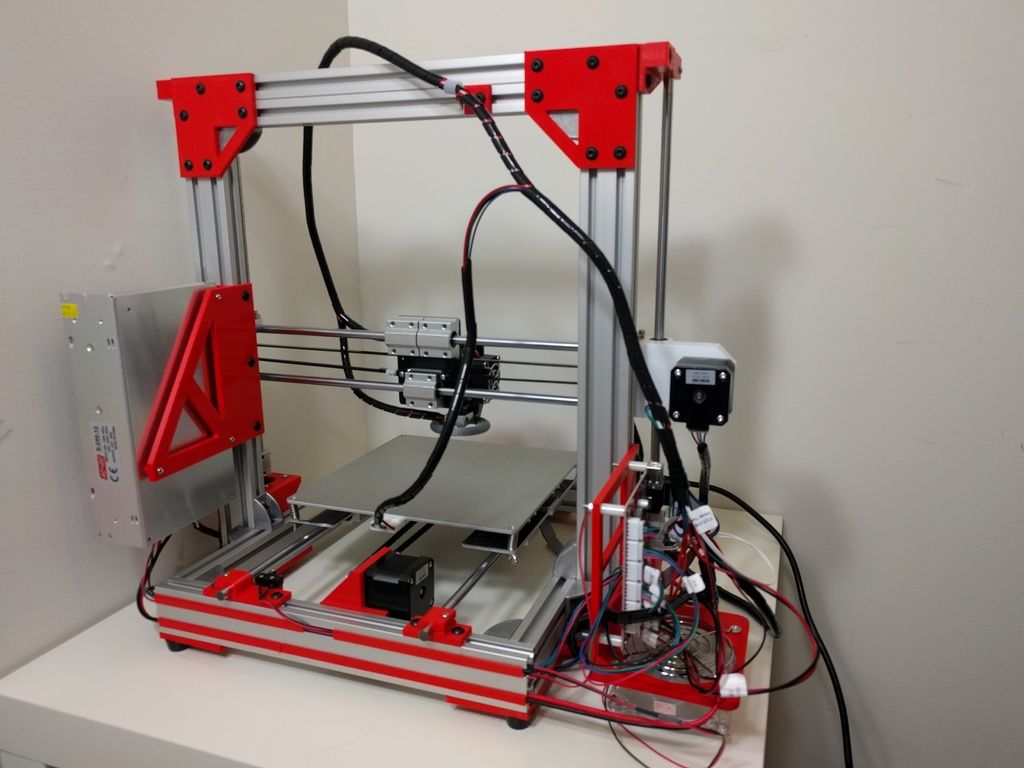

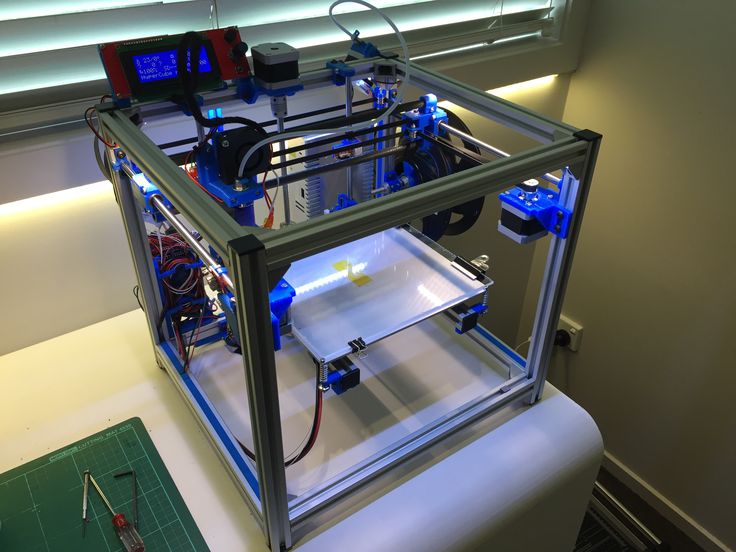

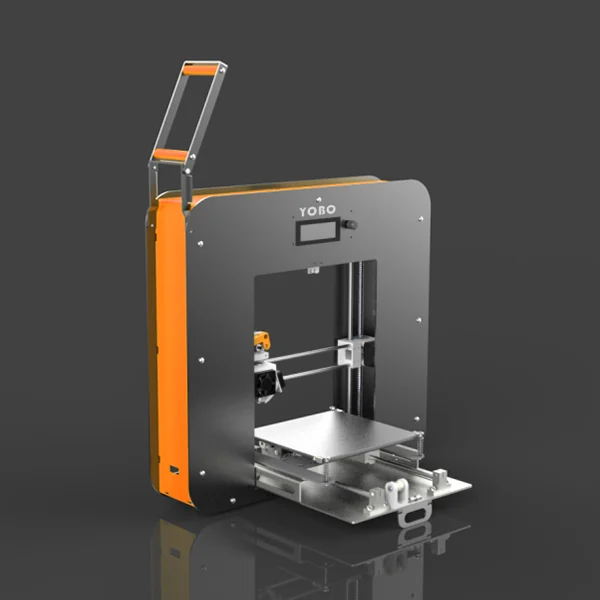

Hevo 500 3d printer

Best CoreXY 3D Printers 2022

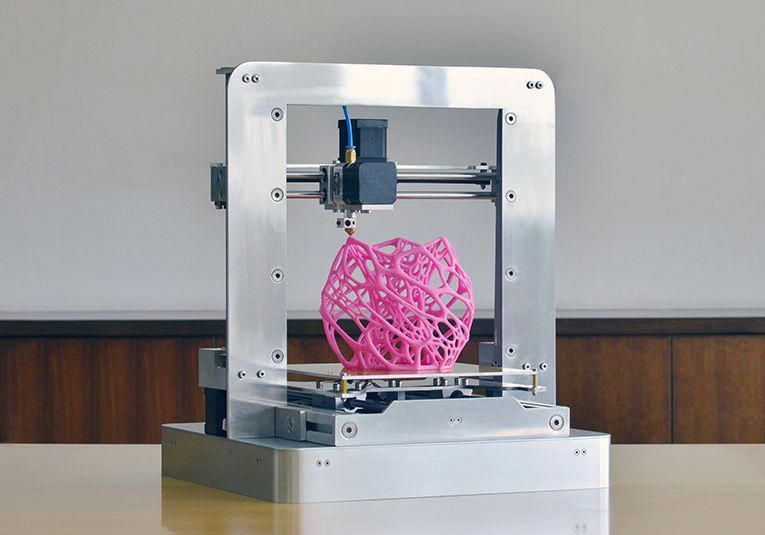

Best CoreXY 3D Printers 2022With so many 3d printer kits and open source build plans available, it can be a challenge to choose an option for your 3d printing needs. Every 3d printer design has different design goals for different needs as well as different compromises. Whether you’re building a new printer or just in need of a new 3d printer, there are many options to choose from with each of them having their own advantages and compromises.

In this article we review the corexy kinematics and discuss the advantages and disadvantages of each 3d printer option that uses the corexy motion system.

- DIY 3D Printer Kits

- Design and Build Plans

- Plug and Play- Ready to Print

- New Projects Soon To Be Released

- All Metal Parts

CoreXY Design Considerations

- Build Volume

- Print Quality

- Cost

- Print Speed

- Open Source

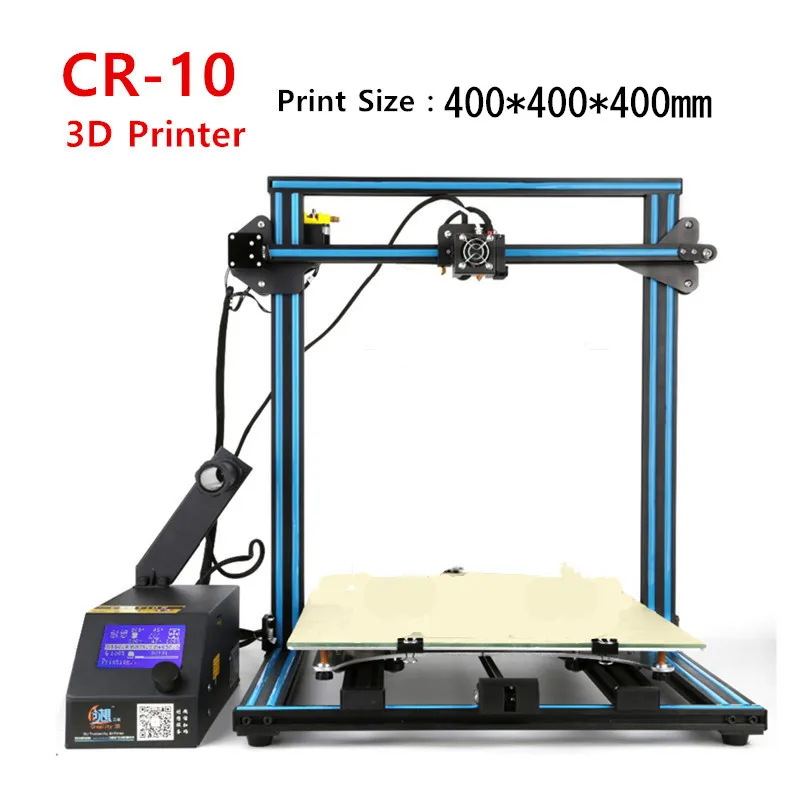

Build Volume

Build volume is an important consideration when deciding on a 3d printer. The size of the parts that you can print is usually one of the first limitations makers have.

BEST COREXY 3D PRINTERS 2022

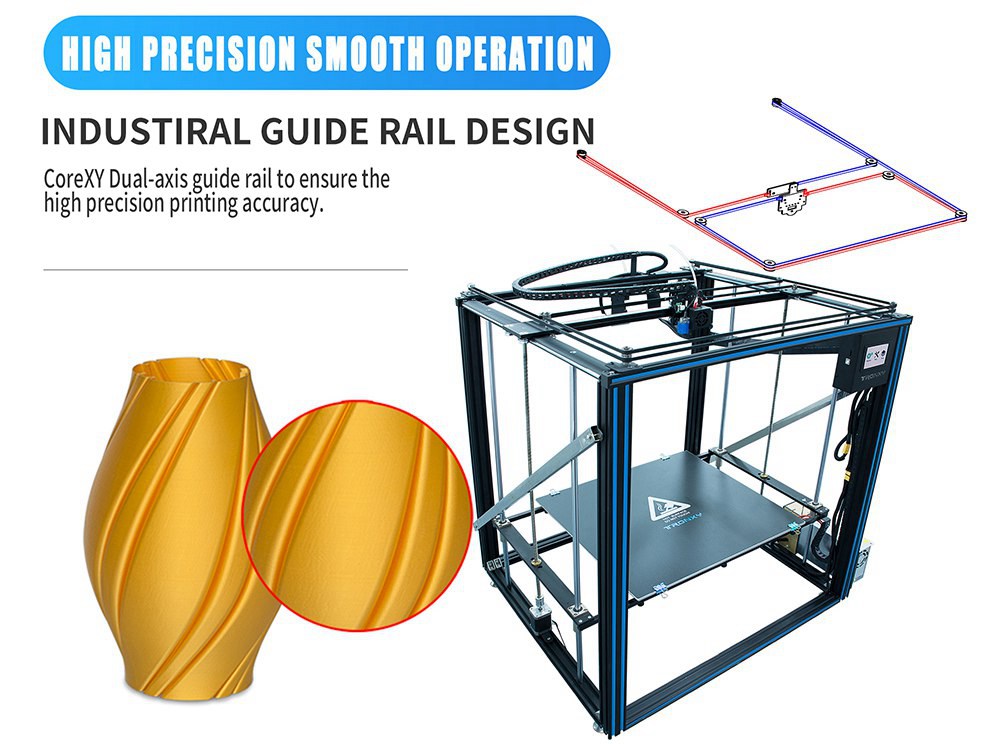

SolidCore CoreXY Belt Path DiagramWhen you think about a good machine build you have to consider a few things. How developed is the design? Many common designs will have:

- Contributors designing fixes, mods and other spun off remixes.

- How many mods are there that could allow you to modify your printer for custom applications

- Is there a user group that you use as a resource to troubleshoot or upgrade and update your build. While there are many resources to draw upon User groups will keep you in the circle of news, updates and creative solutions.

see CoreXY Kinematics Explained

Researchgate Paper CoreXY vs Cartesian

BEST COREXY 3D PRINTERS 2022

- Jubilee

- SecKit

- Voron 3D Printer

- BLV MGN Cube

- Railcore

- HyperCube

- E3D ToolChanger

- VzBot

- CrazyCreatorCube

- HeVort DIY 3D Printer

- SolidCore CoreXY

BEST COREXY 3D PRINTERS 2022

Mechanical Arrangement

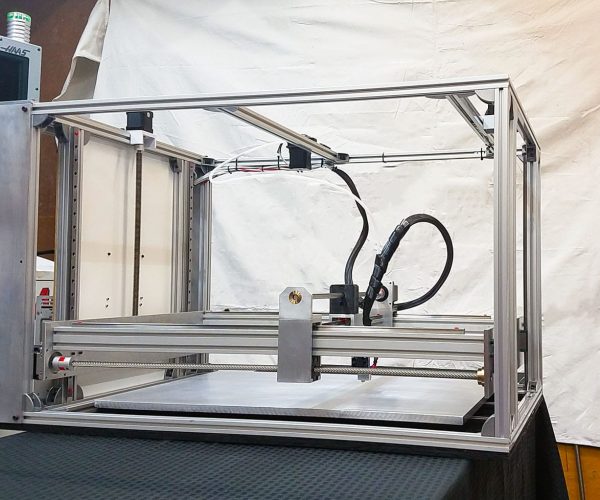

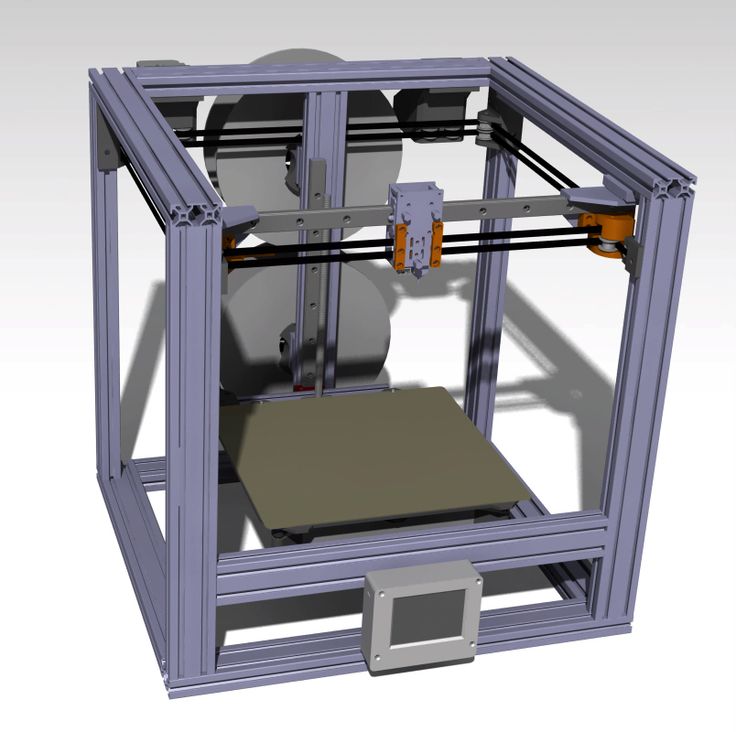

SolidCore CoreXY Mechanical ArrangementThe mechanical arrangement of components such as motor and idler mounts, linear rails, carriage and gantry may or may not allow for add-ons such as an enclosure or heated chamber. For example, motor and idler mounts placed on the inside corners of the frame gives the needed clearance to mount an enclosure. Each design has it’s own advantages and disadvantages. The configuration above eliminates any design constraints of scalability so the overall length and width of the 3d printer build can be completely scalable.

For example, motor and idler mounts placed on the inside corners of the frame gives the needed clearance to mount an enclosure. Each design has it’s own advantages and disadvantages. The configuration above eliminates any design constraints of scalability so the overall length and width of the 3d printer build can be completely scalable.

BEST COREXY 3D PRINTERS 2022

HeVort-Advanced DIY 3D Printer

HeVort-Advanced DIY 3D PrinterHeVort DIY 3D Printer: Non-Planer 3D Printing

The HeVort is a design that takes bed leveling to the next level. The Hevort 3-point bed tilt also changes the way parts need to be supported so for models with overhangs facing ‘uphill’ into the angle, supports aren’t needed. Although non-planar printing is not really widely implemented yet, there are new slicer post and processor components for printing at fixed angles other than 90. In the future, we may see more non-planar printing. This would allow you to print a part in vertical mode and add another component at an angle without need of support material or other mechanical aids.

With non-planar printing becoming more and more popular, it’s not surprising that slicer toolpaths are available. This means you can optimize how your layers are printed and reduce support needed thanks to angled orientation. One problem with 3D printing is that it can be difficult to support overhangs.

True 3-Point Bed Leveling

HeVort Z Axis DesignBEST COREXY 3D PRINTERS 2022

The HeVort uses a mechanical setup that consists of linear rails mounted to the bottom of the build plate along with 3-point bed leveling. It’s a concept called Non-planer 3d printing. Some refer to the setup as True Bed Leveling.

As slicer software advances, software will soon be able to generate optimized toolpaths for printing fixed angles. Combined with layer optimization, support material will no longer be needed.

HeVort 3D Printer Github

HeVort DIY 3D PrinterBEST COREXY 3D PRINTERS 2022

JUBILEE 3D PRINTER

Jubilee 3D Printer

Jubilee corexy is one of the most hackable 3d printers. If your looking for a highly customizable printer you’ll have to take a look at this. It’s a multi-tool motion platform that has made much progress in the last year. Out-of-the-box, Jubilee is configured for multimaterial 3D printing compatible with current E3D toolchanger parts. Jubilee is meant to be extended by the community through custom tools and applications.

- Modular Platform

- ToolChanger

- Customizable

- Awesome

The Jubilee toolchanging platform was quick to adopted as manufactures began to offer all-metal upgrades for the platform. Mandala Rose Works offers a range of lightweight machined parts. The Tool changer platform has a big community on Discord.

Mandala Rose Works offers a range of lightweight machined parts. The Tool changer platform has a big community on Discord.

- Jubilee GitHub Page

BEST COREXY 3D PRINTERS 2022

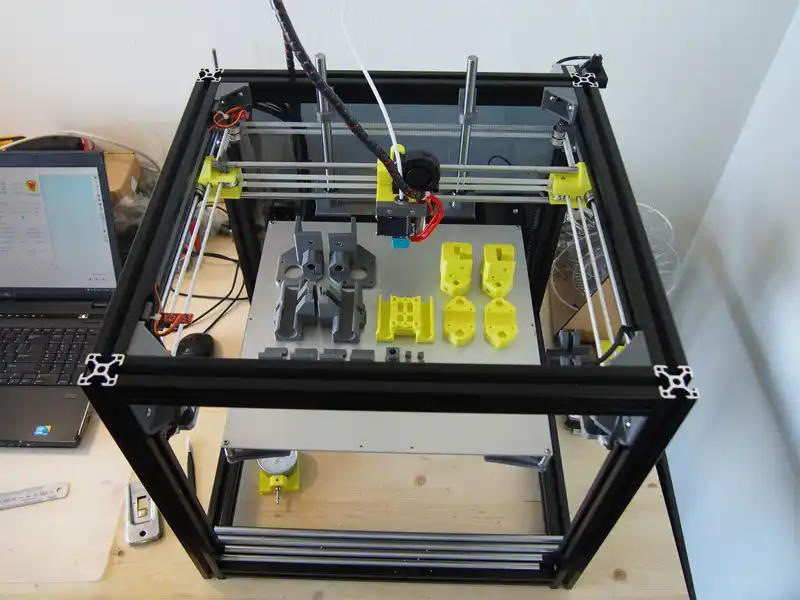

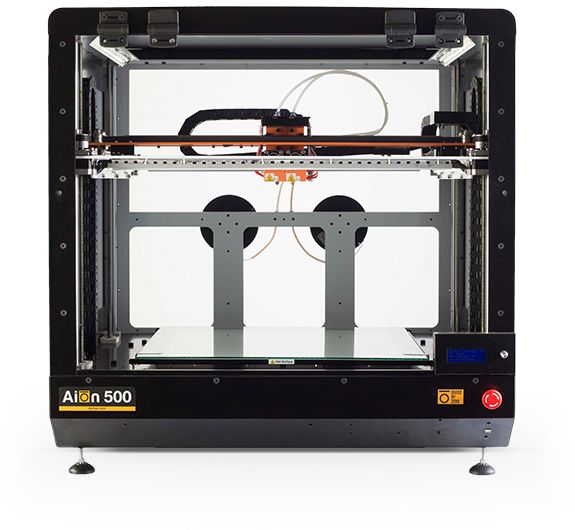

Rat-Rig V-Core 3

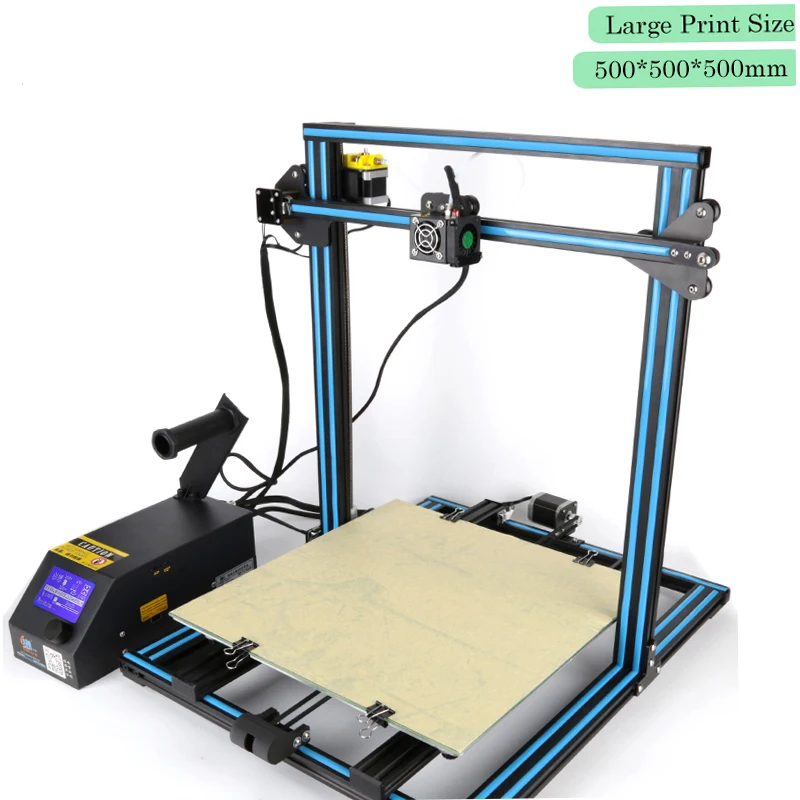

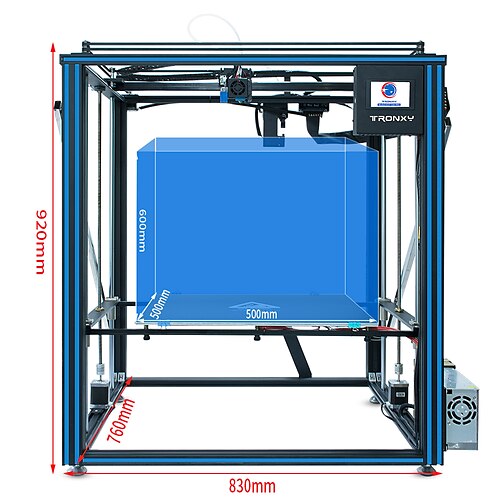

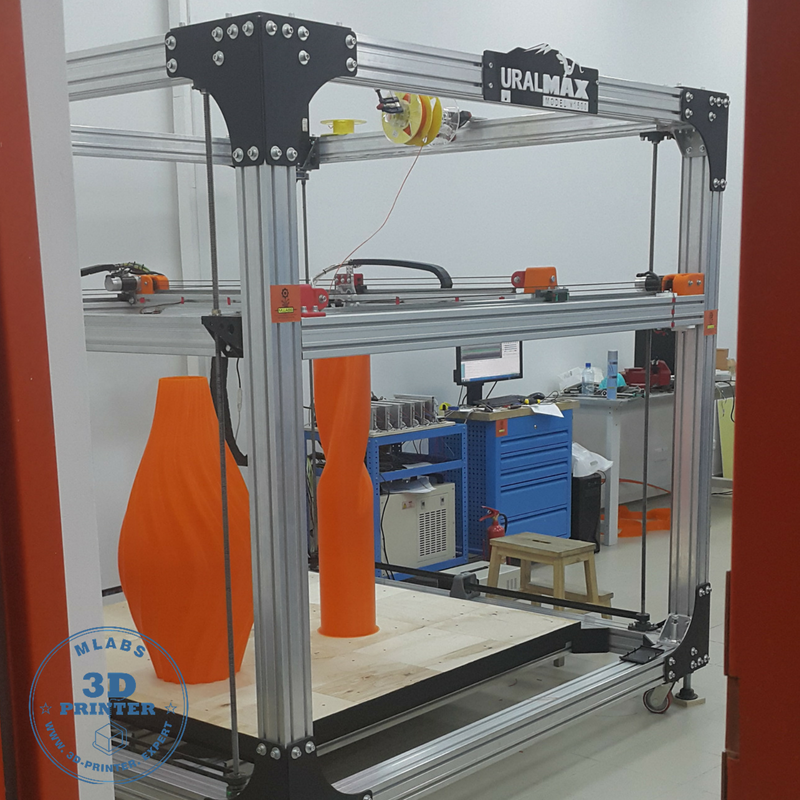

Rat-Rig V-Core 3The Ratrig V-Core 3 is a premium DIY kit for your CoreXY needs. The “Configurable” kit is simple for beginners but built with advanced users in mind. The Rat Rig V-Core is quickly getting traction with a growing community that’s pushing the limits of corexy scalability as many are diving into 3d printer builds as big as 500mm x 500mm x 500mm.

Rat-Rig V-Core 3The RatRig “Configurable kit” is as complete as possible with many choices of components, including aluminum frames, precision rails, linear bearings, stepper motors & belts. This complete and customizable DIY kit can be as simple or complex as you’d like it to be, with many choices of bits that will go into the printer when assembling your CoreXY 3D Printer. See Rat Rig V-Core 3

Related Content

Kinematic Bed Mounting

Kinematic Bed Setup

CoreXY

CoreXY Parts

Belt Routing

Discord Channel

BEST COREXY 3D PRINTERS 2022

CrazyCreatorCube

The CrazyCreatorCube is a new project that is the alpha state as it launches it’s new open source design. The tool-changing 3D printer can utilize up to four extruders at a time. The tool holder uses neodymium magnets to mount the tools into the tool stations with a mechanical, latching mechanism. The central fan unit and air duct is optimized air flow. The CrazyCreatorCube has a well designed carriage well suited for belt tensioning.

The tool-changing 3D printer can utilize up to four extruders at a time. The tool holder uses neodymium magnets to mount the tools into the tool stations with a mechanical, latching mechanism. The central fan unit and air duct is optimized air flow. The CrazyCreatorCube has a well designed carriage well suited for belt tensioning.

- Build volume: 350x330x400mm

- ToolChanger Mechanism: Magnetic

- Open-Source

- Electronics: Duet2 with Duex5 Expansion Board

See CrazyCreatorCube Website

CrazyCreatorCube Toolchanger

The CrazyCreatorCube Toolchanger was designed by Hendrik and Andy to develop a stable and efficient tool changer 3d printer. The main focus of this tool-changer project is to make a 3d printer tool changer with great 3d printing quality, easy maintenance, and cost efficiency.

E3D Tool Plate Compatible

The tool changinging 3d printer is 100% compatible with E3D tools and 99% of the CrazyCreatorCube parts can be found in stores or ordered online. Another goal of the 3d printer project is that the printer build should be possible for anyone with basic technical knowledge to build and assemble the CrazyCreatorCube.

Another goal of the 3d printer project is that the printer build should be possible for anyone with basic technical knowledge to build and assemble the CrazyCreatorCube.

Kinematic Bed System

The 350mm x 330mm bed or build plate uses a kinematic system to connect to the bed supports and the heated bed is moved along three axes and completely auto leveled.

Magnetic Tool-Changer

The magnetic ToolChanger uses a remote system which means the motor that rotates the safety bolt and holds the tool on the tool changer, sits on the frame and does not increase the weight of the print head.

Print-Head / Extruder

While a remote extruder is used in the classic CrazyCreatorCube version, a normal Direct drive extruder or Bowden extruder can also be used.

BEST COREXY 3D PRINTERS 2022

Voron 3D PrinterBEST COREXY 3D PRINTERS 2022

VORON 2.4

The Voron V2 by Voron Design is a well engineered printer with a very promising future. It has a huge community that loves their DIY builds and is very well documented.

It has a huge community that loves their DIY builds and is very well documented.

- Build volume: Scalable

- Extruder: AfterBurner

- Enclosure: Open or Enclosed

- Moving Gantry

- Electronics: Duet3D / Klipper

The Voron V2.4 is a light weight and compact corexy motion system with a superior design. The printer has a moving gantry / fixed bed that utilizes four point z-axis belts which is very unique for a corexy. The design is easily enclosed and has a lighter moving mass which sets it up for high speed prints with beautiful parts. While the V2 is a great machine it’s probably not the best for first time builders but does have a build guide that some say is far superior.

Although the four Z-axis motors implementation and expansion board may be challenging for some there are many more builds much simpler to choose from that will produce great results. The Voron V2 has precision linear rails for the X- and Y-axes and dual-drive extruder. The design uses four independent z-axis stepper motors that are belt driven which eliminates z-wobble that most machines experience. The light-weight moving gantry design increases print quality with it’s belt driven system which makes this corexy 3d printer design a community favorite.

The Voron V2 has precision linear rails for the X- and Y-axes and dual-drive extruder. The design uses four independent z-axis stepper motors that are belt driven which eliminates z-wobble that most machines experience. The light-weight moving gantry design increases print quality with it’s belt driven system which makes this corexy 3d printer design a community favorite.

Voron Review

Voron 2.4 ReviewVoron 2.4 Specs

- Light-Weight Carriage Design

- High speed prints with fewer defects

- Better at printing tall thin things

- Great community support on Reddit

- Less moving mass of the extruder carriage

Voron 2.4 Build Volume

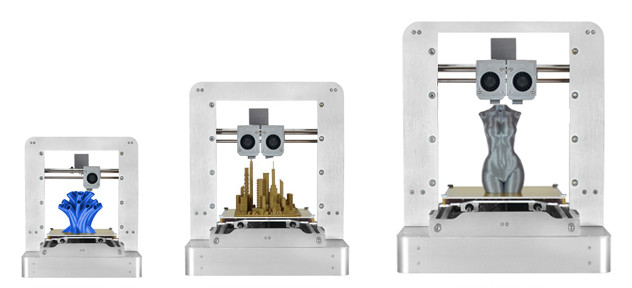

Voron 2.4 3d printer kits are available in three sizes:

- 250mm x 250mm x 250mm

- 300mm x 300mm x 300mm

- 350mm x 350mm x 350mm

BEST COREXY 3D PRINTERS 2022

The advantage the Voron’s fixed bed and belted z-axis that the moving mass isn’t at the top of the printer. While most 3d printers print objects at the top of the machine, the Voron’s fixed bed–Moving gantry travels down to the bed. This mechanical arrangement keeps the moving mass towards the center of the machine This configuration makes the design more stable allowing for faster movements and 3d printing.

Voron Tool Changer

Voron Tool ChangerVoron 2.4 Price

Voron 2.4 Price $1,000.00

Depending on build area and other options such as hotend and extruder, the Voron 2.4 is approximately $1,000.

Voron Website learn more

BEST COREXY 3D PRINTERS 2022

Triple Z

SolidCore CoreXY Triple ZThe advantage of triple z stepper motors allows an additional degree of freedom and bed leveling. Thermal expansion from the aluminum build plate can cause issues. The Hevort and Jubilee uses small springs on to fix the bed. The Maxwell coupling solution applied to the Z-axis by adding a third axis and mounting it with a Maxwell coupling. The Z-axis leveling algorithm is implemented by the RepRap firmware on a Duet Wifi or Duet 3 Mainboard.

The Z-axis leveling algorithm is implemented by the RepRap firmware on a Duet Wifi or Duet 3 Mainboard.

See SolidCore CoreXY Triple Z

BEST COREXY 3D PRINTERS 2022

Blackbox Multi-Tool 3D Printer Toolchanger PlatformWhile there are many open source 3d printer designs available, most of them are limited to specific 3d printable plastics. The Blackbox was designed and created by Marc Schömann of Layershift.xyz, who has a different approach to 3d printing with multi-materials. The Blackbox is designed to be a flexible platform for multitool fabrication. The multitool / multimaterial manufacturing platform for printing highly exotic materials and integrated assemblies.

Water Cooled-Toolchanger

The Blackbox was designed to produce high-end parts that challenge most 3d printers. The Blackbox 3D printer is a fully open source design that uses water-cooled printheads and a direct drive toolchanging system. The water-cooled setup offers more precise thermal control that’s more reliable and consistent. These factors are the secret ingredient to high quality 3D printing.

The Blackbox 3D printer is a fully open source design that uses water-cooled printheads and a direct drive toolchanging system. The water-cooled setup offers more precise thermal control that’s more reliable and consistent. These factors are the secret ingredient to high quality 3D printing.

Most common 3d printers are limited to printing single materials and colors. The blackbox has a different design goal. The Blackbox design aims to provide a machine that can produce high-end parts from a range of many different materials.

Blackbox Specs

- Build Volume: 300 mm x 300 mm x 275 mm

- Full enclosure

- Direct drive toolchanger

- Water-cooled toolheads

- Belted Z-axis

- Automated leveling and calibration

- Price: $2,900

BEST COREXY 3D PRINTERS 2022

Belt Drive Z-Axis

The belt-driven Z-axis has a 1:10 pulley reduction that allows the bed and layer height to precise movement The frame is made from 4040 t-slot profiles and can print up to five materials at a time with the toolchanger.

Water-Cooled Tool Heads

The water-cooled tool heads are exchangeable cooled passively by the tool bank or the x-axis. While the tools use Bowden tube setup, the X-Axis carries one direct driven Extruder for flexible materials and uses a laser to keep the print area warm. The XYZ-axis all use linear rails and the X-Axis uses a lightweight carbon support.

BEST COREXY 3D PRINTERS 2022

BlackBox 3D PrinterThe goal is to print complex composite parts with multiple materials. The idea is that the tools are cooled on the tool bank while they are inactive and on the X-axis after they are picked up by it. This eliminates the need for cooling hoses or fans which make the design more compact and lightweight.

The multi-material 3d printing platform is pushing the boundaries of 3d printing and has plans to open the door to multitool fabrication with integrated assemblies.

BlackBox Specs

- Open-Source

- 300mm x 300mm x 240mm Build Area

Interchangeable Printheads

BlackBox Price

The Blackbox 3d printer can be built for approximately $2,900. 00

00

BlackBox 3D Printer Price

$2,900.00

See BlackBox 3D Printer

BEST COREXY 3D PRINTERS 2022

RailCore II 3D Printer

Railcore 3D PrinterThe Railcore 3D Printer by J. Steve White & Tony Akens of RailCore Labs is core xy design has some kick. Although this a new open source build has a strong and active community. The RailCore Printer is a customizable corexy design that successfully implements 3 point bed leveling. Designed to use X, Y and Z-axis linear rails, the RailCore also is available with machined aluminum parts. Three point bed leveling with automatic bed tramming using the Duet3d electronics allows for a perfect first layer.

BEST COREXY 3D PRINTERS 2022

RailCore Labs

Railcore 3D Printer at Midwest RepRap DIY 3D Printer FestivalWe first discovered RailCore Labs and the open-source corexy design at MRRF 2019. The Railcore 3d printer was designed while Tony Akens and J. Steve White were discussing an idea of a 3d printer with linear rails on the x,y and z-axis on Reprap IRC.

The Railcore 3d printer was designed while Tony Akens and J. Steve White were discussing an idea of a 3d printer with linear rails on the x,y and z-axis on Reprap IRC.

The Railcore uses 15mm frame extrusions and M3 hardware that brings down the cost. 15mm Extrusions use m3 hardware is much cheaper compared to m4 or m5 hardware. Although 15mm extrusions and m3 hardware may be less rigid the printer gains it’s rigidity from the reinforcement of the side panels. Many more design decisions were made to make the printer build as space efficient as possible while maximizing build volume. The printer build gains it’s rigidity

It is a well thought out design that has verity of CNC machined upgrades to pimp your printer. The prints that are made from the machine are absolutely beautiful. This 3d printer build is most commonly found using the Duet Wifi to power the system. The print quality is spectacular with it’s high precision 0.9 degree steppers. The pros of the Railcore corexy is:

The pros of the Railcore corexy is:

- Linear Rails on X,Y and Z-axis

- Enclosure

- 15mm extrusions to reduce the price of BOM

- All-metal parts

- Space & Cost efficient

RailCore II 300ZL

The original Railcore printer is no longer available due to the updated 300 ZL and ZLT version. But here’s the details:

- Linear Rails XYZ Axis

- 300mm x 300mm x 330mm Build Area

- ZLT is 300m x 300mm x 600mm Build Area

- Auto Leveling

- Hotend: E3D V6 or Mosquito

- 0.9 Degree Steppers

- Hardware: 3D Printed Parts or Machined Aluminum Upgrades

BEST COREXY 3D PRINTERS 2022

RailCore Upgrades

The Railcore ecosystem consists of all aluminum machined parts. 713Maker and Mandala Rose Works manufactures a variety of CNC machined aluminum parts such as motor and idler mounts and aluminum heat bed plates. Upgrades such as a kinematic bed mount is also available. The upgrade kit gives you the option to mount the z-yoke and bed to a kinematic coupled system. This setup is based on the Kelvin style kinematics and is better suited to handle the thermal expansion of your bed as it heats up.

This setup is based on the Kelvin style kinematics and is better suited to handle the thermal expansion of your bed as it heats up.

- 713Maker

- Mandala Rose Works

The Railcore 3d printer’s ecosystem of parts also include a variety of CNC machined aluminum parts that can be found by 713Maker and Mandala Rose Works that can make your printer look like a hotrod.

RailCore Tool Changer

While a toolchanger option isn’t currently available you’ll probably see a design oneday. Tony Akens explained in a fb post that the Railcore wasn’t designed for a toolchanger. RailCore Labs plans to retro-fit the E3D Tool Plates but it’s not built for toolchanging. Tony goes on to suggest that one would have to modify the printer and change how the RailCore works. He explains that bolting on components is easy by design but may complicate the RailCore bed leveling. He suggests that the Jubilee is somewhere in between the RailCore and the E3D ASMBL but has future plans to work with Joshua Vasquez the creator of the Jubilee. 3 build volume

3 build volume

BEST COREXY 3D PRINTERS 2022

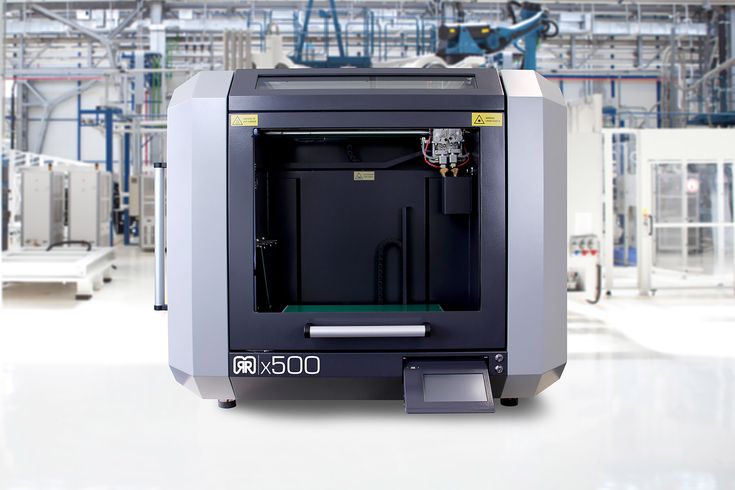

E3D TOOLCHANGERE3D ToolchangerIf you havn’t seen the E3D ToolChanger motion system , you’re missing out. The open source design is most likely the future of 3d printing… or at least the begining of true desktop manufacturing. While the motion system is somewhat in beta testing phase the new platform has a lot to promise and has inspired a wave of new printers exploring different tool changing methods.

E3D Toolchanger Specs

- E3D Toolchanger Price $2800

- Build Volume 200mm x 300mm x 300mm

- Extruder Bowden

- Electronics Board Duet 3

BEST COREXY 3D PRINTERS 2022

CROXY CROSSED GANTRY 3D PRINTER

Designed and built by Wes Cherry

CroXY is a fully enclosed 3D Quadrap printer with a crossed linear rail gantry design, direct drive extruder and a kinematically mounted bed that moves in Z with three ball screws. Although this printer isn’t exactly a corexy it does utilize the same kinematics.

BEST COREXY 3D PRINTERS 2022

WHAT IS A QUADRAP MOTION SYSTEM?

The Quadrap mechanism is similar to a corexy but one or two extra stepper motors. It’s a cross between a core-xy and the ultimaker’s XY mechanical arrangement.

- X- Axis

- Y-Axis

- X2-Axis or Y2-Axis / Both X2 abd Y2-Axis

The crossed members at the print head carriage allow low moving masses because none of the motors (X,Y or E) are moving with the extruder carriage. The corexy’s belt stretch issue is minimized when scaled up but resistance may increase.

The corexy’s belt stretch issue is minimized when scaled up but resistance may increase.

- Minimized belt length

- Increased Resistance

learn more

BEST COREXY 3D PRINTERS 2022

RepRap 3.0

The CoreXY motion system is a good solution if you’re looking to print faster. The 3d printer kinematics has become more popular in the last couple of years as users and DIY builders agree on an increase in print quality. The motion system is more lightweight compared to other 3d printer kinematics such as cartesian 3d printer kinematics. A light-weight gantry is needed to increase print speed without affecting print quality. This is all important when attempting to get a smooth finish on 3d printed parts.

BEST COREXY 3D PRINTERS 2022

3D Distributed Folder

CoreXY Folder

All Metal Part Store

Buy 3D Printer Parts

- Triple Z- Firmware & Motor Movement

- Triple Z-Axis-Belted Z-Motors

- TripleZ Setup

- Dynamic Acceleration Control

- Kinematic Design Principles

- Kinematic Bed Mounting

- Belted Z-Axis Drive

- New Kinematic Bed Mount Design-SolidCore CoreXY 3D Printer

- SolidCore Kinematic Coupling Bed Mount

- Z-Wobble

- Large CoreXY Design – Hardware and Firmware Changes To Reduce Ringing

- X-Carriage

- Y-Carriage

- Is CoreXY better?

- What You Need to Know Before Buying a 3D Printer

- RepRap 3.

0

0 - Belt Tensioning

BEST COREXY 3D PRINTERS 2022

Complete CoreXY Kits vs Self-Sourced BOM Part Lists

While many designs are available in complete corexy kits, some open source 3d printer designs are currently still self-sourced, meaning that builders will have to source individual 3d printer parts and get it all together which results in complexity as some parts may take long to receive and increases the chance that one might order the wrong part number. With that said, is the price still about the same depending on extruder options print size.

BEST COREXY 3D PRINTERS 2022

Exoslide Moving Gantry

Exoslide CoreXY 3D Printer at MidWest RepRap FestivalThe Exoslide is a scalable core-xy design influenced by the Voron II. It has a moving gantry and custom injection molded carriages with 10mm bearings running along the extrusions. The modular linear carriage slides have an adjustable bearing preload and M4 nuts embedded throughout each face for mounting various components and bracketry.

BEST COREXY 3D PRINTERS 2022

As more 3d printer mods and upgrades are increasingly announced in community groups and forums newly published designs that tend to be open-source and contributors announce their next printer designs such as anti-wobble lead screw nuts and belted z-axis drive mechanisms.

While some corexy designs are familiar to others it’s a great environment for the community as design options and functionality evolves. There’s more opportunity for designers and contributors to make their own mark or be the first to design their own unique versions of an idea from one printer applied to a newer 3d printer platform. Design concepts and unique features inspire the development of open-source 3d printers.

Design concepts and unique features inspire the development of open-source 3d printers.

BEST COREXY 3D PRINTERS 2022

Cantilever Bed vs 3-point Bed Leveling

While many of the original corexy printers used cantilever beds, carriage wheels or smooth rod the newer and better corexy published designs are now using linear rails and have adopted more functional mechanisms such as belted z-axis, toolchangers and non-planar 3d printing concepts such as 3-point bed leveling or triple z with kinematic coupling bed mounts for tilting print beds for perfect bed leveling.

Although the simplicity of older corexy reprap printers were less technical and easier for newbies, the increasing number of options and features can easily be adopted from corexy design platform to another, which has exponentially inspired contributors as they work to identify or fix potential issues or increase overall print volume.

3D printer designs such as the HyperCube use a cantilevered bed lifting mechanism which is fine for what is now considered a smaller print bed size. For example, most earlier designs have 200mm print beds but newer 3d printer options are available with larger bed sizes as many 3d printer platforms average around 300mm x 300mm beds and increasingly push the limits of build volume to 500mm if not larger.

For example, most earlier designs have 200mm print beds but newer 3d printer options are available with larger bed sizes as many 3d printer platforms average around 300mm x 300mm beds and increasingly push the limits of build volume to 500mm if not larger.

Heated Bed- DC vs Mains Powered Beds

While older corexy designs used DC-powered heat beds newer machine platforms are implementing mains-powered heat beds which allow users heat build plates much faster, however there’s nothing to stop you using a DC bed on a Voron or a mains bed on a HyperCube. It’s just wiring.

Build Volume- Scalability vs Reliability

While some designs scale up well beyond 300mm and other print volume sizes most 3d printer designs are offered in standard bed size options many people have moved away from the common 200mm bed size. Although, a smaller bed size reduces issues such as bed leveling and simplifies printer movement of a machine’s motion system movement.

BEST COREXY 3D PRINTERS 2022

Dual Z vs Triple Z

While earlier corexy 3d printers used the more common cantilever bed lifting mechanism which utilized a single stepper motor 3d printer with a dual Z axis lead screw setup mechanical layout which also worked well. However, there are plenty of Hypercube and D-Bot mods that implement dual-Z or linear rails or other components that increase accuracy and repeatability.

However, there are plenty of Hypercube and D-Bot mods that implement dual-Z or linear rails or other components that increase accuracy and repeatability.

BEST COREXY 3D PRINTERS 2022

Thingiverse vs Github

There may be more mods available for the HyperCube and D-Bot style designs, but staying current with mods and other design alterations can be messy as previous users downloaded or contributed on platforms such as Thingiverse which is increasingly becoming more and more outdated due to inadequate search results and depreciating usability. Designers and contributors have migrated to platforms such as Github to download or share files which results in a much more organized approach that keeps the community up-to-date with design revisions.

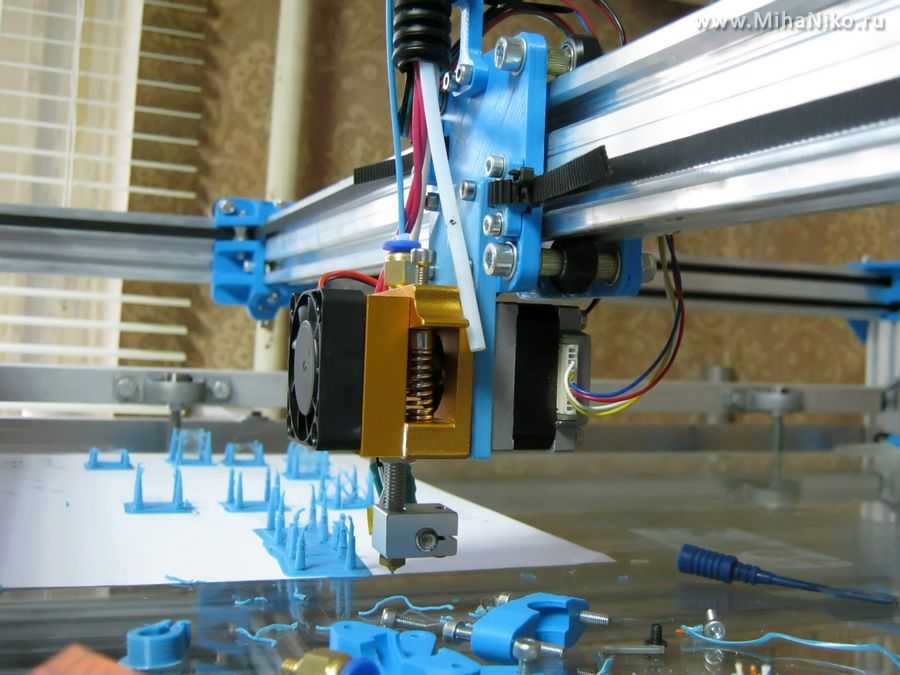

Rods vs Linear Rails

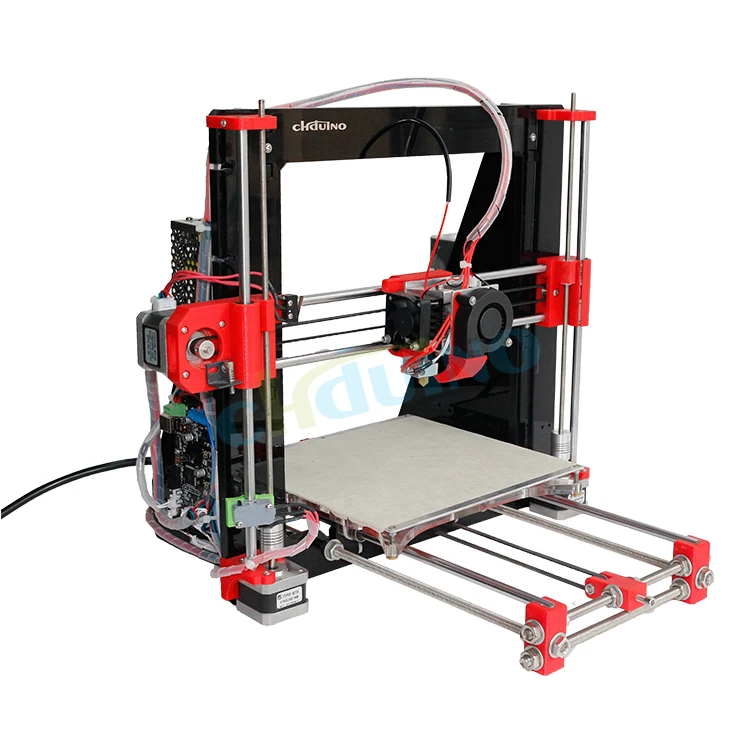

Many of the earlier 3d printers were designed around cheaper mechanical parts such as carbon rods or stainless steel smooth rods which were once commonly used and recommended. As the cost of linear rails become cheaper and cheaper due to the economy of scale and increasing number of buyers and large volume production of manufactures and suppliers. 8mm steel rods and linear bearings are slowly being somewhat phased out but still used on cheap kits found on Aliexpress.

8mm steel rods and linear bearings are slowly being somewhat phased out but still used on cheap kits found on Aliexpress.

8-Bit vs 32-Bit Electronics

The 8-bit Marlin based boards such as the classic Ramps 1.4 have also been abandoned for more functional and customizable control boards and firmware that use 32-bit electronics with 24V Power Supplies and better stepper motor drivers like the Duet3d board. These control boards offer better documentation, support and large communities of technical users that share methods and firmware code to configure almost any 3d printer you could possibly design.

Customizability vs Availability

If you are looking for a cheap way to get started, building open source kits like the HyperCube and D-Bot is a good way to get started as you mod and upgrade your printer to a more functional machine. It’s much cheaper to build as you recycle or reuse parts like linear rods, lead screws and bearingsThe availability and access to mods miscellaneous parts with multiple design iterations.

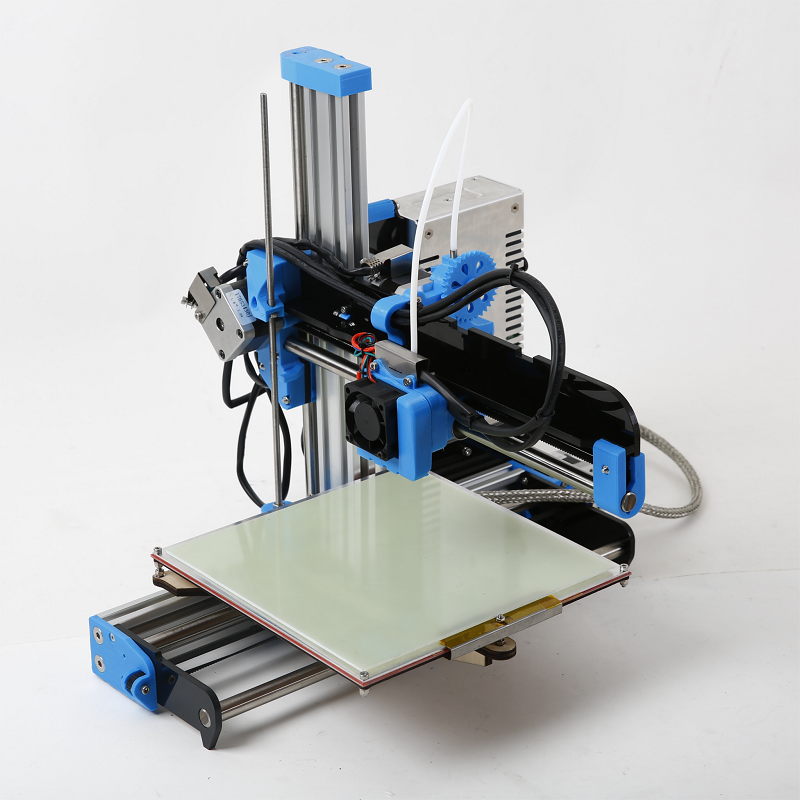

Building a HyperCube or HEVO (Hypercube Evolution) can be quickly built which will get you started 3d printing as quick as a week spending on experience and mechanical knowledge some 3d printer designs can take months with the large number of parts and unfamiliar mechanical parts which may need more skill to assemble correctly. For example, corexy design options such as the Voron 3d printer can be a steep learning curve as one adventures off assembling the large number of 3d printed parts that may or may not fit together depending on how components were printed or choice of filament.

BEST COREXY 3D PRINTERS 2022

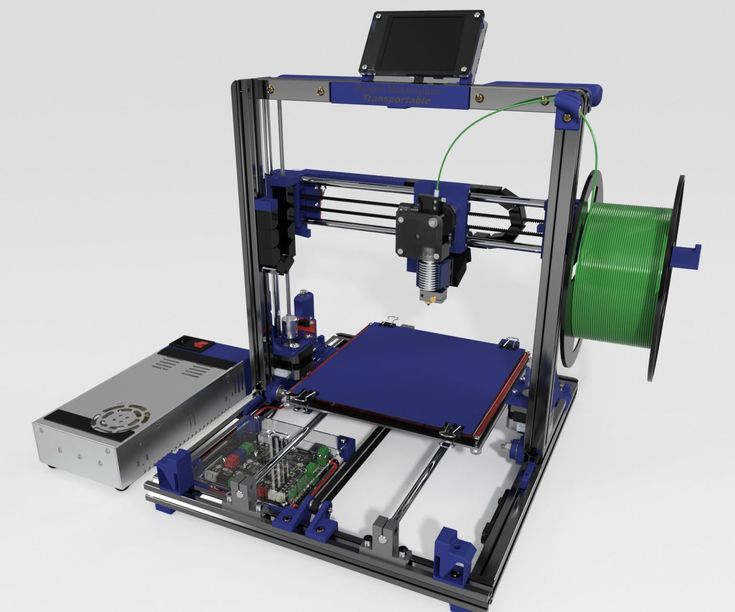

SolidCore CoreXY GantryWe designed our own corexy 3d printer called the SolidCore CoreXY. Our long term goal is to is to build a modular platform, not just a printer. Think of it as an ecosystem of parts that can be arranged in different configurations and adapted for unique applications.

See SolidCore BOM

BEST COREXY 3D PRINTERS 2022

The SolidCore is designed to be a highspeed workhorse for repeated use. All-metal-parts and components will give us the durability and repeatability needed. But we want people to have the option to use 3d printed parts so they can upgrade later on. Solid all metal parts are durable and less likely to deflect at high printing speeds. The aluminum components are also less likely to breakdown over time when introduced to the forces and heat from repeated use.

All-metal-parts and components will give us the durability and repeatability needed. But we want people to have the option to use 3d printed parts so they can upgrade later on. Solid all metal parts are durable and less likely to deflect at high printing speeds. The aluminum components are also less likely to breakdown over time when introduced to the forces and heat from repeated use.

BEST COREXY 3D PRINTERS 2022

RatRig vs Voron

The Voron 2.4 is a light-weight design, but complex design that’s well suited for higher print speeds. The corexy platform is well engineered but more complicated to build compared to other corexy 3d printer designs. New users and builders may struggle building this machine with the large number of parts and the four independent belt driven z-axis motor drive.

The Rat-Rig V-Core 3 is a much simpler core xy design with less parts and a straight forward build guide. While both the Voron 2. 4 and V-Core-3 have linear rails which new users maybe challenged to properly align the linear rails.

4 and V-Core-3 have linear rails which new users maybe challenged to properly align the linear rails.

BEST COREXY 3D PRINTERS 2022

Hevort vs Rat Rig

The HeVort printer is currently available by self-sourcing parts from the BOM parts list. Many builders would prefer to buy a complete kit with all the components instead of sourcing everything on my own.

SecKit VS Voron

Recommended Print Settings PLA PLA / Polylactic acid is a biodegradable thermoplastic most commonly used in most FDM 3d printers. Easy to Print Durable and Relatively Strong Non-Toxic 3d printed parts from PLA are the most common and widely used in prototyping and product development or proof of concept parts. Parts printed from PLA are

The WorkHorse is a large scale machine platform for 3d printing.

Hello world! We’ve finally finished repairing the shop from the last years storm damage. The new shipping department is setup and a better system has been implemented. Just about everything is back online and we’ll be adding products to the store over the next few days. If you have any questions email us at [email protected]

Just about everything is back online and we’ll be adding products to the store over the next few days. If you have any questions email us at [email protected]

Midwest Reprap Festival 2019 was wven more than the year before. There were so many more people attending and exhibiting. The venue was packed to seams with the coolest 3d printer builds you ever seen.

So you’re looking for the CAD download files…… Well E3D has finally released the files. You can find the files at their Github. https://github.com/e3donline/ToolChanger E3D ToolChanger Assembled The E3D tool changer files are published on github but if you’re looking for the assembled files or toolchanger assembly check out EJaworenko on Thingiverse here. “E3D released

How can you calculate the wire gauge and length for 3d printer wiring? Most 3D printers use either 12V or 24V. The hotend of a 3D printer may draw up to 4A, while a heated bed draws nearly 12A. If the wire is not large enough or longer than needed, it will have more resistance

If the wire is not large enough or longer than needed, it will have more resistance

Stepper Motor Color Coding of Wires For any stepper motor to be wired up properly, we’ll need to determine which wires are “pairs” or connected to the ends of each coil. These are usually referred to as coil “A” and coil “B”. The exact order of the pairs Black/Green or Green/Black of pins does not

What Size Stepper Motor Should You Use? While the size of a stepper motor is just the footprint it’s the winding that determines torque. There are Nema 17’s with as much torque as a Nema 23. Most 3d printers use stepper motors to drive z-axis motion lead screws to raise or lower the bed or

While a Duet 3 won’t be replacing the Duet 2 anytime soon, it’s a much more professional electronics board that adds a range of options and functionality to your machine build. Although the Duet 3 may be overkill for most users, these options are not for everyone you do get much more out of Duet

How To Wire The Duet 3 Mainboard 6HC The Duet 3 is a great board for your 3d printer, but wiring it up can be confusing. This tutorial will walk you through how to wire the Duet 3 mainboard 6hc to your Workhorse 3d printer. Duet Wiring Instructions This is a guide on how to

This tutorial will walk you through how to wire the Duet 3 mainboard 6hc to your Workhorse 3d printer. Duet Wiring Instructions This is a guide on how to

DuetWifi Expansion Board Wiring and Firmaware Configuration

The CoreXY motion system is a good solution if you’re looking to print faster. The 3d printer kinematics has become more popular in the last couple of years as users and DIY builders agree on an increase in print quality. The motion system is more lightweight compared to other 3d printer kinematics such as cartesian

The latest design update uses three Z-axis stepper motors. In this arrangement the belt routing to the stepper motor drive the lead screw. Each lead screw will be constrained by an MGN12 linear rail. This should also minimize vibrations that might be transferred from the motors to the z-axis. The belt to pulley ratio gives

Modular

Scalable

Linear Rails

Balanced Carriage Pull

Enclosure

BOM utilizes most available parts

All Metal Parts or 3D Printed

Z-Axis: Independent Driven or Shared Belt Routing

Although there are many 3d printing and additive manufacturing conventions, there is nothing better than Rapid Event. The RAPID + TCT conference, also known as Rapid Event; is a worldwide known 3d printing show / conference in North America. You can find some of the most influential additive manufacturing companies that attend each year ath

The RAPID + TCT conference, also known as Rapid Event; is a worldwide known 3d printing show / conference in North America. You can find some of the most influential additive manufacturing companies that attend each year ath

CoreXY Belt Routing One of the most important parts for corexy movement is belt routing. Here’s a guide to the mechanics of corexy belt routing pulley layout in order to get accuracy and constant belt tension. Belt Routing Methods There are two main ways to implement the corexy belt path. Either a stacked pulley arrangement

CoreXY Kinematics Explained? The corexy kinematics mechanical arrangement includes a unique motor movement where the X or Y motor move together or opposite of each other to move the carriage from left to right or towards or away . If you were to move just one motor you would see the print head move diagonal..

CoreXY Scalability The scalability of a core-xy printer can be an issue when it comes to hardware design and implementation. An increased belt path can also introduce problems resulting in artifacts in 3d printed parts. A rigid gantry setup is needed and proper binding is a must. 9mm and 12mm belts are available to account

An increased belt path can also introduce problems resulting in artifacts in 3d printed parts. A rigid gantry setup is needed and proper binding is a must. 9mm and 12mm belts are available to account

The CoreXY motion system is a good solution if you’re looking to print faster. The 3d printer kinematics has become more popular in the last couple of years as users and DIY builders agree on an increase in print quality. The motion system is more lightweight compared to other 3d printer kinematics such as cartesian

Maker Faire is a interesting gathering of makers and creative people who enjoy learning and who love sharing what they can do with the maker communnity. If you enjoy technology and the DIY approach to life you’ll fit right in. Engineers Artists Scientists Crafters Re:3D Gigabot Large Scale 3D Printer re:3D showcase their new 3d

Layer Adhesion Layer and surface adhesion is a critical component of 3d printing. 3d printing issues increase as object size increases. Large 3d printers can be more difficult when it comes to bed leveling. As the extruded layers bond together they are fused with heat. Proper surface adhesion decreases warping that can decrease part quality.

3d printing issues increase as object size increases. Large 3d printers can be more difficult when it comes to bed leveling. As the extruded layers bond together they are fused with heat. Proper surface adhesion decreases warping that can decrease part quality.

SolidCore CoreXY Z-Axis Bed Leveling We recently started working on the SolidCore 3d printer‘s bed leveling and mounting system. The z-axis uses a 3-point kinematic bed mounting with magnetic pivot spheres on each mount This properly constrains the bed at 3 points of contact. The original SolidCore Z-axis design was somewhat primitive because we only

Duet 3 Error- Failed To Get List Macros Not Found Failed To Get File List Directory 0:/macros not found Firmware Folders Insert sd card in computer and check for proper folders. Create a folder and name it “macros” if needed. Duet 3 running in standalone mode SD Card Folders The SD Card Folders must be

Loose belts are a common problem for users and cause a variety of issues. It may or may not be obvious that your 3d printer is experiencing issues. Belt tensioning defects can occur.

It may or may not be obvious that your 3d printer is experiencing issues. Belt tensioning defects can occur.

While there are many open source 3d printer designs to pick from on Thingiverse. And when it comes to corexy printer designs there are a few that raise the bar. Here are some of the best designs that we would like to talk about.

Prusa XL Update Prusa XL Review – 3D Printing Nerd 3/21/21 Unfortunately the picture above isn’t the new Prusa XL. It’s a clip from Joel Telling’s 3D Printing Nerd Youtube video. While there’s been much talk about the circulating screen shot from Joel Telling’s tour on the internet, Josef commented in a Reddit post that

BigRep has been an industry leader in professional large scale 3d printers for a while now, and we had the chance to see their new machines at Rapid Event + TCT additive manufacturing convention. They showed off two of their printers they had on display: BigRep Studio and the even larger version, the BigRep One.

We first discovered RailCore Labs and their beautiful corexy design at MRRF 2019. The Railcore 3d printer was designed by designed by Tony Akens and J. Steve White when discussing an idea of a core xy printer with linear rails on the x,y and z-axis on Reprap IRC.

Like this:

Like Loading...

Free STL file HEVO-MGN v3 (Hypercube evolution with MGN linear rails)・3D print object to download・Cults

RC boat water jet propulsion - complete open source

Free

Double pencil cup / holder

Free

seven segment LED clock (ESP8266 + WS2812b)

Free

GeeeTech i3 pro B power supply cover

Free

geeetech i3 pro B X-axis rework

Free

seven segment parametric OpenSCAD (7 segment)

Free

Raspberry Pi 4 Case with Fan (extended heat sink remix)

Free

refrigerator egg holder (customizable OpenSCAD parametric design)

Free

Best 3D printer files of the Tools category

MC Hammer Door Hook

Free

Pirates Hook

Free

roll holder

Free

UP! / Afinia Filament Spool Holder

Free

Sony FM500H Battery Holder

Free

Spiral Bed Level Test (Customizable)

Free

Mini Mixer

Free

Drinking bowl with stable design, Perrier compatible 1L.

Waterer with Perrier bottle.

Waterer with Perrier bottle.Free

Best sellers of the category Tools

PRECISION CALIPER 3D PRINTING DIY

€3.05

FAST-PRINT STACKABLE STORAGE BOXES STACKABLE BINS

€1.50 -50% €0.75

Chill Buddy Lighter Case

€1.01

Honeycomb Bed Hold Down Pins

€1.27

Version 2 Alligator 2 || Repeating crossbow || 3d printed magazine || Inspired by Joerg Sprave

€1.50

PRECISION DIAL INDICATOR 3D PRINTING DIY

€1.86

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang. CR-10, Micro Swiss direct drive and bowden compatible. No support needed for printing

€1.67

UNIVERSAL INDICATOR FOR BED LEVELING FOR ALMOST ALL PRINTERS

€3. 18

18

Grinder | Grinder

€1.50

FLSUN SR enclosure

€8.50

well-engineered: Hemera fan duct

€2.50

AIR DUCT 5015 OR 4020 ENDER 3 S1/PRO V3

€2.57 -20% €2.06

NEW GENERATION HOLDER CAR PHONE HOLDER

€2.50

Fire Hydrant Stash Container

€2.03

3D Printer Tool Holder V3.0

€1.12

Fast-Print Paint Bottle Rack (6 Sizes)

€2.89

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

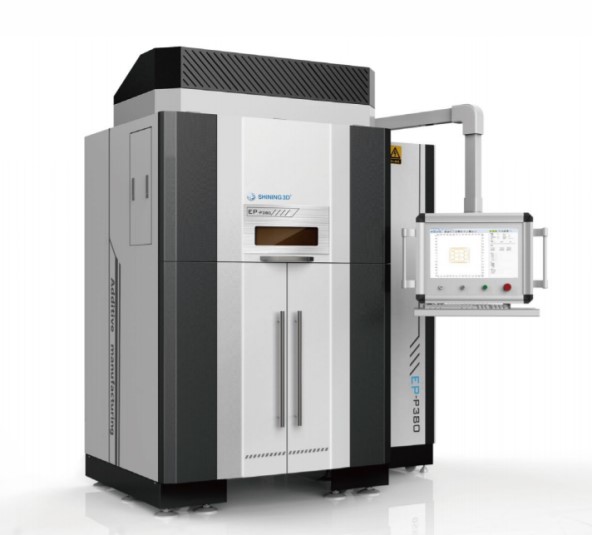

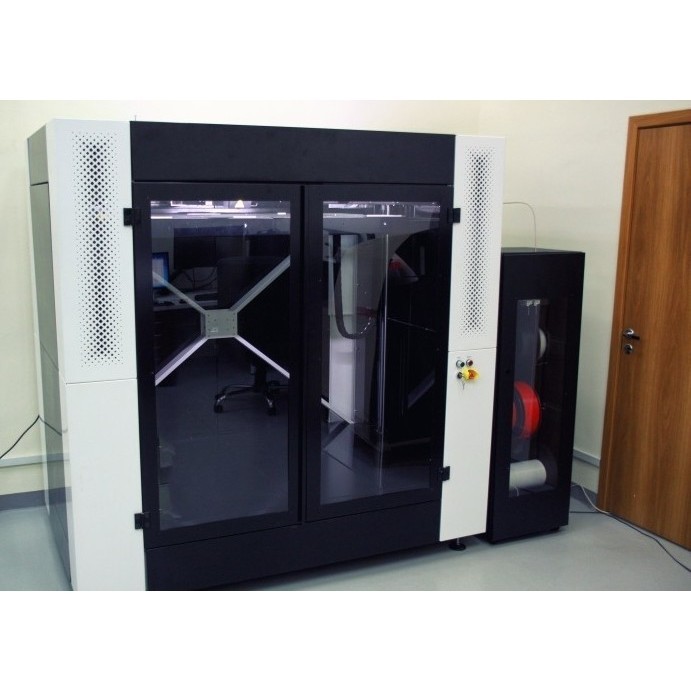

Large format FDM printers Discovery 3D Printer

Rapid Prototyping

Experts recommend

Key Benefits of Discovery 3D Printer | Technology and features of the 3D printing process | Applications | Equipment line | Implementation History: FDM Printing for the Navy | Results: briefly

We are already seeing real examples incredible flexibility and efficiency of additive manufacturing in the context of the global economic crisis. Experts argue that the pandemic will bring the Fourth Industrial Revolution closer, and many businesses today see digital technologies as a means of survival, and not just to increase competitiveness in the market.

Experts argue that the pandemic will bring the Fourth Industrial Revolution closer, and many businesses today see digital technologies as a means of survival, and not just to increase competitiveness in the market.

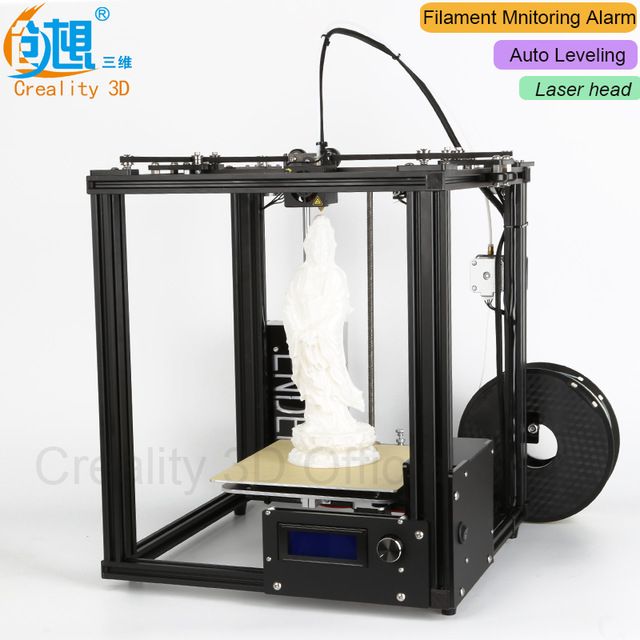

iQB Technologies continues to expand its product portfolio: in April 2020, our company became the exclusive distributor in Russia of Discovery 3D Printer industrial 3D printers from the Spanish manufacturer CNC Barcenas. For the first time, we present equipment for 3D printing of large-sized products and prototypes based on FFF/FDM technology.

CNC Barcenas is a rather young business: it is a little over ten years old. Since 2009, the company has been specializing in the production of CNC machines (milling, engraving and laser cutting), and in 2014 it expanded its capacity by starting the development, design and production of unique industrial 3D printers.

Bumper

Equipment: Super Discovery 3D Printer, material: ABS with carbon fiber, dimensions: 1800 x 600 x 4500 mm, weight: 12 kg

The first solution for the 3D printing market was the Discovery 3D Printer, followed by the even more innovative and large-format Super Discovery 3D Printer, based on the direct extrusion of polymer pellets. In 2019, the Super Discovery 3D Printer Workstation, an industrial 3D printing and post-processing system, was introduced. In 2021, an updated and improved modification of the Discovery 3D Printer 2021 was released, as well as the Super Discovery 3D Printer Compact and Hybrid models.

In 2019, the Super Discovery 3D Printer Workstation, an industrial 3D printing and post-processing system, was introduced. In 2021, an updated and improved modification of the Discovery 3D Printer 2021 was released, as well as the Super Discovery 3D Printer Compact and Hybrid models.

CNC Barcenas continues its pioneering work and is today one of the leaders in the European large format 3D printing market with many large scale projects to its credit.

Submit the online application and we will advise you in detail on the implementation of 3D printing in the industry!

Key benefits of Discovery 3D Printer

-

Much lower cost printers than competitors offering the same technology and quality.

-

Constant development of technologies and expansion of experience in the areas of 3D printing and machine tool building.

-

All equipment is completely designed and manufactured at CNC Barcenas facilities in Spain.

-

The ability to customize the printer for the tasks of each individual client.

-

The best drive and motor components for quality and fast printing.

-

Correction of irregularities during printing (calibration of nozzles and platform).

-

Debugging equipment up to 100% result.

-

The open material system allows a significant reduction in operating costs.

-

Internal cameras in printers that provide remote monitoring of the production process from any device.

-

Easy to operate hardware and intuitive Simplify 3D software.

Cover prototype

Equipment: Discovery 3D Printer, material: 3D850, dimensions: 29 x 19 x 4. 5 cm, weight: 146 g

5 cm, weight: 146 g

Technology and features of the 3D printing process

The FFF (Fused Filament Fabrication) technology used in Discovery 3D Printers is a complete analogue of FDM (Fused Deposition Modeling - layer-by-layer deposition modeling). This is the most accessible and popular additive technology, it is familiar to all users of home 3D printers, but it is also widely used to solve serious production problems. Its undoubted advantages include high productivity, the ability to produce large-sized products and the relatively low cost of equipment and consumables.

The disadvantages of this method are the highest degree of surface roughness among all additive technologies (the quality depends on the nozzle diameter and materials), the risk of plastic spreading and increased sensitivity to temperature changes. Note that the Super Discovery 3D Printer model equipped with a cutter will immediately correct the roughness and post-process the product right in the printer chamber.

As consumables, thermoplastics or composites are used in the form of threads wound on spools (so-called filaments), or granules. Their range is very diverse and allows you to choose the most suitable materials for the tasks to be solved in terms of physical and mechanical properties - ABS, PLA, nylon, polycarbonates, polyamides, polystyrene, polyethylene and many others.

Building an object in Discovery 3D Printer

The process of creating a product using FDM/FFF technology includes the following steps:

-

Export 3D model to 3D printer software in .stl format.

-

Preparation for printing: division of the model into layers and orientation on the construction platform, if necessary, the creation of supports. The result is a G-code containing all print settings.

-

Printing process by layer-by-layer extrusion (extrusion) of molten material. The extruder (print head) moves from bottom to top along the X and Y axes, the working platform moves along the Z axis.

-

Extraction of the printed object from the 3D printer, removal of supports, post-processing.

The filament printing method is used in the junior model of the Discovery 3D Printer line. The Super Discovery 3D Printer and Super Discovery 3D Printer Workstation implement the innovative Direct Extrusion of Pellet technology. The difference from standard FDM is that the consumables are in the form of granules rather than filaments. This method makes it possible to speed up and make more economical the production of large objects.

Helicopter seat

Equipment: Super Discovery 3D Printer, material: ABS with carbon fiber, dimensions: 120 x 70 x 45 cm, weight: 20 kg

Statue

Equipment: Super Discovery 3D Printer, material: ABS with cellulose fiber, height: 1.87 m, weight: 45 kg

Discovery 3D Printer Applications

Every industry is different, which is why CNC Barcenas tailors the 3D printers it produces to the requirements of specific applications and projects that require rapid prototyping or rapid production of end products. Discovery 3D Printer can be successfully used in the following industries:

Discovery 3D Printer can be successfully used in the following industries:

-

automotive industry;

-

aerospace industry;

-

shipbuilding;

-

defense sector;

-

railway industry;

-

household goods and equipment;

-

furniture industry;

-

architecture;

-

the medicine;

-

education;

-

Industrial Design;

-

3D printing services.

We printed large-sized parts and saved about 70% of the costs that are usually spent on prototyping by subcontractors

Juan Galindo Perez, Prototyping Manager, BSH Spain

Equipment line

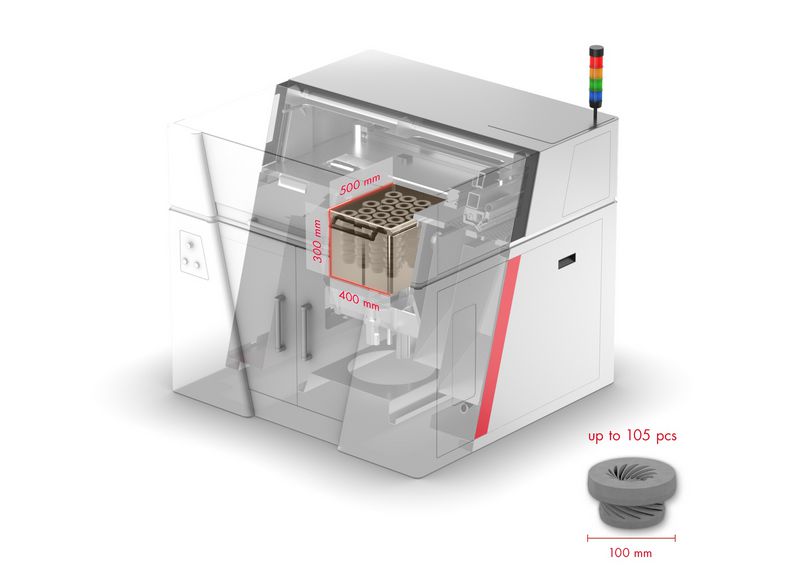

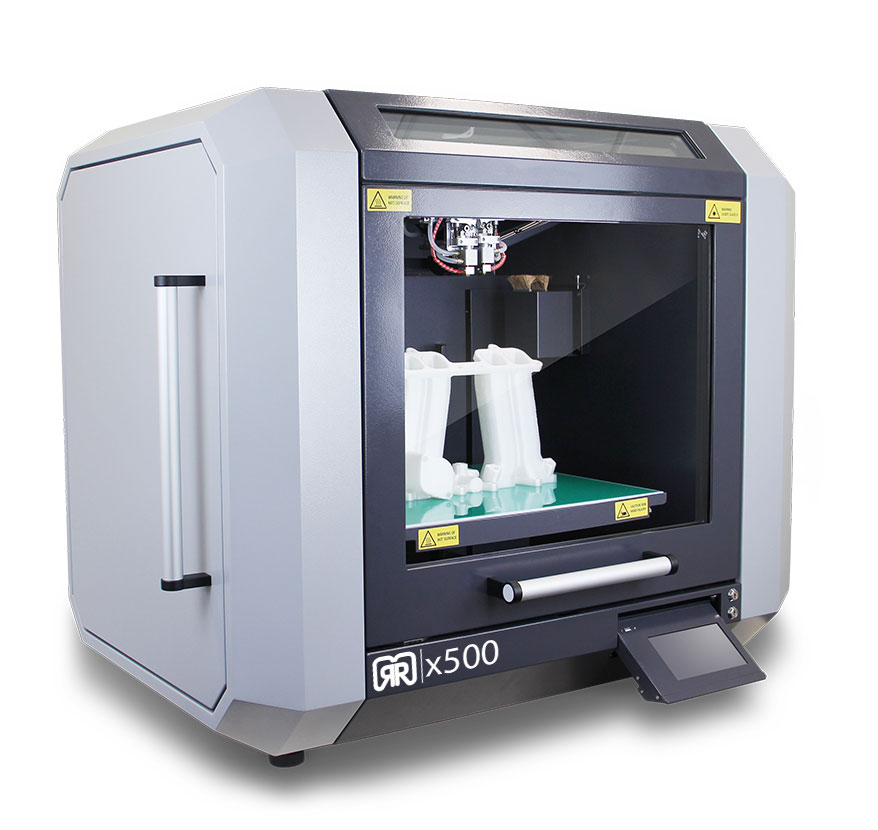

Discovery 3D Printer 2021

The industrial 3D printer based on FFF technology is designed for the production of large parts from technical plastics within the framework of complex and long-term projects. As consumables, all filaments available on the market that conform to the standard 1.75 mm format can be used. The printer is equipped with a built-in dual extrusion system that can be used to create supports and parts from different materials in different colors. Discovery 3D Printer is one of the most attractive solutions on the market in terms of price and quality, given the dimensions of the printed products.

As consumables, all filaments available on the market that conform to the standard 1.75 mm format can be used. The printer is equipped with a built-in dual extrusion system that can be used to create supports and parts from different materials in different colors. Discovery 3D Printer is one of the most attractive solutions on the market in terms of price and quality, given the dimensions of the printed products.

-

Works with ULTEM, PLA, ASA, ABS, PA, HIPS, 3D850, PETG, ABS Medical, ABS Hi and many more

-

Fully enclosed chamber and heated bed (up to 175°C) with auto leveling function that automatically compensates for minor unevenness during printing

-

Build Chamber Size (W x D x H): 1150 x 800 x 500 mm

-

Printer size: 1150 x 800 x 500 mm

-

Weight: 300 kg

-

Extruder (max. temperature): 450 °C

-

Working load: 80-140g/h

-

Print speed: up to 400 mm/s

-

Layer thickness (minimum): 0.

1 mm

1 mm -

Software: Simplify 3D

Super Discovery 3D Printer

The machine was designed as a one-stop solution for Industry 4.0 to produce large-format parts up to 2.5 m in size. general expenses. Individual configuration is possible for any needs of large industry.

-

Works with all thermoplastics e.g. ABS, ABS CF, PC CF, PPE CF, 3D850, ASA

-

Fully enclosed chamber and heated platform (up to 175°C) with automatic leveling function for the most demanding materials

-

Automatic supply of granules, no restrictions on the amount of material and, as a result, on the weight of the product.

-

Build Chamber Size (W x D x H): factory standard 1300 x 2500 x 1000 mm, custom configuration available

-

Printer dimensions with feed funnel and electrical cabinet: 2000 x 3590 x 3000 mm

-

Weight: 1200 kg

-

Extruder (max.

temperature): 450 °C

temperature): 450 °C -

Working load: <6kg/h

-

Print speed: up to 200 mm/s

-

Layer thickness (minimum): 0.5mm

-

Software: Simplify 3D

Super Discovery 3D Printer Compact

Compact and high performance industrial grade 3D printer for pellet extrusion printing. The machine is designed to create small and medium-sized products up to 1100 x 800 x 500 mm, and at the same time has all the advantages of the previous model Super Discovery 3D Printer, allowing you to reduce costs and increase print speed.

-

Fully enclosed chamber and heated platform (up to 150°C)

-

Works with all thermoplastics including ABS, ABS CF, PC CF, PPE CF, 3D850, ASA

-

Polymer Granule Direct Extrusion Technology

-

Build chamber size: 1100 x 800 x 500 mm (modifiable)

-

Automatic feeding of granules and no restrictions on the amount of material

-

Weight: 450 kg

-

Extruder (max.

temperature): 410 °C

temperature): 410 °C -

Working load: 2 kg/h

-

Print speed: up to 100 mm/s

-

Layer thickness (minimum): 0.5mm

-

Software: Simplify 3D

Super Discovery 3D Printer Hybrid

A combined solution that implements two additive technologies at once - the filament printing method and direct extrusion of polymer granules, which can also be used separately. The innovative 3D printer works with any thermoplastics and has a build chamber up to 1100 x 800 x 500 mm, which can be modified to suit your individual needs if desired.

-

Combined solution for printing with filaments and polymer granule extrusion technology

-

Fully enclosed chamber and heated platform (up to 150°C)

-

Works with all thermoplastics including ABS, ABS CF, PC CF, PPE CF, 3D850, ASA

-

Build chamber size: 1100 x 800 x 500 mm

-

Automatic feeding of granules and no restrictions on the amount of material

-

Weight: 300 kg

-

Extruder (max.

temperature): 410 °C

temperature): 410 °C -

Working load: granules - 2 kg/h, filaments - 80-100 g/h

-

Print speed: granules - up to 100 mm/s, filaments - up to 400 mm/s

-

Layer thickness (minimum): granules - 0.5 mm, filaments - 0.1 mm

-

Software: Simplify 3D

Super Discovery 3D Printer Workstation

The perfect combination of a large format industrial 3D printer and a milling system. The plant is designed for the production of large batches of large parts and prototypes. The principle of operation, just like that of the Super Discovery 3D Printer model, is based on the direct extrusion of granules. The special design allows the entire production process to be carried out, including post-processing, since both the extruder and the milling motor are present on the working platform. The Super Discovery 3D Printer Workstation is capable of performing large-scale post-processing jobs, as well as cutting, punching or 3D engraving on plastic, photopolymer, foam, wood and other materials.

-

Works with all thermoplastics including ABS, ABS CF, PC CF, PPE CF, 3D850, ASA

-

Fully enclosed chamber and heated platform (up to 175°C) with automatic leveling function for the most demanding materials

-

Automatic feeding of granules, no restrictions on the amount of material and, as a result, on the weight of the product

-

Build Chamber Size (W x D x H): factory standard 1500 x 2000 x 1000 mm, custom configuration available

-

Printer size: 2000 x 3590 x 3000 mm

-

Weight: 1500 kg

-

Extruder (max. temperature): 450 °C

-

Working load: <6kg/h

-

Speed: up to 200 mm/s

-

Layer thickness (minimum): 0.5mm

-

Milling motor: high-frequency brushless motor with air-cooled ceramic bearings, speed 4500-18000 rpm.

-

Software: Simplify 3D + CNC software

Case History: FDM Printing for the Navy

By order of the Spanish Navy, the state-owned shipbuilding company Navantia has developed and implemented the Shipyard 4. 0 strategy (“Shipyard 4.0”). The goal of the new business model is to optimize the production process using Industry 4.0 technologies, including 3D printing, robotization, digital twins, big data, artificial intelligence, the Internet of Things, etc. Read more about Shipyard 4.0 in the article.

0 strategy (“Shipyard 4.0”). The goal of the new business model is to optimize the production process using Industry 4.0 technologies, including 3D printing, robotization, digital twins, big data, artificial intelligence, the Internet of Things, etc. Read more about Shipyard 4.0 in the article.

CNC Barcenas has been involved in two R&D projects for additive manufacturing. The first of these is called 3DCABINS and involves the production of fully equipped ship cabins through research and selection of the most suitable materials. For example, on the Discovery 3D Printer and Super Discovery 3D Printer installations, prototypes of a modular toilet for a naval ship were made. Compared to traditional production methods, the weight of the products has been reduced by almost 50% and their cost has been significantly reduced. The second project, ADIBUQUE, uses 3D printers to manufacture complex components for the navy sector, which are installed and tested on ships under construction.

Objects printed on the Super Discovery 3D Printer for the 3DCABINS project:

- modular toilet, material: flame retardant ABS, dimensions: 2200 x 1700 x 1200 mm, weight: 250 kg

– ventilation grille, material: ABS with carbon fibre, dimensions: 59 x 89 x 4.5 cm, weight: 3500 g

Using the Discovery 3D Printer enabled Navantia to:

-

modernize the production process and increase productivity;

-

reduce production and assembly time;

-

reduce labor costs;

-

reduce the amount of work on processing and painting;

-

increase the energy efficiency of production;

-

improve product quality.

Summary: briefly

The Discovery 3D Printer is a Spanish-made range of additive machines with an excellent price/performance ratio for creating large-sized products and prototypes. The main features of the printers are large print format (up to 2.5 m), affordable FFF / FDM technology, ease of operation and unique technological solutions, such as an integrated dual extrusion system, correction of unevenness during printing, individual configuration of printers, 3D printing and post-processing in one system. All these advantages will optimize the production of enterprises in various industries - from the automotive industry and shipbuilding to medicine and household appliances. Discovery 3D Printer will suit both large industrial productions and innovative companies in the small and medium business segment.

The main features of the printers are large print format (up to 2.5 m), affordable FFF / FDM technology, ease of operation and unique technological solutions, such as an integrated dual extrusion system, correction of unevenness during printing, individual configuration of printers, 3D printing and post-processing in one system. All these advantages will optimize the production of enterprises in various industries - from the automotive industry and shipbuilding to medicine and household appliances. Discovery 3D Printer will suit both large industrial productions and innovative companies in the small and medium business segment.

Discovery 3D Printer Solutions are available to order at .

Article published on 04/23/2020, updated on 11/30/2021

How 3D printing changes the world / Sudo Null IT News

A new era of technological revolution According to the CONTEXT research group, the 500,000th 3D printer was shipped in 2015, and by 2017, about a million devices had been sold.

3D printing is already being introduced as a manufacturing technology. For example, in 2016 company General Electric began selling aircraft engines with 3D printed fuel injectors. Atlas-5 rockets with parts printed with the same technology were launched into space. Brands Under Armor and New Balance launched small batches of partially 3D printed athletic shoes, while Organovo launched commercial bioprinting of human kidney tissue.

3D printing is already being introduced as a manufacturing technology. For example, in 2016 company General Electric began selling aircraft engines with 3D printed fuel injectors. Atlas-5 rockets with parts printed with the same technology were launched into space. Brands Under Armor and New Balance launched small batches of partially 3D printed athletic shoes, while Organovo launched commercial bioprinting of human kidney tissue. So far, this is just the foundation. Throughout the history of mankind, there have been many technological revolutions, each of which went through three phases. 9 comes first0512 "conceptualization" , when visions and ideas are formed that determine the future path. Then "realization" , during which previously seemingly impossible plans begin to be partially realized. And the third phase - "mass commercialization" , when enterprises master the production and application of new technology.

And what phase is 3D printing in? The use of a 3D printer to turn a digital file into a physical object is already widespread. For example, in such areas as engineering, law, economics, business, geography and art. There is already debate about the implications of exchanging digital objects over the Internet to print them out immediately on a printer (let's say a firearm). Clearly, we are far from the day when personal 3D printers put an end to capitalism by placing production in the hands of the majority. However, there is no doubt that the 3D printing revolution has reached its second phase, implementation.

By this time, enough methods have been invented to make solid objects by printing them in many thin successive layers. In fact, the most common 3D printing technologies have been around for decades.

Although the technology continues to evolve, I will assume that the last revolutionary phase - mass commercialization - is about ten years away. The pioneers of 3D printing are already using it to make a wide variety of things. However, this market is still niche and limited in commercial applications. In particular, these are companies that are engaged in small-scale, piece production or goods that cannot be manufactured using traditional methods.

However, this market is still niche and limited in commercial applications. In particular, these are companies that are engaged in small-scale, piece production or goods that cannot be manufactured using traditional methods.

Notwithstanding the above, we must remember that ten years ago, no industry sector reported selling products entirely or partially made with a 3D printer. So what is happening now is impressive. As 3D printing techniques evolve and new ones emerge, and old processes become faster and cheaper, we can expect 3D printing to move closer to a mass commercialization phase in the late 2020s or early 2030s. Innovators in the field plan to take advantage of the technology long before that.

3D printing technology

How does 3D printing work? To a large extent, it is an evolution of 2D printing, already used ubiquitously in offices and homes.

Most of us are familiar with inkjet or laser printers that allow you to print documents or photos. They create them by controlling the application of ink or toner to the surface of a sheet of paper. Similarly, 3D printers produce objects by controlling the placement and adhesion of successive layers of "building material" in 3D space. For this reason, 3D printing is also known as Additive Layer Manufacturing (ALM) or "additive manufacturing" ( AP or AM - Additive Manufacturing).

They create them by controlling the application of ink or toner to the surface of a sheet of paper. Similarly, 3D printers produce objects by controlling the placement and adhesion of successive layers of "building material" in 3D space. For this reason, 3D printing is also known as Additive Layer Manufacturing (ALM) or "additive manufacturing" ( AP or AM - Additive Manufacturing).

To print an object on this printer, you need a digital model on your computer. It can be created using a computer-aided design (CAD) application or other 3D modeling software. Also, a digital model can be captured by scanning a real object with a 3D scanner and processing with CAD or other programs.

The model must then be run through yet another "slicing" program that will cut the digital object into multiple cross-sectional layers - typically about 0.1mm thick. These digital ribbons are sent to a 3D printer, which makes them one on top of the other until a real object is formed.

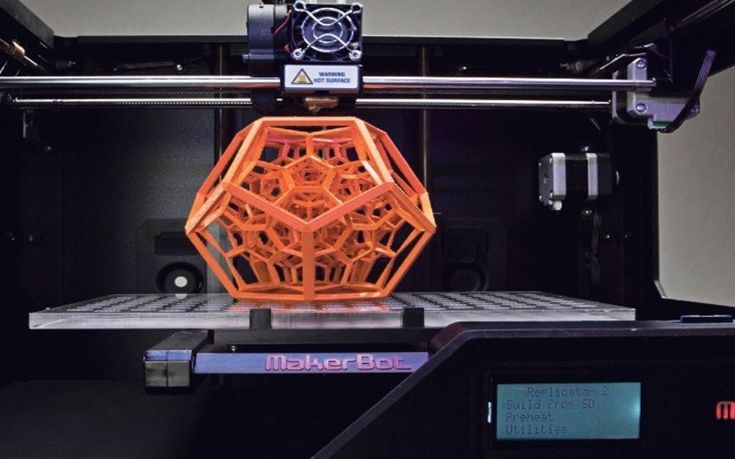

3D model in CURA-a popular open-source cutting program

The same model printed by the Ultimaker