3D print shop new york

3D Printing Service New York | Instant Quotes Online

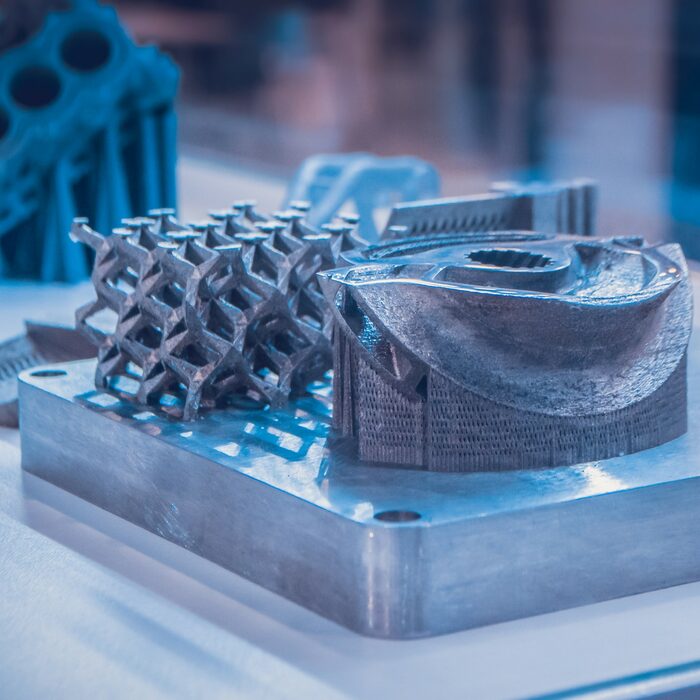

Our 3D printing capabilities

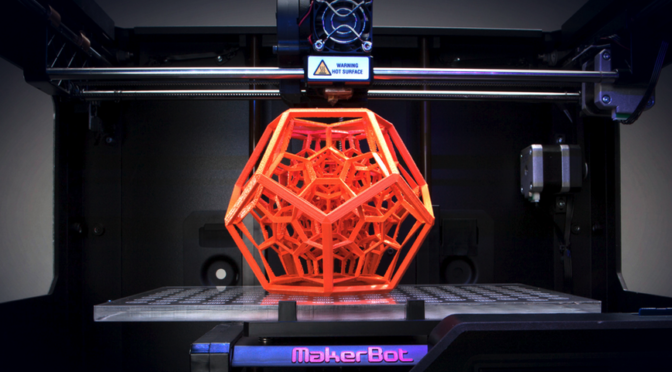

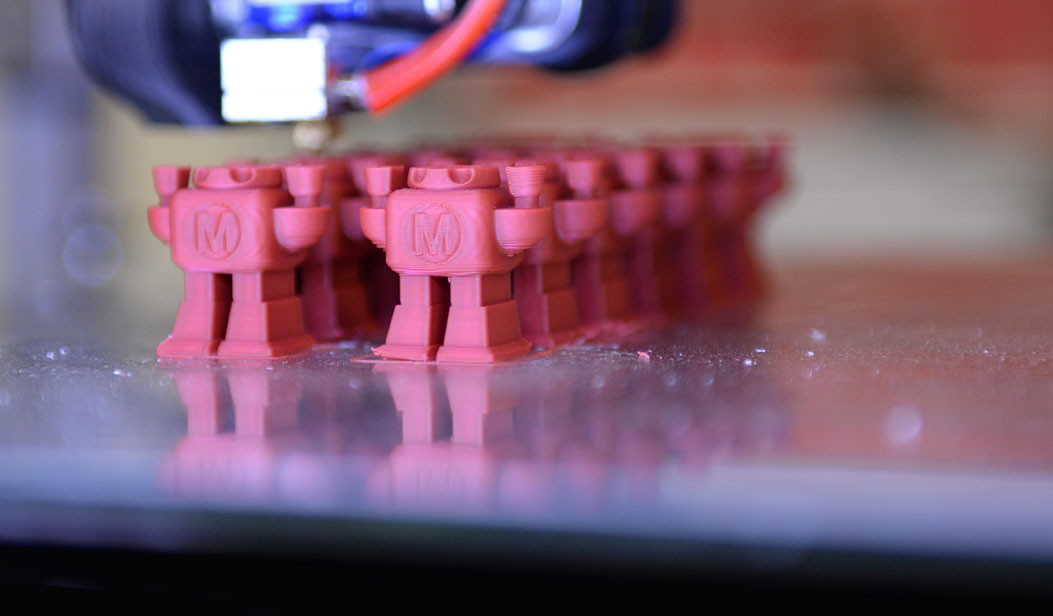

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

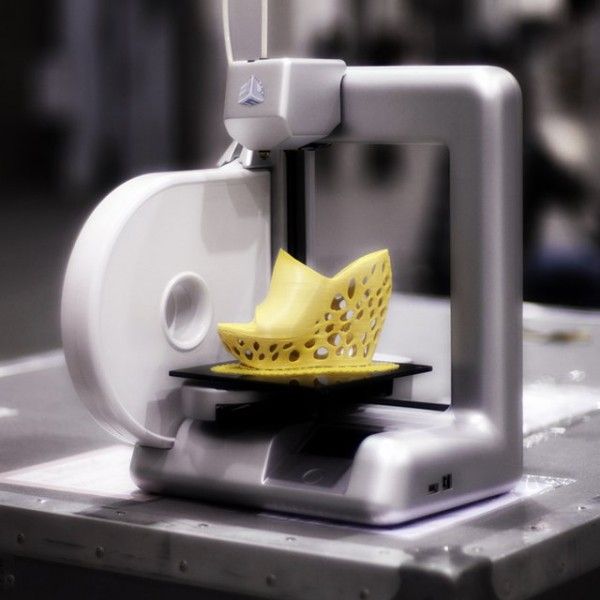

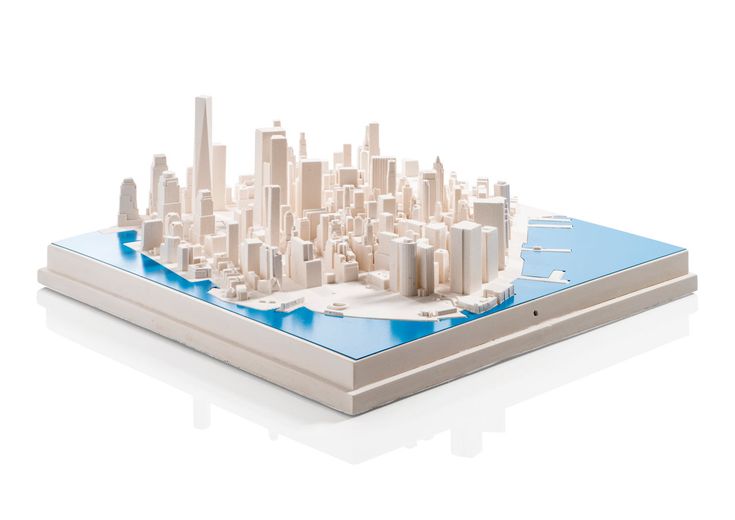

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

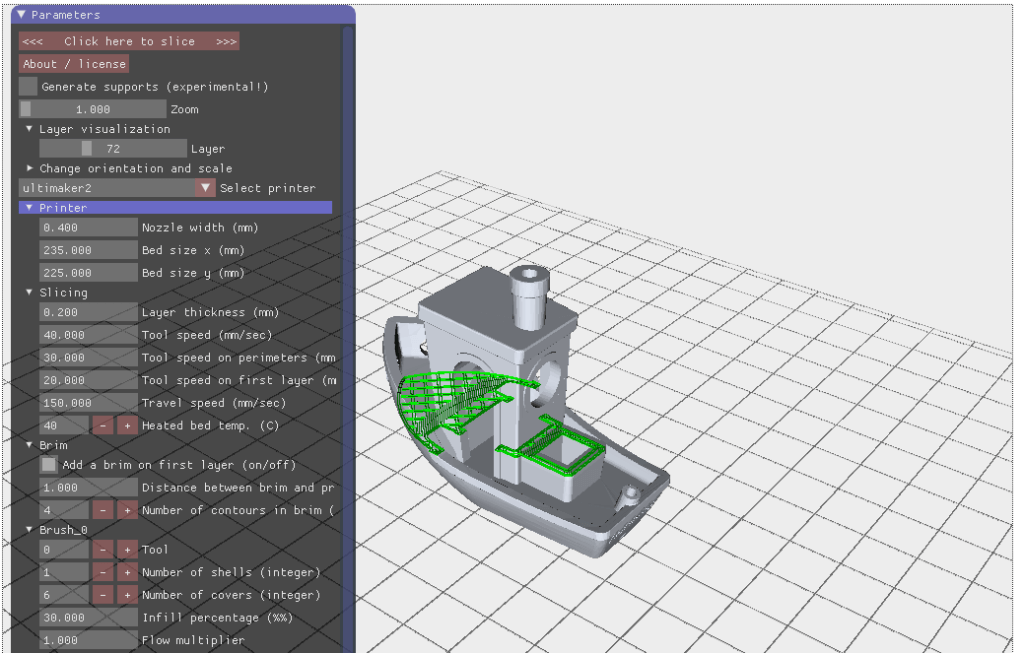

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc.

.

. -

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.9/5

Over 279 customers are satisfied with our 3D printing service.

“Great prints, great communication. Will use this seller again.”

“looks like the photos, was a tough print and will serve its purpose well”

“Just as expected. Fast delivery. No issues.”

“Awesome service and great products. Couldnt ask for more.”

“Great job and shipped quickly. Item was received before quoted delivery date. ”

“Service was quick, friendly and well done. will use in the future. ”

“Quick and courteous,with high qualify results, I would definitely work with them again”

“Very prompt communication, excellent print finish, met all my expectations.”

“The best 3D printing service in the world !”

“Always PERFECT Prints. I measure with calipers. Oh, and fast shipping. What more could you want? Best printer around!”

“Print as expected. Communication and flexibility was excellent.”

“Well packaged, on time, and got frequent updates.”

“Outstanding quality and quick delivery, would order again any time. ”

”

“Great service. Communications and speed were exceptional.”

“Arrived quickly with updates throughout the process, exactly as requested.”

“My order was printed and shipped quickly. Excellent service and communication.”

“I ordered a print at the cheapest level and the quality is much better than I anticipated. These guys examined my drawings in no time, got the print started, snapped images post-print, and got it out the door in the same day. A+ service.”

“Great part, works and fits exactly as i needed”

“Excellent service. Great person. Very helpful. Quality work!!!”

“Perfect. Prints were started the day of upload and delivered before the deadline. Quality is near perfect! ”

“Great communication and custom part fit perfectly. Thanks! ”

“Always a wonderful experience and perfect print. Thank you!”

“Fast turnaround, quality print, good price.”

“Very quick and professional. Will buy from again. ”

“Great communication and printed parts looked great. Highly recommend!”

Highly recommend!”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near New York

Middletown, NY Scranton, PA Binghamton, NY

Kingston, NY East Stroudsburg, PA Union, NY

Utica, NY Poughkeepsie, NY Ramapo, NY

Parsippany

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

3D Printing | Large-Scale | The Factory NYC

3D-Printing

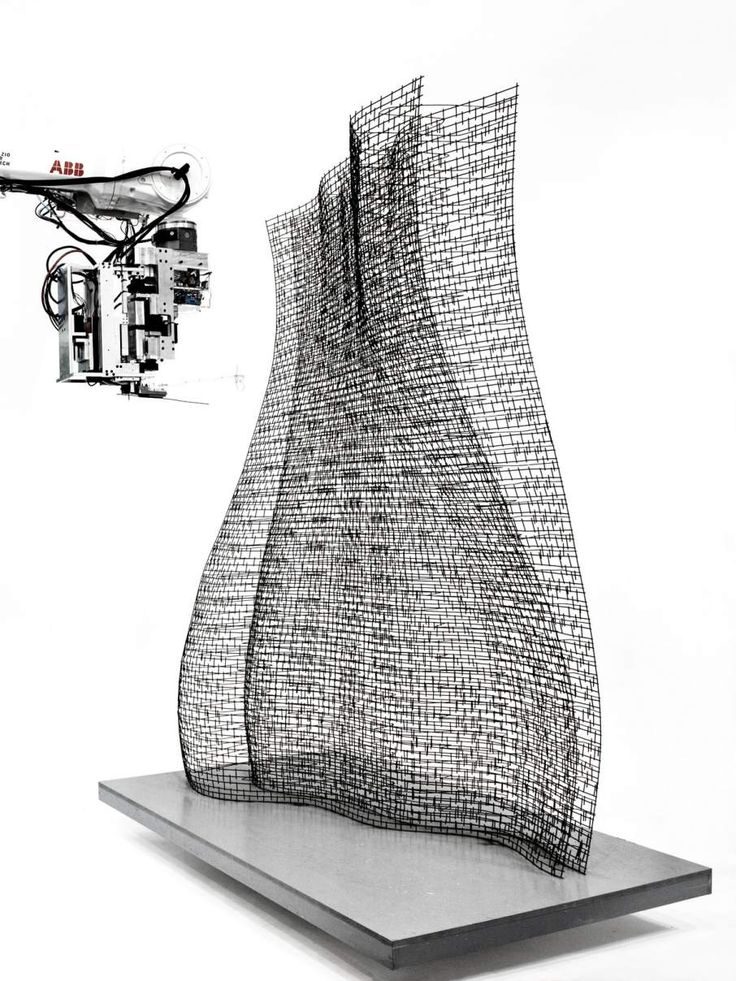

LARGE-SCALE 3D-PRINTING SERVICES

Massive 3D PrintsWe offer large-scale 3d printing for artists, engineers, and designers. Start your Project |

Oversized 3D-printed headphones with built-in audio made for City Eventions |

Start thinking in 3DRapid large-scale 3D Printing opens up a world of possibilities. The Factory NYC can take any object, scan it or model it, and bring it to massive scales. Our 3D Printer using a proprietary UV-cured acrylic polymer which allows a whole new scale and speed of rapid prototyping:

|

The future of storytelling is sculptural(and it's here)

Click to set custom HTML |

Big Print EnergyThe Factory NYC is the only event fabricator in NYC with a large-format 3D-printer — and its up to a 100x times faster than typical 3D Printing; and there is no size limit. We can print and assemble hundreds of parts to build forms at colossal scales. |

Requirements

| Adding sculpture to your next event is easy. You don't need 3D modelers on your team — we have you covered. The only requirement is bring your vision with a budget.

Even if you just have a 2D logo or design on pen and paper. We can create a digital model from scratch, and/or use 3D models from open source libraries. There are many ways to get started. |

Huge 3D-Printing — Get Inspired and Imagine

Delivering amazing projects, daily. | Our team of installers works throughout the New York City greater area. Local, domestic, and international delivery available through air, land, and sea. |

Join our Email list:

Sign up, and we'll share the latest event fabrication technologies:

3D Printing at the New York Invention Show

Archive

Subscribe Author

Subscribe

Don't Wish

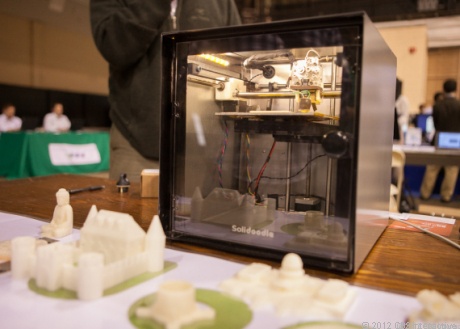

At the end of September of this year, the New York Hall of Science became a DIY paradise as it hosted International Exhibition of Inventions MakerFaire. 2 days dedicated to Science, Technology and Innovation. 3D printing has been especially popular. Let's see the photos.

2 days dedicated to Science, Technology and Innovation. 3D printing has been especially popular. Let's see the photos.

Frogs and shoes

This photo shows frogs, a flowerpot and shoes (probably not the most comfortable) made by 3D printing enthusiasts and displayed at the 3D printing booth.

Computer code

In front of you is a demonstration stand of a cartoonist with his creations created using computer code.

Made in New York

New York-based design startup b_hold showcases homemade everyday items.

Giant 3D Printer

Shapeways Giant 3D Printer, one of the ones used by people who upload their designs to the Shapeways website. Still too big to print on at home.

Printed products

Some of the items printed on Shapeways are made of plastic or ceramic.

More 3D printed items

More Shapeways items made of plastic or ceramic.

Printed toys

ModiBot toys are made from interlocking pieces that assemble into robot-like figures that can wear 3D printed accessories.

Printing a vase

The photo shows a 3D printer in the process of printing a vase.

3D-printed souvenirs for lovers

In the picture 3D printer, printing the first layers of the heart form

Ottominoles during printing 9000 9000

9000 gingerbread house is built on a 3D printed stage.

Frog during print on a 3D printer

Practical 3D -ip

Some of the 3D-print lovers preferred more than the creation of households. objects of various kinds.

objects of various kinds.

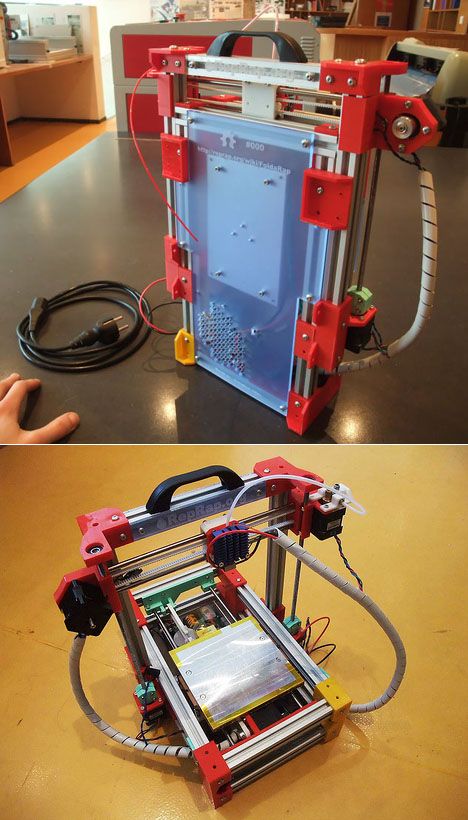

3D printed 3D printer

RepRap 3D printer built almost entirely from 3D printed parts

Simpson Printer

Another RepRap 3D printer called Simpson has only 3 arms.

LeChatNoir

Printed Black Cat - the symbol of the famous Parisian cabaret LeChatNoir in Montmartre.

Photos: Bahar Gholipur, LiveScience

Follow author

Follow

Don't want

More interesting articles

6

Subscribe to the author

Subscribe

Don't want

One of the newest developments in 3D printing devices has been the advent of extruders. No, it's not...

Read more

four

Subscribe to the author

Subscribe

Don't want

If yesterday 3D printing was the lot of boys of different age groups trying to adapt new. ..

..

Read more

3

Subscribe to the author

Subscribe

Don't want to

Not so long ago, we talked about an interesting engineering and architectural project that is directly related to the app...

Read more

3D printing in the fashion industry: a new dimension

1 We are witnessing what many call the third industrial revolution: 3D printing, or additive manufacturing, could move us away from the era of mass production and lead us to a new reality of customizable manufacturing. A good example is fashion. In the recent past, "fashion houses" were more like multidisciplinary research institutes. To create a collection of clothes, in addition to an expert sense of style, you need knowledge in anatomy, advanced sewing machines, appropriate fabrics and accessories, accessories, shoes, people (cutters, seamstresses, models and many others). Through trial and error, an art object is created, rarely successful, but always laborious. 3D printing is a toolless manufacturing method that allows physical objects to be produced from a 3D model, usually in layers. The term is also used generically as a synonym for rapid prototyping. The scope of the technology is endless: from tools and toys to robots and mechanical parts. There is no limit to what a 3D printer can create.

Through trial and error, an art object is created, rarely successful, but always laborious. 3D printing is a toolless manufacturing method that allows physical objects to be produced from a 3D model, usually in layers. The term is also used generically as a synonym for rapid prototyping. The scope of the technology is endless: from tools and toys to robots and mechanical parts. There is no limit to what a 3D printer can create.

Alexander Kornveits, expert in the field of additive technologies, founder and CEO of Tsvetnoy Mir

Fashionable futuristic design requires innovative production technologies, here 3D printing comes to the rescue. A wide variety of fashion accessories including bracelets, rings, brooches, necklaces and pendants can now be easily 3D printed. Let's take a closer look at how this technology can be used in the fashion world...

Custom Design

One of the unique aspects of 3D printing is the ability for designers to create custom shapes and sizes that would be impossible to produce with traditional methods.

Photopolymer 3D printing allows designers to produce products in small batches. Fashion designers can now create bold, one-of-a-kind pieces. In addition to time, technology can significantly reduce costs.

Accessories

The range of fashion accessories depends more on the imagination of the creator than on the possibilities of your wallet. All this can be easily printed using a conventional photopolymer 3D printer. Need a flower ring? No problem! 3D printing can do this and more. What else can be produced in this way?

Brooches

Brooches are intricate pieces of jewelry that highlight your personality. Business women especially like to use them to decorate and complement their business suits. For example, Madeleine Albright, the first female US Secretary of State, over the years of her career has created a new diplomatic language, full of metaphors and secret meanings. Through jewelry, she expressed her mood, intentions or the situation at the negotiations, and political scientists and journalists vied with each other to interpret the images on the left lapel of her jacket. 3D printing can be used to produce a custom brooch that can complement the look, and perhaps say something to the “initiates”.

3D printing can be used to produce a custom brooch that can complement the look, and perhaps say something to the “initiates”.

Rings

3D printing can be used to make a prototype ring before making it into the final version of precious metals and stones. This will allow the designer to easily and quickly make adjustments, ensuring the ring fits perfectly and matches the client's expectations and end result. Important factors are saving time, money and, of course, a significant reduction in the likelihood of errors in the final product.

If earlier only professional 3D printers costing from $50,000 were suitable for the jewelry industry, now with the introduction of inexpensive mono LCD displays with 4K resolution, such printing is available to any jewelers and designers. The purchase budget fell below $500.

Bracelets

Similarly, intricately designed bracelets can be created using photopolymer or wax 3D printers. It can be an exclusive version, one of a kind, which, if necessary, can be mass-produced. Technology allows you to think more broadly and not be afraid to experiment with expensive precious metals and stones. After all, modern consumables allow you to create prototypes with a high level of reliability.

Technology allows you to think more broadly and not be afraid to experiment with expensive precious metals and stones. After all, modern consumables allow you to create prototypes with a high level of reliability.

Clothing and footwear

Shoes, dresses and other fashion items can also be 3D printed. This allows you to create ready-made items for wear, as well as improve the design of the model before launching into mass production. Shoes with geometrically complex 3D designs often find their way into the fashion mainstream.

And for more mundane purposes, there are sneaker soles. For example, Adidas makes them from a mixture of polymer resin with polyurethane added and prints in a lattice structure that promotes proper load distribution.

Adidas claims the Futurecraft 4D shoes are incredibly comfortable, with unparalleled ergonomics and wear resistance.

Simultaneously with shoes, there are numerous experiments on the use of 3D printing to create designer outfits and especially dresses.

One of the first 3D printed dresses was presented by American model and singer Dita Von Teese in March 2013 in New York. Couturiers Michael Schmidt and Francis Bitonti teamed up with 3D printing service Shapeways to print it using additive manufacturing technology. It consisted of 17 nylon parts, which were painted black and encrusted with 13,000 Swarovski stones.

In 2019, a whole series of such models was presented at the famous MetGala charity ball in New York. In the photo - American celebrities in outfits with 3D printed elements. Everyone was especially struck by the dress in the form of a rose petal (in the center), in which the British model Jordan Dunn appeared at the ceremony.

It, like the entire collection, was created by fashion designer Zac Posen in collaboration with GE engineers and 3D printers and made a splash on the red carpet of the event.

It is too early to talk about the widespread introduction of 3D printing in the fashion industry, but it is already clear that this process will continue.

Individual parts at 72" (177cm), and even larger with sectional fabrication. Start with a napkin sketch, a physical object to scan, or with fully engineered CAD files. Our design and production team at The Factory NYC will bring your project to life.

Individual parts at 72" (177cm), and even larger with sectional fabrication. Start with a napkin sketch, a physical object to scan, or with fully engineered CAD files. Our design and production team at The Factory NYC will bring your project to life. By printing sculptures in multiple sections with interlocking joints, we can assemble even room-sized sculptures and beyond.

By printing sculptures in multiple sections with interlocking joints, we can assemble even room-sized sculptures and beyond. Today, there's nothing more powerful to realize this new vision than large-scale 3D printing. It's here, competitively priced, and within your brand's reach:

Today, there's nothing more powerful to realize this new vision than large-scale 3D printing. It's here, competitively priced, and within your brand's reach: We can accommodate your design concept for most situations:

We can accommodate your design concept for most situations: