Scanning 3d objects on flatbed scanner

What To Expect From 3D Scanning, And How To Work With It

3D scanning and 3D printing may sound like a natural match for one another, but they don’t always play together as easily and nicely as one would hope. I’ll explain what one can expect by highlighting three use cases the average hacker encounters, and how well they do (or don’t) work. With this, you’ll have a better idea of how 3D scanning can meet your part design and 3D printing needs.

How Well Some Things (Don’t) Work

Most 3D printing enthusiasts sooner or later become interested in whether 3D scanning can make their lives and projects easier. Here are a three different intersections of 3D scanning, 3D printing, and CAD along with a few words on how well each can be expected to work.

| Goal | Examples and Details | Does it work? |

|---|---|---|

| Use scans to make copies of an object. |

| Mostly yes, but depends on the object |

| Make a CAD model from a source object. |

| Not Really |

| Digitize inconvenient or troublesome shapes. |

| Yes, but it depends |

In all of these cases, one wants a 3D model of an object, and that’s exactly what 3D scanning creates, so what’s the problem? The problem is that not all 3D models are alike and useful for the same things.

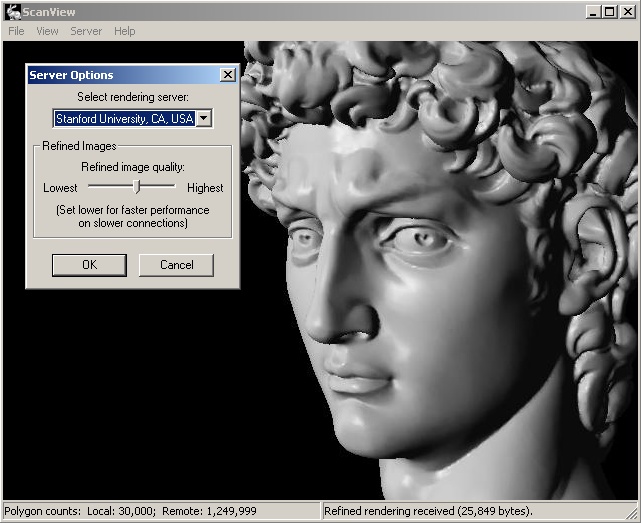

3D Scanning Makes Meshes, Not CAD Models

Broadly speaking, there are two kinds of 3D models: CAD models, and meshes. These can be thought of as being useful for engineering purposes and artistic purposes, respectively. Some readers may consider that a revolting oversimplification, but it is a helpful one to make a point about how 3D scanning, 3D printing, and CAD work do (and don’t) work together.

Hackers designing parts are typically most interested in CAD models, because these represent real-world objects that get modified in terms of real-world measurements. But 3D scanning will not create a CAD model; it will create a mesh.

Typical CAD model editing example, showing a model as a solid object, altered in terms of geometric features and real-world measurements. A typical mesh editing operation. The object is a network of points connected into a mesh, which can be manipulated and deformed.Meshes can be used for engineering purposes — . files are meshes after all, and are practically synonymous with 3D printing — but a mesh cannot be modified in the the same ways a CAD file can. With a mesh, one does not extrude a face by a specific number of millimeters, nor does one fillet a corner to a specific radius. Meshes can absolutely be modified, but the tools and processes are different. stl

stl

To sum up: 3D scanning makes 3D models from real-world objects, but the models that come out of the scanning process aren’t necessarily suitable for engineering purposes without additional work.

Options for the Home-based Hacker

At the beginning of this article I selected three typical intersections of 3D scanning, 3D printing, and CAD work to illustrate the various imperfect fits between them. Now I’ll go into those three use cases in more detail, and provide ways for the average hacker to use 3D scanning to make a project easier.

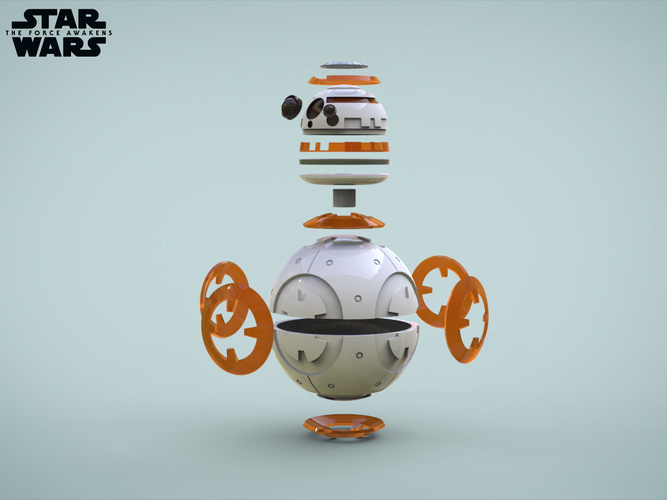

Using 3D Scanning to Create Copies

Photogrammetry is an accessible way to create 3D models, and free as well as paid options exist. Generally, the smaller and more complex an object, the harder it will be to obtain a result that preserves all the features and details.

Generally, the smaller and more complex an object, the harder it will be to obtain a result that preserves all the features and details.

Photogrammetry uses multiple photos of an object taken from a variety of different angles, and software interprets these photos to create a point cloud representing the surface of the object. A mesh 3D model representing the object can then be generated. Some cleanup or post-processing of the model is usually required, depending on the method and software.

-

- This blog post from Prusa Research walks through how to get the best results with Meshroom, a free option for 3D scanning using photogrammetry.

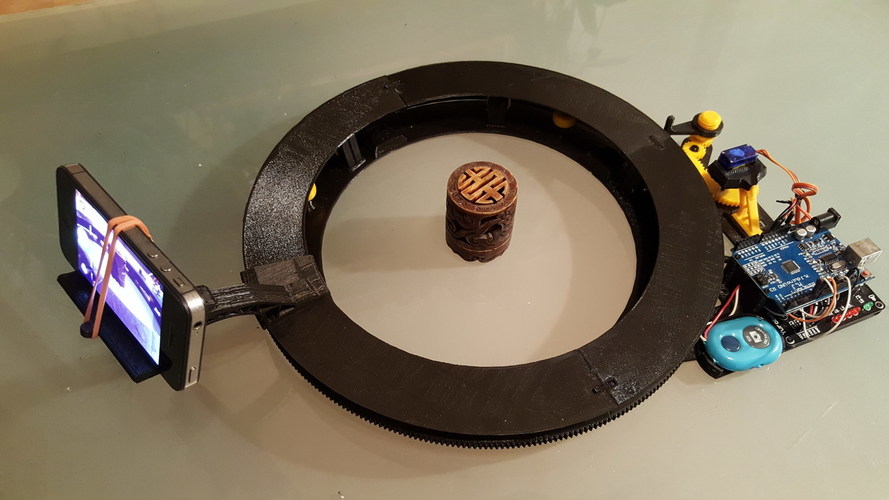

- OpenScan (and OpenScan Mini) is a DIY project by [Thomas Megel] aimed at using photogrammetry to scan small objects with high accuracy.

- RealityCapture is non-free software with a number of useful features and well-made tutorials. Notably, they have a license model option aimed at occasional use and small quantities.

Since most software subscription models rarely make sense for hobbyists and one-off projects, it can be worth a look.

Since most software subscription models rarely make sense for hobbyists and one-off projects, it can be worth a look.

Creating a CAD Model from a 3D Scan

Since 3D scanning will not generate a CAD model, it’s not a direct alternative to designing a part in CAD. Most CAD programs allow importing a mesh, but the imported mesh remains a mesh, which cannot be modified in the same way as other CAD objects. It might be useful as a guide for a new design, however.

A mesh converted to a solid will become an object made up of collection of triangular faces, identical to the ones that made up the original mesh. This is rarely what a novice CAD modeler expects.One may wonder if it is possible to convert from one format to another. It is, but the conversion may not be what one expects. Converting a CAD model into a mesh is simple enough, but converting a mesh into a CAD solid is less straightforward.

If a mesh is not too complex, it can be transformed into a solid (here is one way to do so by using MeshLab and FreeCAD) but it still won’t be a “normal” CAD object, and the image here demonstrates why.

If one’s goal is to use 3D scanning to make the creation of a CAD model easier and the conversion result shown here won’t do the trick, the next best thing is to use the 3D scan as a master and model a new part around it to match, using the imported mesh as a guide. One project that uses this approach is this custom trackball designed around a molded ergonomic prototype.

Some professional software suites have the ability to export to CAD, but the essential workflow is the same, with a scanned mesh being used as the reference for a new design.

3D Scanning to Digitize Inconvenient or Troublesome Shapes

This scan of a laser cutter’s panel is obviously only part of the whole machine, but the important part is present.Sometimes an accurate 3D model of a shape is needed, and that shape isn’t easily modeled or measured by hand. The same photogrammetry tools mentioned earlier are useful here, but their purpose is different. Instead of modeling the object from top to bottom to make an accurate copy, often only part of the object is needed.

For example, modeling the shape of an equipment panel or dashboard requires only the relevant section to be scanned successfully. A person’s head can be scanned to ensure a precise fit for a helmet or mask, and there’s no need to get a full scan of the entire body. In general, fewer pictures are needed and post-processing and model cleanup is easier because there is a smaller area of interest. A size reference must be included somehow for scaling later, because most 3D scans do not intrinsically create 1:1 models.

An excellent example of this approach is this project to design a custom control panel intended to fit an existing piece of equipment. Unlike when scanning a whole object with the intent of duplicating it, there’s no need to capture difficult-to-reach places like the bottom or back. This makes both scanning and model cleanup easier.

Professional Scanning

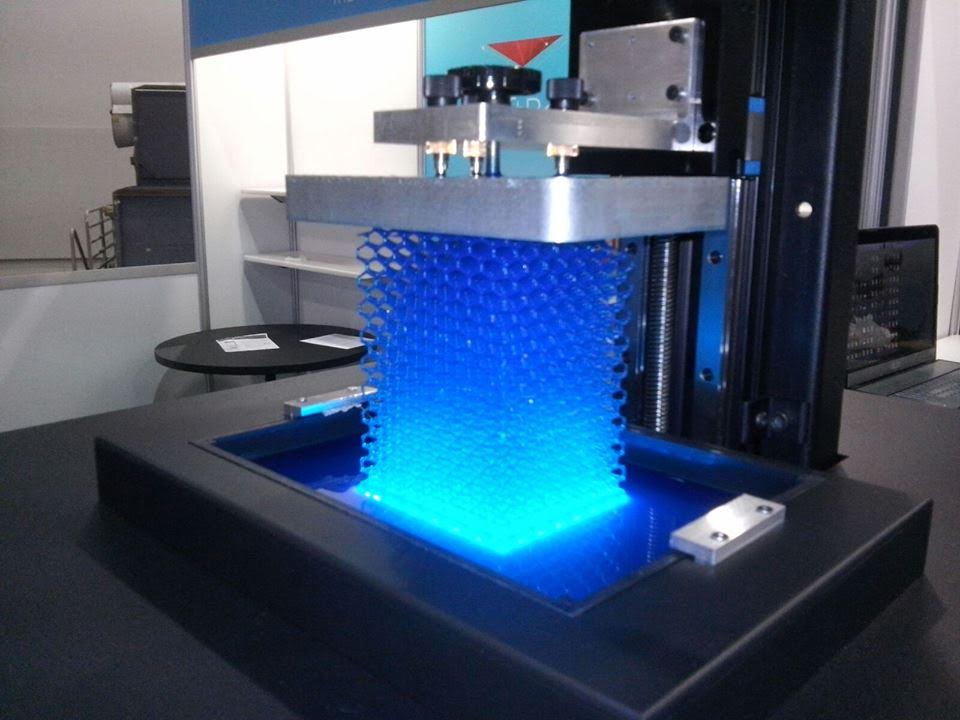

Another option is to pay for a professional scan. Fancy scanners and software suites costing thousands, or tens of thousands, of dollars and aimed at engineering applications exist, and while they are out of the reach of the average hacker, paying for a company to do a scan or two might not be.

Accuracy and resolution can be beyond what’s possible with photogrammetry, and some of the professional software suites have fancy features like aligning multiple scans, accurate size references, or the ability to generate CAD models based on scan results.

A 1:1 model from a professional 3D scanning tool, the product of aligning and merging multiple separate scans from different angles to get a complete model. It is still a mesh, but it accurately represents the original in both features and scale.Shown here is the model of a part I had professionally scanned with a Creaform HandySCAN Black 3D scanner, according to my invoice. It is an old wood grip from an antique firearm. The scan still created a mesh, but it was an accurate 1:1 model of the original that I was able to use to print replacements on an SLA 3D printer.

When getting a quote for professional 3D scanning, be sure to ask about fee structure and be clear about your needs. In my case, it was cost-effective to scan multiple similar objects under a single setup fee.

Know What 3D Scanning Can (and Can’t) Do

3D scanning is getting better and more accessible all the time, but the fact that it generates a mesh means it doesn’t always fit smoothly into a 3D printing and CAD part design workflow. That doesn’t mean it can’t be useful, but it does mean that it’s important to know the limitations, and how they will affect your needs.

Of course, one can always dig out the calipers and manually model a part in CAD, but not all parts and shapes are easily measured or reverse-engineered. 3D scanning is a great alternative to modeling complex, real-world objects that would be impractical or error-prone to create by hand.

Have you successfully used 3D scanning to make a project easier, or have a favorite method or tool to share? We definitely want to hear all about it, so please take a moment to share with us in the comments.

▷ scanning 3d objects on flatbed scanner 【 STLFinder 】

3D Scanner on Wheels

thingiverse

Not satisfied with my Ciclop scanner I designed a version dedicated for use with the Zephyr free version, and use of a Smartphone. ...

The software makes 25 photo's per revolution, so 2 camera positions are possible to have the maximun of 50 Photo's...

...

The software makes 25 photo's per revolution, so 2 camera positions are possible to have the maximun of 50 Photo's...

3D Scanning on Relievo

sketchfab

Great detail performance by KSCAN 3D scanner. ...Show you every Chinese character under blue laser scan mode with 10μm resolution.

Table rotary scanning 3D objects and photo

thingiverse

Table rotary for scanning of 3D objects or taking photos. Intervals of 10 degrees. ...I used ball bearing Z1009.

3D Scanning on Night Owl

sketchfab

PRINCE 3D SCANNER blue laser mode: resolution is up to 0. 02mm, greatly improving detail performance.

02mm, greatly improving detail performance.

3D Scanning on Portrait Sculpture

sketchfab

... hair, moustache and wrinkles. ...The PRINCE 3D scanner captures details with high efficiency under dual laser scan modes. Red laser mode: speed 480,000 measurements/s for great efficiency. ...Blue laser mode: resolution 0.02mm for extreme detail.

3D scanning on ARCore Q1/2019

sketchfab

The current state of 3D reconstruction quality on ARCore.

Cow on Grass - 3D Scanning Tutorial!

thingiverse

This is the model from the [tutorial published on Instructables](https://www. instructables.com/id/3D-Scanning-and-Printing-Statues-Using-TRNIO-and-M/)! Interested in 3D Scanning using your iOS device? ...Check out the full tutorial on how to scan...

instructables.com/id/3D-Scanning-and-Printing-Statues-Using-TRNIO-and-M/)! Interested in 3D Scanning using your iOS device? ...Check out the full tutorial on how to scan...

Shadow 3D : smartphone 3D scanner based on shadow geometry

thingiverse

3D scanner based on shadow geometry. - All you need is your smartphone except a simple jig to be printed and a blank postcard. No laser projectors or motors needed. - It can measure smooth surface which will fail with photogrammetric method,...

Camera Top for Ceb's 3d Scanner based on FabScan

thingiverse

. .. were missing the camera top in an Stl. ... The rest of the items you need to make his "3D Scanner based off FabScan open source project" are located at http://www.thingiverse.com/thing:284142. ...I circled the item I made from Ceb's original SCAD file.

.. were missing the camera top in an Stl. ... The rest of the items you need to make his "3D Scanner based off FabScan open source project" are located at http://www.thingiverse.com/thing:284142. ...I circled the item I made from Ceb's original SCAD file.

Protective scanning case for the Revopoint POP 3D Scanner- including Lens cap

cults3d

*Latest update : Upon request added 2 versions of the case, one with bigger honeycomb holes and bigger space between them to make it more resistant and print better, and one without any holes for those who wish to make their own holes in the STL with...

Printer Scanner Low Poly Subdivison On Low-poly 3D model

cgtrader

On a few models are unapplied modifiers, which you can turn of to get even less polys. --Scale-- This scene is modeled in real world scale. If you got any questions on this model just pm us, we will reply as soon as possible. ... Created by Nele...

--Scale-- This scene is modeled in real world scale. If you got any questions on this model just pm us, we will reply as soon as possible. ... Created by Nele...

Arduino UNO shield for Horus Firmware on ciclop 3D Scanner

thingiverse

On the right side you have to solder a bridge. Powered from the UNO DC-in jack. Use only at your own risk, is used the parts that i had at home, still a betaversion/work in progress . ... Instructions...

3D Scanner

grabcad

3d scanner based on intel realsense d435 camera

scanner 3d

myminifactory

scanner 3d con telefono

3D Scanner

grabcad

First prototype of 3D scanner

3D_SCANNER

grabcad

A 3D Scanner model with distance sensor

Minox film strip holder for flatbed scanner

thingiverse

Put the film strips into the holder, carrier down, emulsion up, secure them in place with the clamp, put the whole holder into the gap of the standard 135 (35 mm) film holder on the scanner glass and scan you pictures. There are four versions.

...

There are four versions.

...

3D Scanner

grabcad

3D Scanner Concept. ...add me: twitter: @martinhajsinger linkedin: @martinhajsinger https://hajsingermartin.wixsite.com/home

APS film holder for flatbed scanner

thingiverse

This is a holder for scanning analog APS film (24 mm wide) on a flatbed scanner (it is designed to work with an Epson V700 and similar models (10 mm between the glass surfaces)). Instructions: The end piece has to be mirrored and printed twice. ...

3D Scanner

thingiverse

This project has been inspired by this project:http://www. instructables.com/id/Lets-cook-3D-scanner-based-on-Arduino-and-Proces/?ALLSTEPS Since I have a 3D Printer, I have made my own design for the turn table, the laser and camera holder. See the...

instructables.com/id/Lets-cook-3D-scanner-based-on-Arduino-and-Proces/?ALLSTEPS Since I have a 3D Printer, I have made my own design for the turn table, the laser and camera holder. See the...

110 Film Holder for Flatbed Scanner - Long

prusaprinters

This works really well on my flatbed scanner, but others have used it for digitizing with their digi-cam (DSLR or mirrorless) scanning stations.To see actual prints of my design, check out the “Makes” tab (I print basically everything I design.)Print...

110 Film Holder for Flatbed Scanner - Short

prusaprinters

This works really well on my flatbed scanner, but others have used it for digitizing with their digi-cam (DSLR or mirrorless) scanning stations. To see actual prints of my design, check out the “Makes” tab (I print basically everything I design.)Print...

To see actual prints of my design, check out the “Makes” tab (I print basically everything I design.)Print...

3D Scanner

grabcad

It is a 3D scanner that is designed for Graphic Designing and Medical Purposes. ...It is a group project done by myself, Brice Veyna, Mohammad and Abdullah Alqahtani

3D SCANNER

thingiverse

some parts can be printed in large parts can be printed grabcad link to drop down https://grabcad.com/library/3d-scanner-14

3D Scanner

thingiverse

After finding the source code to a 3D scanner turntable on the internet I decided to make my own design of a 3D scanner setup. All credits for the source code goes to Whitney Potter for making the code.

Source Code can be found here

...

All credits for the source code goes to Whitney Potter for making the code.

Source Code can be found here

...

3D scanner

thingiverse

was designed to not use as much material as other 3d scanner designs. Phone/camera holder not included yet. requires a 10mmx30mmx9mm bearing and a piece of paper. ... ...

3D Scanner

prusaprinters

After finding the source code to a 3D scanner turntable on the internet I decided to make my own design of a 3D scanner setup. All credits for the source code goes to Whitney Potter for making the code. Source Code can be found here...

3D Scanner

thingiverse

Please be cautious. *** ---------- This is a 3D scanner that can be built and assembled only with 3D-printed parts, apart from the electronics (full list of components below). The scanner is driven by two stepper-motors and a range-sensor, controlled...

*** ---------- This is a 3D scanner that can be built and assembled only with 3D-printed parts, apart from the electronics (full list of components below). The scanner is driven by two stepper-motors and a range-sensor, controlled...

3D scanner

pinshape

3d scanner is for making photos in 360. it's also for apps like heges, trnio, capture etc… You can rotate arm in 360, You can rotate platform (3dscantop.stl) in 360. ...You can rotate arm and phone holder up and down You can change length of...

Scanner 3d

thingiverse

Lo scanner è stato ingrandito al 155% modificato x utilizzare all'interno dei cuscinetti di grandezza 19 x 6mm. ... Alla base sono stati eliminati i perni e sostituiti con dei perni di metallo con testa da 6mm e incollati con colla bi-componente.

... Alla base sono stati eliminati i perni e sostituiti con dei perni di metallo con testa da 6mm e incollati con colla bi-componente.

04/16/2021

Content

-

- What is 3D scan and why it is used by

- How 3D scanner

- 3D scan technologies

- Methods 3D

- Contact 3D scanners

- Non-contact 3D scanners

- Types of 3D scanners according to the principle of use

- Advantages and disadvantages of 3D scanners

- Things to consider when choosing a 3D scanner

- Applications

Currently, few people are not familiar with such a concept as 3D printing. Many companies are using modern 3D printers with might and main, recreating layouts of various shapes and sizes with their help. There are also those that recreate whole objects - not only small ones (for example, phone cases, souvenirs, sneakers), but also large ones (houses, engine parts, etc. ). But all this would not be possible without 3D scanners. It is they who allow you to accurately copy almost anything - from huge buildings and structures to humans, animals, small objects and much more. nine0003

). But all this would not be possible without 3D scanners. It is they who allow you to accurately copy almost anything - from huge buildings and structures to humans, animals, small objects and much more. nine0003

What is 3D scanning and what is it used for

Three-dimensional scanning is a technology that appeared in the 60s of the 20th century. It was created in order to transfer the physical parameters of the object into a digital format in the form of a three-dimensional model. The need for this naturally arose when people around the world increasingly began to use computers both in everyday life and in production.

The first samples of 3D scanners were quite simple and did not have wide functionality. Gradually, they became more complex and improved, making it possible to achieve an ever clearer image of the object. This has become especially relevant with the advent of lasers. nine0003

3D scanners allow you to transfer object data into digital format

3D scanning has opened up new opportunities in various areas of human activity - from the automotive industry and the military industry to design, medicine and cinema.

How a 3D scanner works

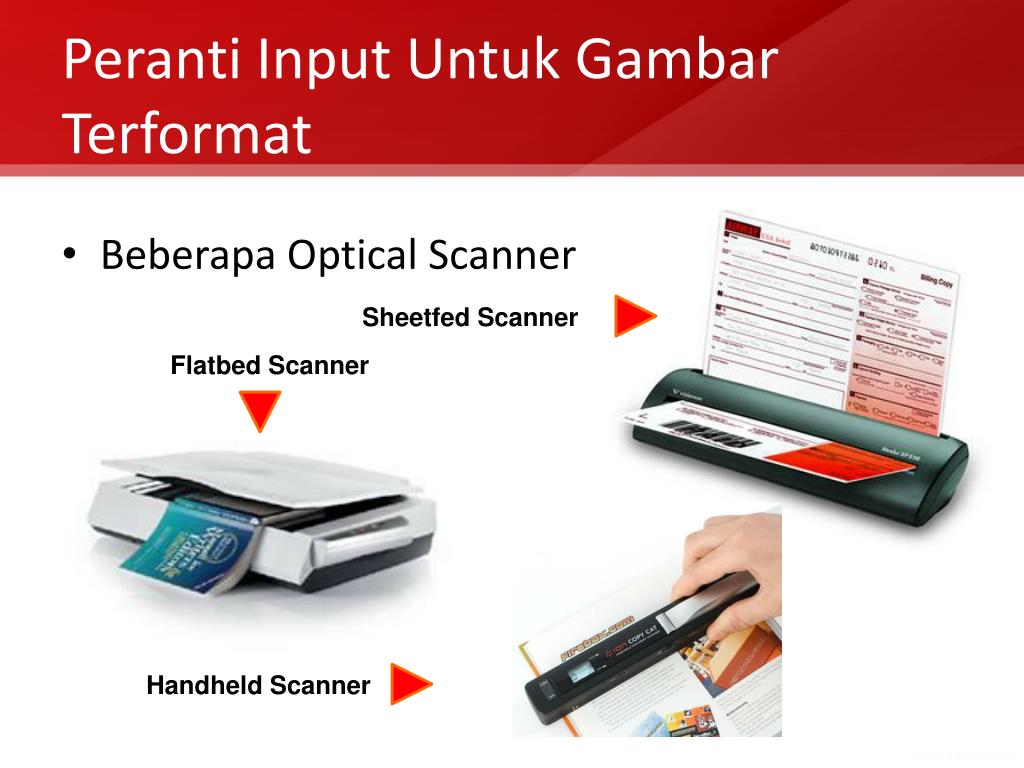

A 3D scanner is a device that examines an object by digitizing it using sensors and using the information received to create a three-dimensional model. In fact, a 3D scanner creates a digital copy of a physical object of any configuration and complexity. In this, it fundamentally differs from its predecessors - conventional scanners that can only read information from documents and photos. nine0003

The scanning process itself can take place in different ways - depending on the type of 3D device and the technology used, as well as on what object you want to process with it - moving or static.

3D Scanning Technologies

There are 2 main types of 3D scanners - laser and optical. Their fundamental difference lies in how and with the help of what the “removal” of data takes place. Let's take a closer look at both.

Laser 3D scanning, as the name implies, uses a laser and can be carried out both at short and long distances from the object. nine0003

nine0003

Laser Scanner

For the most part, 3D laser scanners work on the principle of triangulation, when the camera finds a beam on the surface of an object and measures the distance to it, after which a cloud of points is created, each of which has its own coordinates in space, and a 3D model is built. Their "advantages" are affordable price and ease of use combined with high scanning accuracy. Of the "minuses" - there are restrictions on the remoteness and size of the object. nine0003

Another type of laser scanner works by measuring the response time of a beam from the surface of an object - the so-called laser range finder. They are widely used where it is necessary to create 3D models of various buildings and structures. It is not advisable to use them at short distances, since in such cases the response time is very short and the accuracy of the data is reduced. Otherwise, this type of scanner is characterized by high scanning speed and the ability to read all the details. nine0003

nine0003

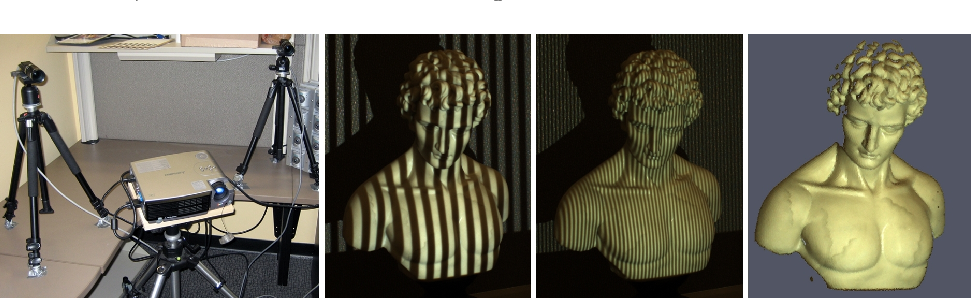

The disadvantage of laser scanners is the impossibility of their use on moving objects. Then optical 3D scanners come to the rescue, which shoot with one or more cameras from different angles an object illuminated by a special projector. Based on the received image, a three-dimensional image is built.

Optical scanner

A "contraindication" for the use of this technology are reflective and translucent surfaces - shiny, mirror or transparent. But when scanning a person, they are simply irreplaceable. nine0003

3D scanning methods

Any object can be digitized both by contact and non-contact methods. In the first case, active interaction with the subject is necessary, in the second, accordingly, no. Both of these methods have their advantages and disadvantages.

Contact 3D scanners

They have a mechanical probe with a special sensor that measures parameters and transmits the collected information to the device. To do this, the object under study is placed on a special surface and fixed (if necessary). Such tight physical contact makes it possible to determine and then build a 3D image as accurately as possible, however, there is a small risk of damage to the prototype. nine0003

To do this, the object under study is placed on a special surface and fixed (if necessary). Such tight physical contact makes it possible to determine and then build a 3D image as accurately as possible, however, there is a small risk of damage to the prototype. nine0003

Non-contact 3D scanners

This category includes all devices capable of scanning at a distance. This is especially true for objects located in hard-to-reach places.

Non-contact 3D scanner

A stream of radiation (it can be ultrasound, light, X-rays or a laser) is directed to the object and reflected from it, it is recognized by the 3D scanner. They are similar in principle to a video camera and may require the use of additional devices for better lighting. nine0003

Non-contact 3D scanners come in 2 types:

-

Active - work with the help of a laser beam or structured light directed at an object, which, when reflected, give information about the location of the object in the form of coordinates.

-

Passive - use time-of-flight rangefinders that read the time and distance that the laser beam travels to the object, and so - for each point in space, which ultimately allows you to accurately recreate its three-dimensional image. nine0003

Desktop 3D scanners are very popular and widespread, since they are mostly simple and safe to use, do not require any special technical skills and are quite cheap. The EinScan-SE 3D scanner is one such example. It can be used both at home and in the office. It has access to the API of many popular 3D printers, which makes it possible to immediately print the created three-dimensional model.

Add to compare

Product added to compare Go

| Manufacturer | Thor3D |

Add to compare

Product added to compare Go

| Manufacturer | Shining 3D |

Add to compare

Product added to compare Go nine0003

| Manufacturer | Shining 3D |

Add to compare

Product added to compare Go

| Manufacturer | Range Vision |

Types of 3D scanners according to the principle of use

There is also a variety of species here. Let's highlight the main ones:

Let's highlight the main ones:

- nine0002 Manual: The are handy and simple models that are easy to use as they are quite compact and do not require special skills. True, their technical capabilities may be somewhat limited.

-

Portable: are mainly used for field work, they are convenient to take with you.

-

Desktop: have extended functionality and are used to create high-quality 3D models. Most often used in offices. nine0003

-

Stationary: are used, as a rule, in production, various enterprises, as they can scan a large number of objects of the same type at once. Mounted on special turntables.

Handheld 3D Scanner Calibry

Such a choice of products allows you to select the right model for a specific task. In some cases, scanners independently measure objects, in others - with the help of a person who sequentially moves the device until all the necessary information is collected. nine0003

nine0003

Such options for hand-held 3D scanners as Calibry are in high demand among buyers. Despite the apparent simplicity of execution, it has a high resolution and scanning accuracy, due to which it is able to digitize objects with a length of 0.2 to 10 meters. Objects that have a non-standard surface - dark or shiny, with a large number of corners and small details will not become a problem either. Among other things, its undoubted advantage is its low weight, only 900 grams. nine0003

Advantages and disadvantages of 3D scanners

Surely, many of the potential buyers are wondering: do you really need a 3D scanner to invest a lot of money in it? What can this acquisition give and will such an investment be justified?

3D scanning has become an integral part of any modern manufacturing process

In order to understand how much you need this equipment, we will list its advantages and disadvantages. nine0003

Benefits:

-

They make it possible to scan objects located at a remote distance and in places inaccessible to the presence.

-

They have the ability to "read" not only colors and images, but also to convey the texture of the surface.

-

Significantly speed up the process of "taking" data from any object, even a very complex one with a large number of planes. nine0003

-

A variety of models allows you to choose the most convenient version of the scanner, including manual or portable, which can be easily taken with you.

Weaknesses:

-

Some scanners are unable to recognize transparent or black and white objects. In this case, their preliminary preparation (treatment with a special composition) is required. nine0003

-

I do not always display complex objects correctly, with a large number of inserts and partitions.

-

To obtain a high-quality result, they require skills and abilities to work with certain computer programs for creating 3D models.

-

If the rules of operation are constantly violated, it may become necessary for expensive repairs to the equipment. nine0003

If you need high-precision and high-quality three-dimensional copies of objects, then you cannot do without a 3D scanner. It makes it possible to work in almost any conditions - indoors and outdoors, and with any objects by type and size. It is not surprising that now these devices are in great demand, which gives rise to the annual release of a large number of models, from which you can always choose the one that suits you in terms of quality and price.

What to consider when choosing a 3D scanner

The computer equipment market offers a huge amount of all kinds of equipment, including devices for three-dimensional scanning. Navigating that variety is sometimes not at all easy: some buyers are only concerned about the cost, others are interested in the number of options (sometimes completely useless), but the most far-sighted look at the ratio of the first and second.

Choosing the right 3D scanner is a big deal

It is not always easy to take into account all the technical points that can significantly affect what result will be ultimately achieved. We will tell you what you should pay attention to if you are thinking about buying a 3D scanner.

Focus on the following parameters:

-

How high is the accuracy of the 3D scanner. This is one of the most important features. It needs to be targeted first. nine0003

-

Resolution also plays an important role. It follows from the first, since the accuracy of measurements and the quality of copying depend on the resolution.

-

In what range the device operates, how close / far it can be from the scanned object.

-

The scanning field is the parameters of that object, thing that it is able to process in 1 session. nine0003

-

Does the scanner capture various atypical types of surfaces with complex terrain - channels, partitions, holes, etc.

).

). -

Portability, mobility of the device - how easy it can be moved if desired, taken with you, its size.

-

The time it takes to prepare for work, as well as the duration of the digitization process itself. nine0003

-

The range of possibilities in terms of copying: are there any restrictions on shapes, textures, material, as well as operating conditions - temperature, light, etc.

Of course, the better the quality of the 3D scanner, the more expensive it is. However, you should focus primarily on the tasks that you face, and only then take into account everything else.

Applications

Three-dimensional scanners are in demand in many areas of human life. They are irreplaceable both in the industry, and for household needs. The range of their application is so wide that it is possible to list for a very long time. It's easier to say where they are not needed.

The most common areas of use are, of course, medicine, industry, architecture, construction, film industry and design.

For example, in dentistry, these devices allow you to create ultra-precise three-dimensional models of dentures. One type of such a scanner is Shining 3D's AutoScan DS-EX PRO, which does a great job with a variety of tasks while being quite affordable and reliable. nine0003

Medical 3D Scanner

In engineering, such technologies are also indispensable. Digital building prototypes are now much easier and faster to obtain than before, when it required multiple manual measurements and then entered into a database. Any physical object can now be recreated in three-dimensional form, moreover, in the shortest possible time and with a minimum error.

In cinemas, we can see with our own eyes "revived" fantastic characters, which were created using motion capture technology, which made them as realistic and impressive as possible. This would not have been possible without 3D scanners.

A few decades ago, it was even difficult to imagine all the things that we use all the time today. And in many ways this has become achievable thanks to three-dimensional digitization. This approach provides huge advantages in work (especially for technical specialists - engineers, designers, designers), however, in order to use them to the maximum, it is also necessary to understand computer programs for 3D scanning. nine0003

And in many ways this has become achievable thanks to three-dimensional digitization. This approach provides huge advantages in work (especially for technical specialists - engineers, designers, designers), however, in order to use them to the maximum, it is also necessary to understand computer programs for 3D scanning. nine0003

We will talk more about this topic in one of our next articles. And if you want to know more about it, stay tuned.

#Useful

Expert in the field of additive and subtractive technologies, 3D equipment and CNC machines with over 10 years of experience.

Share

all materials

Free TRNIO app turns your iPhone into a 3D scanner

Archive

Follow author

Follow

Don't want

While 3D scanning is new to the consumer market, there are already thousands of models available for download thanks to the data collected from numerous 3D scanners. In the next few years, we will see 3D scanners in the hands of hundreds of millions or even billions of people, which means there will be literally billions of free 3D models that can be downloaded from the Internet and then printed on a 3D printer replicas of objects from around the world. You might think that's overly optimistic, but when you consider that anyone with an iPhone already owns a 3D scanner to some extent, thanks to a new app called TRNIO. nine0003

You might think that's overly optimistic, but when you consider that anyone with an iPhone already owns a 3D scanner to some extent, thanks to a new app called TRNIO. nine0003

TRNIO is a completely free app for the iOS platform created by Jean-Michel Tressler. In fact, it brings 3D scanner capabilities to all iPad or iPhone owners. This means that if you see an interesting object somewhere or want to keep a moment for years to come, you can capture it in 3D, and then send the file to a 3D printer and make a plastic copy of the object you like, or better yet, send it to Shapeways or Sculpteo and have it printed in much more interesting material and in higher quality. nine0003

Screenshots from the TRNIO app

The TRNIO app is very easy to use. All you have to do is open the app and press the red button on the screen. The app will take a series of photos as you move your phone around the subject. After completing the scanning procedure, you just need to click the same button and select the ‘upload now’ option. A 3D model will be generated on your phone/tablet, which can be viewed in the traditional zoom in/out mode, just like when working with photos. You can also rotate the object 360°. Don't have a 3D printer? Do not worry! You still have the option to print your object through one of TRNIO's partners, for a fee. nine0003

A 3D model will be generated on your phone/tablet, which can be viewed in the traditional zoom in/out mode, just like when working with photos. You can also rotate the object 360°. Don't have a 3D printer? Do not worry! You still have the option to print your object through one of TRNIO's partners, for a fee. nine0003

Example of 3D scanning at TRNIO:

The company, which was founded back in 2012 by Jean-Michel Tressler and Dana Depew II, is definitely a serious player in the fast-paced world of 3D scanning. For those who are worried they don't have the skills to take full advantage of this app, there is a whole series of tips and tutorial videos available on the TRNIO website.

3D printed objects created from models obtained by scanning with the TRNIO 9 application0047

Considering Google recently teamed up with LG to launch their Tango 3D project next year to develop 3D scanning technology for tablets, and looking at their other apps like Rendor, which will be launched later this year, it becomes obvious that 3D scanning will soon be available to any owner of a smartphone or tablet.