3D printing duke

Bluesmith Printing Service | 3D Printing

Bluesmith Printing Service

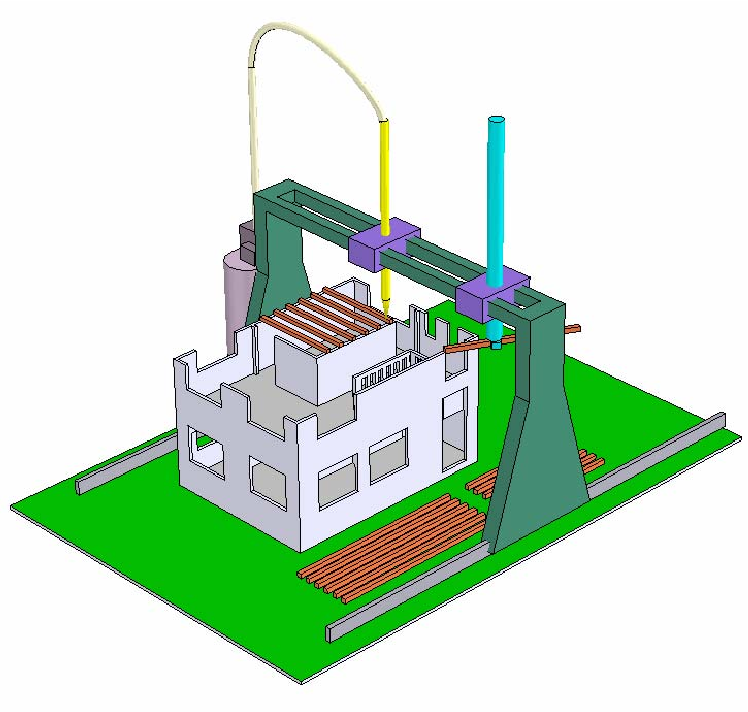

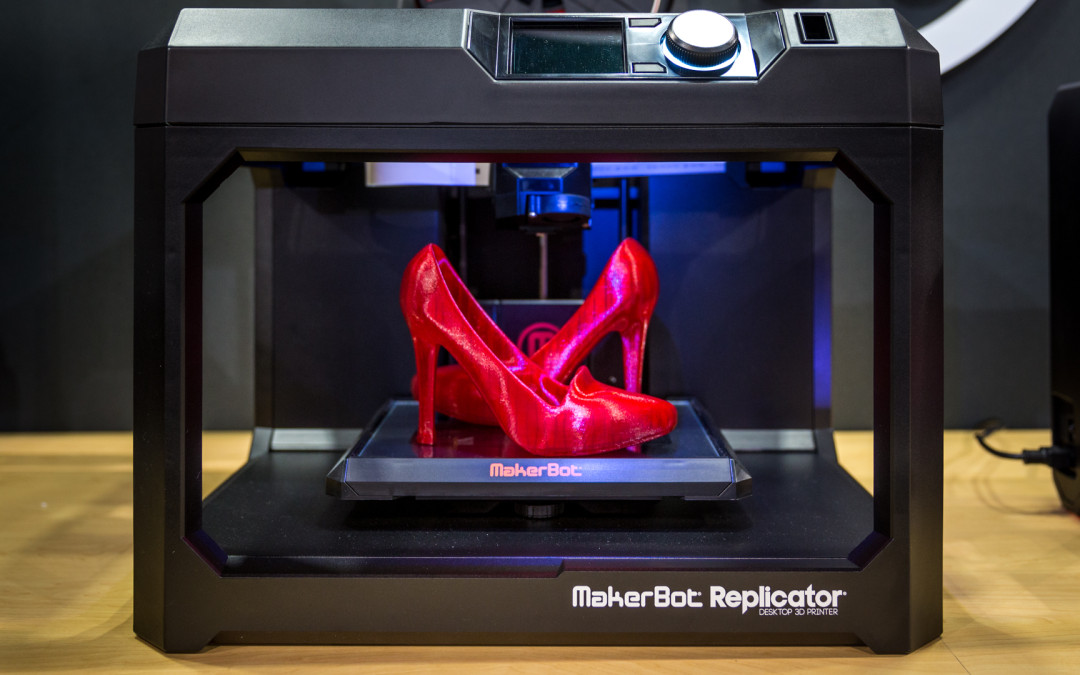

OIT offers the Bluesmith 3D printing service that allows you to submit an .STL file and have the model of your choice fabricated and finished by one of the knowledgeable staff members at the Innovation Co-Lab Studio on West Campus. We offer both Fused Deposition Modeling (FDM) and Stereolithography (SL) for this service. For a small fee, you have the option of a basic service that does not include support structure removal and finishing or you can choose the premium service that includes top priority in the queue over all non-premium orders and also includes support structure removal and finishing. You can submit your .STL file and request an estimate HERE.

Pricing & Types of Service

The cost of 3D printing varies widely based on the technology used and amount of material depending on the size and design of each model.

Technologies & Equipment

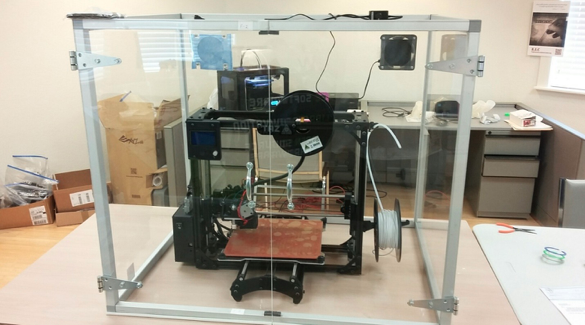

We offer six types of 3D printing technology: Fused Filament Fabrication (FFF), Stereolithography (SLA), Multijet (MJP), Continuous Filament, Polyjet and Laminate (LOM). Most printing technologies generally require an overnight run time of the printer.

- FFF Printing

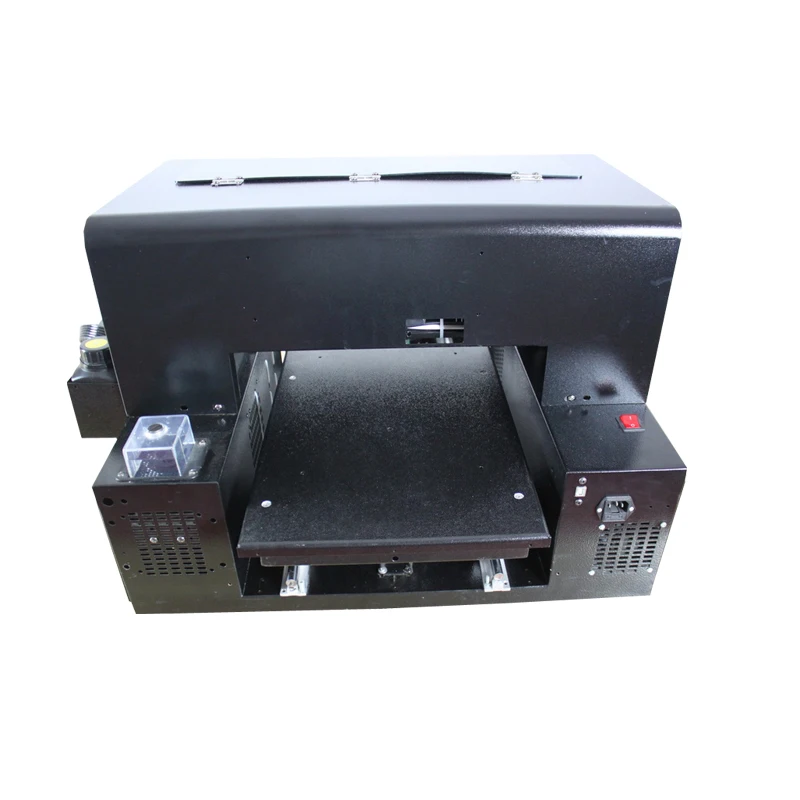

- Equipment – We use several FFF tools but primarily rely on Ultimaker 2+ and 2+ Extended 3D Printers

- Material choices – Nearly infinite. The CoLab supports PLA and PETG but over 1,000 other filament materials exist.

- Strengths – This printing type allows the greatest variety of material types (nearly infinite options exist), is typically the fastest 3D printing technology, has the largest build volume and is by far the cheapest printing method.

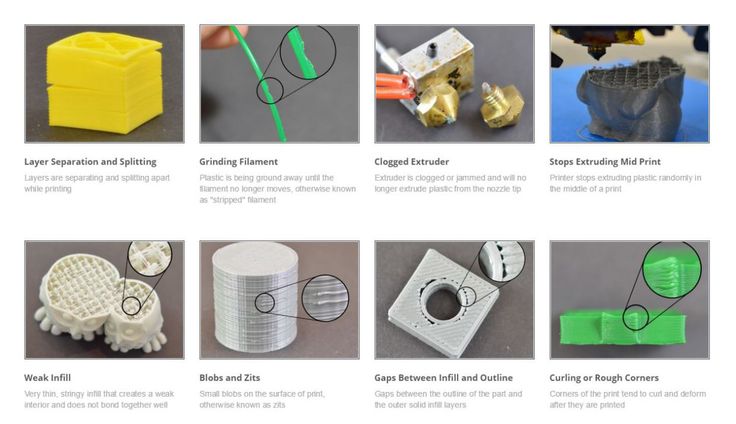

- Weaknesses – This is the lowest resolution 3D printing technology. The support material is difficult to remove and leaves scars on the print. The likelihood of failure increase exponentially with the size of the job.

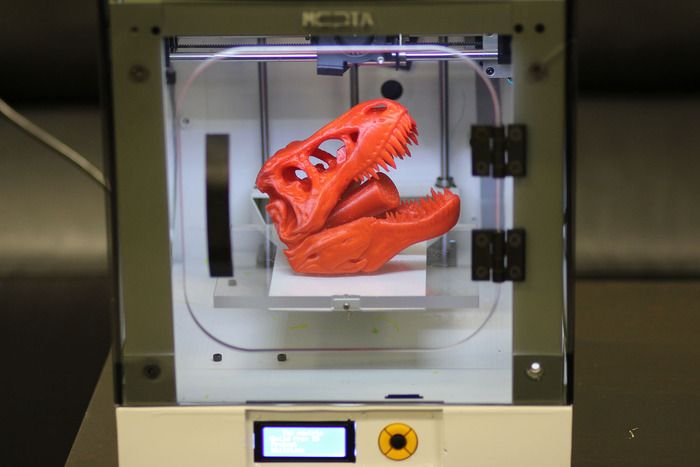

- SLA Printing

- Equipment – Formlabs Form 2

- Material Choices – Acrylic-like materials in

- Strengths – A relatively high-resolution 3D print that balances cost for performance

- Weaknesses – More expensive than FFF, limited selection of materials.

The support material is difficult to remove and leaves scars on the print.

The support material is difficult to remove and leaves scars on the print. - When to use this technology – Use when you need a higher resolution print than FFF can provide but don’t want the expense of MJP or Polyjet.

- Continuous Fiber

- Equipment – Markforged 2

- Material Choices – Carbon fiber or fiberglass embedded nylon

- Strengths – Extremely strong. Very similar to FFF but winds carbon fiber or fiberglass string into the print job creating a part that’s several hundred times more resilient than regular FFF prints.

- Weakness – Limited material choices. More expensive than FFF. The support material is difficult to remove and leaves scars on the print.

- When to use this technology – Use in circumstances where you need to make extremely strong, useable parts

- LOM – Coming Soon!

- Equipment – MCor ARKe

- Material Choices – Colored paper

- Strengths – Multicolor printing

- Weaknesses – Specialty printer

- When to use this technology – This tech is a specialist in color printing.

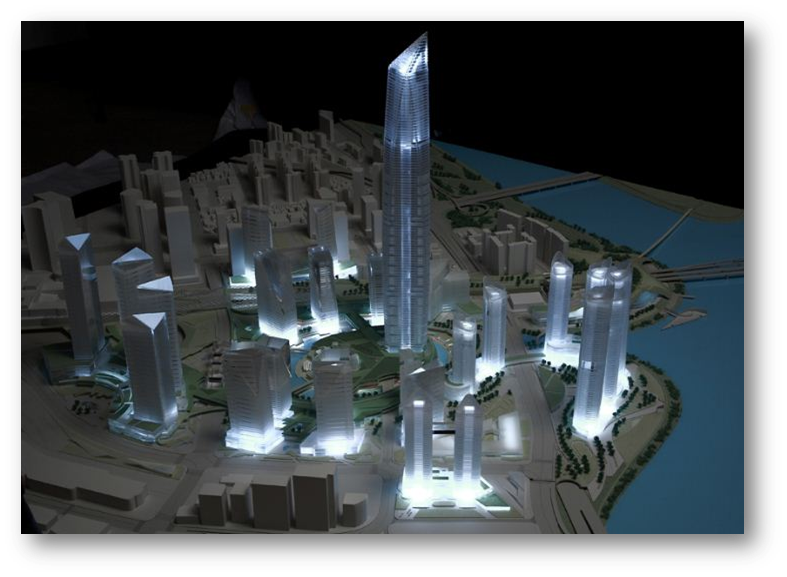

This tool will allow you to build photo realistic models and apply colored surface textures

This tool will allow you to build photo realistic models and apply colored surface textures

- MJP

- Equipment – 3DSystems MJP3600

- Material Choices – White ABS. Navy, white-opaque and black polycarbonate. Cast-able wax.

- Strengths – Similar to SLA but much higher resolution. No surface scars when removing support material. The support material is easily removed. 14-micron layer resolution.

- Weakness – Expensive and limited material selection

- When to use this technology – Use this when you need the highest resolution 3D print possible or prints without surface scars from support material

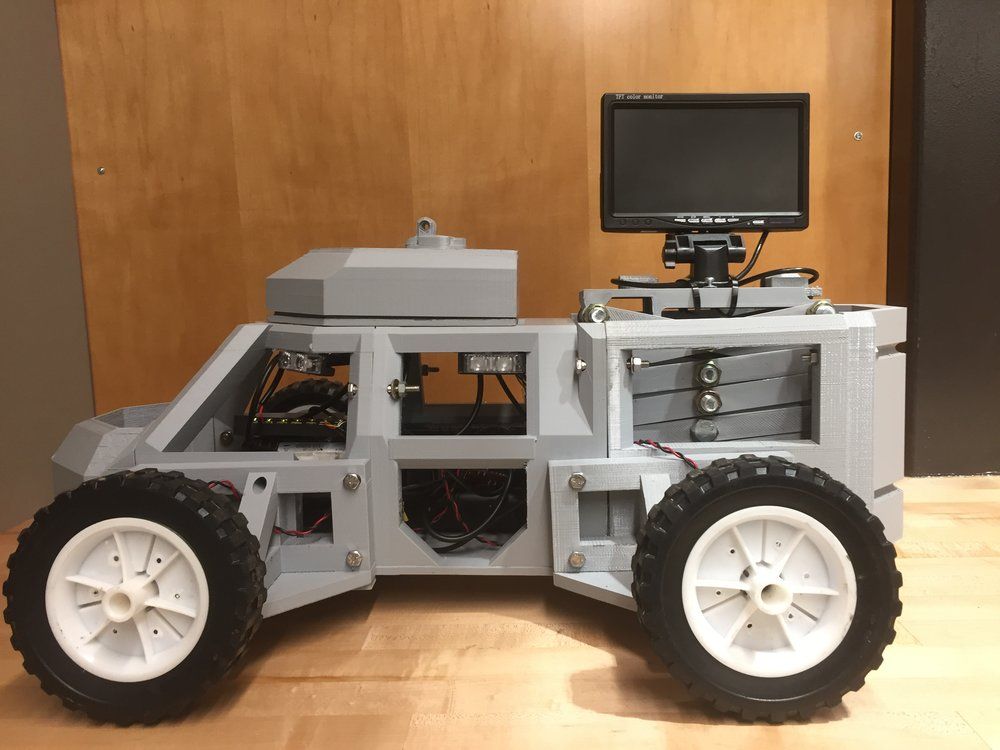

- Polyjet

- Equipment – Stratasys J750

- Material Choices – Nearly infinite.

- Strengths – Highest quality visualization 3D printing available. Full-color 3D printing. Easily removable support material with no surface scars on the part. 17-micron layer resolution.

- Weakness – Expensive…very expensive.

- When to use this technology – When you need full color, high resolution, scar free parts that can be made from a mix of solid and or flexible materials.

Pricing Structure

- FFF

- $10 base charge (100 grams included)

- $5 for each additional block of 100 grams

- Material Choices – Battleship Grey PLA or Blue PETG

- Model must be less than 223 x 223 x 305 mm

- For FFF printing users are welcome self-support and print for free in the CoLab

- SLA

- $30 base charge (100ml included)

- $10 charge for premium materials (flexible or tough resins)

- $10 charge for each additional 50ml

- Continuous Fiber

- $10 base charge

- $5 per 50 cubic centimeters of plastic

- $3 per cubic centimeter of carbon fiber

- $1 per cubic centimeter of fiber glass

- LOM

- Coming soon!

- MJP

- $20 base charge

- $.

50 per gram of material

50 per gram of material - $.25 per gram of support

- Polyjet

- $30 base charge

- $1 per gram of material

- $.50 per gram of support

Failure Policy

3D printing is an experimental technology that often fails. Equipment failures are not unusual. CoLab Staff will make every attempt to print your object successfully. If equipment breaks or the print failed without cause we will attempt to print it again. The likelihood of failure increases significantly with more difficult-to-print models. If the failure is a result of simply submitting too difficult of a model, customers will still be charged an attempt fee of half the price of the initial quote. Users can accept the failed job or we can make a second attempt at the print; in this scenario, we will make additional attempts at 50% of the original estimate.

World’s First Fully-Recyclable Electronic Transistor Produced By 3D Printers at Duke University

Engineers at Duke University have developed the world’s first fully recyclable printed electronics. Their recycling process recovers nearly 100% of the materials used—and preserves most of their performance capabilities for reuse.

Their recycling process recovers nearly 100% of the materials used—and preserves most of their performance capabilities for reuse.

By demonstrating a crucial and relatively complex computer component—the transistor—created with three carbon-based inks, the researchers hope to inspire a new generation of recyclable electronics.

“Silicon-based computer components are probably never going away, and we don’t expect easily recyclable electronics like ours to replace the technology and devices that are already widely used,” said Aaron Franklin, the Addy Professor of Electrical and Computer Engineering at Duke. “But we hope that by creating new, fully recyclable, easily printed electronics and showing what they can do, that they might become widely used in future applications.”

Even though the ever-growing pile of discarded electronics is now on the decline, less than a quarter of it each year is recycled, according to a United Nations estimate.

Part of the problem is that electronic devices are difficult to recycle. Large plants employ hundreds of workers who hack at bulky devices. But while scraps of copper, aluminum and steel can be recycled, the silicon chips at the heart of the devices cannot.

LOOK: 3D-Printing Teen Makes Hundreds of Ingenious Devices to Alleviate Ear Pain for Healthcare Workers

In the new study, published April 26 in the journal Nature Electronics, Franklin and his laboratory demonstrate a completely recyclable, fully functional transistor made out of three carbon-based inks that can be easily printed onto paper or other flexible, environmentally friendly surfaces. Carbon nanotubes and graphene inks are used for the semiconductors and conductors, respectively. While these materials are not new to the world of printed electronics, Franklin says, the path to recyclability was opened with the development of a wood-derived insulating dielectric ink called nanocellulose.

“Nanocellulose is biodegradable and has been used in applications like packaging for years,” said Franklin. “And while people have long known about its potential applications as an insulator in electronics, nobody has figured out how to use it in a printable ink before. That’s one of the keys to making these fully recyclable devices functional.”

RELATED: First Ever 3D-Printed Cornea Could Restore Vision for Millions of People

The researchers developed a method for suspending crystals of nanocellulose that were extracted from wood fibers that — with the sprinkling of a little table salt — yields an ink that performs admirably as an insulator in their printed transistors. Using the three inks in an aerosol jet printer at room temperature, the team shows that their all-carbon transistors perform well enough for use in a wide variety of applications, even six months after the initial printing.

The team then demonstrates just how recyclable their design is. By submerging their devices in a series of baths, gently vibrating them with sound waves and centrifuging the resulting solution, the carbon nanotubes and graphene are sequentially recovered with an average yield of nearly 100%. Both materials can then be reused in the same printing process while losing very little of their performance viability. And because the nanocellulose is made from wood, it can simply be recycled along with the paper it was printed on.

By submerging their devices in a series of baths, gently vibrating them with sound waves and centrifuging the resulting solution, the carbon nanotubes and graphene are sequentially recovered with an average yield of nearly 100%. Both materials can then be reused in the same printing process while losing very little of their performance viability. And because the nanocellulose is made from wood, it can simply be recycled along with the paper it was printed on.

LOOK: 6 Billion Face Masks Used Daily—But Scientists Have a Genius Way to Turn Them Into Roads

Compared to a resistor or capacitor, a transistor is a relatively complex computer component used in devices such as power control or logic circuits and various sensors. Franklin explains that, by demonstrating a fully recyclable, multifunctional printed transistor first, he hopes to make a first step toward the technology being commercially pursued for simple devices. For example, Franklin says he could imagine the technology being used in a large building needing thousands of simple environmental sensors to monitor its energy use or customized biosensing patches for tracking medical conditions.

POPULAR: California Highway Becomes First State Road Made From Recycled Plastic in the US

“Recyclable electronics like this aren’t going to go out and replace an entire half-trillion-dollar industry by any means, and we’re certainly nowhere near printing recyclable computer processors,” said Franklin. “But demonstrating these types of new materials and their functionality is hopefully a stepping stone in the right direction for a new type of electronics lifecycle.”

GENERATE Some Buzz By Sharing the ‘Current’ News on Social Media…

Free STL file DUKE OF TERRORVILLE

SELENA ZODIAC - LEGENDS OF MOBILE COMMUNICATION BACH BACH BACH BACH

Free

HARLEY - MOBILE LEGENDS BACH BACH BACH

Free

DUCHESS FROM THE LAND OF HORROR - FREE FIRE

Free

CLINT - LEGENDS OF MOBILE COMMUNICATIONS

Free

JHIN DARK COSMIC

4,70 €

SERAFINA KDA - ALL OUTPUT

4,70 €

NIGHT HUNTER VINE

4,70 €

YASUO UNFORTIVATED

4. 70 €

70 €

PERVERTED FATE OF THE CARD MASTER

€4.70

Dragonslayer Ornstein - DARK SOULS

4,70 €

LUXURY - LADY OF SHINE

4,70 €

KAY'SA KDA ALL

4.70 €

Best 3D printer files in Game category

Magic Top Toy

Free

LowPolyTurtle

Free

[3Dino Puzzle] Velociraptor

Free

Little adventures - H

4 €

PuzzleLock Dungeon

28.19 €

Nerf Gun Wall Mount

Free

Tyrannosaurus lithophany

Free

Multi-Color Peg Solitaire

Free

Bestsellers in the Game category

Abandoned damaged spaceship compatible killteam in the dark or boarding action game

13,90 €

nine0003 Healer conversion kit SM6 €

Lazy Cat

3,75 €

GIANT CROCODILE HINGED

4. 18 €

18 €

Articulated dragon

3.75 €

Batman Crossbow / Seal in Place

€2.50 nine0115 -25% 1.88 €

Enourmous Imperial Heavy Tank

10 €

Catafrac Heavy Armored Warriors - Civil War Wargear Pack

2,50 €

Heavy Imperial Fire Support Weapon [Preliminary Support]

5 €

nine0003 Chopper motorcycle print-in-place1 €

Bicycle

1.40 €

ALIEN SPACE BEETLE, SCREAMING EXECUTIONER

50 € -25% 37. 50 €

50 €

Nintendo Switch Crystal Dock - Classic & OLED Version

3.13 €

WARFORGED VOIDWALKER EXOSUIT UPGRADE KIT

9,40 €

Flexy Pangolin

€3.62 -thirty% 2.53 €

chaos terminators

€16.66 nine0115 -fifty% 8.33 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable the AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community! nine0006

Filed under: MBO | PUBLISH - 101 Ways to Make Money Printing

Komori buys MBO Group

- Tags

- Mergers and Acquisitions | Printing and finishing | Komori | MBO | nine0183

Komori Corporation (Tokyo) and the shareholders of MBO Group have entered into an agreement under which MBO Group will become part of the Komori Group following regulatory approval of the transaction.

- Read more

MBO Group at drupa 2020: Postpress Alliance debut

- Tags

- Postpress | Post-press equipment | perfecta | MBO | paper cutting machines | Drupa 2020 | Postpress sheet | Finishing for packaging | nine0183

At drupa 2020, MBO Group will be exhibiting for the first time as part of the newly formed Postpress Alliance.

- Read more

The German antitrust authority blocked the announced takeover of Heidelberg of postpress manufacturer MBO

- Tags

- Postpress | Heidelberg | MBO | Digital Finishing | nine0183

The German competition authority blocked Heidelberg's takeover of postpress equipment manufacturer MBO, which was announced in October 2018. If approved by the authorities, the agreement was to enter into force before the end of 2018. dominance in the market." Both companies will continue to operate as independents.

- Read more

Heidelberg acquires MBO Group and begins to explore digital postprinting

- Tags

- Mergers and Acquisitions | Printing and finishing | Digital printing | Heidelberg | MBO | nine0183

Heidelberg has signed an agreement to acquire the international MBO group to further strengthen its position in the growing market for digital finishing equipment and to attract customers in pharmaceutical packaging and direct mail printing.

- Read more

Herzog+Heymann shows creasing and perforating materials up to 300 g/m²

- Tags

- Ipex | Post-press equipment | MBO | Herzog+Heymann |

Herzog+Heymann presented at IPEX 2017 a creasing machine capable of simultaneously creasing and perforating materials up to 300 g/m². nine0006

- Read more

MBO launches take-up with stacker

- Tags

- publish | Post-press processes | MBO | nine0183

After drupa 2016, MBO Group has added a new stacker A500/A700 to its product line.

- Read more

Herzog+Heymann KL-90 Multifold System

- Tags

- publish | Post-press processes | Packaging and converting | Post-press equipment | MBO | nine0183

Herzog+Heymann (part of the MBO group) has developed the KL-90 Panel Outsert Line folding system based on the KL-45 for multiple folding.

- Read more

MBO at drupa 2016: 11 new postpress suites

- Tags

- publish | Folding and Collation | Post-press equipment | Kolbus | Drupa 2016 | MBO | nine0183

MBO and its sister company Herzog+Heymann (Hall 6, Stand B40) will be presenting 11 postpress systems for all offset and digital printing and specialty applications, including direct mail and pharmaceutical packaging under the slogan "Finish First" at the show.