Are 3d printers safe

3D Printing Safety at Work | NIOSH

3D printing, or additive manufacturing, is increasing in popularity. This technology is becoming less expensive and more accessible to both businesses and consumers. It is currently used in a wide variety of settings, such as labs, factories, hospitals, schools, libraries, and homes. Despite its popularity, 3D printing is still a relatively new technology and there are many gaps in the information available about health and safety risks. The National Institute for Occupational Safety and Health (NIOSH) is studying the potential hazards of 3D printing and ways to reduce health and safety risks for workers.

What is 3D printing?

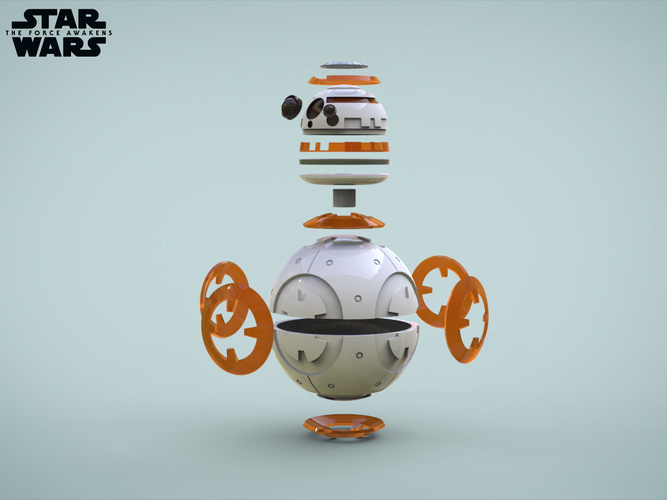

3D printers create three-dimensional (or 3D) objects via computers. A computer file “tells” the 3D printer what object to create and how. 3D printers essentially stack layers of a material to get the desired product. Different types of 3D printers do this in different ways. For example, some use high temperatures, some use ultraviolet light, and others use lasers. 3D printers also use different print materials, such as plastics, rubbers, and metals.

Industries traditionally used 3D printing for prototyping. However, it is now also used for production. Industries using 3D printing include the automotive, aerospace, electronics, medical, and many others.

Potential Hazards of 3D Printing

3D printing hazards vary depending on the type of printer and materials used. For example, print materials that are powders are more likely to be inhaled or cause skin problems than others. 3D printers that use lasers have different hazards than printers that use high temperatures to melt materials. Some common hazards include:

- Breathing in harmful materials: 3D printing can release particulates and other harmful chemicals into the air.

- Skin contact with harmful materials: Users can get hazardous materials, such as metal powders, solvents and other chemicals, on their skin.

- Static, fire and explosion: Some materials used can be flammable or combustible.

High temperatures from some printers can cause burns.

High temperatures from some printers can cause burns.

Ways to Protect Workers from 3D Printing Hazards

NIOSH has studied multiple ways to reduce exposure to 3D printing hazards. Some options include

- Limiting equipment access to trained or authorized personnel

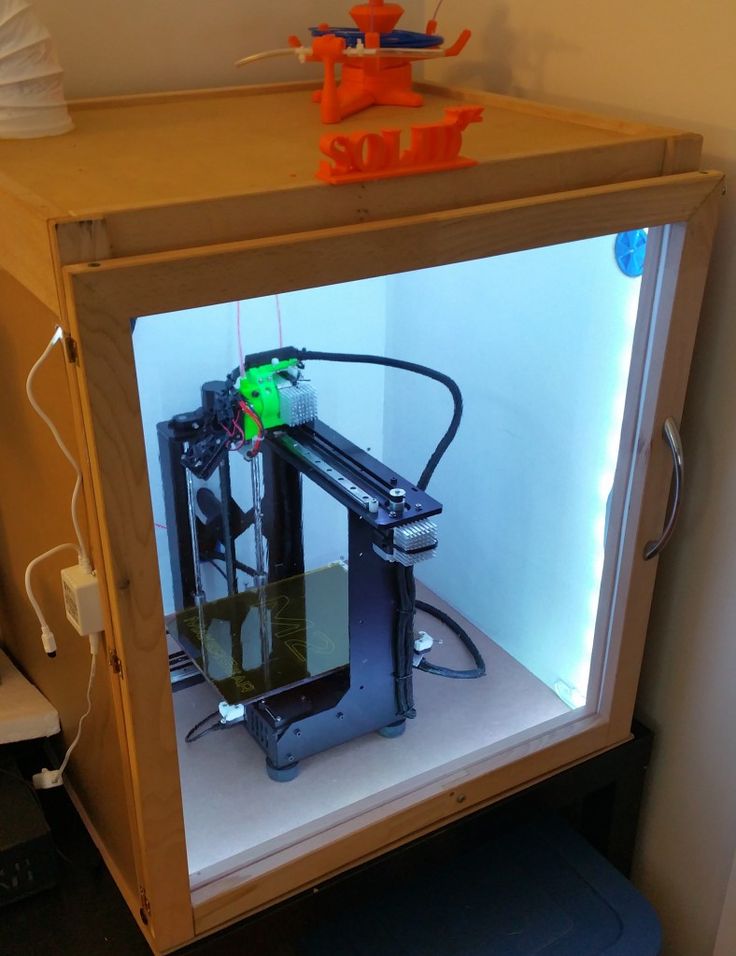

- Using enclosures for 3D printers and ventilation to capture chemical emissions

- Using materials with lower emissions

- Reducing time spent near the printer while it is running

- Training workers on potential hazards and how to protect themselves

- Wearing appropriate personal protective equipment, such as safety glasses, gloves, or lab coats

The ways to reduce exposure depend on the type of printer and materials used. NIOSH has created two posters to help workers explore ways to reduce potential 3D printing hazards. One poster focuses on 3D printing with metal powders and the other focuses on filaments:

- 3D Printing with Metal Powders: Health and Safety Questions to Ask

- 3D Printing with Filaments: Health and Safety Questions to Ask

Help NIOSH Learn More about 3D Printing

Do you use 3D printing in your workplace? You can help NIOSH continue assessing 3D printing hazards and controls. Companies can contact the Nanotechnology and Advanced Materials Field Studies Team to assess possible work-related health hazards with 3D printing in their workplace.

Companies can contact the Nanotechnology and Advanced Materials Field Studies Team to assess possible work-related health hazards with 3D printing in their workplace.

More Information

- Additive Manufacturing

- NIOSH Science Blog: Characterizing 3D Printing Emissions and Controls in an Office Environment

- 3D Printing with Metal Powders: Health and Safety Questions to Ask

- 3D Printing with Filaments: Health and Safety Questions to Ask

Is 3D printing in an office space dangerous for your health?

3D printing news News Is 3D printing in an office space dangerous for your health?

Published on December 16, 2020 by Carlota V.

New studies have confirmed that particles emitted from 3D printers can negatively impact indoor air quality and have the potential to harm respiratory health. Invented 30 years ago, the unintended adverse impacts of 3D printing on human health are not that well documented. However, the increased use of 3D printers, especially in an office space, has warranted more research in recent years. If you remember, we had discussed at the start of the year the study from EPA (Environmental Protection Agency) that explained that many users were not aware of chemical emissions during the 3D printing process; especially the level of volatile organic compounds (VOCs) emitted, and the influence of filament additives on these levels.

If you remember, we had discussed at the start of the year the study from EPA (Environmental Protection Agency) that explained that many users were not aware of chemical emissions during the 3D printing process; especially the level of volatile organic compounds (VOCs) emitted, and the influence of filament additives on these levels.

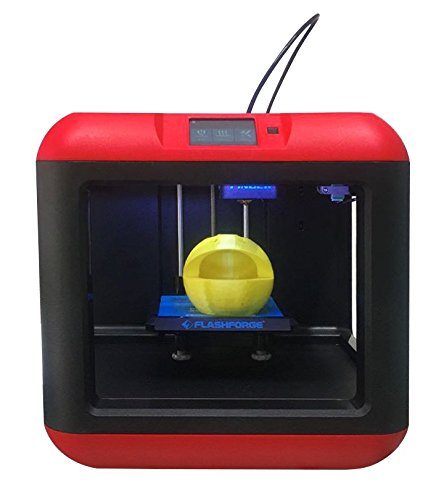

More recently, a new study has emerged to capture the effects of 3D printer emissions and some best practises to protect users in a closed environment, such as an office or school. Of course, the 3D printing process can use different technologies to build objects from plastics, metals, ceramics, etc. Today, many consumer-grade 3D printers use plastic filaments during material extrusion. Published on September 12th, researchers from Georgia Institute of Technology’s new study looked at particles emitted from various types of filament printing, and conducted several tests to gauge their impact on respiratory cell cultures. The study was part of a multi-year research project aimed at characterizing particle emissions, and evaluating their potential for toxicity.

Many consumer-grade 3D printers use plastic filaments during material extrusion.

What is the potential for toxicity of particles emitted?

The team found that the hotter the temperature required to melt the filament, the more emissions were produced. Therefore, ABS filament, which requires a higher temperature to melt than PLA filament, produced more emissions. However, when testing the impact on live cells, the researchers noticed that PLA prompted a more toxic response. “The toxicity tests showed that PLA particles were more toxic than the ABS particles on a per-particle comparison; but because the printers emitted so much more of the ABS, it’s the ABS emissions that end up being more of the concern,” explained Rodney Weber, who led the research. He added: “Taken together, these tests indicate that exposure to these filament particles could over time be as toxic as the air in an urban environment polluted with vehicular or other emissions.”

Additionally, the team found that the particles emitted had different chemical characteristics than the filament itself. To achieve certain characteristics, it is quite common for manufacturing companies to add small mass percentages of other compounds. These additives were shown to affect the amount of emissions, particularly for ABS: “Because there can be great variability in the type and amount of additives added to ABS, a consumer may buy a certain ABS filament, and it could produce far more emissions than one from a different vendor.” Finally, the study looked at which types of environmental scenarios were more dangerous. In an office or commercial building, they estimated that better ventilation could limit exposure. However, in a typical residential setting, the exposure could be much higher.

To achieve certain characteristics, it is quite common for manufacturing companies to add small mass percentages of other compounds. These additives were shown to affect the amount of emissions, particularly for ABS: “Because there can be great variability in the type and amount of additives added to ABS, a consumer may buy a certain ABS filament, and it could produce far more emissions than one from a different vendor.” Finally, the study looked at which types of environmental scenarios were more dangerous. In an office or commercial building, they estimated that better ventilation could limit exposure. However, in a typical residential setting, the exposure could be much higher.

Some Measures

• Operating 3D printers only in well-ventilated areas

• Setting the nozzle temperature at the lower end of the suggested temperature range for filament materials

• Standing away from operating machines

• Using machines and filaments that have been tested and verified to have low emissions.

To achieve certain characteristics, it is quite common for manufacturing companies to add small mass percentages of other compounds.

Even more recently, multiple studies that aim to characterize and quantify the release and composition, particle size, and more from 3D printer emissions, were presented during the 2020 Society for Risk Analysis in a symposium entitled: Exposure and Risk Assessment of 3D Printing and Emerging Materials on December 15th. The symposium found similar findings, which you can read about HERE.

You can find more information about the study from Georgia University of Technology HERE. Were you aware of the toxicity of 3D printer emissions? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

3 main dangers of a 3d printer that you didn’t even think about

Most people who use household appliances don’t even think that their use can cause real harm to health, not to mention the use of production equipment at home, which includes even the most simple 3D printer

Danger #1 - VOCs

VOCs are volatile organic compounds. This is a group of chemical compounds that, when evaporated, can cause significant harm to health and the environment. These VOCs are plentiful in print filaments. In the process of printing, the hot end of the printer heats up the plastic and VOCs begin to evaporate from it, extremely actively, then evaporation continues on the hot table until the product has completely cooled down. Many sources say that printing with PLA filament is absolutely safe - it is an environmentally friendly material made from corn. In fact, PLA plastic is even more toxic than, for example, ABS when heated to the same temperature, but PLA plastic is printed at a lower temperature and therefore less VOCs are released. nine0003

This is a group of chemical compounds that, when evaporated, can cause significant harm to health and the environment. These VOCs are plentiful in print filaments. In the process of printing, the hot end of the printer heats up the plastic and VOCs begin to evaporate from it, extremely actively, then evaporation continues on the hot table until the product has completely cooled down. Many sources say that printing with PLA filament is absolutely safe - it is an environmentally friendly material made from corn. In fact, PLA plastic is even more toxic than, for example, ABS when heated to the same temperature, but PLA plastic is printed at a lower temperature and therefore less VOCs are released. nine0003

Hazard #2 - Microplastics

It turns out that the printing process releases not only volatile organic compounds into the air, but particulate matter that can damage the human respiratory system. These hard particles are called in another way "microplastics". They are essentially particles of plastic 100 nanometers or smaller. They fly freely in the air, are inhaled by humans and settle inside us. This problem has not been thoroughly studied yet, since it appeared in the last 10-15 years, but the negative impact of microplastics on all systems and organs of living beings has been proven. nine0003

They fly freely in the air, are inhaled by humans and settle inside us. This problem has not been thoroughly studied yet, since it appeared in the last 10-15 years, but the negative impact of microplastics on all systems and organs of living beings has been proven. nine0003

Hazard #3 - Fire

A 3D printer is such a specific device that includes heat, moving parts, flammable plastics, and long, continuous operation. Almost everyone who has ever printed massive parts with print times over 12 hours has left their printers unattended for hours or even overnight. To date, there have been cases of fire in 3D printers during operation. The main problem is overheating of the structural elements and the microprocessor. nine0003

One answer to all questions

Experts who deal with this problem recommend equipping 3D printers, especially if they are used at home, with cases with an air cleaning system, visual control and remote power off.

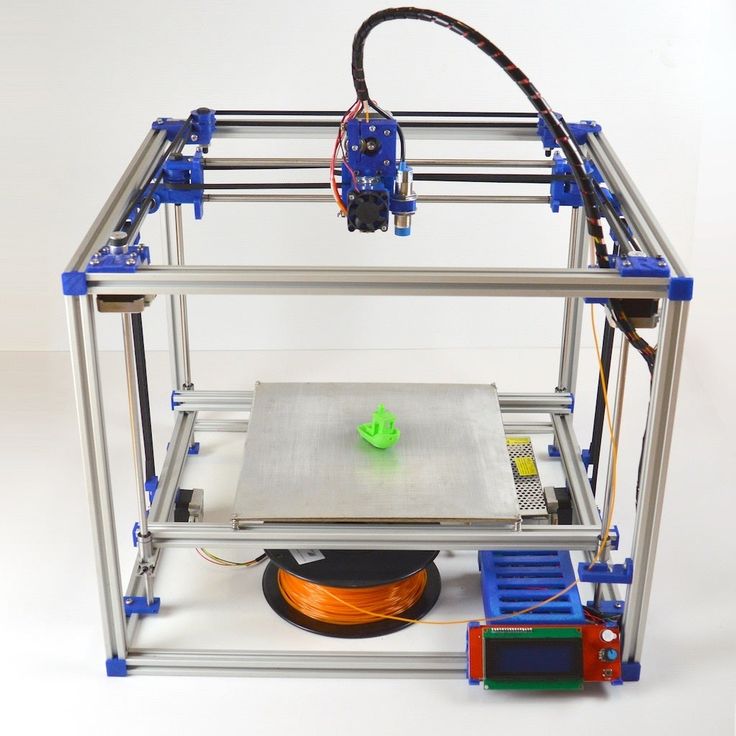

3d printer housing It is easiest to make a simple housing from a structural profile, you must remember that such a housing must be airtight, since microplastics and VOCs can penetrate through the smallest cracks. The case must be equipped with exhaust ventilation and several layers of HEPA filters at the outlet, ideally a carbon filter, this will increase the level of microplastic cleaning. Taking the air duct outside is also an option, but there is a possibility of a drop in temperature inside the case, which will affect print quality. nine0003 3d printer case

The case must be equipped with exhaust ventilation and several layers of HEPA filters at the outlet, ideally a carbon filter, this will increase the level of microplastic cleaning. Taking the air duct outside is also an option, but there is a possibility of a drop in temperature inside the case, which will affect print quality. nine0003 3d printer case

If you still don’t change your mind about leaving printers unattended, equip the case with a simple webcam with remote access via the Internet, this will allow you to periodically monitor the situation and take the necessary measures if something happens.

Housing 3d printer Well, to control the work, it is necessary to equip the printer's power supply system with a remotely controlled relay or socket that can be de-energized remotely via the Internet. This not tricky gadget will not only provide security, but also save money, if the model suddenly fell off and printing continues, then the printer can be turned off from the smartphone. nine0003

nine0003

And of course it is useful to keep the printer clean, regularly clean the motherboard and motor drivers from soap and microplastics

Printing has come offHow safe are resins for 3D printing?

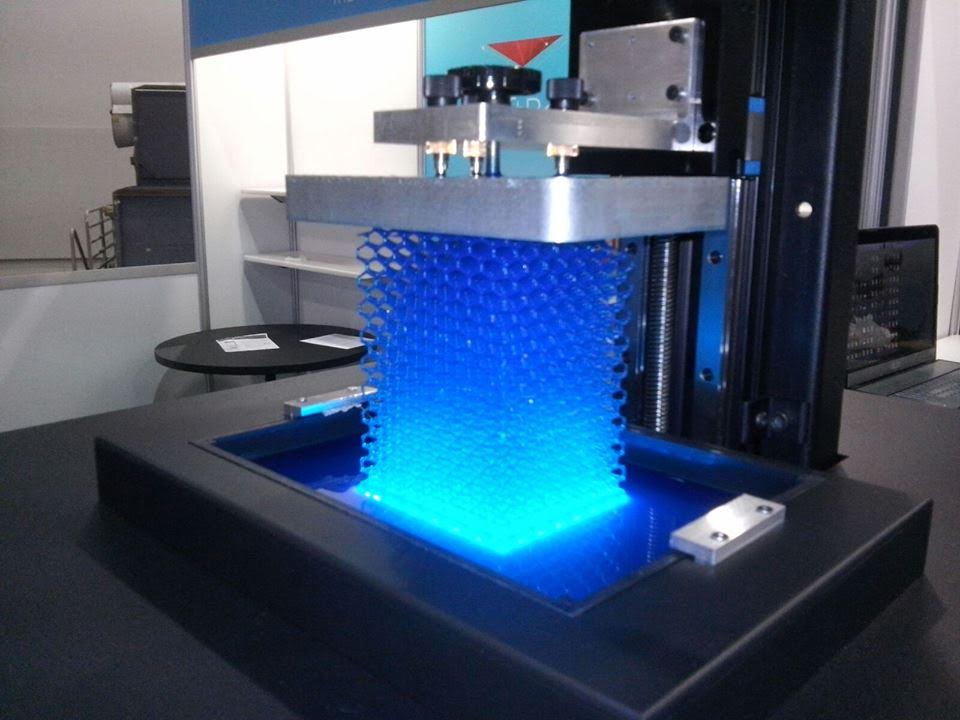

Filament Deposition Modeling (FDM) material extrusion is the most popular polymer 3D printing method, but resins are becoming more and more important to consumers. Resin technologies such as stereolithography (SLA) were previously only used in dental laboratories, engineering departments and manufacturing plants due to the high cost of the equipment. Now that machines have become more affordable, more and more ordinary users are using SLA technology, which calls into question their safety. nine0003

Unlike FDM devices, resin printers use photosensitive liquids to print, curing materials with ultraviolet light. Liquid polymers pose a greater potential health risk than raw materials in fiber form. The toxicity of the resource may put off some users, but printing with resin can be safe if the right algorithm is followed.

What are the Potential Risks of Resins

The word "toxicity" is troubling, but according to the definitions developed by occupational health and safety professionals, any substance that, under certain conditions, can cause harm to health or disease, is "toxic". According to this formulation, many substances around us are potentially dangerous, including perfumes and mattress filling. But are there any particular risks when using liquid resins for 3D printing? nine0003

The main concern with photopolymer resins is that they can cause skin irritation on contact. In some cases, contact of the substance with unprotected skin results in burns and blisters, which may require medical attention. If the materials come into contact with the eyes, they will cause irreparable damage.

Many resins are sensitizers, which means that prolonged exposure sometimes causes a mild allergic reaction. The chemicals that make up most resins are irritants that provoke the appearance of dermatitis - inflammation of the skin due to rejection of foreign elements. The skin quickly absorbs such chemicals, so prolonged contact with the composition or exposure to a large dose can lead to more serious consequences. nine0003

The skin quickly absorbs such chemicals, so prolonged contact with the composition or exposure to a large dose can lead to more serious consequences. nine0003

Another problem with resin 3D printing is air pollution. The material releases fumes, potentially reducing indoor air quality (IQA). Poor IQA scores can lead to headaches, fatigue, or more serious reactions such as breathing problems. These effects are due to volatile organic compounds (VOCs) and other small particles that cause an inflammatory response in the airways, leading to swelling or tenderness.

Long-term effects from working with liquid polymer are rare but significant:

• If the vapors are inhaled for a long time, chronic diseases of the respiratory system may appear.

• Some of the VOCs emitted by resins are suspected to be carcinogens, so they are likely to cause cancer after prolonged exposure.

• Constant physical contact can lead to severe allergies.

Standards and manufacturer's instructions

On the other hand, most resins on the market do not pose a significant hazard. Companies that produce such materials must comply with government standards and additional recommendations ISO 9001. Regulations ensure that chemicals produced by businesses are minimally harmful. However, some hazardous elements, such as asphalt fumes and synthetic mineral fibers used in fiberglass, are still widely used and over half a million workers are exposed to them.

Companies that produce such materials must comply with government standards and additional recommendations ISO 9001. Regulations ensure that chemicals produced by businesses are minimally harmful. However, some hazardous elements, such as asphalt fumes and synthetic mineral fibers used in fiberglass, are still widely used and over half a million workers are exposed to them.

Manufacturers usually provide Material Safety Data Sheets (MSDS) that list any potential health concerns. For example, corneal burns from overexposure to the eyes, or nausea and vomiting if swallowed. All these documents are provided in order to provide users with maximum safety when using consumables. nine0003

Some compounds may be more dangerous than others for certain people. If a person does not know if they are allergic to any materials, they should act as if they are and handle the product with care.

Safety Steps

Several government agencies have conducted research into the safety of epoxy 3D printing. They all showed that long-term emissions from printing are mostly negligible, although risks exist if proper precautions are not taken. Since studies have found traces of hazardous substances when working with resin formulations, safety regulations must be observed. nine0003

3D printing resins are not as scary as they seem, but they still need to be handled with care. First of all, direct contact of the mass liquid with any part of the body must be avoided. Safety goggles and nitrile or latex gloves should always be worn to prevent toxins from getting into the eyes or onto the skin.

Also make sure that the workplace is well ventilated. Ventilation is critical for any 3D printer, but especially for resin printing equipment. It is best to work under an exhaust hood, but if this is not possible, it is advisable to print near an open window with a fan. nine0047 Read the safety data sheet from the manufacturer before opening the photopolymer container. If there are any special instructions regarding the use of the material, then they are reflected in the document.