3D printer captain america shield

Captain America 3d - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 855 relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

▷ captain america shield full size replica 3d models 【 STLFinder 】

Captain America Shield - Full Size, 4 Pieces

thingiverse

This is Captain America's shield, full size, broken into 4 pieces. Each piece is positioned to fit on a 300 x 300 bed (such as the CR-10). ...Print the 4, glue them together, and get to painting!

Captain America's Shield - Full Size

thingiverse

This is a full size model of Captain America's Shield. I have it sliced in halves and in quarters. The halves will print on a Gigabot. If you need to chop it up into smaller pieces, Meshmixer's plane cut tool does the trick. Remember - This is the...

Captain America Shield - Movie Replica

grabcad

I've decided to build a replica of the shield the Cap uses in the movies. In order to best figure out the dimensions and parts that I need, I started by creating the shield in Autodesk Inventor 2013. Over the next few weeks I'll be building it for...

Over the next few weeks I'll be building it for...

Captain America Shield (earring size)

thingiverse

Miniature Captain America shields for your ears! Disks are the size of a US quarter. Instructions Print at low layer height and high infill for best results. I used a raft to reduce any curling that...

Captain America Shield (earring size)

prusaprinters

Miniature Captain America shields for your ears! Disks are the size of a US quarter. Print instructionsPrint at low layer height for best results. ...I used a raft to reduce any curling that may occur. </p> <p>Paint (battle damage optional).</p> <p>Use a...

</p> <p>Paint (battle damage optional).</p> <p>Use a...

Captain America Inspired Full Sized Shield

myminifactory

Full size Captain America Shield (based on the Movie version) Need a fairly large print bed since longest piece is 254mm.

Full Scale Sliced Captain America Shield

thingiverse

Full Scale Captain America Shield(No handle) sliced to be able to print. HAS NOT BEEN TESTED. This creation is probably highly impractical to actually print. If you do print it, please let me know and upload a picture(My printer is currently out of. ..

..

Captain America shield (SHIELD)

cults3d

Captain America shield to assemble.

Captain America Shield

thingiverse

A palm-sized Captain America Shield!

Shield Captain America

cults3d

Shield Captain America

captain america shield

thingiverse

captain america shield

captain america shield

grabcad

Its captain america shield

Captain America Shield Coaster

cults3d

Captain America Shield Coaster

Captain America Shield

thingiverse

Captain America Shield

Captain America Shield

thingiverse

Captain America Shield

Captain America Shield

thingiverse

Captain America Shield

Captain America Shield 2D

grabcad

Captain America Shield 2D

Captain America Shield

grabcad

Captain America Shield

Captain America's shield

grabcad

Captain America's shield

captain america's shield

grabcad

captain america's shield

Captain America Shield

grabcad

Captain America Shield

Shield(Captain America)

grabcad

Shield(Captain America)

captain america shield

grabcad

captain america shield

Captain America shield

grabcad

Captain Americas vibranium shield

captain america shield

grabcad

captain america shield

Captain America's Shield

grabcad

Captain America's Shield

Captain America Shield

myminifactory

Captain America - Shield

CAPTAIN AMERICA SHIELD

grabcad

CAPTAIN AMERICA SHIELD

Captain america shield

grabcad

Captain america shield

Captain America Shield

grabcad

Captain America Shield

90,000 3D printing in cinema - how technology has changed the film industry! For the creators of entertaining science fiction films, there has always been a problem of the real embodiment of the most daring author's ideas. Many fascinating plots did not become masterpieces of world cinema due to weak and unrealistic effects that caused laughter from the audience and criticism from professionals. It seemed that in our era of digital technologies, when any scenes and fantastic attributes can be reproduced using computer graphics, the problems of filling any fantasy film with colorful spectacular details will become a thing of the past. However, screen masters have become convinced that not everything can be created with a graphic image, and therefore directors are still looking for ways to realistically convey the incredible appearance of the intended characters and create amazing objects of the fictional world. The graphics help to reproduce the overall environment in an incomparable way, but the human eye cannot be deceived and close-ups are often impossible to make believable using the style of a computer game. And then 3D printing came to the aid of directors and cameramen, thanks to the possibilities of which make-up artists and effects specialists today create unimaginable screen images.

Many fascinating plots did not become masterpieces of world cinema due to weak and unrealistic effects that caused laughter from the audience and criticism from professionals. It seemed that in our era of digital technologies, when any scenes and fantastic attributes can be reproduced using computer graphics, the problems of filling any fantasy film with colorful spectacular details will become a thing of the past. However, screen masters have become convinced that not everything can be created with a graphic image, and therefore directors are still looking for ways to realistically convey the incredible appearance of the intended characters and create amazing objects of the fictional world. The graphics help to reproduce the overall environment in an incomparable way, but the human eye cannot be deceived and close-ups are often impossible to make believable using the style of a computer game. And then 3D printing came to the aid of directors and cameramen, thanks to the possibilities of which make-up artists and effects specialists today create unimaginable screen images.

Where and how did the 3D printer work?

A quarter of a century ago, it was hard to imagine that technological and scientific progress would so significantly change the technologies for preparing props for the film industry. Even in such a cult film of 1997 as "Men in Black", which was replete with alien guests, the process of creating unprecedented characters consisted in hand-molding from clay, familiar to the "kitchen" of the cinema. Not a single worthwhile spectacular scenario could do without the work of experienced craftsmen. The manual production of unique layouts and details for effects was time consuming and costly. And at the same time, there were always risks that the created images would not be able to fully convey what was intended. But 3D printing has changed everything, without which it is now difficult to imagine the process of modern film production.

Fans of Stranger Things may not know that it was the 3D printer that was used to create objects for the scariest scenes. The task of the authors was to accurately reproduce the atmosphere of the 80s, and to achieve their goals, the creators used a kind of hybrid method, combining the possibilities of graphic editing and 3D printing. As a result, we can say that both technologies perfectly complement each other. From simple sketches of the monster, with which the authors turned to the special effects studio, the creators came to a realistic embodiment on the screen not only of the character himself, but also completely reproduced the whole bewitching inverted world. A striking example of technological interaction is the Demogorgon model, which was created by a 3D printer, but the mouth mucus appeared with the help of graphics, and the fire was brought up for real. As a result, the viewer is completely immersed in believable footage, and the series has been in the top of the best films since the first season.

The task of the authors was to accurately reproduce the atmosphere of the 80s, and to achieve their goals, the creators used a kind of hybrid method, combining the possibilities of graphic editing and 3D printing. As a result, we can say that both technologies perfectly complement each other. From simple sketches of the monster, with which the authors turned to the special effects studio, the creators came to a realistic embodiment on the screen not only of the character himself, but also completely reproduced the whole bewitching inverted world. A striking example of technological interaction is the Demogorgon model, which was created by a 3D printer, but the mouth mucus appeared with the help of graphics, and the fire was brought up for real. As a result, the viewer is completely immersed in believable footage, and the series has been in the top of the best films since the first season.

New technologies could not ignore the mastodon of Hollywood fiction, the recognized master and creator of space worlds Ridley Scott. The 2020 series Raised by Wolves, produced by HBO Max, required the director to think outside the box when it comes to screening another sci-fi story in which androids are busy creating a new population of people on a desert planet. Almost all the components and elements of the new world were reproduced by 3D printing. It was only thanks to the technological acceleration of behind-the-scenes production of props and furnishings that the famous director's production team was able to keep up with the tight schedule of working in the challenging conditions of South Africa. Each episode took 2-3 weeks to prepare and shoot. During this time, sketches were prepared, layouts were designed, final details were agreed. Everything happened with the direct participation of the art director of the picture Yako Snaiman and Ridley Scott himself.

The 2020 series Raised by Wolves, produced by HBO Max, required the director to think outside the box when it comes to screening another sci-fi story in which androids are busy creating a new population of people on a desert planet. Almost all the components and elements of the new world were reproduced by 3D printing. It was only thanks to the technological acceleration of behind-the-scenes production of props and furnishings that the famous director's production team was able to keep up with the tight schedule of working in the challenging conditions of South Africa. Each episode took 2-3 weeks to prepare and shoot. During this time, sketches were prepared, layouts were designed, final details were agreed. Everything happened with the direct participation of the art director of the picture Yako Snaiman and Ridley Scott himself.

The most difficult thing was to create the main character of the film - android. This required a head scan of the actress. Next, a transparent polymer copy was printed through which the liquid could be seen. Metal parts were highlighted in chrome, and the containers were filled with water with a common food coloring that mimics yellow acid. Small details of the severed head, muscles, skull were created by the Zbrush program. Many elements were printed separately and assembled together. When installing the details on the actor's head, it was possible to achieve a real feeling that an artificially created person was in front of the audience. If not for the possibilities of 3D printing, no previous technical tricks and skill of design technicians would have allowed the series team to meet the allotted time and give the characters such a realistic look.

Metal parts were highlighted in chrome, and the containers were filled with water with a common food coloring that mimics yellow acid. Small details of the severed head, muscles, skull were created by the Zbrush program. Many elements were printed separately and assembled together. When installing the details on the actor's head, it was possible to achieve a real feeling that an artificially created person was in front of the audience. If not for the possibilities of 3D printing, no previous technical tricks and skill of design technicians would have allowed the series team to meet the allotted time and give the characters such a realistic look.

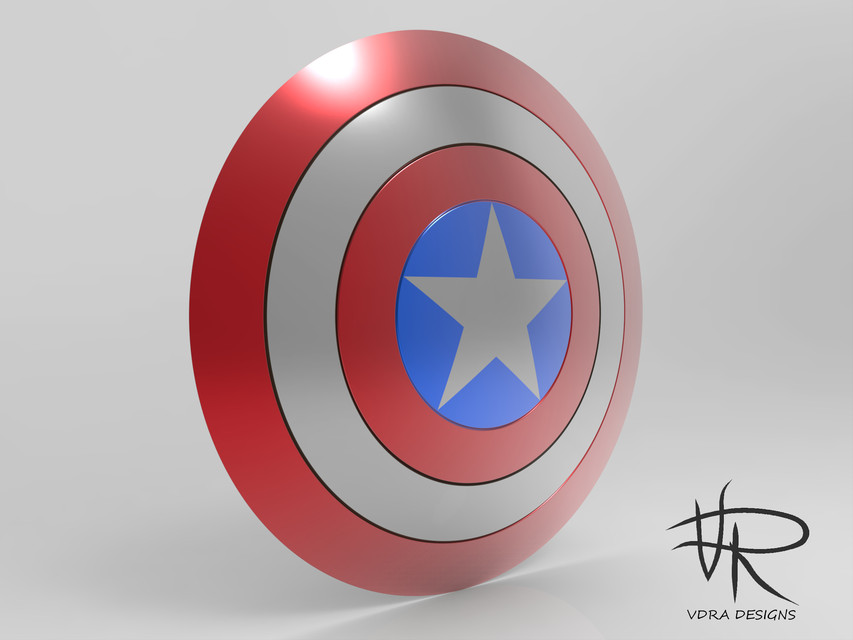

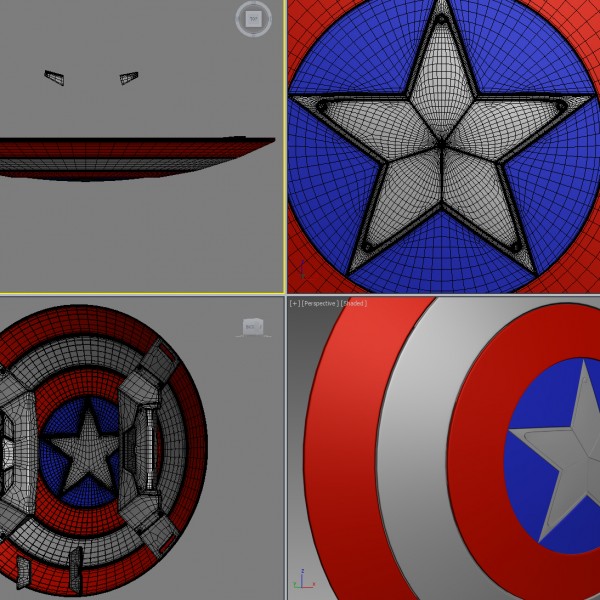

Most of all, the creators of the Marvel Universe know about the indispensability and practicality of 3D printers. Not a single studio film is complete today without the use of 3D printing technology. Only such fast and precise production is able to provide the film sets with the necessary props. Russell Bobbitt, who is in charge of this direction at Marvel Studios, says that everything that we see on the screen in the hands of the Avengers, on their costumes and in the setting, is created only through printer printing. Without it, such an unthinkable number of objects and details simply would not have been physically possible to recreate. Thor's hammer and Captain America's shield, Iron Man's reactors and hundreds of other elements of a fictional space future - all this became possible only thanks to the latest technologies. Russell remembers first encountering 3D printing on the set of Star Trek in 2009.1999, where director and producer J.J. Abrams introduced him to new technology.

Without it, such an unthinkable number of objects and details simply would not have been physically possible to recreate. Thor's hammer and Captain America's shield, Iron Man's reactors and hundreds of other elements of a fictional space future - all this became possible only thanks to the latest technologies. Russell remembers first encountering 3D printing on the set of Star Trek in 2009.1999, where director and producer J.J. Abrams introduced him to new technology.

The first 3D printer that Bobbitt himself used cost an insane $150,000. Today, these technologies have become much more accessible. And most importantly - cost-effective. At a time when the financial success of films and series has become directly dependent on the speed of the filming process, when it is necessary to shoot not just spectacular science fiction, but entire series of space battles and sci-fi everyday life in the shortest possible time, only 3D printing provides the film industry with the necessary amount of stage props. Professionals are delighted with the prospects that have opened up and understand that with all the development of computer graphics, the times of 3D printing are just beginning, and the viewer will see more and more incredible frames with real and live special effects.

Professionals are delighted with the prospects that have opened up and understand that with all the development of computer graphics, the times of 3D printing are just beginning, and the viewer will see more and more incredible frames with real and live special effects.

Making a movie is an exciting and creative process. The result that the viewer sees on the screen is created by tens and hundreds of people using the most modern technology and digital technologies. As in any other field, it has its own peculiarities and secrets. We are ready to provide you with all the necessary consumables for the filming process, which you will find on our website kinosklad.ru.

Back to list

Formlabs 3D in Cinema | All About Filmmaking

How fantastic movie worlds are created with the help of 3D printing

Every filmmaker has several difficult tasks: from choosing an interesting plot to finding the right effect that will completely immerse the viewer in the work. Sometimes it takes a lot of time, because the picture needs to be thought out to the smallest detail, and even then it happens that the invented world or characters cannot fully convey the author's original idea. It would seem that now, in the digital age, where everything is created using graphics, what else could be needed?

Sometimes it takes a lot of time, because the picture needs to be thought out to the smallest detail, and even then it happens that the invented world or characters cannot fully convey the author's original idea. It would seem that now, in the digital age, where everything is created using graphics, what else could be needed?

It turns out that not everything is so simple. The creators of the pictures say that it is impossible to achieve the desired realism only with the help of special effects. The created world or characters often look artificial, which is why the viewer is unlikely to believe what is happening on the screen. Therefore, to create the necessary images, directors are increasingly turning to 3D printing, which allows them to achieve the most natural effect. Thanks to this, trembling in the knees or exclamations of admiration are provided. The creators of Stranger Things, the Marvel universe, and Raised by Wolves have gone the same way, taking advantage of 3D printing. And how exactly - we will tell in this material.

And how exactly - we will tell in this material.

How to bring your creation to life

Even 30 years ago, no one could have imagined how far the film industry would progress. In 1997, when the cult film Men in Black was being created, eccentric characters were molded from clay. Today, physical layouts and hand-crafted special effects are largely out of fashion. But the point is not even the lack of interest in them, but rather the speed, tight deadlines and limited budgets. They have been replaced by 3D printing. The creators of the series “Stranger Things” decided to turn to her.

They set themselves an interesting task - to recreate the retro atmosphere of the 80s, causing a special nostalgia. To achieve this effect, they turned to a hybrid method that combines 3D printing with digital technologies. It was important that the design process reflected the traditional methods of the 80s.

How did the creation process take place? At first, the directors of the series came to the special effects studio with only a sketch of the monster, but as a result, not only a character was created, but also a whole upside-down world that is really mesmerizing. The first step was to create a model of the Demogorgon monster using a 3D printer. The results were amazing - there was a feeling that they returned to the times when everything was still sculpted from clay. After the character was created, the team moved on to finalizing it with the help of computer graphics, for example, the slime in the creature's mouth was created digitally, while the fire was real.

The first step was to create a model of the Demogorgon monster using a 3D printer. The results were amazing - there was a feeling that they returned to the times when everything was still sculpted from clay. After the character was created, the team moved on to finalizing it with the help of computer graphics, for example, the slime in the creature's mouth was created digitally, while the fire was real.

The real success here was how the two techniques complemented each other.

Creating a new world

Bringing new worlds to life is a challenge for the film and television industry, especially when it comes to creating sci-fi creatures and artifacts. Most people watch TV shows and movies without being aware of what is going on behind the scenes. The reality is that a large number of teams put a lot of effort into making these worlds come to life or even small objects appear on the screen for one second.

In the new HBO Max series Raised by Wolves, filmed in South Africa by director Ridley Scott, 3D printing has helped create a sci-fi world in which two androids raise human children on another planet. We had to work on a tight schedule, with an interval of approximately two to three weeks between each episode, in order to develop the concept, prototypes, validate and produce final details for each subsequent filming unit. Each creative process began with a meeting between the art director of the project Jako Snaiman and the director, at which they discussed how the episode should look. Then sketches were created, and after their approval, it was possible to start making the design by the already determined date of filming. At the same time, the production of a design could take from one day to several weeks.

We had to work on a tight schedule, with an interval of approximately two to three weeks between each episode, in order to develop the concept, prototypes, validate and produce final details for each subsequent filming unit. Each creative process began with a meeting between the art director of the project Jako Snaiman and the director, at which they discussed how the episode should look. Then sketches were created, and after their approval, it was possible to start making the design by the already determined date of filming. At the same time, the production of a design could take from one day to several weeks.

The most difficult thing was to create an android - the key character of the series. For its manufacture, the actress's head was first scanned, after which the product was printed from a transparent polymer so that the liquid inside could be shown. Then the metal parts were painted with chrome paints, and the transparent bottles were filled with a mixture of water and yellow food coloring to simulate acid.

Severed head skull structure and fine detail muscle was created using Zbrush based on a scan of the actress. After that, the 3D model was divided into parts and printed from a transparent polymer. The 3D printed parts were then put together and polished, then glaze was added to make the skull look aged. With a 3D model in hand, the designers were able to design the details and 3D printed the skull's split sections out of transparent polymer. After assembly, they installed them on the actor's head. There was a complete feeling that this was a man with a robot head.

A clay sculpture of such a skull with a hard surface would take much longer, especially with all the polygonal faces and machined details. Therefore, the decision was made to print the skull using 3D printers, reducing the production time to one day instead of a week or more.

Cinema in detail

Not only does the creation of characters require a lot of creativity, imagination and precision, but the creation of props plays an important role in immersing the audience in the atmosphere of films. Without props, some of Hollywood's biggest blockbusters wouldn't exist. This is where 3D printing comes in handy.

Without props, some of Hollywood's biggest blockbusters wouldn't exist. This is where 3D printing comes in handy.

Russell Bobbitt, Head of Props at Marvel Studios, has over 30 years experience in film design. He has used his skills in blockbusters like Iron Man, The Avengers, and Guardians of the Galaxy. Russell, as the main props man, is responsible for many of the key elements that appear on screen, such as Captain America's shield, Thor's hammer, Iron Man's arc reactors, the lantern he wears on his chest, and more. But Bobbitt doesn't just work on outstanding items - just about everything an actor touches is considered a prop, even doorknobs.

Bobbitt was introduced to 3D printing by JJ Abrams during the making of the Star Trek remake in 2009. At that time, 3D printers were not as affordable as they are now. Bobbitt recalls that the first 3D printer he used cost $150,000. Now they have become not only more affordable, but their use has also become cost-effective, since 3D printing can significantly reduce production times.

3D printing workflows are different for every industry and application. Bobbitt fine-tuned his workflow for the booming entertainment industry. This is where it all starts with reading the script. Then you need to think, for example, what will weapons look like in space in 2,200 years? A list of important props is made, work is done with the illustrator team to draw the props, and then the sketches are presented to the director. Bobbitt and the director then decide which sketches to turn into props. Once approved, the sketches enter the CAD (computer-aided design) world. It is very important that the CAD drawing is of high quality, as it is used to create a suitable prototype, and then molds are made from it, cast and props are prepared. This is followed by a meeting with the actor to discuss any adjustments that need to be made. If the actor is happy with everything, then things are scaled on 3D printers. So, for example, Thor's new hammer was made from 34 parts, assembling it as a designer. To create the perfect hammer, Bobbitt worked directly with Chris Hemsworth, who plays Thor, as it was very important to find the right scale.

To create the perfect hammer, Bobbitt worked directly with Chris Hemsworth, who plays Thor, as it was very important to find the right scale.

3D printing saves time on props and encourages creativity in the design process, allowing you to create dozens of your own prototypes, making the whole process very flexible.

Achieve audience recognition

Making a cult film or series is not an easy task. There is no universal formula that will allow the film to remain in the memory of the audience for many years, but there are components that are responsible for whether a film can be considered good or not. In historical films, the reliability of the facts is responsible for this, the use of props that corresponds to the time. In sci-fi films - the spectacular effects, unique characters and atmosphere - something very difficult to explain, but making us watch films forever, allowing us to plunge into a magical and wonderful world again and again. To achieve this effect, many means are used, and one of these is 3D printing, which allows directors to embody the desired images on the screen with minimal time.