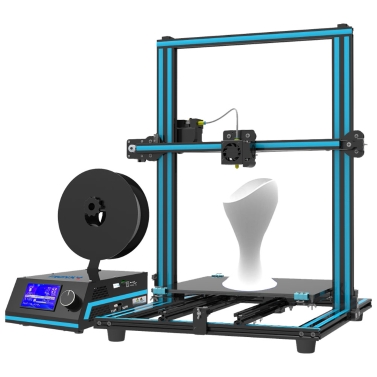

Anet a8 plus 3d printer

Anet A8 Plus DIY 3D Printer with 300*300*350mm Large Print Volume — Anet 3D Printer

Save $50.00

Original Price $279.00

Current Price $229.00

United States / A8 Plus (US Plug) - $229.00 United States / A8 Plus (US Plug) + Tempered Glass Hotbed Platform - $239.00 EU (VAT included) / A8 Plus (EU Plug) - $229.00 EU (VAT included) / A8 Plus (EU Plug) + Tempered Glass Hotbed Platform - $239.00 Brazil / A8 Plus (EU Plug) - $339.00 Canada / A8 Plus (US Plug) - $269.00 Russia / A8 Plus (EU Plug) - $229.00 UK (VAT included) / A8 Plus (EU Plug) - $229.00 UK (VAT included) / A8 Plus (EU Plug) + Tempered Glass Hotbed Platform - $239.00 Vietnam / A8 Plus (EU Plug) - $276.00

United States

EU (VAT included)

Brazil

Canada

Russia

UK (VAT included)

Vietnam

A8 Plus (US Plug)

A8 Plus (US Plug) + Tempered Glass Hotbed Platform

A8 Plus (EU Plug)

A8 Plus (EU Plug) + Tempered Glass Hotbed Platform

1 2 3 4 5 6 7 8 9 10+ Quantity

Quantity

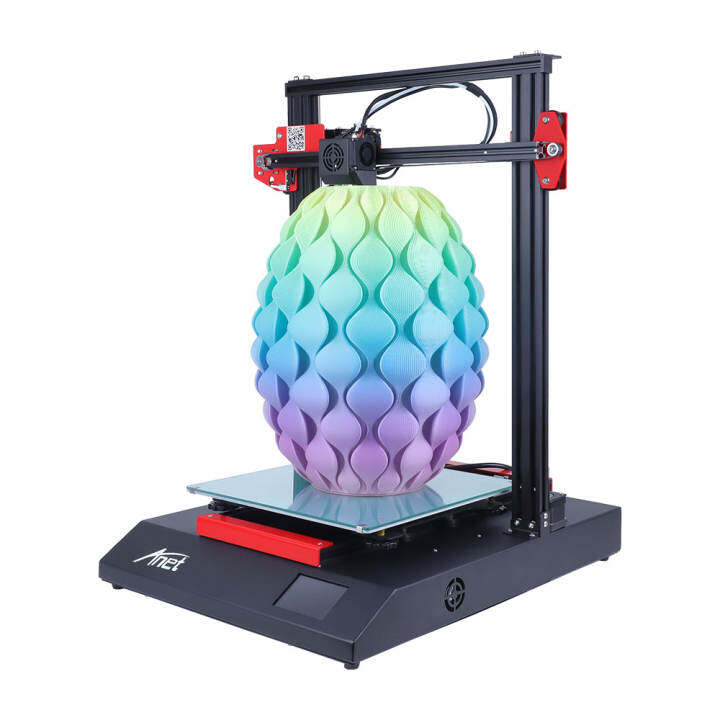

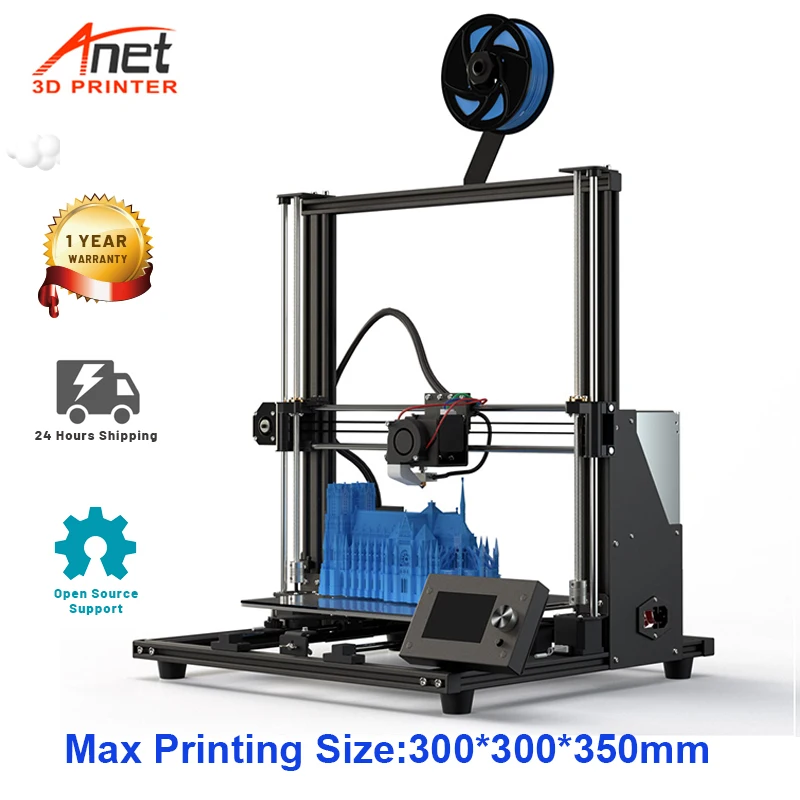

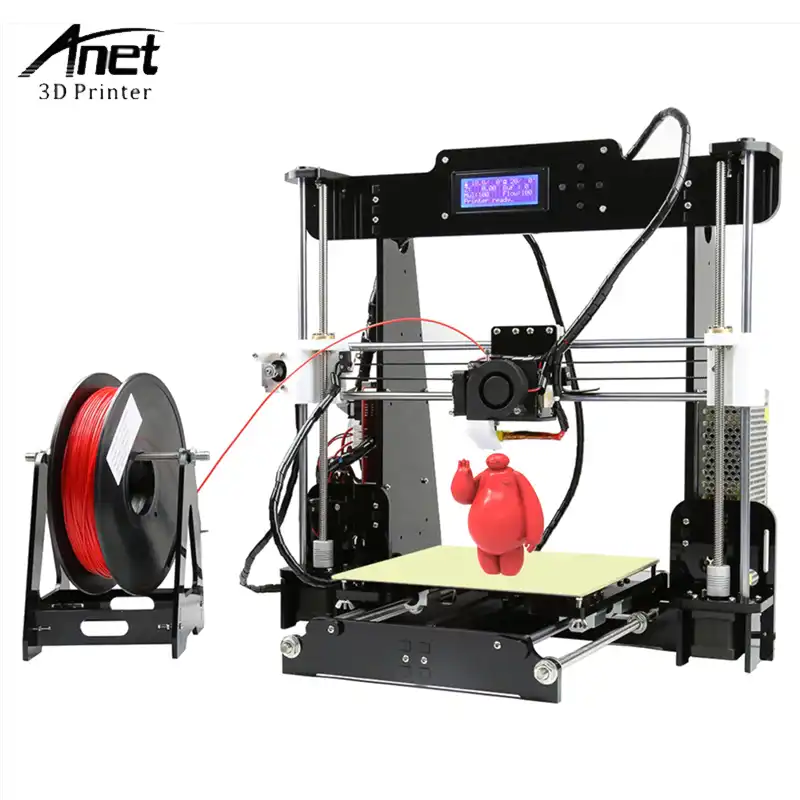

Share this:Anet A8 Plus is an upgraded version of Anet A8, comes with 300*300*350mm build area, aluminum frame, and redesigned motherboard, extruder feed, belt tensioning and much more.

【Unleash your Creality】Ideal DIY kit with open-source firmware for creative people like to do upgrades and modifications on their printers.

【All-metal body】Stable structure and high printing precision.

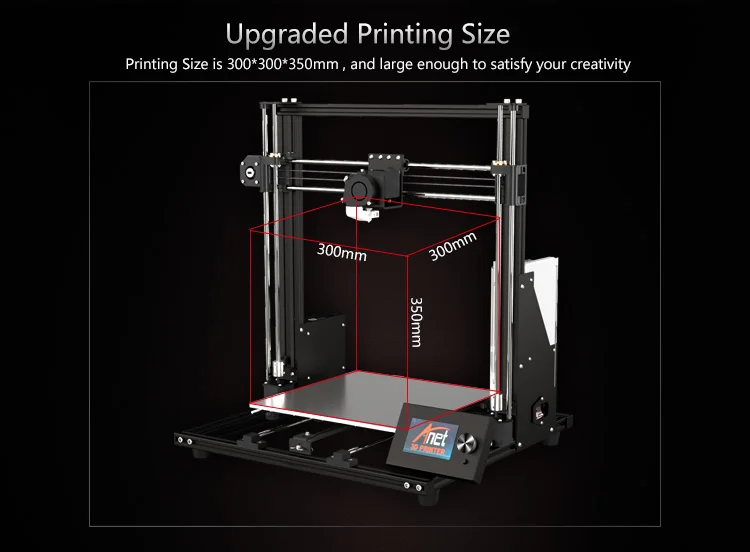

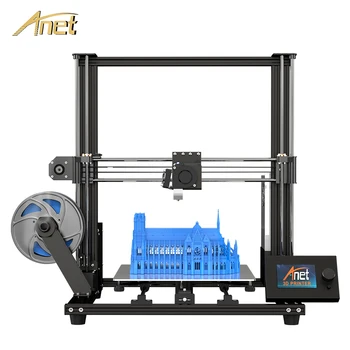

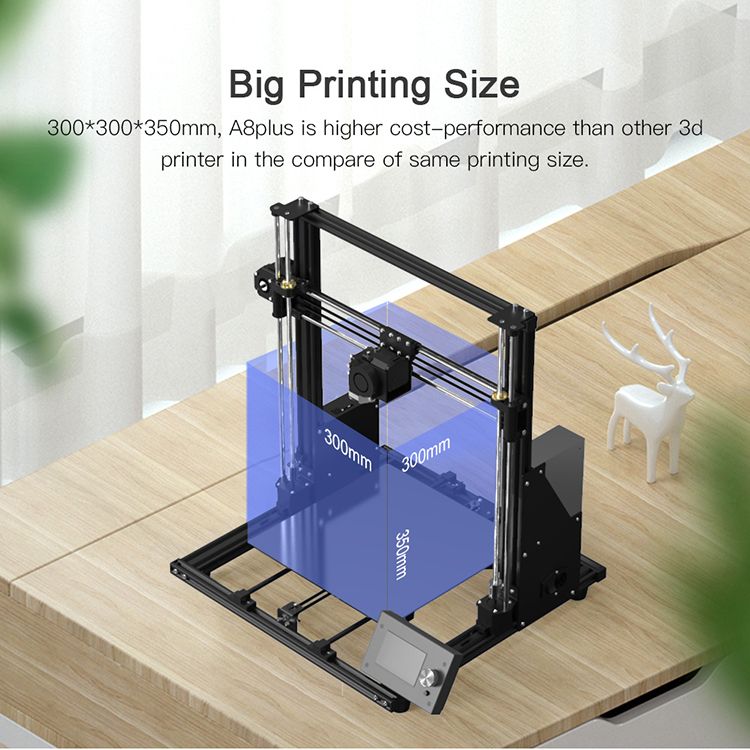

【Large Printing Volume】 Printing size is enlarged to 300*300*350mm, and large enough to satisfy your creativity. The magnetic movable LCD control panel makes your operation more efficient and more flexible.

【Automatic Filament Feeding】Automatic loading and unloading filament function.

【Upgraded Heatbed & Mainboard】Aluminum substrate heatbed comes with a glass panel so that the printing is smooth without a sharp edge and the model is easy to remove. The mainboard is safe designed with over-current protection, short-circuit protection, and a smaller current configuration.

【Anet Official Store Warranty】We provide a 6-month warranty on the printer (nozzle and build plate sheet excluded) and lifetime technical support with fast response in customer service.

Note: Please be noted that Anet A8 Plus has Full DIY version and Semi-DIY version, we'll arrange the shipment in random depending on the local warehouse stocks.

A8 Plus — anet3d.com

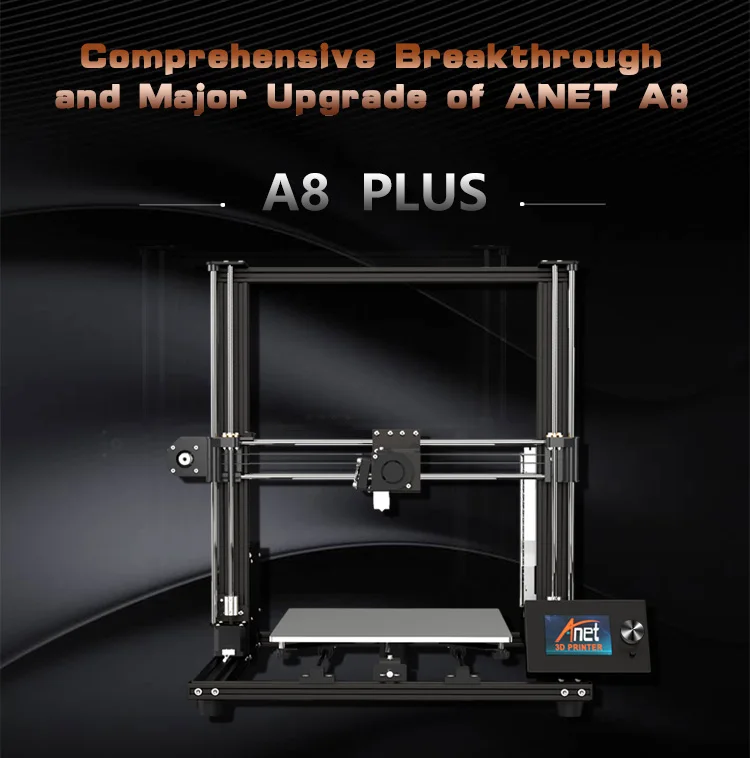

ANET A8 Plus

Upgraded Version of A8

300 x 300 x 350mm Build Area

WHAT WE ARE PROUD OF...

THE MOST SIGNIFICANT NEW FEATURES OF A8 Plus

Stable Aluminum Frame

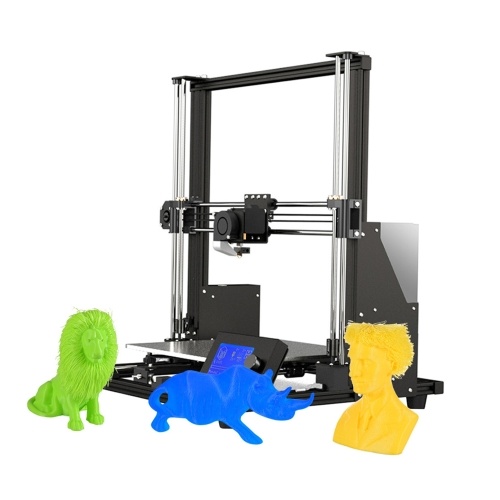

Large Printing Volume

Removable Glass Heat Bed

Sturdy aluminum frame with two Z-axis double-threaded rods design leads to greater stability and high printing precision.

Printing size is enlarged to 300*300*350mm, and large enough to satisfy your creativity.

The removable glass panel makes your printing smooth without sharp edge and more easy to remove the models.

Magnetic LCD Control Panel

Upgraded Mainboard

Convenient Belt Tensioning Mechanism

The magnetic movable LCD control panel makes your operation more efficient and more flexible.

The mainboard is safe designed with over-current protection, short-circuit protection, and smaller current configuration.

Convenient belt adjustment with a slider that can be moved by tightening a wing nut (Y-axis) or turning a screw (X-axis).

READ MORE ABOUT FEATURES OF OUR BRAND NEW ORIGINAL A8 Plus IN THE RELEASE ARTICLE AT ANET AND IN THIS UPDATE ARTICLE ABOUT NEWS.

Official Announcement Video

A8 Plus Use Guideline

What They Say About A8 Plus

The Anet A8 PLUS is big, cheap and won't catch fire. 3D Printer Review

"I can actually recommend this machine for those of you who want a cheap enough but fairly capable large-volume 3D printers kit that would benefit hugely from a few basic mods and upgrades. "

"

Unboxing 3D Printer Besar - Anet A8 Plus

"Body atau rangka dari 3D printer ini walau kelihatan nya sederhana, tapi sangat kokoh dan tidak goyang. Karena frame nya yang kokoh, hasil cetak nya pun menjadi bagus seperti yang ada pada video. "

FULL FEATURES LIST

Product Specification

- Product Dimension: 612*462*573mm

- Screen: LCD12864

- Extruder Quantity: 1

- Nozzle Diameter: 0.4mm

- Power Supply: 115V/230V AC 360W

- Slicing Software: Cura / Simplify3D

- Data Input Format: STL, OBJ, JPG

- Data Output Format: Gco, Gcode

- Operating System: Windows, MAC

- Language: English

- Connectors: USB/TF Card/Online

- Main Frame: Metal

- Packing Dimension: 580*375*175mm/600*570*215mm

- Net Weight: 10±0.1kg

- Gross Weight: 12.1±0.1kg/12.8±0.1kg

Printing Specification

- Build Volume: 300*300*350mm

- Precision: Z: 0.004mm; XY: 0.012mm

- Printing Precision: ±0.1mm

- Printing Speed: 40-120mm/s

- Layer Thickness: 0.1-0.4mm

Working Condition

- Temperature: 0-40℃

- Humidity: 5-80%

Recommended Filament

- Filament Diameter: 1.75mm

- Printing Material: PLA, ABS, HIPS etc.

Anet A8 PLUS 3D printer assembly kit

Out of stock

Add to compare

Item added to compare Go

10% discount on materials

35 900 ₽

Notify me of admission

Official distributor

We work directly with manufacturers.

Any form of payment

The opportunity to see the 3D printer in action in our demo room.

Own warranty service

Warranty and post-warranty service for equipment purchased from us.

Permanent 10% discount on consumables

When you buy a 3D printer from us,

you get a 10% discount on all consumables.

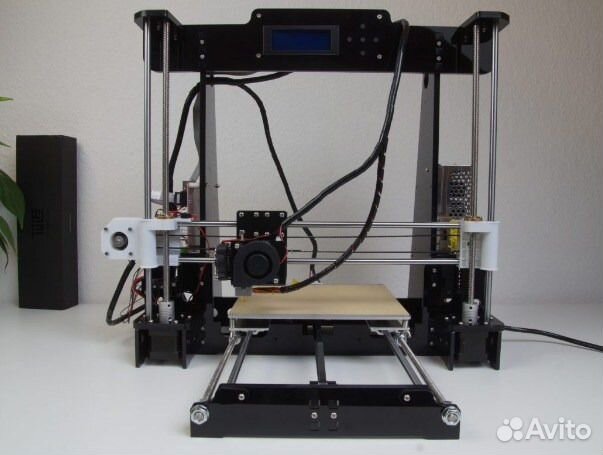

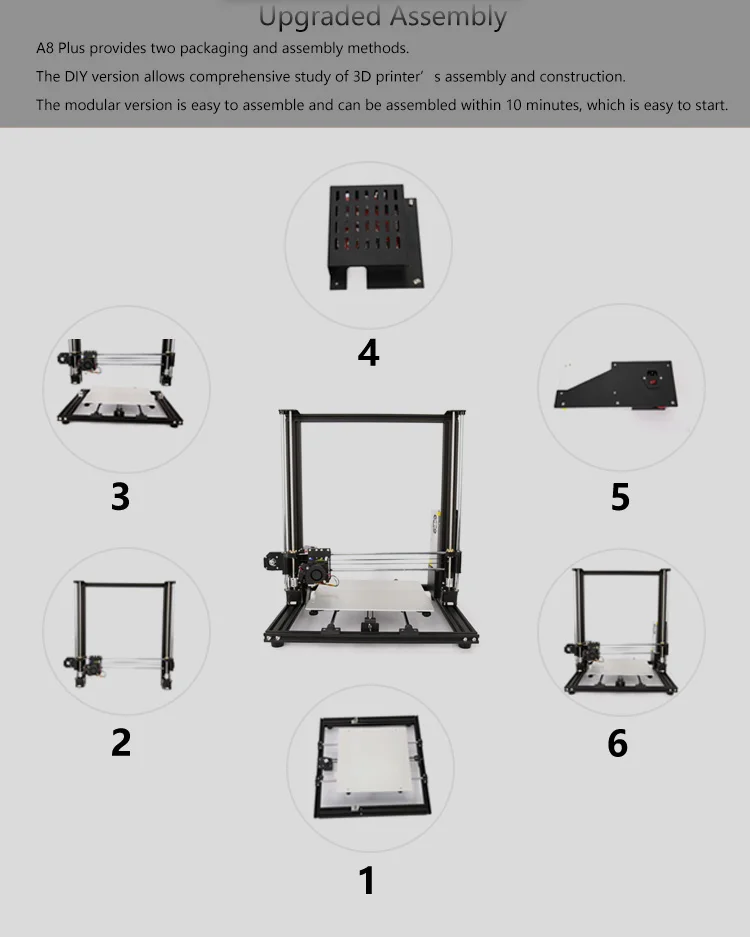

Anet A8 PLUS is a budget high-performance desktop 3D printer based on FDM printing technology and has received a number of improvements and innovations compared to its predecessor A8. An important advantage is a large build area of 300mm*300mm*350mm, all-aluminum frame, ensuring reliability and stability during printing. In addition, the electronics have been improved: an improved motherboard is integrated and protection against overcurrent and short circuit is installed. The printer comes as an assembly kit that can be assembled in just 10 minutes.

The printer comes as an assembly kit that can be assembled in just 10 minutes.

What's changed:

- Anet's unique development is a movable magnetic LCD screen with an ergonomic design and a knob to make printing easier

- Free adjustment of belt tension in Z and Y with screws. Two additional Z-axis threaded rods in front of the printer's aluminum frame and two Y-axis guides. These innovations guarantee a stable, stable printer design and high print quality

- Glass coated aluminum print bed for good first coat adhesion

- Updated extrusion mechanism with automatic smooth filament feeding and loading system. There is also a convenient automatic filament unloading function The

- A8 PLUS prints with a wide range of filaments, including flex and decorative laminas. Improved mechanism for printing with flexible plastics. However, the recommended plastic is still PLA 9.0037

- Printing can be managed both online and offline by loading a job from a TF card

- Intuitive Cura Slicer

- Large build area 300mm*300mm*350mm, allowing large models to be printed

Payment and delivery

Delivery scale

Delivery to all regions of Russia and countries of the Customs Union.

Free shipping

When you buy a 3D printer (except assembly kits) you get free shipping.

Cash

In our store you can pay for your order in cash.

Online payment on the website

You can pay for orders with a bank card on the website of our online store.

Updated Anet A8 Plus. Large and metal / Habr

Hello! I am pleased to present to the attention of readers a review of the updated hit from Anet3D - the Anet A8 Plus printer. It really became noticeably larger and truly metallic. In addition, the manufacturer has done some serious work on the bugs and the printer is now assembled very easily and really prints out of the box, even despite some minor problems.

We are talking about this device:

Under the cut, letters, photos and videos about preparation for work and modest operating experience.

Main technical specifications (from official sources):

- Print area 300x300x350mm

- Structural aluminum frame 20x20mm and 20x40mm

- Double 8mm polished shafts and linear bearings on each axle

- X and Y axis drive with belt tensioner

- Two Z-axis stepper motors with trapezoidal drive screws

- Additional fuses for overheat protection

- Removable control panel (display with encoder)

- Heated table

Unpacking

The printer begins to pleasantly surprise already at the stage of delivery. Everything is very well packaged in a neat polyethylene foam brick. The size of the box is quite reasonable, despite the fact that the printer is already almost completely assembled.

Everything is very well packaged in a neat polyethylene foam brick. The size of the box is quite reasonable, despite the fact that the printer is already almost completely assembled.

On top of this brick is the base of the printer with the rails and table installed. Glass for printing has already been thrown on the table and there are stationery clips. I always printed just like that and advise everyone. I just like the mirror better.

At the bottom is the vertical part of the frame with the X and Z axes, as well as all the electronics from the printer.

Printer also includes:

- Two screwdrivers

- Hex key set

- MicroSD memory card 8 GB with USB adapter

- Side cutters

- Spool holder

- PLA Probe (approx. 10m)

- Braid for wires

- Spare fuses

- Air nozzle

- Fingerguards

- Instruction

Assembly

The vertical axis is set first. To begin with, it is screwed with a corner and a screw at the end of the profile. You can immediately remove the transport ties, fixing straps and tighten the set screws of the Z-axis studs. That's it! This completes the assembly of mechanics!

To begin with, it is screwed with a corner and a screw at the end of the profile. You can immediately remove the transport ties, fixing straps and tighten the set screws of the Z-axis studs. That's it! This completes the assembly of mechanics!

Frame base made of 20x20mm aluminum structural profile. Guides along the Y axis 20x40mm. There are very few plastic parts and almost all of them are made by casting. Even the auxiliary parts of the extruder are made of thin sheet metal. Both X and Y belts have normal tensioners.

With all this, it's the same, good old Prusa. On belts, ball screws, shafts and linear bearings. Here I must make a small digression. Despite all the disadvantages of this linear movement system, I consider its use in budget machines more than justified. If the shafts are bent or the bearings have deteriorated, they are always very easy to find and change. Also, if the shafts are not parallel, they can always be moved a little and adjusted. If you take a machine on rails or rollers, then this will be a completely different price category.

The power supply is mounted on the right side of the machine and plays the role of an additional scarf that adds rigidity to the structure. Please note that it also has a metal casing, a network cable connector and a toggle switch to turn it on. And all this, of course, is already assembled and connected.

Next, the limit switches for the X and Z axes are installed. Everything is already thought out and molded in plastic. All fasteners are optimally matched. X-axis limit switch seat:

Even the Z-axis limit switch holder is made of metal. It is attached very securely, and it is very easy to move it for calibration.

One of the RAMPS variations from Anet3D is also used as a motherboard. The drivers are soldered, there is an adjustment of the Z-axis current. On the one hand, this is a minus (the fact that the drivers are not removable), on the other hand, in my practice, not a single driver was damaged. There is a fuse on the table and a slot for printing from a memory card. The board is also stitched with some Marlin assembly from the manufacturer. At the end of the article I will give a link to the software for this machine, but even on the stock firmware everything started up confidently for me.

The board is also stitched with some Marlin assembly from the manufacturer. At the end of the article I will give a link to the software for this machine, but even on the stock firmware everything started up confidently for me.

Connecting the wires takes much longer than assembling the mechanics. But everything is signed and you can connect especially without looking at the instructions. You don't need to solder anything. All switching is thought out very competently. Even for limit switches, special cable lugs are made.

By the way, the table heats up from 24V. With the old model, I had a problem that the heater contacts in the connector were heated. Anet A8 Plus has two contacts in the table connector for plus and minus (and the wires themselves are also duplicated), and the contacts themselves are filled with sealant.

I'll add an illustration here with a picture to connect. It just shows the board itself better. In fact, it doesn't even need it. There are signatures on the board, and nameplates on all cables. This generally applies to the entire machine as a whole. Everything is assembled very clearly and intuitively.

There are signatures on the board, and nameplates on all cables. This generally applies to the entire machine as a whole. Everything is assembled very clearly and intuitively.

As a result, after fully assembling and cleaning the wires into a braid, it looks like this: By the way, it is installed in a very original way on a spear with a magnet and you can remove it, pick it up and control the printer like a large adult CNC machine from the remote control!)

Display with encoder and reset button is in a separate metal box. Having disassembled it, I still found something to complain about in this machine!

Extruder

At first glance, it makes a very good impression. It is not much different from the popular MK2 and it will be easy to find spare parts for it. In fact, the manufacturer made sure that the coolers for cooling the extruder and the model were immediately conveniently installed on the printer. The thermal barrier itself has an additional heatsink installed right in front of the cube - a very elegant solution compared to how it was on the previous version.

Additional plastic guides available. I have tried printing with Flex and have had no problems loading or extruding.

Calibration

With such a large print area, it turned out to be much more difficult than I expected.

At first I had problems with too little current being set on the Z axis. The right engine began to skip steps and the entire calibration immediately floated away. But I figured out this problem very quickly, and then the dancing around the frame began.

Looking ahead, I will say that in the end I was able to calibrate the printer only on a flat piece of chipboard with a piece of fiberglass under my near right foot. And to come to this decision, I spent 8 hours!

The large size of the printer causes more calibration problems. Even with a very small diagonal skew of the frame, this becomes almost impossible. I put it on a flat chipboard panel and tried to align all the mechanics with it. Perhaps I managed to eliminate some large irregularities, but in the end I just experimentally selected under which leg and how thick to put the part. But in the end everything turned out just perfect. I even dragged it from place to place in this form.

Perhaps I managed to eliminate some large irregularities, but in the end I just experimentally selected under which leg and how thick to put the part. But in the end everything turned out just perfect. I even dragged it from place to place in this form.

Video

Much of what I said and something else new can be seen in the video:

If you try to sum up, I would say that nothing has changed fundamentally. Yes, the structure has become metal, but everything has become larger and heavier.

In other words, there is a clear increase in print volume, but not in quality. It remained quite suitable for printing various structural elements. And there is a nice bonus from the fact that the printer began to print noticeably quieter (probably due to the rubber feet in the first place).

To an inexperienced viewer, it may seem that the test model is printed very poorly. It is made with a 0.