta 3D printer?

A delta 3D printer is a machine that uses a triangular configuration of linear actuators to move the print head around the build area. Its print bed and stepper motors are stationary, and the print head is capable of moving in the entire XYZ plane.

Its print bed and stepper motors are stationary, and the print head is capable of moving in the entire XYZ plane.

This design results in a lightweight print head that can be moved at high speeds for fast 3D printing. An average Delta printer can print at speeds above 100 mm/s with ease. The best delta 3D printers can print well beyond 250 mm/s, with maximum print speeds close to 500 mm/s.

Let’s understand the workings of a delta 3D printer’s mechanism and how it can print at such high speeds.

How does a Delta 3D printer work?

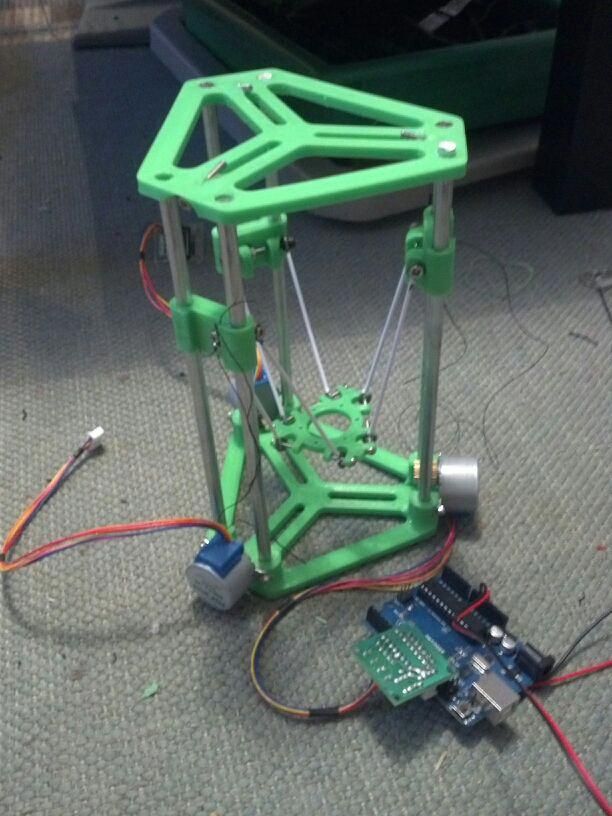

Image: HeatSync Labs via Flickr, CC BY-SA 2.0

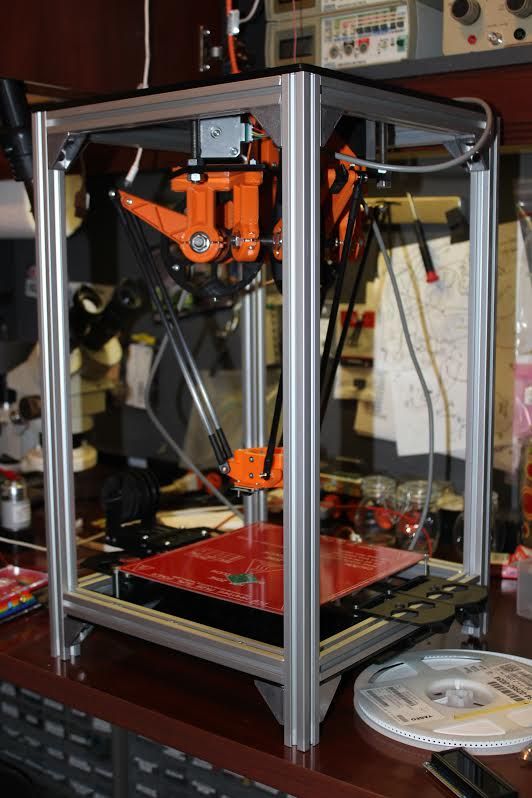

Every Delta 3D printer has three effector arms. These three arms are interlinked via the print head carriage, and moving any one arm will cause the others to move too. These effector arms work together and convert their angular motion to precisely position the print head in three-dimensional space.

This unique motion system allows the build surface to remain stationary, removing the need to drive the build surface with a stepper motor. As there is little mass to move by the effector’s arms, Delta 3D printers can accelerate and decelerate quickly and sustain high printing speeds.

As there is little mass to move by the effector’s arms, Delta 3D printers can accelerate and decelerate quickly and sustain high printing speeds.

The effector arms, vertical extrusions, and the stationary print surface are three significant components of any Delta 3D printer. These decide the printing area, print height, and motion capacity of a Delta 3D printer.

What are Delta 3D printers good for?

Delta 3D printers are designed for fast printing speeds while maintaining the 3D print’s accuracy.

The combination of a fast printing speed, small footprint, and a towering build volume make the Delta 3D printers handy for printing tall and large objects that need to be printed in a single part. Swords, buildings, architectural models, vases, cosplay components, and tall figurines will benefit from a Delta printer’s design.

Additionally, if you have a small 3D printer table or need to 3D print in a cramped space, the small footprint of Delta printers will save you valuable space. Some of the best Delta 3D printers occupy an area significantly smaller than Cartesian printers or CoreXY 3D printers with a similar print volume.

Some of the best Delta 3D printers occupy an area significantly smaller than Cartesian printers or CoreXY 3D printers with a similar print volume.

- Fast printing speed

- Small footprint

- Excellent for tall models

- Easy to level

- Complex workings

- Difficult to repair and maintain

- It takes up a lot of vertical space

- Limited support

- Limited upgradeability options

The Best Delta 3D Printers in 2022

FLSUN SR Super Racer

Best overall

Check Price

AmazonAliExpressBanggoodGeekbuying

FLSUN is one of the most popular brands in the Delta 3D printer market. Currently, the FLSUN SR Super Racer is one of their top-line models. It has a generous build volume, a maximum print speed of 200 mm/s, and a sturdy aluminum frame. These features are part of why it is one of the best Delta 3D printers on the list.

These features are part of why it is one of the best Delta 3D printers on the list.

The SR Super Racer features a maximum print volume of ø260 x 330 mm. The printer nominally prints at 150 mm/s printing speed, almost three times that of an average Cartesian printer. The fast printing speeds enable you to print models quicker, reducing your print times.

FLSUN features linear rails for precision motion on the Super Racer’s three axes. Besides adding structural rigidity to the printer, the linear rails help deliver smooth motion and highly accurate 3D prints.

The machine has a 3.5″ touchscreen that you can position on the printer’s frame at your convenience. Its UI gives you access to all important data and functions and comes with a real-time speed indicator on the touch screen display.

The SR Super Racer prints fast, outputs high-quality prints, and has several features developed to deliver a premium 3D printing experience. It will be an excellent fit for users who need a high-speed Delta 3D printer without breaking the bank.

Standout Features

- High printing speed

- Linear guide rails

- 32-bit motherboard

Technical Details | |

|---|---|

| Build volume | ø260 x 330 mm |

| Machine size | 440 x 390 x 960 mm |

| Max hot end temperature | 260 °C |

| Max bed temperature | 100 °C |

| Bed leveling | Automatic |

| Connectivity | SD Card, USB |

| Materials | PLA, ABS, PETG |

What We Like

- Easy assembly within 30 minutes

- Silent 3D printing

- Easy to use touchscreen UI

Could Be Better

- Needs considerable calibration

- Generic hot end and extruder

Find FLSUN SR Super Racer at

AmazonAliExpressBanggoodGeekbuying

WASP 2040 PRO

Best high-end

Check Price

AmazonMatterHackers

WASP is an Italian 3D printer manufacturer and one of the pioneers in Delta 3D printers. Their Wasp 2040 Pro is a flagship Delta 3D printer. With excellent build quality and steel reinforced driving belts, it is a highly durable and sturdy machine.

Their Wasp 2040 Pro is a flagship Delta 3D printer. With excellent build quality and steel reinforced driving belts, it is a highly durable and sturdy machine.

The company claims a maximum printing speed of up to 500 mm/s, which is 10x that of an average i3 style 3D printer. Yet, it isn’t sustainable to print at these speeds, and you can realistically print between 200-250 mm/s without sacrificing too much on print quality.

Combining a heated print bed and a hardened steel nozzle increases the printer’s material compatibility, letting you print with filaments like PLA, ABS, PETG, but also wood- and carbon-filled varieties.

You can also add a clay extrusion setup on the WASP 2040 Pro. Using this setup, you can 3D print pots, vases, busts, and many other clay models. The clay extrusion kit is an optional purchase and isn’t included with the base WASP 2040 Pro model.

One of the significant drawbacks of the printer is its outdated 12864 LCD. The knob-controlled display isn’t ideal either and doesn’t justify the high price tag of the 2040 Pro. The connectivity is also limited, and there is only an SD card port on the printer to work with.

The connectivity is also limited, and there is only an SD card port on the printer to work with.

If these points do not matter to you, the WASP 2040 Pro is a high-quality, industrial Delta 3D printer suited for professional applications. The clay extrusion system is an exciting addition that extends the use case of the 2040 Pro beyond the usual plastic 3D printing process.

Standout Features

- Suspended Bowden system

- Auto calibration feature

- Swappable extruders

Technical Details | |

|---|---|

| Build volume | ø 200 x 400 mm |

| Machine size | 490 x 440 x 870 mm |

| Max hot end temperature | 250 °C |

| Max bed temperature | 110 °C |

| Bed leveling | Automatic |

| Connectivity | SD Card |

| Materials | PLA, PETG, ABS, carbon/wood/metal-filled |

What We Like

- >200 mm/s printing speeds

- Industrial design and build quality

- Clay 3D printing capabilities

Could Be Better

- Large relative to its print volume

- Outdated user interface

- Limited external connectivity options

Find WASP 2040 PRO at

AmazonMatterHackers

Monoprice Mini Delta V2

Best on a budget

Check Price

Amazon

If you need an entry-level, small, and portable Delta 3D printer, the Monoprice Mini Delta V2 is the best Delta 3D printer option available right now.

The Monoprice Mini Delta V2 is the second generation of the original Mini Delta printer. Monoprice has improved the V2 significantly based on user feedback.

The 3D printer retains the familiar design of the Mini Delta series with sheet metal construction and a carry handle on the top. As a result, the structure remains sturdy on the V2. This helps to minimize the vibrations that occur when printing at high speeds and reduces 3D printing artifacts.

The Mini Delta V2 features an updated touchscreen with a brand new UI. The redesigned UI is intuitive and makes using the printer easier to use for beginners. Also added is integrated Wi-Fi, so you can 3D print remotely using Monoprices’ PoloPrint app.

As for shortcomings, the two limiting factors of the V2 are the small build volume of ø110 x 120 mm and the lack of a high-temperature heated printer bed. This means that you’re mostly limited to printing with low-temperature filaments like PLA and PETG.

Considering its low price and ease of use, the Monoprice Mini Delta V2 is an ideal beginner’s 3D printer. It is priced well under $200 and comes fully assembled right out of the box. It is a great choice as your first Delta 3D printer or for operation in classrooms or other educational settings.

It is priced well under $200 and comes fully assembled right out of the box. It is a great choice as your first Delta 3D printer or for operation in classrooms or other educational settings.

Standout Features

- Built-in Wi-Fi connectivity

- Easy to use color touchscreen

- Silent stepper drivers

Technical Details | |

|---|---|

| Build volume | ø110 x 120mm |

| Machine size | 360 x 440 x 480 mm |

| Max hot end temperature | 260 °C |

| Max bed temperature | 60 °C |

| Bed leveling | Automatic |

| Connectivity | USB, SD Card, WiFi |

| Materials | PLA, PLA+, PETG |

What We Like

- Sturdy build quality

- Intuitive and informative UI

- Remote monitoring and control

Could Be Better

- Small build volume

- Only suitable for low-temperature filaments

Find Monoprice Mini Delta V2 at

Amazon

FLSUN Q5

Best value

Check Price

AmazonGeekbuyingBanggood

The FLSUN Q5 is a budget-level 3D printer by FLSUN that mainly aims toward beginners. The Q5 comes with all the essentials of a basic Delta 3D printer and delivers excellent printing performance for its price.

The Q5 comes with all the essentials of a basic Delta 3D printer and delivers excellent printing performance for its price.

To ensure silent 3D printing, the FLSUN Q5 comes with a 32-bit electronics motherboard and silent TMC 2208 stepper drivers. The stepper drivers are capable of delivering up to 256 microsteps for smooth and silent 3D printing. This means that if 3D printer noise is something that bothers you, the Q5 is a good option.

The heated bed on the Q5 has a maximum bed temperature of 110°C, so you can easily 3D print with higher-temperature filaments, like ABS and PETG. This puts it one step ahead of the Mini Delta V2, which can only 3D print with lower-temperature filaments.

To increase print bed adhesion, the glass print bed has a ceramic coating. This reduces the chances of your prints failing due to improper adhesion. Some users have reported that the coating’s adhesive properties wear out quickly, so keeping a container of Magigoo at hand might still be useful.

The FLSUN Q5 is a great starting point for first-time 3D printer users and hobbyists on a budget. Just like the Mini Delta V2, it is also an excellent Delta 3D printer for use in schools and colleges, considering its inexpensive pricing and ease of operation.

Standout Features

- Ceramic-coated glass bed

- Powerful Titan-style extruder

- 32-bit motherboard with silent TMC 2208 drivers for X/Y/Z

Technical Details | |

|---|---|

| Build volume | ø200 x 200 mm |

| Machine size | 330 x 290 x 710 mm |

| Max hot end temperature | 250 °C |

| Max bed temperature | 110 °C |

| Bed leveling | Automatic |

| Connectivity | USB, SD Card |

| Materials | PLA, ABS, PETG, TPU |

What We Like

- Simple construction

- Easy to assemble

- Budget pricing

Could Be Better

- Extruder motor uses noisy A4988 stepper driver

- Bed coating is not very durable

Find FLSUN Q5 at

AmazonGeekbuyingBanggood

FLSUN QQ-S-PRO

Best large Delta

Check Price

AmazonAliExpressGeekbuying

The FLSUN QQ-S-Pro is a large format Delta 3D printer that is relatively well-priced and has a solid build quality. It has a ø255 x 360 mm build volume for $400, offering great value for your money.

It has a ø255 x 360 mm build volume for $400, offering great value for your money.

FLSUN has used its own version of the Titan-style extruder on the QQ-S-Pro. This extruder delivers improved performance with flexible materials, which is often a significant drawback in Bowden 3D printer extruders on Delta 3D printers.

The hot end, too, has a maximum printing temperature of 270 °C, which gives you wide material compatibility when coupled with its maximum 110 °C heated bed.

A 32-bit motherboard along with silent stepper motor drivers acts as the brains of the printer and allows it to keep up with the blistering 3D printing pace. And to help you get perfect first layers, the QQ-S-Pro also features an automatic bed leveling probe.

The filament run-out sensor and power-resume functionality on the QQ-S-Pro are equally useful. These additions make sure that you don’t have to start your prints from scratch in case of a power outage or a filament jam.

This machine sits perfectly in the middle of FLSUN’s lineup of Delta 3D printers. It has a mix-n-match of all basic and advanced features along with a generous build volume.

It has a mix-n-match of all basic and advanced features along with a generous build volume.

Overall, the FLSUN QQ-S-Pro can be an excellent alternative to Creality’s CR-10 series, like the CR-10 Smart Pro. It is a great candidate for 3D printing helmets, creating 3D printed armor, vases, or other massive models that won’t fit on typical fused deposition modeling 3D printers.

Standout Features

- Powerful Titan-style extruder

- Lattice glass print bed

- Sizeable build volume

Technical Details | |

|---|---|

| Build volume | ø255 x 365 mm |

| Machine size | 290 x 350 x 800 mm |

| Max hot end temperature | 270 °C |

| Max bed temperature | 110 °C |

| Bed leveling | Automatic |

| Connectivity | SD card, Wi-Fi, USB |

| Materials | PLA, ABS, PETG, etc. |

What We Like

- Comes 95% pre-assembled

- Touch screen UI is well laid out

- Excellent print bed adhesion

Could Be Better

- Poor quality control

- Bed leveling can be tricky

Find FLSUN QQ-S-PRO at

AmazonAliExpressGeekbuying

HE3D K280

Best Delta 3D printer kit

Check Price

Amazon

For someone who enjoys a hands-on approach and building Delta 3D printers from scratch, the HE3D K280 is a great DIY Delta 3D printer kit. The K280 is a tall Delta 3D printer with a massive build height of 600 mm. The total size of the printer is slightly above 1000 mm, making it one of the largest Delta 3D printers on this list.

The giant print area is built out of 2020 aluminum extrusion, with acrylic panels for the rest of the printer. The printer uses V-slot wheels on the 2020 extrusions, with a conventional belt and pulley arrangement for motion. This straightforward design helps with the maintenance of the K280 while making the assembly process familiar for experienced 3D printer users.

To help you print with ABS and other warp-y filaments, the heated bed on the K280 can reach up to 110°C. Printing to the K280’s maximum height with ABS without warping will be challenging, however, so 3D printing with ABS might be best for small-to-medium print sizes.

HE3D does not mention the presence of any filament run-out sensor or power resume function with the K280. These features would’ve been helpful, considering the large build volume of the machine. Without them, you risk losing an entire print job in case of a power loss or a filament snag.

The K280 is not designed to deliver excellent print quality right out of the box, and you will have to fine-tune it and work on various parameters to get a high-quality print from it. But, if you like a DIY approach and need a large printing volume for under $600, the HE3D K280 will be well worth your time.

Standout Features

- Massive print volume

- Solid frame

- Customizable electronics design

Technical Details | |

|---|---|

| Build volume | ø280 x 600 mm |

| Machine size | 430 x 430 x 1120 mm |

| Max hot end temperature | 260 °C |

| Max bed temperature | 110 °C |

| Bed leveling | Automatic |

| Connectivity | USB, SD Card |

| Materials | PLA, ABS, PETG |

What We Like

- Ideal for printing extremely tall models

- Upgrades to enable dual-color 3D printing

- Easy-to-configure automatic bed leveling

Could Be Better

- Small and outdated display screen

- Complex assembly process

- Not suitable for beginners

Find HE3D K280 at

Amazon

Silhouette Alta Plus

Best Delta 3D printer for kids

Check Price

Amazon

The Silhouette Alta Plus is a small Delta 3D printer designed for basic 3D printing use. It has a small build area of ø124 x 130 mm and comes with a clean industrial design. The use of white shades and an acrylic enclosure help it stand out from the rest of the best Delta 3D printers on this list.

It has a small build area of ø124 x 130 mm and comes with a clean industrial design. The use of white shades and an acrylic enclosure help it stand out from the rest of the best Delta 3D printers on this list.

There’s a proprietary extruder and hot end setup on the Alta Plus, and its nozzle can only reach up to 210 °C. The removable print bed also does not have heating, and you’re limited to 3D printing with PLA on the Alta Plus.

You receive ten protective platform tapes with the printer. These tapes protect your print bed from the hot nozzle and aid with the first layer adhesion of your prints. The Alta Plus lacks connectivity options, as it has only a USB 2.0 port. The small build volume, too, restricts you from printing any big models.

Silhouette aims the Alta Plus at first-time users and kids getting started with 3D printing. It is helpful for 3D printing small items such as cookie cutters, tiny busts, Christmas decorations, and toys.

Standout Features

- Fully enclosed design

- Easy filament loading

- Great design aesthetics

Technical Details | |

|---|---|

| Build Volume | ø124 x 130 mm |

| Machine Size | 251 x 228 x 476 mm |

| Max hot end temperature | 210 °C |

| Max bed temperature | N/A |

| Bed leveling | Manual |

| Connectivity | USB Cable |

| Materials | PLA |

What We Like

- Compact build

- Comes fully assembled

- Easy operation

- Design and slicing software included

Could Be Better

- Tiny build volume

- Limited features in slicing software

- No heated bed

Find Silhouette Alta Plus at

Amazon

What to Look for When Buying a Delta 3D printer?

Print VolumeThe print volume of a Delta printer is one of its major benefits. A Delta printer’s mechanism helps to get a taller 3D print height with a smaller footprint. You can use this to your advantage for printing vases, cosplay pieces, and tall buildings.

A Delta printer’s mechanism helps to get a taller 3D print height with a smaller footprint. You can use this to your advantage for printing vases, cosplay pieces, and tall buildings.

But, due to its construction, the overall height of a Delta 3D printer is twice that of its actual print height. Furthermore, the length of the connector arms, print height, and the bed area are codependent on each other, and altering any one value will affect the other parameters too.

For this reason, Delta 3D printers are not easily scalable, and you will seldom find any extension kits. Even so, compared to most 3D printers with a cartesian coordinate system, a Delta printer occupies significantly less floor space. You must have considerable space above your printer’s position if you focus on getting a large print volume.

This Delta printer calculator by Danal’s lets you visualize a Delta printer’s working and dimensions. In real-time, you can alter different parameters and notice their effects on a Delta printer and its print volume.

Even the most basic Delta 3D printer can print at speeds of above 100 mm/s without problems, nearly twice that of cartesian printers. The best Delta printers like the WASP 2040 Pro are rated to print at around 500 mm/s. This printing speed is almost unattainable by many advanced cartesian printers simply due to their construction.

The high print speeds will help you reduce your printing times and significantly lessen your lead times for professional applications. A high printing speed will also result in cost savings on 3D printer electricity usage in the long run.

However, a Delta 3D printer is not free of surface artifacts such as ghosting, ringing, and rough side walls that occur at high speeds. You will need to fine-tune and calibrate your Delta 3D printer to achieve high-quality prints at faster speeds.

If print quality is your priority, the FLSUN Super Racer is one of the best Delta 3D printers. It can print at speeds above 125 mm/s and move at rates of 200 mm/s, without sacrificing much on your part’s quality.

A Delta 3D printer’s mechanism is complicated and challenging to configure. It can be difficult to assemble every component of a Delta’s printer’s kit correctly, without any errors. Everything needs to be perfectly calibrated, and any minor mistake in the assembly process will result in poor 3D printing quality.

In contrast, a factory-assembled Delta 3D printer usually undergoes testing and works flawlessly right out of the box. You also save significant time with a pre-assembled printer, as there is no need for assembly and fine-tuning, like with a Delta 3D printer kit.

But as with any 3D printer, a kit costs considerably less than a pre-assembled printer. If you’re up for the challenge or on a budget, you can save a few hundred dollars by going with a kit.

A Delta 3D printer kit is an especially good option if you’ve previously assembled Delta printers and have experience using them. However, if you’re a first-time user, a beginner, or do not want the hassles of setting up a Delta printer from scratch, a pre-assembled printer is the best way to go.

The Monoprice Mini Delta V2 and the Silhouette Alta Plus arrive fully assembled from the factory. But, if you like the assembly part, the FLSUN Super Racer provides an excellent middle ground as it comes partially pre-assembled from the factory.

Filament CompatibilityMost Delta 3D printers use Bowden extruders to maintain a lightweight extruder design and to 3D print at fast speeds. The downside of this is that you need to use a PTFE tube to guide the filament from the spool to the hot end.

This can introduce friction, which in turn can lead to under-extrusion and poor print quality. Dialing in retraction settings and using a high-quality filament is essential to getting good results with a Bowden extruder.

Many Delta printers also use PTFE-lined hot ends that keep a more straightforward design and are easier to combine with Bowden extruder systems.

The PTFE tube in the hot end starts to degrade when exposed to 250 °C or higher for extended periods. This limits the types of filaments you can use with many Delta printers unless you choose to upgrade to an all-metal 3D printer hot end.

This limits the types of filaments you can use with many Delta printers unless you choose to upgrade to an all-metal 3D printer hot end.

The combination of these factors limits the compatible materials with a Delta 3D printer. In most cases, you are limited to PLA, ABS, and PETG filament materials. A Bowden extruder is also not the most preferred extrusion method for printing with flexible filaments. And therefore, printing TPU on a Delta printer is challenging for many users.

In conclusion, an unupgraded Delta 3D printer may not be your best choice if you need wide material compatibility. But if PLA, ABS, and PETG are your primary printing filaments, most Delta printers will work just fine.

You can also choose to upgrade your Delta 3D printer with an all-metal hot end to expand the range of compatible filament materials or switch to a direct-drive extruder for printing with flexible filament materials.

Spare Parts

Due to a Delta printer’s unique construction and uncommon part designs, finding the exact component in the aftermarket store can be challenging. Therefore, it is good if the Delta 3D printer you buy comes with spare parts such as extra connector rods in the box.

Therefore, it is good if the Delta 3D printer you buy comes with spare parts such as extra connector rods in the box.

Usually, Delta printer kits come with more spare parts than a pre-assembled printer. The extra components save you considerable time and effort and let you repair the 3D printer quicker if you run into any issues.

The HE3D K280 printer kit comes with four nozzles of different sizes. Likewise, you’ll find several spare components with the FLSUN Delta printers, like the FLSUN SR Super Racer.

Community Support

Printing on Delta printers can be challenging. As they’re not the mainstream style of 3D printers, you might have difficulty finding solutions to specific issues. In such cases, strong community support is helpful for both beginners and experienced users.

FLSUN and Monoprice are well-known in the Delta 3D printer market. Their subreddits have 1k+ members, and you’ll find lots of videos and troubleshooting guides online for these printers.

Good community support can save you considerable time and frustration with your machines. Therefore, if you’re a beginner, a first-time user, or getting a Delta 3D printer for a kid, choosing a reputable brand is an excellent way to ensure easy support if you encounter any issues.

Verdict: Which Delta 3D Printer Should You Buy?

If we are to choose one, the FLSUN SR Super Racer ranks at the top of this list of the best Delta 3D printers. It has fast printing speeds, a generous print volume, excellent build quality, and a plethora of features, all at a reasonable price. For the majority of users, the SR Super Racer is more than sufficient.

As runner-ups, the Monoprice Mini Delta V2 and the FLSUN Q5 are excellent choices. Both these printers are suitable for beginners and come with all the essential features to deliver a good print quality and an enjoyable printing experience. They don’t cost an arm and a leg, yet offer good value for the money.

Which Delta 3D printer would you choose? Or do you still prefer a more conventional Cartesian or CoreXY printer? Let us know in the comments below.

calibration, setting up a 3d printer delta, which one is better (pros and cons)

3D printers with delta kinematics stand out among other models with a high printing speed of very complex parts. Such devices are quite expensive, but they can be assembled independently. Consider the assembly steps, configuration and nuances of using a delta printer.

Which 3D printer is better - delta or cartesian?

Cartesian (also called Cartesian) and delta printers use the same filaments for printing. In addition, they have the same working parts (extruder, platform, motor), but their location is different. nine0003

For Cartesian 3D printers, the movement of the extruder or platform is along the rods of the X, Y and Z axis (Cartesian plane). That is, work items move left, right, forward, backward, up, and down.

Delta 3D printers are based on a different movement system. The machine is equipped with three brackets that support the extruder. The brackets themselves are attached to three vertical posts, which are arranged in the shape of a triangle. The extruder on a delta printer can move in all directions, and each arm can only move vertically up and down. nine0003

The extruder on a delta printer can move in all directions, and each arm can only move vertically up and down. nine0003

Considering the structural features of both types of equipment, you can determine which one will be better used for certain purposes. To do this, we highlight the advantages and disadvantages of the Cartesian and delta printers.

Pros and cons of the delta printer

The main advantages of the delta printer are:

- very fast printing of complex objects;

- high detail of thin and small parts of the product;

- easy replacement of the extruder. nine0022

Along with the advantages of the delta printer, it also has the following disadvantages:

- a small amount of information about the operation, assembly and configuration of the device;

- complex assembly, adjustment and calibration for correct operation of the printer;

- Difficulties with the selection of parameters and settings when printing complex objects at high speed.

Pros and cons of a Cartesian printer

Traditional printers based on the Cartesian coordinate system have a number of advantages when used:

- stable print result in mass production;

- a large amount of free information about the structure, operation, configuration and maintenance of the printer on thematic forums;

- the size of the created product is not limited, since the model for printing on a Cartesian printer can be divided into its component parts.

The main and significant disadvantage of the Cartesian printer is a much slower print speed than that of the delta device. This is because the Cartesian printer spends a lot of time accelerating and decelerating the system. Because of this, the print head moves more slowly to the desired point. nine0003

How to make a Delta 3D printer with your own hands: step by step instructions

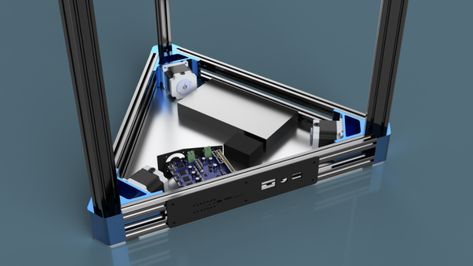

Before you start assembling a delta printer, you must select all the parts correctly. The following components are required to construct a workable device:

The following components are required to construct a workable device:

- frame with plastic bushings;

- guide rollers;

- heated table;

- stepper motors;

- RAMPS 1.4 expansion board;

- mechanical stops;

- microcontroller Arduino Mega 2560 R3; nine0022

- Threaded rods M5 format;

- step-down voltage regulator;

- power supply 12 V;

- extruder;

- optical limit switches;

- filament spool;

- two coolers (for blowing parts and for blowing drivers).

- display and button with 220V terminal.

Assembly of the delta 3D printer is carried out in the following order:

- First, the frame and end supports are designed. The lead screws at the top remain free. nine0022

- The voltage regulator is soldered to the power input. A microcontroller is installed and a regulator is attached to it from behind.

- The expansion board is then soldered separately to the legs.

Mechanical stops are set in the direction of correct polarity.

Mechanical stops are set in the direction of correct polarity. - Before setting up the firmware, the printer is connected to electronic components and optical ends. They also install a table, an extruder, coolers and a material reel.

- The firmware for the printer is configured based on its size. Also, when installing, it is important that all the rods are the same length. nine0100 Help. To make rods of equal length, it is necessary to screw the hinges on equally cut pieces of the stud on both sides. After that, you should install neodymium magnets on the finished bar and rotate the pin until the hinges are clearly in the middle of the magnet. After adjusting all the rods, it is necessary to fix the thread at the hinge with glue.

Setup and calibration

The most convenient way to calibrate the delta printer is with the OpenDACT utility or Pronterface. These programs will auto-calibrate the equipment by electrical contact between the metal nozzle and the table. This procedure is carried out in three stages:

This procedure is carried out in three stages:

- Aluminum tape to stick on the work table.

- One end of the wire is crimped into a block, the other two ends are fixed on the radiator and on aluminum tape. After the three ends of the wire are connected to the 3D printer.

- The printer is then connected to a computer from which the auto-calibration program is launched. The whole process can take a long time, as it requires you to select all the necessary geometry parameters.

After or before calibrating the printer, you must also calibrate the device desktop. This will achieve maximum print accuracy. Table calibration is performed as follows:

- Heat the table to +90 °C, tighten the screws and move the print head to the center of the table. A sheet of white paper is placed directly under the extruder nozzle. It should not be strongly pressed down by the nozzle, but it should not “walk” under it either.

- After adjusting the central part of the table, move the sheet to the corners of the work surface and calibrate the table in the same way.

Errors during creation and tips on how to avoid them

When assembling and setting up the delta printer on your own, the user can make a number of errors that will negatively affect the operation of the device:

- Incorrect printer calibration. It will lead to backlash and deviations in the geometry of the structure. And these problems will cause serious distortion of the part when printed.

- Sliding rods off the magnets. It can lead to deformation of the printed product. You can avoid slipping of the rods from the magnets by providing clamps for the rubber bands. They will not allow the hinge to come off the magnet.

- The product cannot be printed to the full working height of the printer. This problem occurs because the print head is not properly positioned. It must be provided with a separate space in the printer that does not take up useful working space. nine0022

Having considered the features of the assembly and configuration of the delta 3D printer, the user can independently create an apparatus for fast printing of complex structures. However, it should be noted that the assembly of such equipment is very complex and special knowledge is required for its design.

However, it should be noted that the assembly of such equipment is very complex and special knowledge is required for its design.

- March 28, 2021

- 2364

Get expert advice

Delta 9 FAQ0001

Questions about Delta style 3D printers.

For questions regarding faults, design, repair of delta robot-style 3D printers.

- What could be the reason for underextrusion in some areas? When I print the gcode repeatedly, the extrusion happens in the same place. Underextrusion occurs not only on the first layer. I noticed that part of the second layer is also not extruded, but not in that...

- What causes the pattern over a large area? nine0167 Every time I print a large area, I get a pattern in the middle. The picture below was taken during printing. The material is uneven on the table and some of it…

- Delta printer calibration extended question Specifications: Printer Configuration: Delta Firmware: Marlin 2.

x Probe: Conductive nozzle (tested repeatability of 0.01 mm) I'm working on calibrating my...

x Probe: Conductive nozzle (tested repeatability of 0.01 mm) I'm working on calibrating my... - RAMPS Plus2 board pinout? nine0167 I temporarily purchased two different 3D printers that I am helping someone reassemble. These are delta style printers that worked great at some point. They were stored on a large public…

- Delta printer: Minor print misalignment on assembly After assembling the Delta printer, I noticed that all my prints were slightly tilted around the z-axis compared to a slicer (eg Cura). There is no layering here. This means that the prints themselves…

- Delta printer distortion I did a little test with 4 points aligned with tower A, tower B and C. The distance W and S are the same in stl but not in print. I've tried different values for the diagonal root, but S is always less than W, and... until one of the buttons detects being pushed...

- Why not use a geared, high speed, high microstep stepper motor in a 3D printer? The 3D printer uses stepper motors to move the print head and extrude the filament.

They must have good torque and resolution. Microstepping improves...

They must have good torque and resolution. Microstepping improves... - Delta 3D Printer Slow I am using a large delta 3D printer with Repetier firmware. The problem that annoys me is that the speed of the carriages is too slow, like an old lady who walks on…

- Anycubic Kossel Delta switch from Trigorilla to MKS Gen L 1.0 I have an Anycubic Kossel Delta 3D printer. The original Trigorilla motherboard died and I decided to buy it but only found the Makerboard MKS Gen L 1.0 which is said to be compatible with…

- How to improve the dimensional accuracy of the delta printer? I have a delta printer that I am trying to set up. I printed a 20mm calibration cube and got the following measurements: X: 20.5 Y: 20.3 Z: 20.0 How can I calibrate my…

- Looking for files for printed parts for my Kossel XL kit from Builda3Dprinter.eu A couple of years ago I got a Kossel XL kit from builda3dprinter.

eu as a gift, but I stopped building it because a few parts were missing, including printed parts . Now that I'm building...

eu as a gift, but I stopped building it because a few parts were missing, including printed parts . Now that I'm building... - Deltaprinter scratches print About a year later I bought a used little Tevo monster. It was a bit dirty but (as far as I could see) unchanged. I removed that noisy "MKS SBASE" board from smoothieware and installed a good one...

- Why does the Anycubic Predator print backwards? My Anycubic Predator prints very well, except everything is backwards. Text and anything that is right or left handed comes out mirrored. The same files print correctly on...

- Minimum solid figure drawn by the Delta 3D printer In Cartesian printers, the extruder moves along the X-axis, Y-axis and/or Z-axis. Each axis has its own resolution, this is the minimum length that can be reach on this axis, and is connected to…

- How to change the voltage on the FLSUN QQ I just bought the FLSUN QQ and the instructions say I need to change the voltage from 220 to 110.

Unfortunately the instructions don't say how. Can someone tell me how it is...

Unfortunately the instructions don't say how. Can someone tell me how it is... - AnyCubic D (aka Predator) - Z-nulling and first layer problems In short, my wife and I are now the proud owners of the AnyCubic D, also known as the Predator. It's not our first 3D printer, but it's our first "delta" design with a circular mounting plate and extruder...

- FLSUN QQ does not print and stops at Z=15mm When I try to print something that is not a test model already on SD, which means when I try to cut something in Cura 4 and then start printing , the nozzle stops at Z=15mm, and...

- Still getting poor print quality after calibrating my Anycubic Predator I have an Anycubic Predator (aka Anicubic D). I followed the official instructions and leveled the printer. The first annoying problem I ran into is that after…

- Underextrusion towards the end of print I have a really weird problem. The thing is that my print (first layer) started normally, not good and not perfect, but good, and everything went well, but then suddenly, towards the end of the print, .

..

.. - Partial underextrusion in the walls I encounter strange "pillars" of underextrusion on the outer walls of my XYZ test cube. In the pictures below, I printed PLA test cubes with a 0.4mm nozzle, 0.2mm height, and a temperature of…

- Knocking sound from Delta printer carriages I have a knocking sound from my carriages (belt and wheel style) in my delta printer. The sound is like a car crossing a rumble lane on the road and this problem gives me different...

- Printer Delta Homing Problem Homing only happens when my X and Y max end stops fire together. If only one of them fires, then the Repeater window shows an error. I am using Marlin 2.0…

- Marlin Firmware Auto Leveling only re-centers the XY axis (Delta printer) I'm trying to get my printer to automatically level my table with Marlin firmware using the following: Printer: Kossel Linear plus (Delta 3D printer) Board: MKS Base V1.

5 Firmware:…

5 Firmware:… - Having bumps/warts on the surface, Cura doesn't want to brush them? I was unable to print smooth and round shapes with Cura 3.3.1 (or earlier) without bumps. I think it's stitches? The filament is PLA. Brushing is included, which I thought made it so…

- LV8729 about kossel problems with print sizes (steps) I installed an LV8729 on a kossel configured with SKR 1.3 and marlin 2.0 with all jumpers configured the same for 16 micro steps in X Y Z. Everything seems fine, printer…

- Getting wrong measurements on my Kossel Linear Plus after installing SKR 1.3 with Marlin 2.0 So I replaced the Trigorilla board in the printer with SKR 1.3 with TMC2208 drivers and installed the latest Marlin 2.0 with a configuration based on this . You can find config.h here…

- Why are delta bots so picky? I've had anycubic kossel for quite some time now and whenever I print something it seems to go out of calibration very quickly.

The biggest example is that the prints are like...

The biggest example is that the prints are like... - 0.9° motors for Delta printers? I built a cheap Delta printer with an ATmega board and 1.8° motors. Microstepping is limited to 1/16. In addition to decent print quality, I see a moiré effect on flat surfaces. Moire is clearly caused by…

- What methods and mechanisms can be used to operate a multimaterial FDM printer? I now have a Prusa3D MMU2. Benefits, costs and experience gained by others are well documented. I'm interested in rebuilding my big delta home machine by making it...

- Can I repurpose most of the components of this Prusa clone for Delta? I have a generic Prusa clone that I don't use (my main problem with it is the lack of rigidity of the frame body as it was built). Will they fit…

- Delta Printer: After calibrating the X and Y axes are slightly different I noticed that my x axis is slightly longer than the y axis (~0.

6%) if I print an object. What setting in Marlin can be tweaked to fix these issues? The stem length parameter seems to be rather...

6%) if I print an object. What setting in Marlin can be tweaked to fix these issues? The stem length parameter seems to be rather... - Replacing FAN0 with FAN1 on the TriGorilla Printer Board I connected a new fan to the PCB fan (TriGorilla v1.4) Fan0 which I found to be broken. I am trying to upgrade the cooling fan parts for a bigger size. K…

- Printer goes crazy in the middle of printing In the middle of printing, the print head will crash into the print, then crash into the table, rise about 3 inches, and begin to wobble back and forth over one part of the table. I have had successful…

- Delta printer nozzle not moving squarely with a perfectly flat table (as if the table is curved... but it isn't) I had this problem with my delta 3D printer where my nozzle does not move smoothly along with my printtable (like the table is bent), but I used the edge of my steel ruler and it...

- XY plane distortion calibration in Repetier I built a delta 3d printer (eg mini Kossel) and am now trying to calibrate it.

I made all the horizontal and vertical rods out of wood myself and bought the gussets (between the rods)…

I made all the horizontal and vertical rods out of wood myself and bought the gussets (between the rods)… - Print speed and settings for printing below 0.1mm on PLA I recently bought an Anycubic Kossel Linear Plus delta printer and I interesting to try printing slightly below the set lower layer height limit of 0.1mm. I'm not interested in…

- Cura print time estimate I know that the actual print time is longer than Cura's calculated time due to the acceleration and jerk factor. However, I printed a small pyramid for which Cura estimates 4.0 minutes in…

- Clean or wipe move for delta 3D printers I have a delta 3D printer. The problem is that at the beginning of the print, the extruder outputs a dirty filament. I need a clean filament thread at the beginning of my prints! How can I get hotend to exit from…

- Best 32-bit delta electronics? I want to upgrade my Delta printer electronics from 8-bit to 32-bit.

So I checked Marlin and found out that they are working on a project they call Re-ARM and as far as I can…

So I checked Marlin and found out that they are working on a project they call Re-ARM and as far as I can… - RAMPS PLUS 2 and E1 socket issue (K200 Delta, but PCB related, not printer related) ) Total 3D printing newbie here, apologies in advance if my terminology is wrong. I have a K200 dual head delta printer with heated bed that I built 8 months ago but…

- Kossel clone print quality for Print in Place models My first printer is a Delta style Kossel clone and I have no luck with Print In Place (PIP) models, especially with hinges. I suspect my printer just can't reach low enough tolerances...

- At what point does the delta 3d printer change G-code to work in its cartesian space? For example, to make a DIY Cartesian 3D printer, you can use/do the following: Create a G-code with the program of your choice. Load it into Universal G-code…

- Delta printer does not respond to changes in DELTA_RADIUS As mentioned in my previous question, I have some issues with printer table alignment.

Following the link in @tjb1's answer, I figured they were all about to be solved - just...

Following the link in @tjb1's answer, I figured they were all about to be solved - just... - Delta Printer Offset on the first few layers On the first few layers, each layer has an offset in the -X/-Y direction on the previous layer . But above ~2 mm it is vertical. I checked the printer assembly that there is no noticeable error in the towers. Tried…

- Nozzle moves very slowly from home to home position I am currently working on a custom Delta printer running Marlin 1.0.2 firmware. To manage it, I use the Repetier Host software with built-in software…

- Creating a new Repetier firmware for the delta (D-force) printer So my printer's calibration was messed up after a sudden reboot, and since the current firmware (0.92.6) is licensed, I can't edit it. So I'm building a new one. Here…

- Delta 3D printer extruder? I've never owned a 3D printer and don't know much about them, but I'm considering buying a delta 3D printer kit for around $450.

Learn more