3D printed baby items

3d Printed Baby Gift - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

Best 3D Printer/Materials for Baby Toys - Materials - Talk Manufacturing

TriniNoob

#1

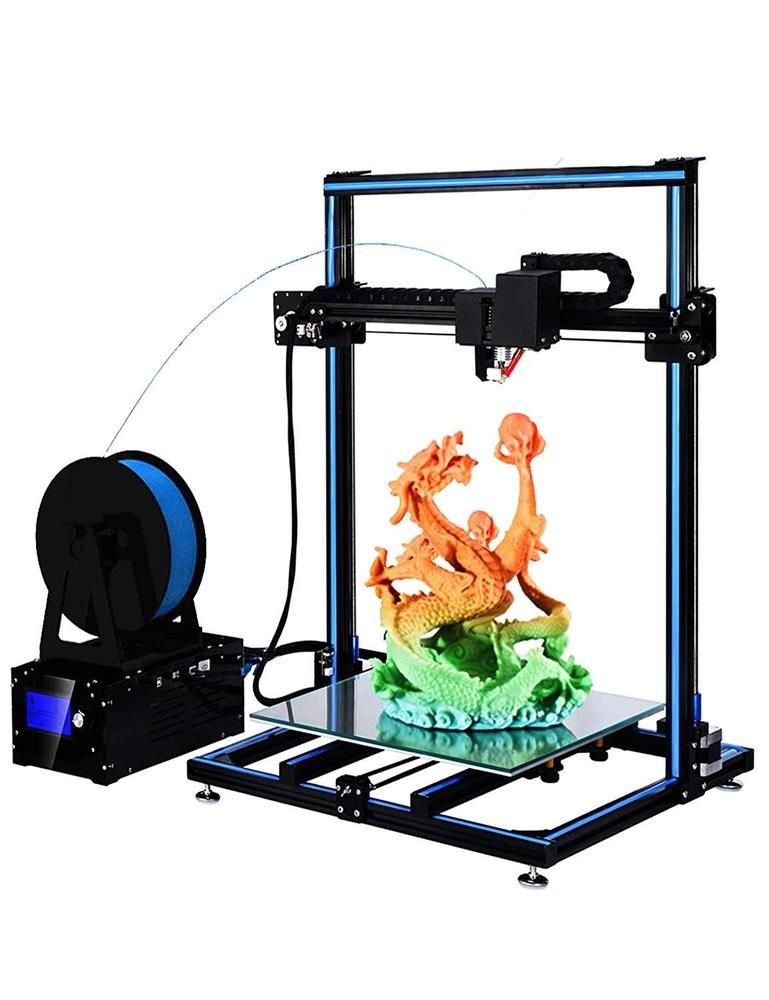

Hi I am new to the 3D Printing world and I am trying to decide on which one to get, my goal is to be able to print toys for my 1yr old. At first I though I would just get a SLA printer but with different materials like TPU, Resin, ABS etc I am not sure which way to go.

Any suggestions would be appreciated.

keebie81

#2

None. 3d printed toys are not baby suitable. They will be putting them in to their mouth and parts break easily. Buy safe toys that are already tested and available at the store.

1 Like

MaddieG

#3

In addition to @keebie81’s comments about parts breaking, SLA prints (resins) are not food safe at all and this should not be attempted.

It does sound like a cute idea to be able to make custom toys for your little ones, unfortunately this poses more hazards than it’s worth and I can’t recommend this.

TypeR

#4

Just came across this topic.

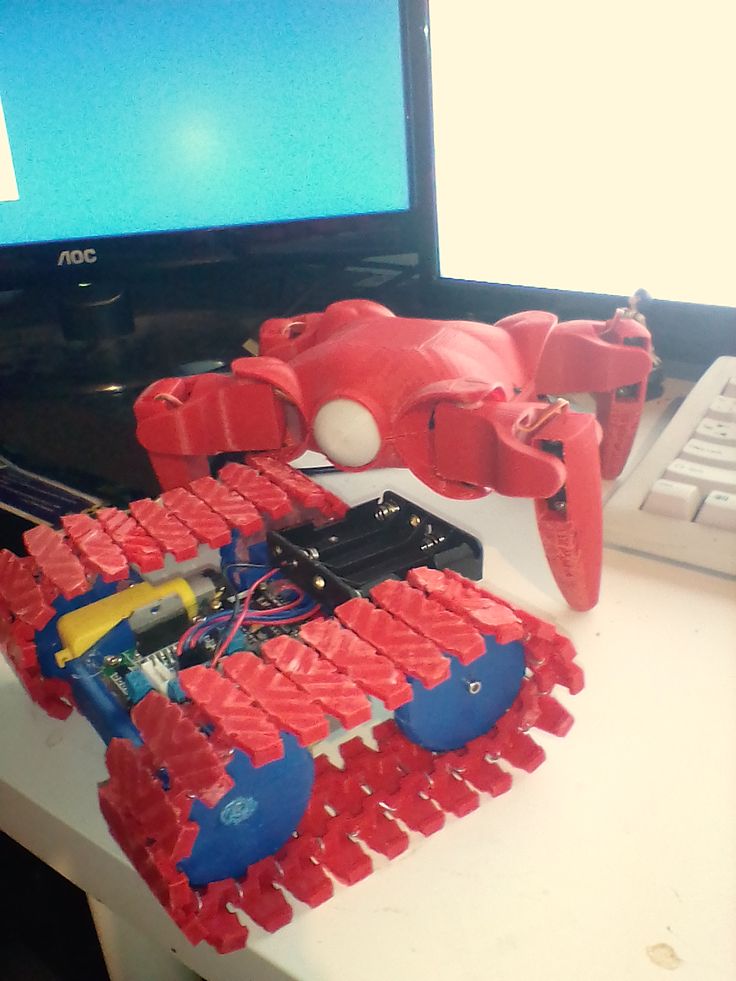

I have a now almost 2 year old son and have already printed quite a bit of toys for him of my own design. Mainly some toy cars (in PETG and PLA) and a walking bike.

I’ve put a number of the earlier design on Thingiverse, like these:

thingiverse.com

Toy car by MvM

Toy car for small children. Small and light enough for any child from six months onwards. Top of the car is shaped for easy grabbing and holding. Print in any material of your choosing. As long as you print it with 30+% infill (higher for the...

thingiverse.

com

com Walking Bike for children (fully functional) by MvM

This is a fully functional children's walking bike, ment for small children age 1 to 3. In addition to all 3D printed parts, you will need the following parts: 1 meter long 8 mm threaded bar 5x Z608 (8 mm) bearings. (2x needed for front wheels, 2x...

One thing though, you should not make any parts too small and delicate. My son is able to destroy anything that’s not really strong. That goes not only for the things I’ve made but also about 80% of all the toys he got, so even the factory made stuff often does not last long

1 Like

TriniNoob

#5

Thanks @TypeR that’s the info I was looking for.

Almajed

#6

Well. I use PLA to print toys for my kids. I started printing toys for them when they was 2&4 and still after 2 years they still have the toys in their collection.

I use PLA to print toys for my kids. I started printing toys for them when they was 2&4 and still after 2 years they still have the toys in their collection.

I recommend printed toys for babies 2+ years as some parts my break and can harm

SusanneAdam

#7

even I have A 3D printer by which I make DIYs and for my kid I also made some toys but after realising that the material which is making the toy is not safe I stopped it and went to buy some soft toys from market but now as he is 3 years old and love to have superhero series,I 3d print them for him.

sonali31

#8

Point to be noted. Safety first comes regarding babies .

Safety first comes regarding babies .

steve3dprinters

#9

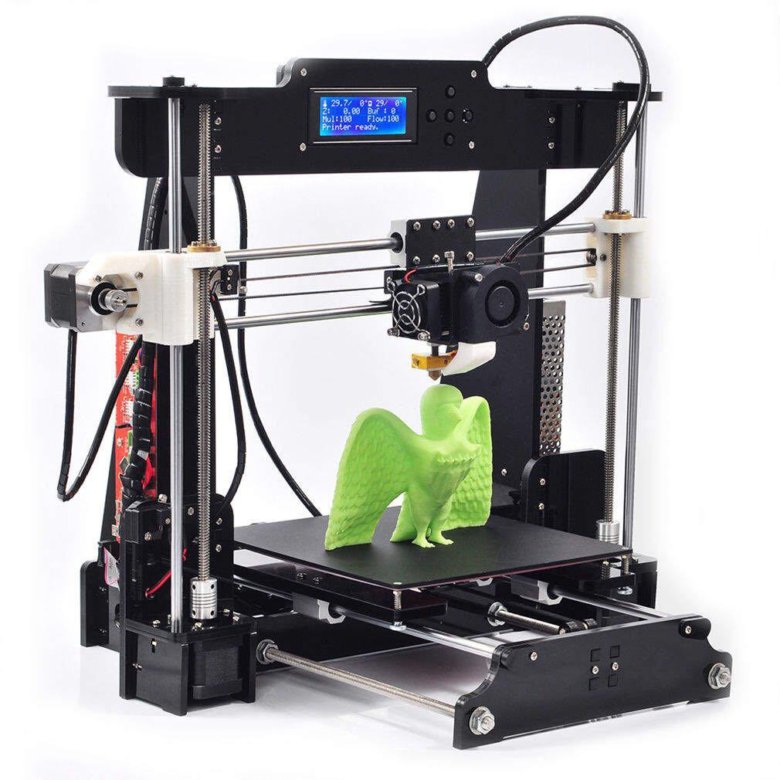

For printing 3D toys for your toddlers, you can use almost any kind of 3D printer. However, when it comes to 3D printing materials, you cannot take a chance with all of these and need to use only food-safe materials as almost all the babies put toys in their mouth.

You can use PLA and PETG which are food-safe products. Plus, you can order these printing materials and 3D printers online from a 3D printer store such as ‘3D Printers Bay’.

About the safety of 3D printed toys

Miscellaneous

Subscribe to the author

Subscribe

Don't want to

30

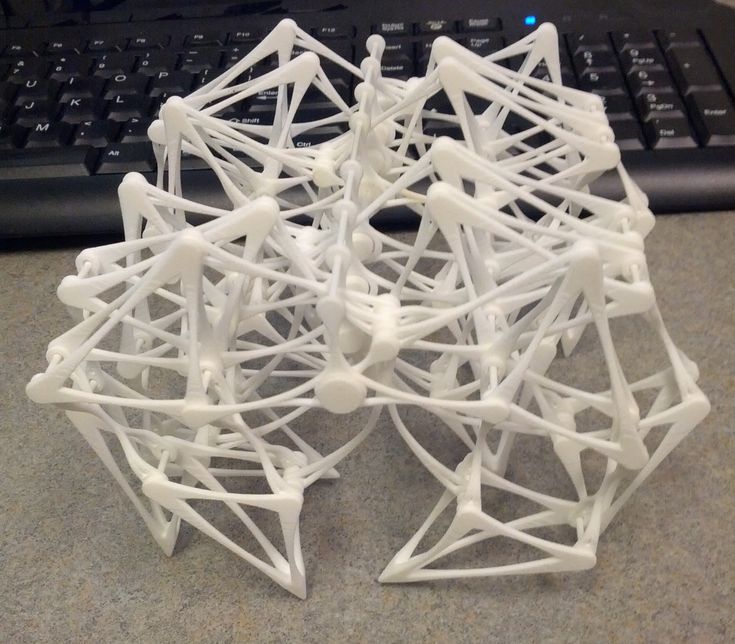

Recently, the topic of the safety of plastics used in printing has often popped up on the site. Their chemical safety is mainly discussed.

Their chemical safety is mainly discussed.

But I want to go the other way.

The one with which I have some experience. Since he was engaged in the sale of toys and had his own store.

Introductory.

Some short-sighted people began to print toys for babies. All normal people know that such products are subject to more stringent requirements for chemical composition, strength and safety.

Toys are usually made large enough to prevent a child from swallowing them. Or bite off a piece of them and swallow.

These toys even have a sign that they are approved for use by children under 3 years old. And many manufacturers, in order not to undergo numerous certifications, specifically write that toys can be used from 3 years old.

And what do we see when looking at the materials on the market?

PLA

PLA seems to be considered safe. Good. We look at the strength - yes, excellent soldering of the layers. But I would not give small parts to small children. That is theoretically possible, but not worth it.

That is theoretically possible, but not worth it.

ABS

Poor interlayer adhesion. To tear off a piece, especially when applying force - yes, no problem. Yes, there are ABS toys. Same Lego. But it is made by injection molding and the strength there is many times higher. And the sizes are also not small. Therefore, no printed toys for children under 3 years old!

Flex

Excellent use as “adult toys”. ;) Marco Bruni agree with me ;)

But I'm not talking about them today. :D

But if you remember that Flex has not the best interlayer adhesion, then it becomes somehow sad. Especially when sharp objects are used to separate the layers. Teeth. Baby.

Gnawing something is a matter of time. Especially when the part is small.

Therefore, I am struck by the irresponsible statements of some people.

It is clear that there are no problems for older children. But I consider the use of 3D-printed toys for babies under 3 years old to be irresponsible and I am categorically against it.

But I consider the use of 3D-printed toys for babies under 3 years old to be irresponsible and I am categorically against it.

How to ruin your children is, of course, a matter of personal responsibility. But I would like to prevent the promotion of such activities so that others do not suffer.

For those who don't know what to do with teething babies, there are things called teethers. And toys made of EVA, which are allowed by all authorities, and which cannot be chewed. Here I can tell you responsibly.

Who thinks about this safety aspect of printed toys?

Beaver to all.

All current news from me in social networks.

My https://www.instagram.com/daymon.nt/Instagram

Like I'm in https://vk.com/daymonntVKontakte

My BLOG

More interesting articles

four

Follow author

Subscribe

Don't want

Today's story is about Alexander Mikhailenko, the head of the RedFab company, acting as the CEO. ..

..

Read more

2

Subscribe to the author

Subscribe

Don't want

Hello 3DToday!✌️

Today after 18:00 a new regular and popular video-...

Read more

CEPKO777

Loading

02/08/2018

139185

273

Subscribe to the author

Subscribe

Don't want

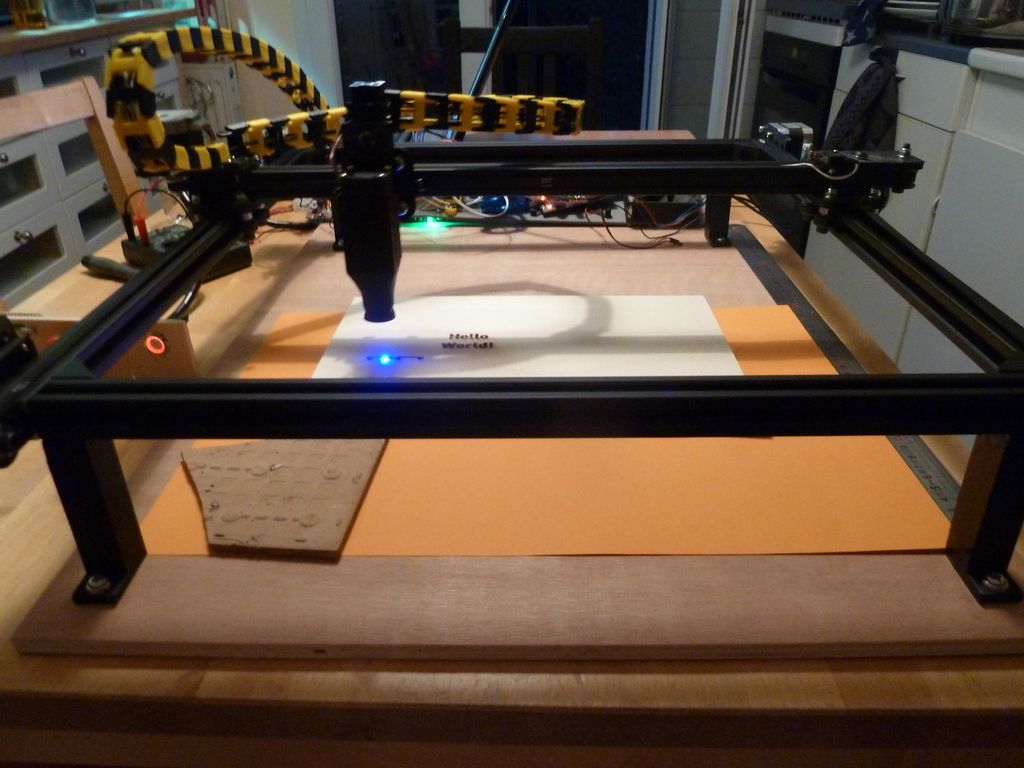

Hello everyone. After buying a printer and realizing the principle of operation of CNC machines, I began to look at others . ..

..

Read more

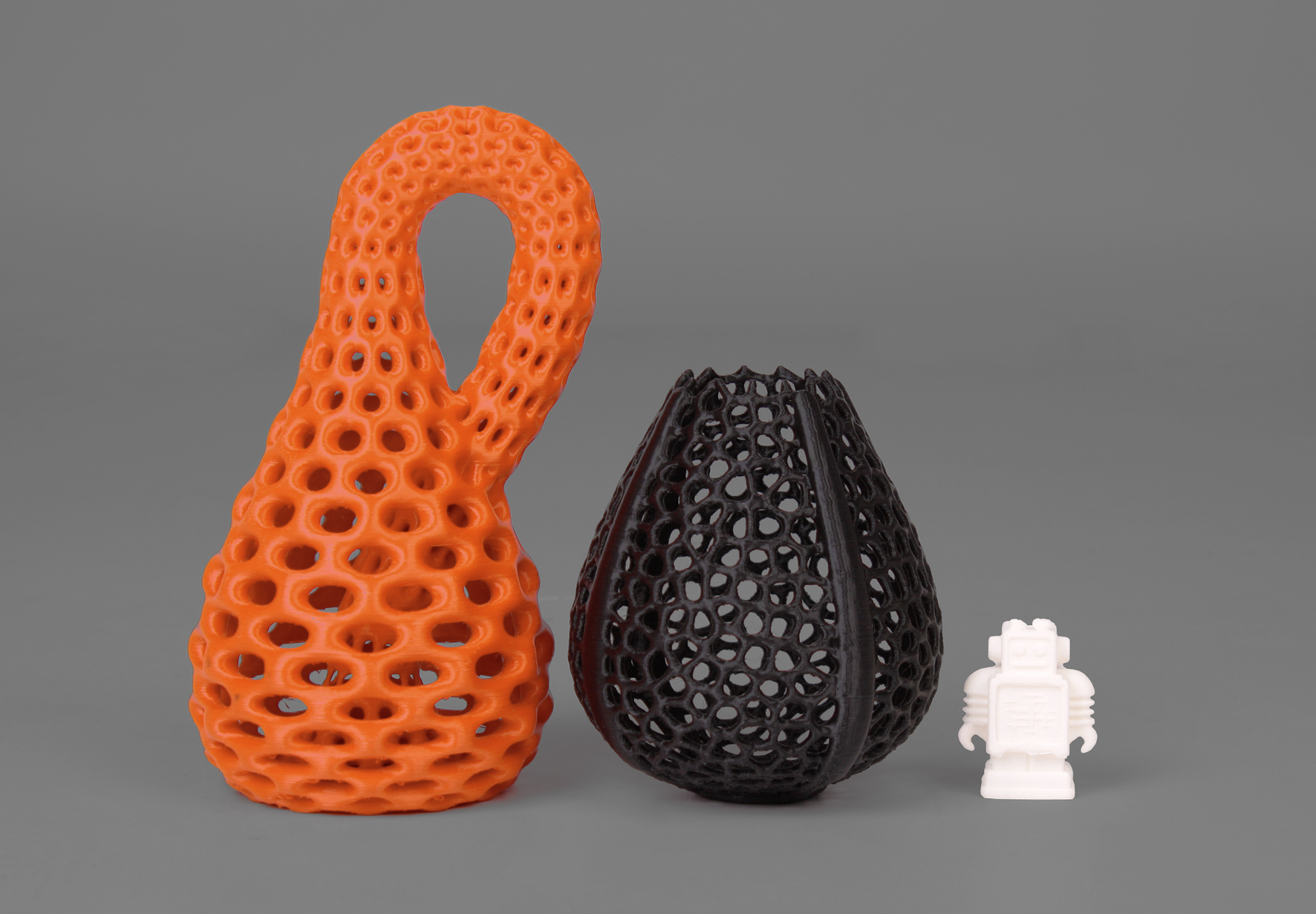

8 unusual things printed on a 3D printer

Many people think that 3D printers create products that are beyond our everyday life, but 3D printed products are already being used by many consumers who appreciate the benefits of the new technology.

In recent years, the global trend towards personalization is changing the picture of the entire consumer market. The opportunity to purchase a special product, made to measure, is increasingly becoming a determining factor in the purchase. In addition to attracting the consumer, 3D printing also gives companies a competitive advantage in production, significantly reducing the time for the implementation of each individual project. Now, instead of lengthy logistics, complex supply chains, stockpiling, the entire production process can be packed into a few days, and 3D printing of most objects will take hours. Thus, it turns out to optimize resources and reduce the cost of the final product.

Already today with HP Inc. Multi Jet Fusion 3D printers. companies all over the world from different sectors of the economy print unexpectedly interesting and useful things:

Multi Jet Fusion 3D printers. companies all over the world from different sectors of the economy print unexpectedly interesting and useful things:

1. Orthopedic insoles

Startup Invent Medical operates under the motto "Help through innovation." This is the case when medicine combined 25 years of human biomechanics research with 3D printing, scanning and design algorithms.

The company prints unique orthopedic insoles according to the individual parameters of the client in order to match the physiological characteristics and lifestyle of each consumer.

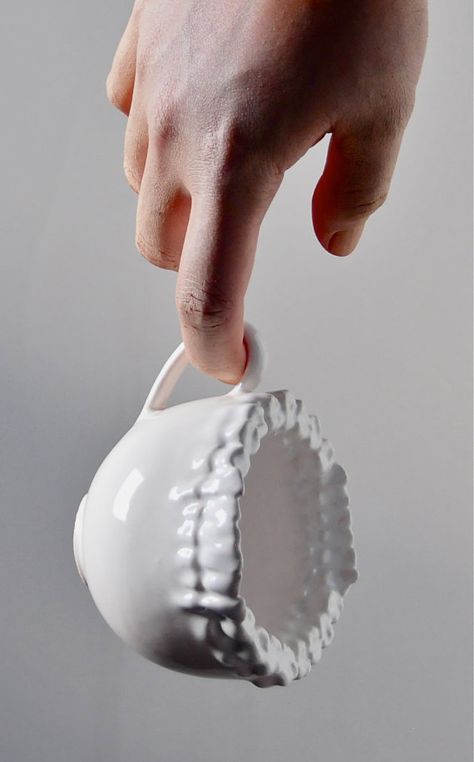

2. Glasses

Horizons Optical is not your typical optical manufacturer. The brand does not just create glasses, but develops innovative products and services.

One of the company's most innovative projects is the Made4U concept, which uses imaging and 3D printing technologies to create fully personalized glasses that perfectly fit any face type. To create them, a special system for scanning the structure of the face has been developed, which allows printing frames taking into account all the individual characteristics of the client.

3. Shoes

Designer Annie Fu has created a collection of futuristic women's shoes.

Don't let the bright and unusual shape of these shoes scare you: in fact, all models are comfortable and absolutely comfortable to wear, because each pair is created according to the measurements and shape of the foot of a particular client.

4. An alternative to braces

The Swiss company Nivellmedical has developed an aesthetic alternative for those who are embarrassed by iron shackles and dream of a beautiful smile. Instead of installing classic braces, the company offers transparent caps, using 3D printing and thermoforming to make them. Virtually invisible plastic elements gently yet effectively align teeth

To create molds, the doctor first scans the patient's jaw and then creates a virtual object that is quickly 3D printed.

5. Helmet of the Guards

The military unit of the Swiss Guards of the Vatican, existing since 1506, is responsible for the protection of the Pope. Their 3D-printed helmets are exactly the same as the original 16th-century models, but weigh just over 500 grams. The helmets are made in just fourteen hours, when the previous ones took about seven times longer to create.

Their 3D-printed helmets are exactly the same as the original 16th-century models, but weigh just over 500 grams. The helmets are made in just fourteen hours, when the previous ones took about seven times longer to create.

6. Dolls

The Spanish toy manufacturer Look Real has implemented a project to create personalized dolls that are like two drops of water similar to their owners. Psychologically, this could set the trend for the entire gaming industry.

It has been scientifically proven that the proportions of a doll affect the mental and physical health of a child and form his idea of his body. Since the doll acts as a prototype of a person in a children's game, it is important that her appearance is as close to real as possible. In the first seven years, the child's psyche is characterized by special mobility and the ability to project: the most striking features of the toy remain in the mind. The goal of the startup was to take into account these features and, using innovative technologies, create a special doll for each child, helping to form a healthy perception of their appearance.

7. Personal protective equipment

During the coronavirus pandemic, the speed of developing and producing new products has become a key advantage of 3D technology. If in traditional production it takes weeks to reconfigure devices, then the new method allows you to send a file with a product layout for printing in one click, just like we start printing any document on a regular printer.

Literally within twenty-four hours, the technology allows hundreds of elements to be simultaneously produced from scratch. In the first months of the pandemic alone, more than 3.3 million parts for hospitals around the world were quickly printed on HP 3D printers. These include face shields, mask holders, face shields, nose swabs, touchless door openers and respirator components. In addition, in order to provide the largest number of patients and medical institutions with scarce protective equipment, HP Inc. created a page where 3D model files are published in the public domain, which can be downloaded and sent for 3D printing anywhere in the world.

8. Car Parts

Racing car brand Cupra uses 3D printing to produce side windows and air vents. Thanks to these developments, the company has the ability to print several elements in a short period of time and change their configuration in the car during the production process.

The German automotive concern Volkswagen has produced more than ten thousand models of the ID.3 mid-range electric car, also using 3D printing to produce gear levers and mirror attachments.

Recently, the Nissan brand has also joined these companies: spare parts for rare cars are created on 3D printers. Long out of production retro model parts like these are no longer available in warehouses and used to take many months to find, but now they can be 3D printed in just a few hours.

Finally, to help make 3D printing waste sustainable, Ford and HP are collaborating on waste-free 3D printing of automotive parts. So, from recycled materials, Ford creates clips for fuel hoses for Super Duty F-250 pickups.