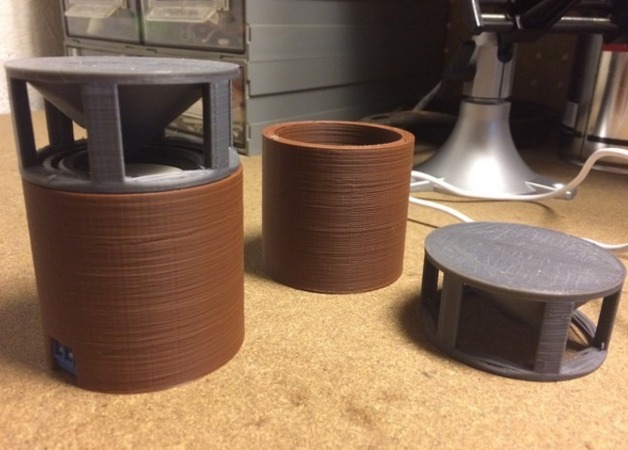

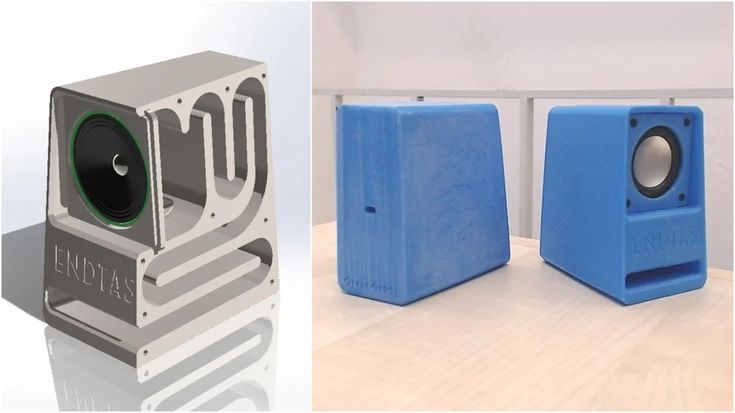

3D printed speaker enclosure

3D Printed Speakers: An Overview - 3DPrint.com

One unforeseen 3D printing application is in the production of speaker parts and even entire speakers. This particular area is surprisingly vibrant, with many hobbyists using 3D printing to make their very own designs come to life. But, commercial companies are also making money off of 3D printed speaker components in very high-end applications. So, we thought it was time to look at the field as a whole to see what has been going on in 3D printed speakers.

In 2009 Cornell researchers 3D printed a fully functional speaker:

“We’re trying to move the printing away from just printing passive parts made of plastic or metal, to printing integrated systems, active systems that can do something,” says associate professor of mechanical and aerospace engineering, Hod Lipson. Lipson led the project with graduate students Apoorva Kiran and Robert MacCurdy… the loudspeaker is a relatively simple object, consisting of plastic for the housing, a conductive coil, and a magnet.

Silver ink was used as the conductor and a viscous blend of strontium ferrite was used to create the magnet.”

Hod again showing us that he’s lightyears ahead.

This dodecahedron speaker was shared in Thingiverse in 2012. Projects such as this Raspberry Pi based speaker have been created a number of times as well. And many people have made speaker rings, other spare parts for speakers or things such as wall mounts.

People have even produced horn based speakers, as shown above, or holders for Google Minis. It’s clear that the maker community is really working towards making speakers more extensible and integrating them into our lives. There’s even a Reddit community devoted to DIY audio.

Paul Ellis’s Polymate3D is doing something much more advanced by creating speaker drivers, magnets, and designs and sharing them. The open design movement has not really taken off, but this kind of thing could enable many more people to build much more advanced speakers. In contrast to most of the projects listed in this post, this could truly revolutionize speakers. Below, we can see how Thomas Sanlanderer 3D prints an entire Paul Ellis speaker.

The open design movement has not really taken off, but this kind of thing could enable many more people to build much more advanced speakers. In contrast to most of the projects listed in this post, this could truly revolutionize speakers. Below, we can see how Thomas Sanlanderer 3D prints an entire Paul Ellis speaker.

Mass Portal material extrusion printers and Covestro TPU were used for a sieve to reduce interference on these Audiolens speakers.

Disney showed off 3D printed speakers in 2014. Their idea was to use 3D printing for housing to integrate the speakers into our every day lives and, of course, give them mouse ears and the like. They also wanted to show that “both audible sound and inaudible ultrasound can be produced with the same design, allowing for identifying and tracking 3D printed objects in space using common integrated microphones. ”

”

In 2015, Formlabs showcased flexible SLA resin in its speaker design.

Boaz Dekel’s Aleph speaker has been in development since around 2015. 3D printed on a Stratasys Connex PolyJet machine, the unique design integrates a diffuser, reduces resonance, and is optimized so that it “allows wavefront diffraction to propagate the sound cleanly in a room.”

In 2019, Czech design studio DEEPTIME showed off its speakers, 3D printed from sand. The shape of its Spirula speakers were inspired by ammonite shells. The team touts their unibody design and unique forms.

in 2020, IKEA, together with Teenage Engineering, encouraged us to design and 3D print add-ons to the Swedish furniture giant’s Frekvens speakers. I really believed that IKEA was going to go huge with this, but they didn’t.

26 hour print.

Available on Thingiverse, the Back Load Horn speakers are a doozy of a project, if you’ve got a week to spare. Here you can learn how one user made them.

Node Audio’s super high end HYLIXYA speakers are a now very recognized form. Made with 3D Systems’ powder bed fusion, they’re futuristic and use a radical new shape to engineer superior sound. 3DPrint.com was even given a virtual walkthrough tour of their production process. You can watch that below.

All in all, we can see that there are a number of trends in 3D printing speakers that are notable.

- People are using 3D printing to integrate speakers into cars, their homes, and surround them with enclosures to make them fit into their world.

- There is real open source and maker activity going on, which aims to democratize the fabrication of speakers. This seems rather far off, but it would be quite exciting if we could produce an entire speaker. This has been demonstrated a few times, but it is not yet easy or perfect.

- High-end companies are using 3D printing’s design freedom to manufacture better speaker components, housings, and parts, such as diffusers, to increase the performance of their sound products. Increasingly, 3D printing could play a part in high-end audio and we may at one point see more of this occurring.

Will we all 3D print our speakers at home? This is very unlikely, as we’re mostly lazy and/or busy. Will every speaker be 3D printed? Also highly unlikely, since traditional methods make for inexpensive high-performance products already. Will we change the sound landscape somewhat with uniquely performing shapes and components? This is probably the most likely scenario. Listen to this space.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed speaker • 3D printing speakers • Aleph Zero • aleph2 • diffusers • hylixya\ • hylizya • mass portal • Node Audio • sound • speaker components • speakers

Please enable JavaScript to view the comments powered by Disqus.

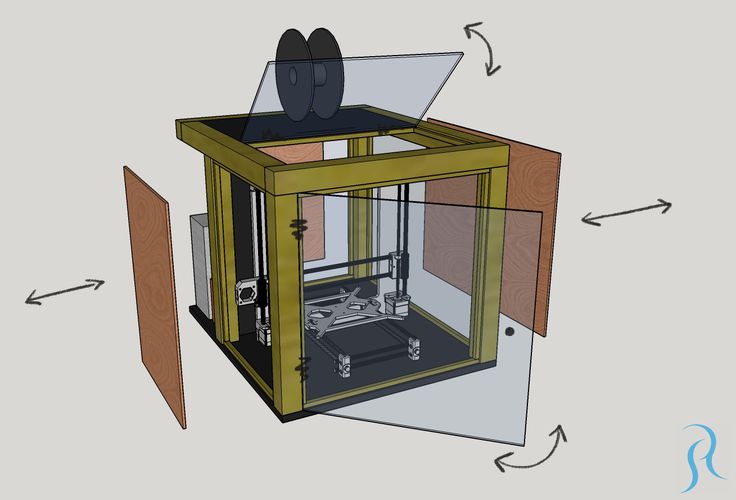

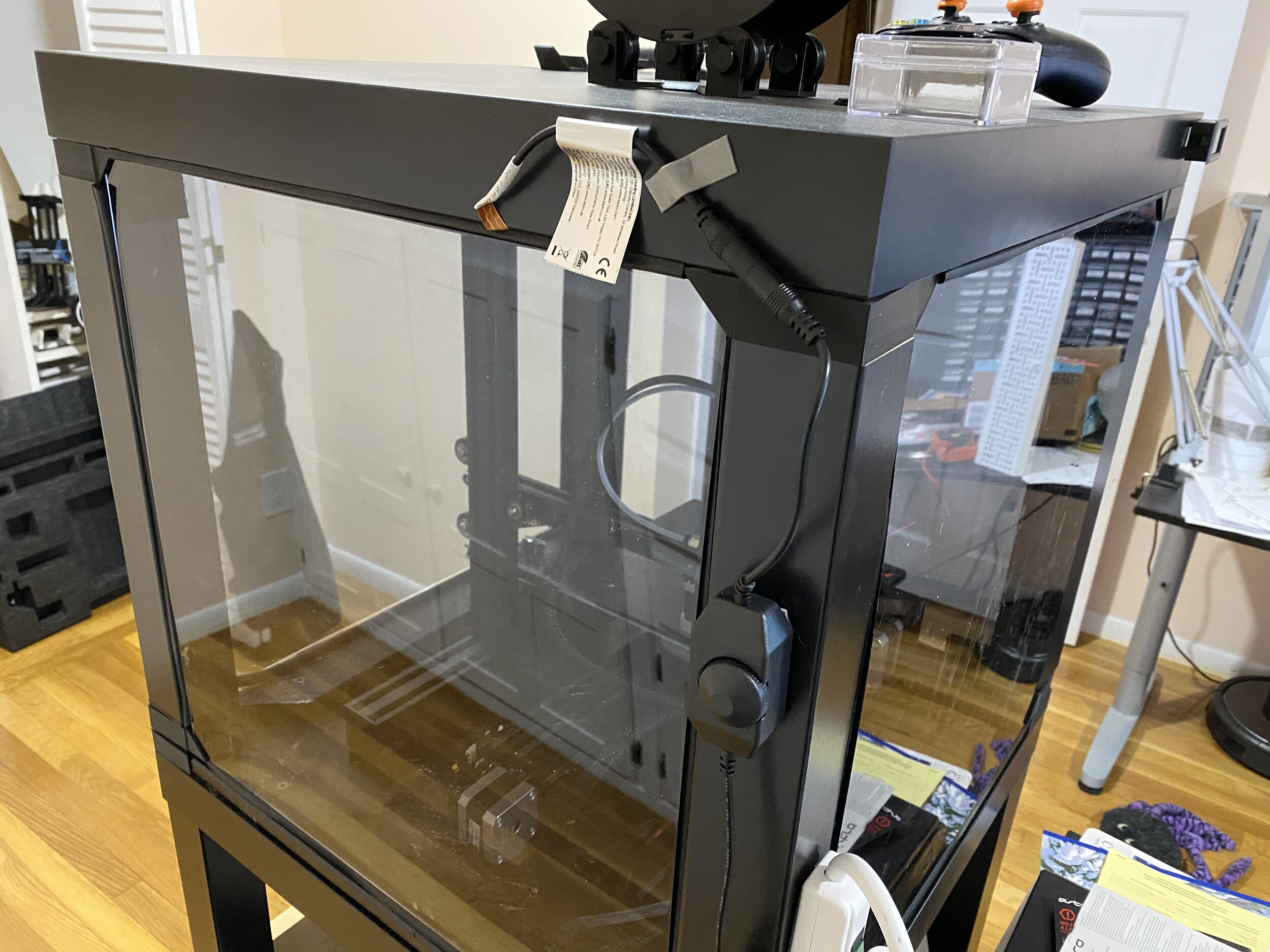

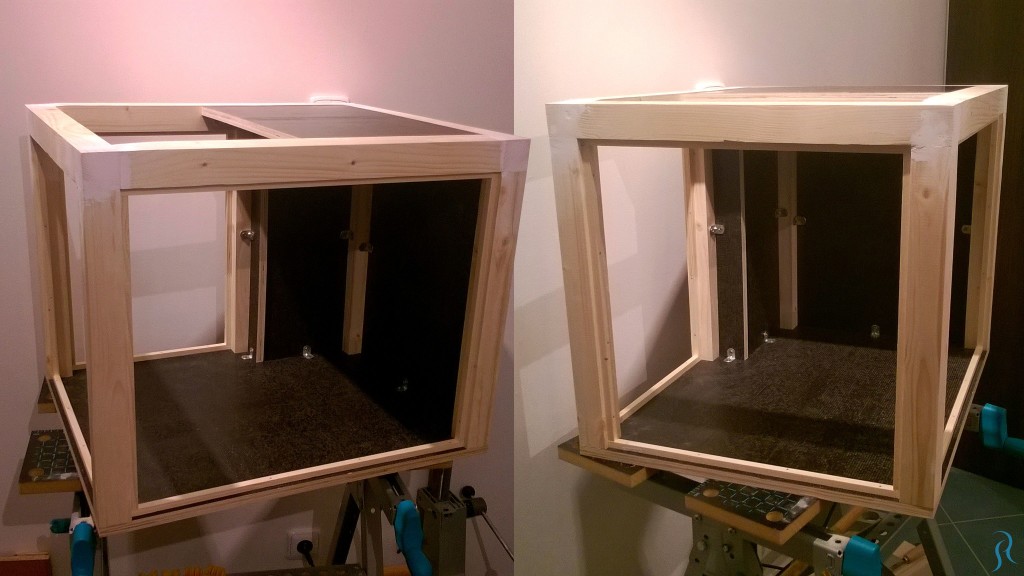

3D printing - RD Physics

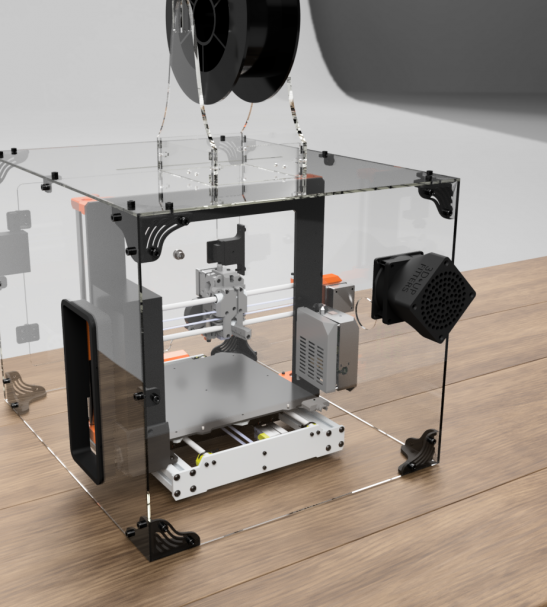

The first version of our 3D printed coaxial CX loudspeaker series was made using the Desktop Metal Forust method, which is, at the moment, too expensive for most DIY audio enthusiasts. Therefore, the CX2 was designed based on fused filament fabrication (FFF).

3D printing gives design freedom

The starting point for the design is simple but effective: sealed enclosure and coaxial driver. This inherently gives us controlled cone displacement in the low-frequency region and a coherent radiation source in the crossover region. 3D printing allows to easily implement two more acoustically beneficial geometries: large roundovers and compound curved walls. These translate into a Minimal Edge Diffraction Enclosure (MEDE™) and reduced panel vibrations, respectively. Curved walls mean that the loudspeaker requires a stand. This requirement can be turned into a benefit: the symmetric loudspeaker can be tilted or laid on its side when placed on a so-called Isopodd stand 3D printed from soft TPU material. 3D printing allows complex shapes at no extra manufacturing cost. For example, the front baffle is stiffened on the inside with a honeycomb strucure that acts also as support for the overhangs, but robs very little internal volume.

3D printing allows complex shapes at no extra manufacturing cost. For example, the front baffle is stiffened on the inside with a honeycomb strucure that acts also as support for the overhangs, but robs very little internal volume.

What you need to build your own CX2

- 3D files for 3D printing, sold on Etsy. Dimensions 210x273x170 mm, ~1200 grams of filament.

- SB Acoustics SB13PFCR25-4 COAX or SEAS MP15 (contact us)

- Active crossover, miniDSP recommended

- Two channels of amplification per speaker, ICEpower module recommended

- Neutrik NL4MPR SpeakON connectors and fastON crimp connectors

- 4.2 mm wood screws

- Bitumen or similar visco-elastic damping sheet and fibrous damping material such as pillow stuffing

- Soldering capability (super easy)

How to build it

3D print the enclosures using the files mentioned above. It’s a single-piece print with no support needed. Wood-filled PLA or similar material is easy to sand and no other surface finish besides sanding is needed. If you are using the SEAS drivers you also need to print the TPU gasket/adapter. The speaker can be tilted and rotated when you print a small stand for it from TPU material. Some rubber feet on a plate will do the same job just fine. The assembly order is as follows:

If you are using the SEAS drivers you also need to print the TPU gasket/adapter. The speaker can be tilted and rotated when you print a small stand for it from TPU material. Some rubber feet on a plate will do the same job just fine. The assembly order is as follows:

- Finish the outside of the enclosure and make sure the driver and SpeakON connector fit.

- Line the inside with bitumen damping material and fill it quite densily with wadding.

- Solder wires to the speaker drivers and crimp fastON connectors at the other end. Mark woofer and tweeter positive and negative wires.

- Feed the wires through the SpeakON connector opening and mount the driver using wood screws. Use gasket/adaptor if you have the SEAS driver.

- Connect the fastON connectors to you SpeakON connector and mount it.

- Setup your bi-amping and crossover configuration. A good starting point for crossover frequency is 2 kHz. On-axis response will be bright, so keep that in mind when equalizing.

Some toe-in may be beneficial.

Some toe-in may be beneficial.

Video

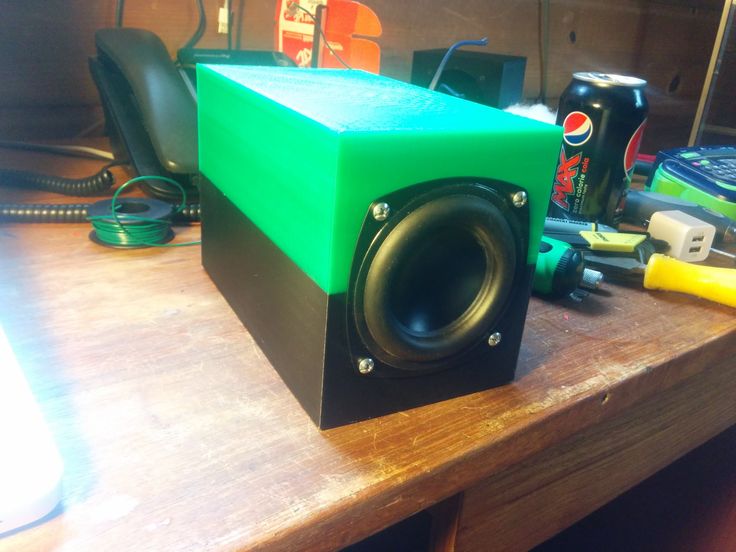

3D printed bluetooth speakerWhat’s wrong with having batteries in your portable boombox?

Wireless electronics, such as bluetooth speakers, are extremely popular nowadays. All such devices must have a power source and typically it is a lithium-ion battery. However, the demand for battery raw materials is rising at an alarming rate:

The supply of some of these [battery] materials, in particular cobalt, natural graphite and lithium, is of concern today and for the future in view of the large quantities needed and/or very concentrated supply sources.

European Battery Alliance (EU)

As we have discussed earlier, when launching our Circular Sound program, the best solution for reducing reliance on critical raw materials is to reduce their use. The RD Physics BB1 boombox enables you to do just that. It is designed to use existing external power sources and therefore no new batteries are needed. Battery service-life or battery replacement is no longer a concern.

The RD Physics BB1 boombox enables you to do just that. It is designed to use existing external power sources and therefore no new batteries are needed. Battery service-life or battery replacement is no longer a concern.

Alternatives to dedicated batteries

The BB-project started by looking at how power tools are sold without accompanying batteries. The idea being that the user needs only one battery (plus spares) that fits all tools. While this approach reduces the amount of batteries needed, it is also used to tie the customer to a specific brand. We wanted a universal solution and therefore the USB-C standard was chosen. The BB1 and BB2 boomboxes use a USB-C port as an interface to feed power to the amplifier. The boombox can be connected to any USB port: power banks, phone chargers, laptops, extension cords, solar panels etc. Obviously, the input voltage and current draw is limited, which leads to limited sound pressure level (SPL).

Components

What you will need to build your own batteryless boombox:

- Geometry files for 3D printing (free under Creative Commons License at Thingiverse)

- 3D printer big enough to fit a 235 mm diameter sphere

- Slightly over 1 kg of filament depending on your settings

- Two active drivers. Either Peerless 3″ (BB1) or Dayton Audio 4″ (BB2)

- One 6½” Dayton Audio passive resonator

- A Sure (Wondom) bluetooth board with additional cables set

- USB-C panel mount plug (from eBay) and 6 mm DC plug

- Wood screws (4.2 mm for the drivers and resonator, 3 mm for the BT board)

- Drawer handle, IKEA Eneryda 703.475.16

- Damping material (bitumen or similar automotive damping mat and fibrous wadding, for example pillow stuffing)

- Optional: Wall mount bracket, Genelec 4000-410B

- Minimal soldering capabilites

The enclosure for the BB1 and BB2 can be downloaded from the link above. Assembling everything takes 30 minutes.

Assembling everything takes 30 minutes.

How to build the BB1/BB2 bluetooth speaker

- Start by soldering the 6 mm DC plug to the USB connector. Red (+) goes to center pin and black (-) to outer shell.

- Connect DC power and speaker cables to bluetooth board and fasten the board inside the enclosure by tightening the screws via the driver openings.

- Mount the USB connector and handle.

- Line the inside of the enclosure with bitumen or similar visco-elastic damping material. Heat will aid in conforming to internal shapes. Make sure the damping material is fully bonded to the walls.

- Bring the speaker wires through the driver openings and solder them to the drivers. Make sure polarity is the same for both drivers. Then fasten the drivers using wood screws.

- Fill the enclosure with fibers (cotton, polyester, wool etc.) and fasten the passive resonator.

- Optional: Attach the wall mount bracket.

- Connect a USB port and the bluetooth board powers on automatically.

Pair your signal source with the device (“WONDOM”). Enjoy!

Pair your signal source with the device (“WONDOM”). Enjoy!

Assembly instructions

Concept and sound test

3D printed enclosure from BrightBio material and natural blue dyeIntroduction

The loudspeaker industry, like all other industries, needs to transform into a circular economy model. Why? because only 8.6% of the materials we use circulate back into the economy, according to the Circularity Gap Report 2021. We need to increase this number in order to reach the Sustainability Development Goal 12.5 set by the United Nations:

We need to increase this number in order to reach the Sustainability Development Goal 12.5 set by the United Nations:

By 2030, substantially reduce waste generation through prevention, reduction, recycling, and reuse.

United Nations Sustainability Development Goal SDG 12.5

Circular Economy of Loudspeakers

Some loudspeaker manufacturers use recycled or renewable enclosure materials, but the biggest problem is circulating the electronics and loudspeaker drivers back into the economy. There is an abundance of old loudspeakers being discarded or sold very cheap every year, because demand for old models has diminished. Buying new loudspeakers made from virgin materials is not sustainable, especially due to the rare-earth elements (REE) used in loudspeaker magnets.

Rare earth elements (REEs) are essential for manufacturing permanent magnets. Permanent magnets are critical components in most decarbonisation technologies.

European Union EIT Raw Materials

The European Union is dependent on imported magnets and REEs. A circular economy model would not only be good for the environment, but also for the reliability of supply chains.

Additive manufacturing enables circular economy

Additive manufacturing offers many opportunities for a circular economy, where repair and remanufacturing are some of the best options to reduce the consumption of mass-produced products made in far-away lands. Circular economy can be described by the 6 REs:

- REduce – Don’t buy anything

- REuse – Buy second-hand

- REpair – Fix it, if it’s broken

- REmanufacture – Make something new using old components

- REcycle – Cycle the raw material back into the economy

- REcover – Burn for energy

As far as loudspeakers are concerned, the best option is of course not to buy anything. The second and third best options are to buy used loudspeakers or fix broken loudspeakers. These two options, however, do not consider the fact that the user may want something different compared to their current product or what is available second-hand. In other words, it does not help if a product can be used forever if nobody wants it anymore. Circular Sound tackles this issue by relying on remanufacturing with the help of 3D printing. In this context, remanufacturing means using the drivers and electronics from old loudspeakers and 3D printing a new enclosure. Obviously, the material of the new enclosure needs to be sustainable, too. Recycled and bio-based plastics are promising, but require special design considerations to obtain the necessary acoustic properties from the enclosure.

These two options, however, do not consider the fact that the user may want something different compared to their current product or what is available second-hand. In other words, it does not help if a product can be used forever if nobody wants it anymore. Circular Sound tackles this issue by relying on remanufacturing with the help of 3D printing. In this context, remanufacturing means using the drivers and electronics from old loudspeakers and 3D printing a new enclosure. Obviously, the material of the new enclosure needs to be sustainable, too. Recycled and bio-based plastics are promising, but require special design considerations to obtain the necessary acoustic properties from the enclosure.

RD Physics CS-012 proof-of-concept prototype

The RD Physics CS-012 is the first loudspeaker design in the Circular Sound line-up. The donor components come from an old Yamaha YST-SW012 bass-reflex subwoofer. Additive manufacturing was used to produce a smaller, sealed enclosure loudspeaker. The material used in the prototype is a bio-based material produced by BrightPlus. It has a natural dye made from woad by Natural Indigo Finland. The original Yamaha loudspeaker is designed to be used as a single subwoofer unit placed somewhere on the floor out of sight. The new product, on the other hand, is designed to be used in stereo configuration (2 pcs) and placed under the main speakers. It serves a different function compared to the original product, but no new materials need to be consumed. We are not injecting a new product made from virgin materials into the economy. Instead, we are taking two old ones out and replacing them with one value-added product. This is what Circular Sound is about. You don’t have to wait for distributors to bring sustainable products to your local market.

The donor components come from an old Yamaha YST-SW012 bass-reflex subwoofer. Additive manufacturing was used to produce a smaller, sealed enclosure loudspeaker. The material used in the prototype is a bio-based material produced by BrightPlus. It has a natural dye made from woad by Natural Indigo Finland. The original Yamaha loudspeaker is designed to be used as a single subwoofer unit placed somewhere on the floor out of sight. The new product, on the other hand, is designed to be used in stereo configuration (2 pcs) and placed under the main speakers. It serves a different function compared to the original product, but no new materials need to be consumed. We are not injecting a new product made from virgin materials into the economy. Instead, we are taking two old ones out and replacing them with one value-added product. This is what Circular Sound is about. You don’t have to wait for distributors to bring sustainable products to your local market. You can start making these today. The files are shared for free under a Creative Commons license on Thingiverse.

You can start making these today. The files are shared for free under a Creative Commons license on Thingiverse.

3D printed loudspeakers do not have to be made out of plastic anymore. There is a new way of 3D printing wood called Forust. It is a binder jetting process where upcycled sawdust is used together with a binder to form the closest thing we have to 3D printed wood. We are particularly interested in the possibilities this offers loudspeaker manufacturers.

RD Physics CX1 – A coaxial loudspeaker

RD Physics has been developing speakers with full-range drivers for some time now and while they have their inherent benefits, it is time to look what coaxial drivers have to offer. The starting point was a spherical shape, which is known for its benefits. However, the limitations in build volume favored a shape closer to a rectangular cuboid. The shape of the CX1 has the largest possible roundovers, with the constraints imposed by driver size and maximum baffle dimensions. This is to reduce edge diffraction. The sides are compound curved to maximize stiffness. There is also internal ribbing to stiffen the enclosure without taking up internal volume like a sandwich structure would. The enclosure is made in two parts; the front baffle has a separate cover that conceals the driver flange and mounting screws. The driver is a proprietary SEAS unit designated MP15 (15 cm diameter). The idea is to have an external active crossover and bi-amp the loudspeaker via the Neutrik SpeakOn 4-pin connectors at the back.

The starting point was a spherical shape, which is known for its benefits. However, the limitations in build volume favored a shape closer to a rectangular cuboid. The shape of the CX1 has the largest possible roundovers, with the constraints imposed by driver size and maximum baffle dimensions. This is to reduce edge diffraction. The sides are compound curved to maximize stiffness. There is also internal ribbing to stiffen the enclosure without taking up internal volume like a sandwich structure would. The enclosure is made in two parts; the front baffle has a separate cover that conceals the driver flange and mounting screws. The driver is a proprietary SEAS unit designated MP15 (15 cm diameter). The idea is to have an external active crossover and bi-amp the loudspeaker via the Neutrik SpeakOn 4-pin connectors at the back.

3D printing a loudspeaker using Desktop Metal Forust method

The geometry files were sent to Forust for 3D printing. The chosen colour is “natural” with the artificial wood grain introduced during manufacturing. The result is a structure that looks like plywood. Parts can be ordered without the grain and with darker colours, too. The grain is more interesting, however, because various surface texture effects can be achieved by aligning the layers at low angles relative to the principal axes of the printed shape giving a zebra stripe effect.

The result is a structure that looks like plywood. Parts can be ordered without the grain and with darker colours, too. The grain is more interesting, however, because various surface texture effects can be achieved by aligning the layers at low angles relative to the principal axes of the printed shape giving a zebra stripe effect.

Post-processing of 3D printed wood

The parts printed with the Forust method can be sanded smooth, but it is not like sanding natural wood. The surface can be varnished, but not stained. The Forust material does not absorb wood stain. It does not tolerate ethanol and perhaps other solvents either. Long-term exposure to water should be avoided, otherwise there will be is a sticky brown residue on the surface. Although a wooden look can be mimicked, post-processing is not similar to wood. Instead, it resembles the wood-filled polymers used in our previous builds. This is not a serious drawback, it just means that 3D printing skills are more useful than woodworking skills. In terms of aesthetics this is the closest thing available for increasing the acceptance of 3D printed loudspeakers in the audio community, where wood veneer is the go-to solution.

In terms of aesthetics this is the closest thing available for increasing the acceptance of 3D printed loudspeakers in the audio community, where wood veneer is the go-to solution.

Video

- Tags 3d printed, desktop metal, diy audio, forust, Loudspeaker, speaker, wood

The third version of our 3D printed full-range FR loudspeaker series used metal-filled filament to add density and stiffness to the enclosure. It worked in that regard, but the material was unpractial due to brittleness both during printing and in the final product.

What has changed compared to the FR3 speaker

For the fourth version we switched to wood-filled filament, which is more ductile and easier to process. The surface is quite nice straight out of the printer thanks to the matte surface. A quick touch with an orbital sander gives a smooth finish. The spherical shape of the enclosure remains the same as in the FR3 speaker, because it was proven to be very good in terms of resonances and edge diffraction. The diameter of the driver, enclosure and tripod legs was reduced to obtain a more slender design for desktop use. The binding posts are upgraded to sturdy Dayton Audio binding posts. The driver used is the Tang Band W3-1878, and the leadscrews for the legs are 12 mm. Leadscrew nuts are bonded into recesses in the enclosure and allow for adjustment of the legs. Small TPU feet can be printed and placed at the ends of the leadscrews in order to avoid scratching the desktop. These are satellite speakers and need a subwoofer to compliment the lower frequency spectrum.

The surface is quite nice straight out of the printer thanks to the matte surface. A quick touch with an orbital sander gives a smooth finish. The spherical shape of the enclosure remains the same as in the FR3 speaker, because it was proven to be very good in terms of resonances and edge diffraction. The diameter of the driver, enclosure and tripod legs was reduced to obtain a more slender design for desktop use. The binding posts are upgraded to sturdy Dayton Audio binding posts. The driver used is the Tang Band W3-1878, and the leadscrews for the legs are 12 mm. Leadscrew nuts are bonded into recesses in the enclosure and allow for adjustment of the legs. Small TPU feet can be printed and placed at the ends of the leadscrews in order to avoid scratching the desktop. These are satellite speakers and need a subwoofer to compliment the lower frequency spectrum.

You can 3D print your own sub and satellite system by purchasing the STL files from our Etsy Shop.

Video

Subwoofer Concept

Our previous 3d printed subwoofer, the SW1, is a 13 liter subwoofer with a 6.5″ driver, a matching passive radiator and a plate amp. We wanted to develop something smaller that would still offer the bass extension that satellite speakers so badly need. The result is the SW2 using a Tang Band W5-1138 5″ long-throw driver and the same Dayton Audio DSA175 passive radiator as in the SW1. The enclosure is now only 5 liters and much easier to fit on a desktop. The passive resonator allows tuning the resonance frequency to avoid overlap with room modes, for example. The spherical shape is optimal for material use and stiffness. Combined with the small diameter driver with large surrounds, the appearance is quite unique. If a traditional box is what you want, then this build is not for you.

Measurements

The measured resonance frequency of the passive radiator indicates that some air-coupling occurs due to the downward firing placement. Simulated resonance frequency matches the measured value (53 Hz) when 16 grams of added mass is used. Mass can be further added using washers to tune the response. In practice, the frequency response starts to drop below 50 Hz. The Arylic amplifier offers DSP capabilites and using a computer as the source allows unlimited DSP with zero cost. Therefore, frequency response in not that meaningful especially when considering the room effects, but we have included some measurements to give an idea of the natural response especially around the lower cut-off.

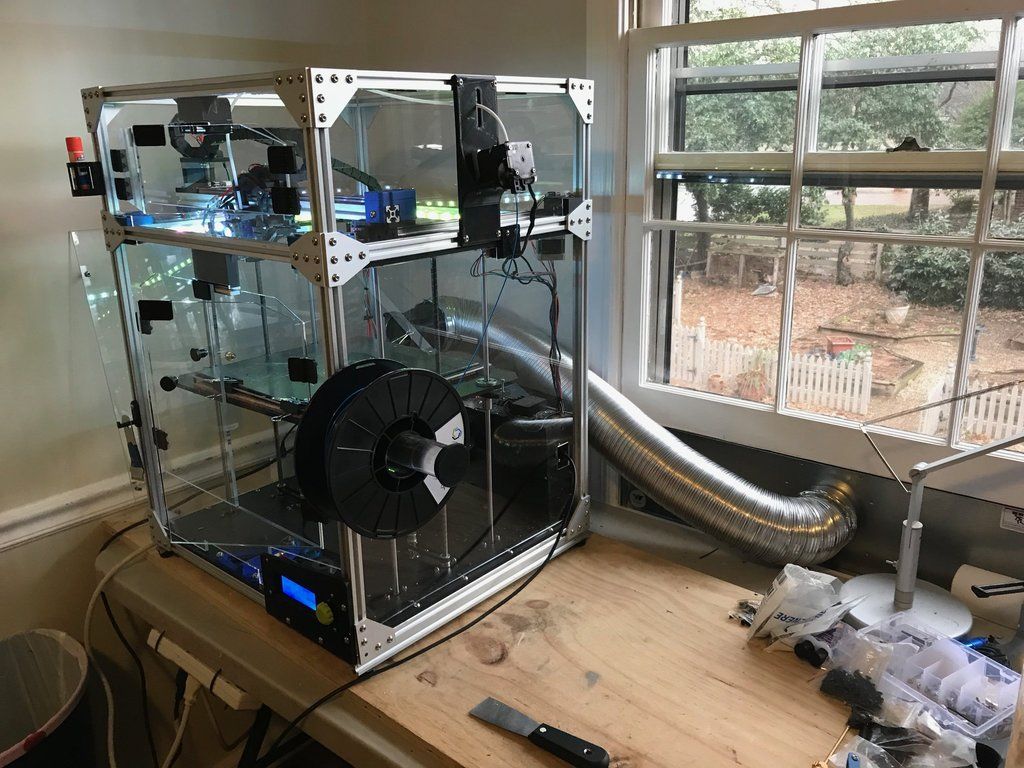

3D printing

The enclosure is printed in one part (234 mm diameter) and takes approximately 1.5 kg of filament. Print time is about 48 hours. The mass can be increased by lining the walls with sound deadening mat. Although the external wall is spherical, there is a cylindrical inner wall that braces the woofer to the passive resonator and, thanks to a single curvature surface, allows easy installment of thick sound deadening mat. The drivers are fastened using 4.2 mm wood screws. There is a geometry file for a gasket for the woofer which can be printed from TPU. Traditional gasketing methods will work, but the 3D printed gasket is seamless and has the screw hole pattern accurately incorporated. The binding posts are recessed deep into the enclosure and only accept banana plugs in that configuration. An O-ring under the binding post washer is recommended and there is a chamfer for it. 3D printing using a wood-filled filament allows easy sanding for a smooth surface finish. The photos show 15 minutes worth of post-processing making this a very easy and fast build without compromising in function and looks.

The drivers are fastened using 4.2 mm wood screws. There is a geometry file for a gasket for the woofer which can be printed from TPU. Traditional gasketing methods will work, but the 3D printed gasket is seamless and has the screw hole pattern accurately incorporated. The binding posts are recessed deep into the enclosure and only accept banana plugs in that configuration. An O-ring under the binding post washer is recommended and there is a chamfer for it. 3D printing using a wood-filled filament allows easy sanding for a smooth surface finish. The photos show 15 minutes worth of post-processing making this a very easy and fast build without compromising in function and looks.

Images

Sound quality

The subwoofer was compared to the much larger, THX certified Logitech Z623 subwoofer. The sound is very similar, but in a much smaller package. The SW2 is a great companion for small satellite speakers and brings fullness to the bass. Electronic music will benefit from the “boom” offered by this small unit, while other types of music may require turning down the level a bit for a tighter bass.

Links and video

The 3D files can be found in Etsy store:

https://www.etsy.com/shop/RDPhysics

Please support us by using the affiliate link below just before ordering the components:

TangBand W5-1138 on SoundImports.eu

Dayton Audio DSA175-PR on SoundImports.eu

Arylic 2.1 BT amp on SoundImports.eu

Our 3D printed full-range speakers needed something to beef up the lower end of the frequency spectrum. We set out to design a compact subwoofer that can be used together with our FR3 speakers. The result is a 13 liter enclosure with a 6.5″ driver, a matching passive resonator and a plate amp. The passive resonator allows tuning the resonance frequency to match room modes, for example. The plate amp can power satellite speakers and has a fixed high-pass filter. The low-pass cut-off frequency for the subwoofer can be adjusted and the level too, which means that this system can be easily mated with signal sources that do not have equalizing or DSP capabilities in themselves.

The plate amp can power satellite speakers and has a fixed high-pass filter. The low-pass cut-off frequency for the subwoofer can be adjusted and the level too, which means that this system can be easily mated with signal sources that do not have equalizing or DSP capabilities in themselves.

3D printing

The enclosure consists of two parts, which are glued together after printing. Total print time is about 100 hours and uses about 4 kg of filament. Support is only needed for the small recess where the plate amp is mounted. Dual-material printing is not needed. The mass of the enclosure can be increased by filling the walls with epoxy through the holes in the back. A geometry file for 3D printing a matching funnel is provided, too. 2 kg additional mass can be obtained this way.

The 3D files can be found on Thingiverse for free:

https://www.thingiverse.com/thing:4802531

Please support us by using the affiliate link below just before ordering the components:

Dayton Audio DSA175 on SoundImports. eu

eu

Dayton Audio DSA175-PR on SoundImports.eu

Lepai LP210PA amp on SoundImports.eu

Video

The video below explains the concept in more detail.

Metal-filled filament and internal support add significant mass and rigidity.

The first version used internal ribbing and bitumen paint to reduce enclosure resonance. The second version used an external carbon fiber shell. Both approaches were a bit cumbersome. For the third version we wanted to fully use the capabilities of 3D-printing. Therefore, a high-density metal-filled filament was used and internal gyroid-shaped support was used even where overhanging surfaces would not have required it. In addition, height and tilt can be adjusted using three threaded rods that form a tripod. The finished enclosure with three 14 mm trapezoid-threaded nuts bonded to it weighs 1.2 kg.

In addition, height and tilt can be adjusted using three threaded rods that form a tripod. The finished enclosure with three 14 mm trapezoid-threaded nuts bonded to it weighs 1.2 kg.

Please support us by using the affiliate link below for ordering the Dayton Audio RS-100 drivers:

SoundImports.eu

Full-range speaker with carbon fiber skinAdditive manufacturing

Using additive manufacturing (AM) has many benefits over traditional construction methods, such as design freedom, fast product development and integration of functions into one part. There are drawbacks as well. The plastic AM parts tend to be low in mass and not very stiff. Air-tight walls are sometimes difficult to achieve, too. Adding mass by increasing fill density of the print is not a good solution, since it adds build time and material cost. Stiffeners and bitumen paint were used in (Version 1). However, the stiffeners were cumbersome to paint with bitumen and it did not add significant weight. For Version 2, we used the vent as a part of the mechanical structure and used a thicker wall. But some additional means were needed to bring 3D printed enclosures on par with traditional cabinet materials.

Adding mass by increasing fill density of the print is not a good solution, since it adds build time and material cost. Stiffeners and bitumen paint were used in (Version 1). However, the stiffeners were cumbersome to paint with bitumen and it did not add significant weight. For Version 2, we used the vent as a part of the mechanical structure and used a thicker wall. But some additional means were needed to bring 3D printed enclosures on par with traditional cabinet materials.

Carbon fiber in loudspeker building

Dry carbon fiber tow was wound around the enclosure and then wetted with epoxy resin. The composite skin was sanded after curing and additional coats of epoxy were added. The result is a unique unidirectional carbon fiber surface finish. The composite shell adds mass and stiffness to the enclosure. The loudspeaker sits on four feet printed from TPU material, which allows rotating the speaker.

Make them yourself

The following changes were made to Thingiverse:

- Updating the driver dimensions and screw pattern to the latest Alpair 7 MS.

- The weight of the loudspeaker will try to bend the speaker stand. It was therefore changed from a shell-like structure to a solid.

If you plan to order the drivers, please support us by using the affiliate link below:

SoundImports.eu

Video

Construction

The first version of #3D-Fi speakers are spherical (180 mm diameter) full-range loudspeakers with 3 liter internal volume. The box is vented with two rectangular ports on both sides. The ports act as stiffeners and also give more space to assemble the connectors and amplifier inside the enclosure. Internal wall stiffeners are used in order to maximize internal volume as opposed to simply increasing wall thickness, since a small external size is typically desired while internal volume needs to be high enough for the driver to work properly. We use bitumen paint to both seal the enclosure and also to add mass. The enclosure is printed as one part using UPM Formi3D cellulose composite filament. Metallic nuts are pressed on the backside of the flange to receive the machine threaded screws that hold the emitter.

We use bitumen paint to both seal the enclosure and also to add mass. The enclosure is printed as one part using UPM Formi3D cellulose composite filament. Metallic nuts are pressed on the backside of the flange to receive the machine threaded screws that hold the emitter.

Setup

Our setup uses a laptop PC as a source which allows equalizing the frequency response at the digital source. The signal is transferred via USB to a USB-powered DAC/pre-amplifier with volume control and a power switch. The analog signal is then transferred to one of the speakers where it is amplified using a two-channel chip amplifier board that is powered by a 65 W laptop charger. The amplified signal of the other channel is then transferred to the other speaker for reproduction. The design uses 6 cm full-range emitters without any analog filters or corrections.

The design was updated for Thingiverse:

- Machine screws and nuts replaced with 2.5 mm hole for wood screws

- Fully passive design without the amp.

Instead, 4 mm holes for binding posts only

Instead, 4 mm holes for binding posts only - Sealed enclosure

If you like the design and plan on building one yourself, please support us by using the affiliate link below for ordering the components:

MarkAudio Alpair 6 on SoundImports.eu

Sound

A reference system with Genelec 8040 speakers was used for comparison. The sound of the 3D-Fi speakers is very unique and quite tricky to get the most out of. The full-range emitters are very sensitive to off-axis listening and the listening distance also changes the sound markedly. Even slightly tilting one’s head has an effect. It seems that finding the best spot is challenging and takes time. It’s hard to remember not to move an inch while listening to these speakers. However, all the effort pays off, because there is a reward at the end. The sound stage is unbelievably good and there is a huge presence from such a tiny speaker. The Genelecs sound distant and all over the place compared to the very precise and point-like sound of the 3D-Fi speakers. Obviously the bass is not very deep and the sound pressure levels achievable with 6 cm cones is limited. On the other hand, they seem to tolerate significant bass boost without distortion and in normal listening the cone travel stays in check. Overall, a very difficult set of speakers to get into and they are quite picky with the type of music played, but once a good recording is found together with the right listening conditions…Bliss!

Obviously the bass is not very deep and the sound pressure levels achievable with 6 cm cones is limited. On the other hand, they seem to tolerate significant bass boost without distortion and in normal listening the cone travel stays in check. Overall, a very difficult set of speakers to get into and they are quite picky with the type of music played, but once a good recording is found together with the right listening conditions…Bliss!

Acknowledgements: We wish to thank UPM for the materials and support. J-P Virtanen took the studio pictures and Markus Markkanen the ones in the library.

Acoustic reality suppression device, or music from a 3D printer / Sudo Null IT News

Good day to you, dear geeks and sympathizers!

According to my observations, almost all owners of 3D printers are divided into two groups: those who need it, and those who really need it. It was with the aim of stimulating the growth of the number of citizens in the second group that this publication was written.

It was with the aim of stimulating the growth of the number of citizens in the second group that this publication was written.

Anyone who is interested in what connects a 3D printer and music, why some old sayings have lost their relevance, and how to turn a simple cardboard into a steel blank - welcome under the cut! nine0007

It's no secret that thanks to the efforts of greedy scoundrels effective management and unscrupulous scammers modern marketers, the shelves of audio equipment stores are mostly filled with ordinary garbage, the real technical characteristics of which are skillfully hidden under kilometers of advertising texts with incomprehensible abbreviations and inflated results of some meaningless tests.

What should a lazy and stingy person who wants to buy inexpensive, but high-quality "desktop" speakers do? As in most of these cases, the question already contains part of the answer: the columns need to be done. nine0003

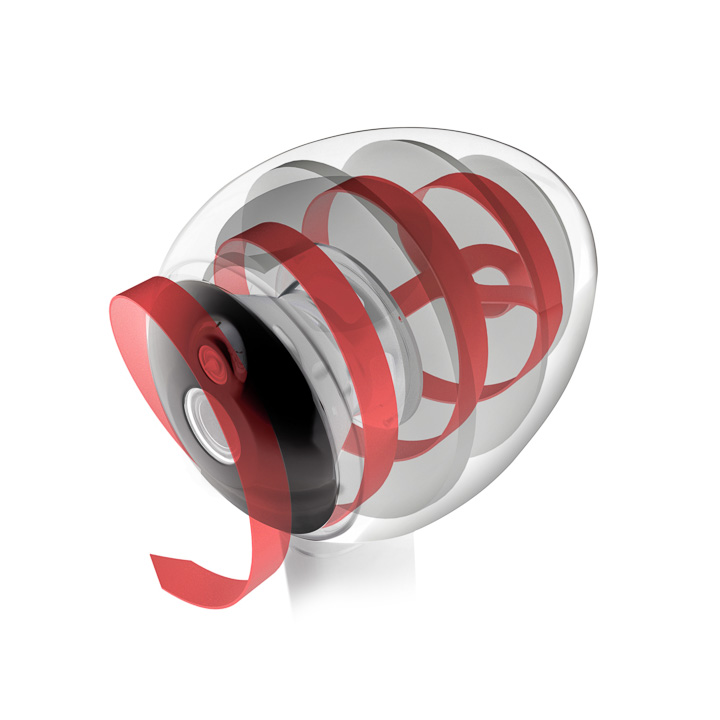

Taking this opportunity, I decided to realize my old dream - omnipolar loudspeakers. These speakers differ from conventional front speakers in that sound waves are emitted simultaneously in all directions with the same amplitude and phase, which in theory should create the most natural sound picture. In its simplest form, this is achieved by placing a diffuser cone on top of the upwardly directed full-range loudspeaker head. The correct calculation of such acoustic systems (hereinafter referred to as AC) is not an easy task and requires serious education in this area. Therefore, I chose the oldest method of conducting research

These speakers differ from conventional front speakers in that sound waves are emitted simultaneously in all directions with the same amplitude and phase, which in theory should create the most natural sound picture. In its simplest form, this is achieved by placing a diffuser cone on top of the upwardly directed full-range loudspeaker head. The correct calculation of such acoustic systems (hereinafter referred to as AC) is not an easy task and requires serious education in this area. Therefore, I chose the oldest method of conducting research incomprehensible garbage complex processes - empirical. Simply put, you will have to act at random and at random, with alterations and design improvements in the manufacturing process.

The most important component of any speaker, which cannot be modified at home, is the loudspeaker head (hereinafter referred to as HG). Since I decided to make a compact and inexpensive single-way speaker, choosing a head turned into a non-trivial task with many unknowns.

For myself, I have developed the following search algorithm: suitable size - bandwidth - uniformity of frequency response and phase response - nominal resistance - price. nine0003

The leader of the search was the broadband GG FR88EX manufacturer Fountek:

This driver has an aluminum frame and cone, a wide frequency range, smooth frequency response and phase response. All parameters are given by the manufacturer in the technical documentation:

For the speakers, the simplest design was chosen: a cylindrical body, a GG is fixed on the upper end. A sound-diffusing cone should be fixed above the GG. The design of the case is an acoustic impedance panel at the bottom end, loose sound-absorbing material throughout the volume of the speaker. For the case, a pipe made of thick cardboard with a diameter of 125 mm (corresponding to the dimensions of the GG) was chosen. Self-adhesive bituminous vibration-absorbing mats were glued to the inner surface of the pipe, which made it possible to completely suppress vibrations and the boom of the body. The technology is simple: heating the mats with a hair dryer, we roll them with the sticky side to the pipe from the inside using an aluminum “rolling pin”. The hardest part here is finding a woman with a hair dryer. nine0003

The technology is simple: heating the mats with a hair dryer, we roll them with the sticky side to the pipe from the inside using an aluminum “rolling pin”. The hardest part here is finding a woman with a hair dryer. nine0003

Further, highly scientific experiments were carried out. In absolute contradiction to the proverb “Measure seven times, cut once”, diffusers were printed, crushed, cut, melted, thrown away and reprinted for the sake of experimental curiosity. By the way, PETG as a material is ideal for printing experimental parts of the speaker.

The conical sound diffuser is the undisputed winner. On the right side of the photo, this cone is visible above the GG, mounted at the end of the case on a plug-holder printed on a 3D printer. nine0003

A few words about the design: due to the use of dissimilar materials and the complex shape of parts, I excluded gluing with some kind of veneer or similar material as unnecessarily labor-intensive. The black color was considered boring, the silver color was considered vulgar. I decided to make my modest contribution to the creation of the post-apocalyptic universe and give the AU the appearance of a battered military equipment created using radioactive materials.

I decided to make my modest contribution to the creation of the post-apocalyptic universe and give the AU the appearance of a battered military equipment created using radioactive materials.

The process of creating parts of the speaker looked like this: creating a model in DesignSpark Mechanical - printing on a 3D printer - cleaning the part - priming - painting. At the same time, in the process of priming the AC case, the wet primer was partially erased with fingers, which ensured the presence of distinct traces of metal corrosion hello Spider . The parts were painted in several stages: first, the parts were painted with stainless steel effect paint and thoroughly dried on the heated working platform of the printer. The next layer was applied transparent varnish, followed by drying for 24 hours. The last layer was applied paint "khaki forest green", roughly corresponding to the color of the old Soviet military equipment. After two hours of drying, you can begin to create the effect of worn metal. To do this, with a piece of cloth soaked in acetone, you need to carefully wipe off the last layer of paint from protruding parts, edges, roundings, edges and “corroded” surfaces. As they say, it's better to see once:

To do this, with a piece of cloth soaked in acetone, you need to carefully wipe off the last layer of paint from protruding parts, edges, roundings, edges and “corroded” surfaces. As they say, it's better to see once:

A very complex detail: bottom cap with acoustic impedance panel grille and cable connector panel.

After painting and drying, one speaker was assembled to check the sound quality. The next photo shows a part of the structure: the M3 studs are passed through the end cap - the holder and the holes in the flanges of the GG and the sound-diffusing cone. All parts are secured with M3 flange nuts. The cone is fixed high enough above the GG: this position was determined experimentally by the maximum of reproducible high frequencies. nine0003

Unfortunately, in this case, the considerable length of the relatively thin studs resulted in significant vibration of the diffuser cone.

As a measure to eliminate this unpleasant effect, I decided to make the sound diffuser heavier and “muffle” by filling it with loose vibration absorber. Since the volume of the cavity of the sound diffuser cone is small, an additional hollow part with a cap was designed and manufactured:

Since the volume of the cavity of the sound diffuser cone is small, an additional hollow part with a cap was designed and manufactured:

A mixture of lead shot and fine quartz sand was chosen as a filler. Lead was chosen for its high specific gravity, and fine quartz sand suppresses vibrations well and prevents the shot from turning the cone into a rattle. Due to the presence of lead in the cone, the cap with the radioactivity symbol is not only decorative, but also a functional element (lead contains a certain amount of radiogenic isotopes). nine0003

The final version of my homemade omnipolar speakers looks like this:

Unfortunately, on this optimistic note, my camera gave its soul to God, and more photos did not come out. The sound quality of these speakers fully meets my needs: gray everyday life melts into the enchanting sounds of “Spente le stelle” by Emma Shapplin already at a third of the available volume, and if you wish, you can effortlessly eject from reality along with “Teutonic Terror” from Accept. nine0003

nine0003

Published under WTFPL license

And the traditional: Have fun!

At the request of workers 3D models and dimensions of the case: drive.google.com/folderview?id=0B3W31PA4TxKDdjU3ZHA4bEt4Rms&usp=sharing

6 models for 3D printing of speakers. Realize your idea

What is a speaker? This is not just an opportunity to immerse yourself in the world of music. The 3D printed models are a broad view of the solution, from Star Wars-inspired designs to physics-based designs. We have compiled our rating of 3D printed speaker models that pump the most

As a rule, speakers are mostly made of wood and have a boring rectangular shape. And only a few commercial projects have managed to change this by creating products of a higher level and interesting design. Next, we present to your attention a range of desktop speakers with an interesting design. Although in fact, who can forbid you to print products on a larger scale? But before we start, here are some tips:

• The walls of the 3D printed speaker cabinet should be as rigid as possible. This will avoid resonance, which means that the sound will be cleaner. nine0007 • A 5mm thick wall with more than 50% fill can provide the basis for a compact cabinet that delivers quality sound.

This will avoid resonance, which means that the sound will be cleaner. nine0007 • A 5mm thick wall with more than 50% fill can provide the basis for a compact cabinet that delivers quality sound.

• The inside of the speaker cabinet should be covered with a soft material. You can use acoustic wool used for damping in loudspeakers. It can even be ordinary wool or glass wool. The sound will be softer, warmer, as the unwanted resonance that creates a piercing sound will be leveled.

So, let's go directly to the models ...

Model - Spirula

Akemake has introduced a model inspired by the most emblematic design in the field of high-quality sound. We are talking, of course, about the famous Bowers & Wilkins Nautilus speakers. To eliminate negative side effects, they still need some kind of additions. That is why the body took a spiral shape. As a result, unwanted resonances are significantly attenuated, resulting in a much cleaner sound. The best solution is to complement the design with quality material. Wood is ideal for this, as it has the best acoustic characteristics. And for printing, you can use Wood PLA, which will also achieve relative success. nine0007

Wood is ideal for this, as it has the best acoustic characteristics. And for printing, you can use Wood PLA, which will also achieve relative success. nine0007

Model - Nomoon

The sphere is one of the most difficult shapes to make, especially when there is some other design on the surface in addition to everything. In this case, 3D printing is the ideal solution. Through 3D printing, it is very easy to create a variety of spherical products with a design.

Initially Nomoon was not supposed to imitate the Death Star, at least, Rich Olsen, the creator of the design, did not pursue such a goal. But as it turned out, the image of a frightening space station came in handy for solving this problem. The model can be adjusted to the size of the speaker, which is also a big plus. nine0007

Model - Super Bass Speaker

This model allows you to increase the reproduction of low frequencies, which is very useful when it comes to jazz or modern dance music. And everything is based on physical laws.

At the very beginning, we noted that for high-quality sound it is necessary to acoustically isolate the front surface from the back. The Super Bass Speaker has a so-called transmission line that shifts the sound wave until it matches the front wave. This is how frequencies are amplified. nine0007

Model — Egg-shaped speakers

These speakers are distinguished not only by their original design, but, as practice shows, they are also capable of reproducing very high-quality acoustics. Everything is explained again by physics. In standard rectangular speakers, parallel walls can create negative effects in sound that detract from the overall quality. As a result, the waves are reflected, superimposed, and can interfere with each other, as they are in each other's way. The most ambitious form in the field of Hi-Fi and Hi-End is the egg. The speaker also accompanies the egg-shaped Heine Nielsen, which creates a bass reflex. In simple terms, the speakers are equipped with a hole in the front, which outputs the bass frequencies.