Xyz junior 3d printer

XYZprinting da Vinci Jr. 1.0 A Pro Review

It's easy to imagine a 3D printer as something of a magic cube in which all sorts of wonders are created. The $449 XYZprinting da Vinci Jr. 1.0 A Pro does its best to evoke this: a translucent-orange box that takes plastic filament and turns it into innumerable objects, practical and decorative by turn. This romanticized perspective of 3D printing, or some variation on it, doubtless runs through the heads of many of the newbies and students for whom the da Vinci Jr. 1.0 A Pro is intended, and this moderately priced 3D printer delivers an experience that should capture the imagination of young users, while offering add-ons to help stave off obsolescence for more experienced ones. Only a balky filament-feeding system encountered in our testing prevents it from earning a top pick.

A Newbie-Friendly Focus

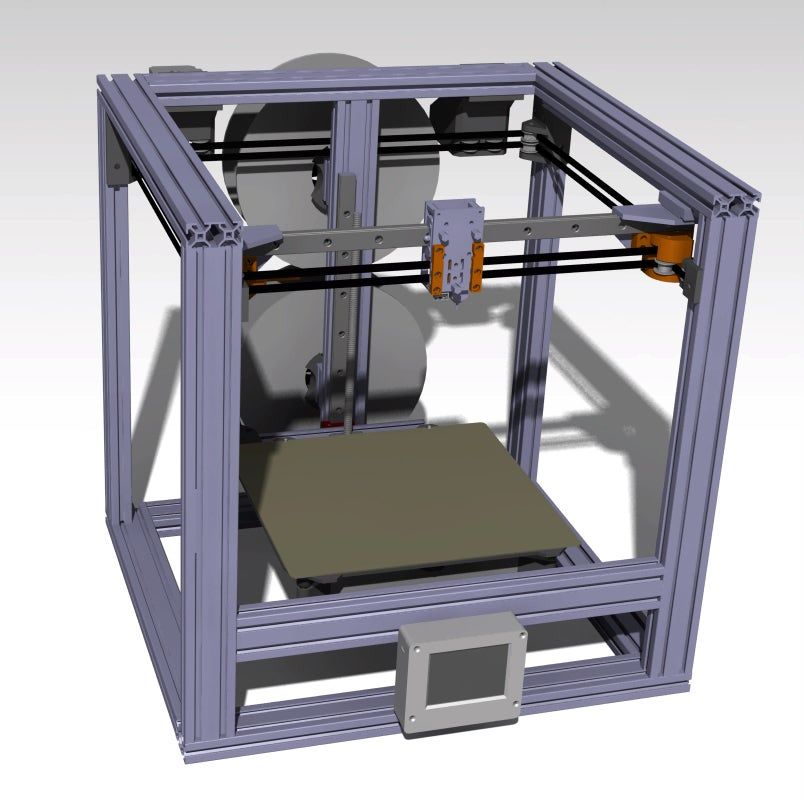

The da Vinci Jr. 1.0 A Pro is a closed-frame 3D printer with a boxy shape, rounded corners, and angled top edges. In front is a door that swings upward, below which is an LCD for easy control of functions such as filament loading/unloading and setting the extruder the proper distance above the print bed (Z-axis alignment). The 1.0 A Pro’s closed frame reduces both noise and the potential for accidental burns from its hot extruder. Its primary supported kind of filament, polylactic acid (PLA), is easy to work and odorless. These factors make the da Vinci Jr. 1.0 A Pro a good choice for 3D-printing beginners, (supervised) children, and classrooms.

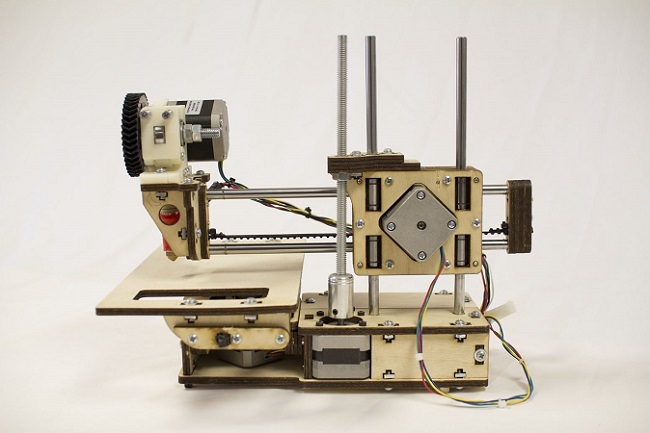

The da Vinci Jr. 1.0 A Pro combines elements from both XYZprinting’s Junior and Pro series. Junior models are customizable, supporting add-ons such as—in the case of the printer under review—a laser engraver module (a $200 option) and a hardened-steel nozzle extruder (see the image below) that supports printing with XYZprinting’s carbon-fiber filament as well as metallic PLA. (XYZprinting often sells the hardened-steel extruder as part of a bundle with the 1.0 A Pro, which costs little more than the printer alone). Both the aforementioned accessories were sent to us with our test unit.

The company also describes its Junior printers, geared to the classroom, as small enough to fit on a desktop. I suppose that depends on whether you need to use that desk for anything other than 3D printing; the 1.0 A Pro measures a sizable 15 by 16.5 by 16.9 inches.

I suppose that depends on whether you need to use that desk for anything other than 3D printing; the 1.0 A Pro measures a sizable 15 by 16.5 by 16.9 inches.

Similar Products

4.0

Excellent

XYZprinting da Vinci Mini

4.0

Excellent

XYZprinting da Vinci Jr. 2.0 Mix

3.5

Good

Flashforge Finder 3D Printer

3.5

Good

Monoprice Cadet 3D Printer

3.5

Good

Polaroid PlaySmart 3D Printer

3.0

Average

Monoprice Voxel 3D Printer

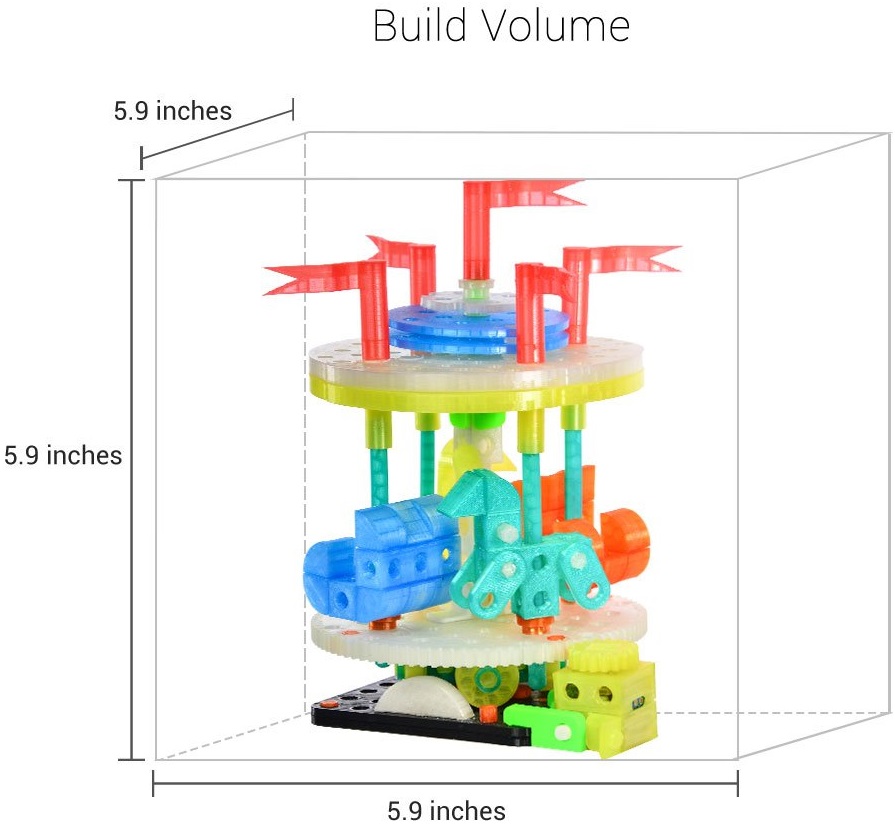

The 1.0 A Pro’s jumbo frame does allow for a large build area (6.9 inches in each dimension). That is slightly larger than the XYZprinting da Vinci Mini’s 5.9 inches and considerably larger than the Monoprice Cadet (4.1 by 3.9 by 3.9 inches) and Polaroid PlaySmart 3D Printer (4.7 inches in all dimensions).

Like the printers in the Junior series, da Vinci Pro models support add-ons and also allow for the use of third-party filaments and software. The da Vinci Jr. 1.0 A Pro is an upgraded version of the da Vinci Jr. 1.0 A. I had reviewed an even earlier model, the XYZprinting Da Vinci Jr. 1.0, in 2015, and the printer under review here is a marked improvement over it, with a larger build area and better software, among other advancements.

The da Vinci Jr. 1.0 A Pro is an upgraded version of the da Vinci Jr. 1.0 A. I had reviewed an even earlier model, the XYZprinting Da Vinci Jr. 1.0, in 2015, and the printer under review here is a marked improvement over it, with a larger build area and better software, among other advancements.

Care and Feeding of Filament (and Feeders)

After removing a copious supply of tape, clips, cardboard, and foam-rubber spacers—in place to prevent the 1.0 A Pro from being damaged in shipping—you install the XYZware suite of software, either from an included SD card or from XYZprinting’s website. (To run it, you will need to set up and log into a free account with XYZprinting.) Next, you will cover the print bed with a square sheet of what resembles masking tape. Objects adhere to the sheet during printing, yet they can be pulled off with a minimum of effort when printing is complete.

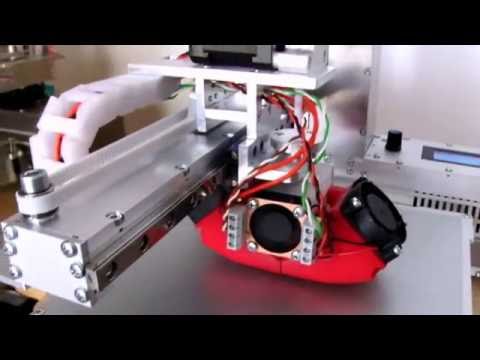

The trickiest part of the printer’s setup is in getting the filament to feed properly from the spool to the extruder. Much of this involves correctly seating the filament-feeding guide tube—a so-called "Bowden tube," whose inner diameter is just larger than a strand of 1.75mm filament—that runs from the top of the filament feeder into the extruder assembly. You have to jab one end of the tube into a small hole on top of the filament feeder, and the other end into the top of the extruder assembly.

Much of this involves correctly seating the filament-feeding guide tube—a so-called "Bowden tube," whose inner diameter is just larger than a strand of 1.75mm filament—that runs from the top of the filament feeder into the extruder assembly. You have to jab one end of the tube into a small hole on top of the filament feeder, and the other end into the top of the extruder assembly.

To get the tube to stay in place required surprising force. It was helpful to press downward with the index and middle finger of my free hand on the sides of a tiny black gasket located on top of each hole while inserting the tube with the other hand. This was relatively easy to do for the extruder assembly, but harder for the less-accessible filament-feeder top. Even when the tube was in place, I learned to give it a gentle tug to make sure it was securely fashioned. (Left to its own devices, one end of the tube popped out a couple of times during printing, scuttling my print jobs.)

Once the feed tube is in place, you can add a filament spool to the spool holder located on the left side of the printer’s interior. You then feed the free end of the filament into the bottom of the filament feeder, pressing down on a lever to clear its path upward into the guide tube. You can then run the loading routine from the printer’s LCD, in which the extruder is heated up, and the filament gets pushed through the guide tube into the extruder.

You then feed the free end of the filament into the bottom of the filament feeder, pressing down on a lever to clear its path upward into the guide tube. You can then run the loading routine from the printer’s LCD, in which the extruder is heated up, and the filament gets pushed through the guide tube into the extruder.

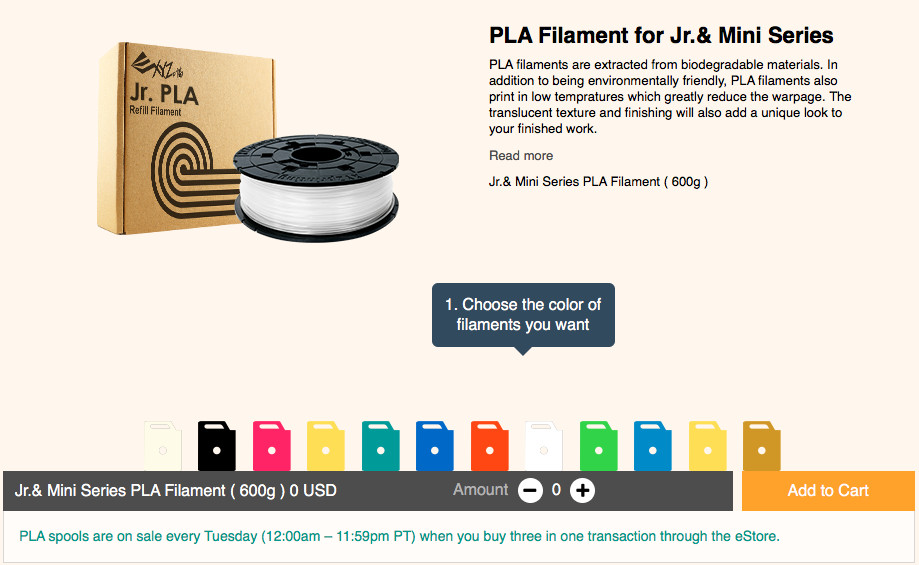

The print bed is unheated, limiting the filament types that the 1.0 A Pro will support. XYZprinting sells 600g filament spools of standard PLA for $22.95, carbon-fiber ones for $29.95, and metallic PLA for $34.95. (The latter two require the hardened-steel extruder nozzle.)

You can use compatible third-party filaments, though they lack the RFID chip of XYZprinting's own spools, and you'll have to enter some settings in the software. You can also use larger filament spools, though you'd have to print your own external spool holder to support them.

Connectivity and Software

Connectivity is twofold. For standalone printing, you can process a file and save it to an SD card, which you then insert into the printer’s card slot. You can then view the files on the SD card on the LCD and access the one you wish to print. Alternatively, you can connect the da Vinci Jr. 1.0 A Pro to a computer via an included USB cable. I did all of my printing over a USB connection, first loading a file in XYZware’s XYZprint program, processing (resizing, and so on) the object to be printed, which you can monitor on a representation of the build plate onscreen.

You can then view the files on the SD card on the LCD and access the one you wish to print. Alternatively, you can connect the da Vinci Jr. 1.0 A Pro to a computer via an included USB cable. I did all of my printing over a USB connection, first loading a file in XYZware’s XYZprint program, processing (resizing, and so on) the object to be printed, which you can monitor on a representation of the build plate onscreen.

You then "slice" the file (the software breaks it into layers for printing), choose the type of filament to print with, and launch the print. XYZprint is adequate, although it lacks the range of settings found in the open-source program Cura(Opens in a new window), which many 3D printer manufacturers use as the basis of their software. Although Cura isn't included with the da Vinci Jr. 1.0 A Pro, you can print files created in Cura and saved to SD card on the printer.

The nine test prints I completed showed average overall print quality. The only misprints were from two cases in which the feed tube became detached from the filament feeder as described above. I did eight of the prints at Normal (200-micron) resolution, and one at High Detail (100-micron). I noted a slight improvement at the latter resolution, but not enough to warrant the extra time consumed in high-resolution printing, except in cases where the best print quality is paramount.

I did eight of the prints at Normal (200-micron) resolution, and one at High Detail (100-micron). I noted a slight improvement at the latter resolution, but not enough to warrant the extra time consumed in high-resolution printing, except in cases where the best print quality is paramount.

The da Vinci Jr. 1.0 A Pro did well with a test object in which a variety of geometric shapes, as well as raised text, are printed at a steep angle—nearly all of the shapes were well formed. A couple of test prints looked a bit rough-hewn, with obvious layering, but most looked decent.

Verdict: Good for Beginners

The biggest selling point for the da Vinci Jr. 1.0 A Pro is its spacious build volume, which allows users to print considerably larger objects than they can with most open-frame budget 3D printers. (A related downside is that this makes it larger than many competitors.) The difficulty in securing the filament feed tube was an annoyance, but once firmly in place, it should stay secured (except, perhaps, if you get the hardened-steel nozzle and frequently change extruders).

On the whole, though, the XYZprinting da Vinci Jr. 1.0 A Pro’s closed frame and its PLA-centric bent are ideal for newcomers (either at home or in a classroom), while it offers enough versatility and accessories to keep intermediate users happy.

XYZprinting da Vinci Jr. 1.0 A Pro

Pros

-

Spacious build area

-

Works with third-party filaments

-

Self-leveling print bed

Cons

-

Build plate is not heated

-

Limited to PLA- and PETG-based filaments

-

Guide tube is prone to detaching

The Bottom Line

The XYZprinting da Vinci Jr. 1.0 A Pro is a moderately priced closed-frame 3D printer with a large build volume and overall good performance, but a potentially balky filament-feeding system.

Like What You're Reading?

Sign up for Lab Report to get the latest reviews and top product advice delivered right to your inbox.

This newsletter may contain advertising, deals, or affiliate links. Subscribing to a newsletter indicates your consent to our Terms of Use and Privacy Policy. You may unsubscribe from the newsletters at any time.

Thanks for signing up!

Your subscription has been confirmed. Keep an eye on your inbox!

Sign up for other newsletters

XYZprinting, da Vinci Junior 3D Printer

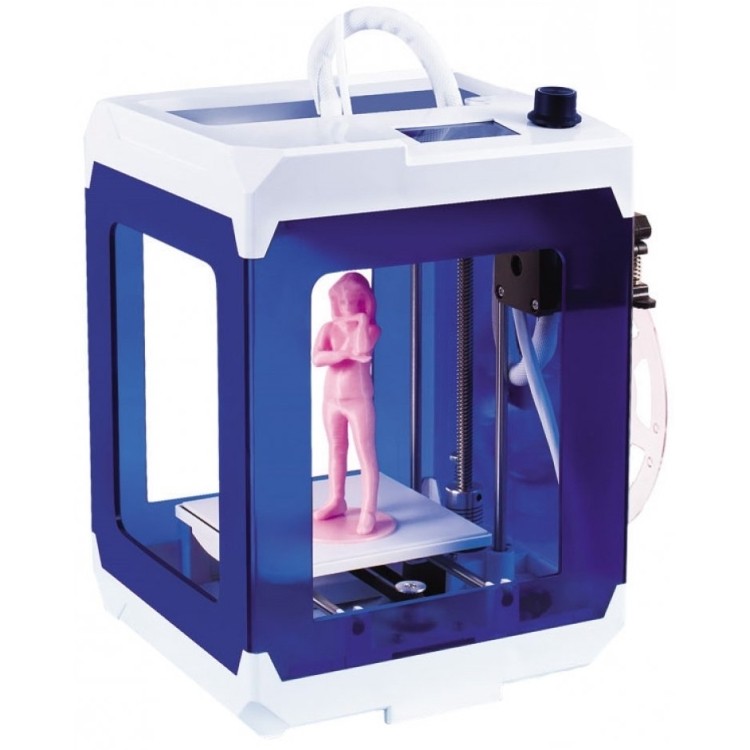

XYZprinting’s da Vinci Junior is the latest innovative and compact 3D printer designed for the consumer market. The device’s all enclosed printing area and non-heated bed ensures user’s safety, and since the printing system utilizes a low amount of power, it makes the da Vinci Junior one of the most eco-friendly 3D printers on the market.

329,75 €TAX exc

Under demand, Shipping in 7 days

- Shipping 24/48 h

- 7 days return

- Secure payment

- Description

- Opiniones

- Questions 0

Know more about XYZprinting, da Vinci Junior 3D Printer

XYZprinting’s da Vinci Junior is the latest innovative and compact 3D printer designed for the consumer market. The device’s all enclosed printing area and non-heated bed ensures user’s safety, and since the printing system utilizes a low amount of power, it makes the da Vinci Junior one of the most eco-friendly 3D printers on the market. Complete with the innovative and user-friendly features of XYZprinting’s current award-winning and top-selling printers, such as smart filament cartridge systems, nozzle cleaning, and one-year limited warranty at no-cost, the da Vinci Junior is the best valued 3D printing solution available, especially for educational and entertaining application.

The device’s all enclosed printing area and non-heated bed ensures user’s safety, and since the printing system utilizes a low amount of power, it makes the da Vinci Junior one of the most eco-friendly 3D printers on the market. Complete with the innovative and user-friendly features of XYZprinting’s current award-winning and top-selling printers, such as smart filament cartridge systems, nozzle cleaning, and one-year limited warranty at no-cost, the da Vinci Junior is the best valued 3D printing solution available, especially for educational and entertaining application.

- Features

- Build Size: 5.9”x5.9”x5.9” (150 x 150 x 150 mm)

- Safety-ensured: The non-heating bed ensures a safe printing environment.

- SD Card Support: Built-in SD card slot allows users to print from SD card directly.

- Easy Loading: Adopting NFC technology makes filament detecting and replacing easy.

- Cloud Database: XYZprinting’s design gallery is a public cloud database with thousands of 3D models for downloading.

The gallery is also open for uploading users’ designs.

The gallery is also open for uploading users’ designs. - Lightweight Design: The compact and seamless printer weights only 12kg.

- Low Electricity Consumption: The system consumes only 75W of power for printing.

Specifications

- Technique: FFF (Fused Filament Fabrication))

- Printer Dimension: 420 x 380 x 430 mm

- Display: Mono LCM

- Connectivity: USB wire and SD card

- Build Size: 5.9”x5.9”x5.9” (150 x 150 x 150 mm)

- Layer thickness: 0.4/0.3/0.2/0.1mm

- Print Material: PLA

- Software: XYZware

- Operating System: Win 7/Win 8/Mac OSX 10.8

- File Types: STL and XYZ format

Read more about da Vinci Junior here

Big Things Come in Small Packages

Don’t let its new slimmer and lighter look fool you! XYZprinting’s brand new 3D printer, the da Vinci Jr.,has a robust build size of 5.9” x 5. 9” x 5.9” and a resolution of 100 to 400 microns all at the amazing price of $349! Easily the most affordable and accessible 3D printer in the market, the da Vinci Jr. is perfect for first time 3D designers and aspiring inventors. This desktop 3D printer makes for a fantastic addition to your home, office, or classroom.

9” x 5.9” and a resolution of 100 to 400 microns all at the amazing price of $349! Easily the most affordable and accessible 3D printer in the market, the da Vinci Jr. is perfect for first time 3D designers and aspiring inventors. This desktop 3D printer makes for a fantastic addition to your home, office, or classroom.

Say Goodbye to Calibration!

Calibrating your 3D printer for your prints can be a huge pain, but now with the da Vinci Jr. you no longer have to! This simple and easy-to-use 3D printer requires no calibration and also a new auto-loading fillament system for an easy, more convenient, 3D printing experience.

Just Press and Release!

The da Vinci Jr. now features a fluid press-and-release extruder-- making for an easy extruder replacement. Simply open up your 3D printer, press the release button, and the replacement can be done within few seconds.

Print Smart, Print Green

The da Vinci Jr. has a brand new refillable filament system!Simply replace the filament spool in the da Vinci Jr. to make refilling easier than ever before! Our new PLA filaments are a non-toxic,biodegradable plastic that is recyclable and safe for the environment! And that’s not all, due to its new compact design, the da Vinci Jr. only consumes 75 watts of power! This eco-friendly 3D printer makes sure that nothing goes to waste when you 3D print with XYZprinting.

to make refilling easier than ever before! Our new PLA filaments are a non-toxic,biodegradable plastic that is recyclable and safe for the environment! And that’s not all, due to its new compact design, the da Vinci Jr. only consumes 75 watts of power! This eco-friendly 3D printer makes sure that nothing goes to waste when you 3D print with XYZprinting.

The #1 3D printer for home and school

The da Vinci Jr. is built with your safety in mind ; with it’s completely enclosed designed and non-heated print tray, children, first-time and seasoned printers can enjoy countless hours of creative 3D fun. Get connected and be inspired by joining our online 3D design community,the Artist Collection, where you can share or upload your 3D designs online. A 3D printer for everyone to enjoy… XYZprinting’s da Vinci Jr 3D printer.

Questions and answers

No customer questions for the moment.

Ask a question

Your Question has been successfully sent our team. Thanks for question!

Thanks for question!

Your Answer has been successfully sent our team. Thanks for answer the question!

Name*:

Email *:

Image :

Answer *:

Captcha *

Name*:

Email *:

Image :

Answer *:

Captcha *

View more XYZprinting

Shipping in 7 days

Under demand, Shipping in 7 days

The da Vinci Pro allows you to adjust the temperature settings. ..

..

Under demand, Shipping in 7 days

The da Vinci Pro allows you to adjust the temperature settings...

Best 3D Printing STL Files Xyz・Cults

number 39: utopia - yugioh

1.09 €

Twisted two-color XYZ calibration cubes

Free

XYZ horizontal expansion test

Free of charge

XYZ 3D handheld scanner TRIPOD STAND

Free

XY-CUBE Christmas

Free

Minecraft Calibration Cubes

Free

Tiger Cub

1. 36 €

36 €

Modified brush for cleaning and storing Da Vinci tools

Free

Right hand rule

0.71 €

Useful calibration cube XYZ 20 mm cube

Free

Two-color cube

Free

XYZ pitch calibration

Free

Thread spool holder

Free

XYZ RPS Coordinate system Automotive

3.29 €

Printer calibration

Free

XYZ Cubes

Free

Xyz yugioh

9.53 €

XYZ davinci 1.

0a E3DV6 Drop in cartridge Remix

0a E3DV6 Drop in cartridge Remix Free

XYZ calibration 100x100x100 10x10

Free

SL_ST XYZ CUBE in progress

Free

SL_ST XYZ CUBE in progress

Free

SL_ST XYZ CUBE in progress

Free

Davinci XYZ Print Filament Cartridge Flash Adapter for arduino

1.19 €

XYZ calibration cube

Free

Calibration cube with pitch/mm XYZ

Free

STAND X Y Z CUBE

Free

XYZ Printing Da Vinci Jr Mini NFC Tag Insert Blank

Free

nine0002 Calibration rod XYZ 120 mmFree

DaVinci 1.

0 extruder fan

0 extruder fan Free

Apple Watch Strap !

Free

2016 Gimbal

Free

Turntable - arduino

Free

nine0002 da vinci mini object coolerFree

Fast and Economical XYZ calibration tool / Cube (40mm / 150mm)

Free

XYZ Coordinate Triads

4.71 €

XYZ Printing Fillament Holder

Free

Da Vinci Pro Side Window Blank with HD locking Tabs MK1

Free

Da Vinci 3in1 Hotend PCA Model MK1

Free

Da Vinci Pro Carriage Hotend and Electronics Mounting Brackets

Free

Da Vinci Dual Side Fan Adapter w/Slide on Cover

Free

DaVinci Pro E3D V6 cartridge mount using nut inserts

Free

Calibration Cube Tray

Free

Calibration Cube_ICPI

Free

20mm calibration cube

Free

Benchy & XYZ Calibration Stand

Free

XYZ calibration

Free

Xyz Da Vinci Heat Bed Thumb Wheel m3 Square nut

Free

Test [Z] BedTest LEVEL [Z].

stl3dmodels.com

stl3dmodels.com Free

The Iron Man suit revolutionizes stop-motion animation

XYZ Media

A technology that has already impacted industry and medicine is now changing cinema.

One of the most difficult tasks in filmmaking is the creation of objects important to the plot, whether they be weapons, figures for animation, complex mechanisms and futuristic costumes.

All this requires the right material. Usually objects are created manually, which takes a lot of time and money and often brings inconvenience in operation.

3D printing could be the solution. This technology has already been used in cinema and there is every indication that it will significantly affect the industry in the future. nine0005

Author: Mark Tyutyunnik

What is 3D printing?

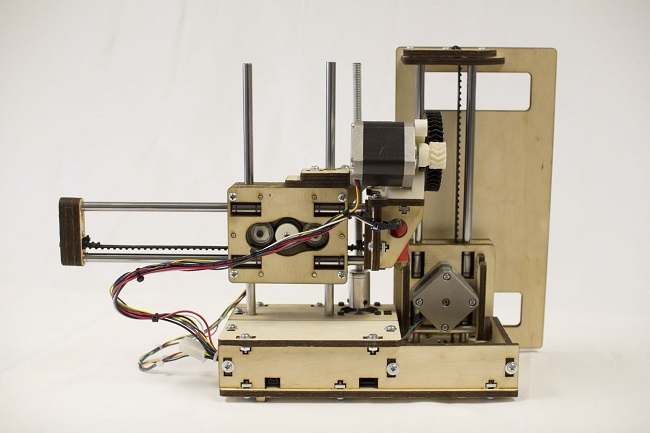

3D printing (additive manufacturing, AM) is the construction of three-dimensional objects from models created in CAD (computer-aided drawing programs) or other 3D digital models.

It is not necessary to draw up drawings for future objects on your own, you can download already developed 3D models - for example, here. Then you need to cut the model into thin layers (using special programs for slicing), in accordance with which the material will be superimposed during printing. By uploading the file with the model to the printer (via an SD card, flash drive or Wi-Fi), even a beginner can print the object. nine0197

Additive manufacturing has greatly influenced the development of a wide range of industries. It is used in the creation of weapons, the construction of buildings, the development of medicines and in other areas.

Gradually, this technology was adopted in the cinema.

The benefits of 3D printing are many. Firstly, the production of objects is carried out quickly and efficiently. Secondly, very complex objects can be made using this technology, which eliminates additional assembly steps and provides more freedom for designers. nine0197

nine0197

Another advantage of additive manufacturing is the variety of materials. Printer manufacturers offer a set of sources, but the user always has the opportunity to mix different substances and even simulate ceramics or metal.

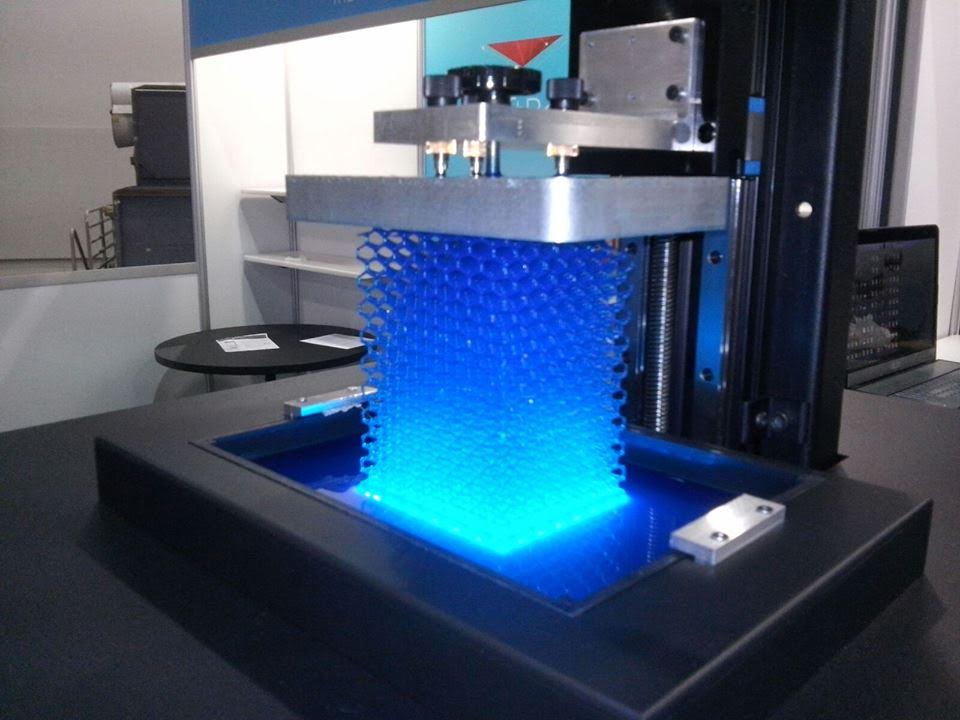

How 3D printing works

One of the most important parts of 3D printing is the scanner. It collects the physical data of an environmental object or (volume, texture and color) to create a digital model. nine0197

There are two main types of 3D scanners: contact and non-contact. The former explore the object through physical contact. The second is to collect radiation from the target object using a laser, structured light, photogrammetry, or optical coordinate measurement.

SLS technology is used to manufacture machine parts and objects with complex geometry. It helps to achieve high strength and precision. A roller rolls the powder, consisting of 50 micron diameter nylon spheres, onto a platform, and the printer heats it up to sintering temperature. Then, with the help of a laser, these spheres are sintered layer by layer until the necessary detail is obtained. nine0197

Then, with the help of a laser, these spheres are sintered layer by layer until the necessary detail is obtained. nine0197

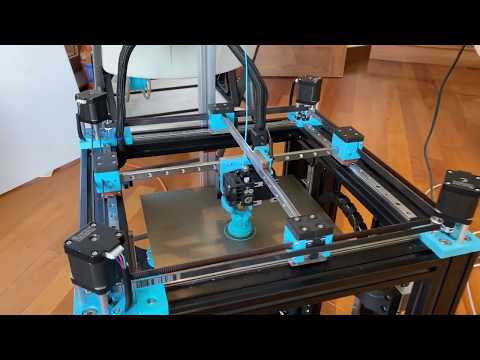

BigRep ONE brand printers are mainly used in cinema. A build chamber with a volume of >1m3 simplifies the additive manufacturing of large-scale objects.

The fast speed and convenience of this production is possible thanks to the camera, which creates large life-size parts and allows you to directly monitor the process. When NeoMetrix Technologies released a video of the development of a functioning car on the BigRep ONE printer, the reason for the technology's popularity in film production was perhaps obvious. nine0197

The use of 3D printing in animation

Laika Entertainment has pioneered the full scale application of technology in film. The company has resorted to additive manufacturing to provide naturalistic facial animation for stop-motion dolls. The idea was to take puppet "acting" to the next level.

When working on The Nightmare Before Christmas, director Henry Selick used hand-sculpting and the usual replacement of faces - first they shot the head with one facial expression, and in the next frame they replaced it with another. But the range of emotions with this approach turned out to be very meager. When producing Coraline in the Land of Nightmares, Selick wanted the main character to be able to show as many subtle expressions as possible. That is why the director decided to conduct an experiment using 3D printing. nine0005

Leading additive manufacturing industry advocate Brian F. McLean Visual effects specialist for Coraline, Paranorman, Family of Monsters and Kubo: The Legend of the Samurai. He has probably the most experience with 3D printing in the film industry today.

In Coraline, McLean used traditional stop-motion animation, combining it with new methods. Additive manufacturing has been used to create facial expressions of characters with thousands of details. The specialist used three Objet printers, with the help of which the animators developed about 20 thousand facial areas that could convey more than 200,000 facial expressions. nine0200

The specialist used three Objet printers, with the help of which the animators developed about 20 thousand facial areas that could convey more than 200,000 facial expressions. nine0200

The image above clearly shows the line of alignment of the upper and lower parts of the face, which was removed in post-production. Using traditional methods, this amount of work would have taken about 30 years, but thanks to 3D printing, it turned out much faster.

It is even more difficult to imagine how many years Paranorman would have taken to produce. The animators used about 40 thousand different facial elements to expand the emotional range. Each of the 40,000 elements was put into a special face library. Thanks to their combination, Norman alone had about 1.5 million facial expressions. Each short half-minute episode required about 250 different expressions for one character. nine0197

About 56,000 faces were printed for "The Monster Family", which were divided into two main areas: eyebrows and mouth.

Each of the options had special names, such as "raised eyebrows" or "pursed lips." Combining them, McLean got the unique expression he needed.

According to McLean, the aim of the rapid prototyping department was "to push stop motion into uncharted territory." This idea reached its peak in The Monster Family, where they tried to touch every muscle of the face, and the heads were printed specifically for one frame and were no longer used in the production of the cartoon. nine0197

McLean credits lead texture artist Tori Bryant for finding a way to recreate the nuances of coloring layouts by hand using additive manufacturing. She figured out how to compensate for the lack of color calibration on the printer and found that applying traditional drawing and coloring techniques to digital models resulted in a more believable result.

McLean also used 3D printing on Laika's last two projects: Kubo: The Legend of the Samurai and Lost Link. The scale increased again - only the main character could have 48 million facial expressions. In addition, when creating both cartoons, PolyJet 9 technology was used.0238 , with the help of which painted the printed objects in the required colors.

The scale increased again - only the main character could have 48 million facial expressions. In addition, when creating both cartoons, PolyJet 9 technology was used.0238 , with the help of which painted the printed objects in the required colors.

3D printing in big-budget movies

Disney pioneered the use of 3D printing in feature films - Jason Lopez (Legacy Effects specialist who worked with Marvel Studios from Iron Man 2 to Guardians of the Galaxy 2 ”) using this technology greatly accelerated the creation of the Iron Man suit. First, experts scanned the body of Robert Downey Jr. - this was necessary to make wearing the suit more comfortable - and then printed armor fragments on Objet Geometries from various materials. Rubber was used for action scenes and fast movements, and metal for close-ups. nine0197

For Thor: Ragnarok, Hela's helmet was designed by José Fernandez, costume designer at Ironhead Studios, using this technology. It used SLS (laser sintered nylon powder) with the addition of reinforced carbon fiber so that the headgear was not heavy.

It used SLS (laser sintered nylon powder) with the addition of reinforced carbon fiber so that the headgear was not heavy.

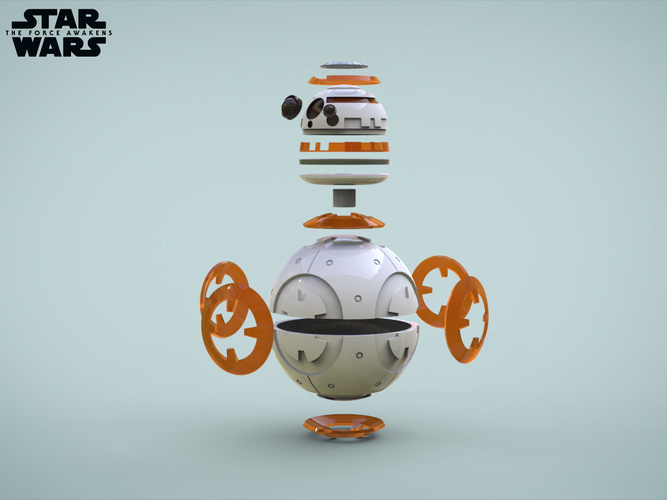

3D printed synthetic materials such as nylon have also been used in the development of other Disney projects: Queen Ramonda's headdress from Black Panther; Kylo Ren costume, shining chrome stormtrooper armor, some parts of Rey's staff, C3PO droid as a costume for actor Anthony Daniels from The Force Awakens, Interpol car from The Muppets 2. Disney is again the first to apply new technologies, as it was with virtual production or the first “animation” of an actor using a mockup. nine0005

Additive manufacturing is also used by Sony Pictures Entertainment, Universal Pictures and Warner Bros.

Rapid prototyping for 007: Skyfall produced an Aston Martin DB5 and a one-third life-size helicopter specifically for the explosion scene, which proved to be significantly cheaper than any other method.

Stratasys printers were used to design armor for the 2014 RoboCop remake.

A The red stripe on the visor was printed using a transparent photopolymer material. nine0197

The Apollo 11 spacecraft for Man on the Moon was also recreated using large scale printers - it was created using BigRep ONE V3.

Weta Workshop, a special effects and props company, used this technology to design helmets, sword hilts, spears and axes for the Hobbit trilogy. Animatronics engineer Rob Sheeney has stated that using 3D printing is beneficial as it is more economical and less time consuming. Then, in 2012, Weta Workshop also tested large-scale printers. nine0200

How 3D printing will change cinema

Cinematographer Victor Marin (Young Americans) believes that this technology will play an increasingly important role in the future. He recommends combining methods, instead of replacing traditional ones with innovative ones.

Julia Koerner (helped with 3D printing for the Black Panther designers) also calls for a combination of these methods. She sees the benefits of additive manufacturing in creating really complex and detailed structures that can't be created with traditional methods. In his work, Koerner tries to combine traditional methods with progressive ones. nine0197

She sees the benefits of additive manufacturing in creating really complex and detailed structures that can't be created with traditional methods. In his work, Koerner tries to combine traditional methods with progressive ones. nine0197

Gilles-Alexandre Deschaux, creator of the stop motion short Chase me :

“3D printing is already widely used in the film industry, from stop motion films to big American blockbusters and commercials. 3D printing is often used to create decorative items and props, but not only there. At the development stages, it is used to promote new individual projects and conceptual solutions.

According to Pinewood Studios 3D supervisor Jet Cooper, the possibilities of this technology are already “incredible”, because if you want, you can even scan someone's face with all the wrinkles and pores. nine0005

Jet Cooper, Pinewood Studios 3D Supervisor:

“Voxeljet has the biggest printers. Their maximum format: 4000 mm x 2000 mm x 1000 mm. This is the largest printer in the world as far as I know. We have a 1060mm x 500mm x 600mm resolution printer at Pinewood. Anything over this size, we print in parts and then put them together.

Their maximum format: 4000 mm x 2000 mm x 1000 mm. This is the largest printer in the world as far as I know. We have a 1060mm x 500mm x 600mm resolution printer at Pinewood. Anything over this size, we print in parts and then put them together.

3D printing is used to create props, and the metal coating of the material makes it strong and durable. But the Germans are working on a new material - epoxy resins, which are as strong as stone. They are extremely hard." nine0200

3D printing is developing rapidly and is becoming cheaper every time, especially when compared to traditional methods or the use of computer graphics. Perhaps the day is not far off when handmade props and scenery will almost cease to be used in films - they will be replaced by cheaper and faster “printed” counterparts.

Like this article?

WANT TO GET BEST ARTICLES

FROM XYZ ONCE A WEEK?

Subscribe to the newsletter XYZ

By clicking on the button, you agree to the terms of data processing

How physics was used to create animations in Star Wars Jedi: Fallen Order.