3D printed concrete house youtube

Habitat for Humanity's 3D-Printed Concrete Home for a Family

Photos: Habitat for Humanity's 3D-Printed Concrete Home for a Family Search iconA magnifying glass. It indicates, "Click to perform a search". Insider logoThe word "Insider".US Markets Loading... H M S In the news

Chevron iconIt indicates an expandable section or menu, or sometimes previous / next navigation options.HOMEPAGE Save Article IconA bookmarkShare iconAn curved arrow pointing right.Download the app

The exterior of the Habitat for Humanity 3D-printed house in Virginia.- Habitat for Humanity partnered with Alquist, a 3D-printing home-construction company.

- Together, the team built a 3D-printed concrete home in Virginia for a mother and her son.

- See inside the three-bedroom, two-bathroom home with a zero-interest mortgage.

- See more stories on Insider's business page.

On December 21, 2021, Habitat for Humanity dedicated its newest home built in Virginia to a woman named April Springfield and her 13-year-old son.

The ribbon-cutting ceremony for Habitat for Humanity’s 3D printed home. Habitat for Humanity Peninsula and Greater Williamsburg

Habitat for Humanity Peninsula and Greater Williamsburg Source: Habitat for Humanity, NPR

The three-bedroom, two-bathroom unit may look like your typical suburban residence, but the walls of the home hide a secret that may be unnoticeable to an oblivious passerby.

The exterior of the Habitat for Humanity 3D printed house in Virginia. Habitat for Humanity Peninsula and Greater WilliamsburgUnlike traditionally constructed homes made of lumber and bricks, the team used a 3D printer and concrete, among other materials, to build the new Virginia house.

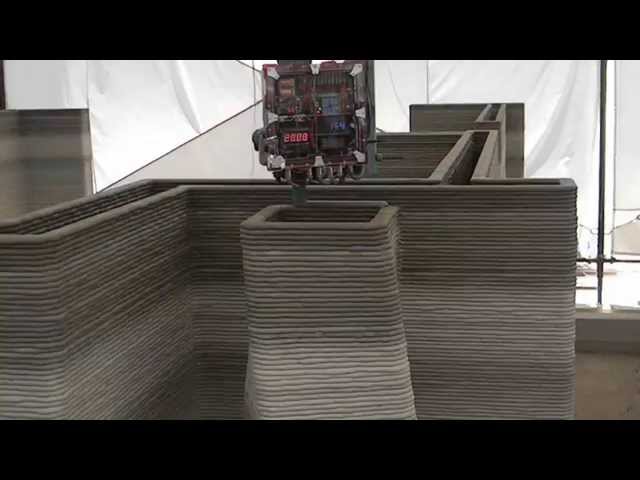

A 3D printer printing Habitat for Humanity's home in Virginia. Habitat for Humanity Peninsula and Greater Williamsburg

A 3D printer printing Habitat for Humanity's home in Virginia. Habitat for Humanity Peninsula and Greater Williamsburg But the nonprofit didn't do it alone: Habitat for Humanity partnered with Alquist, a 3D-printing home-construction company, to create the single-story abode.

People installing roof trusses onto Habitat for Humanity's 3D printed house in Virginia. Habitat for Humanity Peninsula and Greater Williamsburg

Habitat for Humanity Peninsula and Greater Williamsburg This isn't Habitat for Humanity's first 3D-printing rodeo, but this is the organization's first completed printed home in the US.

Stephen Abbitt, Habitat for Humanity's president, on the construction site. Habitat for Humanity Peninsula and Greater WilliamsburgSource: Habitat for Humanity

In March 2021, the nonprofit began using Germany-based Peri's Cobod "build on-demand printer" — or the BOD2 — to 3D-print a home in Tempe, Arizona.

The home is expected to close in February. The site of the 3D-printed home in Tempe, Arizona. Habitat for Humanity

The home is expected to close in February. The site of the 3D-printed home in Tempe, Arizona. Habitat for Humanity Source: Insider

"If we can deliver decent, affordable, more energy-efficient homes at less cost, in less time and with less waste, we think that could be a real game-changer," Jason Barlow, president and CEO of Habitat Central Arizona, said in the press release at the time, echoing other 3D printing home builders.

Someone installing metal "ladders" into the walls for added strength. Habitat for Humanity Peninsula and Greater Williamsburg

Someone installing metal "ladders" into the walls for added strength. Habitat for Humanity Peninsula and Greater Williamsburg Source: Insider

Now, Habitat for Humanity has delivered its 3D-printing dream to the East Coast with the help of another Cobod partner, Alquist.

The 3D printer laying the foundation of the home. Habitat for Humanity Peninsula and Greater Williamsburg

Habitat for Humanity Peninsula and Greater Williamsburg Source: Insider

The team began constructing and printing the Virginia home in late July 2021.

April Springfield watching the 3D printer. Habitat for Humanity Peninsula and Greater WilliamsburgThey then spent 28 hours printing the 1,200 square-foot home's exterior concrete walls .

.. A carpenter bolting down pillars that'll be used to hold the 3D printer. Habitat for Humanity Peninsula and Greater Williamsburg

.. A carpenter bolting down pillars that'll be used to hold the 3D printer. Habitat for Humanity Peninsula and Greater Williamsburg Source: Habitat for Humanity

... reducing construction time by four weeks compared to traditional building methods, according to a press release.

The 3D printer layering cement for the home. Habitat for Humanity Peninsula and Greater Williamsburg

Habitat for Humanity Peninsula and Greater Williamsburg Source: Habitat for Humanity

Like the Tempe, Arizona home, the goal of the Williamsburg, Virginia home was to address the US' ongoing housing crisis, specifically skyrocketing home prices and slow build times.

A 3D printer printing Habitat for Humanity's home in Virginia. Habitat for Humanity Peninsula and Greater WilliamsburgAlquist's printing system uses concrete, creating a time and money-saving method of construction.

April Springfield watching the 3D printer. Habitat for Humanity Peninsula and Greater Williamsburg

April Springfield watching the 3D printer. Habitat for Humanity Peninsula and Greater Williamsburg Source: Habitat for Humanity

The concrete also insulates the home while making it tornado and hurricane resistant, according to the nonprofit.

A 3D printer printing Habitat for Humanity's home in Virginia. Habitat for Humanity Peninsula and Greater Williamsburg

Habitat for Humanity Peninsula and Greater Williamsburg Like other 3D-printed concrete homes, the exterior walls look akin to stacks of piped icing on a cake.

The exterior of the Habitat for Humanity 3D printed house in Virginia. Habitat for Humanity Peninsula and Greater WilliamsburgBut inside, the home looks like any typical new build with a kitchen lined with shiny appliances and an island …

The kitchen inside Habitat for Humanity's 3D printed house in Virginia. Habitat for Humanity Peninsula and Greater Williamsburg

Habitat for Humanity Peninsula and Greater Williamsburg Source: Habitat for Humanity

… a dining and living room …

The kitchen inside Habitat for Humanity's 3D printed house in Virginia. Habitat for Humanity Peninsula and Greater Williamsburg… a laundry room, a coat closet …

The laundry room inside Habitat for Humanity's 3D printed house in Virginia. Habitat for Humanity Peninsula and Greater Williamsburg

Habitat for Humanity Peninsula and Greater Williamsburg … two side-by-side bedrooms …

A bedroom inside Habitat for Humanity's 3D printed house in Virginia. Habitat for Humanity Peninsula and Greater Williamsburg… and a large primary bedroom with a walk-in closet and en-suite bathroom.

A bedroom inside Habitat for Humanity's 3D printed house in Virginia. Habitat for Humanity Peninsula and Greater Williamsburg

A bedroom inside Habitat for Humanity's 3D printed house in Virginia. Habitat for Humanity Peninsula and Greater Williamsburg The home also comes with a 3D printer so the Springfield family can print their own home necessities, like doorknobs and light switch covers.

Someone from Alquist showing April Springfield how to use the 3D printer. Habitat for Humanity Peninsula and Greater Williamsburg

Habitat for Humanity Peninsula and Greater Williamsburg But Habitat for Humanity doesn't gift its homes for free.

A contractor installing the floor inside Habitat for Humanity's 3D printed house in Virginia. Habitat for Humanity Peninsula and Greater WilliamsburgInstead, it sells its houses to people with "excellent" credit and an income that falls between 45 to 80% of the neighborhood's median income, the nonprofit says.

The exterior of the Habitat for Humanity 3D printed house in Virginia. Habitat for Humanity Peninsula and Greater Williamsburg

The exterior of the Habitat for Humanity 3D printed house in Virginia. Habitat for Humanity Peninsula and Greater Williamsburg Source: Habitat for Humanity

But in exchange for her hundreds of volunteer hours, Springfield now has a home with a zero-interest mortgage.

The exterior of the Habitat for Humanity 3D printed house in Virginia. Habitat for Humanity Peninsula and Greater Williamsburg

Habitat for Humanity Peninsula and Greater Williamsburg The home will also have solar panels, among other tech, to reduce the family's future energy bills.

A light switch inside Habitat for Humanity's 3D printed house in Virginia. Habitat for Humanity Peninsula and Greater Williamsburg"I always wanted to be a homeowner," Springfield said through tears during the ribbon-cutting ceremony of her new home.

"It's a dream come true." April Springfield at the dedication ceremony for Habitat for Humanity’s 3D printed home. Habitat for Humanity Peninsula and Greater Williamsburg

"It's a dream come true." April Springfield at the dedication ceremony for Habitat for Humanity’s 3D printed home. Habitat for Humanity Peninsula and Greater Williamsburg Read next

LoadingSomething is loading.

Thanks for signing up!

Access your favorite topics in a personalized feed while you're on the go.

3d printed home 3D Printing Housing CrisisMore...

MudBots 3D Concrete Printers - Print a House

Our printers come in a variety of sizes, from smaller 15'x15' up to 100'x50'

Shop Printers

Want to see how much you will save when 3D Printing a home versus traditional building? Check out our cost calculator.

Cost Calculator

Marketable Designs

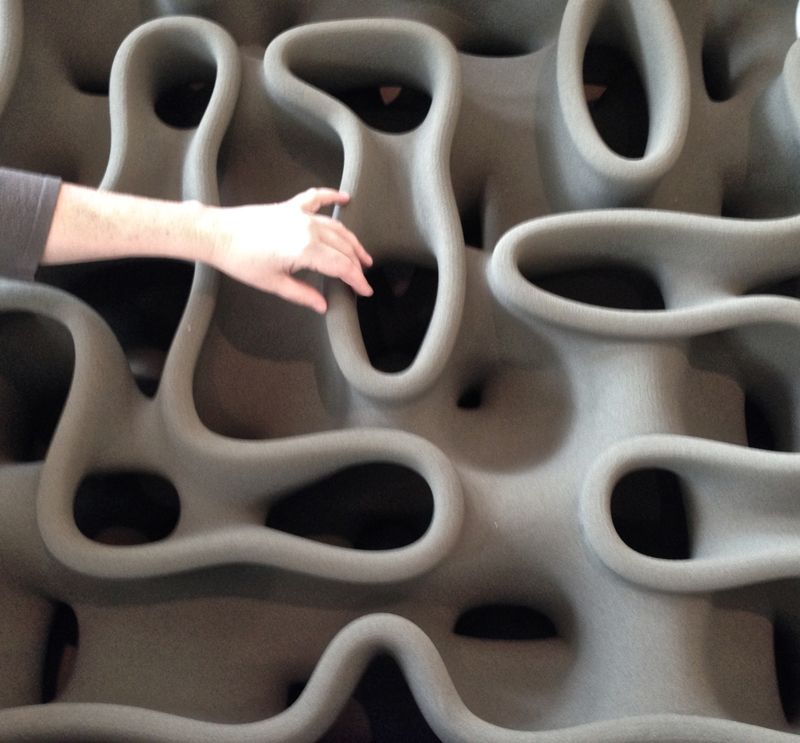

We’ve been told that if the printer wasn’t any faster and wasn’t any cheaper to build with, it would still be the most significant tool ever, because it allows architects everywhere to begin offering designs that were cost prohibitive in the past.

Consumers are tired of the costs associated with conceptual designs. Traditional construction is limiting without astronomical costs. Architects have the ideas, but most consumers aren’t willing to pay for them. With a printer the cost between boring and amazing is the same.

Industries

Want to build one? Call us.

3D Print Walls

Want to build one? Call us.

3D Print Fireplace

Want to build one? Call us.

3D Print Monument Letters

Want to build one? Call us.

3D Print Benches

Want to build one? Call us.

3D Print Fences and Walls

Want to build one? Call us.

3D Print Signs

Want to build one? Call us.

3D Print Monuments

Want to build one? Call us.

3D Print Fountains

Want to build one? Call us.

3D Print Retainer Blocks

Want to build one? Call us.

3d Print Monument and Waterfalls

Want to build one? Call us.

3D Print Planters

Want to build one? Call us.

3D Print Sheds

Want to build one? Call us.

3D Print Monument Boulders

Want to build one? Call us.

3D Print Drainage

Want to build one? Call us.

No More Forming

Want to build one? Call us.

3D Print Stairs

How It Works

1

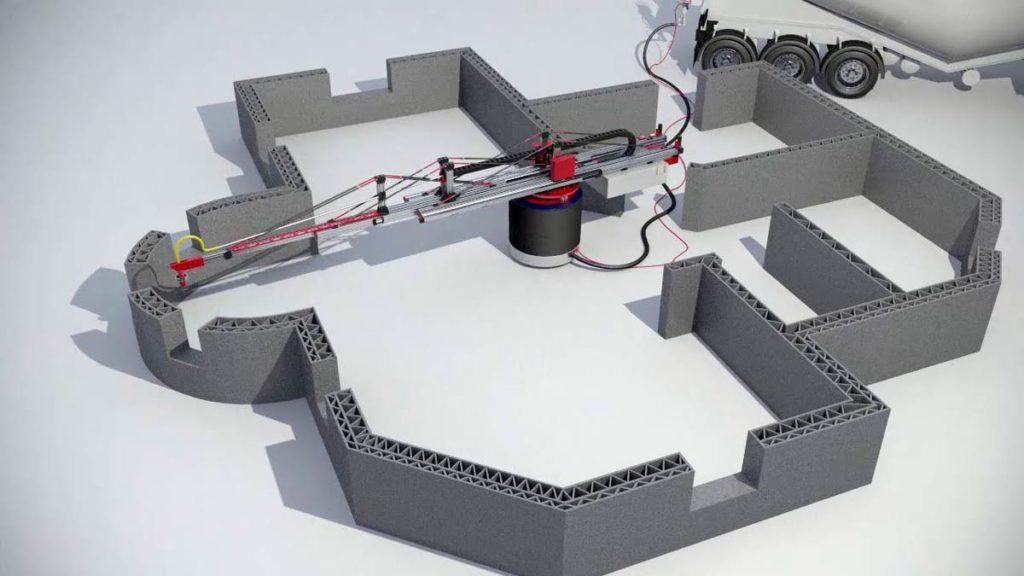

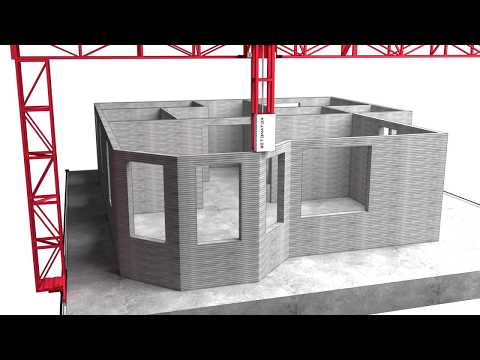

Concrete printing is possible with the construction of a large 3D printer capable of printing large scale structures, from spas and barbeques to homes and larger commercial buildings, without the need of traditional framing, forming or blocks. MudBots offers printers from 15' x 15' up to 100' x 100'.

MudBots offers printers from 15' x 15' up to 100' x 100'.

2

There are hundreds of different mix formulas that closely resemble a mortar type mix. Each mix requires months of testing for different characteristics, such as fluidity, bonding, water impenetrability, Seismic resistance, as well as curing and strength. Mixes are designed for 1200 PSI up to 10,000 PSI, depending on the structure and engineered objectives.

3

First step is to decide what you want to print.

4

The next step is to conceptualize a 2D design using a CAD program, and then converting the design to a 3D model using any 3D software that can export an STL file.

5

Once the 3D model is ready, the STL file is imported into a slicing software, where the height of each printed pass is specified.

After slicing the model into individual print passes, the system exports the code which is interpreted into actual nozzle movement.

6

Electrical boxes and plumbing are added during the print leaving perfect finish without gaps.

7

The mix is batched on site after which, the liquid ingredients are added to the dry mixes and mixed for delivery to a computer-controlled pump, which works in unison with the printer to control nozzle speed, and the volume rate of material at the nozzle.

8

After printing the walls, windows and doors are cut out while the print is still green, leaving perfect openings for window/door casings.

9

The key to printing without stopping every 12" as seen by the rest of the world, is utilizing a batch plant that meters all the dry and liquid ingredients as the temperature, wind and humidity change. the mix formula being used at 5am is not the mix being used an hour later. MudBots provides a variety of mix formulas with differing strengths and cure times without being forced to buy proprietary mixes and paying 5 times as much when everything needed is already available at local batch plants.

Process

Step 1

Three men assembly in 3 hours without any lifting devices or need for heavy footings

Step 2

Print layout for footings with spray nozzle attachment

Step 3

Move printer for escavators in just 10 minutes

Step 4

Print forms for footings and flatwork

Step 5

Print walls up to 10' without stopping

Step 6

Add electrical boxes, rebar, and trowel walls while printing

Understanding What We Do & Don't Do

Here's how you can save.

Layout for Footings Dig

The first cost savings will be the elimination of 3 men, string lines, and marking paint. Simply add the airless attachment to the nozzle of the printer, and your entire layout for footing is done in minutes. Push the printer out of the way and start digging.

(The printer is able to print forms for footings)

Footing Forming

The layout and forming for footings and stem walls are very time-consuming. It takes a lot of lumber, diesel, stakes, and labor that is no longer necessary. Simply level the area, compact them, level the four corners of your printer, and PRINT.

(Forms do not need to be stripped when printed)

Footing Stripping

Perfect level and square forms are printed right from the computer. Grading is also easier, as the only real important level is the 4 corners of the printer. Printer can be set up for uneven grades.

Printer can be set up for uneven grades.

(The printer can print the forms for slab)

Slab Forming

The slab layout and forming is critical to all other subs on the job. If a mistake is made at this point of the project, nothing else is square, and all other subs suffer. With the Concrete Printers, the house is square every time.

Slab Finishing

Not there yet, but our concrete printer will be finishing slabs within the next 6 to 12 months, and can be ordered as an option. If you’re waiting for all the options to be available before buying, you’ll never buy a printer, because we will never stop innovating. All upgrades will be available and are designed to be added to all of our printers.

(We can print basements)

Basements

Our printers easily print basement walls without the need of forming, backfilling, stripping forms, forming interior walls, drywall, insulation or taping. All of this is done by the printer.

All of this is done by the printer.

(There is no need for the labor or time to do layout on slab)

Framing Layout

The printer knows where your wall is going to be. No chalk lines needed. Once the slab is poured, all you have to do is hit print.

(No need for framing)

Framing

No warped studs, better fire rating, no mildew. No matter how you look at it, printing a home is far better than framing a home. Concrete printing is faster, more accurate, just better all around.

(No need to drill studs for electrical)

Rough Electrical

This is not necessary as walls can be printed that are hollow. Depending on the mix that is used, there is also no need for rebar or solid pour exterior and bearing walls. We know the idea of exterior walls and bearing walls without rebar seems ridiculous, but it's time to learn something new. Look up 20,000 PSI concrete and geopolymer. It's real.

Look up 20,000 PSI concrete and geopolymer. It's real.

(No need to drill studs for plumbing)

Rough Plumbing

This isn’t necessary as walls can be printed hollow. Same as above. Your electrical and plumbing will be less expensive.

(Printed walls are finished without additive material during the print)

Drywall

You will still need to hang the lid, but not the walls. This goes for the basement. Just trowel the printed wall and when done, it's as smooth as a 3-coat drywall. Most countries do not wood frame at all. They build with bricks and then send a crew of mason finishers, and when it’s done, it’s smooth as anything.

(No need for taping as the walls are troweled smooth during printing)

Taping

Some print finishes may not need to be finished if acceptable to the customer. Taping takes days for each coat to dry. This is not the case with mason finishing. Within 3 hours of the walls being printed, the walls are already finished.

Taping takes days for each coat to dry. This is not the case with mason finishing. Within 3 hours of the walls being printed, the walls are already finished.

Finishes

If builders want to finish the smooth walls with a knock down broquet, orange peel or other finish, just come back the next day and spray with a hopper, top coat and trowel.

(Exterior walls are finished during the print)

Stucco / Siding

No paper, mesh or additive material is needed. This isn't a process that is done days after framing and sheeting. The finish is done real time as the wall is printing.

(Printers can be purchased with an insulation attatchment)

Insulation

You can have any R Factor you want depending on the density and material. A solid concrete wall has an R9 Value. If you print a hollow wall and back fill with fiberglass, polystyrene or cellulose, you can achieve any R value you desire.

(Mudbots is working on a composite truss system that can be printed on site)

Trusses

Additionally, house plans can be modified to allow for dome roofing, which can also eliminate trussing and sheeting costs. The truss system utilizes the same printer, but with the use of a different mixer/pumping system. As new advances become available, they will be bolt-on solutions with your existing printer.

Underground

More and more customers are starting to experiment with additional uses. Underground is definitely something worth considering. The cost is high for underground but can be significantly reduced by printing on site.

Landscape and Hardscape

The 3D Concrete Printer is a landscaper’s dream. Never before could you have offered products at a fraction the cost of your competition while still earning profits. It is basically unheard of. Developers will rethink their offerings when they realize how affordable the little extras are. The extras will set them apart from all the others.

The extras will set them apart from all the others.

Pool and Spa

By now, you may be realizing how significantly concrete printing is about to change so many industries. Pool and spa is just another market that will benefit. The cost for traditional pool construction is about to change. Homes can be sold with included water features at a fractional cost.

Signage

Very seldom do we see breathtaking signage. Everyone is looking for ways to stand out, but it keeps getting back to budgets. Imagine the development entries that are possible now. These printers like to print and with everything they can do, it would be foolish to have any down time.

Registration is required to access our Cost Calculators. We provide online tools for calculating the cost for mix formulas and “side by side” project costs comparisons using 3D technology.

Apples Comparison Test New

Complete the worksheet to have a better idea of where you will save in terms of Materials and Labor.

Bag Cost

Use this worksheet to determine the Cubic Inch Cost of the ingredients that will be used in the specialty mix for printing.

Mix Formula

This is a necessary first step to determine the material cost of any mix formula.

3D Printing Costs

Use this calculator to estimate costs to build using concrete printing over traditional construction methods.

Will It Pass Code?

First time callers don’t have any problem recognizing that concrete printing would be far faster and cheaper. They also don’t question the feasibility of learning the tech. The single most asked question relates to passing code. No fear of the tech, just fear of their building department.

Truth is concrete printers are already building homes and commercial buildings all around the world, so when considering the application in your backyard, here are a few things to consider.

ICF Construction

The best way to wrap your head around concrete printing is to start with the basics, and there is no better way than to liken 3D Concrete Printing, or 3DCP, to Insulated Concrete Block construction. ICF code is accepted everywhere yet a foam block has virtually no structural strength at all. So when you are considering how you would pass code, keep ICF in mind. For the most part, a concrete printer is doing nothing more than printing a hollow wall shell that can be filled with rebar and concrete. The only difference is foam has no strength at all, compared to what we print in most cases, which is twice the strength of cinderblock.

CMU Construction

Now with that in mind, let's look at the similarities with CMU (Cinderblock). No one questions the ability to build with cinderblock. While we don’t encourage it, take into consideration the fact that you can print walls that are the exact dimension and design as cinderblock yet twice as much the strength, and without grouted joints that are susceptible to seismic cracking.![]()

The advantage of concrete printing is the ability to print hollow walls which reduced costs for electrical, plumbing and insulation. Additionally, hollow walls can be insulated to almost an R factor with ease with the absence obstructive studs.

The challenge isn’t whether or not it's possible, as it's already being done everywhere. The challenge is whether or not you can find a structural engineer that makes it possible. It's all about math. The code already exists, all you have to do is exceed the code, and to do that, you need to start with the mix.

Testing and Math

We have developed and tested a myriad of different mixes with different characteristics, such as PSI, tensile strength, water impenetrability, fire resistance, as well as cold weather mixes, hot weather mixes, accelerated mixes, and retarded mixes. We provide the formulas and the lab results that your engineer will need to determine what the wall designs will be. Once they have the testing results, they can design a wall that exceeds any code anywhere.

Once they have the testing results, they can design a wall that exceeds any code anywhere.

Some choose to stay close to traditional methods by printing walls that resemble ICF and CMU, but others, who have more confidence, take it all the way by utilizing stronger mixes, so that they can capitalize on ALL the cost-saving benefits.

Plans and Details

As for the other considerations, we have plenty of videos that address common questions about headers, attaching hurricane straps, installing electrical boxes, securing plumbing, mounting top plates for trussing and methods for tying the wall to the foundation. Although, most engineers want to see the methods being used by others first before reinventing the wheel, as they learn more and more until there isn’t a question that they can’t offer up to 4 or 5 solutions when asked. Most of this is common sense, nevertheless, we have the plan details and math to share.

As we’re saying this, bear in mind that every state, and sometimes even cities, have different building codes. What we will share is determined by specific code and conditions that are not specific to your state. Far too many factors come into play, such as mix characteristics, code, water table, frost level, annual snow loads, wind, seismic, soil compaction for starters. We do not provide structural engineering, but we can point you in the right direction.

What we will share is determined by specific code and conditions that are not specific to your state. Far too many factors come into play, such as mix characteristics, code, water table, frost level, annual snow loads, wind, seismic, soil compaction for starters. We do not provide structural engineering, but we can point you in the right direction.

Deal Breakers?

Everyone who is considering the use of concrete printing has a lot of work to do before they can commit to a purchase. There is no shortcut. The investment of time is inevitable. As you start down the path to making a decision, it’s easy to get confused as to what’s most important, and where you should spend your time, but as you consider the options presented to you, there will be some paths that obviously are a waste of time. Everyone needs to know what their deal breakers are. They will be different for each person, but from speaking with others, we have a pretty good idea of what most consider their deal breakers.

Design

From the onset, our engineers understood the importance of creating a design that had all the same features but was also easily understood. A printer that is lightweight and easily assembled in the field. MudBots printers weigh 75% less than any printers in the industry, with an assembly time that is 80% faster. This is a printer that does it all, does it faster, and is half the price of anyone.

Basements and Second Story

In some parts of the world, the ability to print basements and a second story isn’t a big deal, but in North America, it’s essential. Look around and you will find that most printers in this marketplace don’t have the ability to do either without tremendous unnecessary excavation or back filling. If you’re going to invest in a printer, most agree that the ability to quickly set up for footings, basements and second story is a must.

Assembly

Look at any other printer and you will recognize right off that assembly is going to be an expensive challenge. Imagine the worst IKEA assembly ever. That’s about what you get. Think about parts that are heavy to manage without forklifts and cranes, imagine hundreds of nuts and bolts. In some cases, needles cosmetic plastics that serve no function, waste hours of assembly, and will undoubtedly be broken and expensive to replace. Most printer designs make sense to the engineers that built them, but not so much to the contractors that will need to assemble it in the field. A 20' x 20' MudBots printer can be assembled with 2 workers in two hours without any mechanical lifting. MudBots can also be moved from one lot to another without disassembly by simply adding wheels. Additionally, the printer can print entire structures without being moved multiple times.

Imagine the worst IKEA assembly ever. That’s about what you get. Think about parts that are heavy to manage without forklifts and cranes, imagine hundreds of nuts and bolts. In some cases, needles cosmetic plastics that serve no function, waste hours of assembly, and will undoubtedly be broken and expensive to replace. Most printer designs make sense to the engineers that built them, but not so much to the contractors that will need to assemble it in the field. A 20' x 20' MudBots printer can be assembled with 2 workers in two hours without any mechanical lifting. MudBots can also be moved from one lot to another without disassembly by simply adding wheels. Additionally, the printer can print entire structures without being moved multiple times.

Proprietary Mixes

If you think your printer cartridges are expensive, wait until you have to buy and ship proprietary concrete mixes from halfway around the world or even the USA. MudBots is the only ones that provide the mix formulas for your printer and allow you to use any mix without voiding your warranty. This should be a deal breaker for everyone as they begin to realize what they will be paying for are mixes that are (mostly) available at their local hardware store, not to mention the cost of and any delay in shipping.

This should be a deal breaker for everyone as they begin to realize what they will be paying for are mixes that are (mostly) available at their local hardware store, not to mention the cost of and any delay in shipping.

Customer Service

Does it feel like the others are sleeping on the job? There is far more to consider when thinking who to buy from than a few online videos and website. This is a significant purchase for most, but as you're out knocking on doors, the one thing you should consider the most is customer service. Start calling around and you’ll discover that there’s no one to talk to. Phone numbers are hidden, and emails go unanswered for weeks. You have to ask yourself, if no one will talk to you now when you have the money on hand, what’s it going to be like when you need support.

Price

If you’ve been lucky enough to get this far with anyone, the first thing you will find is that MudBots isn’t just a little better in price. MudBots is 1/2 to 1/3 the price of other printers, with more features and options than anyone. Price is always a factor, as well as ROI. Do the numbers and you’ll find that within 60 days, you’ll have already paid for your printer in savings, and likely will be looking for your second purchase because of the advantages.

MudBots is 1/2 to 1/3 the price of other printers, with more features and options than anyone. Price is always a factor, as well as ROI. Do the numbers and you’ll find that within 60 days, you’ll have already paid for your printer in savings, and likely will be looking for your second purchase because of the advantages.

Franchise

Most of our customers contact us because they are excited about the income possibilities that our printers will offer them, but for this very reason, the greater opportunity is in securing the exclusive distribution rights for their state. By merely owning and using our printers, our customers will undoubtedly generate tremendous excitement as they begin printing unbelievable designs at a third the cost and a third the time. It would be impossible to keep such a tool a secret. As news of this innovation begins making its way to the public, demand will become unimaginable. Since our customers are creating the exposure and excitement, it’s only right that they share in the success and residual income opportunity.

Jurisdiction

Most contracts start off with optimism and the best intentions, but if you’ve been doing this a while, you have learned that in the event of any legal actions, jurisdiction is an issue. If you’ve ever had to litigate outside your state, you recognize the challenges, but litigating outside the country is altogether different. We take a lot for granted in America, but that is not the case intentionally. Imagine trying to hire legal counsel abroad and trying to interpret international laws. This does not certainly offer home court advantage, and asking anyone who has tried, you’ll see that this is problematic at best. But even if you prevail, collecting on a judgement with corporate assets abroad is nearly impossible.

RegionalMaster Dealer

We thought so!

Want more time with your family?

Want to earn over 100K a month?

Want to have your own company?

MudBots is looking for the best. If you have a background in construction, love new technology, and especially love business in general, you're in the right place. MudBots has developed the first line of 3D Concrete Printers available to the world. Media everywhere is saying that the new technology will change the construction industry forever. Seldom do opportunities come along with the huge market interest and untapped market. This is what business opportunist dream of.

If you have a background in construction, love new technology, and especially love business in general, you're in the right place. MudBots has developed the first line of 3D Concrete Printers available to the world. Media everywhere is saying that the new technology will change the construction industry forever. Seldom do opportunities come along with the huge market interest and untapped market. This is what business opportunist dream of.

Quality of Life

Success is measured in many ways, but true success is measured by the peace a person feels when they know they are doing something they love, their efforts are rewarded with increased gain, and they have the time to enjoy both with the ones they love. There are countless ways to make a living, but if you don’t enjoy what you’re doing or you don’t have the time to enjoy anything else, it’s hard to be satisfied. MudBots Master Dealers enjoy all three. They earn a remarkable living, they have the freedom to work when they want and because of their success, they get to focus on the more important things in life – their Family.

Job Description

The only way to manage a company that is growing as fast as MudBots is to have qualified individuals in every region of the country who can demonstrate products and serve their dealers. The Master Dealer program gives the company and its dealers the representation needed while offering a significant opportunity to those who embrace the call.

Exclusive Region

As an RMD, you will be given an exclusive license to represent and profit off of ALL the MudBots sales in your state/region. It is generally a full state, but in larger markets, a state may be divided to provide for better reachability and service.

Residual Income

There are many ways to profit as an RMD but the “residual commission” is by far the most enticing. Sell it once and continue earning for years to come. As an RMD you will earn up to 10% on every printer sold. With printers ranging from 284k to 1.3 million, it’s not hard to see how lucrative the venture can be. If RMDs sign up one new dealer every month who sells one printer a month within 12 months, depending on the profit sharing each RMD sets up with their dealers, earning after 12 months of work with 12 compliant dealers should be well over 100k a month. Why so much? Quite simply, we want to attract the best in the industry. An organization is only as good as its people. We want professionals, self-motivated individuals who are passionate about building their own business along ours.

If RMDs sign up one new dealer every month who sells one printer a month within 12 months, depending on the profit sharing each RMD sets up with their dealers, earning after 12 months of work with 12 compliant dealers should be well over 100k a month. Why so much? Quite simply, we want to attract the best in the industry. An organization is only as good as its people. We want professionals, self-motivated individuals who are passionate about building their own business along ours.

Economy

One of the best thing about concrete printers is the recession-proof nature of products. If the economy slows, the need for faster and more affordable construction methods increases. Those trying to compete with traditional construction methods will quickly discover they can’t even come close, resulting in even more demand for MudBots products. Prospects can get on board now or wait until they are losing contracts without one.

Previous Next

Minimum Requirements

Training

Attend a 4-week training in Utah

Printers

Purchase two (2) demo printers equaling 500k or more

Truck

Must have a late model truck

Trailer

Must have an enclosed branded trailer

Demo Product

Demo product to 2 dealers each week

1 Dealer / Month

Sign one dealer each month

Work or Fun

The best thing about a career with MudBots is that it’s just plain fun. As more and more ways are discovered for utilizing 3D Concrete Printers, every day is an exciting adventure. It’s fun to make money doing what you love and this is definitely an exciting product that sells itself. Industry professional everywhere are in awe when they see products being printed without the need of straight lines and forms. This is a product that people will watch for hours in amazement. The longer they watch, the more they realize how valuable 3D Printing will be to their business.

As more and more ways are discovered for utilizing 3D Concrete Printers, every day is an exciting adventure. It’s fun to make money doing what you love and this is definitely an exciting product that sells itself. Industry professional everywhere are in awe when they see products being printed without the need of straight lines and forms. This is a product that people will watch for hours in amazement. The longer they watch, the more they realize how valuable 3D Printing will be to their business.

Getting Started

To get started, call and request an NDA and RMD application. Once accepted, you may attend the next RMD training where you will spend three full days of training and Q&A. You will learn about the industry, the opportunity, printer operation, specific mixes, lab testing, structure engineering, potential markets & marketing strategies. By the time you return home, you will be confident in your ability to promote and service the dealers in your area.

Welcome to MudBots.

Connect The Dots

As companies begin down this road the process and solutions for building with 3DCP’s can seem daunting at first but it doesn’t take much looking around to realize that answers and solutions are not far away. Here are some videos that will help with connecting those dots.

Fiber Cement Siding to Block

Hardy Plank over Block

Hardy Plank Siding on Block

Architectural Foam Accents

Applying Architectural Foam Accents

Spraying Finish on Artictectural Foam & Finishes (1/2)

Cement Screws and Fasteners

Cement Board Screws

Faux Concrete Wall Panels

Wall Cladding Systems

Concrete Counter Tops 1

How To Layout like a PRO - NOT NEEDED ANYMORE

Engineering Footings

Soil and Footings

Tiny Home Village - Making a Difference

Affordable Housing in Detroit

Spec Mix Delivery

Site Tools and Methods

Read an article about the first 3D printed houses?

3D printing has been used in construction for several years now. In this article, you will learn about the first real houses printed on 3D printers.

3D printing of houses is still quite new to the layman. While construction 3D printing technologies have been developed for many years, only a few “real” projects have already seen the light of day. We are still far from technology taking over conventional construction methods. But with each new project, she is getting closer to becoming mainstream.

There are many benefits to 3D printing. For example, the cost of a 3D printed house can be much lower. And it will take much less time to build.

In order to draw a line under what has already been achieved in this area and show some interesting projects, we have devoted an article to the "first" and the best. These projects will always remain milestones in the 3D construction printing industry as they set the stage for future advances in the field.

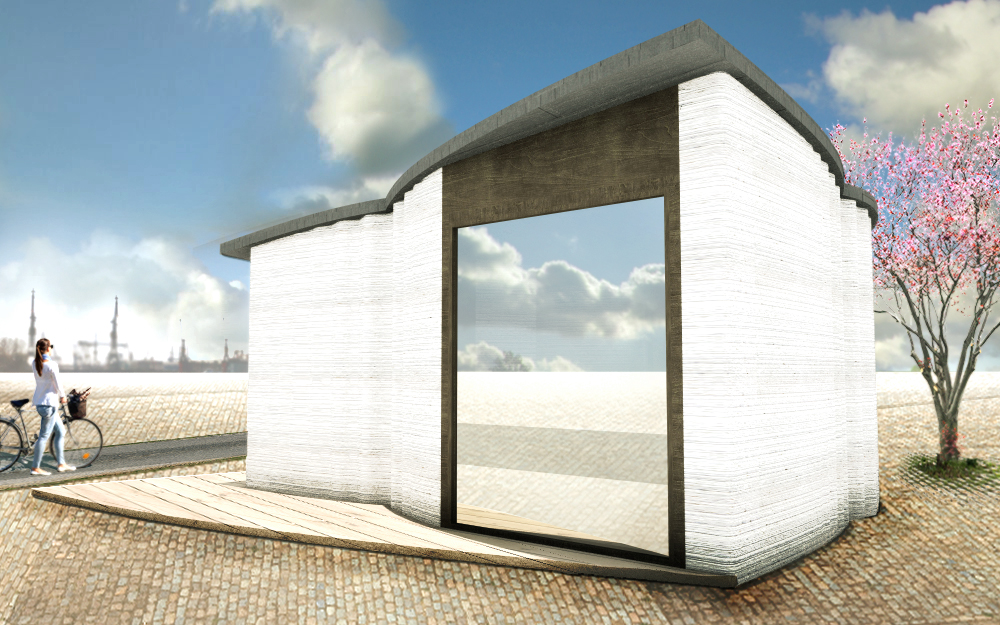

First 3D printed house in Germany

Germany is a country often associated with cutting edge engineering, so let's start our list with Germany's first ever 3D printed house.

The house itself is located in Beckum, a city that is partly located in North Rhine-Westphalia, next to Holland and Belgium. This is the first 3D printed house to be fully certified to official building codes. This project will give way to many other 3D printed construction projects in Germany as well as the rest of Europe.

The project is the result of a collaboration between German construction company Peri and Danish construction 3D printing firm COBOD. Peri is a large corporation that operates not only in Germany, but throughout the EU. Its portfolio includes many products, including scaffolding and formwork solutions that every construction site needs.

Its portfolio includes many products, including scaffolding and formwork solutions that every construction site needs.

Peri followed the construction 3D printing segment for years before acquiring a stake in COBOD in 2018. Now they are pushing the technology together and further. The construction of the house in Beckum began two years after the acquisition of the share.

For 3D printing at home, a BOD2 modular 3D printer from COBOD was used. The printing itself took just over 100 hours.

• Built: (started) September 17, 2020

• Commissioned: summer 2021

• Where: Beckum, North Rhine-Westphalia, Germany

• By: Peri, COBOD

First occupied 3D printed home in the US

Several homes have been printed in the US, but this home is the first officially occupied home, according to CNN. Its creators: the construction company Alquist and the humanitarian organization Habitat for Humanity Peninsula.

From a distance, you might think that this is an ordinary house. However, when approaching it, the layered structure of the concrete walls becomes noticeable. After all, 3D printing creates an object in layers.

However, when approaching it, the layered structure of the concrete walls becomes noticeable. After all, 3D printing creates an object in layers.

Surprisingly, the 111.5 square meter concrete structure of the house (was printed in about 12 hours, significantly faster than traditional construction methods would allow.

The house was reportedly purchased by April Springfield, who lives there with her son and dog She bought the house through Habitat for Humanity's housing program, and given that the nonprofit's goal is to help solve the global housing crisis, it makes sense to use 3D printing to create affordable homes that will make many people's dreams of home ownership come true.0005

• Built: 2021

• Commissioned: December 22, 2021

• Where: Williamsburg, Virginia, USA

• By: Alquist 3D, Habitat for Humanity Peninsula, Greater Williamsburg

The first five-story 3D printed house

This project, made by the Chinese company WinSun, is a real record holder. It is a 3D printed five-story residential building with a height of 10 meters - the tallest 3D printed building so far.

It is a 3D printed five-story residential building with a height of 10 meters - the tallest 3D printed building so far.

The house is located in Suzhou Industrial Park in Jiangsu province in eastern China. It stands next to a mansion that was also built by WinSun using a concrete 3D printer.

Looking at the WinSun designs, you can't help but notice that they don't look like they've been 3D printed. Usually 3D printed structures are gray in color, the layer lines are clearly visible. But WinSun adds color and makes walls smoother. Nowhere is it stated how the company achieves the smoothness of the walls, but we assume that the workers smooth them by hand. WinSun projects are not like the ones we're used to.

• Built: Winter 2014

• Commissioned: Not specified

• Where: Suzhou, Jiangsu, China

• By: WinSun

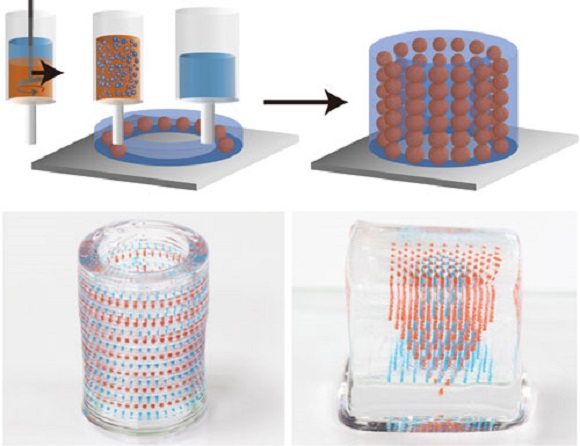

First 3D printed biodegradable house

Can you guess that there is rice in the walls of this house?

Most 3D printed buildings are made from concrete mix. But this project is different from the rest. With the aim of creating housing solutions with little to no environmental impact, Italian company WASP 3D printed Gay's house using soil and agricultural waste.

But this project is different from the rest. With the aim of creating housing solutions with little to no environmental impact, Italian company WASP 3D printed Gay's house using soil and agricultural waste.

WASP developed the sustainable blend in collaboration with Ricehouse, a company that specializes in using natural and agricultural materials such as clay and rice in construction.

The house is named Gaia in honor of the ancient Greek goddess of the earth. In fact, 25% of the mixture contains local soil, 10% hydraulic lime, 25% rice husks and 40% crushed rice straw (a by-product of rice production at harvest).

An innovative solution not only in terms of material, but also in the design of the walls themselves. The specific corrugated structure was used to provide ventilation on warm days as well as insulation on cold periods, virtually eliminating the need for air conditioning.

Gay's house is small - about 20 square meters. The wall printing took only 10 days, while the estimated materials cost is just under $1,000.

• Built: not specified

• Commissioned: October 7, 2018

• Where: Massa Lombarda, Ravenna, Italy

• By: WASP, Ricehouse

AirBnB's first 3D printed house

The perfect weekend getaway.

You can find many different types of accommodation on AirBnB, but what about a 3D printed home?

The so-called Fibonacci house is the first 3D printed house to be offered for booking through AirBnB. Considering that it is located in rural British Columbia, it will be a wonderful place to stay.

Although the Fibonacci house looks small, it has a lot to offer vacationers. About 35 square meters is enough to accommodate up to four people.

The concrete walls of the house were designed and printed by Dutch 3D printing firm Twente. 20 concrete parts were produced offsite in just 11 days. The material was produced by Laticrete. The parts were later transported and assembled at their current location.

• Built: 2020

• Commissioned: Not specified

• Where: Kootenays, British Columbia, Canada

• By: Twente Additive Manufacturing

First 3D printed houseboat

Prvok is not only the first 3D printed house in the Czech Republic, but the world's first floating 3D printed house on a pontoon.

The project was implemented by the start-up company Scoolpt. The concrete structure of the houseboat took only 22 hours to print.

Approximately 43 square meters of living space divided into bathroom, bedroom and living room with kitchen. Weight isn't usually discussed in the context of houses, but given that this one is on water, it's interesting to note that Prvok weighs 43 tons.

The house is equipped with a built-in recirculating shower and tanks for drinking and municipal water and has a service life of at least 100 years.

• Built: June 2020

• Commissioned: August 18, 2020

• Where: Prague, Czech Republic

• By: Scoolpt

Europe's first 3D printed residential house

Not every 3D printed house has visible line layers.

More often than not, 3D printed houses are demos made to show what the technology can do. For most of them there is no information about the actual residents. But in 2017, the couple did move to live in a 3D printed house located in Nantes, France. Thus, the house of "Yanov" became the first of its kind, which was inhabited in Europe.

Thus, the house of "Yanov" became the first of its kind, which was inhabited in Europe.

The house is a project of the University and the Laboratory of Digital Sciences of Nantes. An interesting aspect of the project is the special technique used in its construction by BatiPrint3D. Instead of 3D printing a concrete structure, the robotic arm created wall shells using polyurethane, a material used for insulation. Later, these membranes were filled with concrete.

It took a total of 54 hours to print. It took a little over 4 months to complete the construction. Mainly due to the fact that the rest of the components were created using conventional means. House area - 95 square meters.

• Built: 2017

• Commissioned: March 2018

• Where: Nantes, France

• By: University of Nantes, Nantes Digital Science Lab

India's first 3D printed house

This building was built in a couple of days.

India's first ever 3D printed house was completed back in 2020. The project was carried out by construction startup Tvasta, founded by graduates from the Indian Institute of Technology Madras. In fact, the institute's Chennai campus was chosen as the location of the building.

The project was carried out by construction startup Tvasta, founded by graduates from the Indian Institute of Technology Madras. In fact, the institute's Chennai campus was chosen as the location of the building.

The significance of this project lies in its possible impact on the solution of the housing crisis worldwide and in India in particular. The ability to build such a house within a few days and at a low cost cannot be underestimated.

House 55.7 sq.m. with a spacious layout, one bedroom, combined kitchen and living room.

The concrete structure of the house was 3D printed off site and the parts were later transported and assembled on campus. The foundation, meanwhile, was built using the conventional method of pouring concrete into the ground.

• Built: 2020

• Commissioned: Not specified

• Where: Chennai, India

• By: Tvasta Construction

Africa's first 3D printed house

Back in 2019, in the Moroccan city of Ben Guerir, Spanish firm Be More 3D created Africa's first 3D printed house. The project originated during the team's participation in the Solar Decathlon in Africa. This is an international competition during which teams design and build solar-powered houses.

The project originated during the team's participation in the Solar Decathlon in Africa. This is an international competition during which teams design and build solar-powered houses.

Be More 3D printed house 32 sq.m. in about 12 hours, took first place and received the title of the most innovative startup.

Be More 3D didn't stop building in Africa and later created the first 3D printed house in Spain and developed its own concrete 3D printer in partnership with several corporations from the automation and materials industries.

• Built: 2019

• Commissioned: Not specified

• Where: Ben Guerir, Morocco

• By: Be More 3D

First 3D printed home for sale in the US

Last on our list is the first 3D printed home for sale in the US.

This house was printed in the same place by SQ4D, a company specializing in the development of robotic building systems. The building was printed with SQ4D's Arcs concrete extrusion system and has a 50-year warranty on the printed structure.

Living area of 130.7 sq.m. with three bedrooms and two bathrooms. There is also a garage for 2 cars.

The house was listed for sale in January 2021 for $299,999. Considering the size of the house and the fact that it is priced 50% below the cost of comparable newly built houses in the same area, the deal is pretty good.

• Built: 2020

• Commissioned: 2021

• Where: Riverhead, New York, USA

• By whom: SQ4D

Translation source: https://m.all3dp.com/2/first-3d-printed-house/

On our website you can choose and order a construction 3D printer for both building construction and small building forms. To do this, go to the catalog of construction 3D printers. "Tsvetnoy Mir" is a reliable supplier of 3D printers with many years of experience, supplying directly from manufacturers and guaranteeing their quality.

reportage about construction 3D printing in Russia

News

a developer and manufacturer of construction 3D printers based in Yaroslavl and successfully operating in the Russian and foreign markets.

The narrator is the head of the enterprise Alexander Maslov.

The narrator is the head of the enterprise Alexander Maslov.

In already completed projects, AMT-Spetsavia printed houses both on top of the foundation and in blocks in workshop conditions. In the video, Alexander clarifies this point, which is related, among other things, to weather conditions.

“If we print the prefab in the shop, then [the process] does not depend in any way on weather conditions. Both winter and summer are about the same temperature, which is good. When you print on a foundation (which everyone loves because it eliminates the assembly step, which is quite a lot of time and money), then of course the weather conditions come into play. The construction season is usually from spring to autumn. It's hard to print in very hot weather because the long, thin concrete walls start to crack. To do this, various additives are introduced into the concrete or the printing is transferred to a more convenient night time. Comfortable temperatures are from spring to autumn, from about 5°C to 25°C. Of course, precipitation and strong winds have a very strong influence - the structure still has windage, and there is a slight shift in the printed layers. Light rain is not a hindrance, in heavy rain the wet concrete will erode, so you need to keep an eye on the weather. As a rule, an hour and a half before the approach of a thunderstorm, we stop printing, wash the equipment and wait. There is another option to close it with some kind of canopy or a greenhouse, but it’s actually easier to miss two hours of printing than to fence the roof, ”said Alexander.

Of course, precipitation and strong winds have a very strong influence - the structure still has windage, and there is a slight shift in the printed layers. Light rain is not a hindrance, in heavy rain the wet concrete will erode, so you need to keep an eye on the weather. As a rule, an hour and a half before the approach of a thunderstorm, we stop printing, wash the equipment and wait. There is another option to close it with some kind of canopy or a greenhouse, but it’s actually easier to miss two hours of printing than to fence the roof, ”said Alexander.

A 100 square meter 3D printed box takes thirty to thirty five hours to build. Fixed formwork is printed, which can be poured with foam compounds after one or several days, depending on the brand of concrete.

Alexander did not dare to give an exact figure, since the pace of work for each team is different, but in general, a small house can be built in about a month, including pouring the foundation and curing, 3D printing of formwork, inserting windows, doors, and so on.

According to Alexander, there are about forty companies currently operating in the global market for 3D construction printing — some are engaged in the development and production of equipment, some directly in construction, some combine them. According to Alexander, AMT-Spetsavia accounts for 70% of the world production of construction 3D printers, with half of them going to Russian customers. In six years, the company has sold two hundred and forty pieces of equipment to sixteen countries.

AMT-Spetsavia produces two main types of portal 3D printers - workshop systems and larger options for outdoor work. The former are used in 3D printing of small architectural forms and building blocks, while the latter are installed on construction sites and print formwork directly on top of foundations.

The working area of such large-sized systems varies from one hundred and twenty square meters with the possibility of erecting two-story structures up to four hundred and twenty square meters.