3D level scanner

APM 3D - Level - 3D Level Scanner by Echo Process ...

APM 3D - Level - 3D Level Scanner by Echo Process ...- Home breadcrumb

- Companies

- Echo Process Instrumentation, Inc.

- Products

- Model APM 3D - 3D Level Scanner

From Level

0

Share Share with Facebook Share with Tweeter Share with LinkedIn

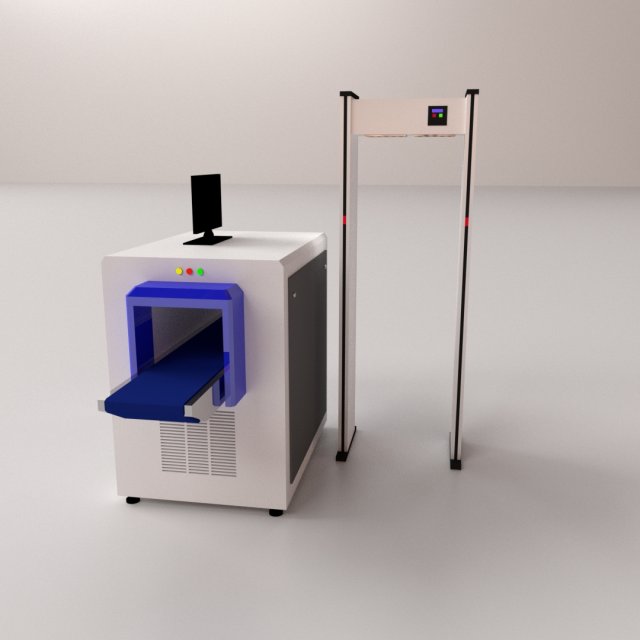

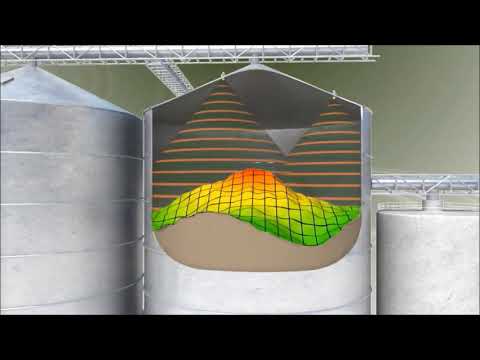

The 3D Level Scanner - Model S determines the average volume of bulk solids stored in small silos with diameters up to 4 or 5 meters (13 - 16 feet) and height up to 70 meters (230 feet). The 3D Level Scanner - Model M maps the entire surface area of practically any kind of bulk solids stored in large silos, open bins and stockpiles (up to 15 meters / 49 feet in diameter and heights of up to 70 meters / 230 feet), and generates highly accurate measurements of the level and volume of the contents.

The 3D Level Scanner - Model M maps the entire surface area of practically any kind of bulk solids stored in large silos, open bins and stockpiles (up to 15 meters / 49 feet in diameter and heights of up to 70 meters / 230 feet), and generates highly accurate measurements of the level and volume of the contents.

The 3D Level Scanner - Model MV maps the entire surface area of practically any kind of bulk solids stored in large silos, open bins and stockpiles(up to 15 meters / 49 feet in diameter and heights of up to 70 meters / 230 feet), and generates highly accurate measures of the level and volume of the contents.

All models incorporate APM's proprietary non-contact dust-penetrating technology enabling it to overcome the challenges of harsh, dusty environments regardless of the type or characteristics of the material being stored. APM software provides a3D representation of the contents- including material build-up and other irregularities that form over time - for display on remote screens to facilitate timely intervention and maintenance.

- Real Level Measurement

- Non-Contact Dust Penetrating

- Patented Self-Cleaning Technology

- Works With Any Dielectric Constant

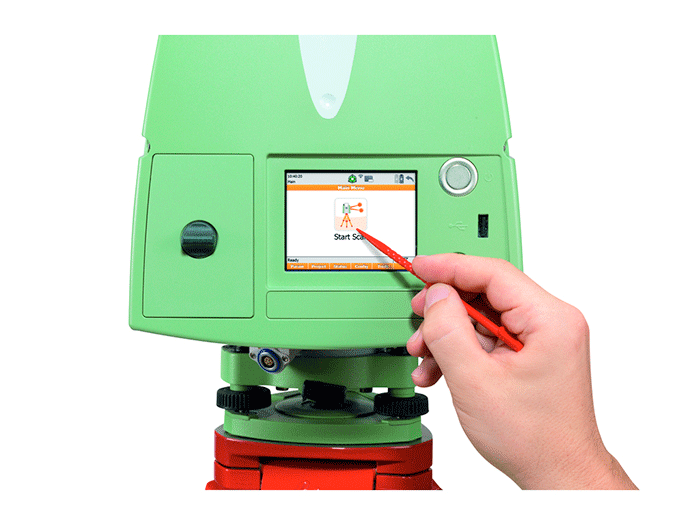

- LCD Wizard Configuration

- Housing & Antenna: Painted Aluminum die cast

- Ambient, Storage, transport and process temperature: -40...85ºC (-104...185ºF)

- Vessel pressure: 0.2...3 bar (-2.9...43.5 PSI)

- LCD: 4 lines x 20 characters

- Adjustment elements: 4 keys

- Supply Voltage: 18...32 VDC

- Power Consumption: max 1.5W @ 24VDC

- Protection: IP67 according to IEC 60529

- Measuring Range: 70m (230ft)

- Beam Angle: 15 degrees

- Frequency: 4.5 KHz

- Reaction/Setting Time: < 5 s (dependent on the parameter adjustment)

Rosemount 5708 Series 3D Solids Scanner | Level Transmitters

Skip to Main Content

Low frequency acoustic waves deliver accurate volume and level measurements of bulk solids and powders.

Learn more...

Learn more...

- Rosemount 5708 Series 3D Solids Scanner

- Rosemount 5708 Series 3D Solids Scanner

- Rosemount 5708 Series 3D Solids Scanner Basic Configuration Guide

- osemount 5708 Series 3D Solids Scanner Installation Guide

Retired products cannot be ordered

The Rosemount 5408 Radar Level Transmitter is the recommended replacement

View Company Reviews Trustpilot

Manufactured

- By Rosemount

Includes

- FREE Ground Shipping

- FREE Lifetime Tech Support

Product Manual Product Specs

Overview

Features

- Dead band is 19.

6in (0.5m) from top of antenna

6in (0.5m) from top of antenna - Up to 230ft (70m) measurement range

- Minimum bulk density of 12.5lb/ft3 (200kg/m3)

- Process fitting thread, angle adapter

- 2.3 to 7kHz emitting frequency

- Polyurethane covered aluminum housing material

- 4-20mA & RS-485 with Modbus signal output

Description

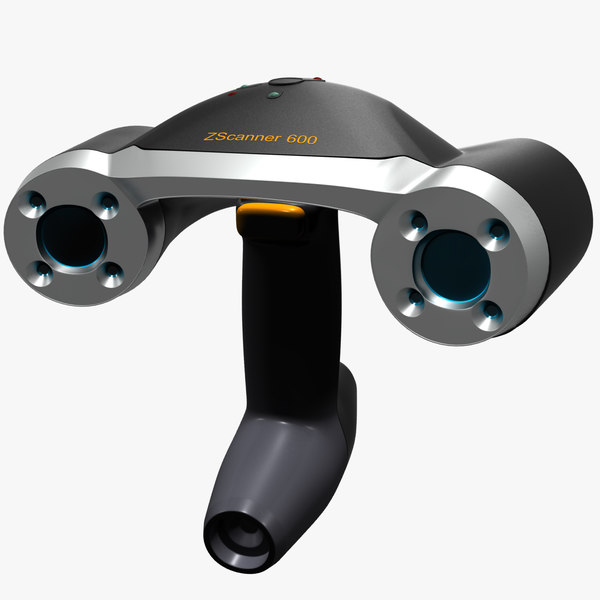

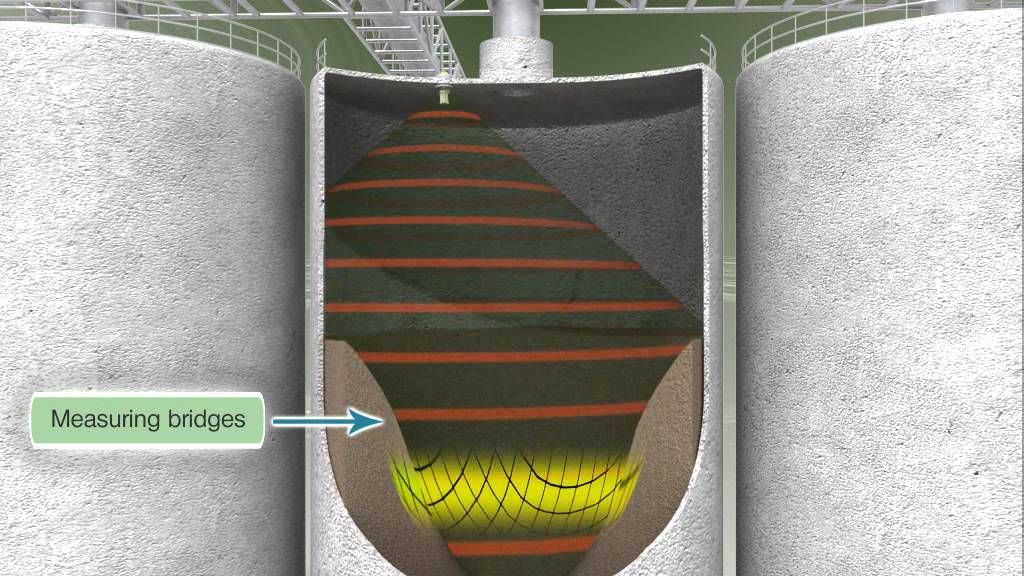

The Rosemount 5708 series 3D solids scanner uses a multiple point measurement technology to deliver accurate volume and level measurement of bulk solids and powders regardless of material type, product characteristics, storage silo type, size, or harshness of the storage environment. The 5708L, 5708V, and 5708S models enable efficient process measurement and true inventory management of bulk solid materials used in industrial applications including:

- Large open bins

- Bulk solid storage rooms

- Stockpiles and warehouses

- Loads that randomly form over time inside silos

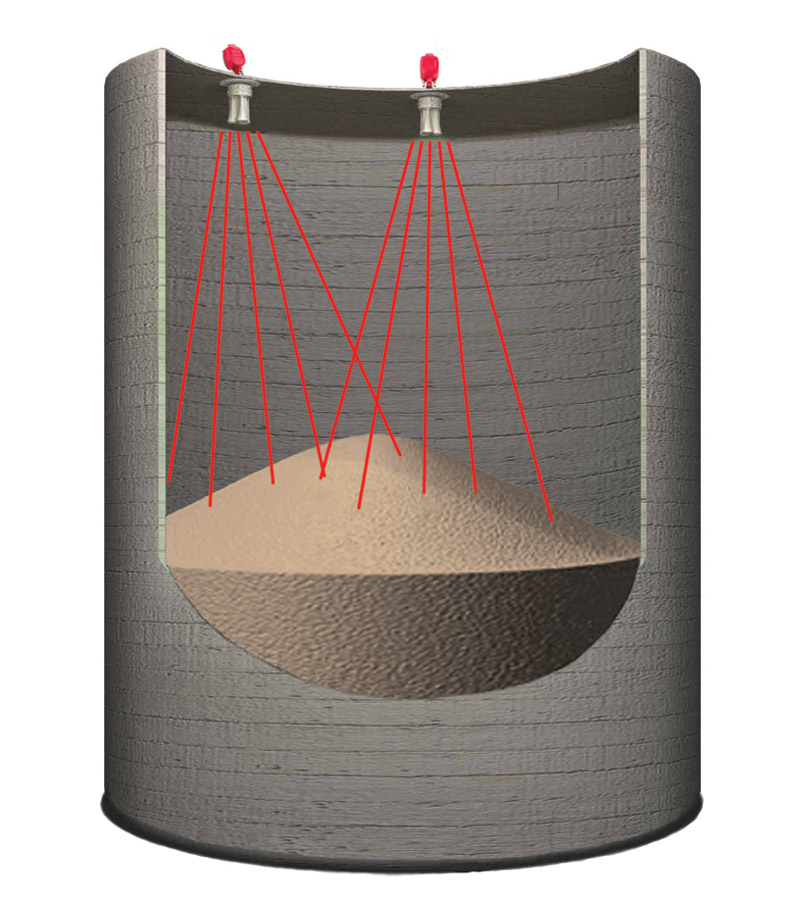

The device includes an integral array of three antennas that generate unique dust-penetrating low frequency acoustic waves

and receive echoes from the contents. Using these antennas, the unit measures not only the time/distance of each echo, but also

its direction.

Using these antennas, the unit measures not only the time/distance of each echo, but also

its direction.

Collecting multiple echoes from different directions and distances enables the scanner to accurately calculate the volume of stored material. It also enables the 3DVision software to generate the 3D visualization of the material.

The acoustic waves combined with self-cleaning capabilities prevent material from adhering to the internal workings of the antenna array, ensuring long-term reliable performance with very low maintenance requirements, regardless of harsh dusty conditions.

Documents

Spec Sheets

- Rosemount 5708 Series 3D Solids Scanner Datasheet PDF (3.5 MB)

Manuals

-

Rosemount 5708 Series 3D Solids Scanner Manual PDF

(34.

1 MB)

1 MB)

Other

- Rosemount 5708 Series 3D Solids Scanner Quick Start Guide PDF (25.6 MB)

- Instrumart's Level Application Form PDF (141 KB)

Accessories

Service Options

$2,294. 56

56

Starting at $4,800.00

Accessories

Please consider these optional accessories.

Starting at $2,605.51

Starting at $6,368.43

Starting at

$1,120. 51

51

Need Help? Call a Calibration Engineer at 1-800-884-4967

We're open 8:00am to 5:30pm ET

Brynn O.S.

Applications Engineer

Mark D.

Applications Engineer

11 years at Instrumart

John A.

Applications Engineer

16 years at Instrumart

Shawn S.

Senior Applications Engineer

27 years at Instrumart

Angelo S.

Applications Engineer

3 years at Instrumart

Mike K.

Cal & Pressure Engineering Lead

11 years at Instrumart

Mike C.

Senior Applications Engineer

21 years at Instrumart

Recently Viewed

RangeVision PRO

RangeVision PRO You have disabled JavaScript. It scares.Partners

-

Software and regular updates

-

Online support

-

Blue-Light Technology

-

Industrial Precision

-

Excellent value for money

Industrial solution,

available to any company level

Get accurate 3D models for your production

- Registered measuring instrument

- Reverse engineering

- Measurements and quality control

- Detailed visualization

Sign up for a free online demo!

Get a unique opportunity to test the RangeVision PRO 3D scanner online before choosing. Convince yourself of its capabilities!

Convince yourself of its capabilities!

RV PRO - scanning objects from jeweler size to car scale

Variable scan areas

- Small size

- The average size

- Big size

Applications

Excellent value for money

RangeVision 3D scanner delivers excellent performance at a price significantly lower than systems with

comparable features. Get an affordable price for a professional solution that meets your needs

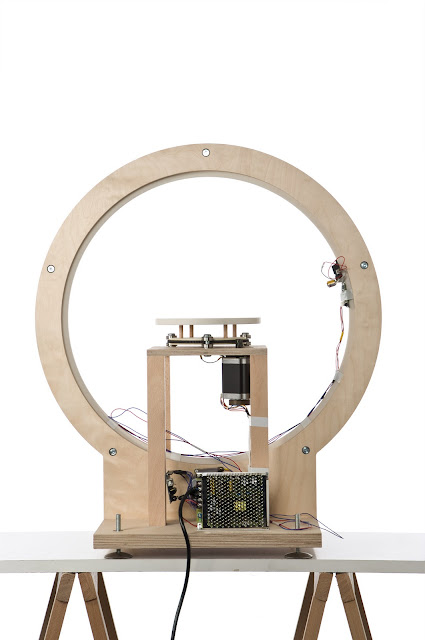

Three scanning modes

For convenient work with different types of objects

Choose the right mode for your tasks

-

Scanning on a turntable

Quickly and easily scan an object mounted on a turntable platform with the push of a button.

When the object is rotated, the fragments of the model are aligned automatically.

When the object is rotated, the fragments of the model are aligned automatically. -

Scanning with markers

Automatic alignment of model fragments by markers applied to the surface of the object. Used to improve the accuracy of stitching large objects. External photogrammetry systems are supported.

-

Basic Scan

Used to scan objects that cannot be digitized in other ways, such as museum exhibits. The fragments of the model obtained from different angles are combined according to the features of the object surface geometry.

Fully equipped with everything you need

Standard scope of supply includes:

Additional options

-

License key

If the main license key is lost or damaged, a new license can be generated for your scanner and an additional key issued.

The previous license is then blocked.

The previous license is then blocked. -

Protective case

The RangeVision PRO 3D scanner comes in a special plastic box with a tray for easy transportation and storage of the scanner. If you want to have additional guaranteed protection against impacts during transportation, instead of a standard box, the 3D scanner can be supplied in a special protective case. Depending on the configuration, the tripod and turntable can be supplied separately.

-

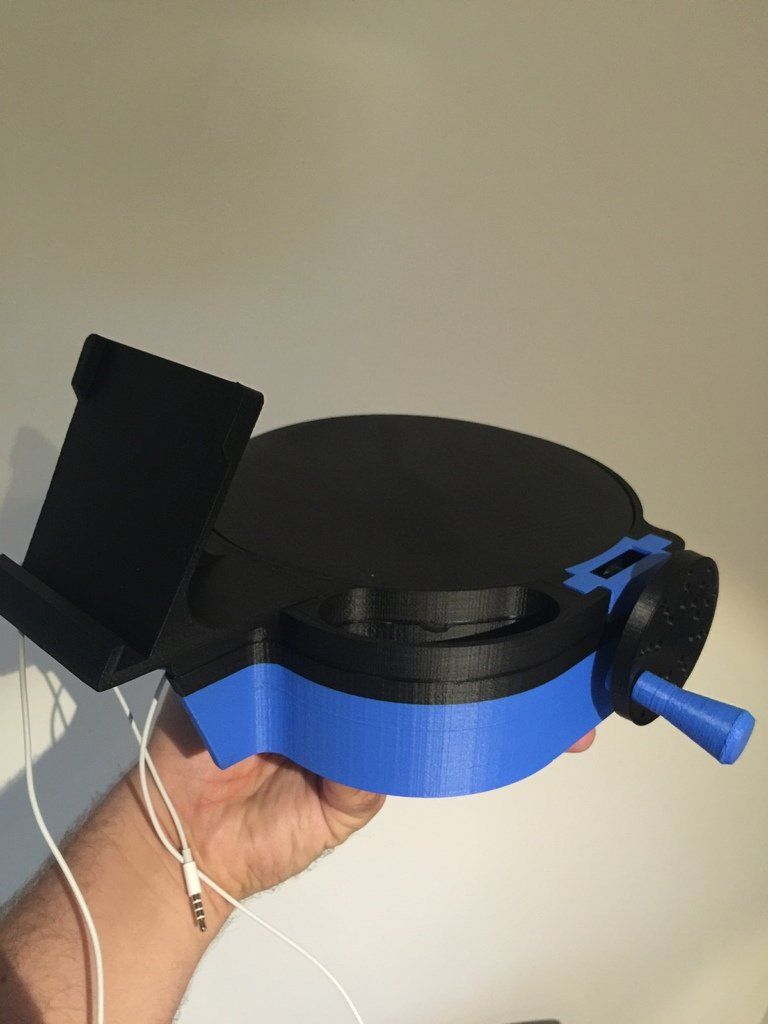

Turntable TL

The turntable allows you to automate the process of scanning small objects. The table platform rotates 360° through a predetermined angle, allowing you to scan an object from different angles and automatically combine scans. The turntable is connected to the control computer via a USB port, and to a 220V network via a power adapter.

Load capacity 60 kg Diameter 32 cm

-

Calibration fields

Set of additional calibration fields for working with different scanning areas.

-

PC

Control PC not included with RangeVision PRO 3D Scanner. It can be purchased separately if desired.

10 questions before buying a 3D scanner

3D model examples

-

Pinion View on site

-

Bracket

-

Disc View on site

-

Screw View on site

-

Game miniature View on site

-

Baseball View on site

-

Cork View on site

-

Car door handle View on site

-

Eastern imperial eagle skeleton.

Made by the Museum of Fine Arts in Budapest, Hungary. Solution Provider: 3D Parade 3dparade.com. View on site

Made by the Museum of Fine Arts in Budapest, Hungary. Solution Provider: 3D Parade 3dparade.com. View on site -

Chair leg View on site

-

Skull View on site

-

SsangYong Rexton

Specifications

| Scan Technology | structured illumination | ||

| Projector Resolution | 1920 x 1080 | ||

| Scan area, mm | 550x340x360 | 320x210x200 | 140x90x80 |

| Working distance, m | 0. | 0.52 | 0.35 |

| Accuracy, µm | 60 | thirty | eighteen |

| 3D resolution, mm | 0.18 | 0.10 | 0.04 |

| Object Size | from 5 mm to 5 m | ||

| Ability to capture texture | there is | ||

| Camera resolution | 6.4 MP | ||

| Model stitching | by markers, by geometry | ||

| Received formats | OBJ, PLY, STL, PTX, ASCII | ||

| Scanner Power | 220-250V | ||

| Connection interface | HDMI, 2x USB 3. USB 2.0 for desk | ||

| Supported OS | Windows 8.1/10/11 64bit | ||

| Rotary table | there is | ||

| Table platform diameter | 32 cm | ||

| Maximum table load | 60 kg | ||

| Table food | 220V-15.5V/2A | ||

| Dimensions of the scanner in the case | 620x420x460 | ||

| Scanner weight | 6.5 kg | ||

| Weight of the scanner in the case | 17.5 kg | ||

| Certificates | EAC | ||

| Guarantee | 1 year | ||

Note: Product appearance may differ from website photos. Control computer specifications are subject to change. Input devices, image output devices, cables, etc. are not included in the delivery.

Control computer specifications are subject to change. Input devices, image output devices, cables, etc. are not included in the delivery.

We are trusted

User reviews

Evgeny Bogosyan

EntrepreneurWe specialize in creating STL for CNC machines and 3D printing. Mostly we are approached by wood carvers and sculptors. All customers are impressed by the detail with which RangeVision PRO works. We are completely satisfied with the performance of the scanner and can recommend it.

Aleksey Kanaev

Scanning EngineerWe provide scanning services and regularly use PRO (except for scanning people). The versatility of the scanner is impressive! Due to variable scanning zones, we can work with any objects - from small parts of fasteners to body parts of construction equipment.

Where to buy

To purchase a 3D scanner, contact a distributor in your city!

Articles and reviews

Reverse engineering propeller for UAV

3D models of ancient artifacts or digital archeology

RangeVision PRO helps create UMATEX Rosatom sports body kit for YAMAHA R3 9 motorcycle0078

Converting a Maserati Levante into a Funeral Car

Any questions?

↑Thank you for your question!

Our manager will contact you shortly

Thank you for your application!

Our manager will contact you shortly

This site uses cookies. By clicking ACCEPT or by continuing to browse the site, you consent to their use. More.

By clicking ACCEPT or by continuing to browse the site, you consent to their use. More.

Structured Light Digitization vs. Handheld 3D Laser Scanning

With continuous advancement in technology, the 3D scanning market boasts a wide variety of brands, device categories and price ranges. Today we will take a detailed look at the key selection criteria for an industrial 3D scanner and provide information on the characteristics and applications of various types of metrological systems.

3D metrology scanner selection criteria

When evaluating the capabilities of various 3D scanning devices, the following points play the most important role:

User side:

- requirements for data quality, accuracy and detail;

- usage scenarios, size of scanned objects, textures and digitization time;

- budget.

From the manufacturer:

- user reviews;

- brand and services offered;

- software and updates.

Let's compare two examples of 3D scanning systems in our range:

OptimScan 3D Metrology Scanner with Blue LED Structured Illumination

The OptimScan system is designed to digitize relatively small objects with high precision and detail: cast and forged parts, molding and foundry tooling, plastic components, fine detail products, and the like. It can be used in conjunction with collaborative robotic arms, for example, for digitizing large objects - car bodies, stamped parts, and so on. Applications include automotive and transportation, electronics, molding and foundry tooling, aerospace, and others.

FreeScan UE Handheld 3D Laser Scanner

The FreeScan UE 3D Scanner lets you capture medium to large objects, as well as work with dark and reflective surfaces. Examples include casting dies, clay models, automobile bodies, aircraft engines, large blades and vanes, and the like. Applications include automotive, rail, energy, construction and others.

Structured Illumination 3D Scanners: Precision and Detail

High-precision systems based on structured LED technology and handheld 3D laser scanners generate point clouds in different ways. The former build the cloud in separate solid frames, while the latter generate a cloud by combining and merging frames with a partial display of the object.

Structured light 3D scanning provides:

- stable accuracy of the metrological level, in the case of 3D scanners of the OptimScan line, reaching 0.005 mm;

- good detail.

Level of detail when digitizing with the OptimScan 3D scanner

3D handheld laser scanners: compact and versatile

Handheld 3D scanners offer the advantages of being compact and able to adapt to a wide range of materials through the use of laser emitters:

- handheld 3D laser scanners are flexible, easy to use and fast: the FreeScan UE 3D scanner weighs only 750 grams, and it takes about ten minutes to digitize a car;

- wide range of material compatibility: dark and reflective surfaces can be digitized without the need for frosting sprays;

- high accuracy, in the case of FreeScan UE up to 0.

02 mm with high repeatability.

02 mm with high repeatability.

Key points for choosing between two types of metrology 3D scanners

The main thing to pay attention to is data quality requirements and working conditions.

For high demands on quality and detail, we recommend using 3D scanners with structured illumination technology. Examples:

3D scanning of small objects with high precision and detail

3D scanning on the production line with the required accuracy in the range of 0.005-0.015 mm

If compactness and versatility are in the forefront, handheld 3D scanners are worth using. Examples:

3D scanning of stationary, bulky, non-separable objects

3D scanning of dark and/or reflective surfaces without matting spray option

In general, structured light 3D scanning is best suited when there are strict requirements for accuracy and detail. When working with dark and reflective surfaces, matting sprays can be used. Handheld 3D laser scanners, on the other hand, are well suited for working in tight spaces and are highly compatible with various types of surfaces.

Handheld 3D laser scanners, on the other hand, are well suited for working in tight spaces and are highly compatible with various types of surfaces.

There is a misconception that 3D scanning systems based on structured illumination technology are not versatile enough and have too low performance. In fact, these 3D scanners demonstrate high capture speeds and good repeatability, especially when scanning objects on turntables, working with complex geometries, and even in cases where repeatability control of production batches is required.

For example, digitizing an 8 cm impeller pump using a turntable takes only about one minute.

In addition, high-precision structured light 3D scanning systems are very effective in conjunction with collaborative multi-axis robotic arms and coordinate measuring machines with automatic data processing.

3D inspection of the F-35 fighter assembly line

3D metrology scanner applications

3D scanning with structured LED illumination

Example #1: 3D scan of the bottom of the optical modem case

Example #2: 3D scanning of mobile phone components

Example #3: Digitizing thin walls with a minimum thickness of 0. 16 mm

16 mm

Example #4: Digitizing a 6 mm part

Example #5: Digitizing a form with the required accuracy of 0.03 mm

3D handheld scanner applications

Example #1: 3D scan of an aircraft engine

Example #2: 3D scanning of cast metal parts

Example #3: 3D scan of a reflective mold die

Conclusion

We hope that we have been able to provide useful information for the selection of the most suitable equipment. To summarize:

- For precision 3D scanning of small and medium-sized parts, use 3D inspection scanners with structured LED technology;

- For medium to large parts, choose handheld 3D laser scanners;

- Many users with high requirements for measurement control prefer to keep both structured light scanning systems and 3D laser scanners on hand, using one or the other depending on the task at hand, thereby increasing the overall efficiency of design and manufacturing processes.

Learn more

9

9  0

0