3D printed guitar picks

The Pros And Cons Of 3D Printed Guitar Picks – FuelRocks

//

By

Eric

//

Guitar Equipment

3D printed guitar picks are becoming increasingly popular among guitarists. While many guitarists still prefer the feel and sound of traditional picks, others are finding that 3D printed picks offer a unique playing experience. So, are 3D printed guitar picks better? There is no simple answer to this question. It depends on the preferences of the individual guitarist. Some guitarists find that 3D printed picks provide a better grip and more control over their playing. Others prefer the traditional feel and sound of picks made from materials such as celluloid or tortoise shell. Ultimately, it is up to the individual guitarist to decide whether 3D printed guitar picks are better for their playing style. If you are curious about trying out a 3D printed pick, there are many companies that offer them for sale.

Guitar picks are 3D printed in the printer. What do you love about playing guitar? With a 3D printer, you can now make your own guitar picks that are entirely custom-made. You can make as many selections as you need for the next show using only a few clicks and under $10 using our online tool. 3D printing has managed to hijack my interest in music history. Adam Beane, in collaboration with 3D printer manufacturer Trion Design, created a unique, highly accurate replica of the 1962 Gibson J-160E acoustic guitar designed by John Lennon. The print’s movement allows it to be used as a wind gong.

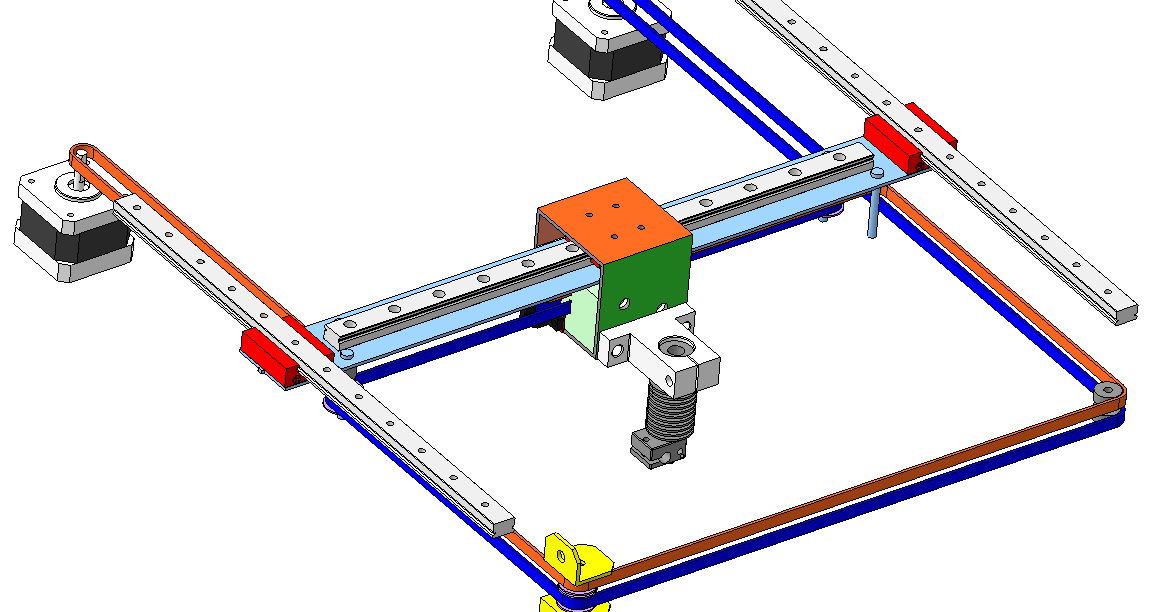

The world premiere of a 3D printed guitar replica of John Lennon’s J-160E acoustic guitar took place in New York City’s Discovery Times Square. Using open-source 3D tools like the MakerSlide or V-Slot Linear Guide System, you can accurately replicate your guitar’s neck geometry and scale lengths. Carbon fiber is wrapped in a cloth to create a series of accessories for the bass guitar made out of wood. A very old bass guitar neck, which had sat in a corner of our filthy workshop for many years, was used in the first two pieces. Since then, I have printed a few other pieces that fit in the series, and I am currently looking for vintage/broken bass necks and bodies. My own basses are in need of replacement parts, and I’ve begun working on them with 3D printers. Because Shapeways does not allow custom designs, these items will only be available on Etsy. If you have any questions about this project or if you have any suggestions for me to try, please feel free to leave a comment or email me.

A very old bass guitar neck, which had sat in a corner of our filthy workshop for many years, was used in the first two pieces. Since then, I have printed a few other pieces that fit in the series, and I am currently looking for vintage/broken bass necks and bodies. My own basses are in need of replacement parts, and I’ve begun working on them with 3D printers. Because Shapeways does not allow custom designs, these items will only be available on Etsy. If you have any questions about this project or if you have any suggestions for me to try, please feel free to leave a comment or email me.

Can You Make The Guitar Pick With A 3d Printer?

Source: cgtraderIf you enjoy playing the guitar, you are probably aware that it is relatively easy to misplace a pick. 3D printing might be the solution you’ve been looking for, whether it’s a simple inconvenience or a life-changing event. When it comes to 3D printing, it is no longer necessary to run out another print to replace a pick.

Despite this, there are several low-cost 3D printers capable of producing high-quality guitars. A 3D printer like the Gizmo can be made. With this printer, you can print guitars that are as heavy as 60 percent lighter than traditional guitars. In addition, the Gizmo 3D printer can be used to 3D print guitars that are made of metal or plastic. The MakerBot Replicator 2X is a high-quality 3D printer that can 3D print guitars in good quality. Guitars can be printed using this printer that weigh up to three times as much as traditional guitars. Guitar printing can be accomplished on the MakerBot Replicator 2X using a variety of materials, including metal and plastic. In terms of professional musicians, this technology is likely to increase in popularity as 3D printing becomes more affordable and high-quality guitars can be printed using these printers. Gizmo 3D printers and MakerBot replicas 2X are the best options for beginners looking for ways to make their own guitars.

What Is The Best Material To Make A Guitar Pick Out Of?

Source: guitarsixThe best materials for guitar picks are hard plastics that can be cut into the shape of a pick with a pick punch, but any material can be made into a pick-shaped cutout with a pick punch. If you don’t have a stick, use a credit card, gift card, ruler, or other hard plastic as a pick. You’ll need a cheap piece of plastic to make your picks; don’t worry if it ruins your selection.

Each of the guitar picks can be made from a variety of materials and has an impact on the sound and playability. Plastics, such as nylon, can be found in almost any product on the market today. In addition to wood, stone, and tortoiseshell, other materials are now extinct due to extinction. Many guitars are modeled to resemble tortoiseshells because they have the same design and quality as those made of celluloid. Unlike other guitar picks, the texture of cellular picks is pearl-like, giving them a luxurious appearance. Stone’s density and tone make it a versatile material with a distinct character. The pickups in these guitars produce a similar tone to a standard guitar.

Stone’s density and tone make it a versatile material with a distinct character. The pickups in these guitars produce a similar tone to a standard guitar.

The Different Sounds Of Nylon And Tortex Guitar Picks

Nylon guitar picks produce a crisp, smooth sound that is accompanied by a smooth release from the strings. Tortex picks have a bit more bite, but they do not last as long and wear down quickly. The Dunlop Nylon Standard is an excellent choice for those who require a long-lasting pick.

Is 3d Printed Metal Stronger?

According to a report published today in Nature Materials, certain conditions led to the final 3D printed stainless steels being up to three times stronger than steels manufactured using traditional methods and, in some cases, still ductile.

This is a rapidly growing industry that is becoming more and more prevalent. How strong is 3D printed material compared to traditional metal? Companies can use a 3D printer to make parts that are small, medium, or large in size. Casting and CNC fabrication both produce metals faster than 3D printing. Metals used in 3D printing for large-scale mass production may not work well. The size of the finished product should not be greater than that of the printer. The cost of a 3D printer will be determined by its size, quality, and technology.

Casting and CNC fabrication both produce metals faster than 3D printing. Metals used in 3D printing for large-scale mass production may not work well. The size of the finished product should not be greater than that of the printer. The cost of a 3D printer will be determined by its size, quality, and technology.

The most expensive 3D printer materials are PAHT CF15, which is reinforced with High Temperature Polyamide carbon fiber, and PAHT S120. The cost of 3D printers that can print for metals is one of the reasons that people avoid investing in them. However, due to the fact that the 3D printer produces far less waste than alternatives, you can save a lot of money in the long run.

During laser selective melting, the metal is 3D printed with high mechanical properties. Casting or forged steel parts can be produced in this technology. Parts made of SLS printing can be much stronger than traditional steel parts. In terms of strength, 3D printed parts are not limited by their printing properties. In practice, a 3D printed part can be as strong or stronger than a traditional metal component as long as it is properly designed. It is critical to remember the following points when printing with SLS technology. Make certain that you select the right printing material. The result is that the country is in a deep recession. The design of the part must be considered. To ensure that the part is printed correctly, test it. You can guarantee that your 3D printed parts will be as strong as traditional metal parts by following these three steps.

In practice, a 3D printed part can be as strong or stronger than a traditional metal component as long as it is properly designed. It is critical to remember the following points when printing with SLS technology. Make certain that you select the right printing material. The result is that the country is in a deep recession. The design of the part must be considered. To ensure that the part is printed correctly, test it. You can guarantee that your 3D printed parts will be as strong as traditional metal parts by following these three steps.

3D Print Your Own Guitar Picks On Thingiverse – FuelRocks

//

By

Eric

//

Guitar Equipment

If you’re a musician, you know how important it is to have the right guitar pick. And if you’re a 3D printing enthusiast, you know that you can print just about anything you can imagine. So why not combine the two and 3D print your own guitar picks? With Thingiverse, you can find hundreds of different designs for 3D printed guitar picks. Whether you want a pick that’s simple and functional or one that’s flashy and unique, you’re sure to find something that suits your style. And if you can’t find anything you like, you can always design your own and upload it to the site for others to use. So if you’re looking for a new way to personalize your guitar playing, or just want to try something new, 3D printing your own guitar picks is a great option. Check out Thingiverse today and see what you can create!

Whether you want a pick that’s simple and functional or one that’s flashy and unique, you’re sure to find something that suits your style. And if you can’t find anything you like, you can always design your own and upload it to the site for others to use. So if you’re looking for a new way to personalize your guitar playing, or just want to try something new, 3D printing your own guitar picks is a great option. Check out Thingiverse today and see what you can create!

The guitars are printed on either one or both sides, and the colors are available in a variety of patterns and sizes, with thicknesses ranging from 0.71mm to 0.96mm.

Can You 3d Print Guitar Parts?

Image Source: gadIt may appear that guitars pose a challenge to 3D printing because they can be made from solid or hollow bodies, have long necks, strings, and even electronic components. However, the makerverse will not give up on the challenge. This article will show you some fantastic 3D printed guitars that can be played.

The guitar pick is one of the most common 3D printed accessories for playing a guitar. Capos are used to shorten and raise a fretted string instrument’s pitch. A print-in-place hinge and a ratcheting mechanism allow LoboCNC’s capo to clamp down the strings. You can adjust the strings on your electric guitar by using 3D printed guitar string winder gauges. Wall mounts are an excellent way to add a touch of class to your room. This type of wall speaker is strong enough to stand up to the weight of a heavy guitar but still fits inside the wall. PrusaPrinters.org has many different guitar pick holders, but we only cracked one of them. By printing your guitar in ten minutes, you can prevent it from falling and breaking.

What Are The Dimensions Of A Guitar Pick?

Image Source: pinimgA thin pick (also known as a light pick) can range between 0.45 mm and 0.70 mm in thickness. It can range between 0.660 and 0.80 millimeters in thickness for ‘Medium’ picks. The thickness of the guitar picks in ‘Heavy’ ranges from 0.80 to 1.2 mm. A guitar pick with a thickness of 1.2 millimeters or more would be considered extra heavy.

It can range between 0.660 and 0.80 millimeters in thickness for ‘Medium’ picks. The thickness of the guitar picks in ‘Heavy’ ranges from 0.80 to 1.2 mm. A guitar pick with a thickness of 1.2 millimeters or more would be considered extra heavy.

Choose from a variety of thicknesses, ranging from light to heavy. Because the thickness of the pick affects both tone and technique, it is critical to get it right. Extra light picks can be used when strumming on a rhythm acoustic guitar. Heavy picks produce a more dominant tone with a light tone. The medium pick is the most versatile of all the picks. It can also be used for strumming and playing lead (light and extra light don’t always produce enough oomph or clarity to play single notes). A medium pick produces a bass sound that is more pronounced than a lighter pick type, but it also has a nice balance of mids, treble, and bass.

Pickmakers are typically made of a wide range of materials, including stone, wood, leather, and even steel. It is not only the material that changes the stiffness of the pick, but also how grippy it feels on the strings depending on which material is used. The texture of a pick can have an impact on the tone as well as the grip it provides for the guitar.

It is not only the material that changes the stiffness of the pick, but also how grippy it feels on the strings depending on which material is used. The texture of a pick can have an impact on the tone as well as the grip it provides for the guitar.

Why Guitar Picks Matte

Each guitar pick is made of one material in general: plastic (nylon, delrin, celluloid), rubber, felt, tortoiseshell, wood, metal, glass, tagua, and stone. An acute isosceles triangle is usually shaped as follows: two equal corners with a less rounded third.

Free 3D File Guitar Pick / Guitar Pick・Object for Download and 3D Printing・Cults

Water tank cap Citroën/Peugeot/Fiat

1 €

CAME portal key

1.60 €

OM Logo

Free

Plate 2x2 lego

Free

CloseCan to close cans

Free

Propeller shaft 2 mm

Free

Cinder block / cinderbrick

Free

Yin & Yang

Free

The best files for 3D printers in the Tools category nine0037

RGB Matrix Slot Machine

Free

Wolfcraft Corner Clamp 90 degrees

1. 98 €

98 €

Multi-Color Christmas Candle

Free

COCOLOR - for TAMIYA and MR.HOBBY acrylic colors

5,80 €

nine0003 GFCI outlet tester wall mountFree

Headphone holder for office desk divider

0,50 €

Mechanical limit caliper

3.20 €

telephone ring holder

0,90 €

Bestsellers in the Tools category

nine0003 Case for Chill Buddy lighter0,93 €

Bit holder Spartan 4 mm Hex

1,80 €

Phone holder

2.44 €

Quick Print Paint Bottle Rack (6 sizes)

2. 87 €

87 €

Shrek Pooping Toothpaste Topper

2.82 €

3D printed wave transmission (harmonic drive)

4.99 €

UNIVERSAL BED LEVELING INDICATOR FOR VERY ALL PRINTERS

2,81 €

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang. CR-10, Micro Swiss direct drive and bowden compatible. Printing does not require support

1.56 €

ENDER 3 S1, S1 PRO, SPRITE, HOT END DUCT 4020 OR 5015 FAN, PROBE NO Y OFFSET

€2.29 -twenty% 1.83 €

INDICATOR FOR BETTER BED LEVELING FOR ENDER 3 V2

2.81 €

Paint stand with scissors

€5. 20

20

Cut-Man - PET bottle cutter with handle!

€3.49

Tool holder for 3D printer V3.0

1.04 €

PRECISE DIAL INDICATOR 3D PRINT DIY

1.91 €

Ender 3 Briss fang Gen2, red lizard, spider, nf crazy, dragonfly, etc. nine0004

1.73 €

Quick print stackable parts containers / storage boxes

2.87 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so support us in maintaining the activities of and creating future developments is very simple. Here are 4 solutions available to everyone:

-

ADVERTISING: Disable the AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community! nine0006

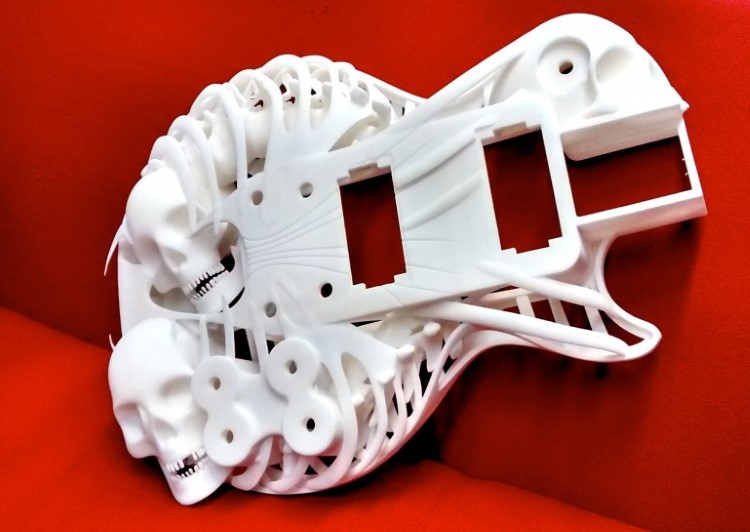

New development for guitars - 3D printed pickups (+ video)

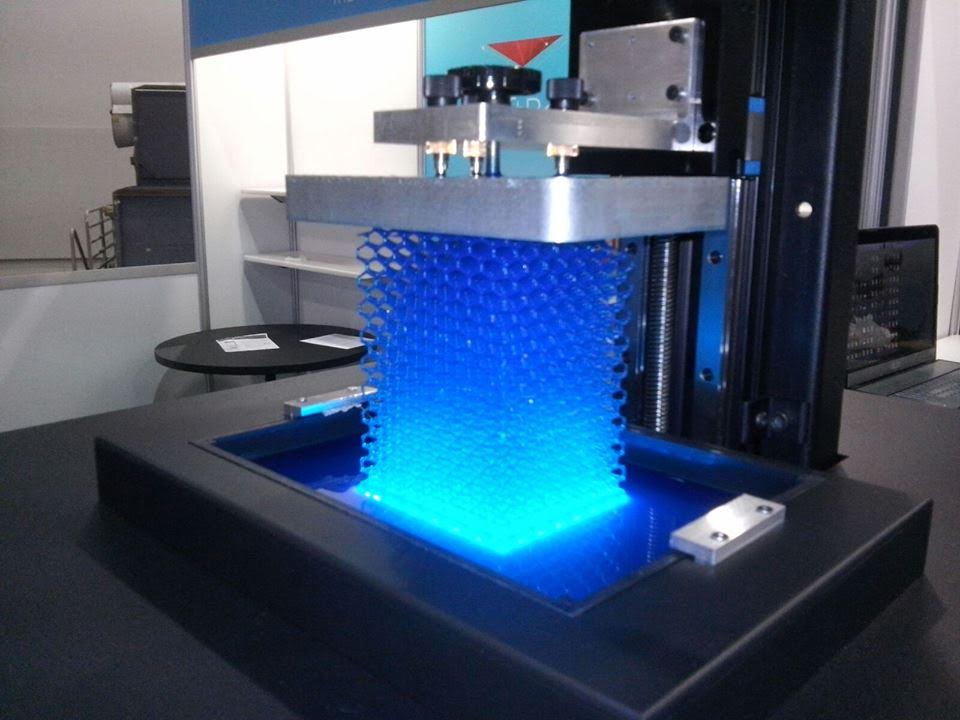

Now 3D printing has reached the point where it can be used to print a guitar that sounds exactly like a traditionally produced instrument. However, in addition to this, 3D printing technologies can be used to radically change the way you play the guitar.

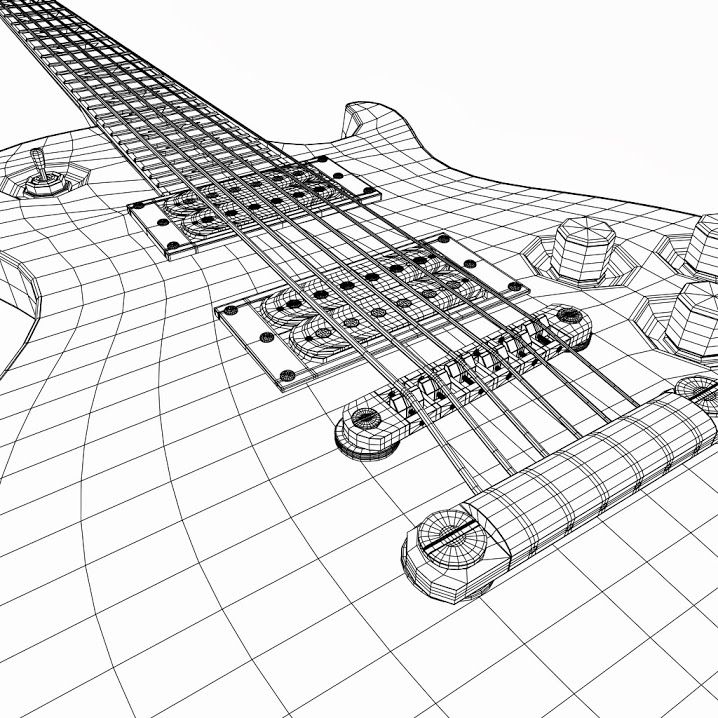

Looking for an innovative way to use guitars, Andrew Strassell, owner of an independent custom guitar company, came up with an idea that could truly revolutionize the industry. One of the main disadvantages of electric guitars is that the pickups that pick up the vibrations of the strings are almost impossible to replace. Since different types of pickups produce different tones, players who want to experiment with sound usually have to use multiple guitars. This is not only expensive and irrational with a limited budget, but also not very convenient, since you have to constantly change tools during the game. nine0006

Since different types of pickups produce different tones, players who want to experiment with sound usually have to use multiple guitars. This is not only expensive and irrational with a limited budget, but also not very convenient, since you have to constantly change tools during the game. nine0006

It's not that the pickups can't be replaced, it's just that the process is time consuming and requires the entire instrument to be taken apart and reassembled, so there is a risk of damage to the guitar. However, Strassell has designed a guitar that uses a 3D-printed cartridge cartridge that is as easy to replace as inserting a different game cartridge into a video console. Thus, musicians will be able to easily switch between the traditional sound of hard rock, blues or country if they wish. In addition, guitarists will be able to install the cartridge upside down - thereby obtaining a reverse polarity, which opens up new facets of sonic experimentation. All this can be done in seconds on the same guitar. nine0006

nine0006

“The biggest beneficiaries of this development are small local groups. They no longer have to spend $1,500 on a Les Paul that they would never take apart because it cost so much. Our solution is much more advanced than the cheap Korean-made guitars, and provides a lot more options,” says Straussell.

“There is a lack of innovation in this area, it's just that no one is promoting it. Fewer people want to play the guitar, and I believe that this is one of the fundamental musical instruments. Guitar manufacturers are basically reissuing the same half-century-old models. I think there is a demand for innovation in this industry and we need to rethink our vision of tools,” Strassell explains. nine0006

The developer also started a fundraising campaign on Indiegogo, where he set an ambitious but achievable goal of $50,000 to jump-start the business. Due to the fact that the campaign takes place on Indiegogo, where there is a flexible funding option, users who support the project will receive custom guitars, even if Strassell fails to achieve his stated goal.