3D printing for disabilities

3D Printing Applications for People with Disabilities

Published on January 13, 2022 by Carlota V.

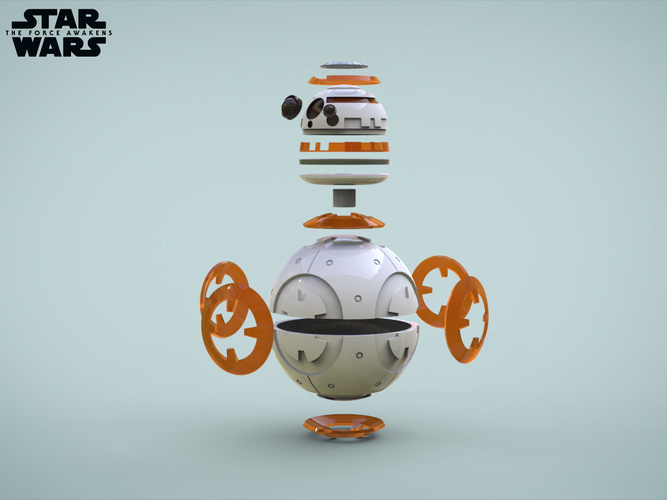

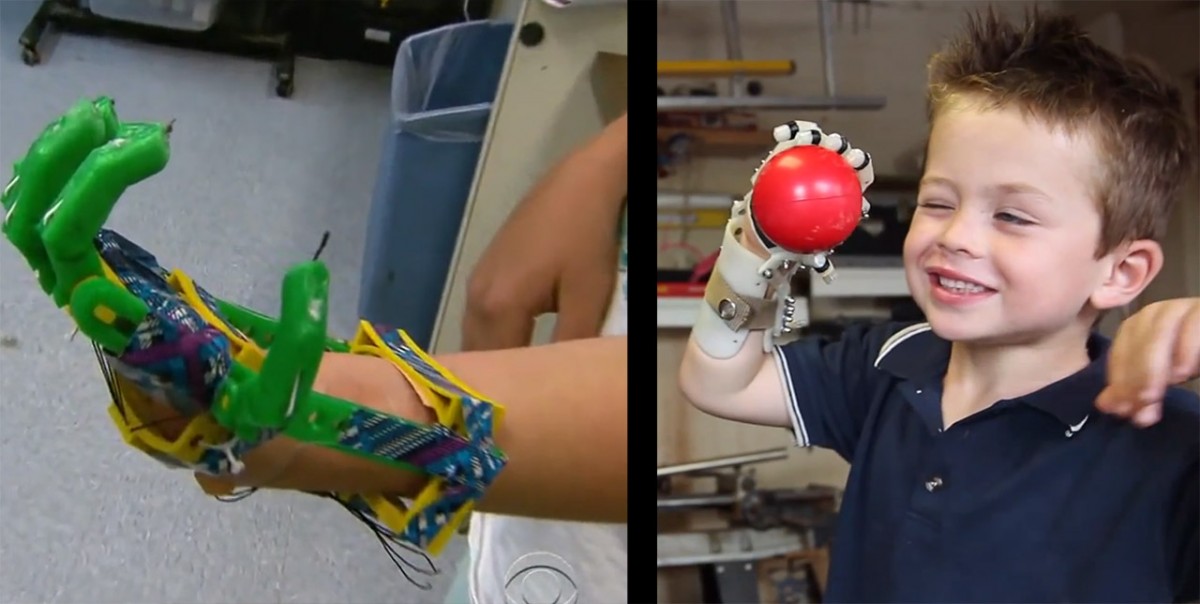

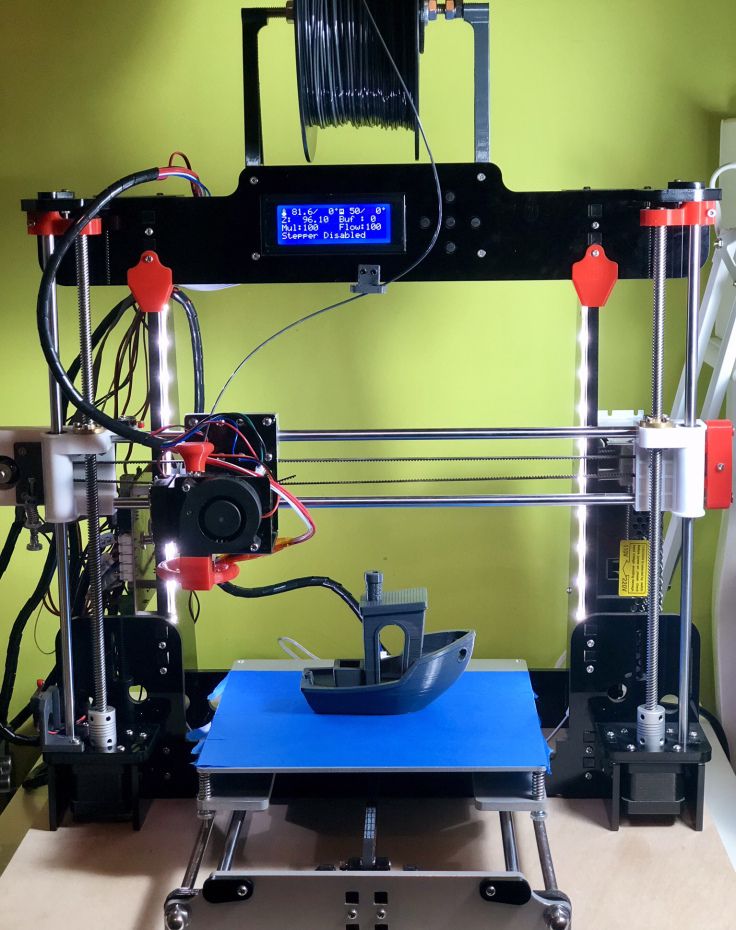

Thanks to 3D printing, the daily lives of many people with disabilities have been improved. The technology enables the creation of objects and services that are easy to use and adapted to disability such as personalised wheelchairs, prostheses, orthoses, etc. Above all, using additive manufacturing makes it easier, faster and cheaper to customize each device to its user. In some cases, it adds an important aesthetic component, changing the way we look at disability. Examples include children’s prostheses inspired by their favourite superheroes. As you will see, the applications for 3D printing in the disability field are becoming more and more numerous. Take a look at some of the innovative projects that we found!

3D Printed Prosthetics

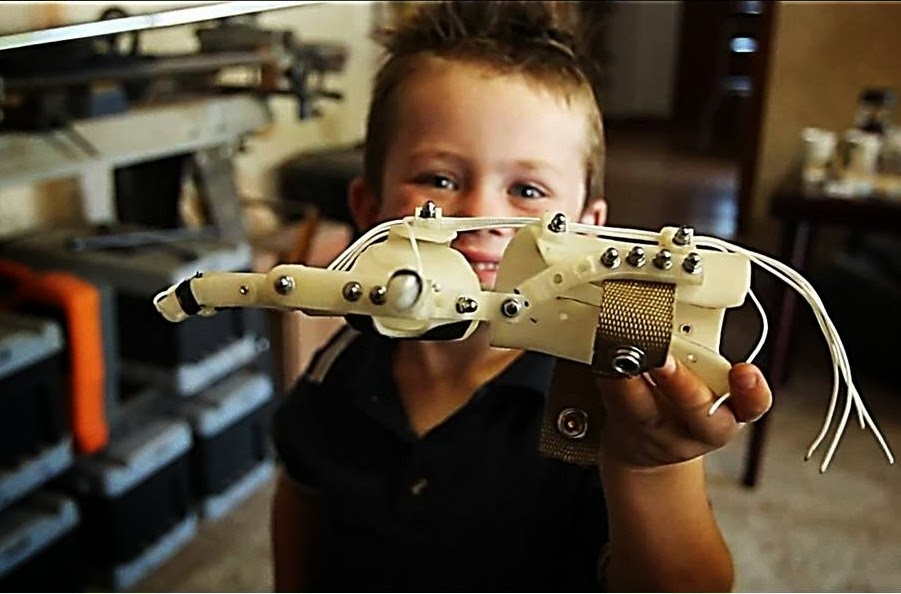

The number of projects combining 3D printing and custom prostheses is increasing, and 3D technologies allow for the design of cheaper and more personalized devices on demand, all in a shorter time. Thanks to the democratization of the FDM process, more and more associations, companies and communities are offering 3D printed prostheses. One example is e-NABLE, which brings together makers from all over the world. They 3D print prosthetic hands for free for people in need, most often for children.

Photo Credits: J. PACHOUD/AFP

Companies like UNYQ have made a business out of it. The American company offers prosthesis sockets for upper and lower limb amputees. The orthopedic device then has a unique aesthetic. Each solution is tailor-made, according to the wearer’s taste, all in only three weeks. There are even more examples, such as Unlimited Tomorrow and its ultra-realistic prostheses, Open Bionics and its Hero Arm, or Exoneo and its foot prostheses. As you can see, the projects are numerous!

Photo Credits: Unlimited Tomorrow

A 3D Printed Prosthetic Eye

In 2021, the Moorfields Eye Hospital achieved a remarkable feat. Doctors gave the first 3D printed eye prosthesis to patient Steve Verze. This is the result of research conducted by the Moorfields Eye Hospital, the UCL Institute of Ophthalmology and Fraunhofer. After four years of development, it is a success. The patient’s eye on only took 2.4 seconds to be scanned before the eye prosthesis itself was 3D printed with a machine from Fit AG. When asked, Steve Verze explained that this prosthesis gives him new confidence and that he has been waiting for this moment for almost 20 years. An example of how 3D technologies are able to dramatically reduce the waiting time for eye prosthesis manufacturing.

This is the result of research conducted by the Moorfields Eye Hospital, the UCL Institute of Ophthalmology and Fraunhofer. After four years of development, it is a success. The patient’s eye on only took 2.4 seconds to be scanned before the eye prosthesis itself was 3D printed with a machine from Fit AG. When asked, Steve Verze explained that this prosthesis gives him new confidence and that he has been waiting for this moment for almost 20 years. An example of how 3D technologies are able to dramatically reduce the waiting time for eye prosthesis manufacturing.

3D Printed Maps for the Visually Impaired

Here, 3D printing helps the visually impaired by creating tactile maps that can reproduce places and routes. Over the years, various projects of this type have been developed, such as See3D, and the latest comes from Italy. The S. Alessio Margherita di Savoia Hospital, in collaboration with 3DItaly, has designed a tactile model for the blind and visually impaired, which will be placed at the entrance to the Spallanzani Hospital in Rome to guide patients to the COVID-19 vaccination center. The model was printed with an Ultimaker S5 Pro Bundle printer, and consists of volumetric shapes, Braille text and bright colors that are easy for the visually impaired to identify. Also among the applications for the visually impaired is a project by French startup FeelObject, which created Virtuoz, a 3D printed interactive touch map. The map is designed to represent the interior of a building or house with audio information and symbols corresponding to landmarks (emergency exit, toilet, etc.).

The S. Alessio Margherita di Savoia Hospital, in collaboration with 3DItaly, has designed a tactile model for the blind and visually impaired, which will be placed at the entrance to the Spallanzani Hospital in Rome to guide patients to the COVID-19 vaccination center. The model was printed with an Ultimaker S5 Pro Bundle printer, and consists of volumetric shapes, Braille text and bright colors that are easy for the visually impaired to identify. Also among the applications for the visually impaired is a project by French startup FeelObject, which created Virtuoz, a 3D printed interactive touch map. The map is designed to represent the interior of a building or house with audio information and symbols corresponding to landmarks (emergency exit, toilet, etc.).

The 3D printed card at the Spallanzani Hospital in Rome. (Photo credits: 3Ditaly)

TypeCase, the 3D Printed Keyboard for the Blind

When a person is visually impaired, writing on a smartphone touch keyboard can be very complicated. To overcome this problem, Dougie Mann, a mechanical engineering and product design graduate from Imperial College London and the Royal College of Art, has developed an innovative application called TypeCase. It is a 3D printed keyboard integrated into the shell of the cell phone, consisting of 5 keys instead of 50. The keys are located on the sides of the smartphone so that they are accessible to each finger of the hand. To compose a letter, a word or a character, it is enough to tap successively on each key. But TypeCase is not just for writing messages, it is also for reading them. Indeed, the user can “feel” the text, using the same code, with small vibrations in each of his fingers. This tool, which is innovative and above all intuitive, is a good alternative to traditional keyboards for visually impaired people.

To overcome this problem, Dougie Mann, a mechanical engineering and product design graduate from Imperial College London and the Royal College of Art, has developed an innovative application called TypeCase. It is a 3D printed keyboard integrated into the shell of the cell phone, consisting of 5 keys instead of 50. The keys are located on the sides of the smartphone so that they are accessible to each finger of the hand. To compose a letter, a word or a character, it is enough to tap successively on each key. But TypeCase is not just for writing messages, it is also for reading them. Indeed, the user can “feel” the text, using the same code, with small vibrations in each of his fingers. This tool, which is innovative and above all intuitive, is a good alternative to traditional keyboards for visually impaired people.

Tailor-Made Vehicles for People with Disabilities

The German company Paravan GmbH has made it its mission to adapt vehicles to the needs of drivers. To help people with disabilities, Paravan offers special electric wheelchairs and makes conversions to motor vehicles. To ensure that the customer’s specific dimensions can be measured, the company relies on 3D scanning. The company uses a Go!SCAN SPARK from Creaform3D to determine the optimal seating position of the driver for the use of different tools (steering and accelerator-brake) in the vehicle. Previously, all adjustments on the customer’s vehicle had to be done manually with the customer. With the 3D scanner, many adjustments can now be made in advance, saving a lot of time in the process.

To help people with disabilities, Paravan offers special electric wheelchairs and makes conversions to motor vehicles. To ensure that the customer’s specific dimensions can be measured, the company relies on 3D scanning. The company uses a Go!SCAN SPARK from Creaform3D to determine the optimal seating position of the driver for the use of different tools (steering and accelerator-brake) in the vehicle. Previously, all adjustments on the customer’s vehicle had to be done manually with the customer. With the 3D scanner, many adjustments can now be made in advance, saving a lot of time in the process.

Photo Credits: Paravan GmbH

Sonova Creates Customized Hearing Aids

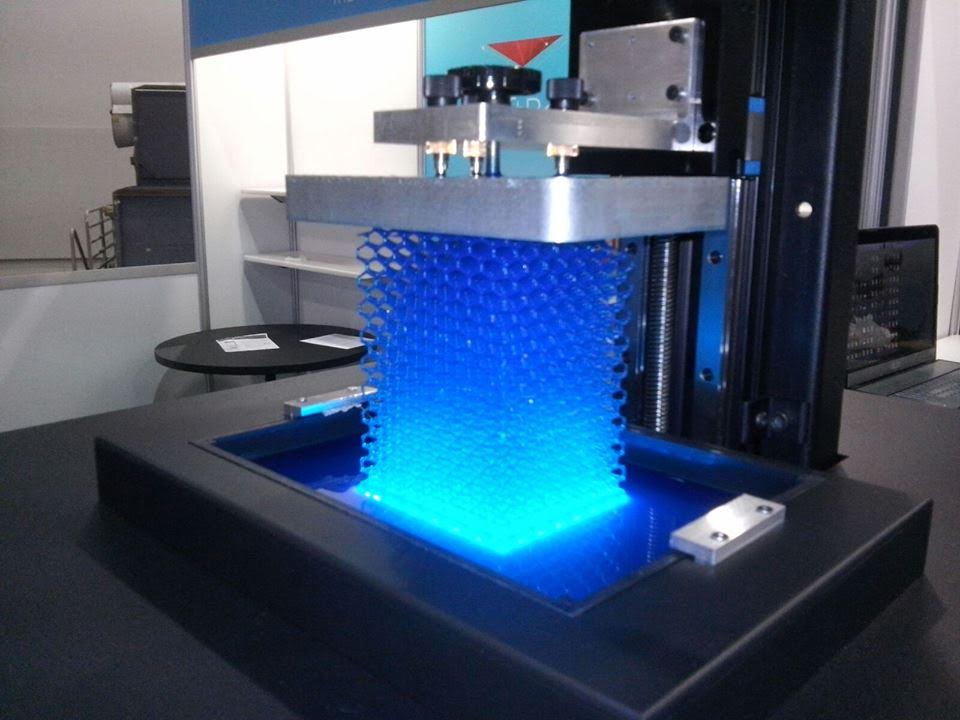

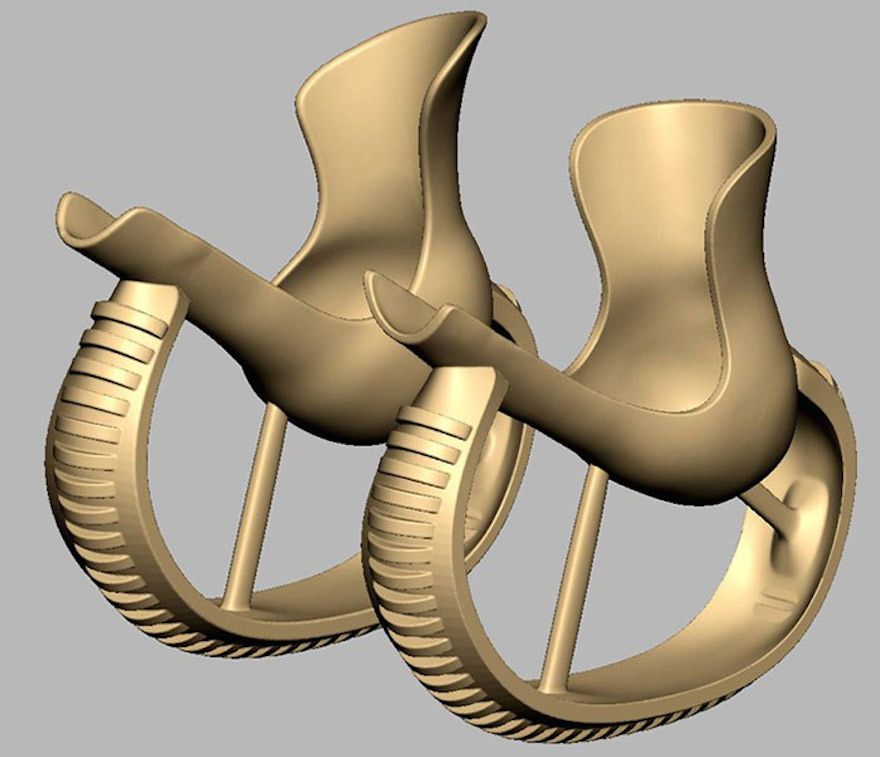

Sonova also relies on 3D printing to develop solutions for people with disabilities. Specifically, they are developing customized in-the-ear and behind-the-ear hearing aids, tailored to the needs of each patient. In this type of application, it is essential that the shape of the hearing aids is perfectly adapted to the user’s ear canal and the degree of hearing loss. In order to design it, the ear canal mold is first created by hand and then the design is digitized. It is then adapted to the corresponding shape before being sent to the 3D printer. During the manufacturing process, a light-curing acrylic resin is used to shape the hearing aid housing layer by layer.

In order to design it, the ear canal mold is first created by hand and then the design is digitized. It is then adapted to the corresponding shape before being sent to the 3D printer. During the manufacturing process, a light-curing acrylic resin is used to shape the hearing aid housing layer by layer.

Photo Credits: Sonova

IKEA and the ThisAble Range

For a few years, Ikea, the furniture giant, has been offering a range of products called ThisAble. It includes 3D printed furniture extensions that can be attached to cabinets, sofas or shower curtains to make daily life easier for people with disabilities. The 3D files of the extensions are available online and can be downloaded for free. The models are more and more numerous, as the range is constantly evolving, and designed for adults and children. For example, it is possible to 3D print an extension to lift the sofa, to sit and stand up more easily, but also window protections to avoid damage caused by the impact of a wheelchair. You can find all the models HERE.

You can find all the models HERE.

3D Printing for Handicapped Animals

Finally, we couldn’t close this ranking without mentioning the animals that have benefited from 3D printing to improve their daily lives. Indeed, in recent years, we have seen many cases where some animals needed a prosthesis, an orthosis or an implant to adapt to their body and regain their mobility. Like Bionic Pets, Wizard of Paws or the company DiveDesign, several companies offer animals medical devices adapted to their needs thanks to additive manufacturing and its ability to design personalized and customized tools.

Which application interested you the most? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! And don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

Adaptive aids with 3D printing

Hello Machine Bros!

Today we will show you different examples, news and models of adaptive aids with 3D printing.

The Machine Bros promotes and believes in the enormous benefits of 3D printing as a technological tool.

Therefore, we wanted to write this article for you, where we will show you how much we can contribute to society with 3D printing, and specifically in this case we will talk about how we can help people with special conditions or disabilities by 3D printing adaptive aids.

What is Assistive Technology (Adaptive Aid)?

Open Assistive Technology – Key Turner

Easy Zipper for Assistive Technology Challenge

Assistive Technology: Bag Holder

Assistive Technology: Parametric Ring Pen Holder

Mouth Cable Bobbin for Assistive Technology Challenge

Bowers Assistive Fork Direct

Knife Assistant

The UnLimbited Arm v2.1 – Alfie Edition

Country Maps

Prototyping Toolkit for Low-Tech Extensions of a Prosthetic Arm

Fin Gripper (Robotic/Prosthetic Hybrid) – Mark VI

Assistive Bottle Opener

Drink holder

Braille and 3D printing

Braille Rubik’s Cube

D20 (20-sided dice) With Braille Numbers

Braille Learning Board V2

Reusable Braille 2L Bottle “Bow Tie” Labels

Costs of Adaptive Equipment

Is it Possible to Use 3D Printing to Help Animals too?

3D Printed Prostheses for Pets

A 3D Printed Beak for a Toucan Named Grecia

3D Printed Titanium Pick for a Red Crowned Crane

Custom Boot Designed for an Injured Penguin

A Penguin Gets to Walk Again Thanks to 3D Prints

With Broken Beak, Toucan is Operated at the Zoo in Brasilia

Let’s Not Just Limit Ourselves to 3D Printing

Assistive Technology Mouse (ATMouse)

AT Switch

BrailleTooth – Bluetooth Braille Keyboard

LipSync

Bot Legs Project (Exoskeleton)

Smart Cane for Visually Impaired People

Virtual Community Ready to Help

e-NABLE

Makers Making Change

Free Course on Designing Adaptive Aids

Pros

Cons

Let’s 3D Print Some Adaptive Assistive Devices

Assistive Bottle Opener

Bag Carrier

Can Opener

Key Turner

Conclusions About Adaptive Aids with 3D Printing

What is Assistive Technology (Adaptive Aid)?The definition of assistive technologies or adaptive aids, is: They are any product (including devices, equipment, instruments, technology and software) that is used to increase, maintain or improve the functional capacities of people with disabilities or special conditions.

This type of technology promotes independence and the empowerment of the person so that they can access or perform a task that they were unable to fulfill, or that they had great difficulty in performing.

With 3D printing we could get into this area, and it is specifically what we will talk about throughout this article.

Makers are known for loving technology, providing solutions to problems with it, working in teams or communities, it is for all this that many makers have been 3D printing these adaptive aids for quite some time.

Next, we want to show you a collection of some adaptive aids printed in 3D:

Open Assistive Technology – Key TurnerKey TurnerIt is a kind of support or holder for keys, with which people with a motor impairment could use their keys to open locks in a simpler way, with less physical effort.

You can access this design by clicking here.

Easy Zipper for Assistive Technology Challenge3D Printed Easy ZipperIt is a base that allows the zipper or closure to be enlarged, it is useful for people who have some motor impairment.

With this invention, there is a greater holding area. You can access this design by clicking here.

Assistive Technology: Bag HolderBag Holder AidIt is a device that makes it easy to carry objects such as bags, wallets and the like, without having to resort to great force with your hands.

It is useful for people who have some motor deficiency in their hands.

You can access this design by clicking here.

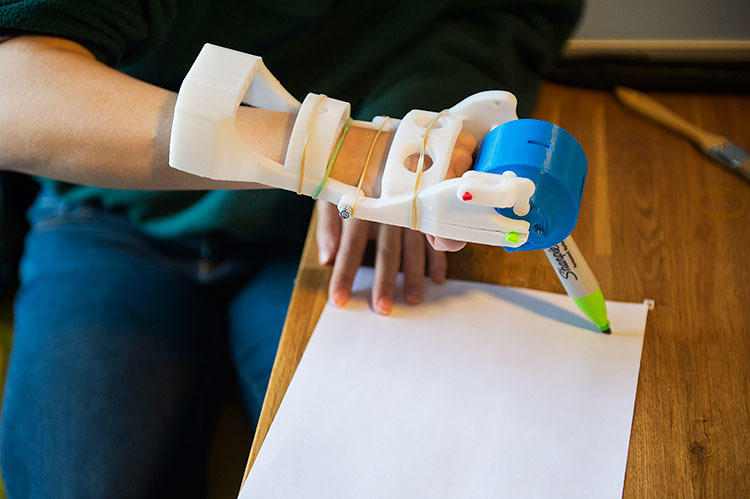

Assistive Technology: Parametric Ring Pen HolderPen Holder AidThis design seeks to facilitate writing in people who have difficulty writing, due to some motor deficiency that they could be presenting in their hands.

You can access this design by clicking here.

Mouth Cable Bobbin for Assistive Technology ChallengeMouth Cable BobbinIt is a device that looks for a way that a person, for whatever reason, could wind or wind their headphones using their mouth and one hand.

You can access this design by clicking here.

If you want to see a video of its operation you can do so by clicking here.

Bowers Assistive Fork DirectCutlery handling aidThe idea of this device is to facilitate the handling of cutlery or eating utensils, to those people who have a disability or special condition that restricts them to use them easily.

You can access this design by clicking here.

Knife AssistantKnife handling aidIf for some reason someone cannot use a knife with only one hand (usually it would be for people with little physical strength), this invention seeks to facilitate this task for these individuals, with this 3D printed object it could be used both hands to exert more pressure or force with the knife.

You can access this design by clicking here.

The UnLimbited Arm v2.1 – Alfie Edition3D Printed Prosthetic ArmThis is a 3D-printed prosthetic arm, a very interesting project, tested and functional.

You can access this design by clicking here.

If you want to see a video of its operation you can do so by clicking here.

Country Maps3D Printed Relief Map of BrazilThis is a relief map of Brazil.

Just as there is this version of Brazil, other makers have been responsible for providing more maps of other countries or locations.

The intention of these maps is that, by having reliefs, people with visual disabilities, through touch, are able to identify the geographical limits in order to interpret said maps.

You can access this design by clicking here.

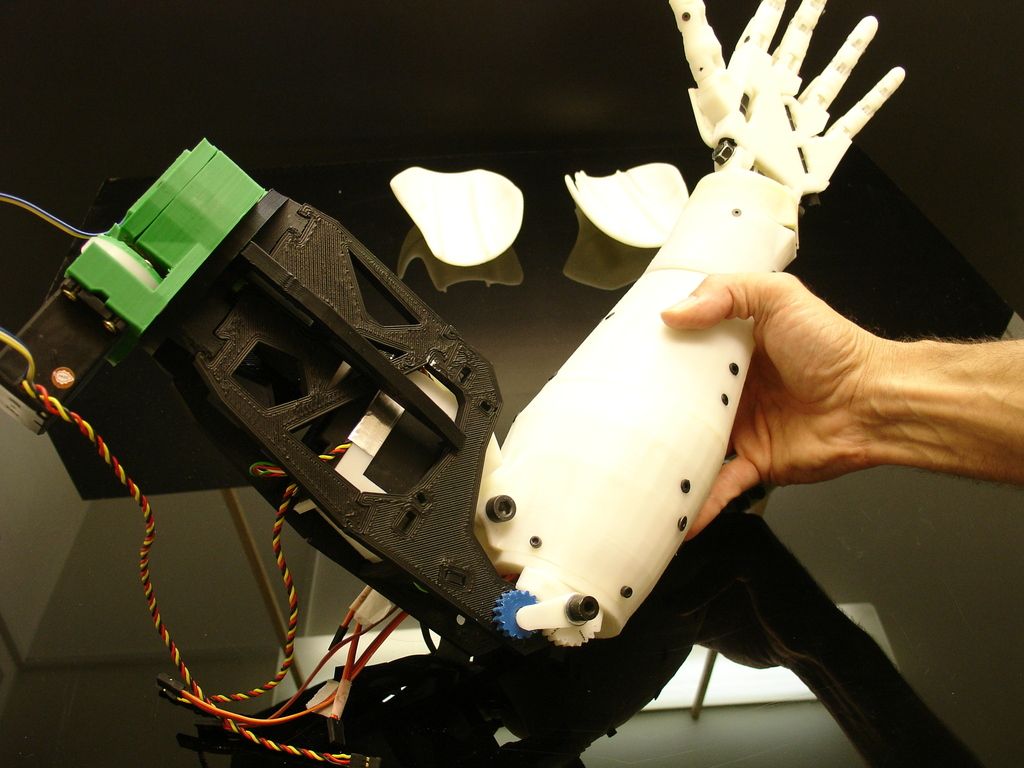

Prototyping Toolkit for Low-Tech Extensions of a Prosthetic ArmToolkit for Low-Tech Extensions of a Prosthetic ArmHere we have another super interesting project, an arm prosthesis, but more focused on mechanical use, with the intention of making it easier for the user to perform certain tasks that involve manual and mechanical skills.

You can access this design by clicking here.

This is a hand prosthesis, this design is intended to be used by people who cannot hold things with their fingers, either because they were amputated, due to lack of physical strength due to some pre-existing condition, or for any other reason.

But it is necessary for the user to have some mobility in the hand to be able to operate the mechanism of this device.

You can access this design by clicking here.

If you want to see a video of its operation you can do so by clicking here.

Assistive Bottle OpenerAssistive Bottle OpenerThis 3D printed object has the purpose that people with lack of strength in their hands, can more easily open (unscrew) the caps of the bottles.

You can access this design by clicking here.

Drink holderDrink holder aidHand clamp with cup holder.

Designed to be used by people who have trouble grasping or holding an object with their fingers.

You can access this design by clicking here.

Braille and 3D printingFirst of all, we would like to give you a brief definition of what Braille is: It is a tactile reading and writing system designed for blind people.

It is also known as cecography.

It was devised in the mid-19th century by Frenchman Louis Braille, who became blind due to an accident during his childhood while playing in his father’s workshop.

When he was 13 years old, the director of the School for the Blind and Deaf in Paris (where the young Braille was studying) asked him to test a tactile literacy system invented by a military man named Charles Barbier de la Serre to transmit orders to outposts without need to reveal the position at night.

Louis Braille discovered after a while that the system was valid and reinvented it using an 8-point system.

After a few years, he simplified it, leaving it in the universally known and adopted 6-point system.

Braille AlphabetA curious fact about braille is that it is also a binary numbering system that preceded the advent of computers.

With 3D printing, the Braille method can be used to somehow improve the quality of life of people with visual disabilities, for this reason, we want to show you some examples.

Braille Rubik’s CubeBraille Rubik’s CubeThe idea is to modify the Rubik’s cube to make it usable for the visually impaired.

This is a design where small squares containing reliefs are 3D printed, then we modify the Rubik’s cube by pasting the 3D printed squares where the colors were initially.

You can access this design by clicking here.

D20 (20-sided dice) With Braille Numbers

20-sided dice with Braille numbers3D Printed 20-sided dice containing the numbers written in Braille.

You can access this design by clicking here.

Braille Learning Board V2Braille Learning BoardA 3D printable table containing the alphabet written in Braille.

You can access this design by clicking here.

Reusable Braille 2L Bottle “Bow Tie” LabelsAid to identify a bottle contentThis invention consists of 3D printed reusable identifiers for bottles.

The intention of this design is that through Braille people with visual disabilities are able to identify the content of the bottle.

You can access this design by clicking here.

Costs of Adaptive EquipmentIn a study titled “Economic Potential for Distributed Manufacturing of Adaptive Aids for Arthritis Patients in the U.S.” Developed by Nicole Gallup, Jennifer Bow and Joshua Pearce, they discussed the economic benefits of 3D printing adaptive aids for people with arthritis.

In this study, among the aspects analyzed, they compare the costs of acquiring these items by buying them and printing them in 3D.

It is a very interesting article, for this reason, we want to share it with you.

Find below a table showing the price comparison.

Source: “Economic Potential for Distributed Manufacturing of Adaptive Aids for Arthritis Patients in the U.S.”Now, so that you can understand a little better what they are and what function these adaptive aids mentioned above perform, we will attach a table where we will give you a brief description of these aids.

We will also provide you with the links so that you can access the designs, and finally, some images that represent each aid.

We still want to leave you the link to the complete article, to access it you just have to click here.

| Image | Adaptive Aid | Description | Design |

| 1 | Scissor aid | Enables the use of scissors using palm for cutting and fist for opening. | Link |

| 2 | Car seat aid | Car seat buckle depressor using a living hinge. | Link |

| 3 | Drawer aid | Drawer and cabinet opener with built in can opener. | Link |

| 4 | Light switch aid | Easier access for turning on and off light switches. | Link |

| 5 | Sock aid | An assistive aid for putting on socks that will not slip on carpet. | Link |

| 6 | Knife guide aid | Used to cut up ingredients with large handle attached. | Link |

| 7 | Phone holder aid | Attaches to write for the easy accessibility of your phone. | Link |

| 8 | Zipper pull aid | Used to pull up zippers of necessary clothing items. | Link |

| 9 | Knitting aid | Large blocks for a better grip on the knitting needles. | Link |

| 10 | Pen holder aid | Provides a larger area that encompasses the pen to hold in hand. | Link |

| 11 | Nail clipper aid | Provides easy access to clip one’s nails by using the palm of your hand. | Link |

| 12 | Cane holder aid | Allows the user to hang their cane for easy access. | Link |

| 13 | Key aid | Attaches to the user’s key for a larger surface area to grab on to. | Link |

| 14 | Typing aid | Round ball can be customized for palm size and allows user to type on keyboard easier./cdn.vox-cdn.com/uploads/chorus_asset/file/14022203/03.1419971849.png) | Link |

| 15 | Pop can aid | Assists in the opening of pop cans by use of a hook. | Link |

| 16 | Dog leash aid | Uses a “lock and key” method to hold onto your dog’s leash. | Link |

| 17 | Gas cap aid | Easy grip handle to be able to open gas cap on car. | Link |

| 18 | Handle adapter aid | Ability to attach to any handle for easier use and grip. | Link |

| 19 | Toothbrush aid | Enables user to grab their toothbrush more easily. Can be customized for hand size. | Link |

| 20 | Pill splitter aid | Users can use their palm to push down and split their medication. | Link |

Yes, this is excellent news for all those animal-loving makers.

3D printing can be used to help animals that for some reason have lost some part of their body or were simply born without it.

For this reason, we want to show you some examples of this.

3D Printed Prostheses for Pets“Researchers from the ULE develop low-cost and custom-made prostheses for pets that have suffered an amputation in one of their limbs.”

This is reported by El Correo de Burgos (Article in Spanish).

Rubén Ferrero, José Manuel Gonzalo, José María Rivera, Francisco Jesús Rodríguez and José Antonio Rodríguez-Altonaga at the Universidad de León – Image from El MundoA 3D Printed Beak for a Toucan Named Grecia“A toucan with the name of Grecia”, who received a 3D prosthesis after losing half his beak due to human aggression, has become a symbol against animal cruelty in Costa Rica and on social media.

This is reported by Los tiempos. (Article in Spanish)

Image of Greece with 3D printed prosthesis – Image from AFP3D Printed Titanium Pick for a Red Crowned Crane“The tripartite team worked on developing the best design for the red-crowned crane beak by studying the anatomy of the species and by creating a series of prototypes.

After testing seven versions of the beak prosthesis made of plastic, the team arrived at the final design.

The chosen model was sent to the Additive Manufacturing Laboratory, which made a 3D impression in titanium of the prosthesis for the crane with the latest generation of three-dimensional printers”.

This is reported by Imprimalia 3D (Article in spanish).

Image of the crane with the 3D printed titanium prosthesisCustom Boot Designed for an Injured Penguin“Students using end-to-end 3D systems solutions integrate 3D scanning, design and 3D printing to deliver a custom fit boot for penguins with damaged limbs.”

This is reported by Goaltech. (Article in Spanish)

Image of the boot with the 3D print for the injured penguinA Penguin Gets to Walk Again Thanks to 3D Prints“The first week of June 2016, Bagpipes (the penguin’s name) got his plastic leg, which he is adjusting to.

Its manufacture took 30 hours and according to Clucas, the most difficult part was scanning the leg, because it is quite restless (referring to the penguin) ”.

This is reported by Mott. (Article in Spanish)

Image of Bagpipes with the prosthesis printed in 3D – Image from T13With Broken Beak, Toucan is Operated at the Zoo in Brasilia“In Brasilia, a team associated with the clinic takes digital images of the beak.

They are sent to a designer in Mato Grosso, who transforms them in 3D.

In social media groups, doctors talk to each other and evaluate the result.

Once approved, the material is sent to Santos, where the forensic dentist Paulo Minioto converts the file for 3D printing”.

This is reported by Metropoles. (Article in Spanish)

3D printed prosthesis for Toucan in order to restore the function of the broken beak in Brasilia – photo fromTony Winston / Agência BrasíliaLet’s Not Just Limit Ourselves to 3D PrintingBy saying “Let’s not just limit ourselves to 3D printing” we mean that we can combine 3D printing techniques with other tools, technologies and knowledge.

In other words, we could use Arduino or Raspberry Pi in conjunction with 3D printing to create adaptive aids (also known as assistive technologies or assistive technologies), we could make use of electronics, electricity, physics, chemistry, and a host of technological and scientific alternatives that we can combine with 3D printing, this with the aim of achieving a greater good.

For this reason, we want to present you some examples.

Assistive Technology Mouse (ATMouse)This device is designed with the intention of offering a solution to computer users who due to a disability or physical condition find it difficult to use a normal mouse, but can still press buttons.

Users with Parkinson’s disease, any condition related to tremors, cerebral palsy, and many other conditions that interfere with users’ ability to perform precise hand movements.

The device is based on the Arduino Pro Micro controller (Leonardo compatible) and is therefore a plug and play input device, which means it will be recognized as a USB mouse without the need for additional drivers.

You can access this design by clicking here.

Assistive Technology MouseAT SwitchAT switches allow users with special needs and/or physical disabilities to activate devices in their environment.

What seems as simple as a button, configured, adapted, and used in the right way could allow access to communication devices, environmental controls, computer software, mobile devices, etc.

You can access this design by clicking here.

AT SwitchBrailleTooth – Bluetooth Braille KeyboardFor now, this is only a prototype.

Its creators have not published the source code.

This prototype is designed so that people with visual disabilities can use their smartphones through buttons that contain the Braille language.

The device would connect via Bluetooth to the smartphone.

You can access this design by clicking here.

BrailleToothLipSyncThe LipSync is an assistive device, which allows quadriplegics and other people with limited hand mobility to use touch screen devices, manipulating a joystick with their mouth, it can also be sipped and blown as the LipSync recognizes these actions.

The unit gives users the ability to control an on-screen cursor with minimal head and mouth movements, allowing them to independently send text messages, make phone calls, and browse the web.

It can be used with most Android and Windows phones and tablets, and with all laptops and desktops.

The designers are looking to release this open-source device to make LipSync a solution that can be developed at the community level for less than $300 (including electronic components).

You can access this design by clicking here.

LipSyncBot Legs Project (Exoskeleton)The idea of this prototype is to help people walk, who have some motor controls but do not have enough strength to walk.

The electric motors would amplify their movements thus allowing greater mobility.

It should be noted that for the design of this device an Arduino, solid-state relays, DC motors, among other components, are used.

At the moment, the design is only a prototype.

You can access this by clicking here.

Bot Legs ProjectSmart Cane for Visually Impaired PeopleThis project consists of a smart cane for people with visual disabilities.

It is a device adaptable to traditional poles, which greatly reduces costs.

The rod uses an Arduino as a controller, uses two ultrasonic sensors to measure distances, a DC motor, vibrator, batteries, etc.

If the smart cane detects any object on top of the user, it will vibrate steadily.

If the cane detects an unevenness, a gap, a step, among others, depths equal to or greater than 10cm, at the user’s lower level (on the ground), the cane will vibrate once for every 10cm in height, that is, if the user encounters a 40cm step, the cane will emit 4 pulses, which means that it will vibrate 4 times, once for every 10cm.

This in order that the user can have an idea of how deep the slope is.

You can access this design on Thingiverse by clicking here.

You can access all the project files (in Spanish) on Google Drive by clicking here.

You can see the video of the prototype operation by clicking here.

You can access more images by clicking here.

Smart cane for visually impaired peopleVirtual Community Ready to HelpMakers are characterized by working as a team, currently, there are virtual communities of organized 3D printing fans willing to help by creating adaptive aids.

Among the various communities that we can find on the web, here at The Machine Bros, we want to show you the following two:

e-NABLEe-NABLE is a global and virtual community of volunteers who use their 3D printers to manufacture free and/or low-cost prostheses, which are usually upper limbs for children and adults who require it.

The open-source designs created by e-NABLE volunteers help those who were born without fingers and hands, or perhaps lost due to war, natural disaster, illness or accident.

There are approximately 20,000 e-NABLE volunteers in more than 100 countries who have given hands and arms to approximately 8,000 recipients.

To access the e-NABLE page you just have to click here.

e-NableMakers Making ChangeMakers Making Change offers a platform so that makers, whether they are engineers, hobbyists, students, corporations, among others, can have their time as volunteers to create solutions to the projects found in the Makers Making Change library.

People with disabilities, their family members or professionals in this branch, can request a project that they believe will help address the barriers that generate the disability or special condition of an individual.

Makers Making Change allows designs to be freely downloaded so that trained volunteers from a community can work with the recipient to ensure that the project meets their needs.

The platform allows everyone to publish and share open-source assistive technology designs, made both by the organization (Makers Making Change) and by other manufacturers.

In general, people can share ideas, solutions and review existing projects.

To access the Makers Making Change page, just click here.

Free Course on Designing Adaptive AidsWe have excellent news for you, if you are passionate about the idea of helping with this type of initiative, creating adaptive aids, but you feel that you do not have enough knowledge to carry out these projects, we tell you that it is possible to take a totally free course to study and learn more about this topic.

For this reason, we ourselves decided to take this course, to tell you a little more about it, the pros and cons that we could observe.

Pros- The course is completely free

- It has a lot of visual and audio-visual content

- Very well explained

- It has examples

- Facilitates 3D files for later printing

- The course is more dedicated to teaching a class, that is, it seems to be more focused on teachers. The course exposes the process by which they explain to students how to generate assistive technologies.

For this reason, if you do not have any knowledge of 3D printing, CAD design, among others, this course may not help you much. But in general lines, you will find good content that will give you a better idea about how to generate adaptive aids using 3D printing.

For this reason, if you do not have any knowledge of 3D printing, CAD design, among others, this course may not help you much. But in general lines, you will find good content that will give you a better idea about how to generate adaptive aids using 3D printing. - You may need to use a VPN to access the course from some countries.

This course can be found at PrintLab and is developed in conjunction with Makers Making Change.

The name of the course is “Assistive Device Academy”.

You can access this course by clicking here.

Let’s 3D Print Some Adaptive Assistive DevicesNext, we will show you the impressions made by ourselves of 4 adaptive aids, the STL files to print these pieces can be found in the free course that we just mentioned “Assistive Device Academy”.

Remember to activate the subtitles by clicking on the CC button:

Assistive Bottle Opener3D Printed Bottle OpenerBag Carrier3D Printed Bag CarrierCan Opener3D Printed Can OpenerKey Turner3D Printed Key TurnerNow that we 3D printed these aids, the intention of The Machine Bros is to collaborate, either by teaching about certain topics or by executing other actions.

Therefore, we made the decision to donate these printed pieces, so that, if someone ever needs them, that person can access the printed aids and put them to good use.

In order for these pieces to end up in the hands of someone who needs them, we donate them to a Pharmacy called Farma Store, which has a very good influx of people, so they will give away these adaptive aids.

Conclusions About Adaptive Aids with 3D Printing3D printing can contribute a lot to society, together we can do great things, make a difference, and this is an essential part of the makers culture.

In 3D printing, we are capable of creating adaptive aids (also known as assistive technologies or assistive technologies), not only this, but we can also greatly reduce costs, thus making this type of technology more accessible for the people who need it.

As mentioned in the introduction, we cannot define technology as “good or bad”, technology is a tool, and in the hands of the right people, many positive things can be generated.

So maker, here at The Machine Bros we want to encourage you, motivate you, give you the knowledge and tools so that you can be part of this wave of good actions and positive changes, as we have already explained, there are virtual communities of makers that work together to generate solutions.

So if you wish, we hope that with this article you can have the impulse to start creating assistive technologies, whether you develop it from scratch, download it from a repository, or join a community of makers, the intention is what counts, every good deed allows us to grow more as individuals and as a society.

Cheers

See you soon Machine Bros!

OTHER ARTICLES

Can 3D printing make life easier for people with disabilities?

People with disabilities often require special, personalized equipment to meet their specific needs. Can 3D printing provide cheap and effective solutions to this problem?

A year ago, Berliner Raoul Krauthausen purchased a 3D printer; he thought it would be interesting to make his own iPhone cases or key chains. After a while, he wondered if he could create something more useful for himself. nine0003

"Because I'm in a wheelchair, I decided to print a ramp. I often have a problem - I can't get literally one step to the entrance. And I often thought about how convenient it would be to have one ramp with me - to attach it behind the back of the wheelchair, but not too big or too heavy."

Krauthausen self-taught with online lessons. He made a pair of plastic pads - on one side their surface is corrugated, which helps prevent tire slippage. nine0003

nine0003

It doesn't have to be a complete mechanism, he says: “Outside, I have to ask someone to help put the lining on, but that's not a problem. When you're in a wheelchair, you get used to constantly asking people for help, and it's not embarrassing."

Printing plastic cost Krauthausen 50 euros, and the process of printing each part on a 3D printer took 26 hours. In December, he posted a 3D printable model file on the Thingiverse 3D print sharing site with the message, “This is my first prototype. Please feel free to print and edit it. I welcome any feedback." nine0003

Krauthuizen says that Facebook users gave him the idea to build the same Lego structure: “I ordered 600 Lego bricks and together with my neighbor we made the same ramp. It turned out that you can make a ramp out of Lego bricks much faster - it took us only half an hour, and it cost about the same.

Consumer 3D equipment can only print simple plastic objects that work well as prototypes. Some Thingiverse users have uploaded files with items designed specifically for people with disabilities. For example, you can download a playing card holder, a device for holding a pen or a spoon at a right angle - all ready for printing. nine0003

Some Thingiverse users have uploaded files with items designed specifically for people with disabilities. For example, you can download a playing card holder, a device for holding a pen or a spoon at a right angle - all ready for printing. nine0003

One user posted a file with a model of a cane for the blind. He notes that he knows next to nothing about the visually impaired market, and says that perhaps the diameter of the cane is wrong, and the color will not meet expectations: “Sorry that it didn’t turn out white. I just could not resist the temptation - and, in any case, the white material was running out for me.

This equipment is usually found in medical facilities or specialty stores. But many complain that such equipment can be unattractive, expensive, and don't always perform well enough. nine0003

Denise Stevens, founder of Enabled by Design , believes that in the future the essential items might be available off the shelf and could only be partially customised.

"I confess I'm not very dexterous," says Stevens, who has multiple sclerosis, "and I, for one, would be very comfortable if the buttons were more grooved, and then it would be much easier for me to press them."

"I imagine that in the future it will be possible to buy things and products online, and already before paying it will be possible to indicate which elements you would like to change for yourself and how. Such parts could be 3D printed and tailored to your special needs.”

Special equipment is often quite expensive because there is relatively little demand for it. Raul Krauthauser says: "It would be nice if we could print, for example, a cup holder for people with disabilities and make it affordable - for example, 10 euros." According to him, now, to get even a small item, specially created for you using traditional production methods, you will have to pay about 100 euros. nine0003

The University of Warwick, Hereward College, is developing a program for people with 'special needs' to create their own assistive products.

With a straw holder, Olli Baskeran can drink from different types of bottles.

21-year-old student Oliver Baskeran, who suffers from muscular dystrophy, explained the difficulty: “When the bottle is too full, the straw falls out; however, if the bottle is tilted, the tube starts to move, and it becomes difficult for me. Thanks to his new 3D printed "cork" that locks a straw into a bottle of any shape and any size, Baskeran now takes drinks in the pub and can drink them without anyone's help. nine0003

“I had to get used to it because I couldn't adapt, but after the fifth time I even started to like it,” says Baskeran.

In special programs for developing 3D models, you can look at the created object from different angles, bring it closer, further away, remake or smooth corners. Full 3D effect.

According to Baskeran, without this technology, he would have to hire a specialist to create such things for him, but it would take a long time. With 3D printing, it takes "about an hour to create a layout and a matter of minutes to print the desired item. " nine0003

" nine0003

Source

3D Systems and e-NABLE: 3D printers help people with disabilities By partnering with 3D Systems, a leading developer of 3D printing technology, organizations can work together to improve the lives of people with disabilities.

Share this story with your friends

The story of e-NABLE began a few years ago when two strangers, a US set designer and a South African carpenter, teamed up to design a prosthetic hand for a small child in South Africa and then made the instructions available to everyone so everyone could make such a prosthesis for yourself. nine0003

This small initiative has since grown into a worldwide movement of researchers, engineers, 3D printing enthusiasts, therapists, designers and anyone else who wants to help people with disabilities.

e-NABLE Global Volunteer Network. Image: enablingthefuture. org

org

Community members are designing and 3D printing fingers and hands for children with disabilities, and now they have help - e-NABLE recently announced a partnership with 3D Systems, a leading 3D printing company. nine0003

With the support of 3D Systems, the community will have new opportunities - creating new designs, attracting developers and designers, as well as new educational opportunities for volunteers, students and those who are helped by the community.

One of the common projects between e-NABLE and 3D Systems will be the development of a new open source hand design K-1.

3D printed arm K-1. Image: enablingthefuture.org

e-NABLE are grateful that the largest 3D printing company not only appreciates their work and mission and is ready to provide support, but also shares their methods of openness and inclusion, which are the basis of open source projects. nine0003

In the very near future, community members will receive the first design files of K-1 and will be able to make them on various printers, test, give feedback and improve together.