3D printer slicer cura

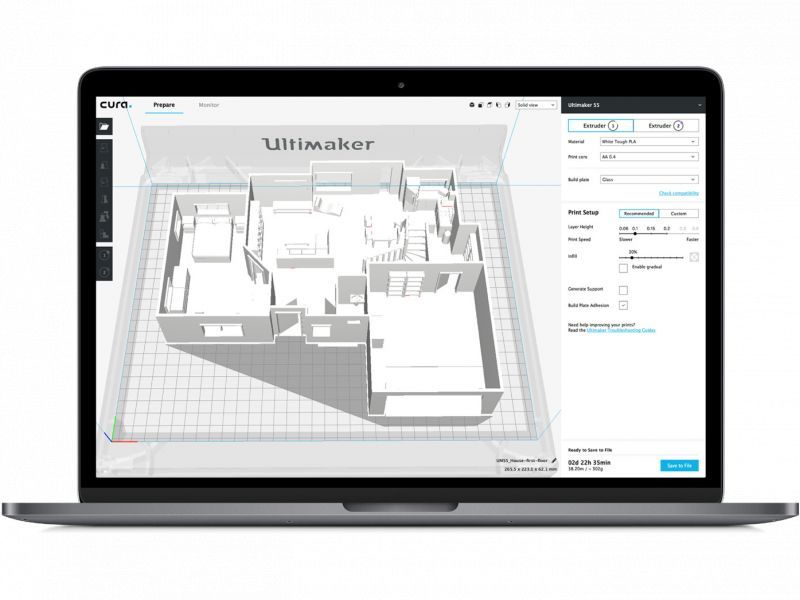

Powerful, easy-to-use 3D printing software

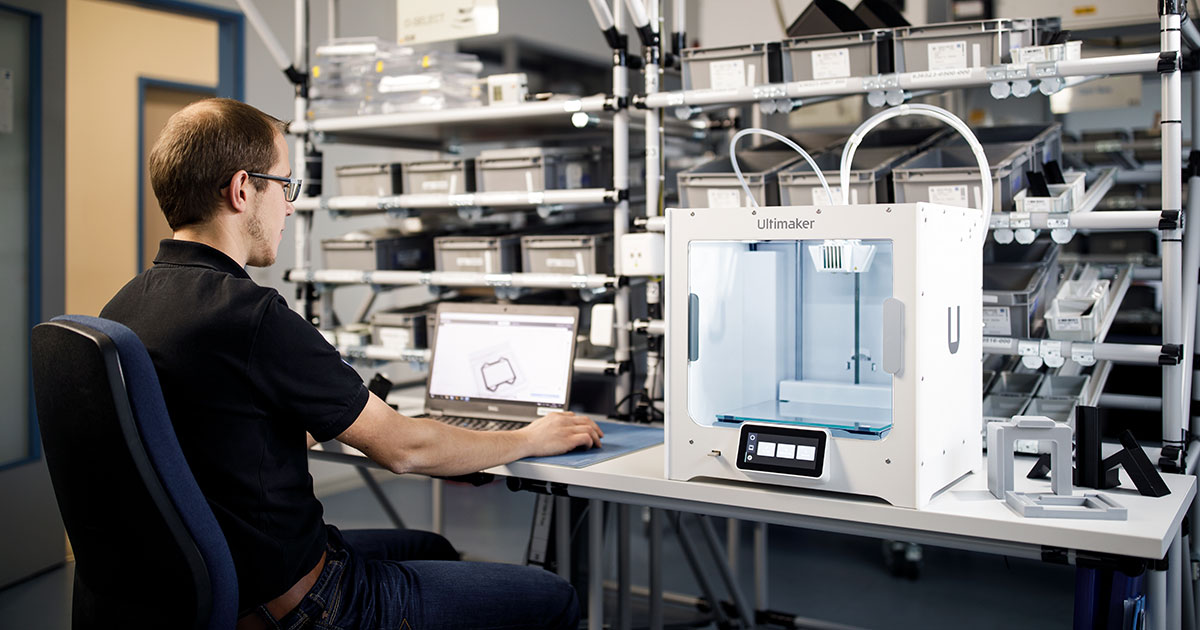

Trusted by millions of users, Ultimaker Cura is the world’s most popular 3D printing software. Prepare prints with a few clicks, integrate with CAD software for an easier workflow, or dive into custom settings for in-depth control.

Slicing features

At the heart of Ultimaker Cura is its powerful, open-source slicing engine, built through years of expert in-house development and user contributions.

Intent profiles print specific applications at the click of a button

Recommended profiles tested for thousands of hours ensure reliable results

‘Custom mode’ gives over 400 settings for granular control

Regular updates constantly improve features and printing experience

Integrated workflow

If you own a 3D printer, software matters. Get the most from your printer with software designed to suit your workflow.

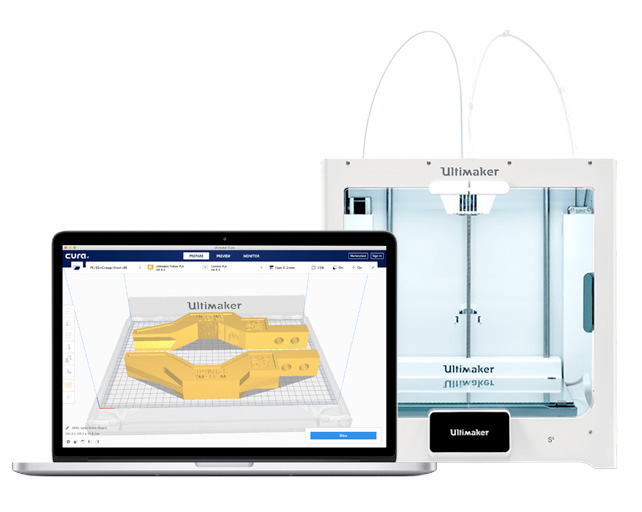

Seamless integration with all Ultimaker products

CAD plugin integration with SolidWorks, Siemens NX, Autodesk Inventor, and more

Compatible file types: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG

Easy to use

Manufacturing doesn’t need to be complicated. We design our software so anyone can use it – both experienced or rookie 3D printer users.

Prepare your 3D model for print in minutes with recommended settings

Simply choose speed and quality settings, and you can start printing

Ultimaker Cura is free and open source software

Ultimaker Marketplace

Being open and collaborating is in our DNA. Now we bring this to the professional 3D printing market with the Ultimaker Marketplace.

Download material profiles from leading brands for your application

Avoid manual setup when using third-party materials

Download useful plugins to customize the print preparation experience, star-rated by our community

An Ultimaker Cura experience that keeps your infrastructure rock-solid

Ultimaker Cura Enterprise delivers stability and security with features that are tailor-made for businesses.

Utimaker Cura Enterprise can be deployed, configured, and managed with cross-platform systems distribution

Ultimaker Cura Enterprise receives two updates a year.

These are thoroughly tested by our community and ensure the most stable desktop application. We support updates for 12 months after release (including security patches and bug fixes)

These are thoroughly tested by our community and ensure the most stable desktop application. We support updates for 12 months after release (including security patches and bug fixes)Each release of Ultimaker Cura Enterprise is independently scanned, tested, and analyzed for vulnerabilities. We publish a summary of that report and we commit to continuously improving security

Backup & sync your materials & plugins

Save projects to the Digital Library

Access 3D printing e-learning courses

Join a community of 40,000+ active users

3D printers that simply work

Our award-winning 3D printers are robust, reliable, and easy to use. They deliver quality parts time and again. Designed and tested to run 24/7, they allow you to achieve the results you need more quickly and easily.

Learn about our 3D printers

Software ready for Industry 4.0

Trusted by millions of users across 14 languages, Ultimaker Cura slices your model and integrates with any workflow through Marketplace plugins. Then scale production and digital distribution with Ultimaker Digital Factory.

Then scale production and digital distribution with Ultimaker Digital Factory.

Material choice like never before

Ultimaker offers the widest material choice on the market. Through our Material Alliance, choose the perfect filament for your application – from advanced polymers to carbon fiber composites.

Learn about our materials

Support dedicated to your success

Wherever you are in the world, Ultimaker support is close by. Our global network of service partners offer professional installation, training, and maintenance in your language and time zone.

Learn about our support

Ultimaker Cura 5.1 arrives with metal FFF printing, better supports, and improved surface quality!

Arun Chapman19 July 2022

News

The latest release of Ultimaker Cura is here and Ultimaker owners who download version 5.1 will now be able to enjoy simple and affordable metal FFF printing, new and improved support structures, and better surface quality.

A new streamlined workflow for metal FFF printing

The following new features have been added which are specific to metal FFF printing:

Automatic shrinkage plate feature. A shrinkage plate will now automatically be created when using a compatible Ultrafuse® metal material profile that prevents your part from deforming during the debinding and sintering process

DD print core support*. The new DD 0.4 print core is now supported which has been especially designed for use with the new Ultrafuse® Support Layer material

Automatic support interface feature. When using the new Ultrafuse® Support Layer material and a compatible Ultrafuse® metal material, an interface layer will automatically be created between the model and the metal supports as well as between the model and the automatic shrinkage plate. This layer makes it easier to remove supports after sintering

These features are enabled by the newly announced Metal Expansion Kit which contains the new DD 0. 4 print core and Ultrafuse® Support Layer materials. Currently the only metal print profiles compatible with these new features are the Ultrafuse® 17-4 PH, Ultrafuse® 316L, and Ultrafuse® Support Layer* materials by BASF Forward AM.

4 print core and Ultrafuse® Support Layer materials. Currently the only metal print profiles compatible with these new features are the Ultrafuse® 17-4 PH, Ultrafuse® 316L, and Ultrafuse® Support Layer* materials by BASF Forward AM.

*Currently only available in Europe. The Ultimaker Metal Expansion Kit is sold without the BASF Forward AM Ultrafuse® Support Layer and Ultimaker Print Core DD 0.4 at a lower MSRP in other territories (including North America).

A metal part printed with Ultrafuse® 17-4 PH. The print sits on a shrinkage plate and the Ultrafuse® Support Layer material is used to create a support interface layer between the print and the supports.

These new metal FFF features mean that a simple and affordable new metal FFF workflow is now available which not only includes the printing of parts, but also the debinding and sintering process that is made possible through BASF’s network of debinding and sintering services.

However, the foundation for this workflow was started in Ultimaker Cura version 5. 0 with the following changes to the Ultrafuse® 17-4 PH and Ultrafuse® 316L print profiles:

0 with the following changes to the Ultrafuse® 17-4 PH and Ultrafuse® 316L print profiles:

Automatic scaling. Metal parts are automatically scaled to compensate for shrinkage that takes place during the debinding and sintering process

Alternate wall directions. The direction of walls is alternated to prevent distortions during the debinding and sintering process

New slicing engine. The new slicing engine reduces internal gaps in your part that can lead to line delamination and cracks during debinding and sintering, as well as allowing for the printing of thinner walls and finer details than was previously possible when printing with metal materials

If you want to find out all of these new features, you can watch our Ultimaker Academy course on metal FFF printing.

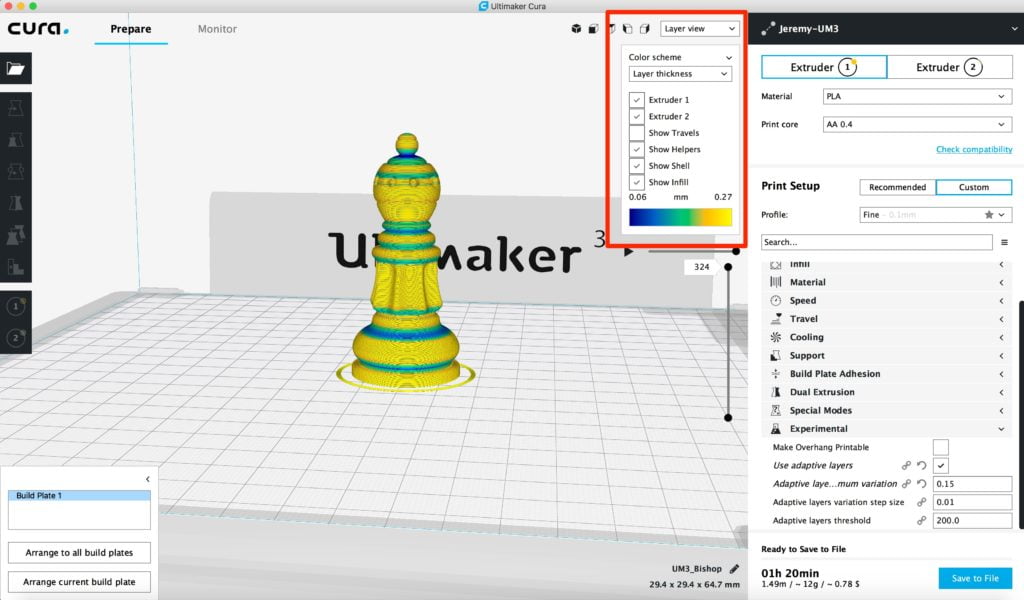

Higher segment resolution results in a improved surface quality

In our never-ending quest to help you get the best-looking prints possible, we have massively increased the segment resolution of your prints when using Ultimaker S-line printers with the latest firmware. Models with smooth curves like spheres, cones, and cylinders, well as more complex models made up of many organic shapes, will display improved surface quality as they will print with up to twice as many individual segments.

Models with smooth curves like spheres, cones, and cylinders, well as more complex models made up of many organic shapes, will display improved surface quality as they will print with up to twice as many individual segments.

This was achieved by implementing a new resolution algorithm, as well as the removal of unnecessary jerk and acceleration from travel commands within gcode. The removal of these redundant commands resulted in reduced printer vibrations, as well as gcode files that are up to 20% smaller.

Left: printed using Ultimaker Cura 4.13 and old firmware. Right: Printed using Ultimaker Cura 5.1 and new firmware.

The biggest differences in surface quality will be seen when comparing against Ultimaker Cura 4.13. This is because the foundation of these improvements was made in both Ultimaker Cura 5.0 and S-line firmware version 7.0.3. The previous Cura update contained various print profile tweaks and the firmware release included changes that reduced buffer underrun.

Note: This feature requires you to be using firmware version 7.0.3 or above on your Ultimaker printer. Download the latest firmware version to make sure your printer is fully compatible.

Faster and more reliable supports when printing with support materials

When printing supports using either Ultimaker PVA or Ultimaker Breakaway support materials, you can now expect faster print times and more reliable support structures. As well as improved surface quality on the part of your print that is being supported.

These improvements have come from a variety of tweaks but the most significant are that when printing supports with these materials, a new zig-zag pattern will be used, instead of the previous triangle pattern. The outer wall around the supports has also been removed and the density of supports has been increased.

Print times can be as much as 20% faster and as an added bonus, PVA supports will also now dissolve much faster, allowing for much speedier removal of supports, especially when using the PVA Removal Station.

A more intuitive slicing process

After extensive user testing, we have tweaked the slicing process to make it more intuitive when printing with materials that use intent profiles. The result is that we have separated the decision of which intent profile and layer height you want to use into two distinct and easy-to-understand choices.

We have also updated the tooltip which notifies you when settings have been changes from the default intent profile settings. You can then identify which settings have been changed by going into custom mode where each modified setting will be in italics and will be accompanied by an arrow symbol which will revert any changes when clicked.

Easier collaboration when using 3MF project files

Collaborating while using any of the 250+ materials available in the Ultimaker Marketplace is now easier than ever. When loading up a 3MF project file that uses a material profile that you do not currently have installed, you will now be prompted to download and install any missing profiles.

Additional improvements

The following improvements have also been implemented in the Ultimaker Cura 5.1 beta:

Material profiles for new upcoming Tough PLA colors (blue, yellow, and gray)

Numerous bugfixes including security fixes and an issue with monotonic ordering that prevented it from applying to the topmost surface layer of prints. A full list of bugfixes can be found here

Give us your feedback

Download this latest release to start using all of these fun new features today. And please, share your feedback with us and the rest of the Ultimaker community!

Download now

Ultimaker Cura, Simplify3D, IdeaMaker, UP Studio, FlashPrint

Contents

-

- What is a slicer? What is a Slicer?

slice – slicer (English)

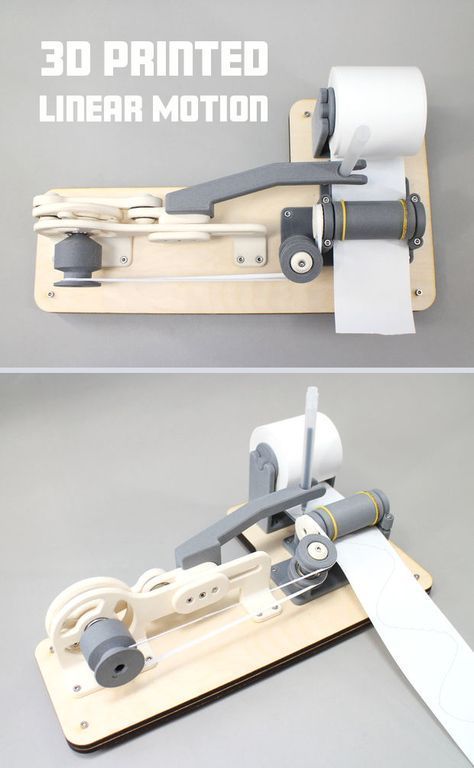

Slicer - a computer program that converts a virtual three-dimensional model layer by layer into machine code (G-code) allowing an additive automated device make a part from a specialized material.

Depending on the used technologies for layer-by-layer or surface formation of a part as a result of work slicer can be files containing data on how to form layers - vector lines, raster solids, paths, normals to surfaces and other defining or control data.

Theory of tilings (parquet) in in a simplified form it says - any surface can be paved (described) an infinite set of polygons without mutual overlaps and gaps. To paraphrase this statement, we can say that any model can be printed, cutting it into layers.

In this article we will look at several well-known slicer programs that allow you to prepare a model and print the part using the most common printing technology today with the abbreviation FDM - Simulation fused deposition modeling (FDM)

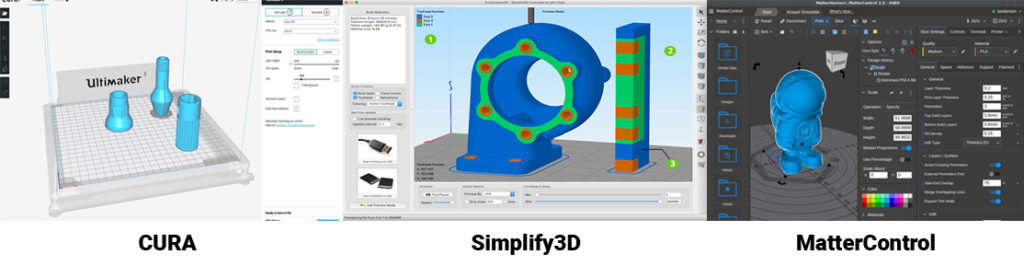

Slicers are divided into two main types: universal and specialized (corporate). Usually, specialized "sharpened" for one technology, brand or model line of printers. Universal have great variability in settings and designed for a wide range of compatible devices.

If you are only planning purchase of your 3D printer, then, among other things, ask the seller, which slicer is included in the package. Some manufacturers prefer use well-known universal slicers, supplementing them prepared specialized profiles of their equipment. Other invest in the development of their own software, as rule tightly "tied" to their equipment. While there are notable exceptions, e.g. developers and manufacturers of Raise3D printers your IdeaMaker, superbly prepared to work with native "equipment", allow set up for any compatible printer.

But if you have already bought a printer and it is supplied with a slicer, which means that the manufacturer filled the program with the necessary profiles and settings. So he tested them. and believes that you will appreciate the effort expended with your purchase. That is, he tried to make your work with the device the most comfortable and predictable.

Therefore, if you are a beginner user of new 3D equipment, do not rush to use third-party slicers, even if they are very popular.

First, you first have to correctly "make friends" the printer with the program by prescribing a number of specific parameters, but it's not easy. Secondly, the acquired "pluses" may turn out to be unclaimed for your routine tasks. Thirdly, the basic principles of operation and the slicing results of all slicing programs are largely identical. Differences can be found in the quality of slicing, interfaces, number of available settings, the resource intensity of the program, the speed of its work and additional services, which, at times, are marketing ploys. Learn first to achieve acceptable printing results by regular means and only then start a comparative practice, being already confident in your equipment.

First, you first have to correctly "make friends" the printer with the program by prescribing a number of specific parameters, but it's not easy. Secondly, the acquired "pluses" may turn out to be unclaimed for your routine tasks. Thirdly, the basic principles of operation and the slicing results of all slicing programs are largely identical. Differences can be found in the quality of slicing, interfaces, number of available settings, the resource intensity of the program, the speed of its work and additional services, which, at times, are marketing ploys. Learn first to achieve acceptable printing results by regular means and only then start a comparative practice, being already confident in your equipment. Other slicer segmentation in FDM printing is described by their accessibility to the user. They are paid and free. In FDM technology, the universal paid program remained, seems to be just Simplify3D.

Slicer structure

Insofar as 3D printing is a process, consisting of a large number of conditions necessary for fulfillment, then there are quite a few settings for them.

And they are all multidirectional linear. Therefore, it is a big task to structure them conveniently and clearly, which is not easy to master. Developers try to build intuitively clear relationships between the main blocks of settings: printer, model, material, print profile, extruder(s), additional options, scripts and macros. They either tie the starting point to the material, then to the printer settings, then to model processing process (print profile) (Simplify, CURA), then to the settings extruder. Each slicer creator applies his own philosophy in this matter.

However, structurally everything slicers, in addition to the main computational core of the program responsible for mathematical calculations of geometric shapes and their conversion into machine language g-code controls have standard settings blocks. There are six in total.

1. Slicer program settings. They are determined by creative the potential of the developer, the presence of an adequate designer and a specialist in graphical interfaces in his team.

Intuition is rare and subjective, therefore the statement "intuitive user-friendly interface of the program" lately makes potential users internally tense.

But, if we discard emotions, then rummaging through buttons, tabs and text menus, you can usually find: program language selection, some action and automation preferences processes, selection of necessary and sufficient settings, design colors, sequences upon completion of work, operations on data and settings, and also legal and marketing information blocks. For print quality, these The settings don't really matter. However, sometimes they allow the user not to "get lost in three pines" and correctly set the units of measurement, speed port connections, visualization of slicing results, model display and other useful options.

2. Your settings printer.

By this term we mean not only the "hardware" of the printer, but also its control electronics.

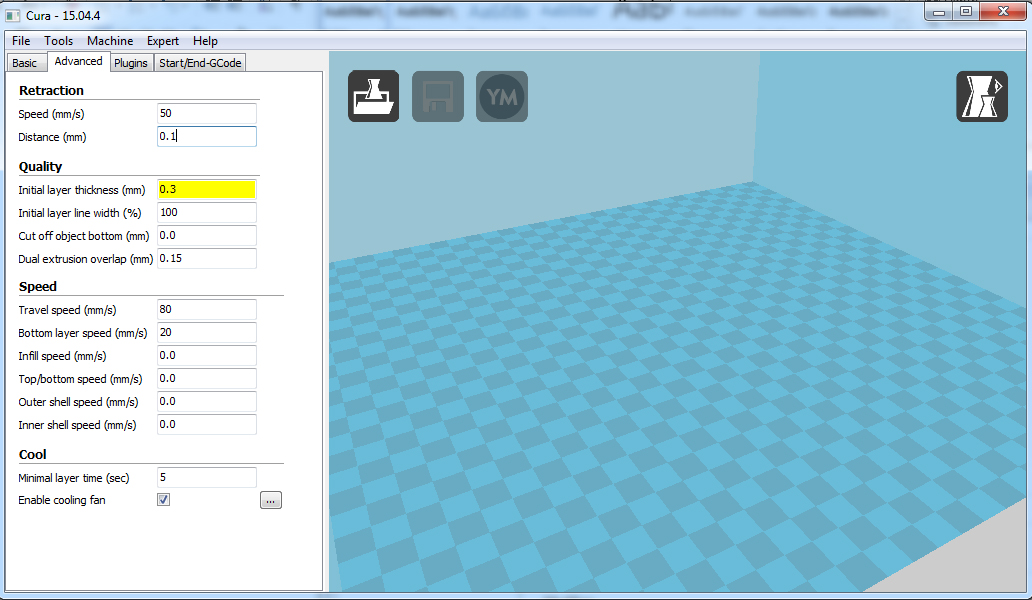

Software compatibility. Number of available settings varies depending on the professional "advancement" of each particular slicer.

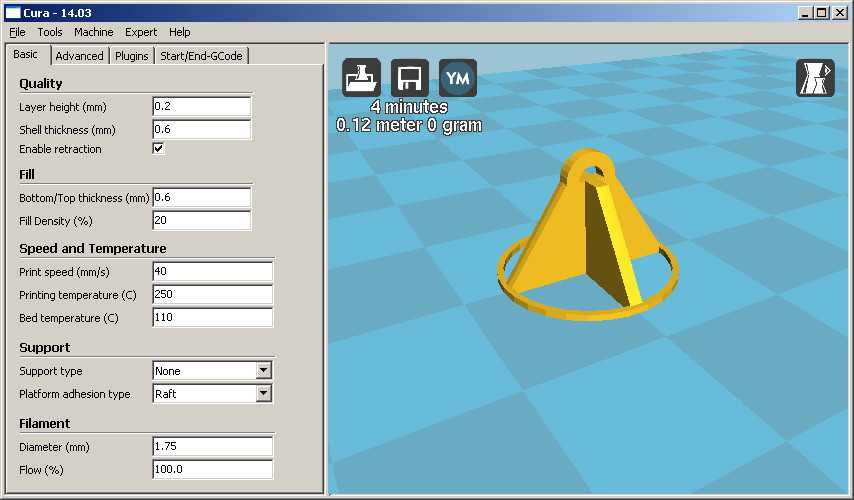

Simplified or "Model" (regular) programs will allow you to select only the printer model. Universal "Pro" versions will require specify which G-code language the control board firmware understands. Sometimes even will allow you to set the values of movement speeds, accelerations, jerks (jerk), retracts (thread rollbacks) (For example, CURA v4.6) which will allow such a slicer more correctly calculate the time to complete the print.

Mechanics. Tell the slicer what he will have to manage. What kind of your printer mechanical movement system - delta, cartesian, hand robot, what are the dimensions of the print area, what margins from the edges are allowed,

Extruders. How many extruders does it have. What diameter is installed nozzle. What is the maximum temperature supported by the hotend design. What is the distance between the nozzles in the dual extruder version.

3. Material settings. Filament profile settings: filament diameter, melting point, density, manufacturer, price, etc.

4. Model settings. Zoom controls and positioning the model in the work area. Tools for "repair" and modifications of the loaded model.

5. Slicing settings. Tools and options forming a part from a model. Auxiliary tools and controls objects - supports, walls, towers, rafts and service operations.

6. Additional services: command sequences - scripts, macros;

Consider in more detail how in some popular slicers implement the above ingredients to transformation of a three-dimensional model into a three-dimensional detail.

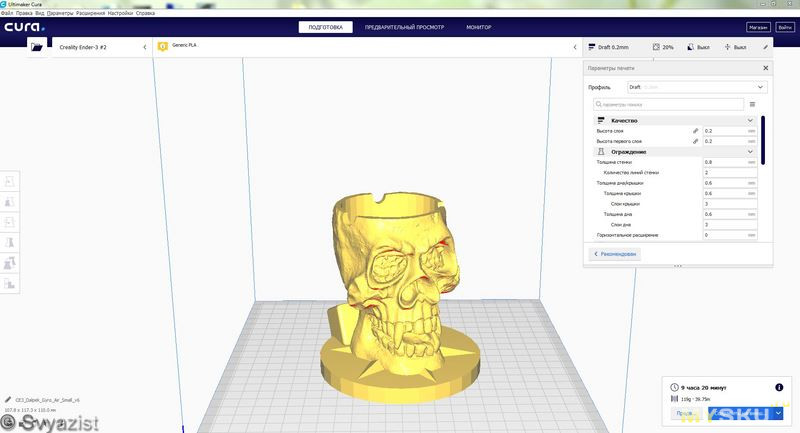

Ultimaker Cura

Official website: https://ultimaker.com/software/ultimaker-cura

Availability: Free

Platforms: Windows (64 bit), MacOS (64 bit), Linux (64 bit)

Language: Russian is.

Cura is one of the oldest universal slicers. The open source slicing patriarch, on par with Slic3r[1], conquered the minds of newly minted 3D printing enthusiasts at the dawn of the additive revolution.

Built on console Cura Engine application - an improved version of the Skeinforge slicer written in C++ using Angusj's clipper system libraries (http://www.angusj.com/delphi/clipper.php).

Built on console Cura Engine application - an improved version of the Skeinforge slicer written in C++ using Angusj's clipper system libraries (http://www.angusj.com/delphi/clipper.php). [1] Slic3r born in 2011 within the RepRap Community and thanks to its high configurability has become the workhorse for 3D printing. First release of this guide was hosted by Lulzbot-Aleph Objects, Inc. and wrote it Gary Hodgson. It served as a platform for the implementation of several new (experimental) ideas that later became technological standards such as multiple extruders, brim, variable height layers, settings for each object, modifiers, post-processing scripts, macros G-code and more. Although it is based on volunteer efforts, Slic3r is still pushing the boundaries of 3D printing. ( https://github.com/slic3r/Slic3r )

The program was originally created by David Braam (David Braam), who was later hired by a manufacturer of 3D printers Ultimaker, for software development and maintenance collaboration security.

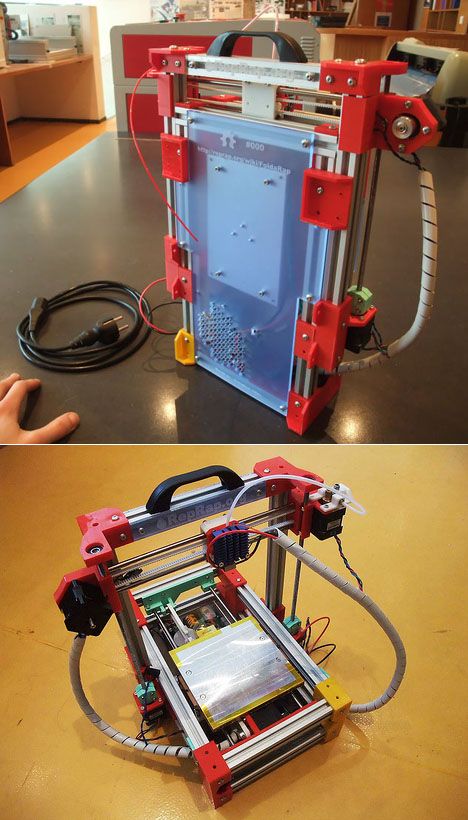

Today, CURA is included with all branded printers. brand Ultimaker, but retained the ability to work with printers from other manufacturers, including homemade printers with compatible mechanics (RepRap printers).

Today, CURA is included with all branded printers. brand Ultimaker, but retained the ability to work with printers from other manufacturers, including homemade printers with compatible mechanics (RepRap printers). According to the structural organization, this the program is a symbiosis of various mini applications - community projects with an open source code. A kind of album of "folk" creativity. List of used projects can be viewed by clicking Ultimaker Cura Help. them there over two dozen. Whether this is good or bad - we do not undertake to judge, but we note that among active users, Cura is the most popular among free slicers.

Cura's popularity is tied first of all, with the mass distribution of budget Chinese 3D printers, most manufacturers who took advantage of the opportunity to use it for free. So or otherwise, but Cura initially captivates with the ease of use of basic templates with more or less predictable print result, but at the same time has on board a huge number of options for fine-tuning the process of translating the model into detail.

So much so that some novice users don't satisfied with template solutions, having seen the breadth of position variability and having spent a couple of kilograms of plastic on their research, they “run” to where everything slightly faster. For example, in Simplify3D.

So much so that some novice users don't satisfied with template solutions, having seen the breadth of position variability and having spent a couple of kilograms of plastic on their research, they “run” to where everything slightly faster. For example, in Simplify3D. Without delving into the wilds of the great many customization options, and there are so many of them that I even had to organize the "Search" line to quickly jump to the desired menu bar, consider this slicer in terms of reasonable operation, no claim to a comprehensive review.

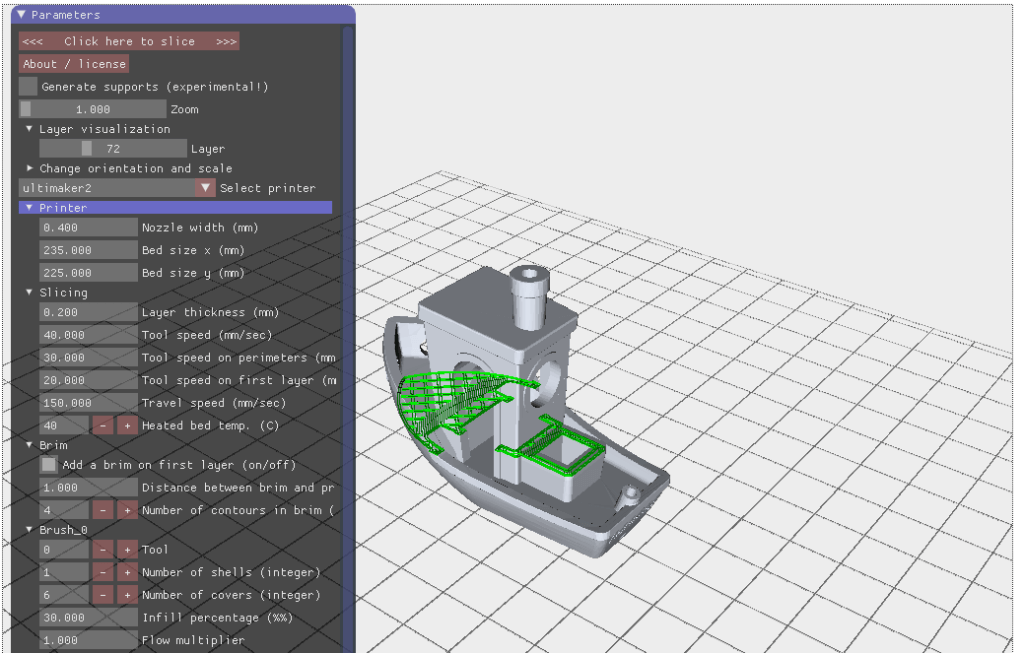

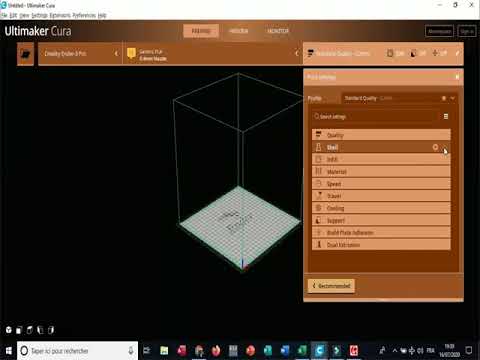

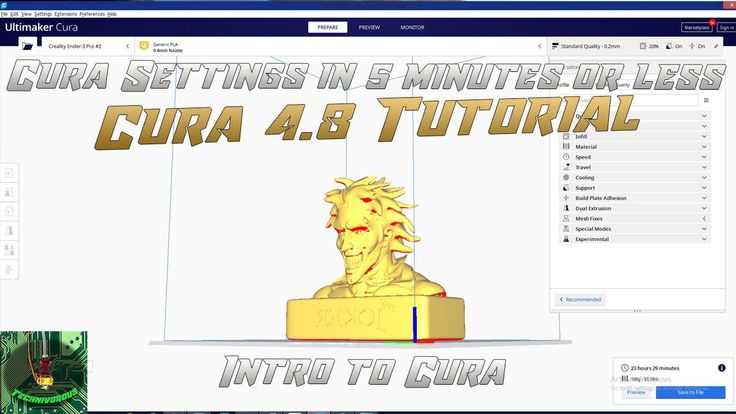

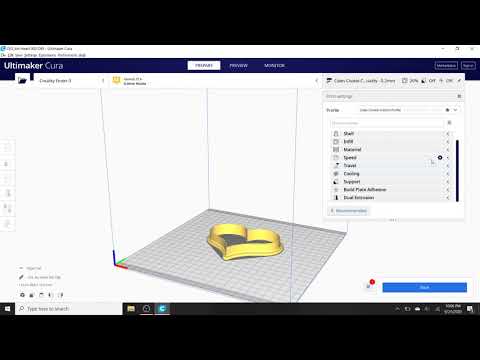

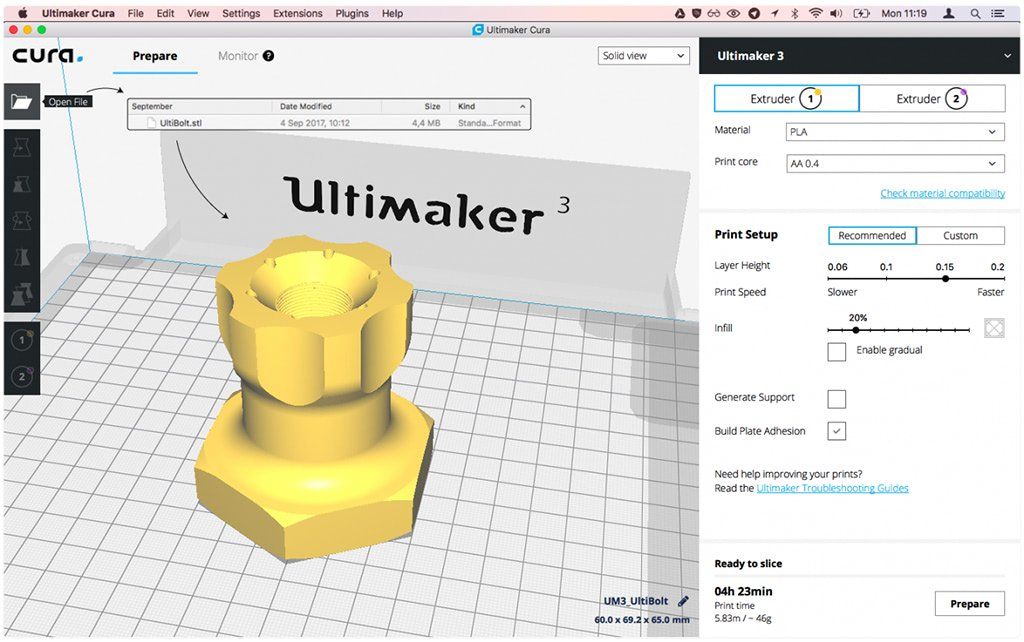

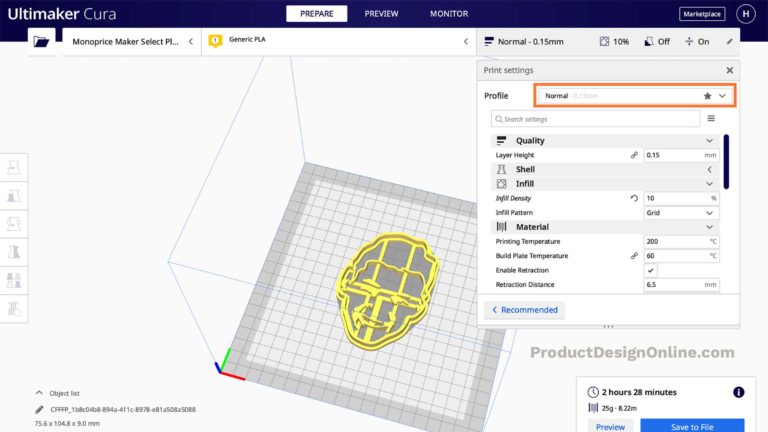

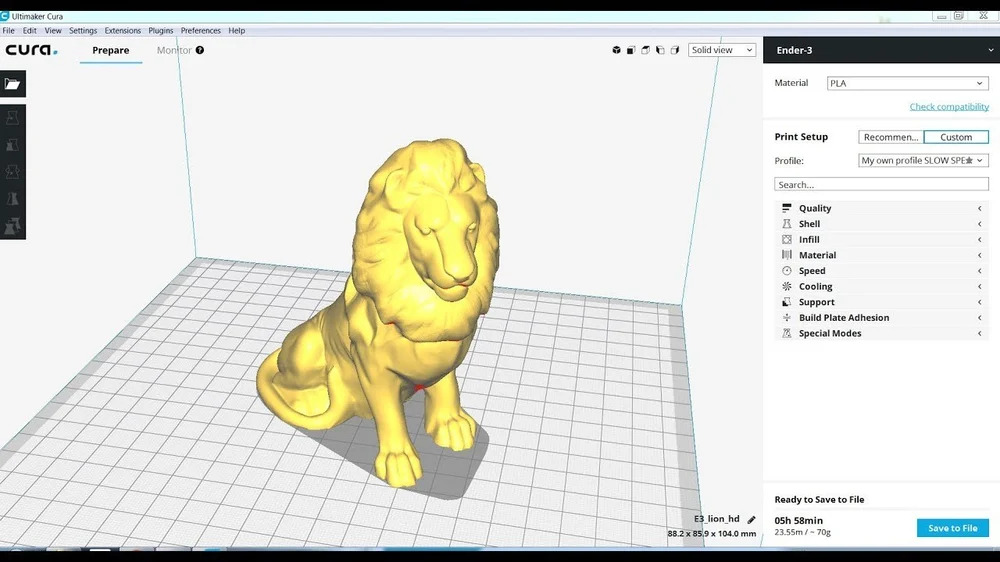

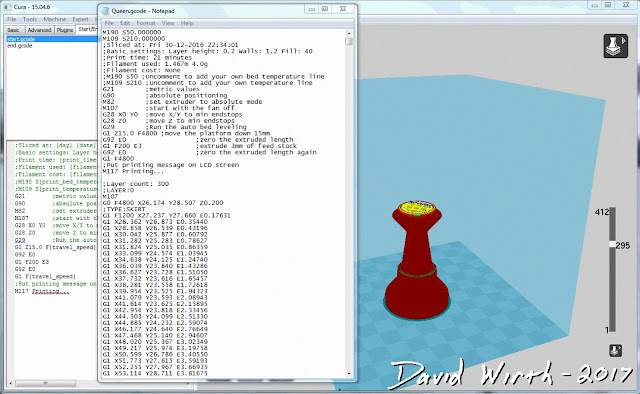

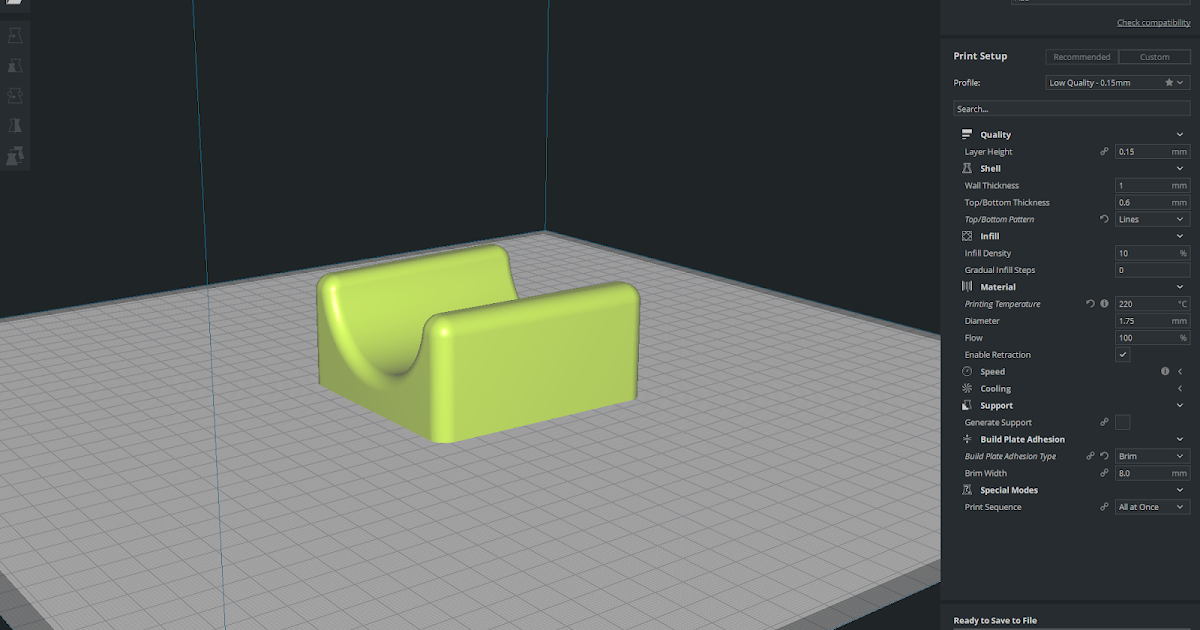

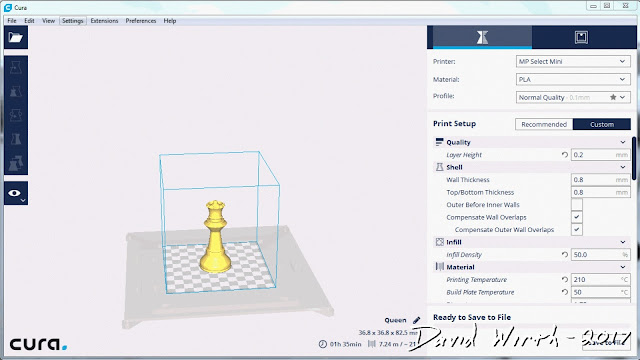

The simplicity of the interface and the availability of settings are perhaps the most important advantage Ultimaker CURA dthcbb 4.6.1

Ultimaker Cura interface deliberately concise and claims a high degree of usability (usability - ease of use). Regular set printer profiles strikes the imagination with its endless variety. It seems that the developers have managed to collect the profiles of all 3D printers in the world from A to Z in a single set.

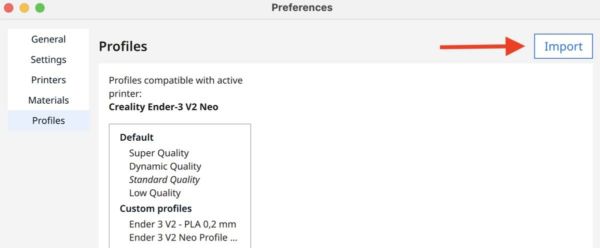

And besides, we left you the opportunity to add your own, "custom" option.

And besides, we left you the opportunity to add your own, "custom" option.

If your 3D printer is not on this list, then…

… set it up yourself.

After selection or setting parameters of your own printer, which we will briefly discuss a little later, you can choose from a fairly rich, but still not complete list materials the one with which you need to print your model.

Many well-known manufacturers can be found in the list of typical materials plastic.

But if you don't find what you need, you can create your own.

And adjust its working parameters.

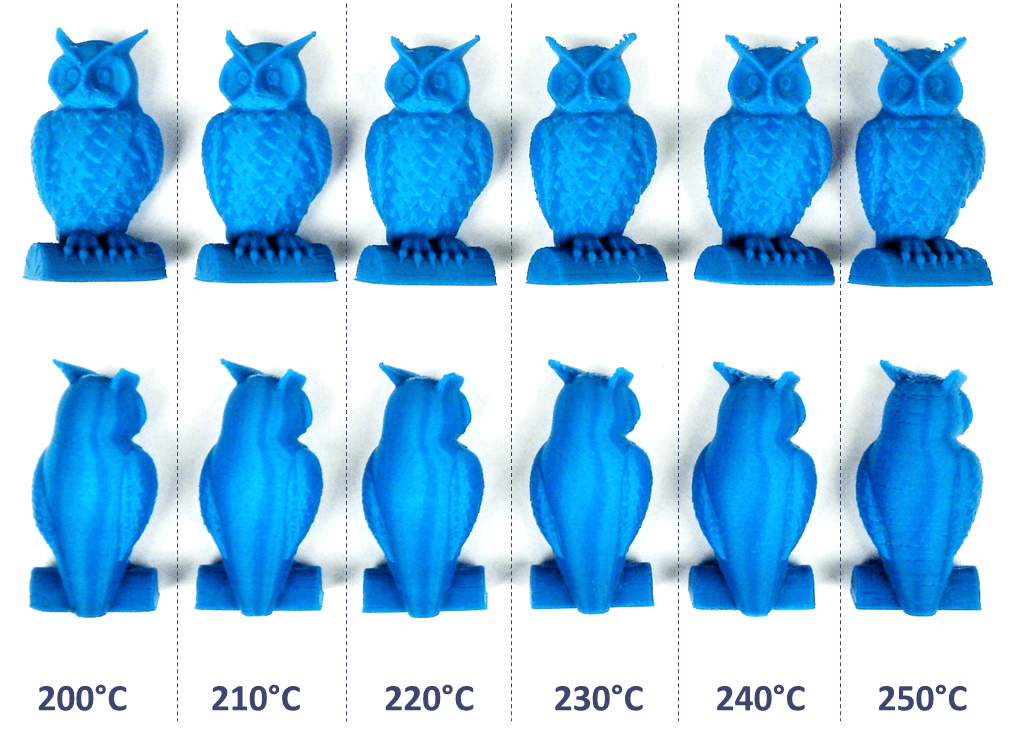

It is important to note that the values nozzle and table temperature when setting up CURA printing, by default, takes from material settings, although they can be changed in the advanced options if desired Custom mode in the Print Settings panel at the top right of the screen.

And another very important note, which will save you a lot of time. You will not be able to select material with desired filament thickness until the Extruser1 tab of the Settings -> Printers menu (how to get there is another story) you don't set the correct number, which is a filter to the list of materials! For example, if you put 3, then only materials with a thread thickness of 2.85 mm will be available to you, and if you put value 2, then you can choose only filaments 1.74-1.75 mm thick.

Such "inconsistencies" in the Cura version 4.6.1 can pop up a lot. Perhaps not all participants in the "folk art" correctly coordinate with each other, or maybe the developers decided in this way way to "simplify" the choice of material.

But since we mentioned the "custom" printer settings, then let's see what they look like.

There are several ways to get to the printer settings. This is one of them.

The main settings of your "custom" printer usually do not cause questions.

The basic settings of the extruder are also easy.

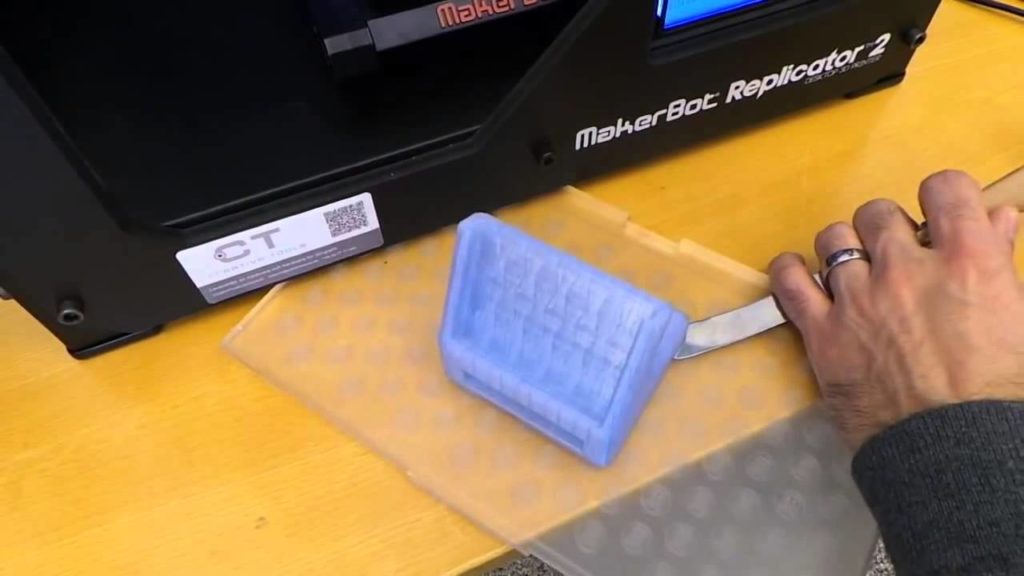

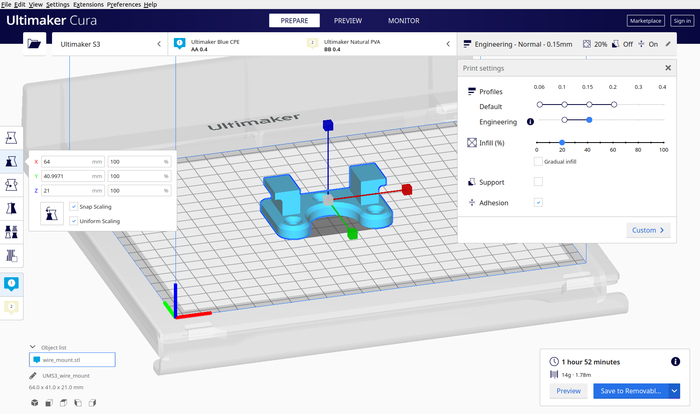

Let's return to the print settings a little later, but for now let's import and place the part in the working volume of the Ultimaker Cura slicer.

By pressing the button with the image open folder in the upper left corner of the screen and selecting the desired model in stl format we place the model on the table. Now we need to position it correctly. For To do this, you can use the tools located on the left in the center of the screen.

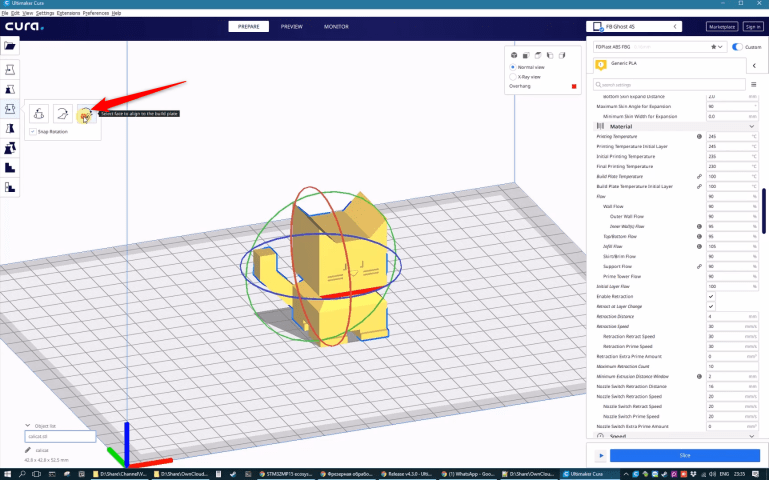

Briefly: Linear movements along the base axes, various scaling options, rotations and rotations models, mirroring, model parameters and supports blocker.

Almost every button has a submenu, and right-clicking the mouse will related settings.

Describe all tree and other cross-links of settings in this article, we will not intentionally. it a topic for a lot of material and, probably, the instructions for the program are better with us fail to write.

For important tips, visit official developer page https://support.ultimaker.com/hc/en-us/sections/360003548599-Using-Ultimaker-Cura

For important tips, visit official developer page https://support.ultimaker.com/hc/en-us/sections/360003548599-Using-Ultimaker-Cura

We will use the extreme on the right with the button in the rotation tool and, having selected the desired plane of the model, let's put it on the table.

We import the model in one of the simple ways - click on the "folder" at the top on the left

Then we do "one" ...

... we do "two" ...

... and we do "three".

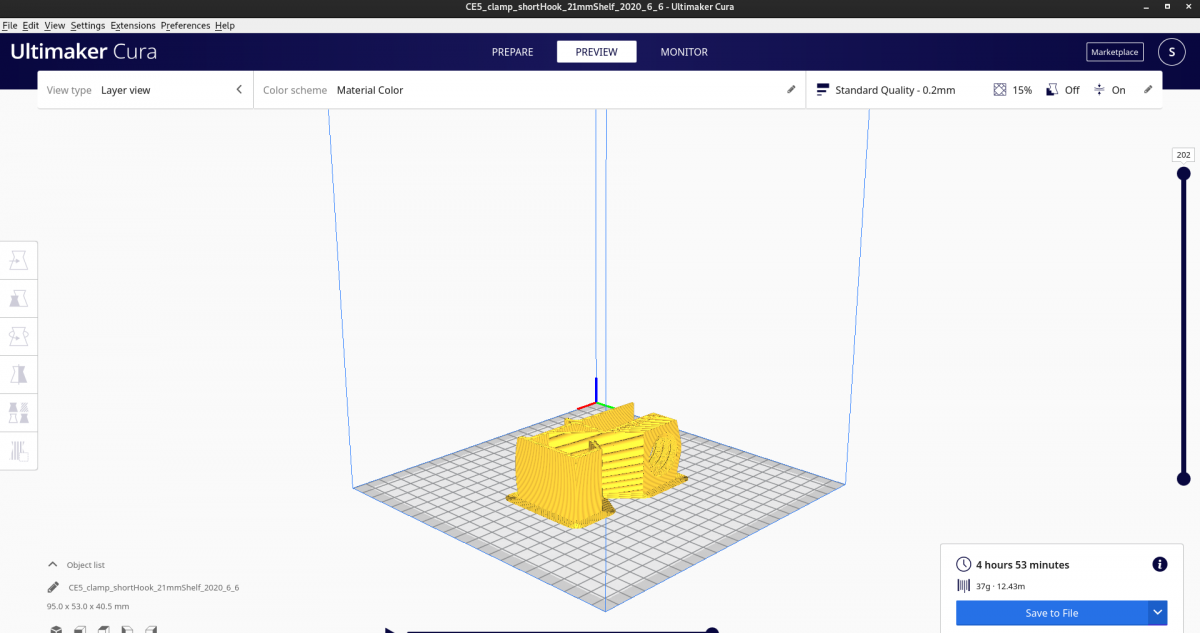

It remains to prepare the print profile.

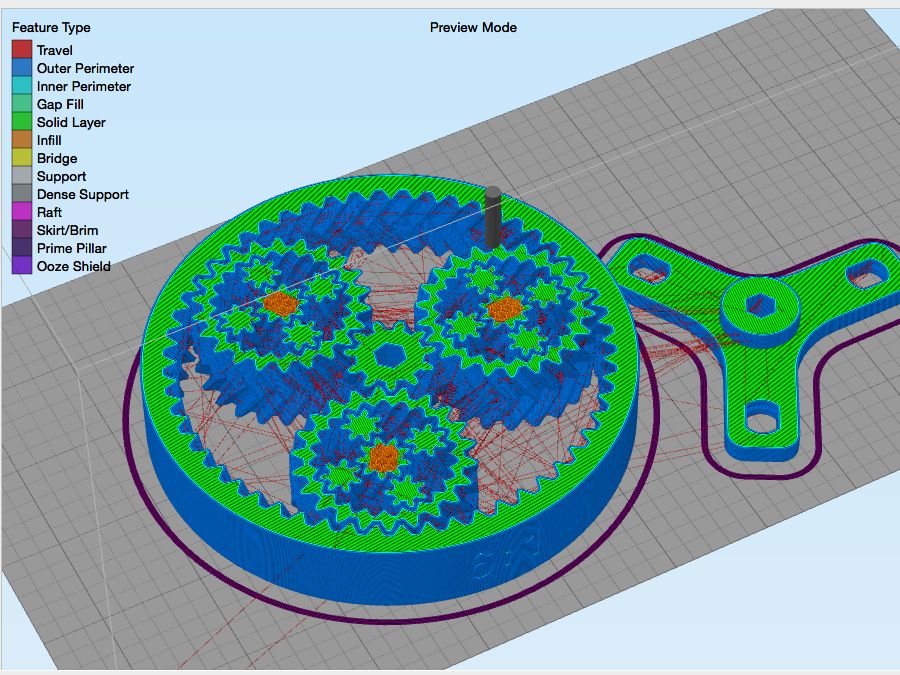

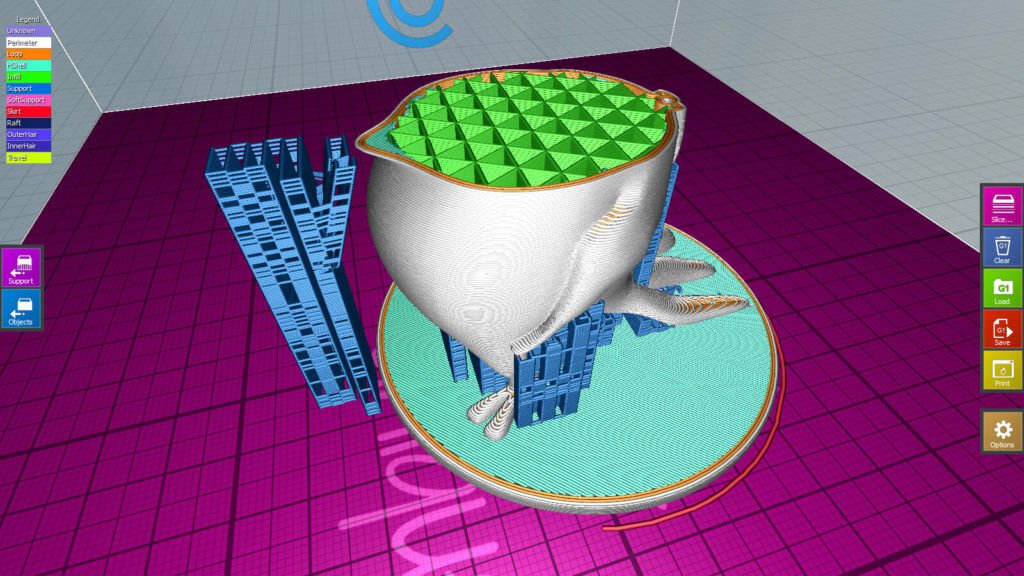

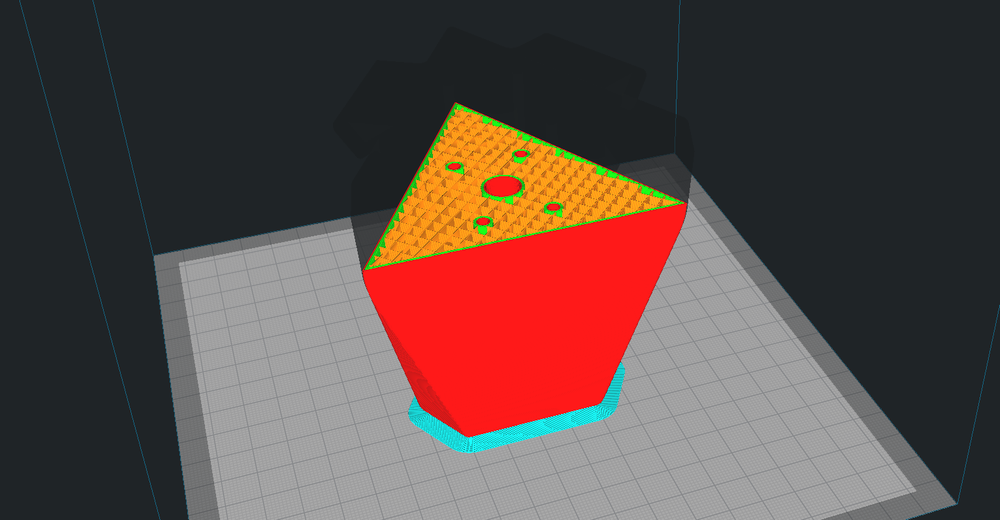

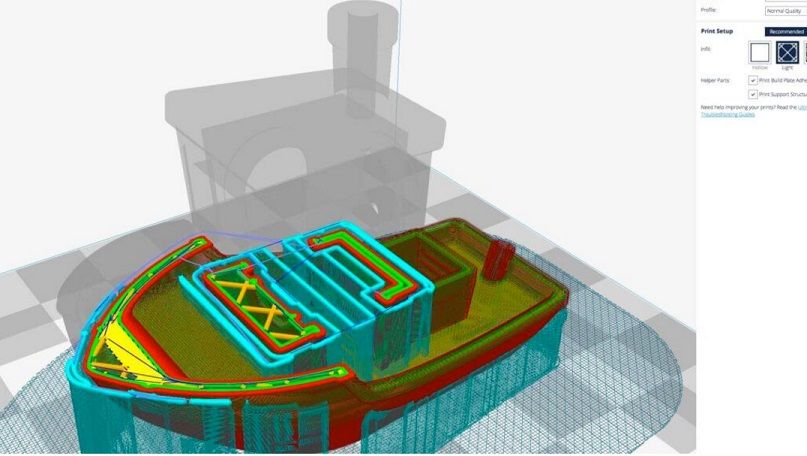

Perform slicing and check its correctness.

Send file with G-code to connected printer or write it to a flash drive.

So moving the blue dot slider to the left or right on the "Print Options" tab, we choose from standard slicer profiles the desired print quality, for example Fine, with a layer of 0.

1 mm and infill of 20%. We add the support prescribed by default in the profile, and turn on additional "sticking" to the table by ticking the appropriate boxes menu.

1 mm and infill of 20%. We add the support prescribed by default in the profile, and turn on additional "sticking" to the table by ticking the appropriate boxes menu. Press the "Slicing into layers" button in the lower right corner screen.

After slicing is completed, the program can show you preview results if you click on the button "preview" at the bottom right.

On the lower information screen indicates the weight of the part, the length of the spent plastic and the approximate time printing, the accuracy of which depends on the correct settings mechanical movements of the moving parts of the printer. As a rule, it is not matches the actual print time if you are printing to a "custom" printer and did not specify the exact firmware data in the extended version of the print settings printer. In the case of using the factory profile of the 3D printer, this time calculated more correctly.

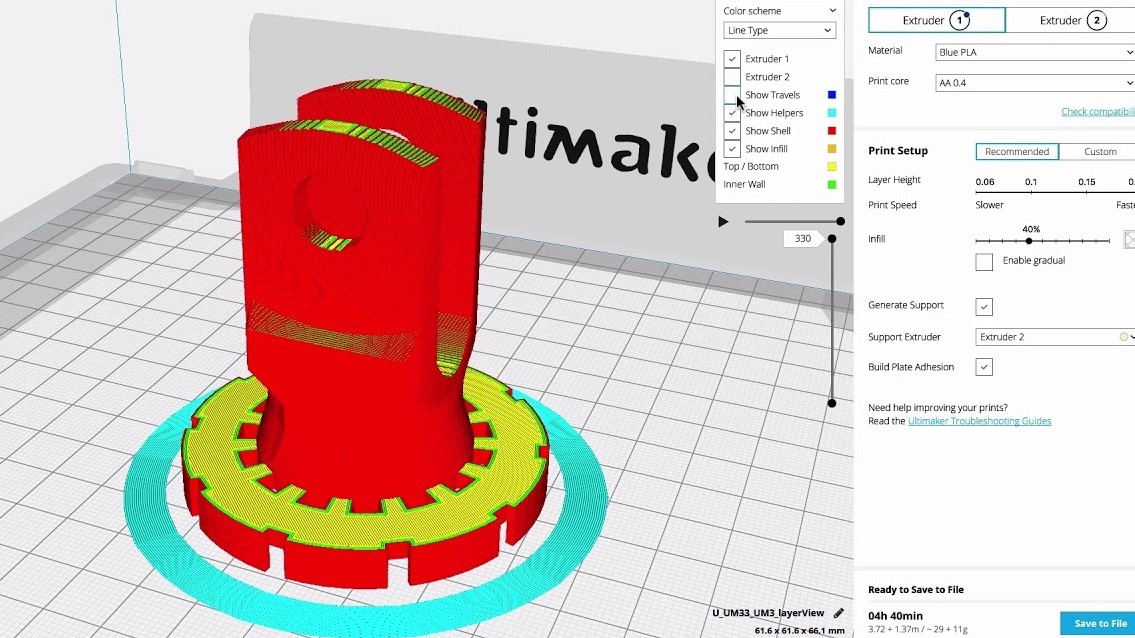

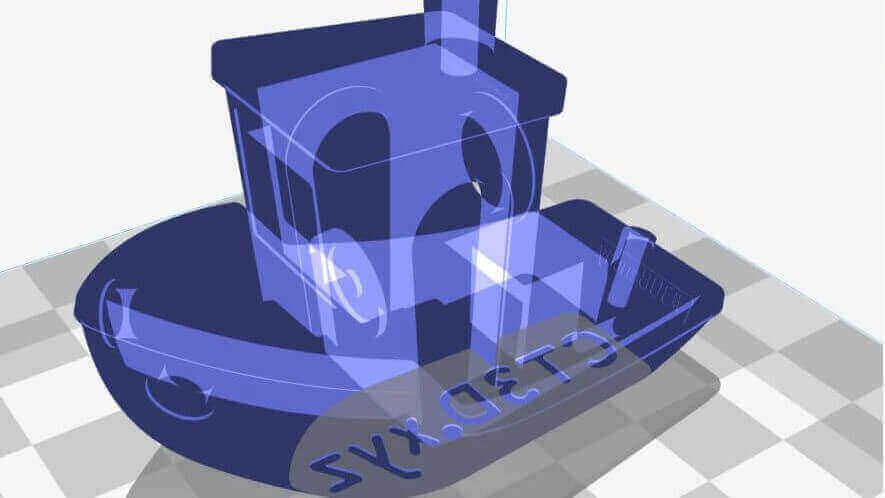

Check the results of the slicer by moving the "sliders" right and bottom for layer-by-layer and line-by-line viewing of model layers.

By moving the right slider, control the correctness of the formation layers and "hanging" parts of the model mentally representing the process of forming the part.

By moving the lower slider, you can check the movement of the extruder nozzle along layer.

Well, you checked everything and if your printer is connected to your computer and ready to print, then feel free to press the button "Seal". If you prefer offline printing, then by clicking on the button "Save to file" you save the print file with G-code to portable media in CFFFP_filename.gcode format.

This is a simplified algorithm of work with Ultimaker Cura slicer. About its advanced settings, there are many educational and informational materials on the Internet both on official resources and in user communities this truly folk slicer.

In short, to to use advanced printing options, you must first customize the visualization of the settings you need.

This is done in the menu Settings -> Options. Each of the more than 200 options can be ticked separately, and you can select several at once using presets, which, in their queue are selected from the drop-down menu in the upper right corner of the window.

This is done in the menu Settings -> Options. Each of the more than 200 options can be ticked separately, and you can select several at once using presets, which, in their queue are selected from the drop-down menu in the upper right corner of the window.

Here, as they say, without comments. "Seek and you shall find." This slicer opens not just big, but huge scope for experimentation. It is interesting to try new materials with him, complex forms of printing, although it has up to for some time it turned out worse than Simplify3D.

Own slicer settings Ultimaker Cura compared to advanced print profile settings looks like obscenely small.

In terms of performance, Cura is average. On the modern office car, he moves confidently enough, but the slicing of complex models takes a lot of time and does not always end in success. Rotation and viewing the result of layer separation is normal and informative.

Ultimaker Cura 4.

6.1 takes about 300 memory Mb. The amount of disk space occupied increases with each new version. Last The chicken "gobbled up" about 600 "mega". And she continues to "swell".

6.1 takes about 300 memory Mb. The amount of disk space occupied increases with each new version. Last The chicken "gobbled up" about 600 "mega". And she continues to "swell". You can download the program on its official website

It should be noted that many manufacturers tried to adapt Cura to their models by cutting off part functionality and simplifying settings. However, for some reason, the matter is far from moved. For example, Cura Wanhao Edition, having undergone several iterations, quietly faded into time a couple of years ago.

To sum up this brief review of the popular slicer Ultimaker Cura can be recommended for beginners users to try first to work with this program on its basic settings. If the result is satisfactory, it makes sense to start immerse yourself in a deep study of its hidden possibilities. If they turn out redundant, then you should think about using simpler software. Try not in a hurry.

Simplify3D

Official website: https://www.

simplify3d.com/

simplify3d.com/ Paid ($149).

Platforms: Windows (32.64 bit), MacOS X (10.7 and later), Linux (Ubuntu (recommended Ubuntu 14.04 LTS and later), Debian, and Fedora (32.64 bit)

Language: English, Russian no.

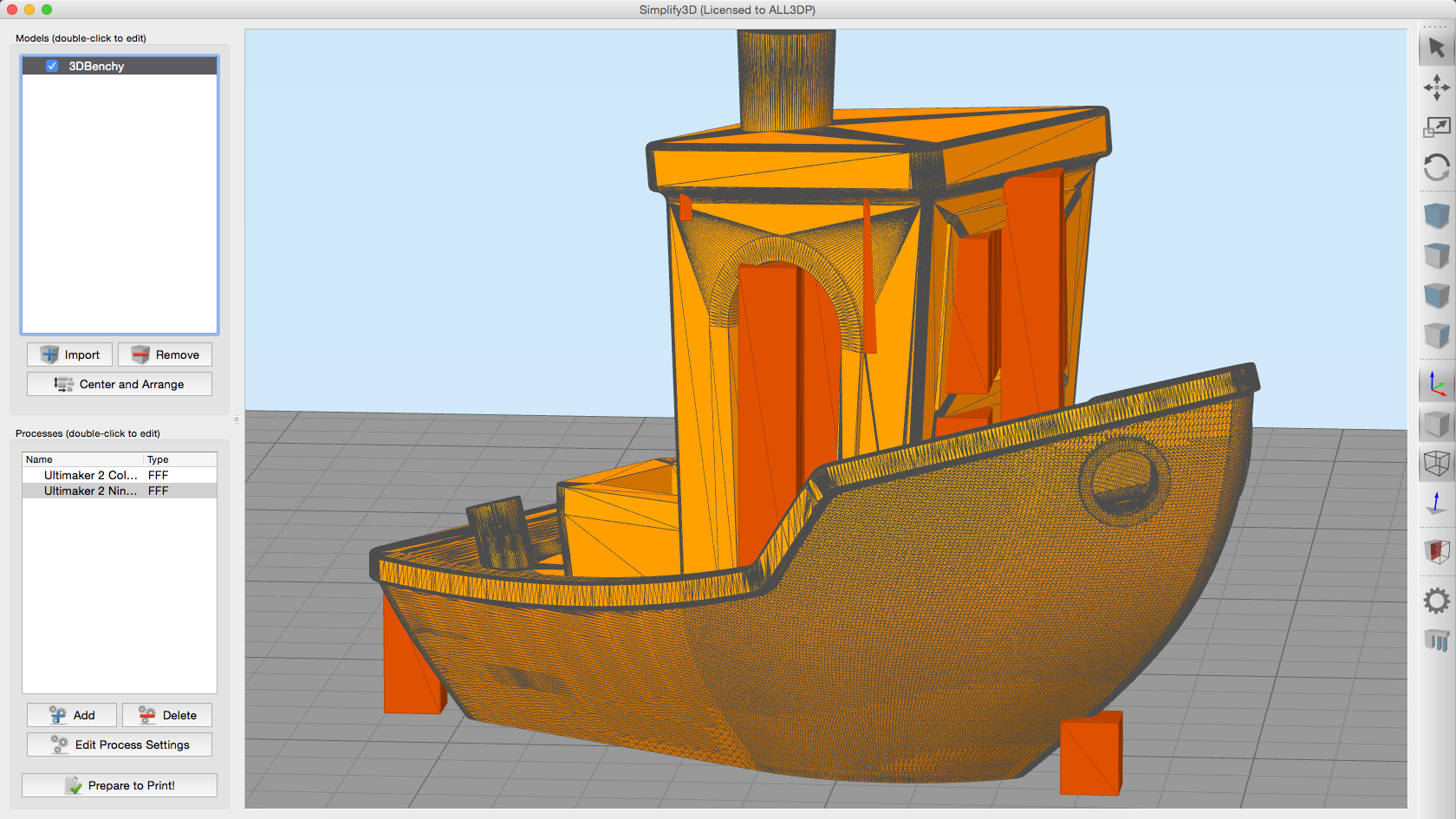

Simplify3D universal paid personal slicer - one license per machine and a year of free updates. He is one of few professional slicers with a long history, combining relative ease of use, powerful and fast mathematical processor, a wide range of auxiliary settings and tools, stable work and, most importantly, a very high-quality result.

Has a large list on board profiles of various models of 3D printers, which helps to set the "Automated configuration assistant. However, for this you need to have access to the Internet and be the registered license holder.

Required process settings slicing can always be downloaded from the official website or customized independently creating your own process profile.

But at the same time allows create your own equipment template for your unique settings with support for a large number of kinematics options, including delta.

Simplify3D is located in Cincinnati, Ohio (USA), in the building where perhaps the most a large collection of various 3D printers in the world. According to employees companies, they work daily with new generation equipment, new materials and advanced technologies to improve their product and adapting it to the latest promising developments. All new functional features are instantly tested using our own 3D database equipment. Since its founding in 2013, Simplify3D has become the world's leading commercial 3D printing software provider, with clients in more than 145 countries. The mission of the company, according to its employees, is to empower innovation with intuitive software tools to unleash the power of additive manufacturing.

What are the possibilities of this not cheap slicer? Let's try to briefly list them, although it is not easy. chief The advantage of Simplify3D, perhaps, should be considered a large variability of settings, based on the creation of profiles or templates for different processes.

At the same time, it should be noted:

- convenient informative interface

- simplified and extended settings modes

- high speed of the slicing process even on large and complex models.

- a large set of customizable parameters for the organization correct printing of complex objects

- very readable, convenient, informative and fast slicing preview

- "smart" and editable in form and content support (no trees)

- creation of multi-process tasks with different settings for several models

- integrated treatment tool for models with wide functions.

- multi-extruder support

- control panel and control of connected printer.

- firmware configurator with support for large number of formats

- a large number of filling patterns

Here is an incomplete list of tools that allow the user to quickly and efficiently prepare and print a model of any complexity.

Powerful online support owners of Simplisy3D in the form of reference materials of various format on the official website of the developer will allow both beginners and experienced the user to quickly master the settings and learn how to use all the widest program capabilities.

Lots of video tutorials about the main functions of Simplify3D allows you to quickly go through the learning process and in to take full advantage of its wide range of possibilities.

And the library of materials will remove many questions about the selection the right filament for your application.

The program is easy to install and works quickly on any computers and even on laptops and tablets. FROM some restrictions for the latest in complexity of printed models.

Simplify3D doesn't have a welcome window and gets straight to the point.

After starting the program, you will prompted to launch the "Configuration Assistant" where you will burn to select a profile the model of 3D printer you need.

If it is not in the list and on the website, then you can form it yourself by selecting Tool -> Options from the menu. There you can also configure the slicer itself, units of measurement, automated operations on the model, visualization modes and network connection parameters.

At you will even be able to visualize your printer's desktop if at hand there is his stl model.

At you will even be able to visualize your printer's desktop if at hand there is his stl model.

After completing the settings printer and slicer, you can proceed to import the model. Just worth it first Familiarize yourself with the tools and interface menu.

More information about the initial launch of the program and its use can be found on the official website developer and on the Internet.

Our task is to carry out the first "speculative" printing entry level.

Loading a model, or several models by clicking on the "Import" button in the upper left window. Simplify3D supports stl, obj, 3mf formats.

Center and Arrange button will position your model or models in the center of the working plane and install on the surface of the table. Move or rotate, mirror and scale as well and produce other standard manipulations can be done using the top four buttons in the right panel tools.

If treatment is needed models can run the procedures listed in the drop-down list of the top repair menu.

Automatic analysis of the quality of the model is not yet provided.

Automatic analysis of the quality of the model is not yet provided. The next step is to create a process or several processes, printing, for all, or for each separately, models. Press the "Add" button in the lower left window of the program.

A window opens that in fact, it is the main window of the main settings necessary for preparation models for printing. Not counting the supports, about them a little later.

Having named this process, you can choose previously prepared or downloaded from the site process profiles printing, and by pressing the OK button, proceed to the slicing process. If finished profile If you don't have it, then you need to make it. The Simplify3D website has detailed recommendations, both in text and video formats, on how to do. But in a nutshell, without delving into the advanced options of options, the procedure can be described as follows.

Set up the extruder in the Extruder tab by assigning it serial number, indicating the diameter of the nozzle, the length and speed of the retract.

Adjust the layer thickness in the tab "Layer" (as a rule, this is the product of the diameter of the nozzle by its half or its two-thirds), the number of upper and lower solid walls, and the number perimeters (not in mm, but in nozzle diameters)

In the "Additions" tab, select method of adhesion of the first layer to the table. You can use a raft, skirt or border with the corresponding settings.

In the "Infill" tab, organize the shape and percentage of filling of the internal volume of the model. Great variability settings gives a wide scope for experiments aimed at achieving best quality.

Support tab needs a little more attention. In this window, you can decide whether to use support and configure their basic parameters, which will be tied to the profile and activated each time it is used again. But, for accurate sampling custom support settings it is better to use the tool on the right panels.

About him later.

About him later.

In the Temperature tab degrees Celsius are prescribed for the table and extruder (s), moreover, with reference to layers, if necessary. However, sometimes, in order to binding, you must first perform test slicing and then, back in the print profile settings, add or change temperature modes. Not very convenient, but very useful.

"Cooling" describes the modes part cooling. They are also fashionable to "bind" to the layers if necessary. As well as configure the "sharp start" (Blip fan to full power ...) of the fan so as not to to allow it to "stick" at low percentages of revolutions.

Description of G-code option settings quite specific and a novice user should focus on default settings or use profile settings. Although useful take the time to study this topic in developer tutorials or in Internet networks.

The “Scripts” tab allows write typical machine operations using standardized commands G-code of your 3D printer when starting and finishing printing, changing tools (extruder), retract and transition to another layer.

print areas in the "Speed" tab are defined as a percentage of the default base speed "Default Printing Speed. They can be assigned to external perimeters, internal filling, supports and movement in the XY and Z planes.

Other tab - Other allows you to set the printing parameters for bridges, diameter and filament characteristics filament, and data for changing the extruder (tool).

Detailed description of specific settings in the “Advanced” tab in this article we will omit, since for the trial printing they are not critical.

all of the above settings, you save our new profile by clicking on "OK". You can always return to editing this profile by clicking on the "Edit Process Setting" button.

Before proceeding to the next stage, remember the organization of "custom" supports that we mentioned previously. It looks like this.

Supports settings quite are simple and include definition of threshold angle and segment thickness support, which, when sliced, will be converted into certain by the support structure user.

With buttons you can generate support automatically, add and delete them, import and export and clean up completely. And the result is this.

With buttons you can generate support automatically, add and delete them, import and export and clean up completely. And the result is this.

Now you can start slicing our models. Select the process and click "Prepare to print". Slicing process takes some time, but as a result the program will automatically show preview of the result.

colored with spectral colors.

"Show in Preview" can be customized visibility of various parts of the model, tool, displacements, supports, paths tool, retracts and other parameters of part formation during printing.

you can write the finished G-code file to portable media by clicking the "Save" button Toolpaths to Disk" or send it to the printer - "Begin Printing over USB" using the button above.

Separate “Control Panel for machine" - "Machine Control Panel", allows not only to control and control the units and components of your printer, but also make up a print queue from finished documents by adding and removing them from the G-code library.

Temperature reports for your printer components in on-line mode.

Controls printer mechanisms and tools.

That's probably all that is possible describe in a short review of this popular Simplify3d slicer. A lot more Information can be found on its official website. Even if you're not ready yet pay 149dollars for the purchase of this wonderful program, then learn it you can use it completely free.

Although the previously popular principle use of the Trial version of the program was replaced by a two-week return of paid funds to you, nothing will stop you from watching video tutorials and reading educational articles. Perhaps this is just the beginning.

Here are just a few useful official links, following which you will collect a large number of useful information about the possibilities and nuances of working with the Simplify3D slicer:

https://www.simplify3d.com/support/articles/#level-1-:-beginner

3D printing - G-code tutorial, Working with file types, Perfecting the first layer, Importing and managing your models.

https://www.simplify3d.com/support/articles/#level-2-:-intermediate

Different settings for different areas of the model, rafts, skirts and brim! Beginner's guide for automatic site leveling, revealing and fixing common mesh errors, adding and modifying structures support.

https://www.simplify3d.com/support/articles/#level-3-:-advanced

parts, printing with multiple extruders.

IdeaMaker

Official website: https://www.raise3d.com/

Availability: Free.

Platforms: Windows (32.64 bit), MacOS X (10.7 and later), Linux (Ubuntu (recommended Ubuntu 14.04 LTS and later), Debian, and Fedora (32.64 bit)

Language: Russian yes.

Having started his life with the creation of the slicer was originally a Chinese, and now a global company, Raise3D steadily holds the highest places in the ratings of professional equipment for 3D printing. The founders of the company initially laid everything in its functionality the necessary characteristics of reliable high-quality trouble-free software, with powerful computing capabilities, with a flexible adaptive interface and with high degree of integration possibilities.

As if foreseeing the future development of the 3D industry and its gradual shift to the services of a global cloud space in symbiosis with automated mini-factories based on variety of 3D technologies, RAISE3D developers and designers paid great attention to constructive network solutions, work autonomy, process control, and storage of the necessary for the operation of information equipment.

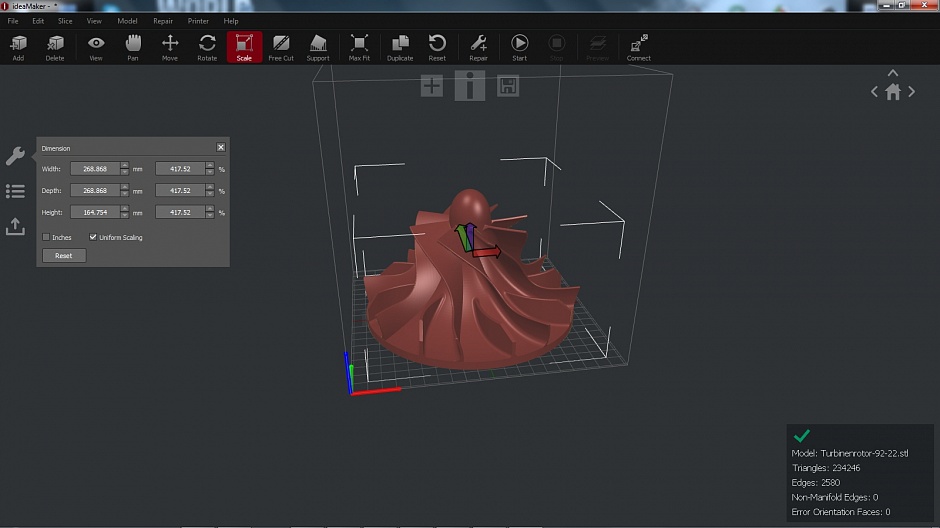

In our slicer digest we are in First of all, let's pay attention to the "basic element" of the complex software software - the ideaMaker slicer, which in its May 2020 update made a breakthrough in the integration of the technological process into the "select and print" system, simplifying the tasks of remote preparation of the model, material selection, print settings and receiving finished model.

This is especially noticeable in the new extremely informative welcome window, where the user immediately it becomes possible to integrate your work into the cloud space, control its execution remotely, even on a mobile phone, and use the services for the selection of ready-made profiles for slicing using a wide range of materials.

opportunities became very convenient from the very first steps, without pressing extra buttons and without going through the menus, go to "Printer Setup" and thread, "Manage profiles", selecting "Preferences". Of course you can still download recent files and select the items of the standard "Start" menu. And if there is free time, then watch news, current videos, find out what's new and refresh the user manual.

Initial program was developed for the Raise3D printer line with wide functionality up to built-in webcam for print control. It is based on a "64-bit engine" with “a good processor”, as ideaMaker developers succinctly report. However, the creators programs have enabled users to create and use custom printer settings, which made it even more attractive. Having gone through several major updates, this slicer could adequately compete with the generally recognized "colleagues" Cura and Simplify3D, if only no restrictions on the compatibility of kinematics.

It can only support Ultimaker type print head movement mechanism and extruder type "rocker" up to 2 hotends.

It can only support Ultimaker type print head movement mechanism and extruder type "rocker" up to 2 hotends.

The program is well Russified, although in some places there are questions about the translation, but something was not in previous versions completely translated. We hope that the new version of these shortcomings is still eliminated.

For all other aspects of evaluation quality and convenience ideaMaker will give odds to many hyped competitors. Apart from powerful engine on board the slicer there is an exhaustive set of utilities for solving almost any problems of preparing models of any complexity for printing and its successful completion.

There is an excellent repair of models. When loading a damaged stl file, an alarm will appear in the project folder. BUT in the lower right corner, an information box will give details.

By clicking on the "Fix" button with the image of a wrench with a plus in the upper panel of tools you run "treatment" process.

If ideaMaker (Implementer/implementer of ideas) coped with his task, then in the lower left A green checkbox and a detailed report will appear in the info window.

Slicer settings algorithm somewhat different from their counterparts. In addition to choosing a ready-made template printer settings or create a profile of your own, you need to configure or select the "Thread Settings" template, which in fact is an analogue of the settings material. And then bind these templates to each of the active extruders.

Then set up, or select from predefined, print profile.

Then select model or group models (this option requires a separate large description) and start slicing, by clicking on the appropriate button.

in the window that opens, you can immediately send the result for printing to a printer or to "cloud".

Or go to the layered view by clicking the layers button.

Or go to the layered view by clicking the layers button.

After completing the control review result, you can return to editing models by selecting right button under the top toolbar called "Exit slicing" or start a new slicing by changing the print setup profiles in the Select Profile window that opens. Either download the print file to the printer or to cloud, or save it on a local disk (removable media).

This is, in general, not complicated how to prepare a model for printing in the ideaMaker slicer. Of course, the use of this program is most suitable for printer owners Raise3d, for example the most popular Raise3D model Pro2 or more modest models - Raise3D E2. But to a greater extent it will be appreciated by entrepreneurs working in the industry 3D print professionally. Especially in system-integrated manufacturing structures.

Although in case of compatibility mechanical parameters of your printer with ideaMaker capabilities this slicer will become, perhaps, the most balanced solution in the organization of printed process for both one and several of your printers, given it free availability.

And the prospects for further development will be very are tempting, because you will get support for up to 2 extruders, separation of the model by a plane in parts for separate printing, adaptive layers and smart editable support, support for sequential printing of multiple parts and many more useful and reliable service options without use of additional third-party programs.

And the prospects for further development will be very are tempting, because you will get support for up to 2 extruders, separation of the model by a plane in parts for separate printing, adaptive layers and smart editable support, support for sequential printing of multiple parts and many more useful and reliable service options without use of additional third-party programs. In general, ideaMaker has such branched, wide and deep settings infrastructure, which for detailed their descriptions and possibilities of use would require publishing a solid book.

Detailed operating instructions for the ideaMaker slicer can be easy to find on the internet. For example here https://cvetmir3d.ru/blog/3d-obzory/slyser_raise3d_ideamaker/

Or here https://www.youtube.com/watch?v=F5GIP2a9ef8

UP Studio

Official website: https://www.tiertime.com/

Availability: Free.

Platforms: Windows 7 and above (32.64 bit), MacOS 10.

10, (iPhone iOS, iPad iOS)

10, (iPhone iOS, iPad iOS) Language: Russian yes.

Tiertime 3D printer lineup as of May 2020: X5, UP300, UP mini 2 ES, UP Box+, UP Plus 2, UP mini 2, Cetus3D

time, the tendency of many manufacturers of 3D printers to shift emphasis from technical aspects of the equipment supplied for sale for convenience and ease of use.

Possibly because technical the advantages of "iron" have almost exhausted their uniqueness in terms of marketing appeal, and the creation of a certain user ecosystem. What is meant by the word "ecosystem"? it when your ability to access, store and prepare models for printing are so wide that they do not tie you to the equipment in time and space.

According to the developers of such complex solutions, you at any time, being in any place where there is Internet access, you can receive, prepare and send to print on any of the printers available to you the model you need. The truth goes on a question to which the developers do not give a direct answer.

How to install the correct filament and remove the part after printing? Although, perhaps, we ourselves can answer. Printers (!) with different materials should always be ready to print, and you can get to the finished model while he is typing, or get it by mail or courier. And then a picture of the future opens up to us, where ads for 3D printing mini-factories will become as commonplace as delivery services pizza.

How to install the correct filament and remove the part after printing? Although, perhaps, we ourselves can answer. Printers (!) with different materials should always be ready to print, and you can get to the finished model while he is typing, or get it by mail or courier. And then a picture of the future opens up to us, where ads for 3D printing mini-factories will become as commonplace as delivery services pizza. For such future owners 3D production and there is a struggle among manufacturers of volumetric printing equipment. One of which, of course, is Tiertime.

The range of printers of this The company is distinguished by stylish industrial design and comprehensive technical solutions where complex unique parts of the printer coexist with 3D printed details. And I must say, it seems to us that this is a good and correct rational trend. Not everything is certain, of course. Many knots and details cause confusion and doubt about their reliability and durability.

Nonetheless, the desire to minimize operator participation in print settings and simplify the process of manufacturing a part from a model is clearly seen in all models of this companies. Probably, this is a conscious policy of the developer.

Nonetheless, the desire to minimize operator participation in print settings and simplify the process of manufacturing a part from a model is clearly seen in all models of this companies. Probably, this is a conscious policy of the developer. As already mentioned, the Up Studio slicer is purely corporate program developed by Tiertime. It is even more than just a slicer and is a key link among other software software that ensures the functioning of the "ecosystem". and interface Slicer, for all its extravagance, is convenient, understandable and functional.

If you are not the owner yet one of the Tiertime printers or it is not connected to your computer, then you won't even be able to load the model. That is, you can download something, but nothing you won't see it on the screen.

After starting UP Studio, you will first need to register yourself and your printer. If you have done this before, then log in your account.

service line.

In addition to model information connected printer and adding a new one, temperature conditions of active zones, and connection status there are 4 buttons, one of which is "Login", we have already seen in previous window. The second button in the form of a gear is “Settings (parameters)”, opens the program settings window.

It prompts you to choose one of nine interface languages, including Russian. You can select or add Printer. Moreover, it is added, including by searching the Wi-Fi network. Present the ability to check the relevance of the program version and, if necessary, update it. You can also clear the cache with a list of downloaded models and configure networks over different protocols and ports.

Also see the program license.

Third shirt button you call up a menu for designing the appearance of the interface with a "rich" choice of options program coloring.

And the rightmost button in the top information field in the form of a scroll with a pen allows you to quickly create and send a request for technical support.

Tool menu in left column consists of four sections (buttons). The "About us" button opens a screen with a general information from the manufacturer. The "Account" button duplicates the top menu and offers to register or sign in. The "Help" button opens a window with links to tutorials and informational video posted on the manufacturer's Youtube channel.

The most functional button in this list, this is the "UP" button. By clicking it, you get access to the functionality slicer. To exit this mode, you need to click on the "Home" button at the top left columns.

Let's take a closer look at this screen. The Plus button allows you to add objects that you want to print. The "Print" button opens a menu of print settings and printer options, in including in advanced mode, if you click on the double arrows in the right the top menu of the window.

Built into Up Studio functionality multiple CAD tools for creative development of users of the printer model line Tiertime.

You can use the "Add" (+) tool not only to import ready-made stl file, but also create, place and modify several "primitives": a cube, a ball, a cylinder, prisms of various shapes, a cone, a pyramid, a torus, a washer, star and text.

Plus, Up Studio is, perhaps the only slicer that integrates a transform tool 2D bitmap into 3d model.

After uploading an image, you can add thickness to it and then print.

interface tool in the form of a circular menu borrowed from programs 3D modeling from the early days of 3D Max and Maya. Looks very organic, convenient, functional and pleasant to work with.

Imported part placement in the working volume of the printer is performed by standard displacement tools and modifications located on the circular menu and with the help of the "right click" of the mouse.

The print setup menu has both a simplified standard view, as well as advanced settings.

After slicing, you can check it results by moving the slider at the bottom of the screen. Printing time and weight are also indicated there. material.

click there are many advanced options for customization and printing as simple as and "heavy" models with a complex organization of supports.

The entire Support Editor is used to form them allowing you to enable or disable the visualization of each support individually, adjust the “activation” angle for it, set the area of its coverage, set "roof density", etc.

From additional, but almost standard options printing, you can mark the printing of parts with different parameters in one printed process.

Sophisticated organization of the 9-point determination process print dimensions and desktop alignment Martix requires a separate menu.

Of course, make a complete an overview of all the possibilities of UP Studio and cloud applications in our modest slicer digest is not possible.

For those who sincerely became interested in Tiertime products, both printers and services, it remains to watch-read the video and the "manual" - instructions. (https://www.youtube.com/embed/gK9F9U1SoSQ).

For those who sincerely became interested in Tiertime products, both printers and services, it remains to watch-read the video and the "manual" - instructions. (https://www.youtube.com/embed/gK9F9U1SoSQ). Details on youtube channel https://www.youtube.com/channel/UC2DpWPWJfSNpcov5GvtYzPQ

FlashPrint

Official website: https://www.flashforge.com/

Availability: Free.

Platforms: Windows (32.64 bit), MacOS, Linux (32.64 bit)

Language: Russian is.

Zhejiang Flashforge 3D Technology Co., Ltd was established in 2011 in China and is one of the largest manufacturers of 3D printers today. The models of this company are in the top ten on the 3DHUBS website. According to many enthusiasts, the printers of this company have excellent reliability with excellent value for money.

Flashprint slicer start window

But if you don't, at least one connected via Wi-Fi network or locally, magnificent in its simplicity and reliability of the printer from Flashforge, you can not spend time to study the manual and interface of the Flashprint slicer.

It is designed to work only with model range of this company and does not know the word "flash drive".

It is designed to work only with model range of this company and does not know the word "flash drive". Toolbar buttons, "Settings" and "Printer Information" in the "Tools" menu in the absence of connected printer call the same window - "Connect to printer".

Printer communication window.

The logic behind this "Corporate" slicer is obscenely simple. You are encouraged to do everything in certain sequence step by step. Opened a slicer - specify which one you have a printer and connect it to the program, and if necessary, update it firmware. Without this, all your actions will be considered only preparatory works, the stages of which, however, you can save on disk in unique slicer formats.

Some printer models do not support network discovery.

Then load the model. None you cannot make other presets without a model. Next slicer automatically checks the model for errors and, if any, treat her with your consent.

It's nice if it heals correctly. Then you can put the model on the table as you like using standard tools manipulations. There is a handy option in the "Rotate" tool - "Surface on platform" will put the selected plane on the table by double-clicking on the desired polygon.

It's nice if it heals correctly. Then you can put the model on the table as you like using standard tools manipulations. There is a handy option in the "Rotate" tool - "Surface on platform" will put the selected plane on the table by double-clicking on the desired polygon.

There is a function of auto -placement of the model in the working volume of

Model Auto repair also there are

and operates quickly

Function “The surface on the platform” in action

as soon as the model is correctly correct fit in the working volume, the "Support" and "Print" buttons are activated in middle of the top of the screen. This means that the slicer has allowed you to move. farther.

By clicking on "support" you get 4 buttons on the top and 3 on the left with the following functionality: parameter settings, automatic placement, adding and removing support, model selection, erasing all supports and returning to the previous menu.

Parameters for two types supports - tree-like and linear - are concise, like the whole program. We will not list - look at the screenshots below.

Parameters for two types supports - tree-like and linear - are concise, like the whole program. We will not list - look at the screenshots below.

Automatic creation of tree supports that can be edit.

Sets tree support parameters.

Support can be added or removed when it is finished.

Tree supports can be replaced by linear ones.

These can also be edited.

You can also place supports manually as you like.

After the formation of supports, you you will be prompted to save these supports in the program's unique *.fpp format. Supposed, that you may need them in the future.

Next, by launching the "Print" button slicing settings, you can choose from several predefined print profiles or tabs specify the values of some standard print parameters: “height Layers, Shells, Fill, Speed, Temperature, and Others. At connected printer, you will be able to call Expert mode - advanced print settings by clicking the Settings menu and selecting the print type settings windows.

In this mode, there is an option to set the internal and external compensation. When you have finished entering the parameters, press the "Select" button and start slicing procedure, along with saving the project with a unique *.gx extension

In this mode, there is an option to set the internal and external compensation. When you have finished entering the parameters, press the "Select" button and start slicing procedure, along with saving the project with a unique *.gx extension

Window for selecting standard print profiles…

… and advanced settings.

Visual result of slicing can scare even an experienced user. In a single pale lilac porridge you it will not be possible to distinguish between external walls, infills, supports and other elements printing process. The developers decided that in addition to layer-by-layer control You don't have to look at the result.

Just press the button "Submit GCode" and control the printing process if you are the owner one of the company's printer models. Otherwise, you can click the button "Back" and save the result of your work in one of the available stl formats, obj, 3mf and fpp.

Regrettably, that if the program performs all the preparatory procedures quite quickly, then after slicing it starts to terribly "stupid". Terribly slow browsing sliced into layers of the object turns the work into torment. Resources are not even very a bad computer is not enough.

At the same time, there is a convenient the “Cut” button that launches the tool for separating a part by a plane for printing her in parts. Planes can be X, Y, Z or drawn with the mouse. ends close automatically. Helpful, convenient and fast.

this corporate slicer has a set of standard amenities for everyday routine work with Flashforge equipment and otherwise unsuitable. True, there is doubtful the ability to import the model even after the arrangement of tree supports save result in stl but fancy tree support in execution Flashprint look like baobabs in a birch grove and many will prefer to use it Meshmixer services.

In addition to the slicers listed, mention should also be made of Slic3R, the Prusa Slicer, which is actually redesign of the previous program, Repetier-Host, Kisslicer, lost somewhere "slicer-ancestor" Skinforge. Some of them deserve a separate review or even a detailed articles. And you can remember about a dozen different quality and convenience programs, allowing you to prepare your 3D model for printing. Even Windows 10 has built-in 3D printing application, ready to process and send to print your model to Microsoft partners, if, of course, it passes built-in expertise. The most important thing to understand for choosing a slicer, that, as with choosing a printer, you first need to focus on your goals and choose a program based on your own priorities and tasks, finding harmony in a reasonable compromise. Another trend that we already wrote about in a recent article on flexible manufacturing is the creation of so-called "farms" of 3D printing, effective management of which will be possible only if there is a cloud system managing and distributing print jobs.

You may also be interested in our articles "How select 3D printer" and "Rating of the best 3D printers for spring 2020»

Tsvetnoy Mir team

printing in 2022

08/02/2022

Contents

-

- Cura

- Prusa Slicer

- ideaMaker

- CHITUBOX Basic

- Lychee Slicer

- Kiri:Moto

- Ice9SL

1

Below is a list of the best free 3D slicers in 2022 - software for converting 3D models into layers for 3D printing.

Cura

Cura is an open source slicing software created by Ultimaker for their 3D printers, but can also be considered a common standard as it is compatible with most other 3D printers. Its functionality can be easily extended with a large number of convenient plugins. Since this is one of the most popular and widely used 3D printer slicers on the market, there's a good chance that a profile for your 3D printer is already available in the software, allowing you to get started right away.

If this is not the case, you can download and import a third party profile.

If this is not the case, you can download and import a third party profile. This 3D printing software is very easy to use and allows you to manage the most important 3D printing settings in a clear interface. Start with "Basic" mode for a quick start, where you can only reconfigure the most basic printer settings. If you need finer control over your print settings, switch to Advanced, Expert, or All for more settings. In these modes, Cura provides users with up to 400 customization options to suit your needs and get the best results.

This slicer is constantly updated and improved, new versions are constantly released, so you can be sure that you get the latest program. Recently, the new version of Cura 5.1 introduced settings for FDM metal printing.

You can also use Cura as a 3D printer remote control software, but the 3D printer must be connected to the PC during printing. Integration with CAD systems such as SolidWorks and Siemens NX makes the software valuable even in professional applications.

But for the vast majority of home users, Cura is a simple and affordable 3D printing slicer.

But for the vast majority of home users, Cura is a simple and affordable 3D printing slicer. In addition to ease of use, you can also find many educational resources on how to best use Cura's latest features, as well as a community forum on the Ultimaker website.

Cure download link.

Prusa Slicer

Prusa Research, the company behind the original Prusa 3D printers, has developed its own slicer, PrusaSlicer, based on Slic3r, an open source slicer. PrusaSlicer has gained a lot of popularity very quickly for a number of reasons: not only does it have a large list of Slic3r's adjustable settings, but it also has some handy features that the original software didn't have.

With a redesigned interface, built-in support for Prusa's own range of printers, and user-friendly settings for a range of common media, there are many improvements over the original software. Key features include customizable supports, support printing with different materials, and flexible layer height settings.

PrusaSlicer can be used to cut models for both FDM printers and photopolymer 3D printers. It has various modes allowing you to edit the settings depending on your experience, and the Expert mode opens up a huge list of customization options. However, even simple profiles can work well in PrusaSlicer. There are fewer printer presets than some other popular slicers, but it's just as easy to set up or import custom settings.

Based on Slic3r, PrusaSlicer supports most of the original features and even accepts Slic3r configuration packages when importing profiles.

Link to download Prusa Slicer.

ideaMaker

Raise3D ideaMaker slicing software is optimized for the company's 3D printers, similar to how PrusaSlicer is optimized for original Prusa printers and Ultimaker Cura for Ultimaker hardware, but like other software, it also works well with third-party 3D printers.

The workflow and user interface is a bit more complex than Cura and PrusaSlicer, but it's worth a little digging and you'll have quick access to advanced per-layer settings and print modifiers, including the ability to texture models or brand your parts.

By connecting to Raise3D cloud services, you can download hundreds of community and Raise3D-created printer and media profiles for faster and better printing, or create your own library of settings and profiles.

Customizable supports, model splicing and mesh correction tools are all provided by ideaMaker, which allows you to get consistent print results every time. Print sequencing and built-in compatibility with OctoPrint are also additional features that improve print quality.

You can also switch between dark and light ideaMaker interface themes for a more comfortable slicer experience.

Download link for ideaMaker.

CHITUBOX Basic

Chances are if you're using a budget desktop 3D resin printer, it comes with CHITUBOX (now known as CHITUBOX Basic). The software is developed by CTB Systems, which also makes many of the motherboards and firmware for these printers (hence the company's default software is software that goes great with anything).

The main purpose of CHITUBOX Basic is cutting 3D models for printing on photopolymer 3D printers. With CHITUBOX Basic you get full control over printer settings as well as a large list of common and popular printer profiles and resins.

The most important element of preparation for photopolymer 3D printing is the orientation of the model and the setting of supports. Orientation is not the easiest - it does not have an automatic mode, but the generation of automatic support is quite reliable and in many cases gives good results. More fine-tuning may be required to properly support parts, but the support customization options are simple and intuitive.

Link to download CHITUBOX Basic.

Lychee Slicer

With a wide variety of 3D printer profiles and resins, the Lychee Slicer is an attractive third-party option for your model slicing needs. This, and being one of the most user-friendly and easy-to-use slicers, makes the Lychee Slicer an excellent multifunctional solution for desktop resin printers.

Automatic model orientation will help you get started preparing for 3D printing, but you can skip it and just hit the Magic button and let Lychee Slicer take care of everything. The results can sometimes be unpredictable, but when working with simple models, you will save time this way.

Some options are not available in the free version of Lychee Slicer, but this is not a problem. The free version is fully functional and has rich functionality.

Link to download Lychee Slicer.

Kiri:Moto

Written entirely to run in the browser, Kiri:Moto is a powerful tool that can be used to prepare models for 3D printing, laser engraving or CNC milling (the common factor here is that they are all exported via G-code) . The settings are simpler than locally installed slicers, but they provide most of what you would normally need, including z-axis retract settings.

There is complete freedom to add printers using a few simple parameters such as build area, G-code type, and number of extruders.

Learn more

-

- What is a slicer? What is a Slicer?