Zmorph vx multitool 3d printer

ZMorph VX Is Our Best Multitool 3D Printer Yet. Here's Why.

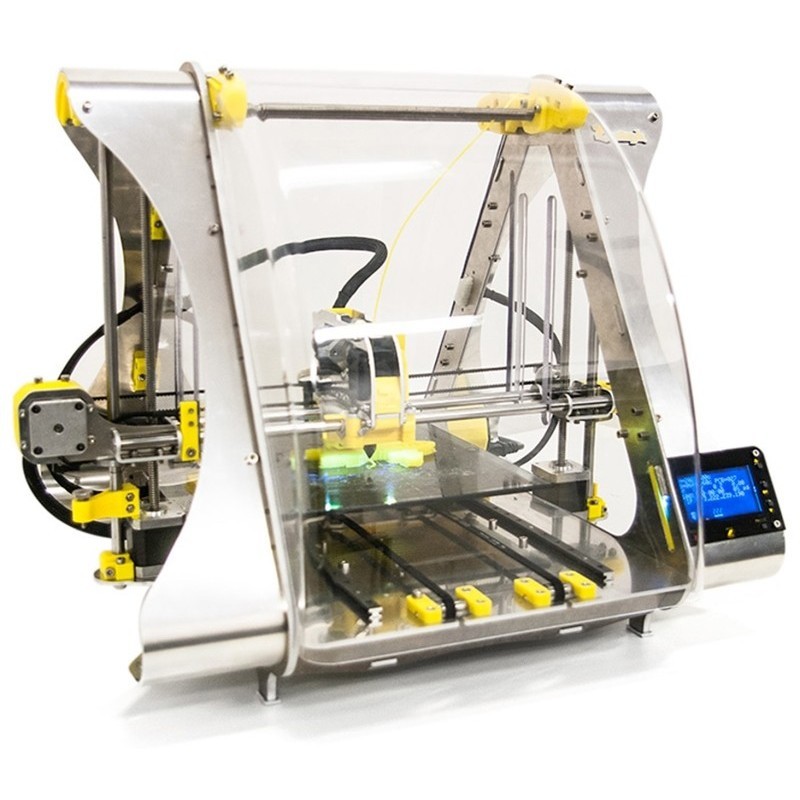

For years ZMorph has been known for delivering the most versatile 3D printers, and this model is a continuation of the legacy - 3 different fabrication methods within one desktop machine and dozens of available fabrication materials will satisfy even the most demanding professional designers, engineers and educators. We want to emphasize that message by introducing a next generation model, featuring advanced solutions in print quality and machine reliability, furthermore making the machine easier to set up and operate than ever before. In addition, more elastic pricing system lowers the barrier for anyone who wants to buy a great 3D printer with an option to upgrade for CNC cutting, laser engraving or even food printing and benefit from an all-in-one solution.

Without further ado, here's 3 key facts making ZMorph VX our best multitool 3D printer yet. .. and the best one on the market.

#1. ZMorph VX print quality is simply superb.

Finer details

0.3 mm nozzle is now a standard. It provides the best balance between resolution, speed and reliability.

Even stiffer printer construction

Zero tolerance for vibrations or even slightly loose fittings affecting the prints.

Improved print cooling system

Higher cooling power concentrated right where the action is. This solution guarantees significantly better results in printing small elements like steeples on buildings and overhangs.

Super-flat borosilicate glass

Borosilicate glass used in the construction offers best-in-class resistance to thermal and mechanical damage. To ensure adhesion at all times, we’re throwing in an adhesion glue with every ZMorph VX.

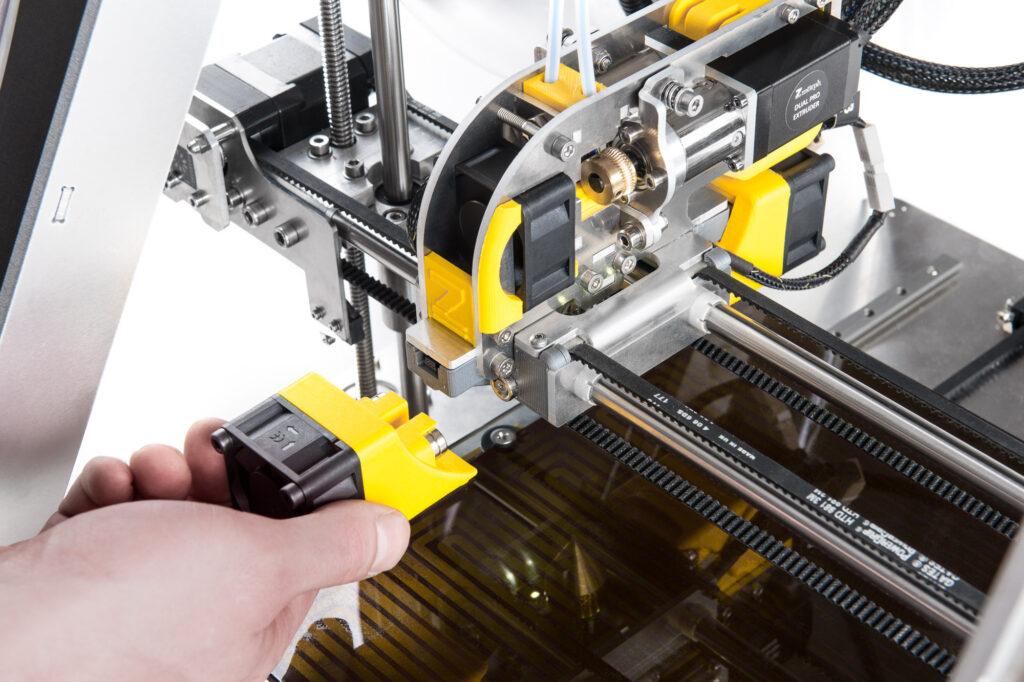

New Dual Extruder

Easier maintanance after heavy duty work and open for future upgrades. All thanks to interchangeable hotends feature.

All thanks to interchangeable hotends feature.

Read also: Professional Applications of ZMorph VX

#2. ZMorph VX is more reliable and safer during shipment.

Strong, certified packing

Each printer shipping box costs us over $100. It’s ISTA certified, but we had to double-check. So we threw the package from a flight of stairs (seriously) and made sure the package is intact - in case the delivery guy has a really bad day.

Improved construction, only top quality components

The previous SX model has been put to the test for 16 months, and that gave us a really good understanding of what’s prone to wear and tear. All those elements have been redesigned and replaced with the best quality components we could find.

Strict production standards

We've upgraded production line standards, including high grade ESD electronics protection system to ensure longer product life and stability.

#3. ZMorph VX was designed for easy and hassle-free usage.

New Voxelizer

Clear, beautifully designed interface, prepared both for inexperienced beginners and pros wanting to grasp full control of the printing process. Updated with faster and smarter algorithms, with the goal to help users make unprintable models printable. Learn more about the new Voxelizer.

Autocalibration

That's right, the machine can calibrate itself by a press of a button.

UX improvements

We went further than autocalibration and new Voxelizer when it comes to usability. We redesigned every aspect of LCD touch interface, Quick Start Guide, and also added a lot of intelligence into the firmware itself, that ensures better product life, reliability and operation. Last but not least, those who like to work with CNC and laser will gladly welcome the new CNC worktable - sturdy aluminum construction with pre-set holes provides stable, flat surface and easy clamping of wood, acrylic glass, modelling boards and PCB boards.

More elastic pricing system

In order to make the new ZMorph VX more affordable, we’ve arranged an elastic pricing plan starting with €2399/$2799 for basic 3D printing setup, upgradeable anytime with additional toolheads, available worldwide from the online store and the network of over 50 resellers.

Summing up, congratulations to the first ZMorph VX owners! For those who are still making up their mind, drop us a line at [email protected] or contact us via livechat at zmorph4d.com and we'll answer all your questions.

Stay tuned for the upcoming weeks - we'll be showing The Official ZMorph Applications Catalog!

REVIEW: ZMorph VX, a strong 3D printer with multi tool capabilities

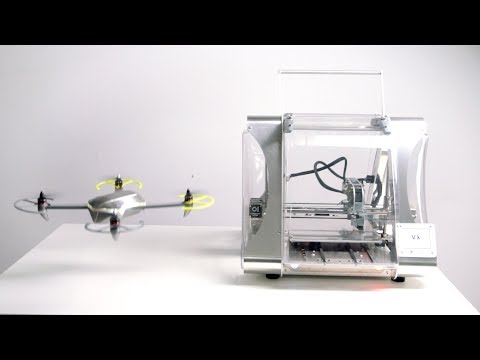

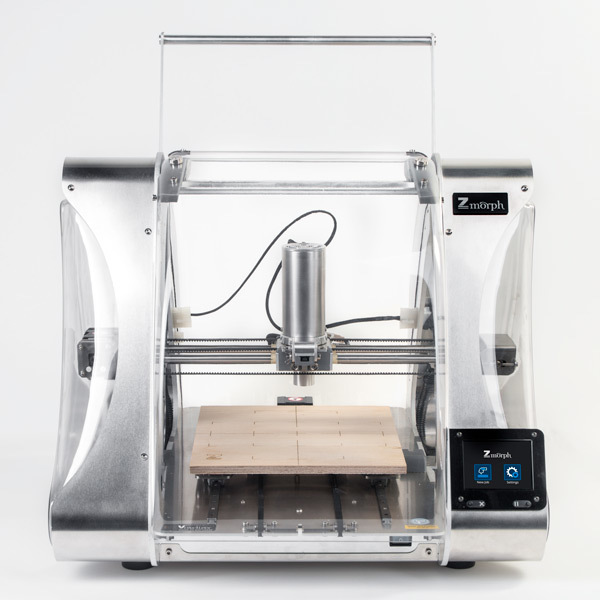

3D printing, CNC carving and laser engraving – the ZMorph VX makes some bold claims about its capabilities. This multiple function desktop system was launched by its Polish namesake manufacturer, ZMorph, at TCT 2017. Now 3D Printing Industry engineers have been given the chance to put it to the test.

According to its core claims, the ZMorph VX is of robust construction and designed for prolonged use. Its multiple toolheads, including a paste extruder and dual extruder, should be easily transferable, and the free ZMorph Academy course should enable users to learn how to operate each one effectively. Though a multitool machine, with CNC PRO and Laser PRO toolheads, the VX promises uncompromising FFF 3D printing quality. Each of these claims have been taken into account throughout testing the machine, and serve as the basis for our review.

ZMorph VX multitool 3D printer unboxed with spool holder attached.The ZMorph VX out of the box

After the five minutes taken to unpack the ZMorph VX, and a further three to attach the spool holder, the machine can be considered as “ready to go.” A concise, quick setup guide is provided in the box detailing each of its five modes of operation, and the customer is also referred to the ZMorph Knowledge Base and ZMorph Academy for extra help and how-tos.

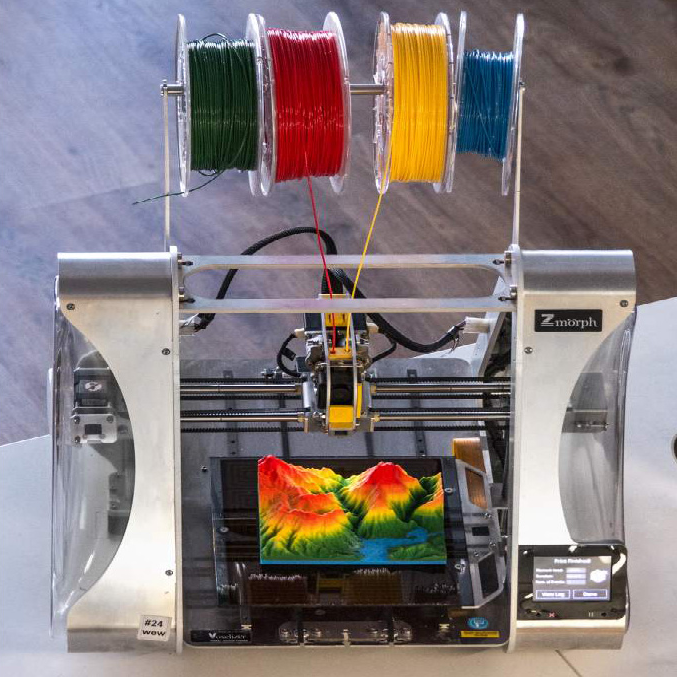

The spool holder has an efficient design and is capable of holding up to four rolls of filament at the same time, only two of these spools, it should be noted, can be extruded simultaneously when the appropriate toolhead is attached.

Each of the toolheads is mounted by a single screw. When exchanging toolheads, this simple construction enables each head to be changed within one minute, as stated by the company in its advertising. It is also easy to switch between functions via the in-built touchscreen panel, which is powered by ZMorph Voxelizer software.

Calibration can be completed both automatically and manually on the VX. In tests we found that auto calibration was more than suitable for every task.

Straight into 3D printing

The first test our engineers performed was, of course, an assessment of the ZMorph VX’s 3D print quality. For this purpose, first with a single extruder, we tried five different models:

– A ZMorph pyramid sample print (PLA silver)

– A 3D Benchy in two different sizes (PLA silver and white)Complex flower vase (PLA silver)

– Large detailed house model (PLA silver)

– 3D Torture test (PLA white)

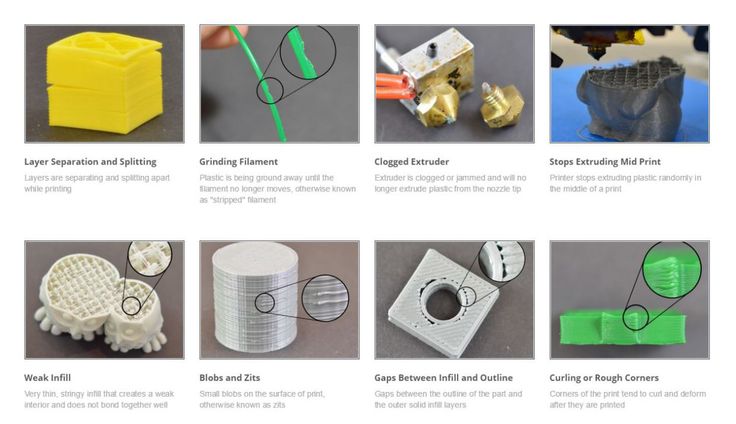

Put briefly, across all test prints, the ZMorph VX worked very well. The sample triangle was 3D printed with fine features, despite the fact that it is a challenging printout for some 3D printers due to its extensive details.

The sample triangle was 3D printed with fine features, despite the fact that it is a challenging printout for some 3D printers due to its extensive details.

Similarly, both 3D Benchy’s were 3D printed without fault. Though of varying sizes, and using a different filament to the ZMorph triangle, the test Benchys were produced at a high quality without any stringing across difficult areas like the windows.

In the vase, a slightly more complex model, the walls were of a good quality, but some stringing could be noticed on the inside. It should be noted however, that the stringing was nothing unusual, and was most likely due to the small size of the object. A test of stamina, the large house model, which took 20 hours to complete, also printed well.

And, in the final torture test, the ZMorph VX proved that it can handle overhangs, bridges, hinges and floating strings with ease.

Pyramid sample print Larger PLA 3D Benchy 3D Torture test 3D printed architectural model printed on the ZMorph VX. Photo via ZMorph

Photo via ZMorphDual extrusion on the ZMorph VX

A similar design to the single extruder, the dual extruder on the ZMorph X has two feeders and two inlets, which lead to a single nozzle. The feeders on this nozzle are open, a welcome feature of the head as it is handy for spotting any clogging. The heating element with the nozzle assembly is modular too, which also helps to just heat up the needed area during a clog.

In a test of dual extrusion capabilities, the team used ZMorph’s Voxelizer to add a basic text 3D Printing Industry (3DPI) logo to the side of a miniature rocket part.

The combination process in Voxelizer was quick and straightforward. Preprogrammed blending options for the two filaments where also clear and easy to understand, i.e. separate, 5050, gradient and texture.

ZMorph VX dual extrusion test.Both sample parts 3D printed using the dual extruder were of a decent quality though the surface finish was not of the same quality when compared to single extrusion 3D prints. Adding text/images to the face of dual 3D printed objects is in fact better served by larger objects, allowing the pictures and characters to become more defined.

Adding text/images to the face of dual 3D printed objects is in fact better served by larger objects, allowing the pictures and characters to become more defined.

Laser engraving, CNC carving, paste extrusion

Now, onto the extra features of the Zmorph VX multiool 3D printer. For laser engraving CNC carving and paste extrusion, first the print bed had to be replaced with the CNC worktable.

Due to the simple, magnetic design of both platforms, the exchange was easy to do. With this construction, planar aligning was also very easy, and calibration process was acceptable.

For the engraving test, we effectively reproduced the ZMorph logo from the sample files provided by the company. In a further test, the team also succeeded in converting a .jpeg image into our own engraving .gcode using a tutorial from ZMorph Academy.

Overall we were impressed by the quality of the engraving, especially considering features were very close together in the tests.

For CNC carving, five types of cutter tip were provided, each easily mountable within the toolhead.

For carving, we used a 6mm thick piece of plywood provided by the company, and tested the sample “Rocket Holder” file downloaded from ZMorph Academy. At 75% and 125% speed, were were decently impressed by the results.

CNC carving test. of rocket holder parts.Sample nylon cog carved on the VX. Photo via ZMorphAnd finally, attaching the partially 3D printed paste extruder, we achieved the successful guided extrusion of a thick chocolate icing. A handy addition for consistently decorating cakes, or experimentation with gels.

A multilayered “M” initial was achieved at layer height 3 mm, path width 3 mm, travel speed 120 mm/s and print speed 5 mm/s.

M initial paste extrusion on the VX.The all in one tool for workshops, schools and FabLabs

Based on our internal testing, the ZMorph VX is indeed a brilliant multitool 3D printer, which performed very well across all functions, especially for 3D printing. All prints demonstrated good layer adhesion, and the ability to pick out fine detail in chosen objects. Generally, the process also made it easy to remove supports, and the ZMorph VX produced a near perfect Torture Test proving its ability to overcome the breadth of 3D printer challenges, i.e. overhangs bridges, hinges and floating strings.

All prints demonstrated good layer adhesion, and the ability to pick out fine detail in chosen objects. Generally, the process also made it easy to remove supports, and the ZMorph VX produced a near perfect Torture Test proving its ability to overcome the breadth of 3D printer challenges, i.e. overhangs bridges, hinges and floating strings.

With the ability to reference ZMorph Academy for free, we were able to conduct our tests with ease, and found instructions incredibly clear and to the point. Simple tool mounting, the integrated touch screen, and Zmorph’s Voxelizer all contributed to an enjoyable, and intuitive user experience. It has a very sturdy frame, and could conceivably be used time and again over a long period of time. In addition, the machine’s multitool features, CNC carving, laser engraving and paste extrusion, all performed well, indicating the ZMorph VX’s capability as an all in one workshop tool.

The ZMorph VX would be a welcome addition to a classroom, FabLab, or the workbench of an in house engineering/design department. Buy the ZMorph VX here.

Buy the ZMorph VX here.

For all the latest 3D printing news and reviews subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows the ZMorph VX multitool 3D printer. Photo via ZMorph.

ZMorph Launches ZMorph VX Multifunctional 3D Printer

News

The Polish company ZMorph has released an upgraded version of its proprietary multifunctional 3D printer. ZMorph VX is equipped with optional engraving and milling modules and has a number of design improvements.

ZMorph 3D printers are an evolution of Mendel's RepRap 3D printer, using a similar layout. In 2015, Polish developers decided to turn their device into a full-fledged "desktop factory" by equipping the printer with an additional set of laser, milling and syringe heads. This variant was designated ZMorph 2.0 SX, and the new version is an already modernized version with design changes aimed at improving reliability, quality and ease of use. nine0003

This variant was designated ZMorph 2.0 SX, and the new version is an already modernized version with design changes aimed at improving reliability, quality and ease of use. nine0003

The new version retains a working area of 250x235x165 mm, although the actual working volume depends on the nozzle used. Calibration is fully automatic and the printing process now uses a borosilicate glass stage. Positioning accuracy reaches 14 microns on the X and Y axes, 0.6 microns on the Z axis. New drivers reduce the noise level by about 50%. The thickness of the applied layers varies between 50-400 microns, and the standard nozzle has a diameter of 0.3 mm. The maximum extrusion temperature is 250°C, the list of consumables for 3D printing includes PLA and composites based on it, ABS, nylon, PVA, polycarbonate, elastomers and other popular plastics. nine0003

According to the developers, only high-quality components are used in the design of the printer, with an emphasis on reliability and reduced backlash and vibration due to increased rigidity. A closed loop feedback system is provided to avoid accidental failures. Interchangeable heads allow you to turn the printer into a milling machine and laser engraver, or print with pastes. Printheads include a single extruder option and a dual extruder Dual Pro mixer with color gradation. nine0003

A closed loop feedback system is provided to avoid accidental failures. Interchangeable heads allow you to turn the printer into a milling machine and laser engraver, or print with pastes. Printheads include a single extruder option and a dual extruder Dual Pro mixer with color gradation. nine0003

The laser attachment is equipped with a 2.8 W blue diode and can work with wood, cardboard, leather, plexiglass and other materials. Management in all operating modes is carried out using the intuitive proprietary Voxelizer software. Data transfer is possible via USB or Wi-Fi connection, as well as via a memory card in SD format.

The base 3D printer has a selling price of $2 799, and with a full set of additional heads sold separately, it can reach $4,399. Additional information is available on the manufacturer's website.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

Follow author

Follow

Don't want

7

Multifunction 3D Printer 5 in 1 Zmorph Full Set (id 81790481)

Features & Description

A complete desktop solution for rapid prototyping, crafting and low volume production.

The ZMorph VX is the most versatile and most practical 3D multifunction printer to put on the table. With three different fabrication methods and a variety of materials available, ZMorph is designed to be your workhorse, a versatile machine for creating objects and solving problems. nine0003

Unique ZMorph VX features:

- 3D printing, CNC and laser all in one machine

- Huge materials manufacturing organization (see material list)

- Interchangeable tools and worktables with simple switching procedure

- High-quality 3D printing with enhanced dual-material features such as mapping and color blending

- auto-calibration

- LCD touch screen

- Rugged aluminum construction with high quality components designed to withstand the high torques of CNC milling and high speed 3D printing

- Enclosed chamber with fully protected electronics

- Innovative closed loop

- Free license for Voxelizer software

Materials:

- 3D Printing: ABS & Derivatives, PLA & Derivatives, PVA, PET, ASA, Nylon, HIPS, Thermochromic, TPU, Flex Materials,

- CNC cutting and engraving: all types of wood, polycarbonate, HDPE, acrylic glasses, processing wax, pattern board, Dibond composites, copper laminates (for PCBs), POM, Styrofoam,

- Laser engraving: all types of wood, leather, copper laminate (for PCB),

- Laser cutting: paper, cardboard, felt, thin spacer materials,

- Thick paste printing: chocolate, cookie dough, cream cheese, frosting, ceramic.

nine0068

nine0068

Applications:

- Functional Prototypes

- Concept models

- End parts and light production

- classes

- Tools, fixtures and fittings

- Signage and setting

- Architectural Models

- Printed circuit boards

- Study

- Historical reconstruction

- Art and decor

- Molds and castings

- Medical Imaging

- Cosplay

Complete ZMorph VX set includes:

- ZMorph VX

- 1.75 mm Plastic extruder with 0.3 mm nozzle

- Double plastic extruder with mixer hotend

- CNC PRO milling tool

- Laser PRO toolhead (2.8 W)

- Thick paste extruder

- Heated 3D Printing Worktable

- CNC work table for milling and cutting

- Printing fan add-on

- Spare extruder nozzle 0.3 mm

- Dimafix for 3D printing

- Tools and accessories

- 2 spools of PLA filament, 0.

Learn more