3D printer router laser

The 5 Best 3 in 1 3D Printers 2022 (with Laser Engraving & CNC!)

Ideally, we would all own one machine that could complete every manufacturing task required – a 3D laser printer that printed, laser cut, CNC carved, and more. While not quite there yet, 3 in 1 3D printers offer jack-of-all-trades versatility across 3D printing, CNC machining, and laser engraving – to various levels.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

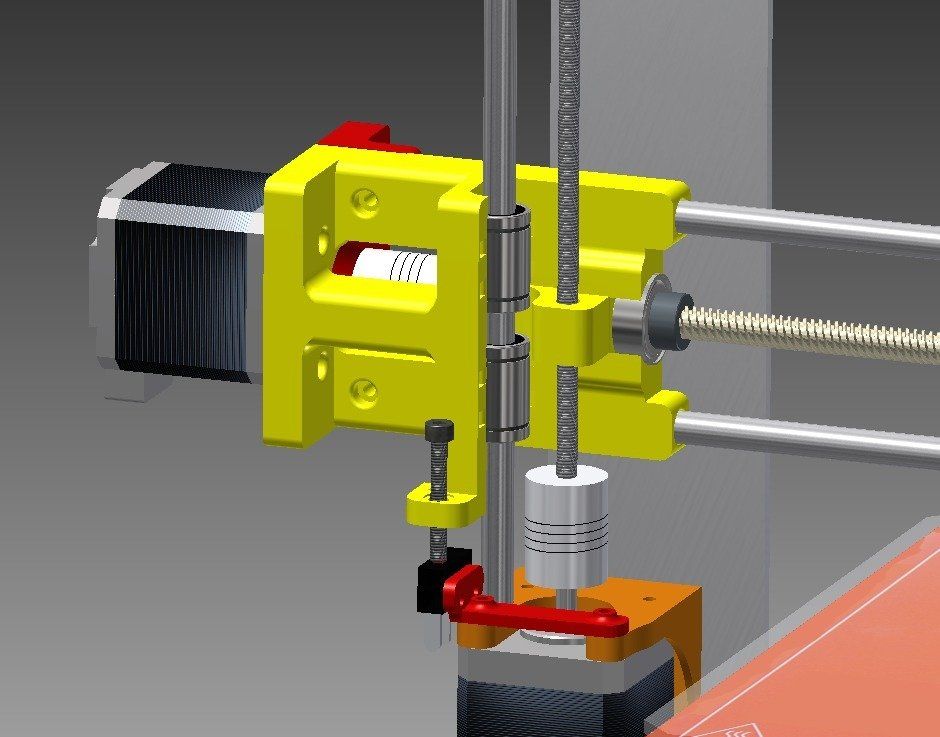

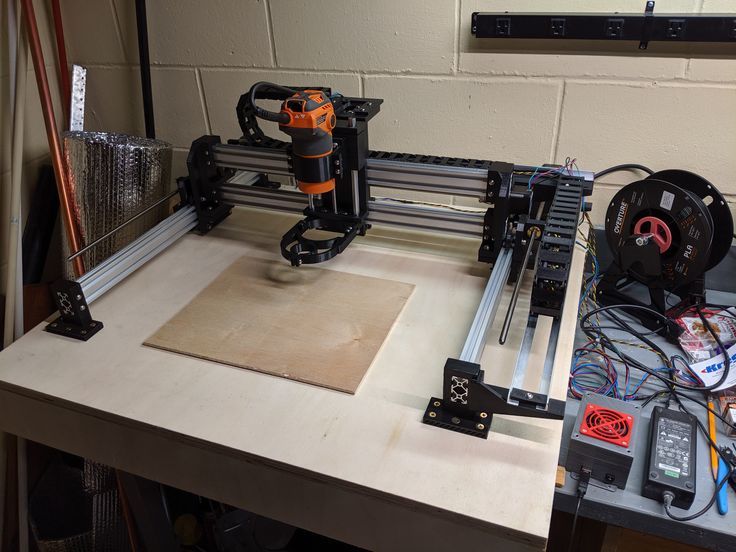

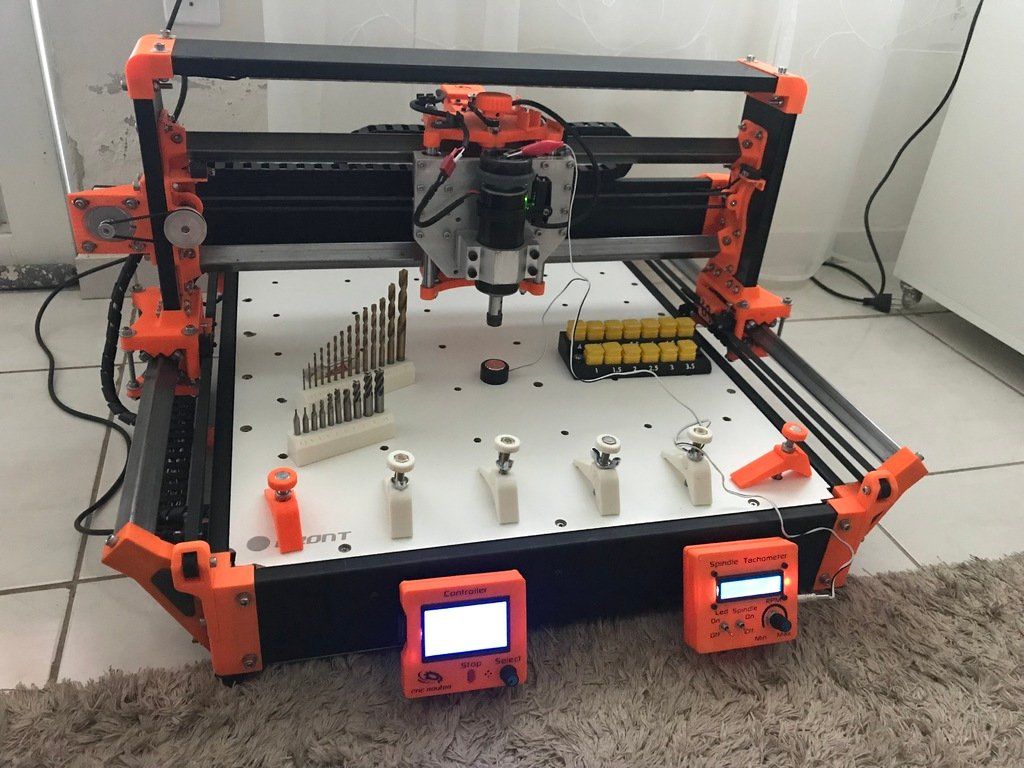

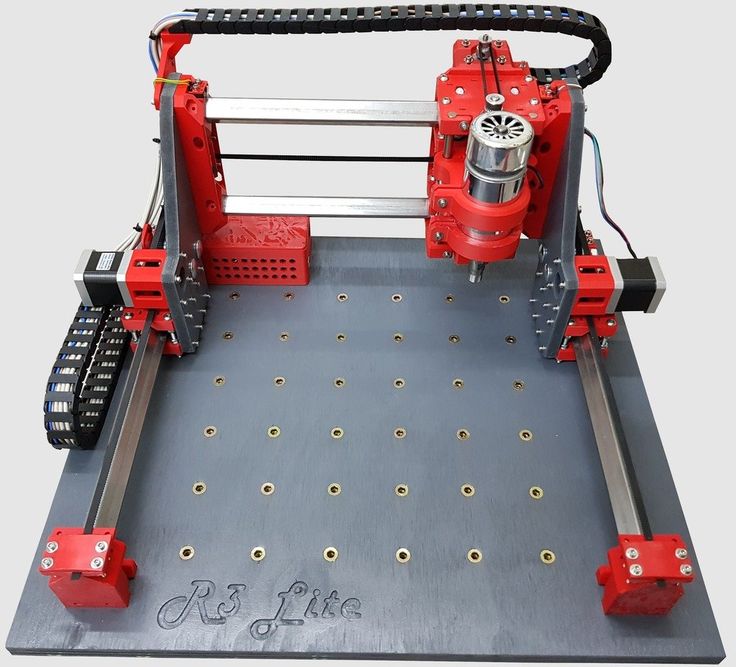

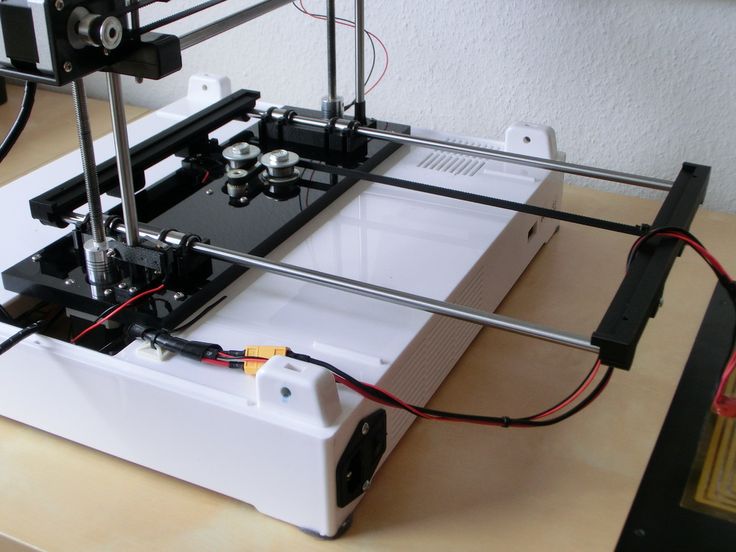

These printers, sometimes called multifunction 3D printers or AIO 3D printers, feature removable tool heads that can be switched out to change their function. If you want to create a prototype and want to carve a wood model first, use the CNC machine, and then switch back to the 3D printer extruder to create the final plastic prototype.

Having tested dozens of 3D printers over the years, including our top pick, the Snapmaker 2.0, we’ve collated our findings into our top recommendations for 3-in-1 3D printers to help you make the best choice for you.

| Name and brand | Type of printer | Build volume (mm) | Price | Available at: |

|---|---|---|---|---|

| Snapmaker 2.0 | 3 in 1 3D printer | Varies by model | $1,199-$1,799 | Snapmaker here |

| Snapmaker Original | 3 in 1 3D printer | 125 x 125 x 125 | $450 | Snapmaker here |

| ZMorph Fab | 4 in 1 3D printer | 250 x 235 x 165 | $4,000 | Amazon here |

| Creality CP-01 | 3 in 1 3D printer | 200 x 200 x 200 | $819 | Amazon here |

| Ecubmaker TOYDIY | 4 in 1 3D printer | 180 x 180 x 180 | $549 | Amazon here |

| 5axismaker | CNC mill 3D printer | Varies by model | £5,500 / £6,800 | |

| Diabase H-Series | 3D printer CNC hybrid | Depends on number of axes | $9,750+ |

How good are all in 1 3D printers?

Naturally, focusing on being good enough at everything means some quality is lost in some areas. Elites athletes could not compete at the top of the NBA, NFL, and NHL simultaneously – even Michael Jordan couldn’t crack baseball – and the same is true for less specialized all in 1 3D printers.

Elites athletes could not compete at the top of the NBA, NFL, and NHL simultaneously – even Michael Jordan couldn’t crack baseball – and the same is true for less specialized all in 1 3D printers.

That doesn’t mean that the 3D printer and laser engraver hybrids we recommend don’t perform well. For hobbyist projects, 3D laser printers are great – but we do not recommend starting a full-service manufacturing company after buying a desktop 3D printer laser engraver CNC mill machine.

The criteria we used to judge the best 3 in 1 3D printers

In rating the 3 in 1 3D printers we recommend below, we compared:

- 3D printer quality: most of these 3 in one 3D printers are made by 3D printer companies and are mostly focused on additive manufacturing. Therefore, the 3D printer’s quality is key.

- CNC mill power: some CNC machines cannot fully mill, but just engrave. More powerful CNC machines spin faster, can carve tougher materials, and work more accurately and for longer.

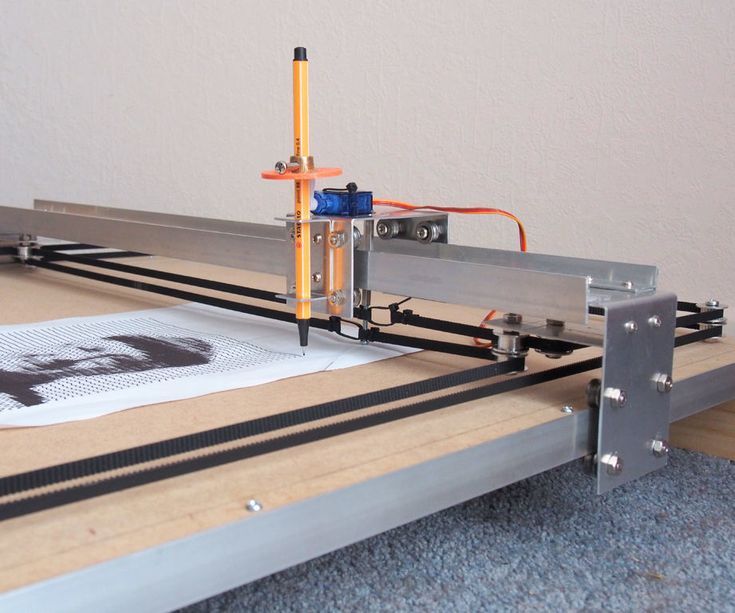

- Laser engraver power: as with the CNC machine, some all in 1 laser engraver 3D printers can only engrave, whereas others can cut through materials.

- How easy is it to change the tool heads: it’s all well and good having powerful tool heads that work perfectly, but if they’re too difficult or delicate to switch out, they may as well only have one function.

- Effectiveness of software: most of our recommendations feature specialized software that can slice models for 3D printing, and prepare CNC and laser projects. The best software is easy to use, yet effective and reliable across every function.

The Best All in 1 3D printers

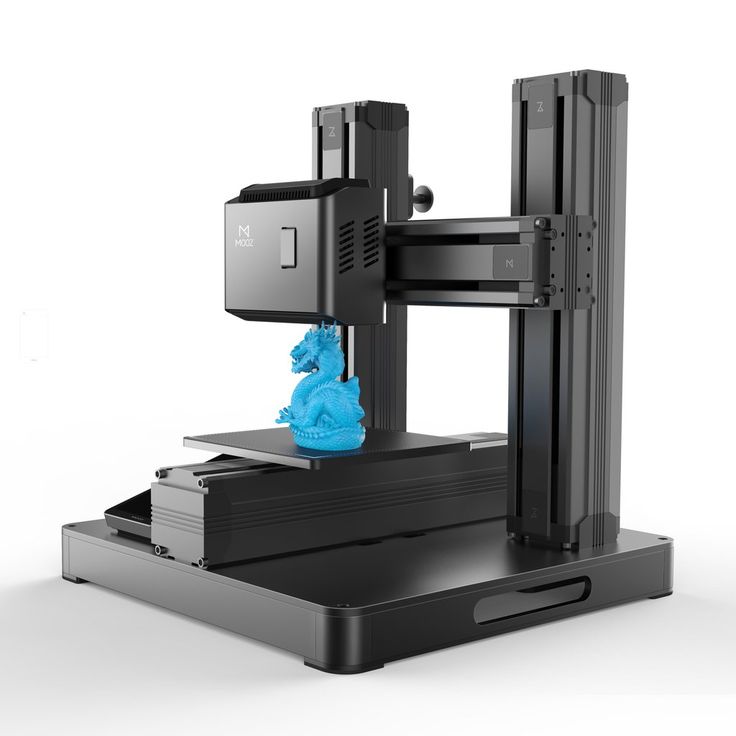

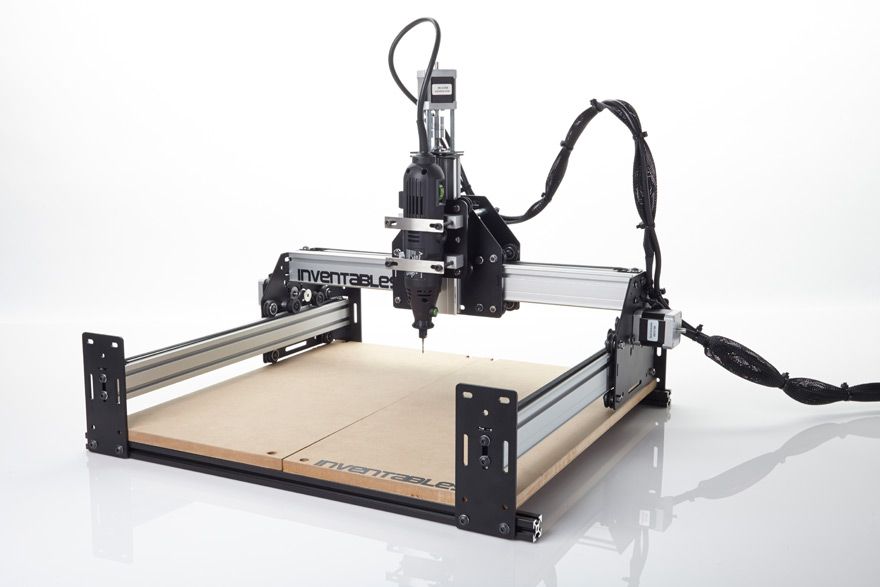

Snapmaker 2.0 – comes in 3 forms: A150, A250 & A350

- Price: $1,199 to $1,799 — Best price on Snapmaker Store here / Available on Amazon here

- Build volumes: A150 = 160 x 160 x 145 mm / A250 = 230 x 250 x 235 mm / A350 = 320 x 350 x 350 mm

- Type: 3D in 1 3D printer: 3D printing, CNC and laser engraving

The Snapmaker Original already made waves when it raised over $2. 2M on Kickstarter, but the Snapmaker 2.0 completely obliterated that by becoming the most funded technology project in the history of Kickstarter, raising an astonishing $7.85M. Thousands of elated fans who loved the Snapmaker Original came back to support the new version, and it has remained the most popular all in 1 3D printer since its full release.

2M on Kickstarter, but the Snapmaker 2.0 completely obliterated that by becoming the most funded technology project in the history of Kickstarter, raising an astonishing $7.85M. Thousands of elated fans who loved the Snapmaker Original came back to support the new version, and it has remained the most popular all in 1 3D printer since its full release.

We have tested and reviewed the Snapmaker 2.0, and waxed lyrical about how great it was. It is undoubtedly the best 3-in-1 3D printer around, offering a fantastic 3D printing experience, as well as a great CNC carving and laser option. Arguably you could even call it a 4-in-1 3D printer, as you can also buy the 4-axis rotary module add-on which turns the laser and CNC toolheads into 360-degree, 4-axis versions. We carved cylindrical chess pieces, engraved cylinder gift boxes, and more with this add-on.Using the 4-axis rotary module to CNC carve a lion.

The 3D printer can print PLA, ABS and flexible filaments like TPU, and with WiFi connectivity as well as a USB port you can print remotely online, or offline using a USB. The portable and movable touchscreen used to operate the printer looks and acts like a smartphone, simplifying your workflow and making it easy to control and manage projects.

The portable and movable touchscreen used to operate the printer looks and acts like a smartphone, simplifying your workflow and making it easy to control and manage projects.

Moreover, the filament run out detector automatically pauses your print when you run out, giving you time to load more filament and resume without ruining your print, and if you buy the enclosure add-on you can more easily print ABS to prevent warping — and it’ll keep dust in from CNC, and the laser brightness out of your eyes.A vase we 3D printed with the Snapmaker 2.0.

As a laser engraver, you can create contrasting images on fabrics, leather, plywood and acrylic materials. The built-in camera lets you remotely monitor your design and ensure everything goes smoothly. It’s an effective low-cost 3D laser printer. We also tested it as a laser cutter, and managed to cut out and assemble a gift box from a thin sheet of soft wood 1.5mm thick.The Snapmaker 2.0 also works as a laser cutter as well as a 3D printer.

The CNC machine can carve designs on walnut, PCB woods, as well as carbon fiber sheets, acrylic and hardwood. A key upgrade on the 2.0 is the increased speed, meaning that larger projects can be created in record time.

Overall, we highly recommend the Snapmaker 2.0 models, of which we tested the largest version — the Snapmaker 2.0 A350. You can optionally buy the enclosure, 4-axis rotary module, and the new 10W powerful laser toolhead, but we did not try the 10W laser add-on.

For our CNC & laser review: we tested the Snapmaker 2.0 CNC and laser toolheadsThe finished lion CNC carved piece, from the Snapmaker 2.0 3-in-1 3D printer.

We recommend picking up the enclosure for safer and more consistent making, as well as spare bits for CNC. Snapmaker’s store has all these in one place, which you can visit here.

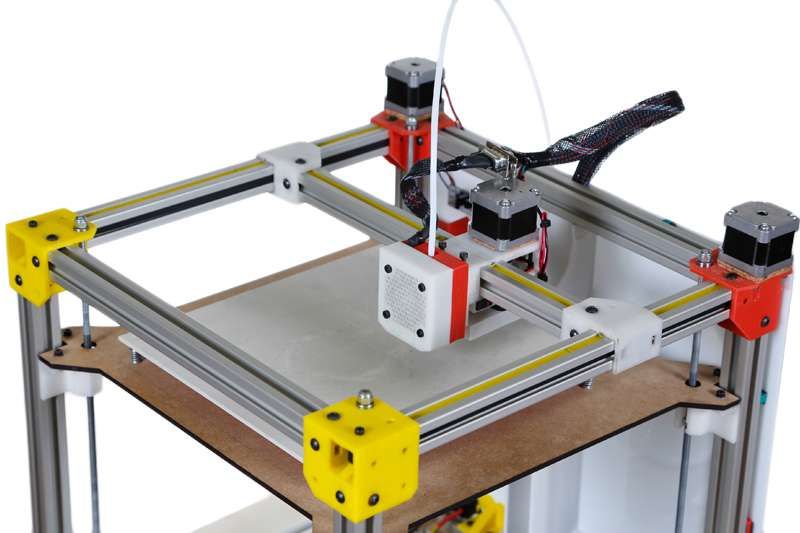

Snapmaker Original — good starter laser engraver 3D printer

- Price: $439 — Available on Snapmaker Official Site here / Available on Amazon here

- Build Volume: 125 x 125 x 125 mm

- Type: 3 in 1 3D printer: 3D printing, CNC and laser engraving

Snapmaker came out and made headlines when they raised an incredible $2. 2M on Kickstarter for their first all in 1 3D printer, the Snapmaker Original. Functional as a small 3D printer as well as able to carve wood and engrave images on phone cases and other materials, the Snapmaker Original captured the hearts of many makers worldwide, becoming a roaring success.

2M on Kickstarter for their first all in 1 3D printer, the Snapmaker Original. Functional as a small 3D printer as well as able to carve wood and engrave images on phone cases and other materials, the Snapmaker Original captured the hearts of many makers worldwide, becoming a roaring success.

- You can also buy an enclosure for the printer here.

The 3D printer’s heated bed can reach up to 80C, allowing for the printing ABS as well as PLA. It’s precise, with up to 50-micron layer resolutions. The heavy metal frame anchors the printer down and improves stability and durability, with the heavier frame less susceptible to vibrations that could affect print quality and surface finish.

The CNC carver can create intricate details in areas up to 90 x 90 x 50 mm, and the laser engraver works on areas up to 125 x 125 mm.

Snapmaker’s 3 in 1 software, Snapmaker Luban, can 3D print, CNC and laser engrave all in one platform and switch seamlessly between each tool head.

Snapmaker claim you can build the 3D printer in just 10 minutes, and that switching out tool heads to change the all-in-one 3D printer’s function is very simple. Highly rated by makers as one of the best 3 in 1 3D printers in its price range, the Snapmaker have since recently followed up the Original with the Snapmaker 2.0, with larger build volumes and a higher price tag.A selection of wood and other material parts carved using the Snapmaker Original’s CNC tool head. Source: snapmaker.com

ZMorph Fab — 4 in 1 3D printer

- Price: $3,999 for the full set — Available on Matterhackers here / 3DPrima Europe here

- Build Volume: 250 x 235 x 165 mm

- Type: 4 in 1 3D printer: with CNC milling, laser cutting & engraving, and thick paste extruder

- Country based: Poland

Polish 3D printer company ZMorph make some of the most versatile all in 1 3D printers around, with the Fab able to 3D print, CNC machine, engrave and laser cut, and can even be switched into a food 3D printer using ZMorph’s thick paste extruder. This edible material option can print chocolate, as well as other similar materials like icing and cooking dough.

This edible material option can print chocolate, as well as other similar materials like icing and cooking dough.

- We also have a ranking of the best food 3D printers.

- We also have a ranking of the best chocolate 3D printers.

ZMorph 3D printers are famed for their reliability and workhorse-like qualities, with the Fab no different. It’s a great 3D printer, with a high-quality heated bed that can comfortably 3D print ABS, HIPS, and other tougher filaments like Nylon. The printer can level itself automatically, and turn from a 3D printer to laser engraver or CNC router with ease.

Additionally, with the dual head option, the ZMorph performs well as a dual extruder 3D printer, able to 3D print multiple colors, or soluble support materials such as HIPS and PVA, and even blend two colors together for multiple different shades in one part. The 3D laser printer CNC hybrid can be adjusted to print both 1.75mm and 3mm 3D printer filaments, and has a large enough build area to print even the largest of projects.

Using ZMorph’s CNC tool head, the ZMorph becomes a powerful CNC mill 3D printer that can mill and engrave almost any type of wood, as well as other materials like acrylic glass and EVA foam. The 300W power mills distances of up to 120mm/s, and ZMorph recommend a cutting depth of up to 0.5mm.

The Laser PRO tool head turns the Fab into a laser engraver 3D printer capable of burning and engraving plywood and many other types of wood, cardboard, leather, and acrylic glass using its powerful yet compact 2.8W blue laser. Though the default speed is 15mm/s, the laser can work up to 120mm/s for faster engraving.

ZMorph’s Voxelizer 2 software acts as a 3D slicer for 3D printing parts, as well as offering CAD CAM software features for CNC and laser cutting models, all in one. Overall, it’s a fantastic and extremely versatile all in one 3D printer, and the closest available option to a full manufacturing suite machine.The ZMorph CNC tool head creating a design from wood. Source: ZMorph on Medium.

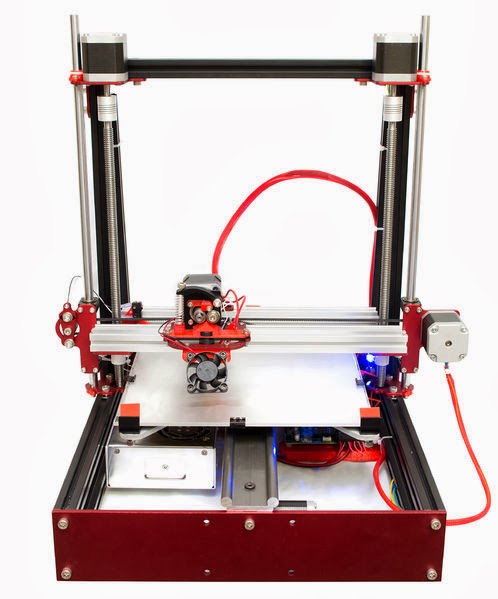

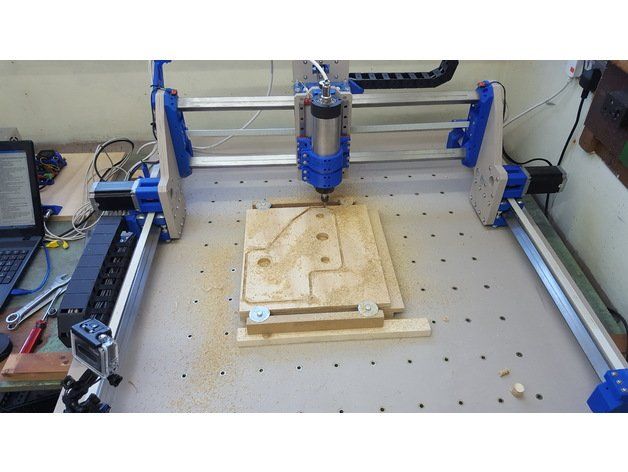

Creality CP-01

- Price: $819 — Available on Amazon here

- Build Volume: 200 x 200 x 200 mm

- Type: 3 in 1 3D printer: 3D printer, CNC & laser engraving

Creality make the current most popular affordable 3D printers in the world, including the Ender 3, Ender 5, and CR-10 ranges. The Creality CP-01 is their venture into the all-in-1 3D printer sector, offering CNC carving and laser engraving along with their 3D printer.

- We also have a ranking of the best cheap 3D printers.

As a 3D printer, it features a good 200 x 200 x 200 mm print volume, and comes with a heated bed that can reach up to 100C. These temperatures mean that ABS, HIPS and TPU 3D printing should be no problem, and in theory means you could even try printing filaments like Polycarbonate and carbon fiber.

The textured glass print bed should help with adhesion and reduce warping, and the direct drive extruder also makes flexible filament 3D printing easier in most cases.

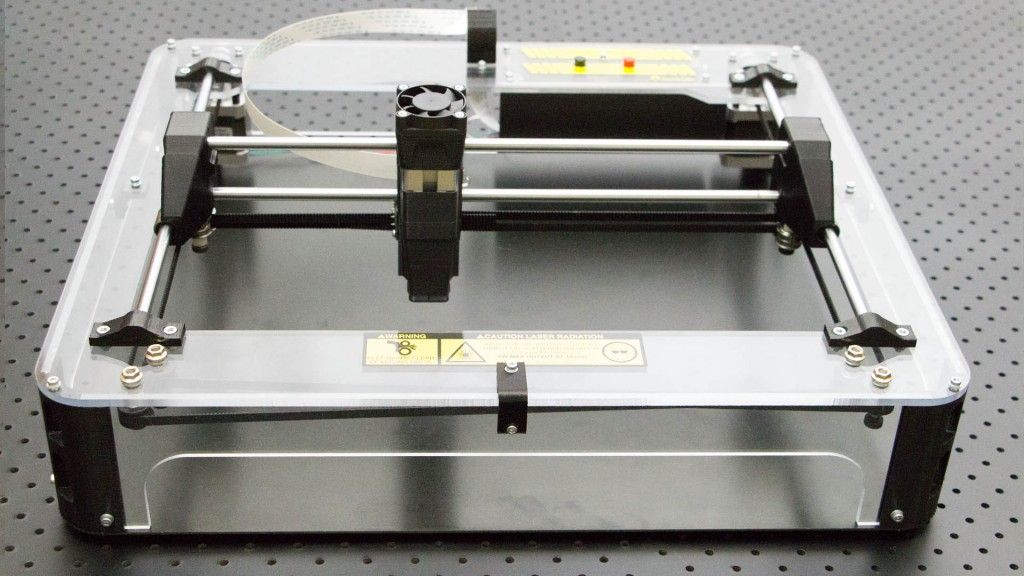

As a laser engraver, the Creality CP-01 3-in-1 3D printer features 0.5W laser tool, which can engrave areas of up to 100 x 90 mm. The engraver can create contrasting greyscale art on paper, plastics, and wood.

As a CNC carver, the CP-01 features a 4800RPM spinning CNC spindle capable of carving plastics, wood and PCB. It can carve the same sized areas as the 3D printer, at 200 x 200 mm.

The CP-01 comes with Creality’s own Workshop 3D printer software, which supports engraving and CNC functions. For 3D printing, Creality’s standalone Creality Slicer works well.

Overall, it resembles the Snapmaker and appears to offer similar specs and functions, so we will have to see if the kings of cheap 3D printers can compete in the all in 1 3D printer sector.Each of the Creality CP-01’s tool heads for 3D printing, CNC cutting and laser engraving.

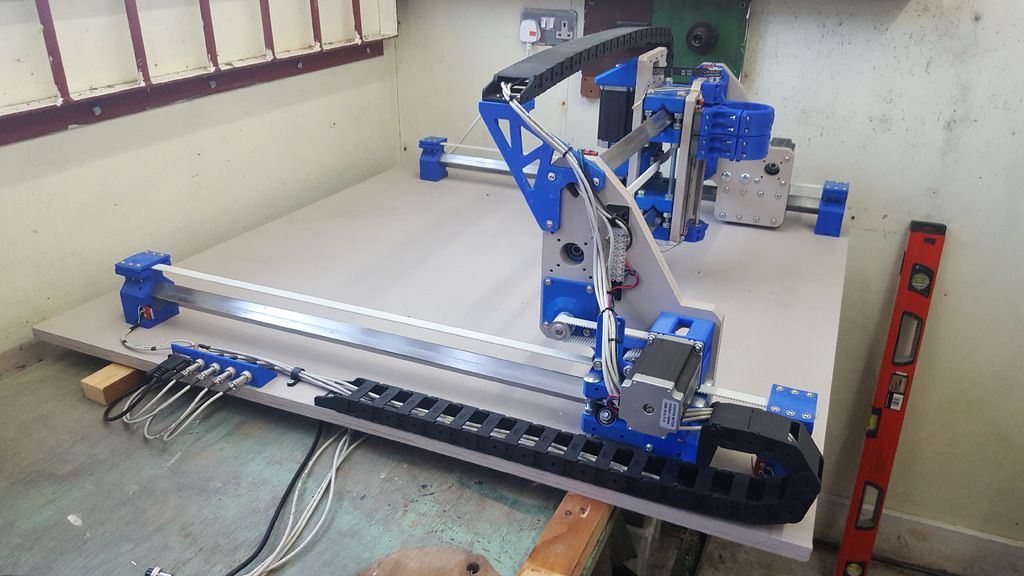

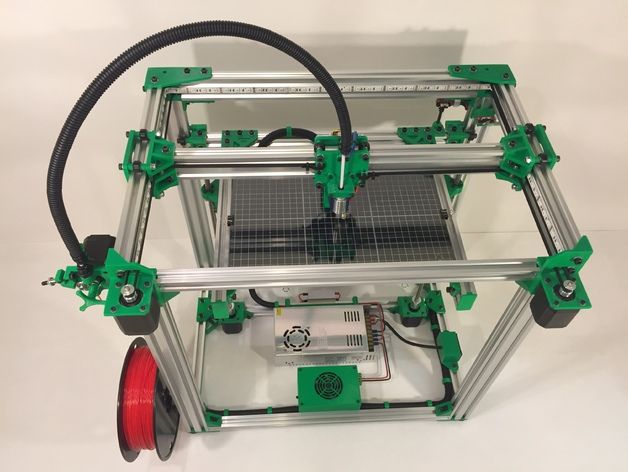

5axismaker — Great CNC 3D printer

- Price: £5,500 / £6,800 depending on size

- Build volume: 5xm400 = 400 x 400 x 400mm / 5xm600 = 600 x 600 x 400mm

- Type: 2 in 1 3D printer with CNC milling

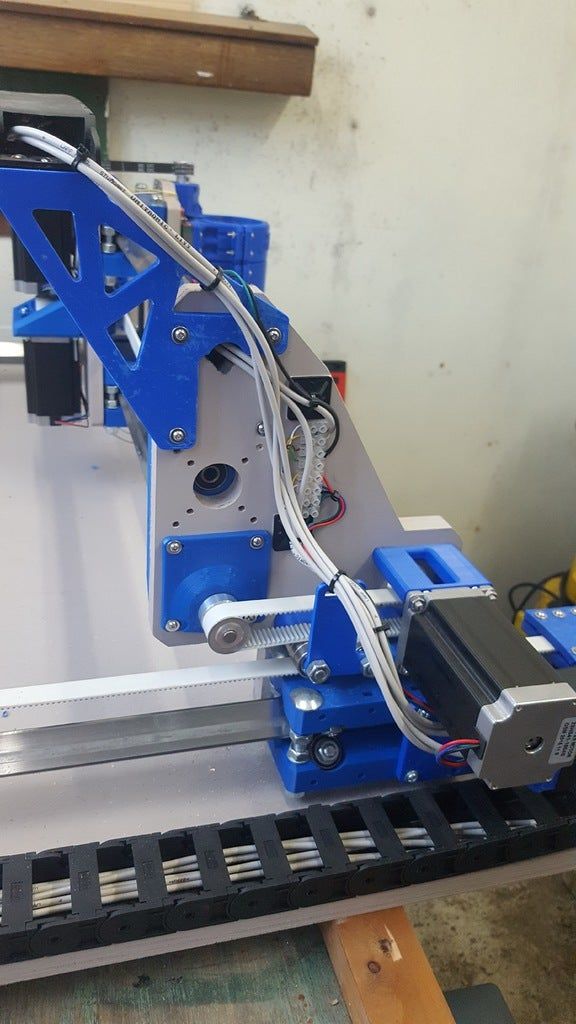

London-based 5axismaker have developed an excellent 3D printer CNC machine multi use 3D printer that comes in two main sizes to cover your manufacturing needs:

- 5axismaker 5xm400 model: 400 x 400 x 400 mm build volume

- 5axismaker 5xm600 model: 600 x 600 x 400 mm build volume

As a 3D printer, the 5axismaker comes with a default 0. 6mm nozzle — though you can switch out to a 0.4mm if you’re used to smaller nozzles, as well as sizes up to 1.2mm where speed is of the essence and you’re willing to sacrifice some precision. The 5axismaker can 3D print with PLA or ABS.

6mm nozzle — though you can switch out to a 0.4mm if you’re used to smaller nozzles, as well as sizes up to 1.2mm where speed is of the essence and you’re willing to sacrifice some precision. The 5axismaker can 3D print with PLA or ABS.

As a CNC machine, the 5axismaker offers fast 10,000-15,000 RPM spindle speeds on a powerful 500-1000W brushless motor capable of milling foam prototypes, hardwoods, carbon fiber, engineering plastics, machinable wax, and more. There is also a touchprobe option — but for this toolhead and any other custom tools, you’ll need to contact 5axismaker directly.

5axismaker have also developed their own in-house CAM software to support CNC milling and generate CNC codes, called 5xmonkey. The 5axismaker focuses particularly on CNC machining, choosing not to offer laser engraving with the 3D printer, but delivers well as a 2 in 1 3D printer.

Diabase H-Series — powerful CNC mill 3D printer

- Price: starting at $9,750

- Build volume: depends on the number of axes

Another 2 in 1 3D printer focusing on 3D printing and CNC milling, Diabase offer three different options within the H-series:

- H5-400A Hybrid: doesn’t have the tool plate, 5- or 4-axis upgrade potential, but can still mill printed parts.

- H5-400A CNC Lite: offers 4- and 5-axis upgrading

- H5-400B CNC Full: offers 4-material printing, a 14-tool changer, and high-power spindle

Diabase are already well known for their excellent 3D printer extruders focused on making flexible filament 3D printing as reliable as possible, previously thought to be difficult to print — especially on Bowden extruders.

They now offer a complete manufacturing solution, with their multifunction 3D printers able to print parts and them mill them seamlessly with each toolhead in a cohesive workflow.

The H-Series CNC mill 3D printer hybrid offers up to 5-axis CNC production along with 12,000 RPM speeds, for very intricate and complex part creation. As a 3D printer, it offers multi-material 3D printing, for example with TPU and PVA, with PVA’s solubility making it ideal for simply removing PVA supports later. The CNC mill part can mill soft metals up to 75 HRB strength — it really is a full-service solution. The Diabase H-Series’ rotary axes offer fantastic part complexity and intricate geometry options for manufacturing.

The Diabase H-Series’ rotary axes offer fantastic part complexity and intricate geometry options for manufacturing.

Ecubmaker TOYDIY — 4 in 1 3D printer

- Price: $549 — Available on Amazon here

- Build Volume: 180 x 180 x 180 mm

- Type: 4 in 1 3D printer: FDM, dual color, CNC engraving and laser engraving

- Country based: China

Though it calls itself a 4 in 1 3D printer, this claim involves splitting the 3D printing part into standard FDM 3D printing, and dual color 3D printing, which both fall under 3D printing. In reality, the Ecubmaker TOYDIY is a 3 in 1 3D printer, but with four easily changeable tool heads for 3D printing, CNC engraving or laser engraving.

For 3D printing, the extruder can reach temperatures of up to 240C, with a heated bed that can reach up to 50C. Therefore, printing higher temperature filaments like ABS and HIPS is not possible, and you’re restricted to using the Ecubmaker TOYDIY as a strictly PLA 3D printer. (Testing has occurred for using the dual extruder to print PVA as a support, though the company do not recommend this). Therefore, if using the dual extruder 3D printing option, you can only print two different colors of PLA, rather than soluble material supports.

(Testing has occurred for using the dual extruder to print PVA as a support, though the company do not recommend this). Therefore, if using the dual extruder 3D printing option, you can only print two different colors of PLA, rather than soluble material supports.

For a 3D laser printer that isn’t specialized in any one dimension, it’s surprisingly accurate – with layer thicknesses of up to 0.05 mm. The bendable, 3-layer build plate also makes removing finished prints easy and helps reduce warping, though PLA rarely warps badly anyway.

As a laser engraver 3D printer, the TOYDIY features a 1500MW purple laser which can engrave wood, plastic, leather, cardboard, and several other materials. However, this is strictly a laser engraver, and cannot cut materials.

The CNC tool head features a 385DC motor, and spins at between 8,000 and 10,000 RPM. The CNC printer can engrave and carve wood, plastics, acrylic and most non-metallic materials, but cannot be used with transparent materials like glass. Ecubmaker also stress that the CNC tool head should not be used for longer than 3 hours at once.

Ecubmaker also stress that the CNC tool head should not be used for longer than 3 hours at once.

The TOYDIY comes with Ecubmaker’s Ecubware 4 in 1 3D slicer software for every application type. The 3D laser printer comes with an SD card containing tutorials for the 3D printer, engraver and CNC carver to help you get started, and if you encounter any serious problems, you can return it within its warranty.Though only offering a small build volume, the TOYDIY is a great entry level multifunctional 3D printer.

If you liked this article, you may also be interested in:

- Our guide to the best 3D pens

- Our guide to the best 3D scanners

- The complete dual extruder 3D printer buyer’s guide

- Our ranking of the best FDM 3D printers

Best 3D Printer, Laser Engraver, CNC Carver for Sale

Snapmaker 2.0 Modular 3-in-1 3D Printer A350T/A250T

Snapmaker 2. 0 Modular 3D Printer F350/F250

0 Modular 3D Printer F350/F250

Quick view

Snapmaker Artisan 3-in-1 3D Printer with Enclosure

Regular price $2,999.00 Sale price $2,799.00

Quick view

Snapmaker Rotary Modules

Regular price $569.00 Sale price from $455.20

Quick view

Snapmaker Air Purifier

Regular price $499.00 Sale price $399.20

Quick view

White Breakaway PLA Filament (1 kg)

$54.99

Quick view

Hot End for Dual Extrusion Module

from $49.99

Quick view

Snapmaker 10W High Power Laser Module

Regular price $459.00 Sale price from $367.20

Quick view

Snapmaker CAN Hub

$59.00

Quick view

ABS Filament (1 kg)

$24. 99

99

Quick view

Black Nylon Filament (1kg)

$59.99

Quick view

Snapmaker 3D Printing Module

Regular price $149.00 Sale price $89.40

Quick view

Extension Cord for Rotary Module (1.5m)

$7.99

Quick view

PEI Glass Plate for Snapmaker Artisan

$54.99

View all

Quick view

Snapmaker 2.0 Modular 3-in-1 3D Printer A350T/A250T

Regular price $1,499.00 Sale price from $1,124.25

Quick view

Snapmaker 2.0 Modular 3D Printer

Regular price $999.00 Sale price from $749.25

Quick view

Snapmaker Dual Extrusion 3D Printing Module

Regular price $599.00 Sale price $399. 00

00

Quick view

Snapmaker 10W High Power Laser Module

Regular price $459.00 Sale price from $367.20

Quick view

Snapmaker Rotary Modules

Regular price $569.00 Sale price from $455.20

Quick view

Enclosure for Snapmaker 2.0

Regular price $399.00 Sale price from $319.20

Quick view

Snapmaker Air Purifier

Regular price $499.00 Sale price $399.20

Quick view

Glow-in-the-dark Green PLA Filament (1kg)

Regular price $27.99 Sale price $22.39

Quick view

Wood PLA Filament (750g)

Regular price $29.99 Sale price $23.99

Quick view

Snapmaker 2. 0 Emergency Stop Button

0 Emergency Stop Button

Regular price $59.00 Sale price $47.20

Quick view

Power Module for Snapmaker 2.0

Regular price $129.00 Sale price $77.40

Quick view

Linear Module for Snapmaker 2.0

Regular price $349.00 Sale price from $209.40

View all

Snapmaker

MAKE SOMETHING WONDERFUL

Modular 3-in-1 3D Printers

Turn Your Desktop into a Workshop

Future Expansions

Modular Design

Snapmaker is more than just a series of machines. The creative application of the Controller Area Network realizes modularity, based on which you can enjoy a lot of amazing features simply by getting new modules or add-ons.

Shop Addons

Snapmaker Luban

Free 3-in-1 Software

Snapmaker Luban is a free, open source CAM software committed to software services that allow full controls over 3D printing, laser engraving and cutting, and CNC carving capabilities.

Learn More

REVIEWS FROM SNAPMAKER USERS

from 2842 reviewsRyan Daw

07/18/2022

Amazing!

Was able to make highly detailed images on tile with absolutely no problems Very impressive results on tile

Laser Engraving and Cutting Platform for Snapmaker 2.0

Nicolas Belin

06/30/2022

Great Snapterrarium ehh Snapmaker.

Great Snapterrarium ehh Snapmaker.

Works great. Had a faulty touchscreen but SM send me a new one and now all works like a charm.

Snapmaker 2.0 Modular 3D Printer

Jaime Ramirez

05/09/2022

Very good laser

My first job was a vernier on my 1600mw module it took 55 min to cut, now with the 10W module only 9 min.

Snapmaker 10W High Power Laser Module

Eric Worrall

04/14/2022

Does exactly what it says

I’ve loved my Snapmaker since I unboxed it.

It’s not perfect, it’s complex, you need to dedicate time to learning 3D technology. The software sometimes needs to be restarted to work, and sometimes has annoying bugs.

The software sometimes needs to be restarted to work, and sometimes has annoying bugs.

But the engineering precision is breathtaking, I’ve created beautiful 3D PLA prints which don’t need finishing, high quality mechanical parts, like a bicycle pump holder, and ornate wooden gift boxes with laser engraved messages for loved ones.

If you have the commitment and time to learn a new skill, Snapmaker will help you realise your creative vision.

Snapmaker 2.0 Modular 3-in-1 3D Printers

Robert Allard

03/24/2022

A good addition to my a350

Very satisfied with my purchase, and service for helping me with problems I had assembly.

Enclosure for Snapmaker 2.0

Mike L

03/12/2022

Printing in an hour!

Was really impressed with how easy it went together, I was up and printing in about an hour, easy calibration and no fussing. Awesome choice for a first-timer! Simple software, takes up little space and the smaller bed is still big enough for most jobs any first-timer would want. Laser engraving works well too! No regrets choosing Snapmaker as my first printer, great value for $$. Highly recommend it! Pictured: Enigma Rotor replica

Laser engraving works well too! No regrets choosing Snapmaker as my first printer, great value for $$. Highly recommend it! Pictured: Enigma Rotor replica

Snapmaker Original 3-in-1 3D Printer

Maker Leigh

02/10/2022

It's my second one :-)

This was my second SM2 350 purchase, Chrismas sale provided a cheap way to upgrade my set up. Super fast delivery over new year in the UK. Well done Snapmaker.

Snapmaker 2.0 Modular 3D Printer

wentsung Peng

09/22/2021

Small problems with using Straight Groove V-bit

I used the Straight Groove V-bit to complete the Rotary Module CNC Carving a few days ago, and everything was almost perfect. My material is wood with a diameter of 50cm. When the Straight Groove V-bit goes deep into the center of the wood, because the radius of the wood exceeds the length of the flute, the wood touches the shaft and generates a lot of friction and noise, causing the 3-jaw Chuck to loosen. The diameter of 3-jaw Chuck Inward-clamping of Rotary Module can reach 60CM. The above problem may be more obvious. Is there a solution?

The above problem may be more obvious. Is there a solution?

Straight Groove V-bits (3 Bits)

Yousif Alsabbagh

09/20/2021

A350

The only negative point is that the machine makes loud noise, other than that it’s fantastic!

Snapmaker 2.0 Modular 3-in-1 3D Printers

The Snapmaker is a hybrid 3D printer, laser etcher, and CNC cutter all in one machine. This isn't the first hybrid we've tested, and while hybrids are capable of doing all the tasks they advertise, they tend to do so with compromises. But with the Snapmaker, I still found it to be a great little printer.

Make: Magazine

Performing an admirable job across three distinct functions, the Snapmaker is a maker’s dream tool for small-scale work. There are better individual tools that cost less than the Snapmaker’s $799, but few, if any, that challenge it for 3D printing, laser engraving and CNC carving all in one.

ALL3DP

The Snapmaker 3-in-1 3D printer doesn’t pretend to be anything it is not.

The presentation and ease of assembly are testament to a company who is clear in their objective, to provide an entry level and affordable solution for those seeking an introduction to not only 3D printing, but the broader world of Makers.

3DPI

It's the best 3D printer packaging I've seen in my life, and I've used many 3D printers over the last years. The assembly process was really easy. Even a friend found it easy, and she didn’t have any previous experience with 3D printing.

Agustin Flowalistik

REVIEWS FROM SNAPMAKER USERS

from 2842 reviewsRyan Daw

07/18/2022

Amazing!

Was able to make highly detailed images on tile with absolutely no problems Very impressive results on tile

Laser Engraving and Cutting Platform for Snapmaker 2.0

Nicolas Belin

06/30/2022

Great Snapterrarium ehh Snapmaker.

Great Snapterrarium ehh Snapmaker.

Works great. Had a faulty touchscreen but SM send me a new one and now all works like a charm.

Snapmaker 2.0 Modular 3D Printer

Jaime Ramirez

05/09/2022

Very good laser

My first job was a vernier on my 1600mw module it took 55 min to cut, now with the 10W module only 9 min.

Snapmaker 10W High Power Laser Module

Eric Worrall

04/14/2022

Does exactly what it says

I’ve loved my Snapmaker since I unboxed it.

It’s not perfect, it’s complex, you need to dedicate time to learning 3D technology. The software sometimes needs to be restarted to work, and sometimes has annoying bugs.

But the engineering precision is breathtaking, I’ve created beautiful 3D PLA prints which don’t need finishing, high quality mechanical parts, like a bicycle pump holder, and ornate wooden gift boxes with laser engraved messages for loved ones.

If you have the commitment and time to learn a new skill, Snapmaker will help you realise your creative vision.

Snapmaker 2.0 Modular 3-in-1 3D Printers

Robert Allard

03/24/2022

A good addition to my a350

Very satisfied with my purchase, and service for helping me with problems I had assembly.

Enclosure for Snapmaker 2.0

Mike L

03/12/2022

Printing in an hour!

Was really impressed with how easy it went together, I was up and printing in about an hour, easy calibration and no fussing. Awesome choice for a first-timer! Simple software, takes up little space and the smaller bed is still big enough for most jobs any first-timer would want. Laser engraving works well too! No regrets choosing Snapmaker as my first printer, great value for $$. Highly recommend it! Pictured: Enigma Rotor replica

Snapmaker Original 3-in-1 3D Printer

Maker Leigh

02/10/2022

It's my second one :-)

This was my second SM2 350 purchase, Chrismas sale provided a cheap way to upgrade my set up. Super fast delivery over new year in the UK. Well done Snapmaker.

Snapmaker 2.0 Modular 3D Printer

wentsung Peng

09/22/2021

Small problems with using Straight Groove V-bit

I used the Straight Groove V-bit to complete the Rotary Module CNC Carving a few days ago, and everything was almost perfect. My material is wood with a diameter of 50cm. When the Straight Groove V-bit goes deep into the center of the wood, because the radius of the wood exceeds the length of the flute, the wood touches the shaft and generates a lot of friction and noise, causing the 3-jaw Chuck to loosen. The diameter of 3-jaw Chuck Inward-clamping of Rotary Module can reach 60CM. The above problem may be more obvious. Is there a solution?

Straight Groove V-bits (3 Bits)

Yousif Alsabbagh

09/20/2021

A350

The only negative point is that the machine makes loud noise, other than that it’s fantastic!

Snapmaker 2.0 Modular 3-in-1 3D Printers

"budget" laser 3D printer for printing with metal powders

News

compositions costing only half a Gelendvagen (we used to measure in Rolls-Royces).

One Click Metal is, in fact, a subsidiary of the well-known German engineering company Trumpf, which is also engaged in the production of industrial additive installations. The startup entered the market in 2019showcasing the first version of a PBF 3D printer of its own design called MPRINT at Formnext. The company is trying to find a specific niche, namely the production of low-cost additive systems for 3D printing with metal powders. Budget is a relative concept, but shortly before the premiere, One Click Metal CEO Bjorn Ullman estimated the cost at fifty thousand euros. In fact, the original 3D printers cost about that much, while the upgraded systems are offered for one and a half times more, but still much cheaper than most competitive offers ranging from a quarter to half a million dollars.

The updated MPRINT+ model differs from the original in a number of improvements aimed primarily at improving performance and resolution. The 3D printer is equipped with a more powerful 200-watt fiber laser compared to the 100-watt in the original version. With the positioning system, not everything is clear yet. The fact is that the original used a moving head with a diode laser from Trumpf - imagine your FDM 3D printer, but with an engraving laser nozzle on steroids. We have already seen something similar on the XM200 and XM300 3D printers of the American company Xact Metal.

The new system allegedly uses a galvanometric scanning system that provides hatching speeds up to 3 m/s. Ullman at one time argued that a radical reduction in the cost of equipment became possible precisely due to the development of his own, relatively inexpensive scanner, so that a noticeable price jump can be fully explained by the transition to a more complex and expensive, but at the same time faster and more accurate galvanoscanner, if such the transition actually took place. Xact Metal, by the way, did just that, a year after the premiere, remaking the XM200 into the XM200S.

The spot diameter is 45 microns versus 100 microns for the original MPRINT, the layer thickness is set within 20-80 microns, the size of the construction area is 150x150x150 mm, and the density of finished products reaches 99. 5%. Printing is carried out in a sealed chamber with a protective nitrogen atmosphere, which allows you to work with active metals and alloys. The company's range of consumables currently includes powders based on aluminium, stainless steel and tool steel.

System accepts four consumable cartridges with 250% overload to reduce downtime. Cartridges are equipped with NFC tags to help you track media type and stock. An optional MPURE station with ultrasonic screening is available for cleaning finished products and preparing residual materials for reuse. The MPREP software is responsible for preparing digital 3D models and managing workflows.

And the moment you've all been waiting for is the cost. The MPRINT+ 3D printer is offered at a selling price of €76,900, and an additional €21,500 will have to be paid for the MPURE station. Additional information is available on the official website of the manufacturer.

Thomas Sunladerer's interview with Bjorn Ullmann about the original MPRINT system (2019):

PBF One Click Metal MPRINT+

Follow author

Follow

Don't want

5

More interesting articles

7

Subscribe to the author

Subscribe

Don't want

In July, the international isolation experiment SIRIUS-21 ended in Moscow, which lasted 240 days...

Read more

6

Follow the author

Subscribe

Don't want to

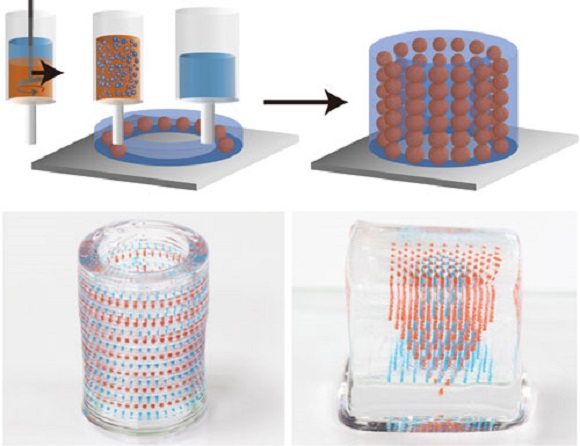

A new method called iCLIP created with the participation of Professor DeSimon - co-founder and CEO ...

Read more

sarkazm

Loading

04/01/2016

39725

68

Subscribe to the author

Subscribe

Don't want

News from the world of printing in a short line

FDplast announced the release of a free. ..

..

Read more

90,000 laser 3D metal printer, industrial 3D printers of the new generation, a printer printer printingJewelry industry

Medicine

3D printer

Science and education

Author: Semen Popadyuk

Author: Author Semyon Popadiuk

Top 7 Benefits of Sharebot MetalONE | Applications and Consumables | How MetalONE was created | Key Features of the 3D Printer

Metal 3D printing is the most complex of additive technologies, but the path to it may be easier than you think. Freedom of design, the ability to optimize the design, reduce the weight of the product and the number of elements in the assembly, the use of materials with unique properties - all these advantages of the technology are invaluable for experimental and research work, the ultimate goal of which is to quickly and efficiently create new high-tech products (or upgrade existing ones), taking production capabilities to the next level.

The integration of metal 3D printers into the production process is associated with considerable difficulties. A metal printer is an installation that requires a large investment, a special facility, strict operating conditions, additional equipment, and a highly skilled operator.

However, recent trends suggest that metal printing can become, as they say, “closer to the people”. When we visited the largest Formnext exhibition in Frankfurt am Main in 2019, we noted the appearance of compact metal 3D printers. These machines have a simplified functionality and are focused primarily on the scientific and educational sphere and small and medium-sized businesses.

One of the most attractive installations in this category in terms of price and quality is called MetalONE and is based on the direct metal laser sintering (DMLS) method. This is a new product of the Italian company Sharebot, which has a solid experience in the development of several 3D printing technologies. The printer is designed for research, product testing and manufacturing of small and medium-sized parts.

The printer is designed for research, product testing and manufacturing of small and medium-sized parts.

Can 3D printing help you optimize production in your organization? Book a consultation with iQB Technologies experts. Services such as 3D training, test 3D printing/3D scanning, site visits, diagnostics or ordering 3D equipment are also available.

MetalONE Metal 3D Printer: Top 7 Benefits of

- Compact working chamber (65 x 65 x 100 mm).

- High performance.

- Economy.

- Possibility of using argon and nitrogen.

- Intuitive, easy to edit print options.

- Easy to operate.

- Low maintenance cost.

Applications and Consumables

This metal 3D printer will be indispensable in the following industries:

- R&D;

- industry;

- dentistry;

- jewelry.

Sharebot CEO Arturo Donghi with MetalONE 3D printer and printed samples

The additive setup is ideal for exploring new materials, and thanks to its small build chamber and DMLS technology, it allows you to create objects from a small amount of metal powder - only 800 g. In addition, the user can edit all process parameters, which will be recorded in a log after printing is completed. With a 250W fiber laser and the ability to use both nitrogen and argon, virtually any powder can be tested.

For industrial applications, the printer is capable of prototyping small parts with incredible precision and producing them quickly and without significant difficulty. Unrivaled print repeatability ensures low-volume production with consistently high quality.

Cobalt-chromium alloys (CoCrMo), which are widely used in dentistry, are also applicable in MetalONE. For dental laboratories, this is a real boon: the 3D printer prints metal fillings, crowns and caps in less than an hour and is exceptionally easy to use.

Due to the compactness and special structure of paper filters, the printer will also be beneficial in the additive manufacturing of jewelry and other miniature products, as it allows you to quickly create objects with the highest degree of detail.

Sharebot's R&D department, in collaboration with several universities, has developed profiles for 316L steel and cobalt chromium, and continues to test new powders for metal laser 3D printer. Next in line are profiles for titanium and aluminum.

How MetalONE

was created Work on the metal printer project began in 2015. At the same time, Sharebot was developing SnowWhite, a machine for printing with thermoplastic powder using SLS technology. After the successful implementation of SnowWhite in different countries, Sharebot gained enough experience to launch a metal 3D laser printer project. It includes other types of powders, software, mechanical components, and build chamber design (involving the creation and maintenance of a modified environment), but this machine can be considered a direct continuation of SnowWhite.

It includes other types of powders, software, mechanical components, and build chamber design (involving the creation and maintenance of a modified environment), but this machine can be considered a direct continuation of SnowWhite.

In March 2019, the first prototype of the machine and the first samples were presented at the MECSPE exhibition in Parma. In the following months, various models were printed to test the metallurgical properties of the objects and their quality, as well as the reliability of the printer itself and the repeatability of printing. All parameters of the printing process are available to the user, allowing you to explore and explore new materials and applications.

So, Sharebot MetalONE will be a profitable solution if you need to research and test complex small-sized products, material properties, and also produce small series.

Key Features of

3D Printer- Build chamber: 65 x 65 x 100 mm

- Layer thickness: 5-200 microns

- Laser: fiber, 250 W (1080 nm)

- Spot diameter: 40 microns

- Maximum speed: 5 m/s

- Software: Simplify 3D - Continuum

- Printer dimensions / weight: 740 x 630 x 1000 mm / 170 kg

MetalONE is available for order on sharebot.