Best selling 3d printed items

14 Things to 3D Print and Sell in 2022 – Clever Creations

Thinking about starting a 3D printing business? Want to try to sell 3D printed items on the side? You may be wondering where to start.

There are several ways to make money with a 3D printer, for example, you can open an online shop to sell 3D printed items, or offer print-on-demand 3D printing services.

In this article, we’ll cover how and where you can sell 3D printed items. We’ll also show cool (and profitable) ideas for things to 3D print and sell, and explain what you need to know before you turn your passion for the hobby into a business.

What to keep in mind when selling 3D prints

Selling 3D printed items can be a lucrative business. However, you need to consider a few things before opening your shop and taking your first orders.

Profit margins

Before setting a price for your 3D prints, you should calculate your costs and margins. This isn’t unique to 3D printing, since all business owners need to know if their product will make a profit.

You need to consider all costs associated with 3D printing the item and selling it. This includes the 3D printer cost, but also the print materials, shipping supplies, 3D printer power usage, seller platform fees, and wages for your time. The more thorough you are, the more accurate the results of your calculations will be.

Copyright

The issue of copyright when selling 3D prints is twofold. If you are printing and selling a 3D model created by someone else, you must follow the designer’s license. If the designer has listed the model as non-commercial, you cannot sell it. If you still choose to do so, they can take legal action against you or your business for infringing on their copyright.

Another layer of the copyright issue is that you cannot sell prints of copyright or trademarked material. This is true even if the model has a commercial license. For example, Bulbasaur is a trademarked and copyrighted character of Nintendo. Thus, you can’t sell Bulbasaur planters even if the 3D model has a public domain license.

Where to sell 3D prints

You can sell your 3D prints using many different channels. Live events like craft fairs, festivals, and trade shows are a great way to garner in-person sales. Consignment shops and displays in local businesses can give your 3D prints a brick-and-mortar presence without the overhead.

Online eCommerce platforms are by far the easiest and most widespread sales channels to use. You can start your own website and sell directly from there or use an existing marketplace.

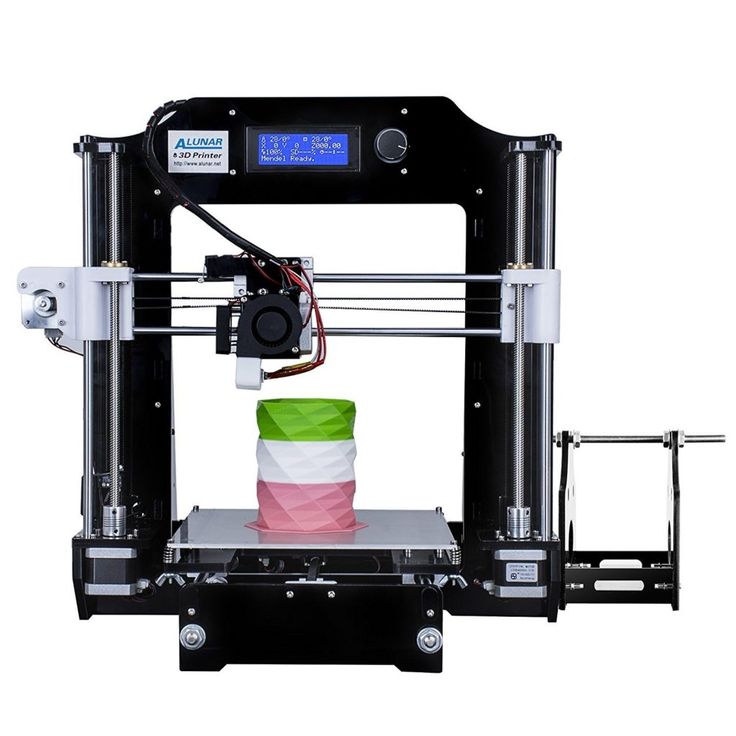

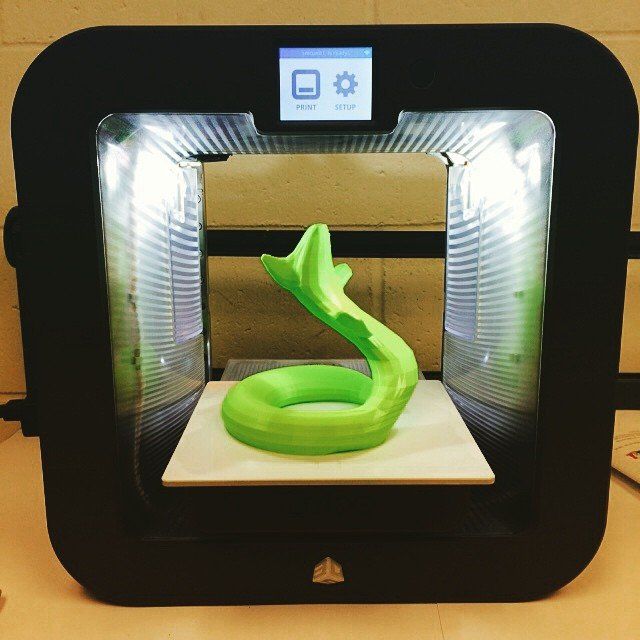

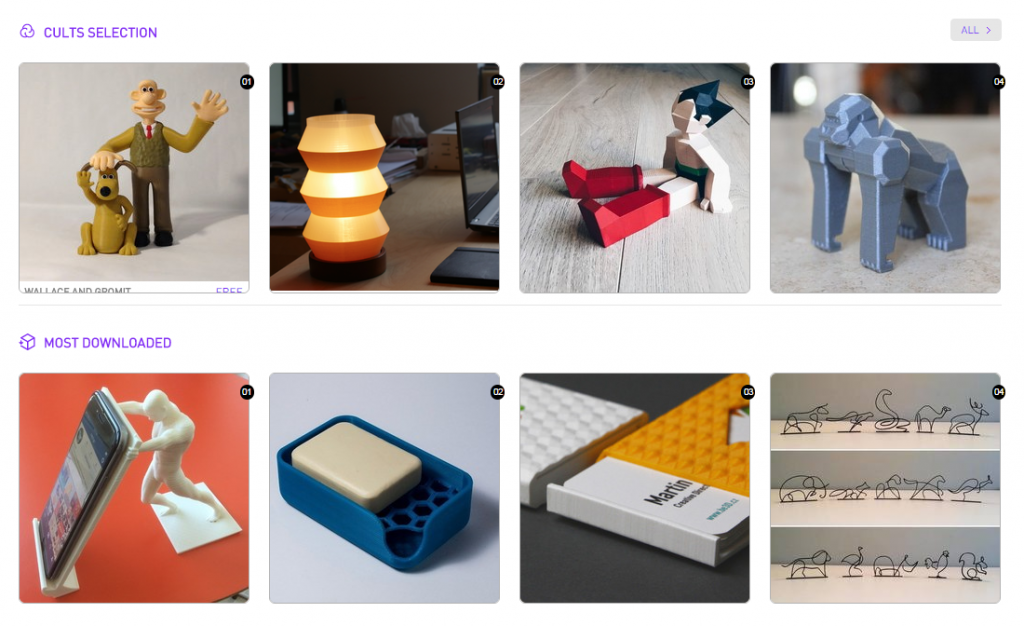

Image: crosslink via MyMiniFactory

3D printed vases are a hit on almost any platformThe latter option is much easier for beginners who don’t know much about online retail. By using existing marketplaces, you can leverage their existing audience and make money with a 3D printer in no time.

Etsy

The online marketplace Etsy focuses on handmade, vintage, and handmade supply products. They charge a $0.20 listing fee per item every four months (or until it sells and is relisted). They also take a percentage of the sales revenue when an item sells.

They also take a percentage of the sales revenue when an item sells.

Many 3D printing shops have been very successful in selling items like planters, cookie cutters, and toys on the Etsy platform. Aside from those, there are plenty of other things to 3D print and sell on the platform.

Recommended:

The 5 Best 3D Printers for Making Cookie Cutters

Amazon

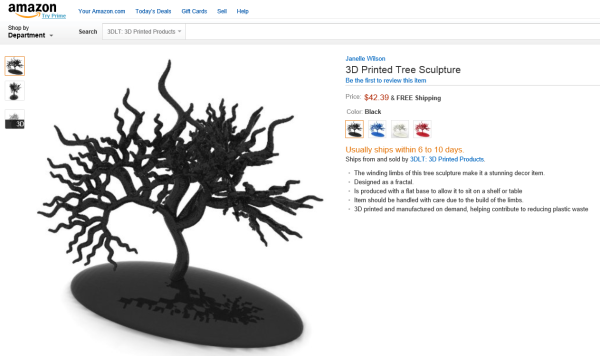

The Amazon marketplace is the largest eCommerce platform available. Amazon integrates third-party sellers into their warehouse system. An independent 3D printing shop using the platform can send their prints to the nearest warehouse and Amazon would process them and ship them out as they sell.

eBay

More dated than most of the other platforms on this list, eBay never quite left its days as an auction site behind. It has at least integrated the ‘Buy It Now’ functions that allow it to work more like an eCommerce platform.

New sellers get free listings to get started, then pay a flat fee per listing and a percentage of their revenue.

eBay shouldn’t be your main eCommerce platform for making money with your 3D printing business. However, it works well as a supplement to the other services we’ve listed.

Fiverr

Starting as a place to pay people to do menial tasks for $5, Fiverr has grown into a labor outsourcing giant. They are now competing with the likes of Upwork, Freelancer, and so on.

Fiverr’s system pays you for your labor, so you are not listing your product. You are listing your ability to 3D print cool 3D prints for other users.

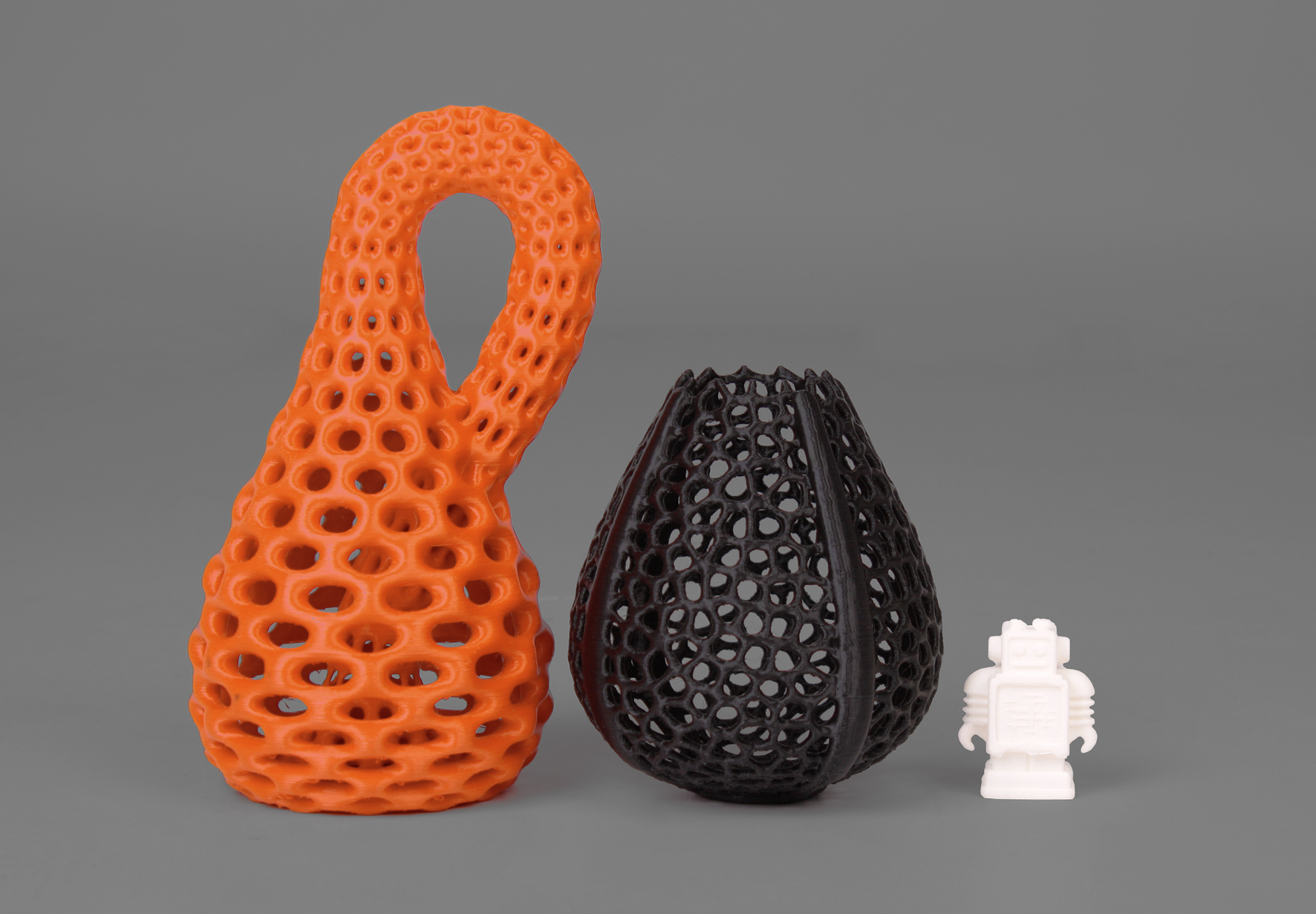

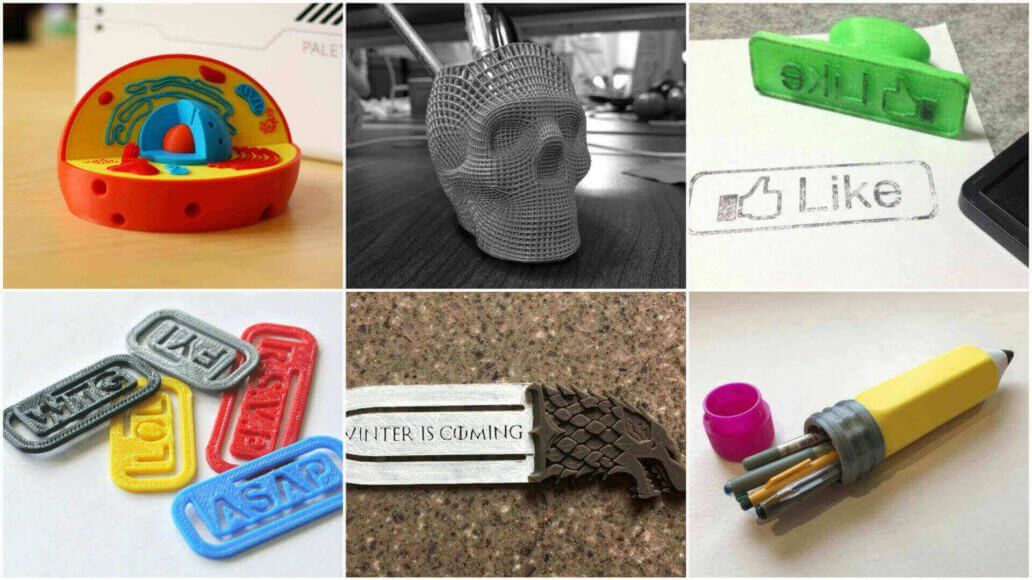

Best 3D Printed Items That Sell

1. Miniatures (D&D, Warhammer, etc.)

Image: BaconuCrazy via MyMiniFactory

One of the best things to print and sell with your 3D printer is miniatures for tabletop games like D&D and Warhammer.

These figurines are small and highly detailed. This means that if you want to make money by 3D printing miniatures, you are best off with a resin 3D printer. On the other hand, larger terrain pieces are best suited for traditional fused deposition modeling (FDM) 3D printers.

Recommended:

Resin vs Filament 3D Printers: What’s the Difference?

Part of the appeal of miniatures is that they are customizable. They are sold unpainted (similar to some model kits) so the buyer can decorate and paint the miniatures as they see fit. This is excellent news for anyone looking to make money printing by selling 3D printed miniatures. No painting means there is less need for post-processing work.

3D printed miniatures are well-liked among consumers, as customers can buy miniatures that aren’t available to them through traditional manufacturing companies.

Consumers also enjoy commissioning customized minis. These figurines are often original characters in their campaigns or stories. If you have the level of skill needed to model and/or sculpt these personalized minis, that can be a significant upcharge for your 3D printing business.

If you want to go this route, you might want to check out our article on the best 3D printers for miniatures.

2. Cosplay items (helmets, armor, props, etc.)

Image: TieKai via MyMiniFactory

Cosplay items are one of the most labor-intensive options on the list of things to 3D print and make money with. Taking hours or days from start to finish, making cosplay costumes and props to sell is not for the faint of heart. These items (especially 3D printed armor sets and 3D printed helmets) are large parts that take hours to print and post-process.

Most users expect their cosplay items to be finished and painted to a professional level when they buy them. This takes a great deal of time and effort on your part as the seller. The upside to this is that you can charge a premium price for these items to make up for the extra time spent 3D printing and assembling them. Customers are often willing to pay well for these items.

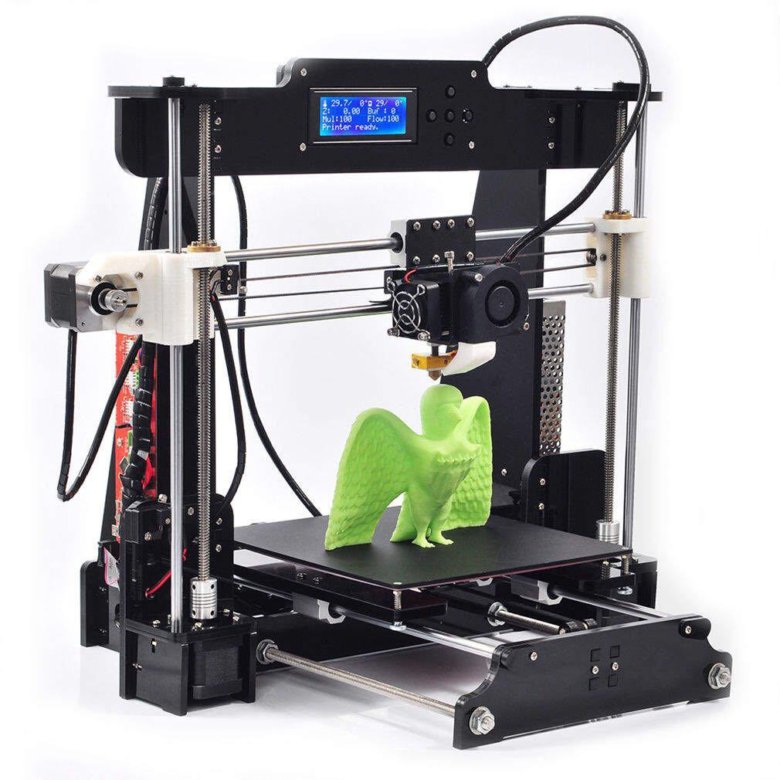

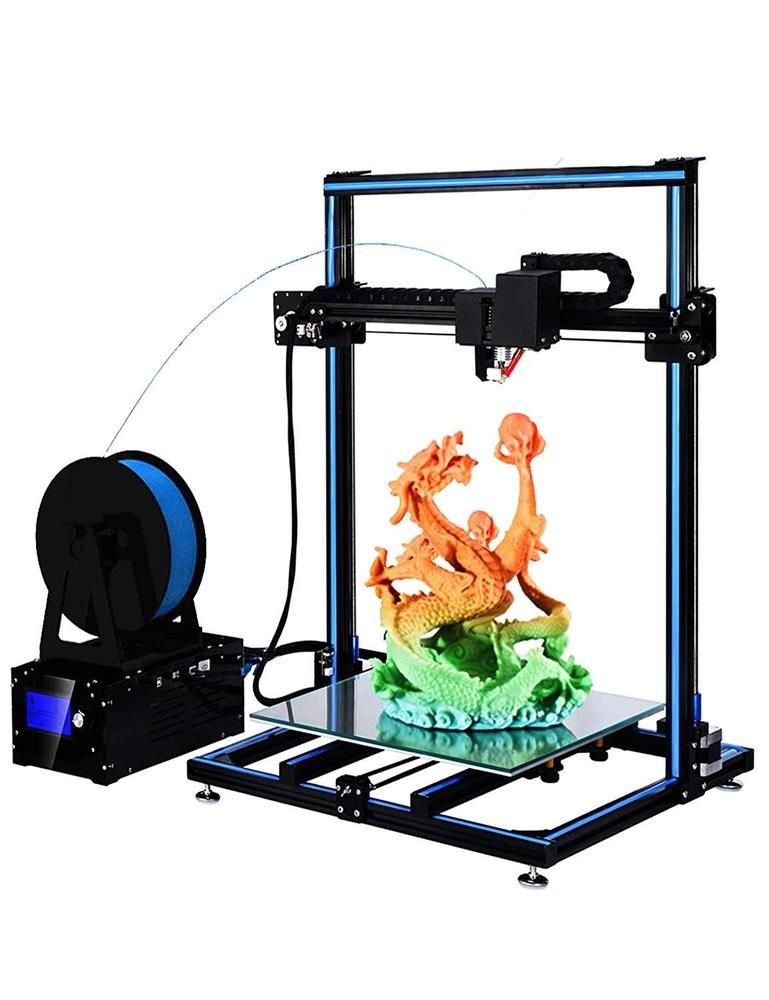

If you want to make money 3D printing and selling cosplay items, it is a good idea to use a 3D printer with a large build volume. That way, you won’t need to spend time splitting parts to fit the build plate and gluing them together when the printing is complete.

Use a large 3D printer for cosplay, and you can simply 3D print full-size pieces in one go.

3. Jewelry

Image: Muttonheid via MyMiniFactory

The jewelry market is a high mark-up market with excellent profitability if approached correctly. Its main problem is that it is oversaturated with artisans and hobbyists. Your designs and marketing both need to be unique and strategic in this space. Otherwise, it is impossible to have any visibility on most of the eCommerce platforms mentioned in this article.

Since jewelry pieces tend to be small, you need negligible amounts of raw material to print each piece. This keeps production costs low and makes it possible to create many at once. Like miniatures, jewelry requires a high level of detail. For the highest-quality pieces, you will need a 4K resin printer or higher (6K/8K).

Recommended:

The 8 Best 4K+ Resin 3D Printers

FDM 3D printers are not entirely ineffective for jewelry making. They can still print forms for silicone molding material. Then use those molds with things like polymer or precious metal clays, resins, low-temperature metals, and other castable materials.

Then use those molds with things like polymer or precious metal clays, resins, low-temperature metals, and other castable materials.

3D printed mold forms need to be smooth and non-porous before molding. You’ll need to sand, fill, or use other extensive post-processing work to achieve the right look.

If you can keep the cost low and produce (customized) jewelry that you promote effectively (e.g. through social media), you will have a good chance at creating a successful 3D printing business in the jewelry niche.

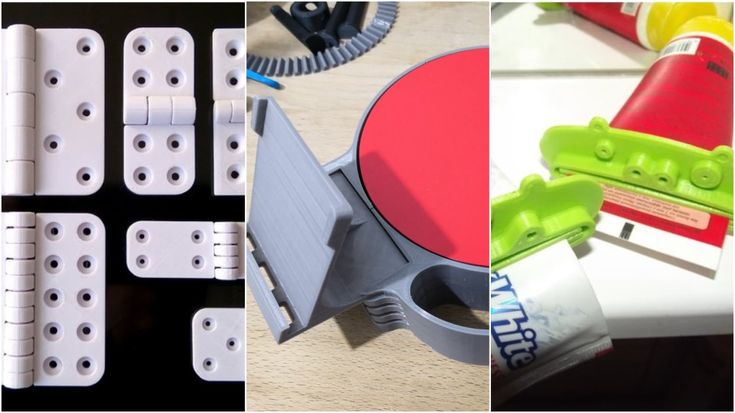

4. Toys

Image: animm07 via MyMiniFactory

3D printed toys are a great option to sell. However, you need to be cautious about regulations on children’s products when choosing to manufacture them with your 3D printer. Some countries require certification to make and sell certain items. This mainly pertains to products for babies and very young children. The guidelines vary from country to country.

Fidget toys and articulated creatures geared towards older kids and adults run a much lower risk of liability and are quite popular. These items are even more memorable when printed from something like color changing, glow in the dark, or filled (Woodfill, Copperfill) PLA filament.

These items are even more memorable when printed from something like color changing, glow in the dark, or filled (Woodfill, Copperfill) PLA filament.

Recommended:

The 8 Best 3D Printers for Kids

Most toys are quick and efficient to make. They print easily on a traditional FDM 3D printer and don’t require much post-processing. Plus there are plenty of cool toy ideas out there that you can 3D print.

5. Nerf gun accessories

Image: GoKidd via MyMiniFactory

Customized or unique Nerf gun accessories and gun bodies are a popular niche in the 3D printing community. They also have quite a demanding retail market.

Items like sights, dart holders, extra clips for discontinued products, larger magazines, and improved barrels are all popular Nerf-related 3D prints. They are easy to create on most 3D printers and fit well with the other ideas of things to 3D print and sell.

It is also not uncommon for Nerf-enthusiasts to want custom guns that the company has not or will not make. Sometimes this means turning a cosplay prop into a functioning dart gun. Other times it means making a gun body that is not commercially available.

Sometimes this means turning a cosplay prop into a functioning dart gun. Other times it means making a gun body that is not commercially available.

Cosplay prop and customized Nerf gun designs are great designs to sell. They have high markup potential and popularity. You can have a profitable business in this niche as long as you don’t overstep trademark rules.

The name Nerf is technically protected under trademark laws. It can help to use generic terms like dart gun, foam dart weapon, etc. in place of the brand in your product listings. This makes sure you don’t gain the attention of any corporate lawyers. They do periodic intellectual property sweeps on popular eCommerce platforms.

Accessories have a lower profit margin than 3D printing full Nerf guns. However, most users don’t care if their dart holders or magazines are not sanded smooth, so they are a quick and easy way to make money with a 3D printer.

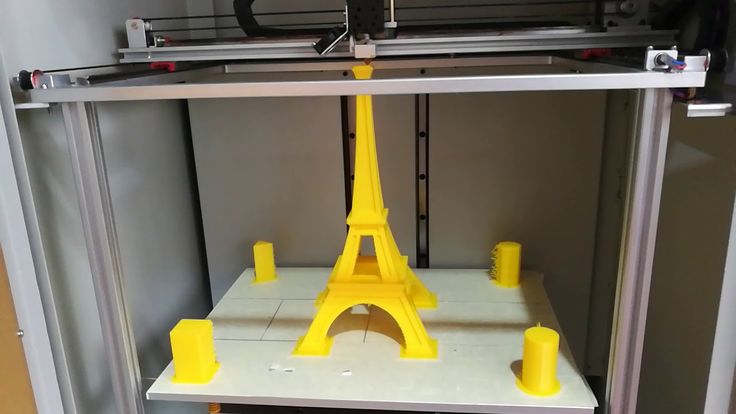

6. Architecture models

Image: Format3D via MyMiniFactory

Architectural models are a difficult 3D printing project. They often recreate both the interior and exterior design of a building. They are usually printed in pieces so that the roof and separate levels can be removed for easy access to all the interior elements. Because of their complexity, they can be sold at a high markup and are a great option to 3D print and sell.

They often recreate both the interior and exterior design of a building. They are usually printed in pieces so that the roof and separate levels can be removed for easy access to all the interior elements. Because of their complexity, they can be sold at a high markup and are a great option to 3D print and sell.

Architectural prints can be used for prototyping/visualization, education, play, and decoration. Selling house models as a dollhouse toy or a recreation of a famous building for education or decoration purposes is a great way to market them to consumers.

Some architectural and engineering firms like to have tangible models of their designs. This is helpful for prototyping, sales meetings, and even for troubleshooting the design. Aligning yourself with local companies looking for this 3D printing service could be a beneficial opportunity.

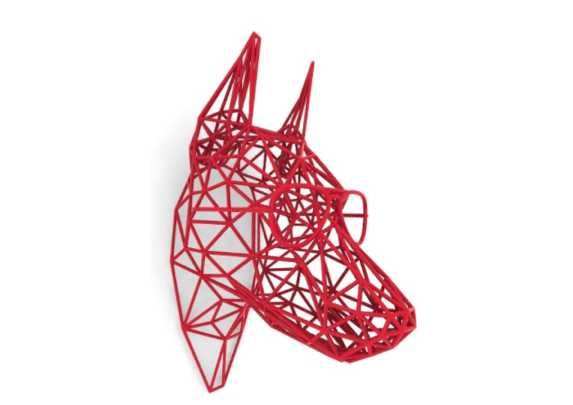

7. Figurines and statues

Image: philippeb66 via MyMiniFactory

Figurines and statues are yet another group of 3D printed products that sell exceptionally well. Many of the figurine and statue 3D models that are available online are of copyrighted content. Things such as characters from video games, movies, or tv shows. These are not particularly helpful resources for making commercial items.

Many of the figurine and statue 3D models that are available online are of copyrighted content. Things such as characters from video games, movies, or tv shows. These are not particularly helpful resources for making commercial items.

Yet, there are still plenty of options for unbranded designs either through ready-made models or customized ones that you design yourself. Animals, mythological creatures, etc. are all popular designs to 3D print and sell without fear of copyright infringement.

Custom figurines of either customers or their pets are another option to diversify your product offerings. This does require an advanced skill level for 3D modeling and/or sculpting. If you aren’t there yet, keep it as an option for the future. In the meantime, you are welcome to look at our recommendations for free 3D modeling software.

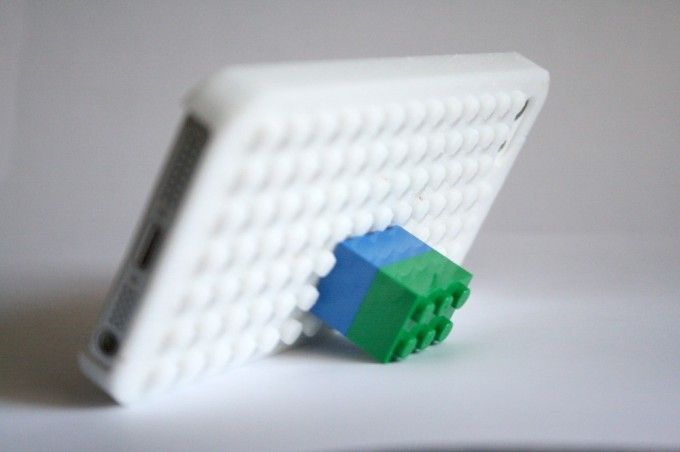

8. Phone cases

Image: Malex via MyMiniFactory

Phone cases are a large market, and 3D printed versions are no exception. There are countless possibilities for making and selling phone cases with your 3D printer. You can print basic stretch cases using a flexible filament like TPU, or decorative hard cases made from PLA or ABS.

You can print basic stretch cases using a flexible filament like TPU, or decorative hard cases made from PLA or ABS.

Recommended:

The 10 Best PLA Filaments for 3D Printing

Basic cases are inexpensive and readily available to the consumer from most stores and online retailers. If you want to sell cases, it’s best to use unique or customized models.

The most eye-catching 3D printed options emphasize the technical capabilities of 3D printing. The geared iPhone case is a great example.

A large difficulty with 3D printing a phone case to sell is that there are so many different phone models available and they update constantly. As such, you may find it difficult to source consistent phone case models. You may also realize your designs are becoming quickly outdated if you model them yourself.

The best solution to the variability of phone case compatibility is to start out 3D printing and selling cases for only a handful of different phone models. From there, you could make the decision to scale up or down as needed.

9. Self-watering planters

Image: diegopvp via MyMiniFactory

Planters in general are a hot seller in the 3D printing world, but self-watering planters are even more popular. They are hard to find in stores, making them a fantastic item to add to your business’ offerings.

Self-watering planters are typically designed in two parts: the planter and a water reservoir.

Since both pieces are in contact with water, they need to be watertight in order to not leak. Typical 3D prints have microscopic gaps between each layer. Water can seep through these layers and onto whatever surface the print is sitting on. A clear, non-toxic sealant is a great solution for this problem and gives customers a much better experience with their planter.

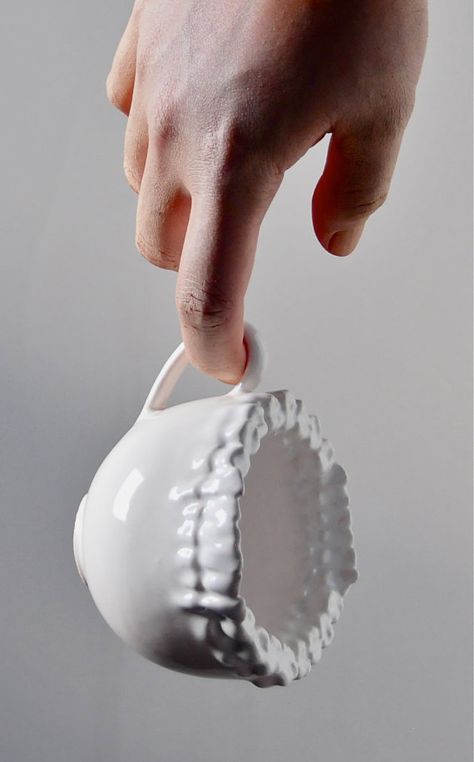

10. Designer vases

Image: didierklein via MyMiniFactory

3D printed vases are another home décor product capable of generating a large number of sales. With the exotic shapes that can be created in CAD and made on a 3D printer, the end results are far more modern and sophisticated than vases that are commercially available.

Like the planters mentioned above, vases need a sealant to make them watertight. They are quick and easy to make and can be 3D printed as one continuous spiral. The continuous print lines that this creates improve the speed and quality of the print job.

Items like vases can be printed on either FDM or resin 3D printers (if the print bed size is not an issue for the latter). Extruder-driven ceramic and clay 3D printers are also an excellent option if you are lucky enough to have access to one.

Regardless of the type of 3D printer you use, vases are an excellent choice for making money with a 3D printer.

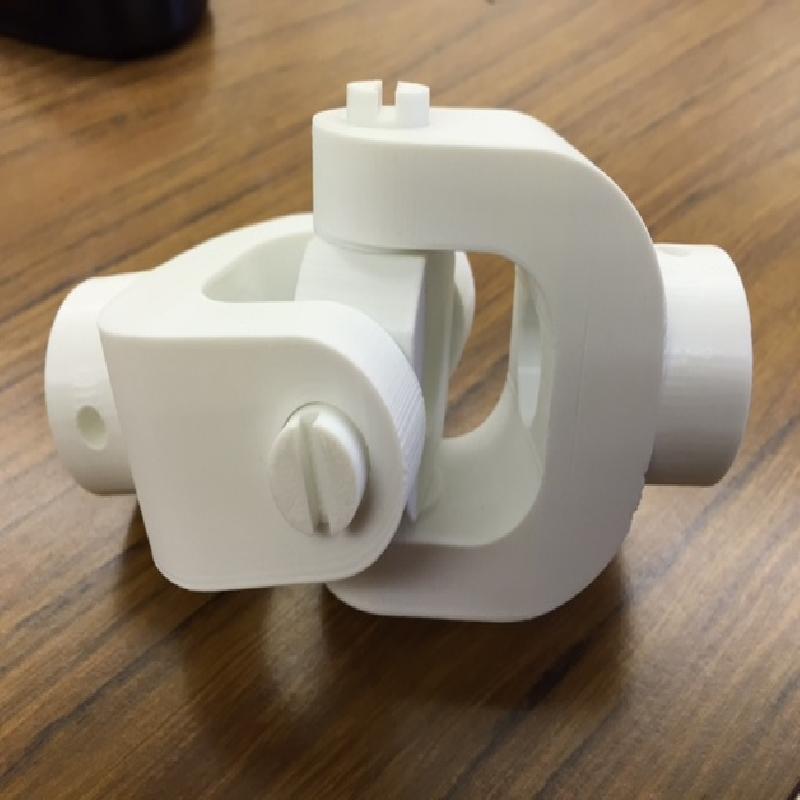

11. Raspberry Pi cases

Image: Laza via MyMiniFactory

Raspberry Pi boards are a common component in homemade electronics projects. Pi boards are inexpensive single-board computers that are suitable for many projects. For example, they can control smart home equipment, act as a controller for other projects, power a video game emulator console, or run as an underpowered but functional DIY computer.

Since Raspberry Pi’s are so small, it is easy to print cases and enclosures for them. The cases not only protect their components but also make them look more functional and professional. Selling the cases to interested tinkerers has sales potential by itself. If you happen to be handy with electronics, you could also sell fully assembled Raspberry Pi projects.

12. Eyeglasses frames

Image: Sacha_Zacaropoulos via Thingiverse

3D printed eyeglass frames have risen in popularity over the years. Several major eyewear companies have started selling FDM-produced 3D printed eyeglass frames. These products are usually made from WoodFill and other specialty filaments.

Even so, consumers are also flocking to smaller businesses that can design a new pair of frames. Sometimes they want new frames designed for their existing lenses if their store-bought frames break. Other times, they want to transfer blue light or sunglass lenses to a new pair of 3D printed frames for comfort or aesthetic reasons.

We don’t recommend using PLA or other low-temp filaments on this project. If the person wearing them spends enough time outside on a hot day, the frames could soften and warp from the heat. ABS and Nylon are safer filament choices, as they have a higher glass transition temperature (i.e. they melt at higher temperatures).

13. Lamps

Image: Frank Cheung via MyMiniFactory

You can make a variety of different types of lamps on a 3D printer. They are popular choices when it comes to making and selling 3D printed items. Home décor is a thriving market. When you can offer something unique for their living space, design-minded consumers take notice.

Lamps (especially pendant lights) most often require a 3D printer with a medium to large build volume. Because of their shape and texture, most designs don’t fare well when split and glued back together. Seams also change the way light passes through the filament, so they may be noticeable once the light is on.

14. Landmarks

Image: ShakeandB1ake via MyMiniFactory

Landmark models and statues recreate well-known buildings, places, statues, and other monuments. They vary from highly-detailed architectural models of famous buildings to sites like Stonehenge. They don’t usually come apart as architectural models do.

These models are popular sellers with tabletop gamers. They are sometimes used in tabletop campaigns and world or story-building exercises. They also make excellent educational tools and are great additions to the modern classroom.

Frequently asked questions

What are the most popular 3D printed items?

Cosplay props, planters, and miniatures are some of the biggest sellers. The popularity depends on which platform you are selling on. For example, on Etsy, the main customer base is looking for pretty, trendy things. Beautiful planters, jewelry, and the like will be most popular.

The best way to learn what is selling on your platform is to do a little research. Find the shops with the best sales numbers, see what their bestsellers are. Use that as an estimate of which categories and niches are most popular. It will be much easier to make money with a 3D printer by finding the niche that works best for you and to fill it with unique products.

Find the shops with the best sales numbers, see what their bestsellers are. Use that as an estimate of which categories and niches are most popular. It will be much easier to make money with a 3D printer by finding the niche that works best for you and to fill it with unique products.

Is it legal to 3D print and sell?

It is perfectly legal to sell your 3D prints. Issues rarely arise if you follow licenses of the models you download and you don’t sell trademarked goods. There are some extra considerations for certain groups of products. For example, you sometimes need special certification to make or sell items directed at young kids or babies.

Certifications vary from country to country, so research the limitations and laws of your country to find out more.

The easiest way to avoid liability is to design your own models to 3D print and sell. Creating your own models avoids the complications of using other people’s intellectual property.

Image: TobiasKuijper via MyMiniFactory

Designing your own 3D models is a good way to avoid copyright issues when selling 3D printsIs selling 3D prints profitable?

Depending on what you make and how you market it, selling your 3D prints can be a very profitable way to make money online. To get the best results from selling 3D printed items, you need to do thorough market research.

To get the best results from selling 3D printed items, you need to do thorough market research.

You should look at what items are selling, where they are selling, and what you can do to stand out.

Do people buy 3D printed objects?

They sure do! As awareness of 3D printing technology increases, more people understand it is an easy way to get their hands on custom or unique items.

Be sure you are very clear in your descriptions about what material the item is made from. It is common to see customers confuse 3D printed items with wood in their reviews.

Conclusion

That’s everything you need to know about selling your 3D printed items. Do you sell your prints? What’s the most difficult part of running a 3D printing business? Let us know in the comments below!

3D Printed Items That Sell - How to Make Money With Your 3D Printer!

3D printers are one of the technological marvels of our time, and people get them for many different reasons. Some are hobbyists wanting to try something new, others are artists and professionals of various kinds looking to expand their craft.

What we’re talking about here is in effect creating your own e-commerce business by looking for those niche things to 3D print and sell.

What we’re talking about here is you finding a product niche that ideally you’re enthusiastic about that you can provide products for sale that a specific group of customers want.

There are many benefits, and little downsides to starting a business this way. If you already have a 3D printer – you’re already half way there to making money with a 3D printer.

Don’t have a 3D printer yet? The best 3D printers in every price range

This article is going to cover the different ways you can set up your own business selling 3D prints, with different product ideas in different niches. Any one of these products can be used right now to create a profitable 3D printing-based business, and hopefully they’ll spark your imagination for thinking of other product ideas and niches.

Table Of Contents

- What Should You Know?

- It’s never been easier to start an e-commerce business

- Copyright

- Marketing

- Make Money With Your 3D Printer By Starting Your Own Site

- What 3D Items Sell Online?

- Nerf Gun Accessories

- Cosplay Clothing and Accessories — hugely popular 3D printed items that sell to superfans

- Customized Shoes (Flip Flops)

- Statuettes and Figurines — great 3D printed items that sell

- Architects’ Modeling

- Jewelry & Ornaments

- Movie-grade Props

- Vases and Plant Pots

- Retro Raspberry PI Cases

- Bespoke PC Cases

- Cell Phone Covers

- Robotics Kits

- Own Range of Drones, RC Planes & Accessories

- Toys

- Current Trend

- Customized Ear Buds

- Where Can You Sell Your 3D Prints?

- Thingiverse

- Etsy

- Fiverr

- Amazon

- Conclusion: is it worth selling your 3D prints to make money?

But first, here’s some key things you should know.

What Should You Know?

It’s never been easier to start an e-commerce business

With a plethora of Marketplace channels to sell your 3d prints on and low-cost ways to create your own e-commerce website. What’s more, often the most problematic issue in e-commerce is product sourcing – but you already have that sorted, sitting on your workbench.

A 3D printer is the perfect micro-factory for many reasons. You can update your designs and print new revisions of your product near-instantly, keeping your inventory up to date in real-time. In fact, you don’t even need to hold a physical inventory.

Let’s say you get your first order at 5:30pm on a Weds night? Set the printer on an overnight batch, pick, prepare and ship by Thursday morning. The customer gets their order (hopefully) on Friday, and you’ll be getting great feedback by the weekend.

OK, so that’s a little over-simplified. Business is never that simple, and let’s face it – 3D printing isn’t always either. But this does illustrate the potential once you’ve smoothed out your processes.

But this does illustrate the potential once you’ve smoothed out your processes.

What we’re not talking about here though is selling 3D printed items that are custom for people. The margins are too low, because so many people do it. You can’t really brand a commodity like that. We’re also not going to choose items that sell simply because of the novelty that they’re 3D printed – like useless cheap trinkets.

The “Ohh wow, that’s 3D printed?!” reaction at your friend’s dinner parties wears thin pretty quickly…

No, we’re talking about creating quality products, that frankly the customer couldn’t care if they were 3D printed or not. They just care that they fill a need, or want that they have and the quality of the product and your service is something they can rave about. See the difference?

All the examples I’m going to list through below are taken from existing businesses that are actually doing this, right now. Many of them are currently our customers. People are doing this stuff right now, on standard FDM printers.

There are many varieties of complexity, from simply ‘print & send’ easy to make prints to high-end prints that need a bit of finishing. It might help to choose something in your range of complexity. Let’s dive into what could potentially be your next e-commerce business!

Copyright

Before making money with your 3D printer, there are a few key things to note. The first of which is the legal ramifications of selling 3D printed items that resemble the likenesses of copyrighted IPs.

While 3D printing figurines of famous characters is fine for personal use, selling them for a profit can have legal consequences. Be sure to know the laws surrounding fair use of copyrighted material before bringing your work to the marketplace.

The easiest way to avoid these consequences is to only 3D print and sell original or open-source designs. However, some referential designs such as cosplay accessories and ornamental logos are safe to 3D print for profit.

To design your own 3D printable models, check out:

Our ranking of the best free 3D modeling software

Or, check out our list of the best sites where you can download free 3D printer files

Marketing

Most online sellers these days turn to social media to advertise their products. Many online retailers will recommend you avoid inundating or spamming particular pages or timelines, so some finesse will be required to make sure you get your product out there without bothering potential buyers.

Many online retailers will recommend you avoid inundating or spamming particular pages or timelines, so some finesse will be required to make sure you get your product out there without bothering potential buyers.

As is the case with many artforms, selling 3D printed items requires good presentation. Professional, high quality photos show off your creations and make them appear more desirable to consumers, as do in-depth descriptions and any necessary instructions for assembly to let customers know they’re in good hands.

Make Money With Your 3D Printer By Starting Your Own Site

Many artists have found a new way to reach their market by cutting out the middle man and starting their own websites and blogs to show off and sell their creations and make money with their 3D printers.

Selling 3D printed items on your own site does remove commission costs, but at the price of having to do just about everything yourself. All marketing and publicity needs to be done by you, and self-made businesses like that take some time as most people are hesitant to give money to unverified businesses.

But with enough know-how, careful self-promotion, and good word-of-mouth, you’ll be able to sell your 3D printed stuff in no time.

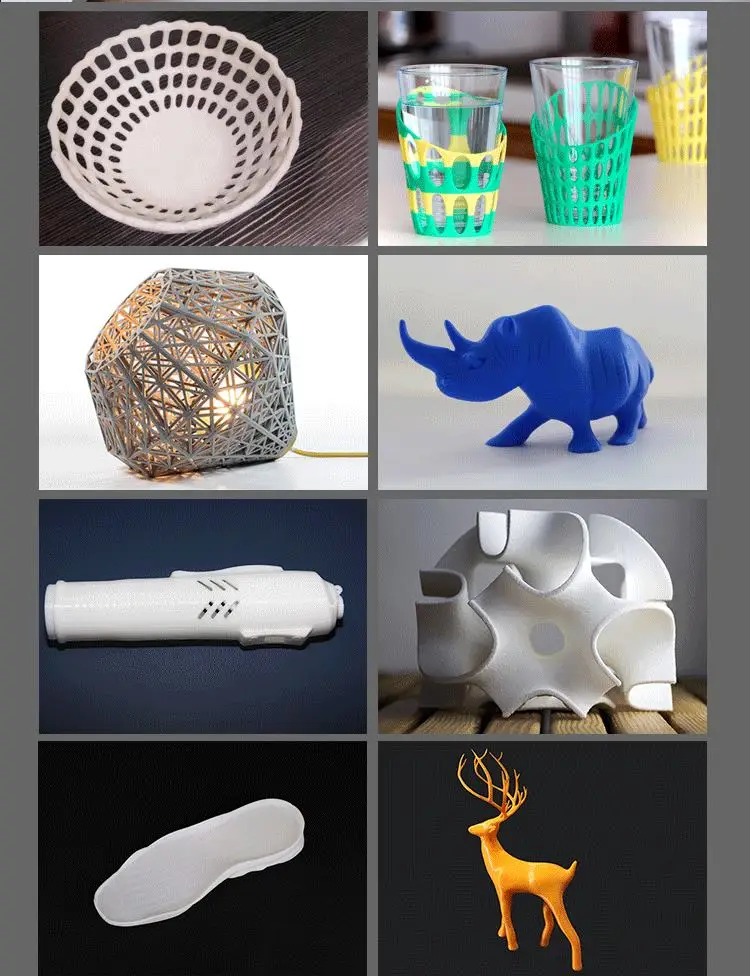

What 3D Items Sell Online?

If you can print it, then you can almost definitely sell it. While choosing which 3D printed items to sell comes down to your own design specialties, preferences, and what your hardware is capable of, making money with a 3D printer can be achieved in many ways.

Below are just a few of our favorite ideas for what you can 3D print to sell.

Nerf Gun AccessoriesThis looks a bit obvious (and yes, I briefly covered Nerf mods in another article) but I wanted to kick things off with something that perfectly encapsulates what I’m trying to get across here. There’s a growing following around Nerf guns, they’ve grown from a child’s toy in just a few years to a necessary component of office warfare.

Just doing a quick search on eBay for “3d printed nerf” lists a host of cool aftermarket mods. From the picture above, you can see that most of them are really very simple prints. That silencer that sells for $34 US? It likely only uses about 50g of filament (at most). That means you could print 20 from a 1KG spool costing around £30. That means those silencers would cost you about £1.50-£2.00 to print each one.

From the picture above, you can see that most of them are really very simple prints. That silencer that sells for $34 US? It likely only uses about 50g of filament (at most). That means you could print 20 from a 1KG spool costing around £30. That means those silencers would cost you about £1.50-£2.00 to print each one.

That’s a pretty incredible profit margin! http://3dprintedsolid.com/ have even gone as far to release their own custom fully modded Nerf guns costing up to $300!

Pros: This business would be very easy to set up. I imagine a lot of the designs for mods are already available free on Thingiverse and the prints are very simple. Prints are fast with no to little post print processing.

Cons: Easy to replicate and potentially lots of competitors could set up quickly (but then again, which business doesn’t?). But you could stay ahead by creating your own unique designs as the demand grew.

Read more: the coolest 3D printed Nerf files you can download and print today

Cosplay Clothing and Accessories — hugely popular 3D printed items that sell to superfans

Cosplaying has seen a huge surge in popularity in recent years, with conventions popping up for just about every fandom from comic books and videogames to TV and film.

Cosplayers take pride in their referential outfits, and many choose to make their costumes themselves to add a layer of uniqueness to the homage of their chosen hero (or villain).

However, many cosplayers don’t have the means to create some of the more intricate or complicated parts of their outfits, and official merchandise of the franchises they seek to emulate can be extremely expensive.

Selling 3D printed cosplay items means providing cosplayers with the clothes and accessories they need to really feel like their favorite characters. There are plenty of 3D printed stuff to sell that will delight cosplayers of all kinds. Batman’s armor, Cloud Strife’s iconic soldier guard, Link’s gauntlets, and the Nazgul’s helmet are all available as pre-made designs, and that’s just to name a few.

See also: our list of the coolest things to 3D print

Or, our ranking of the best 3D printers for miniatures

If you’re creative enough, you can design and 3D print custom items to sell to consumers with specific requests or unique spins on the cosplay of their dreams.

This sounds a lot more high-tech than it needs to be. This is one of the better ideas here, that hasn’t actually been done yet – but I think it would have fantastic potential. I don’t like sharing my best ideas normally, but I’ve got my hands full at the moment. Besides, execution is everything, anyway (meaning ideas on their own, are worth zilch).

But we’re not talking complex multiple-material shoes like the big companies are working on. But yes, this is part of the mass-customization revolution. The problem I personally find with flip flops is that they’re most comfortable when they’re fully worn in. But flip flops typically aren’t made all that well, certainly not to last (even the more expensive ones).

The paradox is that if you made them out of a material hard-wearing enough to last a long time, they’d never wear in properly. Thus never being optimally comfortable.

So why not create 3d printed flip flops, designed to the exact contours of the wearer’s feet? The high grade of flexible materials to print them (such as TPU filament) with would ensure they last a long time and as they were perfectly created for the wearer, they’d feel like they were worn-in from day one.

You might be thinking “I don’t wear flip flops, so who cares?” – well, a lot of people do wear them. And you might be surprised how much people will pay for them. Remember the Crocs fad? They were hideous, and cheaply made, and they sold for a lot of money.

You can also get apps for mobiles now that can accurately scan simple objects – yes, like the bottoms of your feet. You could sell the flip flops for £50-£100 a pair (and yes, people would pay that for the most comfortable shoes they’ve ever owned, and that are stylish and that could last them 10 years+).

Pros: New idea, could easily get PR from uniqueness. Simple to print, wouldn’t take too long to print each one if using a larger nozzle size. High margin

Cons: Need a reliable way of scanning feet (existing apps around?) and need larger print bed to cover all sizes.

Read more: our feature story on 3D printed shoes

Statuettes and Figurines — great 3D printed items that sell

Speaking of fandoms, there’s nothing quite like decorating your home with physical representations of your favorite characters from the big and silver screens.

Like cosplay, officially licensed likenesses of these characters can be pricey, and so they make for some popular 3D printed items that sell well on the internet. Figurines don’t have to be representations of fictional characters, and you can 3D print and sell likenesses of celebrities, animals, and even fictional creatures.

People are always looking to make their home or workspaces as personal to them as possible, which makes custom decorative figurines all the more popular with online shoppers.

They can be made from files found on many sites, and can take the form of these adorable Pokémon statuettes, to extremely detailed figures like the ones found here.

Because figurines and statuettes vary so widely in detail, they can be made as 3D printed things to sell no matter your 3D printer’s size or capabilities.

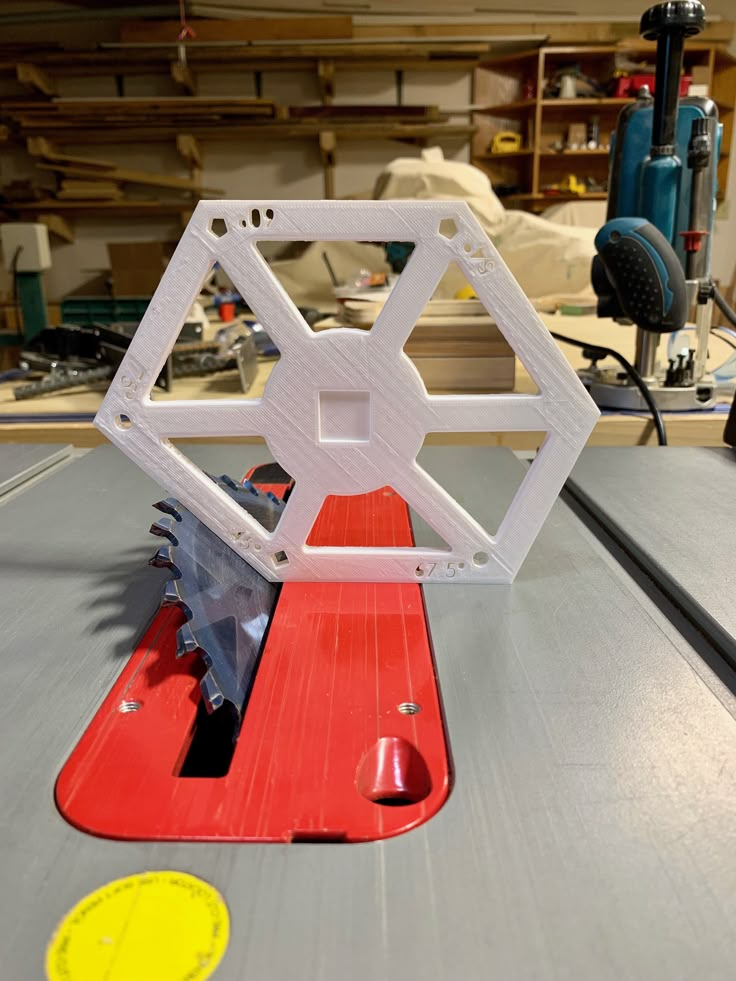

Architects’ Modeling

Now this could be set up as a service business, or an e-commerce business depending on which way you look at it. As a service business, you could offer bespoke quotes for architects to show projects in a physical 3D form and print out all the props custom.

As an e-commerce business, you could offer a huge range of buildings of various sizes and props for Architects wanting to show a project as custom, but on a much tighter budget. Naturally, the building in question would need to be custom printed (perfect up-sell opportunity here) but the surrounding buildings and ‘setting’ can be from more generic stock buildings. The most profitable way here might be to run the e-commerce side and service sides of the business in parallel.

There are many off-shoots you could cover here, like dioramas for model railways, Warhammers etc.

Here’s a picture of one of our customers on Twitter, showing off some work they’ve done. It should give you a better idea of the things that are possible.

Pros: Rapidly expanding area, with high levels of repeat trade from business customers.

Cons: Some level of design skill required, or to know someone who can do it cheaply to make it more viable.

Read more: the best 3D printers for architects

Jewelry & Ornaments

Jewelry is one of those universal likes of which almost everyone owns at least a piece or two. Many people who wear jewelry regularly like to have pieces that are unique to them, especially if they’re custom made.

Many people who wear jewelry regularly like to have pieces that are unique to them, especially if they’re custom made.

Selling 3D printed jewelry can be a nice way to earn some extra cash by following templates and simple patterns that can be found all over the internet, or by creating your own. If you’re open to exploring your creative side, 3D printed jewelry can be made in different ways including pendants resembling famous logos.

With extremely high resolution and the increasing affordability of photopolymer-based resin 3D printers, bespoke “one-off” jewellery can be crafted from lost wax casting.

Essentially this is where you design a ring, for example, and print it with a UV light curing photopolymer wax. The wax can then be used to create a cast mold, and will burn away when filled with molten metal.

Naturally, this takes a little bit of skill to learn the craft properly, but if you’re extremely creative – retailing your own line of exclusive, high-end jewelry could be a popular business, especially if you make a name for yourself.

The key to this type of business is finding a nice targeted niche, and then specialize in materials and designs that lend themselves to that target audience.

It’s also possible to get extremely accurate FDM printers now, printing with just 0.1mm nozzle diameters. You could get wax filament to print lost wax designs for the casts. High precision print using a our clear PLA with a 0.1mm Nozzle size on a Mass Portal 3D Printer

Pros: Again, potentially high ticket and unusual. Lots of potential to be featured by niche publications and blogs. Very big influencers could be persuaded to promote your designs if they get behind them.

Cons: An element of skill and creativity required. Also potentially higher setup costs due to rare metals, and using a resin printer.

See also: our ranking of the best 3D printers for jewelry

Or, our list of the most stunning pieces of 3D printed jewelry

Or even, our list of the best jewelry design software

If you like to draw, jewelry can also be made using 3D pens, which are ideal for those who are better with working directly with their hands.

Movie-grade Props

This could be really high ticket. Extremely realistic props are very sought after by hard-core fans. You’d have to check the legalities of selling items like these though depending on what Game or Film you were basing them on. But private collectors would pay good money for their own Iron Man suit, or a massive gun from a famous game for example.

You’ll need to know how to finish your 3D prints, though.

Pros: High ticket, big sale price items – high virality aspect on social media. People who have their own iron man suit, complete with lights etc. tend to get a bit of attention.

Cons: Large amount of work, but you could make systems to speed up repeat orders (i.e printing small batches of same components, painting them all at once etc.). Potential issues with copyrights.

Vases and Plant Pots

I said vases, but this could be with any high-end designer in-the-home product. Like coasters, clocks, toothbrush holders. You get the idea.

You get the idea.

The key here is that you don’t rely on the fact these items are 3D printed to be the reason people love them. Think high-end, luxury, beautiful-looking items. Are you starting to see a trend here?

I’ve mentioned ‘MeshCloud’ before, but they do this high-end luxury homeware business to a T – they’re a perfect example of how to do this business model right. They have a large range with a variety of prices for unique designs. Etsy, Amazon and NotOnTheHighStreet.com make perfect platforms to retail these kinds of items.

Creative plant pots and other indoor fauna containers are the pride of many an interior décor, and 3D printing lends itself well to these, making them one of the better, and sometimes easier, 3D printed projects that sell well online.

Plant pots can be 3D printed to sell as designs that you either find online or create yourself, and, like many things on this list, can be made to order depending on a consumer’s needs.

Vases and plant pots are known for being both heavy and fragile, and both of these problems are avoidable with 3D printing. By 3D printing plant pots to sell, you can find a wide market of people who want a unique decoration that won’t break so easily and is easy to transport and move around.

By 3D printing plant pots to sell, you can find a wide market of people who want a unique decoration that won’t break so easily and is easy to transport and move around.

Pros: Very easy to setup and build a range. Low skill required to produce, although you’ll need some creativity for the designs. Would be a great business to build further product lines onto (like those mentioned above).

Cons: Competitors could easily copy your designs, so it would be important to build close brand loyalty with customers and innovate new designs or ranges often.

See also: 3D printed vases you can download and print

More: 3D printed plant pots and planters

Retro Raspberry PI CasesThis is a favorite of mine, because it appeals to a specific group of people that love electronics and programming, and therefore are probably pretty nostalgic about the now retro games consoles they used as kids.

This way of tapping into people’s nostalgia speaks volumes and is a powerful combination. You don’t need to stop at retro-themed cases either, you could launch into a realm of new designs. And remember, you only need to print one of each out for photographs – you don’t need to hold inventory of all of these. So why not build the range out?

If you’re just looking for 3D printed items that sell and a simple business model to sell 3D prints online, then a business like this could be for you.

Pros: Fun to do, range of ideas already available. Most competitors aren’t currently marketing their businesses very well, so you’ve got potential to grow easily. Low setup costs.

Cons: Potentially low sale price compared with other 3d printing business ideas here, but plenty of opportunity to scale relatively easily.

Bespoke PC CasesThe ‘Vesper’ by Makirole (Left) and the Star Wars Destroyer by Sander van der Velden (Right)OK, so this is very high-end stuff. But some people will pay serious money for one-off (or very limited run) custom cases. These examples are at the extreme end of quality, but you could easily make more repeatable designs that look almost as good, but a lot easier to create and design.

But some people will pay serious money for one-off (or very limited run) custom cases. These examples are at the extreme end of quality, but you could easily make more repeatable designs that look almost as good, but a lot easier to create and design.

I know I said you want to be looking at scale-able ways to make money 3D printing like printing in batches – but you can make an exception for high ticket stuff like this.

Pros: They’d get a lot of attention on social media. People love geeking out over insane gaming rigs, and these case designs are the cherry on top.

Cons: Can be very time-consuming to make, so ensure you charge accordingly. Choose between more mass appeal, more reasonable cases that you can make faster and more easily, or one-off cases that are truly exceptional.

Cell Phone Covers

Whether we like it or not, our cell phones go everywhere with us these days. Work or pleasure, e-mail or Instagram, they’re an integral part of our day-to-day lives.

As such, customization is key. Not only do we like to make our devices easily recognizable at home, but like many things we take everywhere with us, many people like to decorate our cell phones with covers that express our passions or personalities.

Cell phone covers are a great way to make money with your 3D printer. They are small, often simple projects that don’t take long to print and fit a relatively small variety of sizes. This means that you can keep the base models saved, and alter their designs as necessary to suit your customers.

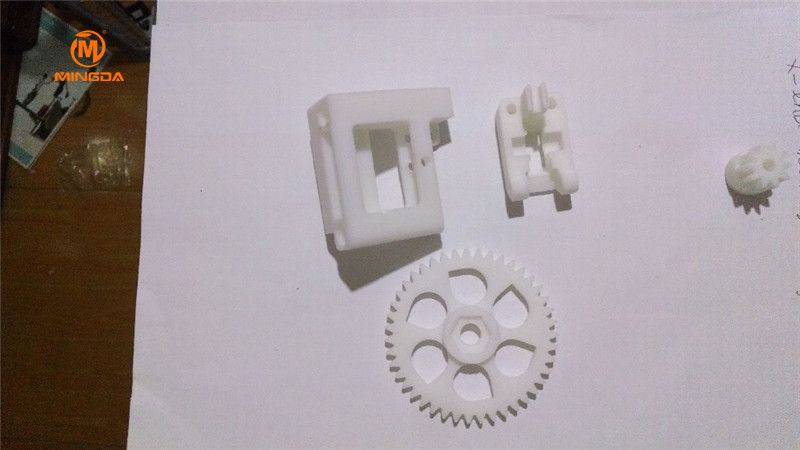

Robotics Kits

You can create fantastically innovative Robotic Kits from repurposed 3D printer parts. The Robots range from self-balancing RC style, to internet-controlled Whiteboards and Airhockey bots.

These are a fantastic educational guide for children to learn from, and there are many sub niches you could target for ‘robots’., but does require skill and creativity to set up.

Pros: This is a high ticket product, and huge potential for innovation on a range of areas. Especially as InternetOfThings gains in adoption – Wifi Controlled Kettle anyone? Set up costs should also be fairly low.

Especially as InternetOfThings gains in adoption – Wifi Controlled Kettle anyone? Set up costs should also be fairly low.

Cons: Of course, this does require some technical skill to design, and implement.

Or: 3D printed DIY robotic arms

Own Range of Drones, RC Planes & Accessories

This is really exciting. Why? For two reasons; a) drones are becoming really popular, because they’re getting faster, more powerful and can fly for increasingly longer (and of course, they’re really fun). b) the materials available to those who 3D print are becoming more impressive, so you can now print stronger, lighter and more durable stuff.

For example, carbon fiber is a low density, hard and durable material, ideal for small aircraft that undergo significant stresses and high impact crashes. Sure you can use regular PLA, but it’s very dense, and not as hard. With new materials like this, you can create ever higher-performing machines.

Another bonus is that when you’re flying a drone or 3D printed RC plane at 70pmh+ into a tree, no matter how strong the parts are, you’ll get some breakages. Leading to repeat business.

Leading to repeat business.

Read more: 3D printed RC planes you can build todayThis is a Spitfire printed by Laurent Muchacho in PLA – Weighs about 500g

Pros: Rapidly expanding niche, open-source designs – low tech 3D printer required. Good margins.

Cons: Some knowledge is required to really gain the best understanding of drones and how to improve them.

See also: our guide to 3D printing drones

Toys

3D printed toys can in more forms than statuettes, and people are always looking for unique gifts for their children or toy aficionado friends.

See also: get some ideas from our list of the coolest 3D printed toys

Board game parts, custom chess pieces, doll house furniture, and marionettes are just a few of the things you can 3D print and sell as gifts for all occasions.

Articulated dolls and puppets will require some assembly, but with enough creativity you can create your own line of unique characters and even give them back stories for a level of intrigue that has been proven to add to marketability (as seen with the likes of American Girl Dolls).

Every now and then, a craze sweeps the world and everyone gets excited about something. Sure these are often a flash in the pan, relatively speaking – and nearly everyone is too slow to react to make a business from them. But things are changing…

With 3D printing, if you have an idea, you can create something overnight. It allows you the luxury of speed. This is great, because with a good idea and the speed to do it, you can launch new exciting products and gain fast press publicity off of the back of the trend.

If you’re a fast thinker with a dash of creativity this could be the answer to your how to profit from 3D printing queries.

In the past I explained the HODOR door-stop reference, which could be made from filament (only really makes sense if you’re a Game Of Thrones fan I’m afraid) – and since then we’ve had the Pokémon Go craze. You may or may not be aware of the ins and outs, but essentially it involved everyone in the world, mindlessly chasing invisible Pokémon everywhere.

And to catch them, you needed to have a steady finger. Except a of people don’t seem to have one of those, so Pokémon ‘aimers’ were devised. There were different designs for different phones.

This sort of thing works fantastically well on crowdfunding sites like Kickstarter – you can then list for sale on Marketplace websites during and after the main Kickstarter campaign to mop up excess sales and squeeze the craze for each last drop.

Pros: If you can be first, the potential is huge. The HODOR door stop raised over $12,000 US on Kickstarter in about a week.

Cons: Short-lived, so you have to be fast and able to jump on what’s trending. Twitter Trends might be a great thing to keep an eye on.

Customized Ear BudsOwnPhones have created a really slick product here – but it’s priceyEveryone’s ear is different. If you wear stock earphones, it’s likely they’re not as comfortable or sound insulated as they could be.

There are a small handful of companies offering this service already – which proves there’s a market for it. Using a phone 3D scan app, the customer ‘scans’ the inside of their ear, for the app to create a 3D file. You can then custom print the earbuds which fit inside the customer’s ear to the perfect size.

The actual earphone part of the product could be bought off-the-shelf, and you package the custom bud as part of the product. This would allow you to retail a high-end sound quality item, with the custom size benefit.

The unit costs would be extremely small as the material used would be next to nothing. So once you’ve paid setup expenses for a high-resolution printer, your margins would be good.

You could later build out the range with different colors and styles. As far as print-on-demand e-commerce businesses go, this has a lot going for it.

With the small size of each earphone, it may even be worth getting these outsourced to a 3D printing service. This would keep fixed setup costs to an absolute minimum in the early days. An SLA printer might only charge £20-£30 for something that you could sell for £100 or more.

An SLA printer might only charge £20-£30 for something that you could sell for £100 or more.

As a way to get started, here’s a fantastic guide to printing your first set of custom earphones.

Pros: High margin and it’s a big niche – so plenty of potential customers, especially if you can create an efficient system to keep price sensible.

Cons: Precision printing and sizing is a must, so make sure you get the correct equipment. Don’t skim on the audio quality of the earphones – or it’ll cheapen your whole product offering.

Where Can You Sell Your 3D Prints?

After you’ve decided on what things to 3D print and sell, you’re going to want to chose the right retail venue to reach customers and maximize sales.

There are many online marketplaces where you can sell 3D printed items, each one offers a different experience depending on what kind of service you’d like to provide.

Thingiverse

Thingiverse is a very popular site for people who want to share their 3D printed creations online. While most of these are shared as free downloads for other users, it is possible to sell 3D printed items on the popular site.

While most of these are shared as free downloads for other users, it is possible to sell 3D printed items on the popular site.

Anyone can list their 3D printed items for sale on Thingiverse provided they’re original designs that neither copy another user’s files nor infringe on copyright laws.

While selling on Thingiverse is possible, most people will use the site to look for free files, which the site is known for, and so are more likely to turn away from a price tag.

Moreover, physical items cannot be sold here, only the files. So as popular as Thingiverse is for 3D printer owners, using it to sell 3D printed items is difficult and may yield little success.

Etsy

Etsy is an online retailer for amateur creators that is normally the first stop for anyone seeking to make a profit out of their hobby.

While not specifically designed for selling 3D printed items, Etsy is an open marketplace for creators of all kinds to offer their designs for sale at a price they set themselves.

Online shoppers go to Etsy for unique, handmade objects, so your 3D printed designs aren’t likely to be buried under mass-produced products that can be found in other marketplaces. This means that customers are more likely to favor 3D printed items for sale on the store.

Etsy charges $0.20 per item up for sale and a transaction fee of 5% of the total value of each sale, even more if you choose their online payment service.

Fiverr

Fiverr is an online resource for freelancers to sell their services. While Etsy caters specifically to handmade items by artists and designers, Fiverr is geared towards all those who work either full- or part-time from home in any capacity, from writing and translations to 3D printing and artwork.

Unlike most online marketplaces, Fiverr is geared towards those who work to commissions, with buyers requesting specific, custom items and works from sellers. This means printing to order, and often to exact specifications, so it’s a marketplace of choice to dedicated designers who are capable of modifying models to specific degrees before printing.

Fiverr has a peer-to-peer review system where both sellers and buyers receive star ratings and notes based on others’ experiences, helping to ensure all users are able to accept or decline orders as they see fit.

Amazon

The Amazon marketplace is probably the most secure of all the online sites to sell products on because of their high profile requiring them to pay more attention to theft and fraud prevention. However, this comes at quite a literal price, as Amazon takes a higher commission than most at 8-15% depending on the product.

While the 3D printer Amazon marketplace is a good place for part-time sellers, many people who have turned to online retail as full-time professions tend to look elsewhere due to the higher commissions that can take wide margins from fully formed businesses.

Conclusion: is it worth selling your 3D prints to make money?

For weighing up whether it’s worth it to start 3D printing commercially, only you can make that decision for yourself.

If you can make it work, using your 3D printer to make money can be a great and fun side hustle.

- If this article has piqued your interest, you should also read our guide to starting a 3D printing business.

- The best 3D printers for small business

Top 20 3D printed toys

Why 3D print toys? What toys can be 3D printed? 1. Mini monster truck 2. Surprise eggs 3. Gliders with elastic band 4. Folding sword 5. Micro catapult 6. Spinning top 7. Moving animals 8. Spirograph 9. Transformers 10. Toy tool set 11. Castle 12. Lego bricks 13 14. Edible toys 15. Anti-stress keychain 16. Chunky Trucks set 17. Sword rattles 18. Vikings Squigglepeeps 19. Math Spinner 20. Jumping Turtles Results

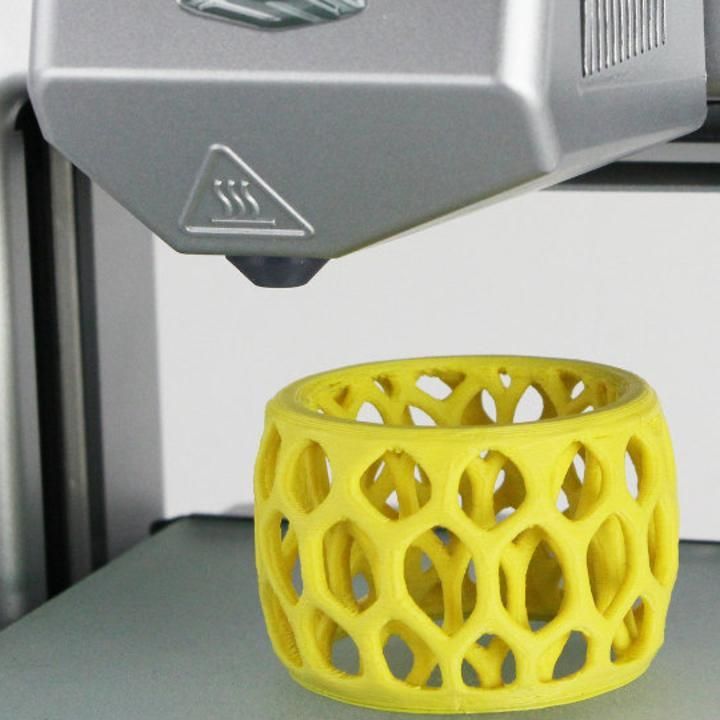

Today, 3D printing is developing and spreading very rapidly, gaining more and more popularity. And no wonder, because 3D printing is an invaluable tool for prototyping designs, creating mockups, fabricating parts, and more. At the same time, it is no longer difficult to buy a 3D printer at an affordable price even for home use. However, a 3D printer is not only a tool, it is also a kind of toy. A toy capable of creating other toys! Using a 3D printer to make toys gives you control over the material, color, size and other components, so the models you create with 3D printing will be unique!

However, a 3D printer is not only a tool, it is also a kind of toy. A toy capable of creating other toys! Using a 3D printer to make toys gives you control over the material, color, size and other components, so the models you create with 3D printing will be unique!

But what if you don't have your own 3D printer and you need to print a toy or some part of it? It doesn't matter, in this case our 3D printing studio will help you! You only need to place an order by uploading the file of the desired finished model, after which our specialists will contact you to calculate the cost and resolve other possible issues.

Why 3D printed toys?

This is probably the first question that comes to mind, and it is not surprising, because often 3D printing can cost you more than the cost of such a toy in the store. But there are also a number of advantages of 3D printing, as well as cases when it would be more profitable and appropriate to turn to creating models on a 3D printer.

- As already mentioned, a toy printed on a 3D printer can be absolutely unique due to the ability to give it exactly the shapes, sizes and colors that you and your child want.

- Some toys can be difficult to find in the store, and their cost may exceed the cost of their printed copy.

- Sometimes you only need to replace one or a few broken or missing parts of a toy, such as a building toy. In this case, it will be much more profitable and more expedient to use a 3d printer than to buy a whole set for a high price.

- An important factor is, of course, the impressions of the 3d printing process itself, which will captivate both a child and an adult. And the positive emotions of your child from the toy you created will be the best reward!

- And for those who are just getting acquainted with their printer and 3d printing in general, the process of creating toys will be an excellent, exciting simulator to improve their skills and gain experience.

Which toys can be 3D printed?

In the context of constant development and increase in the possibilities of 3D printing technology, you can create almost any toy on a 3D printer, but the result largely depends on the capabilities of your device, your abilities, as well as the time, resources and effort that you are willing to devote to this process. Therefore, more or less simple projects are most often created on a 3D printer. But the relative ease of manufacture does not mean boring finished products! Below we will give you a list of 20 interesting 3D printed toys that are not particularly difficult to create. Among these crafts you will find toys for children of all ages, including the smallest: mechanical products, motion figures, building blocks and even rattles! For each toy from the list, we leave a link to the finished model so that you can try them yourself. So let's get to know them better!

1. Mini monster truck

Two monster trucks. Source: Thingiverse

Source: Thingiverse

Not everyone can afford a monster truck, but if you have a 3D printer, you can print yourself a mini copy of it... which is almost as cool. Thanks to the all-printed suspension and removable discs that attach easily and without the aid of glue to the body, this truck is perfect straight from the printed surface.

You can even choose from a variety of body styles and wheels. And for a two-tone tire, stop printing the wheel at 19.8 mm and replace the filament.

Model files for download can be found here.

2. Surprise eggs

Surprise! Source: Twitter

Bigger is not always better. And often the most interesting thing is just a small size, and these 3D printed eggs with a surprise are an example of this.

These tiny cars with moving wheels and other accessories are amazing! Plus, you have plenty to choose from, as you can print surprise eggs with just about anything inside, be it a fire truck or even a fighter plane!

No support required for these models. We advise you to use at least 40% infill to make sure that small elements are both beautiful and durable. Given the number of such tiny parts these machines have, be prepared that printing them can be a real challenge for you, but with good calibration and fine tuning of your machine, everything will work out in the best way!

We advise you to use at least 40% infill to make sure that small elements are both beautiful and durable. Given the number of such tiny parts these machines have, be prepared that printing them can be a real challenge for you, but with good calibration and fine tuning of your machine, everything will work out in the best way!

3. Elastic Gliders

Get ready to take off! Source: Thingiverse

With 3D printed gliders you will be able to “pull out” even more fun from ordinary rubber band ! Just 3 simple steps, and your glider will take off: hook it with an elastic band, pull it towards you and release it.

With this model on Thingiverse, you and your friends can take to the skies a whole fleet of these rubber gliders!

100% infill and a layer height of 0.1 mm are recommended for greater aircraft strength and longer life for thin wings.

4. Folding sword

Telescopic pirate sword. Source: Thingiverse

This toy may not be best given to a child when there are breakable items nearby. But in the right environment, telescopic swords will bring tons of fun and enjoyment to kids! From the designer of this folding pirate sword, you can also find models of telescopic katana, daggers and even lightsabers!

But in the right environment, telescopic swords will bring tons of fun and enjoyment to kids! From the designer of this folding pirate sword, you can also find models of telescopic katana, daggers and even lightsabers!

This Telescopic Pirate Sword is designed for printing at low speed using a 0.4mm nozzle. Also, successful printing requires a printer with a good retract and precise settings for Coast (turning off extrusion at the end of the layer print) and Wipe (“wiping” the nozzle at the end of the layer).

5. Micro Catapult

Hit all your enemies (or at least your deskmates). Source: Thingiverse

This little catapult is a great toy for kids and bored office workers alike. She can throw small crumpled pieces of paper and any other small things that will fit in her. Selected ammunition can fly about 2 meters, which is enough to hit unsuspecting victims at another table!

This model is an all-printed prefabricated assembly that does not require any supports or special adjustments. A minimum filling and layer height of 0.25 mm is sufficient.

A minimum filling and layer height of 0.25 mm is sufficient.

Despite the fact that many catapults are made from PLA plastic, the author of the design still insists that this model is not for PLA, but for ABS plastic. We can also recommend PETG filament for this printing, which has the best qualities of PLA and ABS.

6. Top

The oldest toy for the whole family. Source: Thingiverse

As far as we know, the spinning top is one of the oldest toys in the world. In ancient times, tops were made from almost any material: from stone and wood to fruits and nuts. And now additive technologies allow you to make your own spinning top using a 3D printer! All you have to do is print this model, glue the pieces together and have fun with this simple yet fun toy!

Offered 0.2 mm layer height and 20% infill.

7. Moveable animals

Cute articulated octopus. Source: Thingiverse

Making flexible prints with a 3D printer has become completely affordable and common practice thanks to special filaments such as TPU. But what if we said that you don't have to use flexible plastics to create flex parts?

But what if we said that you don't have to use flexible plastics to create flex parts?

Using excellent hinges that are printed in one piece with the entire model, you can create movable flexing toys even from plastics such as PLA, ABS and PETG, without any additional settings and adjustments.

The standard specifies a layer height of 0.2 mm and an infill of at least 15%.

Most popular models:

- Octopus

- T-Rex

- Lizard

8. Spirograph

Convenient case for creativity at any time. Source: Thingiverse

Everyone knows the children's toy spirograph, which allows you to easily draw masterpieces with repeating geometric patterns. But this model has gone a little further and is a whole case containing a platform for drawing and a compartment for storing gears and paper. It fits easily into your pocket, backpack and bag, so you can take it with you and paint whenever you want!

The case has several levels. The lower level holds slips of paper for notes, drawing gears and, if desired, a small pencil or pen, if, of course, you can find one. The next level provides a secure, flat drawing surface so you can make art while walking! The top level has fixed gear teeth and holds the piece of paper in place.

The lower level holds slips of paper for notes, drawing gears and, if desired, a small pencil or pen, if, of course, you can find one. The next level provides a secure, flat drawing surface so you can make art while walking! The top level has fixed gear teeth and holds the piece of paper in place.

A layer height of 0.2 mm and an infill of 20% or more is recommended. As a loop, a regular straightened 1.75 mm filament thread is used.

9. Transformers

Toys from the planet Cybertron. Source: Thingiverse

Transformers are a hugely popular children's toy to this day, so these Optimus Prime and Megatron are sure to please your kids.

This printed Optimus Prime transforms from a classic Optimus truck into a fully functional standing robot. And it's amazing, considering that you immediately get a ready-to-use all-printed model right from the printing platform, which does not even require supports!

But, of course, every Optimus needs an opponent to fight. Therefore, you can also print Megatron, but it should be noted that his model is more difficult to print and consists of two parts.

Therefore, you can also print Megatron, but it should be noted that his model is more difficult to print and consists of two parts.

10. Set of toy tools

The first tools for little craftsmen. Source: Thingiverse

The Toy Tool Set is a great way to introduce kids to basic tools, their appearance, purpose, and how they work. Print your child's first hammer, screwdriver and pliers and he'll feel like a real craftsman!

The hammer is modeled to fit two pieces together with a screw, but some users simply glue them together, which is just as pretty. You can also use a hammer to assemble pliers: just lay the two pieces on a flat surface with the screw down and tap lightly a couple of times.

Model can be found here.

11. Castle

Build your own medieval world! Source: Thingiverse

This medieval castle playset is meticulously designed for 3D printing. Walls and towers are easily attached to each other with a simple connection. You can make as many details as you want to create a large or small original castle layout of your own! The set contains walls, towers, houses, characters, animals and a variety of props to add to the fun of this medieval set.

You can make as many details as you want to create a large or small original castle layout of your own! The set contains walls, towers, houses, characters, animals and a variety of props to add to the fun of this medieval set.

All parts are small enough to be printed comfortably even on 3D printers with a small printable area: 140x140x140mm. For such purposes, the Flashforge Creator Pro 2 3D printer is perfect, equipped with two independent extruders and has excellent printing accuracy. This printer will cope with the study of small details, and two extruders will help you print several parts at once or one part in two colors!

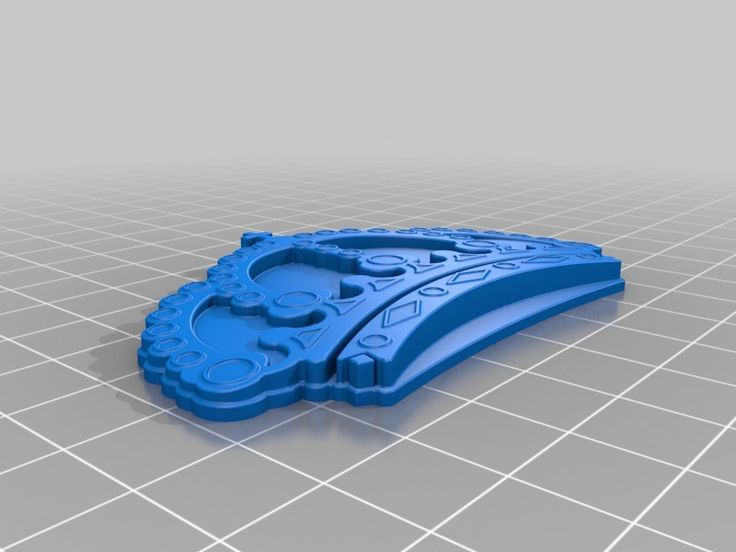

12. Lego bricks

Your favorite constructor is now more accessible! Source: Pinterest

LEGO is one of the most popular toys for children. At the same time, the cubes of this designer are made of ordinary ABS plastic. So, having your own 3D printer, you can print the missing/lost Lego bricks yourself or even some of your author's design of the details of this amazing designer! At the same time, you can use not only ABS, but also other 3D plastics: PLA and PETG are also great.

Thingiverse has a lot of Lego models, and we'll take a look at one of them. It's customizable model of several different LEGO and LEGO DUPLO pieces. These bricks are not completely identical to real Lego, but they are compatible in every way.

13. Ballista

Fire! Source: Thingiverse

Introducing a fully printed ballista model, ready to use right out of the box. One has only to set the string and load the projectile, and this ballista will impress you with its simplicity and good range of the arrow. As a bowstring, you can use several layers of thread or ordinary stationery gum.

Recommended to print in PLA or PETG with 90% coverage and 0.2mm layer height.

14. Edible toys

The Open Toys project turns ordinary vegetables into toys. Source: Thingiverse

The project was originally envisioned as a way to turn commonly discarded residual materials such as wood and cork into toys: helicopters, planes, cars and so on. But soon, wood and cork were replaced by more accessible and easily pierced materials: fruits and vegetables. With this project, you can turn ordinary food items into fun personalized toys.

But soon, wood and cork were replaced by more accessible and easily pierced materials: fruits and vegetables. With this project, you can turn ordinary food items into fun personalized toys.

15. Anti-stress keychain

Entertaining keychain. Source: Thingiverse

Add some flair to your keychain with this cool little toy. She will entertain you wherever you are!

This model is not the easiest, but try it and you will definitely succeed! Important print quality settings are "Outer Walls Before Inner Walls" and being extra careful with temperature. It is printed with supports and requires a certain, sometimes lengthy, post-processing. Remove not only supports, but also make sure that the surface of the part is smooth, otherwise it will cling and stutter. A scalpel or a 1 mm drill will do. Periodically rotate the gears to see where it still sticks, which is especially true when using PLA.

16. Chunky Trucks set

Two models from the fun and cute Chunky Trucks set. Source: Thingiverse

Source: Thingiverse

The adorable Chunky Trucks collection includes various unique models of small trucks, fun builders and even a movable barrier. The cars are specially designed so that even the smallest children can play with them. Unlike builders, who are not recommended to be printed for toddlers so that they do not try to put them in their mouths, but which will greatly amuse older children.

All models can be printed without supports. And for long truck life, at least 25% infill and three-wall use are recommended.

17. Rattleswords

Arm your warrior! Source: Thingiverse

Rattles are an integral part of all babies. But what if we move away from banal and boring designs and build a rattle in the form of a sword for your little warrior? This fun design will not only amuse your baby, but also you, as this rattle will be a lot of fun to print!

All corners of the model are rounded for safety. There are also two versions of the tip. Initially, a gem was attached to the tip, but after some concern that the stone could slip off the tip and be swallowed by a child, a second version was created that did not include a gem.

Initially, a gem was attached to the tip, but after some concern that the stone could slip off the tip and be swallowed by a child, a second version was created that did not include a gem.

Print two sets of peas first. Then, while printing the sword, throw them inside the blade. This will ensure that the peas stay inside the rattle forever. After printing all the elements, simply fasten them with superglue.

As with any printed toy, parental guidance is required. Be sure to throw away the toy if it breaks.

18. Viking Squigglepeeps

Three Viking Squigglepeeps set sail. Source: Thingiverse

Squigglepeeps is another kid-safe toy, this time with absolutely no glue required. These fun chubby Vikings and their boat are too big to choke on, making them suitable for kids of all ages. They look funny even in one color, but they will be even more beautiful if you paint them with child-safe paints! The model also absolutely does not require supports.

19. Math Spinner

A great way to have fun learning math! Source: 3Dtoday

This math spinner is the perfect companion for learning math. Moreover, it is suitable for all ages, because it is never too late to brush up on your arithmetic knowledge! You can print this finished model or modify it for yourself by removing or adding rings. This advanced design contains all the signs of addition, subtraction, multiplication, division, equality and inequality, as well as a pointer to the string to be solved! On the central insert there are special grooves for fixing. For this version, you will need to print 2 caps and 8 rings of numbers, the rest of the details are printed in a single copy.

Recommended coverage 25% and layer height 0.2 mm.

20. Jumping turtles

The variety of these turtles is amazing! Source: Thingiverse

Last but not least, jumping turtles! Agree, even the name sounds fun! And a variety of shell designs will give each turtle its own uniqueness. This model uses the same flex concept as the Mini Monster Truck above, making the Turtles bounce when you tap on the body. Also in this turtle, the head can be drawn into the shell.

This model uses the same flex concept as the Mini Monster Truck above, making the Turtles bounce when you tap on the body. Also in this turtle, the head can be drawn into the shell.

The model is assembled with printed H-clamps and does not require glue. All parts are printed without supports. Also note that using the raft (rafts) and brim (margins) options can have a negative effect on the results if you don't then take the time to sand and clean the edges at the base.

If you have problems with head slip, you can try to print 1 of the 3 narrower shaft head files that the author has specially uploaded for this case.

Results

We hope you enjoyed this selection of toys for 3D printing, and you will definitely choose some option for yourself, because 3D printing of toys is not only fun and interesting, it is also a new experience and knowledge for both you and and for the child. But we have considered only some entertaining options from the many existing ones. And, of course, you can create your own unique designs and implement them on your 3D printer or contact our 3D printing studio for this. And toys printed by you can serve as a great unique gift, which is also one of the reasons to buy a 3D printer for your home.

And, of course, you can create your own unique designs and implement them on your 3D printer or contact our 3D printing studio for this. And toys printed by you can serve as a great unique gift, which is also one of the reasons to buy a 3D printer for your home.

13 BEST CONSTRUCTION 3D PRINTERS OF 2019

A 3D construction printer is a machine that can build houses by applying material (concrete) layer by layer. The paste type material used, in this case concrete or earth, is forced through the nozzle in layers to print buildings.

Concrete 3D printing in the construction industry saves time, effort and material when compared to traditional methods. However, it is important to note that 3D printers are not yet capable of creating a fully functional home, only the frame and walls can be created, other elements such as windows, electricity or plumbing must be installed separately. Concrete 3D printers can also be used to print bridges, benches, or simply outdoor decorations.

To provide a complete overview of the construction 3D printer market, we have listed the top 12 construction 3D printing solutions. Some of them are 3D printers already available for sale, while others are still in the prototype stage or provide 3D printing services for external structures.

HOW TO BUILD A 3D PRINTED HOUSE?

Construction 3D printers use extrusion technology. Some construction 3D printers are similar to FFF/FDM desktop 3D printers, only larger (gantry style), while others consist of a rotating mechanical arm.