Rgb 3d printer

The 6 best full-color 3D printers in 2022

Full-color 3D printers are able to 3D print in photorealistic colors. They are often used for prototyping, signage, and product design. Find out more about color 3D printing in this guide.

Last update May 31, 2022

We removed XYZPrinting's discontinued DaVinci Color series and updated the Stratasys (J55 Prime) and Mimaki lineups (3DUJ-2207).

Table of contents

What is full-color 3D printing?

Full-color 3D printing vs. multicolor 3D printing

The best full-color 3D printers

T10

PartPro350 xBC

3DUJ-2207

J55 Prime

3DUJ-553

ProJet CJP 660Pro

M3D Crane Quad

Mcor ARKePro

SOMETHING 3D Chameleon

ORD Solutions RoVa4D full-color Blender

Apple full-color 3D printer

Ilios Ray

SKY-TECH 3DPandoras

Multicolor 3D printing: alternatives to full-color 3D printing

Benefits of full-color 3D printing and applications

Full-color 3D printing service

How much does a full-color 3D printer cost?

What is the best full-color 3D printer?

It’s complex to 3D print in full, photorealistic color, and there are less than ten 3D printer manufacturers that achieve this.

Until recently, full-color 3D printing was exclusive to expensive industrial additive manufacturing systems from brands such as Stratasys or 3D Systems. Today, more affordable (under $10K) desktop full-color 3D printers also exist.

What is full-color 3D printing?

Full-color 3D printers are able to create objects with photorealistic color.

To do so, the 3D printer must be able to mix different filaments or inks together to obtain precise shades and gradients, similar to regular 2D paper printers.

This is also known as indirect color 3D printing, as the color is applied to the base material (the base material isn’t pre-colored before 3D printing).

Full-color 3D printing vs. multicolor 3D printing

In the 3D printing industry, the term “multicolor” is sometimes used as a synonym for full-color.

However, for clarity in this article, we will only refer to multicolor for 3D printers and accessories that are able to 3D print a few colors (e. g.: 2-color 3D printers, 3-color 3D printers, Prusa multi-material add-on, Mosaic Palette, etc.).

g.: 2-color 3D printers, 3-color 3D printers, Prusa multi-material add-on, Mosaic Palette, etc.).

This type of 3D printing is also called direct color 3D printing, as the filament already has a specific color before being 3D printed.

Examples of full-color 3D prints (left) and multicolor 3D prints (right).The best full-color 3D printers

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| ComeTrue | T10 | 200 × 160 × 150 mm7.87 × 6.3 × 5.91 in | – | $ 30,00030 495 €26,611 £4,471,680 ¥ | Quote |

| XYZprinting | PartPro350 xBC | 350 × 222 × 200 mm13.78 × 8.74 × 7.87 in | Taiwan | $ 30,00016 690 €26,611 £4,471,680 ¥ | Quote |

| Mimaki | 3DUJ-2207 | 203 × 203 × 76 mm7. 99 × 7.99 × 2.99 in 99 × 7.99 × 2.99 in | Japan | $ 39,00035 000 €34,595 £5,813,184 ¥ | Quote |

| Stratasys | J55 Prime | – | – | $ 99,00095 000 €87,817 £14,756,544 ¥ | Quote |

| Mimaki | 3DUJ-553 | 508 × 508 × 305 mm20 × 20 × 12.01 in | Japan | $ 230,000200 000 €204,019 £34,282,880 ¥ | Quote |

| 3D Systems This brand is a certified partner from our network. | ProJet CJP 660Pro | 254 × 381 × 203 mm10 × 15 × 7.99 in | United States | upon request | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Technology | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|

| ComeTrue | T10 | Binder Jetting | 200 × 160 × 150 mm7.87 × 6.3 × 5.91 in | – | $ 30,00030 495 €26,611 £4,471,680 ¥ | Get a quote |

| XYZprinting | PartPro350 xBC | Binder Jetting | 350 × 222 × 200 mm13.78 × 8.74 × 7.87 in | Taiwan | $ 30,00016 690 €26,611 £4,471,680 ¥ | Get a quote |

| Mimaki | 3DUJ-2207 | Material Jetting | 203 × 203 × 76 mm7.99 × 7.99 × 2.99 in | Japan | $ 39,00035 000 €34,595 £5,813,184 ¥ | Get a quote |

| Stratasys | J55 Prime | Material Jetting | – | – | $ 99,00095 000 €87,817 £14,756,544 ¥ | Get a quote |

| Mimaki | 3DUJ-553 | Material Jetting | 508 × 508 × 305 mm20 × 20 × 12.01 in | Japan | $ 230,000200 000 €204,019 £34,282,880 ¥ | Get a quote |

| 3D Systems This brand is a certified partner from our network. | ProJet CJP 660Pro | Binder Jetting | 254 × 381 × 203 mm10 × 15 × 7.99 in | United States | upon request | Get a quote |

Overview of the best full-color 3D printers in 2022

The ComeTrue T10 full-color 3D printer uses sandstone– a neutral, plaster-like powder– as its base material. This material is solidified and colored with ComeTrue’s proprietary liquid binding agent.

Then, users must insert the parts into a dry vacuum unit (available separately) to manually remove excess powder with an airbrush. The final steps involve covering the part in a liquid infiltrant for it to harden and then leaving the part to dry.

Contact manufacturer Get a quote Add to comparison

Targeting professionals such as architects and designers, the PartPro350 xBC 3D prints, colors, and cures materials all at once.

This full-color 3D printer features a removable build tray, enabling users to quickly launch a new print job before taking out freshly 3D printed parts from the previous tray.

Contact manufacturer Get a quote Add to comparison

The 3DUJ-2207 is an affordable full color 3D printer produced by Mimaki. Mimaki is a 3D printer manufacturer based in Japan. This 3D printer offers a build volume of 203 x 203 x 76 mm.

Contact manufacturer Get a quote Add to comparison

The Stratasys J55 Prime is a full-color 3D printer for professionals. Stratasys is a worldwide 3D printer manufacturer based in the United States.

This color 3D printer can print over 1,900 PANTONE colors.

Contact manufacturer Get a quote Add to comparison

Mimaki is a professional inkjet printing solution manufacturer from Japan. The 3DUJ-553 is their first 3D printer, and it produces high-quality, photo-realistic 3D prints.

To do so, its ink heads deposit a layer of colored ink, which the printheads then coat with UV-sensitive material to harden the layer with LED lighting. According to the manufacturer, this full-color 3D printer offers over 10 million colors.

Contact manufacturer Get a quote Add to comparison

This full-color sandstone 3D printer by 3D Systems produces high-quality parts. The ProJet CJP 660Pro deposits liquid color binding agent (proprietary VisiJet PXL) through its 1,520 jets in a process called ColorJet Printing.

Different infiltrants are available from 3D Systems for varying color 3D printed part properties: ColorBond, StrengthMax, and Wax.

Contact manufacturer Get a quote Add to comparison

Other full-color 3D printers

Below are a few mentions of products that are unavailable, discontinued, or suspicious.

M3D Crane Quad

The Crane Quad is a $999 desktop 3D printer that is advertised by M3D as capable of printing full-color objects with its four-in-one-out extruder. However, it has been brought to our attention that some users have never received the machine, while many others have encountered serious issues with it. A recap of user complaints and types of issues can be found in this BBB report. We don’t recommend this company.

We don’t recommend this company.

Mcor ARKePro

Mcor debuted with the Mcor IRIS and Matrix 300+ and then launched the Mcor ARKePro full-color desktop 3D printers for professionals (an updated version of the original Mcor ARKe). The ARKe used Selective Deposition Lamination (SDL) technology, which consists of depositing colored ink on sheets of paper. Mcor is no longer active.

SOMETHING 3D Chameleon

This 3D printer was announced by Israel-based SOMETHING 3D (ST3D) in 2017. The Chameleon mixes five colors together (WCMYK) to create full-color 3D prints.

ORD Solutions RoVa4D full-color Blender

The RoVa4D full-color Blender is another filament-mixing 3D printer. Canadian company ORD Solutions launched this full-color desktop 3D printer on Kickstarter in 2016, but there has been very little news about its availability since then.

Apple full-color 3D printer

There were rumors of the tech giant developing a full-color desktop 3D printer. Apple filed a patent in 2015, which was approved at the beginning of 2018. However, the project appears to be on standby as no official Apple announcements regarding 3D printing have been made.

Apple filed a patent in 2015, which was approved at the beginning of 2018. However, the project appears to be on standby as no official Apple announcements regarding 3D printing have been made.

Ilios Ray

Ilios was a 3D printer manufacturer from Cyprus that closed its doors in late 2016. Their Ilios Ray resin 3D printer was claimed to mix colors with different resin cartridges.

SKY-TECH 3DPandoras

Launched on Kickstarter in 2014, this full-color powder 3D printer was well-received by the community– at first. Since then, its backers have largely denounced this product as a scam.

Multicolor 3D printing: alternatives to full-color 3D printing

As mentioned at the beginning of the article, multi-color 3D printing is different from full-color 3D printing. Multi-filament 3D printers, such as dual extruder 3D printers, are able to 3D print different colors at the same time. These multi-nozzle 3D printers can be considered multi-color, but not full-color.

These multi-nozzle 3D printers can be considered multi-color, but not full-color.

Accessories such as the Mosaic Palette or the Prusa multi-material add-on also allow for multicolor 3D printing with simple single-extruder 3D printers. They enable users to 3D print with up to four or five colors.

With SimplyColor3D software, it’s also possible to program filament color changes. The software also allows users to paint 3D models and allows for less material waste during purge transitions.

Another solution is post-processing. Germany-based DyeMansion provides full-color post-processing solutions (“DyeMansion RAL color palette”) for powder-based 3D printed parts. See our post on multicolor 3D printers and multi-filament accessories for more information.

A multicolor Benchy 3D printed with the Mosaic Palette 2. Source: MosaicBenefits of full-color 3D printing and applications

Full-color 3D printers allow users to obtain photorealistic 3D models with limited post-processing required. This is useful for rapid prototyping as well as for the manufacturing of end-use products:

This is useful for rapid prototyping as well as for the manufacturing of end-use products:

- Realistic prototypes (e.g. packaging, architecture models)

- Customized consumer products (e.g. phone cases, figurines, toys)

- Educational items (e.g. medical models)

Full-color 3D printing service

Full-color 3D printers are quite expensive and they require users to have at least some 3D printing knowledge. If users only need to 3D print a few parts a year, then ordering online service bureaus can be more cost-effective. Here’s a list of a few trusted online full-color 3D printing services:

- 3D Hubs

- i.

materialise

materialise - Sculpteo

- Shapeways

- WhiteClouds

How much does a full-color 3D printer cost?

The price of a full-color 3D printer can range from $550 to over $250,000. It depends on the type of 3D printing technology that the 3D printer uses. Full-color extrusion 3D printers cost less, while complex binder jetting and material jetting are the most expensive.

Find the right full-color 3D printer for sale

The Top Full Color 3D Printers on the Market

Published on December 2, 2021 by Carlota V.

When it comes to choice of a 3D printer, several criteria must be taken into account: which applications it will be used for, the desired printing speed, the final quality of the parts, the quantity to be produced, among others. For some, a particularly essential aspect is the possibility to design parts in color. It is true that color integration is rarely the number one choice, but for some users, it is key. For example when creating a visual prototype that must look like a perfume bottle, or an anatomical model where blood vessels need to be distinguished from nerves and arteries. Enter full color 3D printers.

For example when creating a visual prototype that must look like a perfume bottle, or an anatomical model where blood vessels need to be distinguished from nerves and arteries. Enter full color 3D printers.

Integrating color into additive manufacturing is currently possible, whether through machines that are capable of offering a wide range of colors, accessories to be added to the printers, or post-processing solutions that offer options for dyeing, painting, varnishing, etc. In this listing, we focus on color 3D printers, i.e. machines that can produce a multi-color part at the end of the printing process. We have sorted them by printing process: extrusion, material jetting and powder binding.

Fused Deposition Modeling

FDM technology offers several possibilities for creating coloured parts. For some color 3D printers, the presence of several extruders will allow the user to choose different filaments and combine them. Other manufacturers have developed a system that can color filaments directly inside the 3D printer: the machine releases color inks at the print head, resulting in a colored filament. Finally, there exist additional accessories available to mix different filaments together.

Finally, there exist additional accessories available to mix different filaments together.

Crane Quad

Known for launching the Micro 3D, a successful desktop 3D printer on Kickstarter in 2014, M3D continued to develop various FDM/FFF machines. Among its latest creations, the Crane Quad, a 3D printer capable of combining several filaments to create new combinations of colors or hybrid materials. In fact, the Crane Quad mixes 4 CMYK filaments to achieve more than 50,000 different colors. In addition, it offers a maximum manufacturing volume of 230 x 230 x 250 mm for a minimum layer height of 25 microns. It is marketed by M3D at a price of $999. You can find more information HERE.

da Vinci Color 3D printer and its mini

The da Vinci Color 3D printer combines FDM and Inkjet technologies, as it uses an absorbent, colorless PLA filament that can be mixed with different color inks. According to the manufacturer, CMYK ink cartridges can be used in an almost unlimited color gamut, up to 16 million shades. It has a print volume of 200 x 200 x 150 mm for a maximum print speed of 180 mm/s. In addition, XYZprinting also has a more compact version, the da Vinci Color Mini, with a smaller print volume of 130 x 130 x 130 x 130 mm. Features of this latest version include automatic calibration, wireless connectivity to connect to the printer remotely, and an optional laser engraving module for further customization of projects.

It has a print volume of 200 x 200 x 150 mm for a maximum print speed of 180 mm/s. In addition, XYZprinting also has a more compact version, the da Vinci Color Mini, with a smaller print volume of 130 x 130 x 130 x 130 mm. Features of this latest version include automatic calibration, wireless connectivity to connect to the printer remotely, and an optional laser engraving module for further customization of projects.

Element from Mosaic Manufacturing

The Element 3D printer was launched by the Canadian company Mosaïc Manufacturing. This professional machine makes it possible to achieve complex prints with different materials while obtaining realistic full-color and functional prints by combining flexible and rigid materials. It has a printing plate that reaches 120°C and a layer resolution of between 20 and 230 microns. With a maximum printing volume of 355 x 355 x 355 mm, the Element 3D printer has an all-metal gantry and a precision motion system. Other features include an internal camera for viewing the print, a touch screen control and connectivity via Wifi, LAN or USB. It is compatible with the Canva laminator, with which you can easily create, cut and manage any 3D printing project.

It is compatible with the Canva laminator, with which you can easily create, cut and manage any 3D printing project.

Palette 3

While the Palette 3 is not a 3D printer, it is probably one of the most accessible ways to design color parts. Developed by the Canadian company Mosaic Manufacturing, the machine should be connected to an extrusion 3D printer. It allows the combination of flexible and rigid materials, and users can not only create parts with complex shapes but also print in color in one go. A Pro version of the Palette 3 is also available, with advanced properties that allow users to print with technical materials and create durable, high-volume prints. Finally, the Palette 3 Pro features Splice Core Pro, a cooling system that makes filament bonding more reliable. The Palette 3 is available from €650 and the Palette 3 Pro from €850.

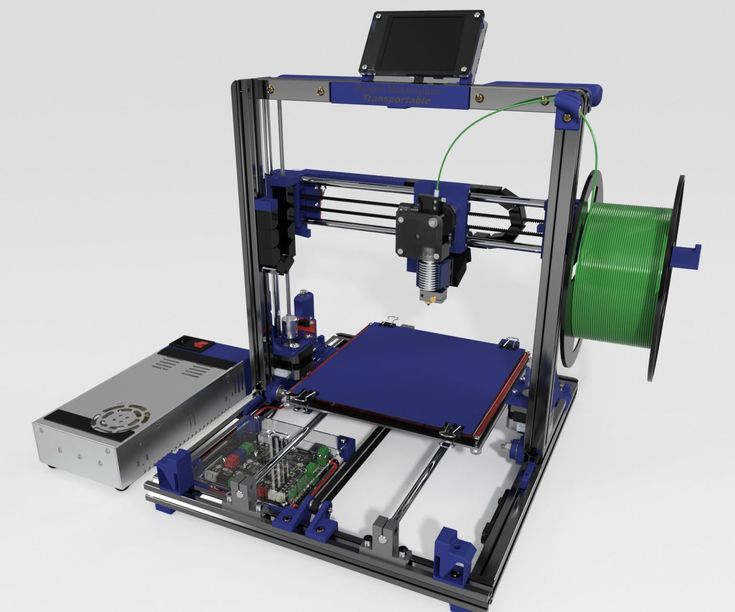

RoVa4D

The RoVa4D 3D printer grew out of a successful Kickstarter campaign by Canadian company ORD Solutions, which after its first Kickstarter campaign has dedicated itself to improving the capabilities of its 3D printer. This latest version supports 5 spools and a print head that allows printing with different materials and colors, from flexible materials to soluble materials. It has a printing volume of 120 x 120 x 180 mm. In order to be able to successfully achieve color printing, the machine has 5 different spools for CMYK colours (cyan, magenta, yellow, black and white), which are then mixed within the patented hotend to give the expected color as a result. The printer can currently be purchased at the manufacturer’s website for $7,500. You can find more information HERE.

This latest version supports 5 spools and a print head that allows printing with different materials and colors, from flexible materials to soluble materials. It has a printing volume of 120 x 120 x 180 mm. In order to be able to successfully achieve color printing, the machine has 5 different spools for CMYK colours (cyan, magenta, yellow, black and white), which are then mixed within the patented hotend to give the expected color as a result. The printer can currently be purchased at the manufacturer’s website for $7,500. You can find more information HERE.

XRIZE

The XRIZE is an industrial 3D printer that uses a hybrid process called Augmented Deposition to produce objects in multiple colors. This hybrid process combines extrusion-based 3D printing with a inkjet technology we know from 2D printers. While the part is created layer by layer with traditional colorless PLA, the 3D printer simultaneously releases CMYK inks (cyan, magenta, yellow, black) in the print head to add color. For example, text, images and QR codes can be printed on the part. Although the device can be described as a desktop machine, its build volume being 310 x 200 x 200 mm, the XRIZE with a price of $55,000 is less suitable for manufacturers and hobbyists but rather for industrial applications. You can find more information HERE.

For example, text, images and QR codes can be printed on the part. Although the device can be described as a desktop machine, its build volume being 310 x 200 x 200 mm, the XRIZE with a price of $55,000 is less suitable for manufacturers and hobbyists but rather for industrial applications. You can find more information HERE.

Material Jetting

3DUJ-553 and 3DUJ-2207 from Mimaki

Japan’s Mimaki, a manufacturer of traditional 2D printers, was the first to make a UV-curable, colored material jet 3D printer. Its 3DUJ-553 solution was launched in 2017 and can create parts with more than 10 million colors. It uses a UV light curing process and is intended for the professional sector. During this process, a layer of material is applied and then covered with a UV-sensitive ink that light can solidify. The process is repeated until the final part is obtained.

More recently, Mimaki developed the 3DUJ-2207, a more compact 3D printer that offers the same color printing capabilities. It is more accessible and easier to use, unlocking a larger section of the current market. The 3DUJ-2207 is particularly suited to medical professionals, researchers and teachers, but also to designers and artists.

It is more accessible and easier to use, unlocking a larger section of the current market. The 3DUJ-2207 is particularly suited to medical professionals, researchers and teachers, but also to designers and artists.

ActiveLab Digital Fabrication by Voxel8

The ActiveLab Digital Manufacturing System from Voxel8, acquired earlier this year by Kornit Digital, is another multi-material 3D printing solution using a technology based on material jetting. Its ActiveMix® technology consists of three possible elements, ActiveMix Extrusion, ActiveMix Spray and ActiveImage. The extrusion works to build 3D structures and thick films on any surface or texture with theologically tuned fluids while the spray rapidly covers large areas of a substrate with an elastomeric spray for textiles. Finally, the ActiveImage uses inkjet technology either through spray or extrusion, or both, to embed high-resolution graphics into elastomers. Users can expect full color graphics and the company points to its use especially in the creation of sporting goods, though it also has industrial and medical applications. You can find out more HERE.

You can find out more HERE.

Photo Credits: Voxel8

J55 Prime

One of the most well-known names in the world of full color 3D printers is of course Stratasys with their PolyJet technology, which has the distinction of enabling the mixing of colors, materials and even textures in one part. Though they have many different machines using Polyjet, we wanted to draw your attention to their J55 Prime which was released in 2020. This more compact solution still has the multi-material and multi-color capabilities of its larger predecessors but at a fraction of the price. It is able to print with 5 materials simultaneously meaning that users can create over 640,000 unique combinations, including Pantone Verified colors. As it has been designed for an office or studio it is also ultra-quiet, operating at the same level as a household refrigerator. Finally, it has a ProAero™ Air Extractor to capture and filter out fumes. You can find out more about the printer HERE.

ProJet CJP Series

The ProJet CJP 260Plus is 3D Systems’ most affordable and office friendly color 3D printing option. The ProJet CJP 260Plus creates photo-realistic parts in full CMY color with small feature details and the ability to use full texture/UV mapping to better evaluate the look, feel, and style of product designs. This 3D printer is based on 3D System’s ColorJet Printing technology, and has a maximum build volume of 236 x 185 x 127 mm.

The ProJet CJP 260Plus creates photo-realistic parts in full CMY color with small feature details and the ability to use full texture/UV mapping to better evaluate the look, feel, and style of product designs. This 3D printer is based on 3D System’s ColorJet Printing technology, and has a maximum build volume of 236 x 185 x 127 mm.

3D Systems manufactures an entire range of color 3D printers, including the ProJet CJP 360, CJP 260 Plus, CJP 860Pro, CJP 660Pro, and the CJP 460Plus. They vary according to their build volume, the 860Pro being the largest solution, with a build volume of 508 × 381 × 229 mm. You can find more information HERE.

Binder Jetting

ComeTrue T10

Developed by Taiwanese manufacturer ComeTrue, the ComeTrue T10 3D printer is based on a Binder Jetting technology and coloured inks (CMYK). The advantage of such a process is the possibility of printing parts without printing supports as well as its speed, the T10 is indeed able to reach a printing speed of 20mm/h. The ComeTrue T10 allows the manufacture of parts with a maximum size of 200 x 160 x 150 mm with a resolution of 1200 x 556 DPI for a minimum layer height of 0.08 mm. The ComeTrue 3D printer requires a post-processing machine to remove the finished prints (Dry Vacuum Cleaner). The ComeTrue T10 is available for a price of about 25,000€. You can find more information HERE.

The ComeTrue T10 allows the manufacture of parts with a maximum size of 200 x 160 x 150 mm with a resolution of 1200 x 556 DPI for a minimum layer height of 0.08 mm. The ComeTrue 3D printer requires a post-processing machine to remove the finished prints (Dry Vacuum Cleaner). The ComeTrue T10 is available for a price of about 25,000€. You can find more information HERE.

PartPro350 xBC from XYZprinting

Launched in 2018 by Chinese manufacturer XYZprinting, the PartPro350 xBC 3D printer uses Binder Jetting. It is compatible with standard thermoplastics, such as ABS and PLA and the machine has been designed for professionals. With a printing volume of 350 x 222 x 200 mm, the printer is, according to the manufacturer, 150% faster than machines using the same technology. Finally, the PartPro350 xBC has a removable tray so that users can easily remove parts after the printing process. According to some retailers, the price is between €25,500 and €35,000.

What did you think of our listing of full color 3D printers? Let us know in a comment below or on our Facebook and Twitter page! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

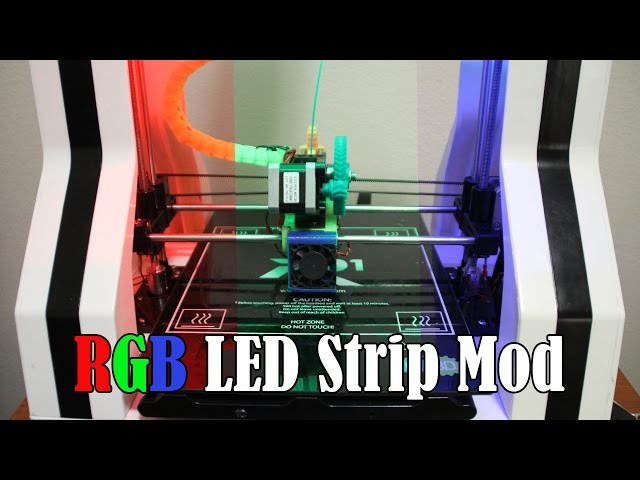

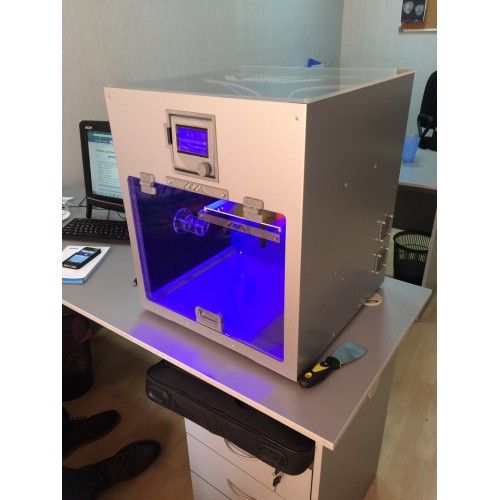

3D printer backlight. Variants and implementation

3DPrintStory Reviews 3D printer backlight. Variants and implementation

Have you ever got up in the middle of the night to check on the progress of 3D printing and frantically illuminated with a flashlight from your mobile? Or do you want your 3D printer to look cooler in the dark? The backlight can illuminate the entire 3D printer, workspace, or even the printhead, so there's room for your creative choices.

In addition to aesthetics and better visibility, another benefit of proper lighting is the accuracy when using a webcam, which is essential for programs like The Spaghetti Detective to track 3D print failures.

In this article, we'll look at several different lighting options for your 3D printer, print head, or entire desktop. However, before we present these options, let's discuss some of the specifics of your lighting setup.

What to look for when choosing a 3D printer light

There are several factors to consider when deciding which 3D printer light is best for you.

- Placement and Orientation: If you direct the light towards the center of the 3D printer, it will illuminate the area of the printed model. If you place the backlight outward, then this illumination will be enough not only for your part, but for the entire 3D printer.

- Power supply: you can implement a backlight for a 3D printer through the printer's power supply or take a separate power source.

If your printer uses a motherboard that supports backlighting, such as the SKR Mini E3 V2 or MKS Robin E3D, you can connect a compatible light source (same voltage) directly to the printer. However, if your motherboard does not have this feature, you can power the lighting from an external source, such as a computer or wall socket.

If your printer uses a motherboard that supports backlighting, such as the SKR Mini E3 V2 or MKS Robin E3D, you can connect a compatible light source (same voltage) directly to the printer. However, if your motherboard does not have this feature, you can power the lighting from an external source, such as a computer or wall socket. - Color: If you need different colors, look for RGB (red, green and blue) lights that can produce any color. If you want a plain white light, we recommend that you choose a richer white color (brighter and whiter) for better illumination.

Now let's look at the options! Please note that although some of the suggested options are for the Ender 3, it is not difficult to change them for your specific 3D printer.

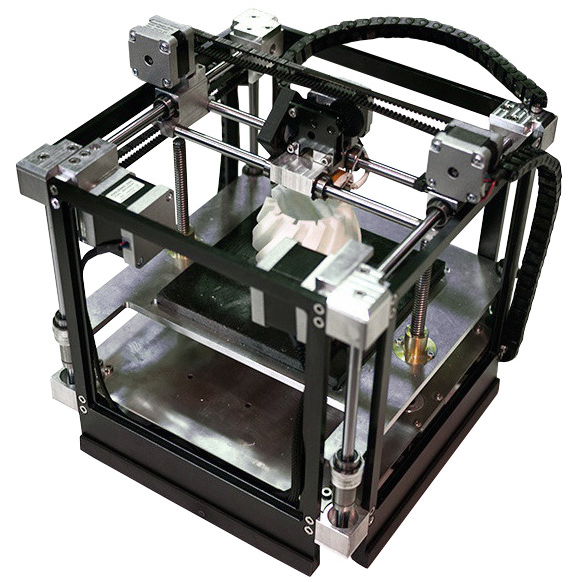

Illumination of the extruder zone on a 3D printer from profiles

The first option involves attaching an LED strip to your 3D printer's horizontal portal profile. Many 3D printers use aluminum V-groove profiles as part of the frame and gantry design, making them a great option for mounting LEDs. There are a huge number of options, it all depends on the number of tapes and your desires.

There are a huge number of options, it all depends on the number of tapes and your desires.

In essence, this lighting option for a 3D printer comes down to mounting an LED strip on a V-groove profile. Implementation may vary, there are many mounting options. For example, you can use mounting strips printed on a 3D printer and attach the LED strip to them already. Or mount the tape directly on the profile without using additional parts.

There is an interesting way to illuminate the extrusion zone with a flashlight. The Thingiverse link below will have a fastener that you can print and mount to your frame if you are using an Ender 3 3D printer. to the body, you can do it in other ways. There are many standard fixtures for lighting fixtures, so there are many options. As a general rule, these mounts are fine if you have a closed-case 3D printer.

You can 3D print fasteners yourself. For example, here is a variant of fixtures for LED strips. You can use screws or glue for fastening. The fasteners are pretty versatile.

The fasteners are pretty versatile.

There are options for more specialized LED strip fixtures for a specific 3D printer. For example, here is a mount for mounting on the body of a Prusa 3D printer. For example, these 3D printable models are designed to fit on the frame of a Prusa 3D printer.

3D Printer Arch Light

Another cool option that requires a bit more effort but works great for lighting your 3D printer is the arch. After installing this arch with LEDs on your 3D printer table, you will be able to monitor both the 3D printing process and, in principle, use the large illuminated area for soldering and repairing small parts and assemblies. To make an arch, you will need a lot of 3D printed models and a rather large piece of LED strip, but the result is worth it.

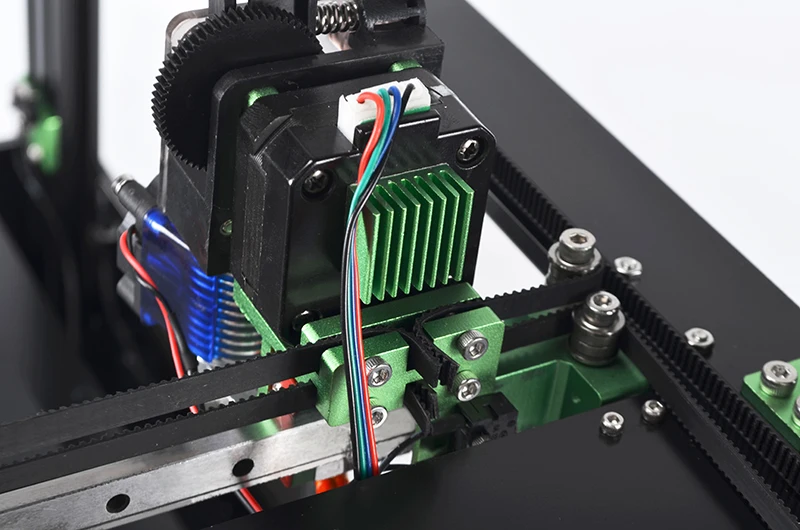

3D printer light on print head

If you want to light the 3D print area directly, you can add light on the print head. This performance will help you directly illuminate the area of the current 3D print, as the source itself will move with the print head. Please note that due to the increased weight of the print head, additional noise and vibration may be generated, which may adversely affect the quality of 3D printing. As a rule, direct illumination of the 3D printing area is implemented using an LED strip, but there are other options. One of the easiest alternative options is to print a mount and hook up a flashlight. The choice is yours.

Please note that due to the increased weight of the print head, additional noise and vibration may be generated, which may adversely affect the quality of 3D printing. As a rule, direct illumination of the 3D printing area is implemented using an LED strip, but there are other options. One of the easiest alternative options is to print a mount and hook up a flashlight. The choice is yours.

For mounts for 3D printer lighting directly on the printhead, you can consider these options that are designed for Ender 3: 2022 3D Printers (each price range)

Photopolymer 3D printers use SLA, DLP, or LCD technology to cure liquid resin, producing sharp, high-resolution prints at high speed. You'd be surprised how many industries use these machines, from jewelry to dentistry.

That's why we've ranked the best resin printers in every price range, from $150 to $5,000+, so you can find the perfect machine for your hobby projects or business.

Contents

- Best cheap resin 3D printers (under a thousand dollars)

- Anycubic Photon Mono is a great low cost resin 3D printer

- ELEGOO Mars Pro / Mars 2 Pro is the best cheap resin 3D printer Monicub Photon Photon 4K

- Phrozen Sonic Mini 4K

- Elegoo Mars 3

- Elegoo Saturn

- Phrozen Sonic Mighty 4K

- Anycubic Mono X - great budget photopolymer 3D printer

- Elegoo Mercury Plus

- Prusa SL1S Speed

- Peopoly Phenom mSLA Printer - large photoresin 3D printer with huge build volume

- Professional photoresin 3D printers (,000+)

- Formlabs Form 3 - Best Resin 3D Printer

- Buyer's Guide - Things to Consider When Buying a Resin 3D Printer

- RGB vs LCD Screens - Differences, Advantages/Cons

- Post Processing Equipment

- How Resin 3D Printer Works Printer?

- Resin 3D printing technologies

- SLA

- DLP

- MSLA/LCD

- LFS

- DLS

- How much does a resin 3D printer cost?

- Resin 3D Printer Applications

- Resin 3D Printing Versus FDM

- Resin 3D Printing vs Selective Laser Sintering (SLS)

- FAQs

dollars)

Anycubic Photon Mono is a great inexpensive photopolymer 3D printer

- Price: $249

- Assembly volume: 120 x 80 x 165 mm

- Screen resolution: 2560 x 1620 pixels

- Screen size: 6″ 2K monochrome LCD

- XY resolution: 51 microns

- Speed: 50 mm/h

- Cleaning/Cure: Anycubic Washing and Curing Station

The new Anycubic Photon Mono printer adds to Anycubic's reputation as a premium manufacturer of affordable LCD 3D printers. Where you used to pay thousands for an entry-level SLA printer, now printers like the Mono offer great resolution at lower than ever prices. The Photon Mono is a new upgrade from previous models, including greatly increased resin printing speed and other accuracy improvements.

Where you used to pay thousands for an entry-level SLA printer, now printers like the Mono offer great resolution at lower than ever prices. The Photon Mono is a new upgrade from previous models, including greatly increased resin printing speed and other accuracy improvements.

It is equipped with a high quality 2K LCD screen, which is more than enough for most resin projects. But for higher resolution and better quality for really complex figurines or miniatures, we recommend getting the Anycubic Mono X with its 4K LCD screen, which we'll cover in more detail later in this article.

Perhaps the most notable upgrade is speed - up to a maximum of 50mm/h compared to previous levels of around 20mm/h on older Photon models. Anycubic has also upgraded the Z axis for more stable printing and better surface finish with a new dual linear motion system.

Overall, we rate the Anycubic Photon Mono, as well as its competitors in the Sonic Mini and Elegoo Mars lineups, as the best cheap photopolymer 3D printers. But if you have a few hundred dollars to spare and need better resolution, go for the Mono X. The

But if you have a few hundred dollars to spare and need better resolution, go for the Mono X. The

anycubic photon mono is a cheap photopolymer 3d printer.

ELEGOO Mars Pro / Mars 2 Pro - Best Cheap Resin 3D Printer

- Price: $250 / $280 - Available on Amazon here

- Print volume: 129 x 80 x 160 mm

- Screen resolution: 2560 x 1620 pixels

- Screen size: 6.08″ 2K monochrome LCD

- XY resolution: 50 microns

- Speed: 30-50 mm/h

- Cleaning/Cure: Elegoo Mercury Plus/X Wash and Curing Station The

Elegoo Mars is another cheap resin 3D printer, just like the Anycubic Photon, which shocked manufacturers with how good it really is. As LCD 3D printing becomes more affordable, accurate and fast, Elegoo is taking advantage of this advantage to create a low cost resin printer that delivers quality and consistency.

An upgraded version of the Mars Pro printer is more accurate with an updated Z-axis linear guide system that smoothes layers and makes each individual layer line less obvious, improving surface quality. There are also a number of safety improvements, such as a silicone seal that prevents resin from leaking on the 3D printer cover.

There are also a number of safety improvements, such as a silicone seal that prevents resin from leaking on the 3D printer cover.

The printer is equipped with a 2K LCD projector and the minimum layer height is only 0.01mm. Elegoo Mars Pro comes with its own 3D resin slicer called CHITUBOX and has a nice max build volume of 115 x 65 x 150mm. It's also fast enough for a budget photopolymer 3D printer.

Elegoo also sells some of the cheapest resins on the market. You can buy them here.

Anycubic Photon Mono 4K

- Price: $289

- Print volume: 165 x 132 x 80 mm

- Screen resolution: 3840 x 2400

- Screen size: 6.23" 4K monochrome LCD

- XY resolution: 35 microns

- Speed: 50 mm/h

- Cleaning/Cure: Anycubic Washing and Curing Station

The Anycubic Photon Mono 4K, equipped with a 6.23″ 4K high-resolution monochrome LCD, is an affordable, performance-oriented 3D printer for the discerning but budget-friendly resin maker.

The construction volume of 165 x 132 x 80 mm is small by FDM standards. Although, as befits resin 3D printers, its volume is slightly larger than most, and it certainly makes up for it with exceptional precision and detail thanks to its 35 micron XY resolution.

In testing, Anycubic Photon Mono 4K proved to be ready to work with any highly detailed models and decorative elements, even quite large ones. Articulated parts, board game figures and even articulated miniatures, the Mono 4K does it all.

Cast on a few copies of a small part and the Anycubic Photon Mono 4K is ready, making it suitable for small businesses and hobbyists alike. The print speed is up to 50mm/h and the printer easily prints layers in less than 2 seconds.

From a usability standpoint, we would like to see desirable features such as resume printing and Wi-Fi connectivity. Anycubic's Photon Workshop slicing software is a functional, if unremarkable, slicer. Luckily, the Anycubic Photon Mono 4K's compatibility with third-party software such as Lychee and ChiTuBox means you don't have to be tied to Anycubic's slicing software.

If you're after impressive 4K screen fidelity, the Anycubic Photon Mono 4K's delivers hassle-free, high-resolution printing at a great price.

Phrozen Sonic Mini 4K

- Price: $349 - Available at Phrozen official store here / Available on Amazon here

- Print volume: 134 x 75 x 130 mm

- Screen resolution: 3840 x 2160 pixels

- Screen size: 6.1″ 4K monochrome LCD

- XY resolution: 35 microns

- Speed: 80 mm/h

- Cleaning/Cure: Phrozen Cure and Phrozen Ultra-Sonic Cleaner

At an affordable price, the Phrozen Sonic Mini features a powerful 4K 6.1-inch LCD screen that delivers 35µm quality and two-second layer print speeds.

This is a powerful, low cost resin 3D printer with everything you need to print, and while if you need more print volume you can go for the Sonic Mighty 4K (more on that later!), if size isn't a big deal, the Sonic Mini 4K is more than fit.

Phrozen claims that the Sonic Mini 4K is ideal for resin mold printers, as well as miniature and desktop model printing.

Elegoo Mars 3

- Price: $349

- Print volume: 143 x 90 x 165 mm

- Screen resolution: 4098 x 2560 pixels

- Screen size: 6.6″ 4K monochrome LCD

- XY resolution: 35 microns

- Speed: 1.5-3 seconds per layer

- Cleaning/Cure: Elegoo Mercury Plus/X Wash and Curing Station

Featuring an Ultra 4K resolution LCD screen and Elegoo's latest mSLA technology, Elegoo Mars now has 30% more accurate XY (35µm) resolution than Mars 2, as well as a 37% larger build volume. For an extra $100, this is a very attractive deal for those looking to get higher-end resin 3D printing.

Other features include an improved light source for more uniform resin curing - even over a larger build area. Built-in 36 high-power LED lamps and a new lens provide higher accuracy, as well as an improved heat sink and cooling fan, which extends the life of the printer and enhances its durability.

Elegoo Saturn

- Price: $499

- Print volume: 192 x 120 x 200 mm

- Screen resolution: 3840 x 2400 pixels

- Screen size: 8.

9″ 4K monochrome LCD

9″ 4K monochrome LCD - XY resolution: 50 microns

- Speed: 30-40 mm/h

- Cleaning/Cure: Elegoo Mercury Plus/X Cleaning and Curing Station

Featuring an 8.9" 4K monochrome LCD screen for fast layer curing, the Elegoo Saturn greatly outperforms the standard models by printing 60% faster than the Elegoo Mars Pro, printing a layer every 2-3 seconds.

You get a number of other key improvements for your money, the most notable of which is the larger build area that turns the Elegoo Saturn into a 3D printer for printing large hard resin models, as well as the ability to print multiple smaller models at the same time in one batch.

Improved precision with the Saturn's double linear Z-axis guide makes it more stable than ever, ensuring accurate and uniform printing. And in case you're a fan, the Elegoo Saturn also has an Ethernet port on the back to keep things fast and efficient.

Phrozen Sonic Mighty 4K

- Price: $549

- Print area: 200 x 125 x 220 mm

- Screen resolution: 3840 x 2400 pixels

- Screen size: 9.

3″ 4K monochrome LCD

3″ 4K monochrome LCD - XY resolution: 52 microns

- Print speed: 80 mm/h

- Cleaning/Cure: Phrozen Cure and Phrozen Ultra-Sonic Cleaner

If you're looking for a low cost resin 3D printer with a large enough footprint for mass production of models or large resin prototypes, the Phrozen Sonic Mighty 4K even outsizes the Elegoo Saturn.

With a strong and reliable Z-axis that delivers print accuracy up to a maximum print height of 22 cm, it offers good print quality, especially with a 4K LCD screen. It also prints fast, with two-second layer printing.

While Phrozen recommends using proprietary 3D printer resins, the Sonic Mighty 4K is compatible with most third-party resins (check first). So if you have spare resins left over from a previous 3D printer, you should be fine.

Anycubic Mono X is a great budget photopolymer 3D printer

- Price: $599

- Printable area: 192 x 120 x 245 mm

- Screen resolution: 3840 x 2400 pixels

- Screen size: 8.

9″ 4K monochrome LCD

9″ 4K monochrome LCD - XY resolution: 50 microns

- Speed: 60 mm/h

- Cleaning/Cure: Anycubic Wash & Cure Statio

Anycubic's original budget Photon 3D resin 3D printer is still one of the most popular 3D printers in the world, and now the Mono X proves that the company can compete with higher-end machines. Mono X can print 3 times faster than standard photopolymer printers at speeds up to 60mm/h, and thanks to the 4K LCD screen, it can create very precise and sharp details.

In addition, the upgraded Z-axis of the Mono X improves stability and makes the surface smooth, unaffected by external factors such as vibrations. The result is jewelry models and miniatures where the layer lines are barely visible.

Another big benefit is WiFi printing, so you don't have to keep unplugging your SD or USB card when printing multiple designs throughout the day. The large 3.5" touch screen makes it easy to navigate, and with a larger build volume, you can print multiple jewelry models or desktop miniatures at the same time. Overall, this is one of the best budget photopolymer 3D printers out there.

Overall, this is one of the best budget photopolymer 3D printers out there.

Curing and Cleaning Stations

Since washing and curing is an inevitable part of resin 3D printing, we have compiled some of the best washing and curing stations to include in your printing system to save you the hassle and mess of subsequent printing. processing.

Anycubic Wash & Cure.

Anycubic Wash & Cure is a versatile station compatible with the vast majority of photoresin printers. Thanks to Anycubic's recent price cut, Wash & Cure is under $100.

The flush mode has adjustable flush cycles including 2, 4 and 6 minutes. Curing mode uses a broad spectrum UV light of 356 nm and 405 nm mounted on a 360° rotating platform to ensure uniform curing of any and all prints 115 x 65 x 165 mm or smaller.

Anycubic has simplified the entire rinsing and curing process with a “set it and forget it” design—select rinsing or curing on the touch button interface and you're done. Station blocks 99.95% UV radiation and has an auto-pause feature if the cap is accidentally knocked off. The station has an adjustable bracket that can be fixed on the Anycubic platform if you are working with a Photon Mono series printer.

Station blocks 99.95% UV radiation and has an auto-pause feature if the cap is accidentally knocked off. The station has an adjustable bracket that can be fixed on the Anycubic platform if you are working with a Photon Mono series printer.

Elegoo Mercury Plus

Another all-in-one station, but this time from Elegeoo, the Elegoo Mercury Plus is an easy-to-use option for hands-free finishing.

The allowed maximum print size is 125 x 85 x 160 mm for washing and 140 x 165 mm for curing. You can either use the included cleaning basket or install the Elegoo build plate with models still attached, making it compatible with most if not all photopolymer 3D printers, not just Elegoo machines.

385nm and 405nm UV lamps and a 360-degree rotatable curing turntable do all the curing work with the ability to enter and control cure times up to 30 minutes on a TFT touch screen. Safety is provided by an anti-UV cap that blocks 99.95% of UV rays and a pause function if the cap comes off during curing.

Anycubic station will cost more, but at around $120 you will complete your 3D printing rig with a quality resin 3D printing station with no mess.

Best desktop resin 3D printers ($1,000 to $3,000)

Prusa SL1S Speed

- Price: $1,999 - available at Prusa store here

- Print volume: 120 x 68 x 150 mm

- Screen resolution: 2560 x 1620 pixels

- Screen size: 5.96″ 2K monochrome LCD

- XY resolution: 47 microns

- Print speed: 50 mm/h

- Cleaning/curing: Original Prusa CW1S

Prusa printers are known for being the best RepRap 3D printers. They are so good that over 150,000 printers have been sold, and company founder Josef Prusa has opened his own printer factories to print parts for more printers! Prusa reception.

Prusa has now moved into the SLA 3D printing sector with the launch of the Prusa SL1 printer based on mSLA technology: using LCD and LED panels to cure photosensitive resin layers. As mentioned earlier, this has the advantage of scalability—multiple parts can be created at the same time without additional time—as well as high accuracy.

As mentioned earlier, this has the advantage of scalability—multiple parts can be created at the same time without additional time—as well as high accuracy.

In addition to the printer, Prusa sells a wash and cure machine that helps wash and cure prints, maximizing the surface finish. The Prusa SL1 has a heavy aluminum chassis designed to anchor the printer to the ground and make it more stable for more accurate printing. It seems to me that the phrase “of course, this is good, this is Prusa” is appropriate here.

Peopoly Phenom mSLA Printer - large photopolymer 3D printer with huge build volume

- Price: $1,999 - Available at Matterhackers here

- Print volume: 276 x 155 x 400 mm

- Screen resolution: 3840 x 2160 pixels

- Screen size: 12.5″ 4K LCD

- XY resolution: 72 microns

- Print speed: 75 mm/h

- Cleaning/Cure: Peopoly Curing Box

We already included the Peopoly Moai 130 in our list, a fantastic DIY SLA 3D printer kit. Now Peopoly is back with the Phenom, a large photopolymer 3D printer that combines LCD and LED technology.

Now Peopoly is back with the Phenom, a large photopolymer 3D printer that combines LCD and LED technology.

Peopoly Moai has a huge print volume for a photopolymer 3D printer - 276 x 155 x 400 mm, as well as 72 microns resolution. This is practically unheard of as photopolymer printers typically have a much lower build volume than FDM 3D printers. Peopoly recommends using their own resins for 3D printing, which they sell for about $70 per litre.

Overall, this is an impressive and accurate large format resin 3D printer.

Professional Resin 3D Printers ($3,000+)

Formlabs Form 3 - Best Resin 3D Printer

- Price: $3,499

- Assembly volume: 145 x 145 x 185 mm

- XY resolution: 25 microns

- Print speed: 70 mm/h

- Clean/Cure: Formlabs Form Wash & Cure

Formlabs has made a name for itself in the 3D printing industry since its initial Kickstarter campaign in 2012. An American 3D printer company was selling a Form 3 SLA 3D printer for 3 49$9 and has since become very popular in the dental and jewelry industries.

Formlabs resins available here.

TheForm 3 comes with a ton of new features. It features the new benefits of LFS technology as well as a new Light Processing Unit (LPU) to improve the surface finish of resin parts as well as better layer registration. The Form 2 was already fantastic, and these additional features take the Form 3 to a whole new level in desktop SLA printers.

In addition, the Formlabs Form 3 has an automated resin supply system and uses smart cartridges that automatically fill the resin reservoir, along with many other advanced features. In addition, it is equipped with a resin tray scanning system after each layer and automatically adjusts according to the type of resin used. In addition, the printer has a fantastic touch screen and can be controlled remotely via a WiFi connection.

This UV resin 3D printer has a very good print volume of 145 x 145 x 185mm and is extremely accurate with 25 micron XY resolution. The Formlabs Form 3 is compatible with a wide range of resins, from ceramics, flexible resins, to cast resins, although Formlabs also sells its own high quality resins.

For those looking for 3rd party resins compatible with Formlabs printers, here's a great place to start.

Formlabs has established itself as a leader in stereolithography with the Form 3 printer. It has received rave reviews and is widely used in dentistry. Formlabs also sells a 3D printer for SLS, the Fuse 1.

Buyer's Guide - What to Consider When Buying a Resin 3D Printer

RGB vs. LCD Screens - Differences, Advantages/Disadvantages

earlier models.

This transition is only to the benefit of manufacturers, since monochrome screens have many advantages over RGB. Although they are more expensive, they are more efficient, less energy intensive, and print faster due to shorter polymerization times.

Unless you choose an old used model, you will most likely buy a printer with a default monochrome LCD screen.

LCD Resolution - 2K, 4K, 6K

Like computer monitors and TVs, LCD resolution determines the level of pixels and detail.

Higher resolution translates into better XY resolution and lower layer height, which is a critical factor for the fine detail and precision we expect from resin printers.

You'll find 2K, 4K and even 8K resolution printers for those who want the ultimate level of detail and intricate detail in their prints.

However, the print quality of the 2K LCD is far superior to that of FDM printers, so it is more than adequate for most applications.

Build Volume

Photopolymer printers typically have a smaller build volume than the more common FDM machines, so manufacturers and professionals use them to create small, intricate parts with high precision.

If you need extra space to print duplicate parts or large figures and models, look to larger format resin printers such as the Peopoly Phenom and Phrozen Sonic Mighty 4K.

Post-Processing Equipment

Resin 3D printing is a messy business and post-processing is a major part of the printing process. Post-processing consists of two parts - washing and polymerization.

Post-processing consists of two parts - washing and polymerization.

Flushing involves removing uncured resin residue from the print with isopropanol.

Polymerization uses additional UV light to complete the polymerization process to improve the finish and overall rigidity of the part.

Do-it-yourself, hands-on processing is one option, but manufacturers now offer versatile washing and curing stations that eliminate many of the hassles associated with this process.

How does a photopolymer 3D printer work?

Each type of resin 3D printing technology cures UV resin, they just differ in how they do it.

Stereolithography (SLA) was the first additive manufacturing technology invented, with patents granted to 3D Systems back in 1986. SLA printing works by using an ultraviolet laser and mirrors (called galvanometers) to selectively cure the resin.

DLP 3D printing was pioneered by EnvisionTEC and uses a projector similar to a movie theater projector. LCD printing uses an LCD screen with individual LEDs that turn on and off to selectively cure specific areas of the resin to form the final object. LCDs are sometimes referred to as MSLA (masked SLA), as in Prusa and Peopoly resin printers.

LCD printing uses an LCD screen with individual LEDs that turn on and off to selectively cure specific areas of the resin to form the final object. LCDs are sometimes referred to as MSLA (masked SLA), as in Prusa and Peopoly resin printers.

Resin 3D Printing Technologies

SLA

Using mirrors, also called galvanometers, an SLA or stereolithography printer directs a UV laser beam onto photopolymer liquid resin in cross sections to cure or print layer by layer.

DLP

DLP, or Digital Light Processing, is very similar to the SLA machine and involves emitting digital light (LED in most printers) through an array of micromirrors onto a light-sensitive liquid resin for flash, or in other words, curing the entire image layer at a time in so-called voxels - rectangles that look like pixels.

MSLA/LCD

Like DLP machines, MSLA or stereolithography (often referred to as LCD) printers use a digital light source (usually hundreds of LEDs) to flash an entire layer at once. Unlike DLP, the MSLA printer uses the LCD as a "mask", directing and illuminating a photosensitive liquid resin rather than mirrors. The mask allows the printer to expose only those areas that need to be cured to the light source.

Unlike DLP, the MSLA printer uses the LCD as a "mask", directing and illuminating a photosensitive liquid resin rather than mirrors. The mask allows the printer to expose only those areas that need to be cured to the light source.

LFS

LFS or Low Force Stereolithography is Formlabs patented pot polymerization technology. LFS overhauls the standard SLA process using a custom-designed Closed Light Processing Unit (LPU) that passes a UV laser beam through a spatial filter and an array of mirrors to polymerize the photosensitive liquid resin cross-section layer by layer.

DLS

Another patented technology from Carbon 3D, DLS, or Digital Light Synthesis, uses an oxygen permeable window to cure a photosensitive liquid resin in what is known as continuous liquid interface manufacturing (CLIP). Light from a special LED engine illuminates ultraviolet rays to match the shape and details of the part's cross-section onto an ultra-thin resin layer supported by an oxygen window known as the "dead zone". The resin in the "dead zone" is then cured to create precise, detail-rich layers.

The resin in the "dead zone" is then cured to create precise, detail-rich layers.

How much does a photopolymer 3D printer cost?

Good cheap photopolymer 3D printers start at around $200. Even ten years ago, resin printers cost thousands of dollars, but with great advancement - mainly in the field of LCD printing - the prices have come down!

However, these budget photoresin 3D printers can't compete with more professional high resolution printers like the Form 3 ($3,499) or the Peopoly Phenom (1 9$99). They can still produce accurate models, for example for miniatures and other fun projects, but as a photopolymer 3D printer for business, they may not be effective.

Resin 3D Printer Applications

Budget Resin 3D printers are commonly used by hobbyists to produce precise figurines and miniatures in detail that FDM printers simply cannot match. They are commonly used for 28mm miniatures, D&D figurines and other similar desktop model projects.

However, these inexpensive options can sometimes be used to create wax molds for casting jewelry. However, for higher quality precious metal casting, it is recommended to use a more professional resin 3D printer capable of better resolution and accuracy.

However, for higher quality precious metal casting, it is recommended to use a more professional resin 3D printer capable of better resolution and accuracy.

photopolymer printers are widely used in dentistry, audiology, jewelry and medical industries. For example, in dentistry, photopolymer 3D printers can print orthodontic models and implants, and in audiology, almost 100% of custom-made hearing aids are now 3D printed.

3D resin versus filament (FDM)

Hobbyists usually turn to resin 3D printing when they want higher precision, smoother surfaces and sharper details on small prints such as figurines or miniatures. While FDM is simpler, it cannot achieve these levels of precision and smoothness.

However, the trade-off between FDM and resin is that, in terms of filament to resin ratio, filaments are cheaper, easier to use and reuse, come in more materials, colors and types, and tend to be stiffer.

Resins tend to be more expensive (although LCD resins are much cheaper now) and harder to use. They require thorough rinsing and post-processing, and extra care must be taken when printing and during post-processing with a resin 3D printer, including wearing protective gear, as the materials can be corrosive.

They require thorough rinsing and post-processing, and extra care must be taken when printing and during post-processing with a resin 3D printer, including wearing protective gear, as the materials can be corrosive.

Thus, resin and thread are used for different purposes, and are not in direct competition for the same use. For the unrivaled precision of cheap 3D printers, as well as the rapid production of dental, jewelry and medical models, resin 3D printers are the way to go. But for more complex - perhaps with multiple colors - basic prototypes, deposition modeling is best suited.

Anti-selective laser sintering (SLS) resin 3D printing

The trade-off between SLA and selective laser sintering is similar: SLS-printed parts are more rigid, with excellent mechanical properties (and make excellent functional prototypes), although parts printed SLA are characterized by a smoother surface and faster printing.

SLS is also great if you're not a fan of additional support structures and don't like post-processing, because the parts printed in the resin powder chamber don't move or deform during printing. SLS offers better material properties than SLA - for example, it is not as susceptible to UV or sun damage. But they are less affordable—even the cheapest printers start at $5,000.

SLS offers better material properties than SLA - for example, it is not as susceptible to UV or sun damage. But they are less affordable—even the cheapest printers start at $5,000.

FAQ

Is resin more durable than PLA?

In general, conventional resin produces brittle, brittle parts that are less resistant to stress and weather than traditional 3D printing materials such as PLA. Therefore, we cannot recommend the resin for making load-bearing, functional, impact-resistant or exterior parts where PLA and ABS work much better, so manufacturers prefer the resin for fragile decorative parts filled with precise detail and a smooth finish.

Increasingly, however, 3D printing media manufacturers are offering "strong" resins such as Formlabs Tough 2000 Resin, which offer superior tear strength and even outperform ABS in some cases. Real world applications in orthopedics (such as splints and braces) and dentistry (aligners and crowns) demonstrate how people are increasingly turning to tough resins to make strong, wear-resistant parts.

Is 3D printer resin expensive?

When viewed in the context of 3D printing and compared to other popular materials and filament types, resin is not particularly expensive. A 1 liter bottle of standard resin costs between $20 and $50 depending on the brand, which is more or less the price of ABS and PLA raw materials.

The number and size of prints you can make from a standard 1 liter bottle can vary, with costs skyrocketing for the most prolific producers.

Is the resin print dirty?

While the resin printing process itself isn't messy, post-processing of the finished print invariably turns into an annoying, messy mess, not to mention a potentially dangerous mess of dripping resin and harsh isopropanol. This is not for the faint of heart and not for those who are afraid to get involved in this matter.

Luckily, curing and cleaning stations help keep resin processing messy, so you don't get your hands dirty by smearing prints in a vat of isopropanol.