3D printer motion

Motion Control in 3D Printing

3D printing used to be an abstract concept. It was something out of science fiction. Or it was what a child thought would happen when they put their favorite toy under the lid of their parent's copier and expected another one to come out...no? Just me?

Today, 3D printing is very much a real thing. What was once rare and exclusive technology is now widely available. Not only is it becoming well-known, it's also becoming an increasingly important part of the design and manufacturing process. Creating prototypes and conceptual pieces has never been easier. But none of it would be possible without precise motion control technology.

What is 3D printing used for?

Creating design concepts and prototypes is a critical part of the engineering process. In many cases, engineers would have to use considerable time and resources completely manufacturing parts that would later be thrown out after one use. Engineers can now forgo making expensive molds for prototype castings and instead design their part on a computer and print it out with a 3D printer. This process is now commonly known as rapid prototyping.

While rapid prototyping is one of the main uses of 3D printers, 3D printing can also be used for production. Some parts are hard to make by other methods. Traditional casting does not allow for the creation of hollow structures. And with the improvements made over the years, 3D printers can print parts with a variety of different materials, including various plastics, waxes, and metals. They can even switch materials mid-print. Especially for custom pieces, 3D printing is becoming an increasingly important manufacturing tool.

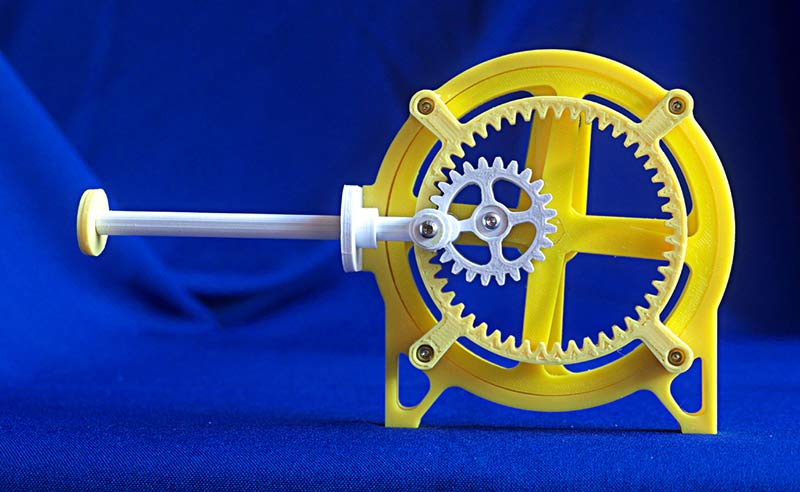

In even more recent years, 3D printing has become something for hobbyists and other individuals outside of the business world. There are dozens of manufacturers for desktop 3D printers. Recent editions of Windows include 3D model building, viewing, and printing programs by default. Toys, crafts, and tools can easily be made with 3D printers in a matter of hours or even minutes. In fact, many of our demos at AMC have 3D printed parts from the desktop printer in our lab.

Toys, crafts, and tools can easily be made with 3D printers in a matter of hours or even minutes. In fact, many of our demos at AMC have 3D printed parts from the desktop printer in our lab.

How does it work?

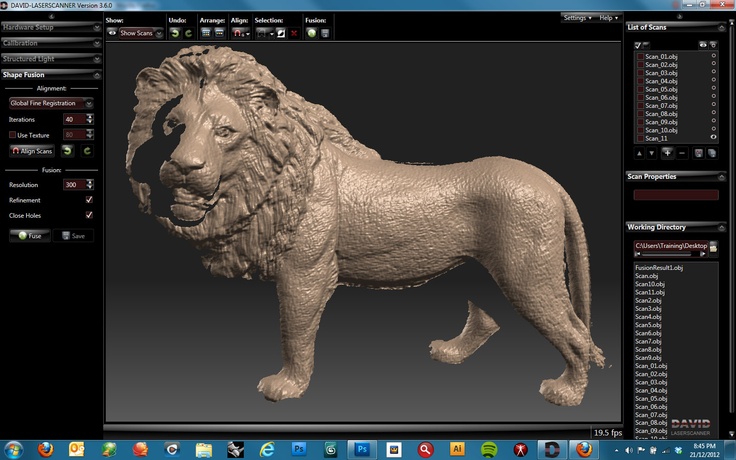

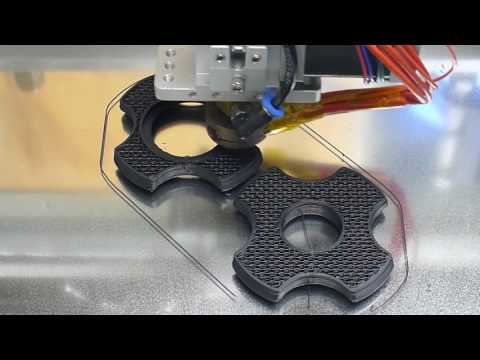

There are a few variations of 3D printing methods. Most 3D prints, however, are done by adding layer by layer of print filament dispensed from a nozzle. The series of layers is defined by a G-code file, usually generated by a slicing program on a computer based on a 3D CAD model.

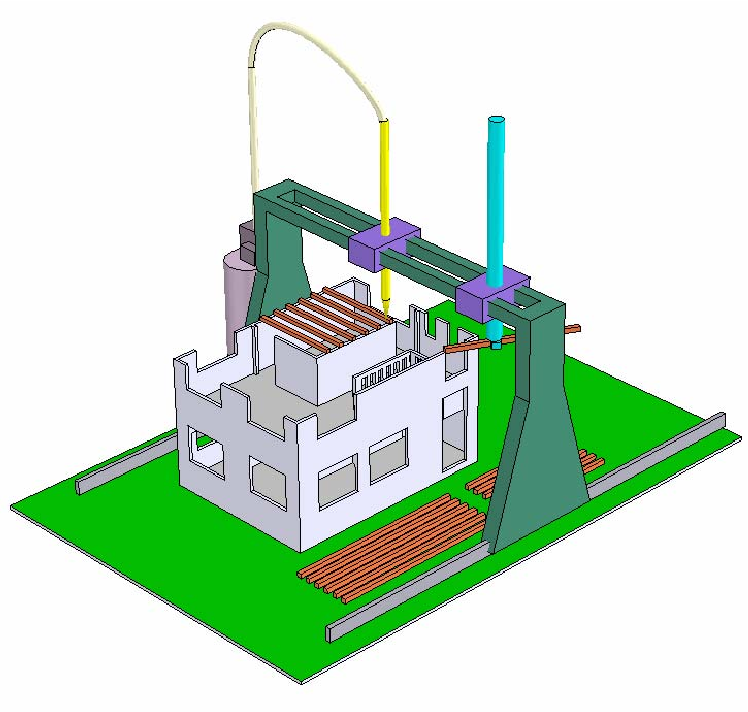

The filament is melted before it leaves the nozzle as print material, but it cools and hardens quickly after exiting. The first layer of the print is printed onto the printer's build plate, which is sometimes heated so that the filament at the bottom stays stuck to it. The nozzle is moved along a dual-axis gantry system to draw out each layer. After each layer is completed, the build plate is lowered, and nozzle starts printing the next layer on top of the previous one. Gradually, the print is built layer by layer. In the cases where one layer overhangs over previous layers, the printer can generate support material, a thin layer of filament that supports the overhanging layers as they cool but can be easily broken off for the final product.

Gradually, the print is built layer by layer. In the cases where one layer overhangs over previous layers, the printer can generate support material, a thin layer of filament that supports the overhanging layers as they cool but can be easily broken off for the final product.

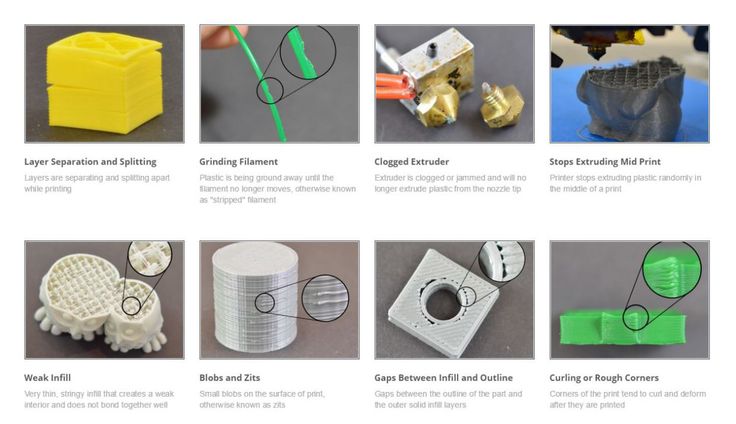

Motion Controlled Components

Both the horizontal movement of the nozzle gantry and the vertical movement of the build plate need to move and be positioned precisely. The material comes out in small increments, but overlapping or diverging too much within the same layer can make the print very messy. The printer nozzle needs to move very carefully in order to draw out the shape of each layer, which can consist of completely separate parts for some layers of certain shapes. There is very little room for error. And if the nozzle is too close or too far away from the build plate, the filament will not stick correctly.

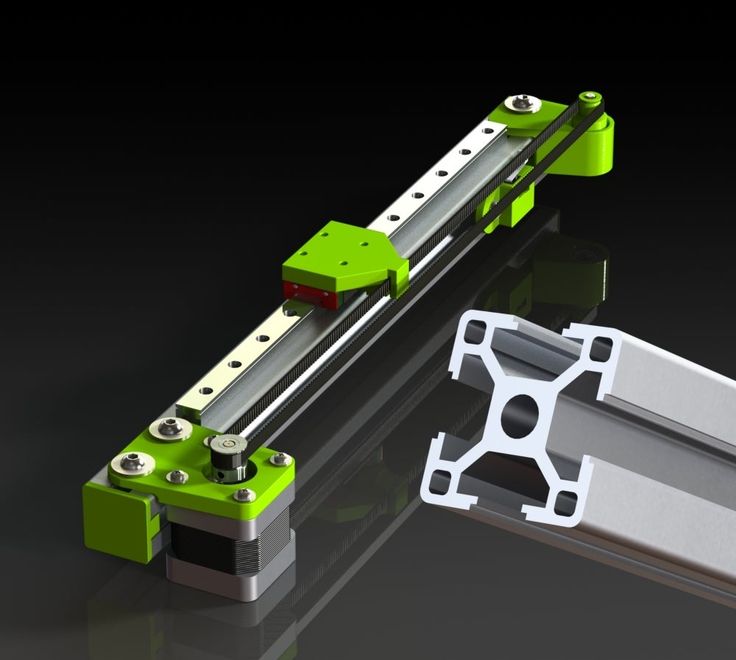

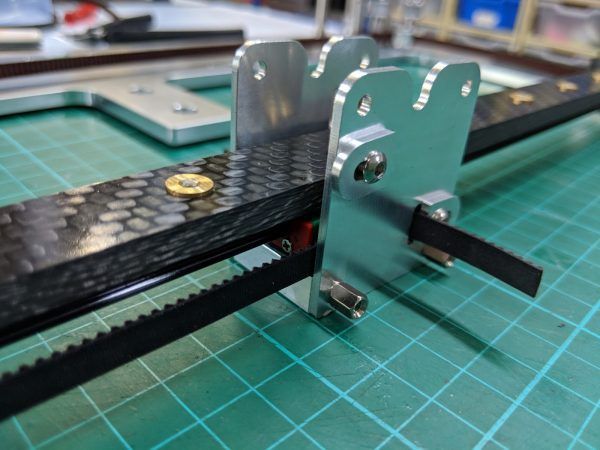

All of the movement and positioning of the build plate are usually accomplished with some form of linear actuator. The nozzle gantry, on the other hand, usually uses linear motors of stepper motors with belts to achieve the necessary positioning and movement. And where there is a stepper motor or linear motor, there must be some sort of drive, often a servo drive.

The nozzle gantry, on the other hand, usually uses linear motors of stepper motors with belts to achieve the necessary positioning and movement. And where there is a stepper motor or linear motor, there must be some sort of drive, often a servo drive.

Since DriveWare update 7.4.2, ADVANCED Motion Controls' digital servo drives can provide closed-loop control for both two phase and three phase stepper motors. In addition, our drives can control linear motors just like any other dc motor. For 3D printers using multiple motors to drive the same axis of motion, our drives can communicate with each other via a network for perfect synchronicity.

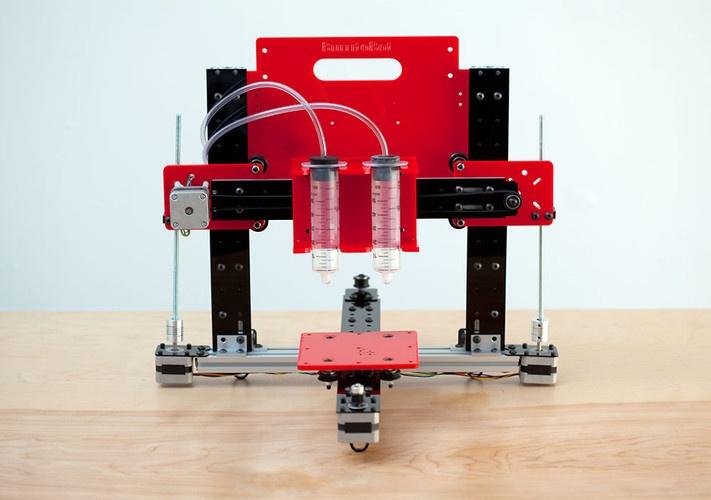

Another critical motion control component is in the extruder, the feeding mechanism that pushes and pulls filament through the nozzle. material isn't always flowing through the nozzle. It needs to stop when the nozzle is moving over a gap in the layer and while the build plate is lowering. The nozzle flow also needs to be regulated when the nozzle moves through different geometries. For example, if the nozzle keeps extruding material at a continuous speed when it makes a sharp turn, you can end up with corner swell. The material flow rate needs to be lowered during the corner to get an even thickness with no swell.

For example, if the nozzle keeps extruding material at a continuous speed when it makes a sharp turn, you can end up with corner swell. The material flow rate needs to be lowered during the corner to get an even thickness with no swell.

Motion Controlled System

So we have a lot of different moving parts in a 3D printer, each controlled by servo drives, but how does it all come together into a coordinated system? That is where you need something like AMC's Click&Move motion control system. ADVANCED Motion Controls has developed Click&Move solutions to run several different 3D printers. Click&Move is able to coordinate all the different axis with different motor types and use the g-code to smoothly generate a perfect 3D print. AMC even developed a custom function block for Click&Move that eliminates the previously mentioned problem with corner swell.

Click&Move can also be used to easily coordinate systems with multiple print nozzles, used for making single parts with different materials or colors. Since Click&Move isn't specifically limited to motion control, it can regulate things such as the nozzle and build plate temperatures, so developers don't have to create a separate system for those.

Since Click&Move isn't specifically limited to motion control, it can regulate things such as the nozzle and build plate temperatures, so developers don't have to create a separate system for those.

The Click&Move can easily be integrated into a 3D printer with one of our motion automation control cards (MACCs). The Click&Move program is stored on the MACC and connected to the servo drives. Click&Move can also be run from a PC. Plus, Click&Move is modular and scalable, so it's very easy for a 3D printer manufacturer to keep using it for future 3D printer models as their product line evolves.

If you are developing a 3D printer, contact us for help designing the motion control to make it run. We'll see if ADVANCED Motion Controls' servo drives or Click&Move can be the solution for you.

by Jackson McKay, Marketing Engineer

3D Printer kinematic types

There are various 3D printing technologies: Digital Light Processing (DLP), stereolithography (SLA), Selective Laser Sintering (SLS), Selective Heat Sintering (SHS) and the others. In this article we are going to explain the FFF technology and talk about its advantages and disadvantages as well as 3D-printers that use it.

In this article we are going to explain the FFF technology and talk about its advantages and disadvantages as well as 3D-printers that use it.

Introduction

FFF printers (Fused Filament Fabrication) are also known as FDM printers (Fused Deposition Modelling). These devices are able to create prints by depositing molten plastic on the print bed layer-by-layer. FFF printers are used both for commercial purposes and at home.

.

Kinematics in 3D printing

Each 3D printer uses its own kinematics that controls the movement of the mechanical parts: print beds and extruders. In this article we will review four types of FDM-printers: Cartesian, Delta, Polar and 3D printers with robotic arms.

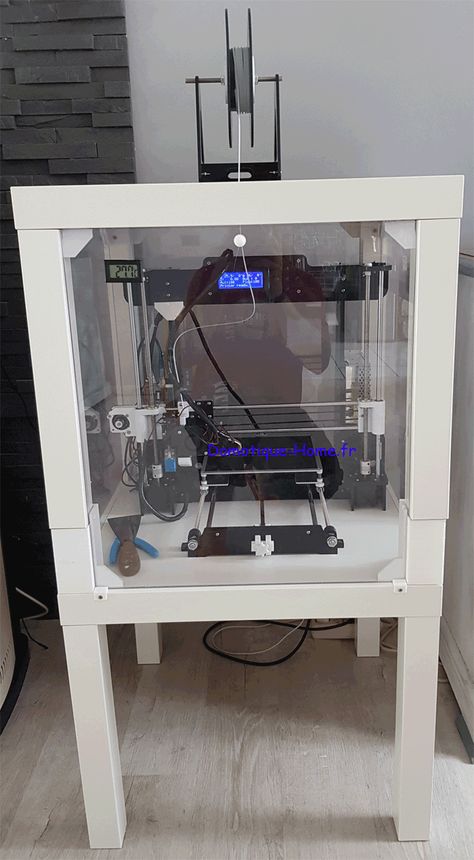

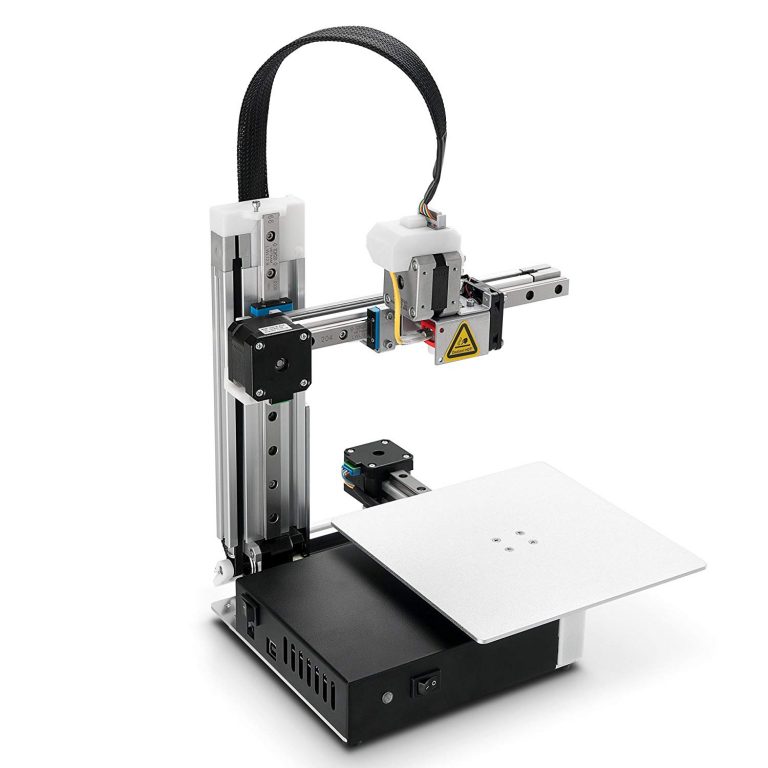

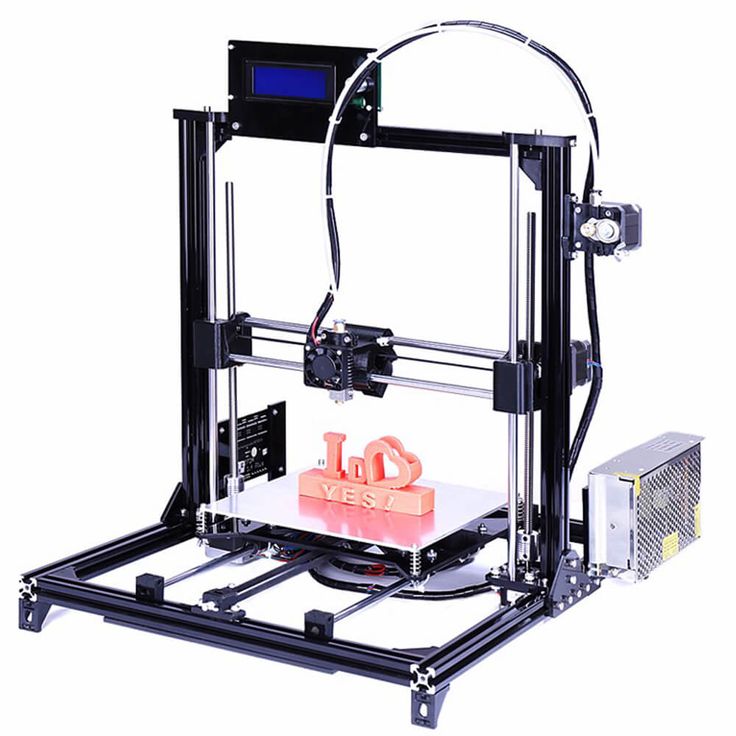

Cartesian printers are the most common FFF/FDM printers on the market. The technology uses three axes – X, Y, Z (Cartesian coordinate system) to determine the movements of mechanical parts: the print head and the bed move according to the coordinates.

There is a limited number of possible ways for platforms and print heads to move:

- The platform moves horizontally along one of the axes — X or Y, the extruder moves vertically along the other axis .

- The platform moves horizontally (Z), the extruder moves two-dimensionally in along the X-Y axes.

- The platform moves vertically and along one of the horizontal axes, the extruder moves horizontally.

- The platform doesn’t move, the extruder moves three-dimensionally.

- The platform moves along the XY axes, the extruder moves vertically.

The second one is the most common — the platform moves vertically and the extruder moves in the XY plane.

Advantages of Cartesian kinematics

Cartesian printers produce some of the most stable results among FDM devices. Consumables for FDM are cheap and available in different colors and materials. Cartesian 3D printers are often used commercially for printing souvenirs, decorations and other custom made things.

Cartesian 3D printers are popular and well established among enthusiasts and professionals. There are many online communities with lots of information about their design, how they operate and how to build them.

Models printed using Cartesian coordinate system can be taken apart and used to build bigger ones, and it allows to make objects of any given size not limited by printer’s build volume. Many 3D printers are available as kits. For newcomers and those who don’t want to learn about building printers, pre-assembled devices are available. They allow to start printing almost right out of box.

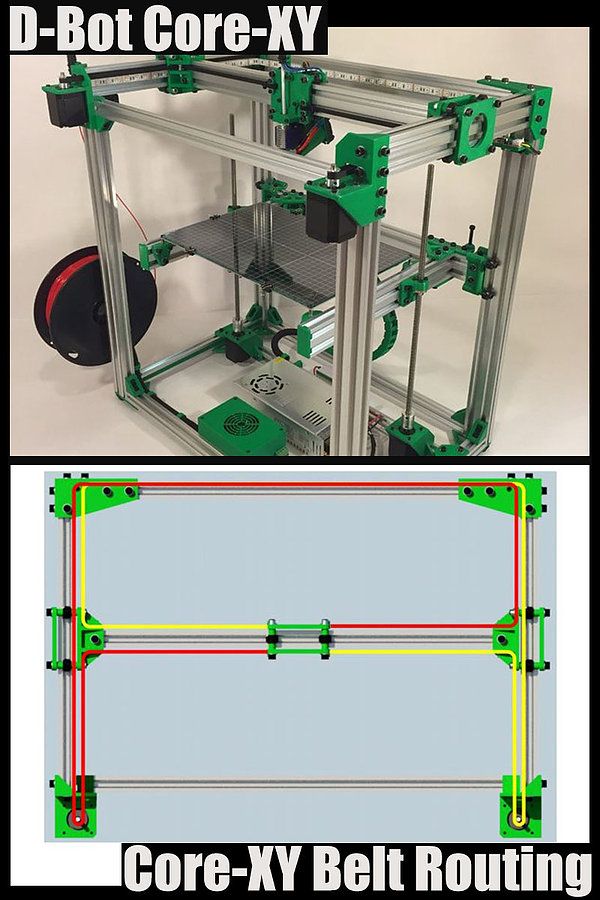

CoreXY and H-Bot Cartesian kinematics

This kinematics is often used for commercial purposes. They have a non-standard extruder movement – it moves vertically.

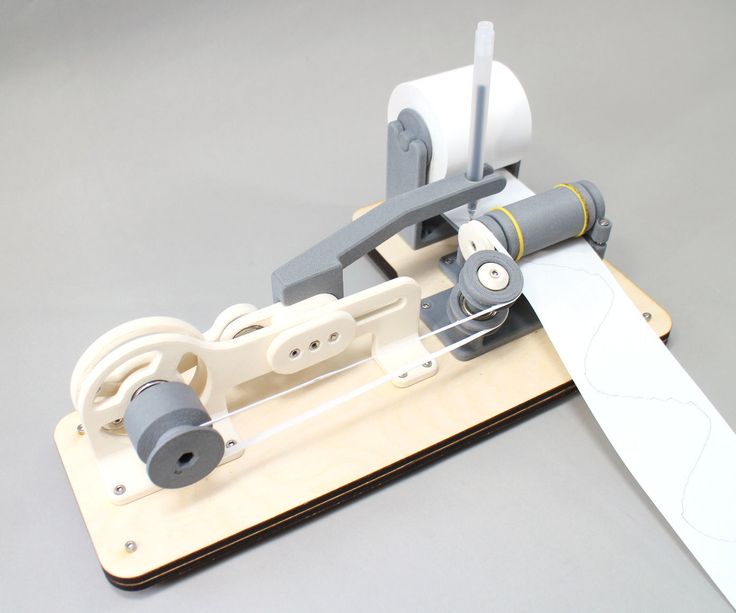

Image source: https://www.pinterest.com

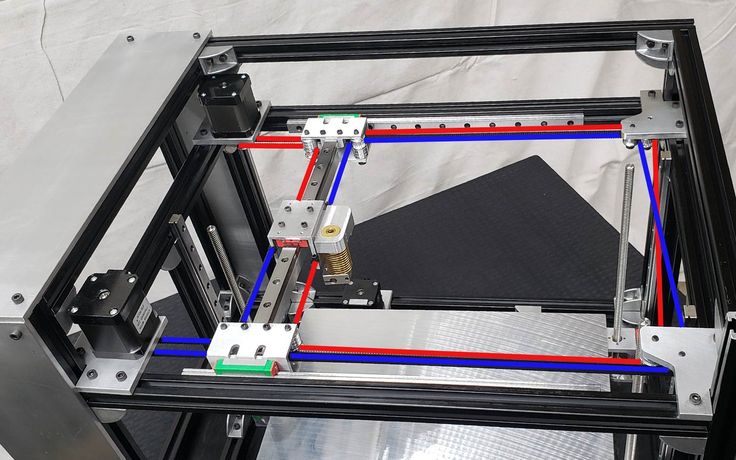

CoreXY features two motors that control two belts moving the extruder in the XY plane.

Image source: smoothieware.org

The H-Bot kinematics is similar but uses a different belt drive system. There’s only one belt mounted to a frame that has an H-shape, hence the name of the kinematics.

Image source: smoothieware. org

org

When both motors rotate in the same direction, the extruder moves along the X-axis, when they rotate in different directions, the extruder moves along the Y-axis. When one of the motors doesn’t move, the extruder moves diagonally.

Among 3D printers with this design, there’s Designer X PRO. The printer has a very high speed, since the JetSwitch technology allows for a faster two-material printing (up to 5 seconds faster in normal mode and 250ms in a draft mode). Redesigned print head with 1µm accuracy and new generation platform allow to print high quality models comparable to manufactured goods. It has a two-material printing function. Software fully controls the printing process, which reduces errors and maximizes efficiency.

Picaso 3D Designer X Pro 3D printer

- Max extruder temperature 380 °C

- Max heated bed temperature 150 °C

- Max print speed up to 100 cm3/h

- Mechanical arrangement Cartesian-XZ-Head

- Nozzle size, mm 0.

3 mm

3 mm - Number of nozzles 2

- Build volume 200 x 200 x 210 mm

- Layer height 50 - 250 Microns

- Technology FFF FDM

Go to product

Printed model example:

Image source: top3dshop. com

com

Delta printers

Delta printers are different from Cartesian ones both externally and in work process. The main difference lies in the way the extruder moves in relation to the print bed.

Image source: https://3dprint.com/

DELTA design has an extruder that is mounted to three points connected to a print bed that doesn’t move.

Advantages and disadvantages of Delta printers

Compared to Cartesian printers, Delta kinematics allows for a higher speed but provides less accuracy. The reason is the fact that extruder movement requires all three motors working simultaneously, which leads to errors in coordinate positioning.

Other advantages:

- Small size. A delta printer is tall, but otherwise doesn’t require a lot of space.

- Absence of protruding parts. The user can make the structure more rigid and get an enclosure.

- Ability to print tall models.

Image source: http://rwgresearch. com/

com/

Disadvantages:

- Higher price.

- Difficult to assemble on your own. Entry-level users could have problems with assembling it correctly, so it’s recommended to buy a pre-assembled printer.

- Working with polar coordinates requires less common software and more expensive parts due to higher processing power.

Examples include the Tevo Little monster 3D printer. Its main use is commercial: design, advertising and educational purposes, but it can also be used at home. It is small and fast. Supported materials: PLA, ABS, Flexible PLA, HIPS, WOOD, PVA, Nylon.

Printed model example:

Image source: https://twitter.com/

Polar 3D printers

This new and interesting polar design is represented on the market by a company named Polar. It uses polar coordinates — it means the positioning is determined by radius and angle instead of commonly used XYZ-axes.

Image source: http://www. purdue3dpc.org

purdue3dpc.org

The platform is circular, it rotates and moves horizontally in one dimension, while the extruder moves up and down. Imagine vinyl record player – print head is like a needle and the platform is like a record. The difference is that the latter not only rotates but also moves, while the former is limited in its movement.

Advantages and disadvantages of the Polar design

3D printers with polar design allow to create large objects, using less space and being energy-efficient. These machines lack accuracy but the manufacturer could probably solve this problem in a foreseeable future.

Image source: https://about.polar3d.com/

Polar 3D is one of these printers. It doesn’t have a heated bed, which makes using Acrylonitrile Butadiene Styrene (ABS) more difficult. The printer is small, efficient but has low accuracy compared to delta and cartesian 3D printers. The manufacturer recommends using the device for educational purposes.

Printed model example:

Image source: https://www.tomsguide.com/

3D printers with robotic arms

They use a programmable mechanical manipulator with an extruder instead of a gripper. Besides their functions as manipulators and 3D printers, large scale industrial robotic arms (the small scale ones also exist) can undertake welding, painting, milling and lots of other functions..

Image source: http://www.dubox.me/

While 3D printing with robotic arms is mainly used in industrial setting, there are models for home use with a broad set of functions.

Dobot Magician Educational robotic arm can do many things. It can draw, write, grip and move objects, laser engrave, etc.

Example:

Image source: https://www.youtube.com/

SCARA

SCARA (Selective Compliance Articulated Robot Arm) is a kinematics design based on a block moving horizontally due to a link lever mechanism.

Devices that use this kinematics are more compact, have very high accuracy and better repeatability than traditional robotic manipulators can provide, lower noise and vibration levels. SCARA robots are not only more accurate but also faster than cartesian robots of similar size and mass.

But these devices are expensive, have limited stiffness along the XY axes, smaller build area and limited movement.

Examples include Dobot M1. It’s a small desktop robot that can be used both as a 3D printer and a manipulator. It’s controlled with software or mobile applications. It has various attachable heads for printing, engraving, soldering and assembling.

Printed model example:

Image source: https://thegadgetflow.com/

Kinematics of robotic systems

The advantages of 3D printers with robotic manipulators are obvious – working area is not limited to the size of a build chamber, since such machines don’t have one. These machines are smaller but have the same printing area.

Image source: https://spectrum.ieee.org/

The extruder is not limited to its moves as in FDM printers, it can move in complex trajectories in three axes with different angles, which simplifies making complex models. Another advantage is that robotic arms can be also used for other purposes, once the extruder is replaced by other modules.

Printing accuracy is not comparable to Cartesian 3D printers but thanks to their versatility and large size, such robots can be used for 3D printing in industrial setting where they become almost irreplaceable.

Small desktop robotic arms are good as a visual aid or as a tool for your hobby.

Conclusion

Before buying a 3D printer, ask yourself why you need one. Would it be for a commercial use, your job or hobby? FFF / FDM 3D printers are versatile because they can be used for different purposes. Whether you want to learn about 3D printing and get a new hobby, turn your creative ideas into reality or start a business – it doesn’t matter. There’s a suitable 3D printer for every purpose but you need to take your time choosing what you really need.

There’s a suitable 3D printer for every purpose but you need to take your time choosing what you really need.

If you need help purchasing a 3D printer, head straight to https://top3dshop.com. We’ll help you choose the best machine to suit your needs.

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

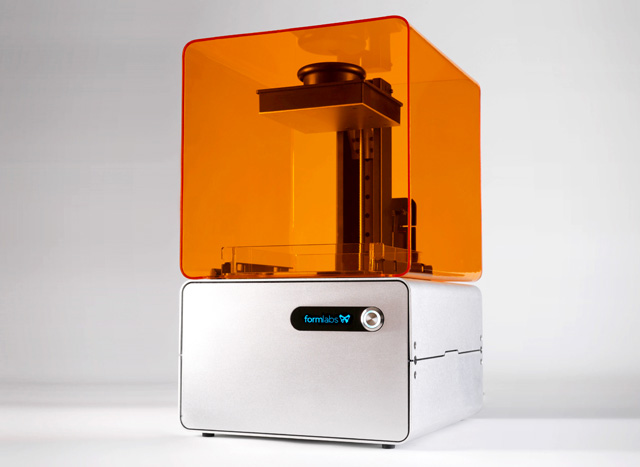

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this processing makes your printed products look as if they were made by professional injection molding. If you want to understand how this is done correctly, then read this article. Aceto Read more→

Kinematics of 3D printers: what are the best types

Kinematics of 3D printers - which device to choose?

The print quality of a 3D printer and how it works depends on several factors. One of the important indicators is kinematics. This article discusses its main types and their features.

One of the important indicators is kinematics. This article discusses its main types and their features.

- What is the kinematics of 3D printers?

- Types and types of kinematics

What is the kinematics of 3D printers?

Each 3D printer has its own kinematics. Models are equipped with a platform and an extruder. These parts move in a certain direction relative to each other. Kinematics in such a device means the scheme along which the extruder and platform move. nine0003

Types and types

There are five types of 3D printer kinematics. The principle of operation of the device and the method of processing the workpiece depend on their features.

Cartesian 3D printers

The most common are 3D printers with Cartesian kinematics. They are based on the Cartesian coordinate system, they work in the X, Y and Z axes. They set the coordinates by which the print head changes position relative to the platform. The printhead has limitations in terms of movement in three axes. nine0003

nine0003

- The extruder moves up when the platform moves in the horizontal X or Y axis.

- The platform moves up in the Z axis, the extruder can move in the horizontal directions at this moment.

- The platform moves along one of the axes in height, the extruder rises along the other axis.

- The platform is static and does not move, the extruder moves in all three axes.

- The extruder moves along the coordinates in height, and the platform moves along the X and Y axes.

The most common options during operation are the first and second.

Cartesian kinematics has a number of advantages.

- This is a simple motion pattern suitable for hobby printing. Many budget models work on its basis.

- The printer can be produced in any dimensions, if necessary, it is upgraded.

- Consumables are freely available. Users are offered a large number of materials and colors. nine0026

- The printers can be shipped unassembled.

This feature allows beginners in the world of 3D printing to understand the principle of the mechanism.

This feature allows beginners in the world of 3D printing to understand the principle of the mechanism. - Devices based on the Cartesian system, suitable for mass production of parts. They are designed to create blanks of different sizes.

Among the shortcomings of printers built on the principle of three coordinate systems, there are two factors:

- models are bulky, after assembly they take up a lot of space on the desktop; nine0026

- The print speed is slow.

Printers based on Cartesian kinematics suitable for hobby printing. They help beginners understand the process of work and learn how to create models.

Example of printing on a device with Cartesian kinematics.

Varieties of Cartesian kinematics CoreXY and H-Bot

The CoreXY has two feed belts, while the H-Bot has only one, but it is long - this is the main difference between the two varieties. The common feature in these devices based on Cartesian kinematics is that the platform moves only along the Z axis. The horizontal X and Y axes are moved by a pair of motors mounted on the frame. nine0003

The horizontal X and Y axes are moved by a pair of motors mounted on the frame. nine0003

Two motors are responsible for movement along the horizontal axes, one motor along the vertical ones. Such kinematics is common not only in amateur printers, but also in professional ones.

CoreXY and H-Bot based 3D printers are more expensive than conventional Cartesian models. For the production of their cases, a metal alloy or composite materials are used. Rail guides unleash the potential of high-quality printing. This kinematics allows you to achieve good detail with fast printing. nine0003

The advantages of CoreXY and H-Bot are:

- high print speed;

- quality detailing of models;

- professional use grade.

But not without drawbacks:

- H-Bot is not implemented on steel shafts;

- you must constantly monitor the belt tension so that there is no play;

- high cost of instruments;

- belts can wear out quickly if they rub against neighboring objects during operation, this factor must be taken into account during operation; nine0026

- the pulleys on which the belts move must be located strictly perpendicular to each other.

Cartesian kinematic printers are widely used in various industries. They are distinguished by high print detail, a durable metal case, and high-quality components.

Help! Cartesian kinematics allows you to create detailed objects at high speed.

Delta Printers

Delta-type printers differ from their competitors in a number of ways. The table remains stationary, and three fixed axes are used to move the print head at once. In such devices, there is no division into the X, Y and Z axis. To move the carriage sideways, you need to lower one axis, and raise the rest.

Help! In the production of 3D printers, the Delta kinematics has not yet found wide distribution. This is a promising direction, which is currently being developed by developers. nine0003

Already existing delta printers offer the following advantages.

- Small dimensions. Devices do not take up much space on the desktop, they are tall, but not wide.

- High print speed. Models can process 300–400 mm/s.

- A new approach to blank production. The equipment does not print using the same technology as Cartesian. It is interesting to watch the process of processing the model.

Deltas also have a few disadvantages. nine0003

- Calibration difficulty. A lens is formed on the printed surface, due to which it is impossible to fully calibrate the printing process. This is the main factor slowing down the mass introduction of kinematics.

- Poor accuracy. High print speeds sacrifice accuracy. All axes perform small movements, errors occur.

- Computing power requirement. Deltas are equipped with 32-bit boards, which is why they do not support interaction with 8-bit systems. nine0026

- The frame must be rigid. This is necessary to avoid backlash, deviations and distortions.

- Not all extruders will fit. Deltas have weight restrictions, so direct type extruders are not allowed.

Printing accuracy remains high.

On deltas, you can build high-quality vertical models, even with large dimensions. There are no protruding parts on the body, which allows you to independently increase its rigidity.

Polar

The polar kinematic scheme is presented only by one company - Polar. The essence of this technology lies in the fact that it does not have positioning along the X, Y and Z axes. The position of the extruder is set by the angle and radius. The platform of polar 3D printers is round in shape, it moves only along the horizontal axis and only rotates in a circle. The extruder moves up and down.

The advantages of 3D printers based on polar kinematics are:

- the ability to create large objects; nine0026

- high energy efficiency;

- material savings;

- small dimensions.

But there are also disadvantages:

- low print accuracy, which was started by Polar representatives;

- platform does not warm up during operation;

- material handling restrictions - ABS plastic cannot be processed.

Polar printers are less accurate than Cartesian and Delta printers. The manufacturer recommends using such models for educational purposes; they are not yet suitable for professional printing. nine0003

Printing example shows that accuracy cannot be achieved. All features are blurred, the figure lacks sharpness and clarity.

With robotic arms

Printers with robotic arms are a design with a mechanically programmable extruder gripper arm. This is a multifunctional robot: it can carry out welding, painting, milling, etc.

The extruder can move in different directions: in layers, along complex paths in three dimensions, at different angles. Thanks to this set of functions, it is possible to create complex designs. nine0003

The main advantages are:

- versatility: the device can perform several types of tasks when replacing the extruder;

- are suitable for industrial applications: you can print large objects with almost no size restrictions.

But there are also disadvantages:

- low accuracy: such equipment is inferior to Cartesian kinematics;

- large size: devices take up a lot of work surface space. nine0026

These models are not suitable for professional 3D printing. They can be considered as an object for a hobby or a tool for it. For industrial purposes, such devices work only when high precision in the execution of parts is unimportant.

SCARA

SCARA (Selective Compliance Articulated Robot Arm) is a kinematics based on horizontal rotation of the platform. The movement is achieved by the articulation of the linkage mechanism.

These devices are highly accurate and repeatable, while operating they emit a minimum of noise and vibration. SCARA also surpassed the Cartesian models in terms of processing detail: the difference is that the former work noticeably faster. nine0003

Advantages of such kinematics:

- print accuracy;

- high workpiece processing speed;

- small dimensions and weight.

But there are also disadvantages:

- stiffness restrictions in the area of the X and Y axes;

- high cost;

- is not the widest area of use.

SCARA kinematic devices are devices that combine the functions of a 3D printer and a manipulator. Device actions are programmed through software or an installed mobile application. nine0003

The choice of kinematics for 3D printers depends on the requirements for technology and application.

- Cartesian kinematic models remain the most common options. They combine high accuracy, good speed, small dimensions. They can be used for amateur 3D printing. They work in a Cartesian coordinate system, the platform and the extruder move along the X, Y, Z axes.

- CoreXY and H-Bot are varieties of Cartesian kinematics. They are highly detailed blanks, suitable for professional use. Their disadvantage is the complexity in the process of operation. The user must constantly ensure that the belts do not come into contact with foreign objects and are well tensioned.

Learn more