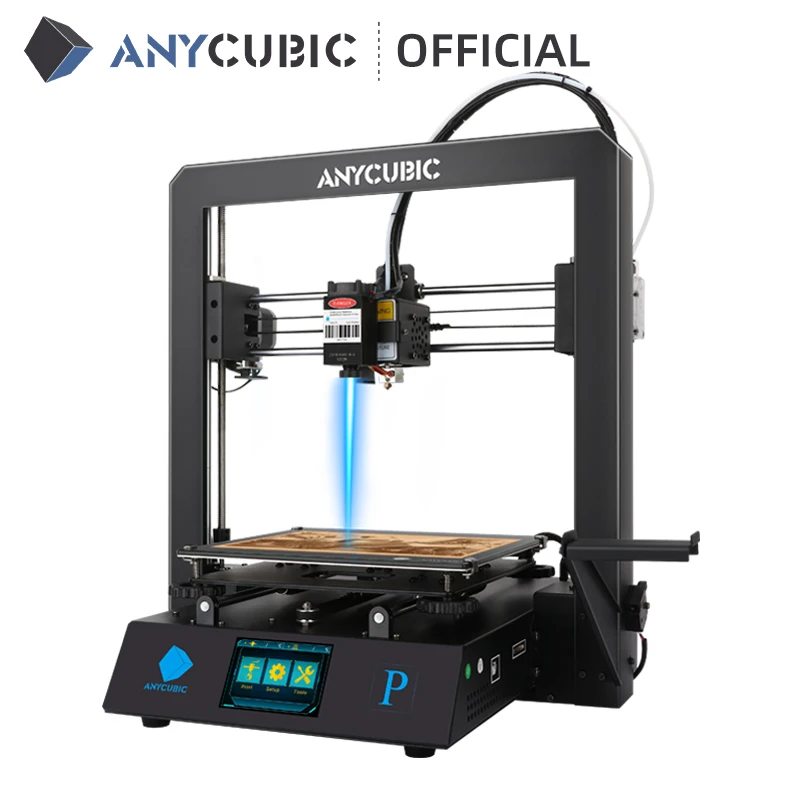

3 pro 3d printer

Creality Ender 3 Pro Best Budget 3D Printers for 2021| Creality 3D Printer

Home Collections Ender 3 Pro 3D Printer: Meanwell Power | Removable Build Plate$ USD

$ USD

110 Reviews Pricing Not Include Tax

Ship From

United StatesUnited KingdomCzech RepublicChina

Model-1

Ender-3 ProEnder-3 Pro+Tempered Glass Kit

Ship to

It is expected to arrive within and will cost $ USD to ship

This item can't be shipped to this Country/Region

Bundles

Quantity

28 Available

Add To Cart Buy It Now

Continue To Shopping View Cart

People who bought this item also bought

Creality Ender 3 Pro advantages and upgrades:

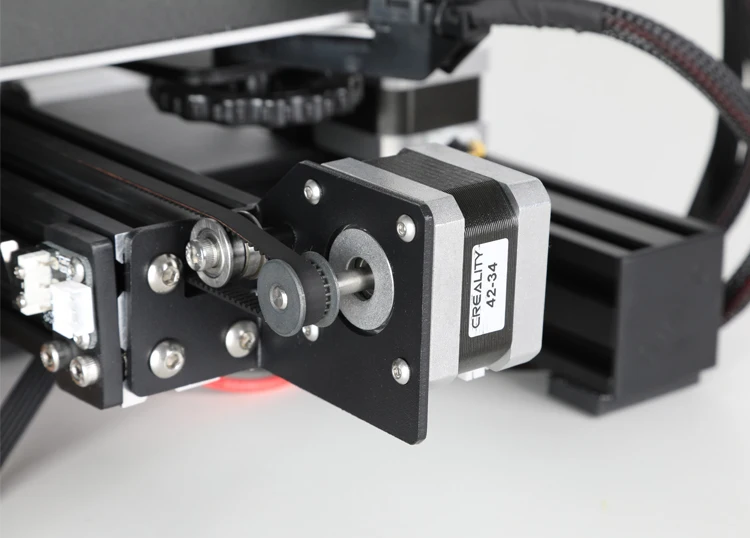

Ender 3 V1 Upgraded Version: Creality Ender 3 Pro is an upgraded version of Ender-3, comes with the Meanwell power supply and new platform sticker, also redesigned the plastic extrusion. The Ender 3 Pro boasts the same outstanding performance as the Ender-3, upgraded components make Creality Ender 3 Pro more stable, durable, and more comfortable to operate.

MeanWell Power Supply: We adopt the MeanWell power supply, which is produced by the listed company with mature technology, and it meets all the needs of fast heating and long-time 3D printing. The printer is shielded by its power supply from voltage spikes and power outages. If electrical power is lost, prints can be resumed from the last layer, saving time and reducing waste.

( Orders and shipments from www.creaity3dofficial.com are MEAN WELL POWER as described on our website. WE REQUIRED/CUSTOMIZED/MUST BE: "MEANWELL". )

More Stable: Redesigned with a much more sturdy, 40x40 aluminum extrusion for the Y-axis base. This provides stability for the printing process, leading to better print quality.

Superior Printing Surface: A new state-of-the-art “C-MAG” magnetic sticker is designed for Ender 3 Pro, it is entirely removable, flexible, and can better adhere to the platform. Once the model is finished printing, remove the magnetic upper from the lower and bend or flex the print surface to watch the model effortlessly pop off the printing surface.

Once the model is finished printing, remove the magnetic upper from the lower and bend or flex the print surface to watch the model effortlessly pop off the printing surface.

Enriched Accessories: It must be surprising that more useful accessories included in our package. Extra parts can save you time while you need them, also cost-effective.

For newcomers, this is the most common problem. Do not worry, you can solve it easily. Generally, the distance between the nozzle and platform is too far or near. So rotary the knob under the platform to adjust the distance between the nozzle and platform again, at a piece of A4 paper distance or less).

So rotary the knob under the platform to adjust the distance between the nozzle and platform again, at a piece of A4 paper distance or less).

- Improving mechanical properties. Reduce friction and provide better dimensional stability.

- Improved extruder, reduces the risk of clogging and uneven extrusion.

- A new magnetic printing surface, removable and flexible, allows you to pluck prints off the build plate easily.

Yes.

What filament does Creality Ender 3 Pro use for printing?PLA,PETG,ABS

Creality ender 3 upgrade parts1. V4.2.7 Silent Board

2. Ender 3 Upgrade Parts Direct Drive Plate Kit

3. Build Plate: Tempered Glass & PEI Build Plate

4. Auto Leveling Kits: Creality BL Touch / Creality CR Touch

5. Touch Screen: Creality 3D Pad

Touch Screen: Creality 3D Pad

Download

Download

Download

Download

Customer Reviews

Based on 110 reviews

85%

(93)

11%

(12)

Write A Review

Ask A Question

Reviews (110) Questions (0)$ USD

$ USD

ADD TO CART BUY IT NOW

Write a review

Ask a Question

Creality3D Ender-3 Pro – Creality 3D

Feature

Parameter

Reviews

Shipping&Return

Download

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

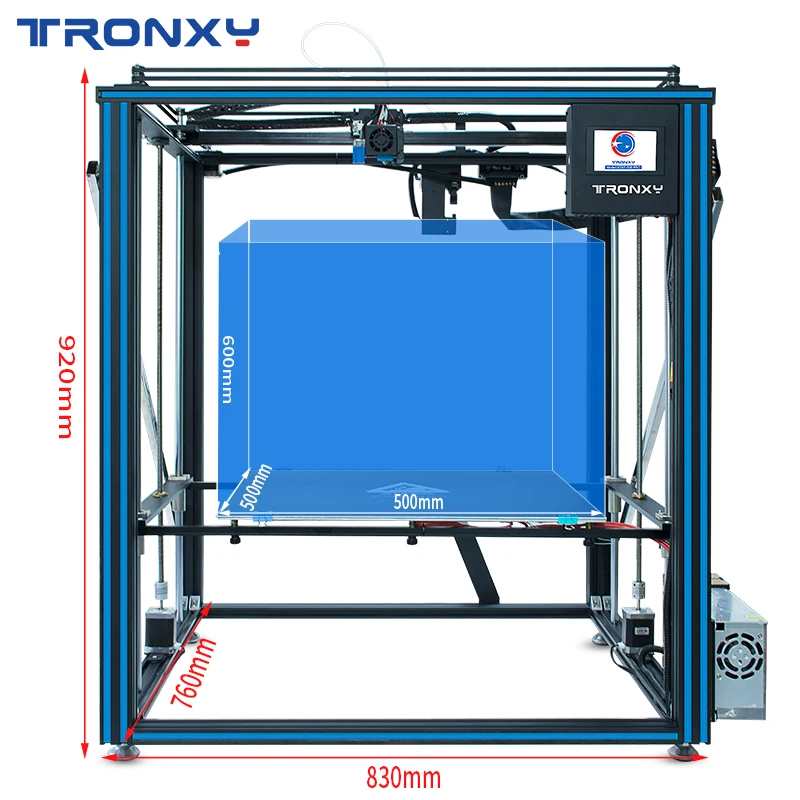

- V Slot cooperate with Prusa I3 frame: extremely innovative design, following the step of the trend, integrating with classic elements, create a new generation economic DIY 3D printers.

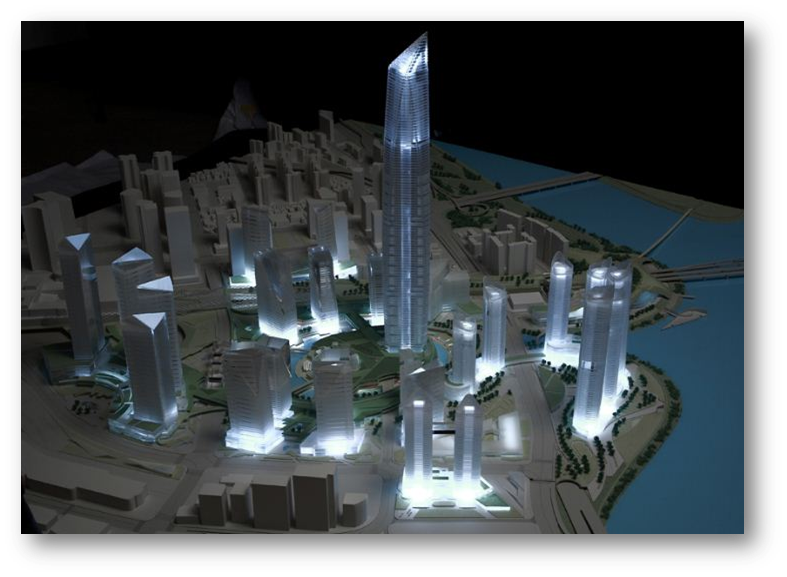

- Super Printing size with one-piece structure, save space but building the world.

- Only 10 minutes with 20 screws assembly before the first printing, simple assembly but more stable performance, Win-Win for fun and time.

- Safety protected Power supply, reach 110℃ for hotbed in about 5 minutes. Additional power cut protection functions to meet the needs of fast heating and longtime printing. Ability to resume prints even after a power outage or lapse occurs.

- CNC machining of Y-rail mounting groove to make sure precise positioning and keep the stable frame with High-Precision printing quality.

- Patent Technology: MK8 Extruder greatly reduces plugging risk and bad extrusion; Patent Technology: V Slot with POM wheel make it move noiseless, smoothly, and durable

- New Viscous Platform sticker to replace reprinting tape and glue, solve warping problem but save the printing cost.

- 24 hours testing for key components before delivery and one year warranty.

- Good printing quality, reasonable cost for the beginners, and good performance for the enthusiasts.

- Modeling Technology: FDM (Fused Deposition Modeling)

- Power Supply: Mean Well UL certified power supply

- Printing Size: 220*220*250mm / 8.6x8.6x9.8 inches

- Machine Size: 440*410*465mm / 17.3x16.1x18.3 inches

- Package weight: 8.6kg / 19 lbs

- Max Traveling Speed: 180mm/s

- Filament: 1.75mm ABS/PLA,WOOD,FLEXIBLE,Carbon firber,PA.

...

... - Input: AC 100-265V 50-60Hz

- Output: DC 24V 15A 360W

- Layer Thickness: 0.1-0.4mm

- Nozzle diameter: 0.4mm

- Precision: ±0.1mm

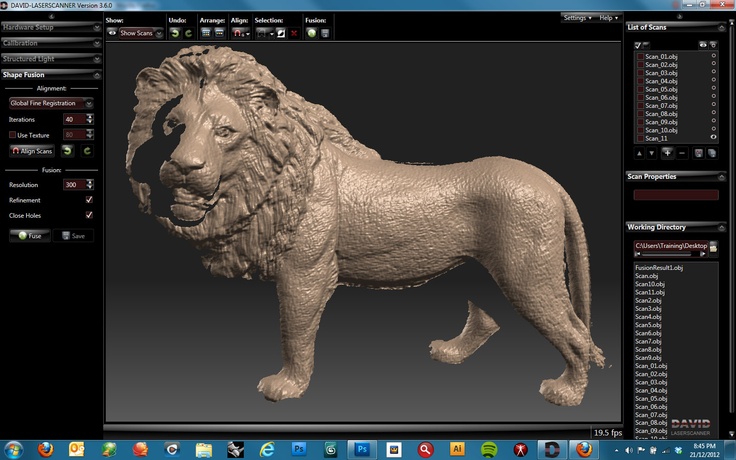

- File Format: OBJ, G-Code, STL(in CURA converted to G-Code)

- Working Mode: USB cable (not included) online compatible or micro-SD (offline)

- Max Nozzle Temperature: 255 ℃

- Max Hotbed Temperature: 110 ℃

| Ship From | To: | Shipping Time |

|---|---|---|

| Czech Republic | Most Countries in Europe | 3-7 business days |

| United States | United States | 3-7 business days |

| Canada and Mexico | 15-30 business days | |

| China | Canada, Australia | 15-30 business days |

| Most 3D Printer parts, accessories and filaments will be shipped seperately from China. | 15-30 business days | |

| Note: Processing Time 1-2 business days | ||

Follow us

Facebook

Reddit

Instagram

Twitter

Tiktok

Latest Firmware

Download

Oops.

. there seems to be no such page

. there seems to be no such page Apparently, you've landed on a page that either doesn't exist or was deleted long ago. Start your search first!

Request a call back

Telephone

By clicking on the button, you agree to the privacy policy of

Item added to cart

Go to cart

Product added to comparison

Compare products

Cannot compare more than 4 products

Invoice or quotation request

Organization name:

Your e-mail

Your phone

Name of contact person:

Legal address:

Comment:

By clicking on the button, you agree to the privacy policy of

Goods on the way, find out when delivery

Your name:

Your e-mail

Your phone

By clicking on the button, you agree to the privacy policy of

Contact us

How to call

By phone +7(495)155-45-19. Your call will be answered by an answering machine. We won't call back if you don't speak up. Each request is processed, we contact clients in accordance with requests. Prepare the information you want to report, send it to the answering machine and we will call you back. We kindly request: do not be silent and do not hang up, this is just an answering machine. 🙂 Other most effective ways to get in touch: nine0003

Your call will be answered by an answering machine. We won't call back if you don't speak up. Each request is processed, we contact clients in accordance with requests. Prepare the information you want to report, send it to the answering machine and we will call you back. We kindly request: do not be silent and do not hang up, this is just an answering machine. 🙂 Other most effective ways to get in touch: nine0003

- Write to Telegam @techno3dru

- Write to Whatsapp +74951554519

- Write Email [email protected]

Is the product in stock

On the product page, under the product name, there are 3 statuses:

- In Stock - We have this item in stock. Make a purchase with the Buy button.

- Pre-order - goods on the way, delivery soon. Find out about delivery times by clicking on 'Delivery times' or make a purchase using the Buy button.

nine0057

nine0057 - On order - The goods are delivered according to your order on a partial prepayment. Place an order using the Order button.

How to get an invoice for legal entities

Add items to your shopping cart, proceed to checkout. Payment method: Organization → Specify details → Get an invoice for payment

How to get a quotation

On the product page, click on the link Request a quote

How much is delivery

On the product page, block Delivery. With an accurate calculation of the cost and timing to your city. On the Delivery and payment page for more details about all delivery methods.

If you did not find your question among the questions, please contact us via Whatsapp

or Telegam

Inquiry

Contact person (name):

Contact phone:

Email:

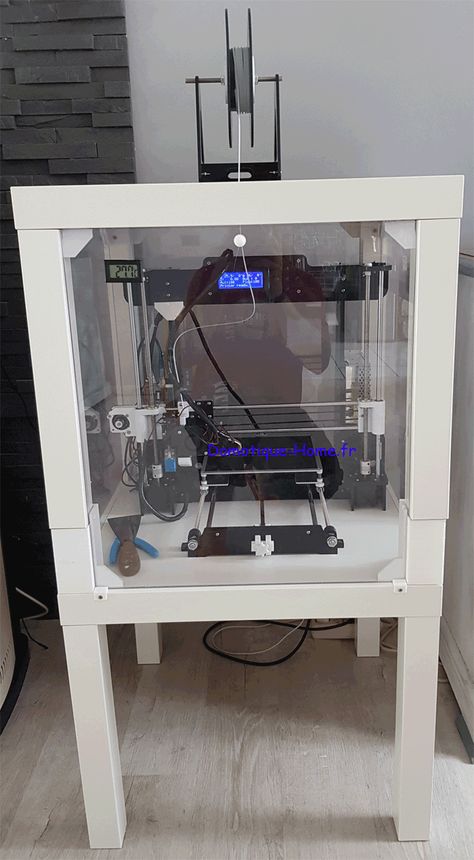

Creality Ender 3: amazing inexpensive 3D printer

3DPrintStory Reviews Creality Ender 3: Amazing low cost 3D printer

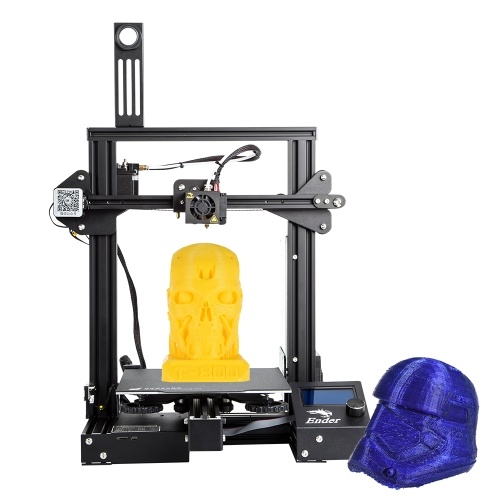

The Ender 3 is a phenomenon in the world of 3D printing: never before have so many people shown interest in an inexpensive 3D printer and this interest is justified! In this review, we will understand why. And yes, spoilers are an amazing and inexpensive 3D printer that surprisingly combines quality-price-upgradeability. nine0003

And yes, spoilers are an amazing and inexpensive 3D printer that surprisingly combines quality-price-upgradeability. nine0003

Creality Ender 3 Features

Let's not beat around the bush and get straight to the point. One of the most compelling features of the Creality Ender 3 is its incredibly low price. While the cost varies a bit depending on the vendor, this 3D printer can currently be found for under $199. The Creality Ender 3 is currently even cheaper than its predecessor, the Ender 2, in some online retailers.

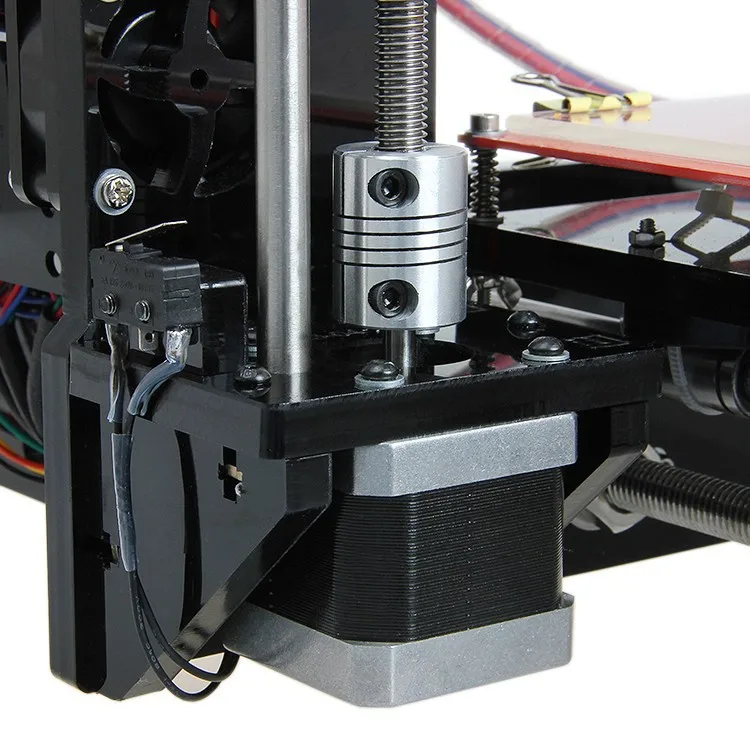

The differences in design between the Creality Ender 3 and Ender 2 are small, but still worth mentioning. The latest iteration still retains the features of the CR-10 with aluminum profiles making up the frame and a single lead screw driving the Z-axis on the left side of the frame. However, unlike its predecessor, which featured a cantilever style in which the X-axis rail protruded into the air, the Creality Ender 3 has a closed frame. nine0003

The Creality Ender 3 is equipped with a heated bed of rather modest dimensions 220 x 220 x 250 mm, which, however, is almost twice as large as the Ender 2. There is a sticker on the table that looks like BuildTak, which should certainly help the adhesion of the first layer and not prevent your 3D model from tearing off during 3D printing.

There is a sticker on the table that looks like BuildTak, which should certainly help the adhesion of the first layer and not prevent your 3D model from tearing off during 3D printing.

Another impressive feature of the Creality Ender 3 is its ability to fully resume 3D printing after a power loss or shutdown. This feature was made popular by the Prusa i3 MK3 3D printer, but the fact that it was implemented in a sub-$200 3D printer makes this feature worth mentioning. nine0003

LCD display with control wheel located to the right of the desktop. The control panel is attached to the 3D printer rather than included as a separate component, making this 3D printer more compact and portable than the CR-10.

Creality recently fully open-sourced the Ender 3, perhaps a first for a Chinese 3D printer manufacturer.

The above features make the Creality Ender 3 quite attractive, but 3D printing speaks louder than words. So it's worth trying out this 3D printer by building it up and sending it out for a little test drive, which we'll talk about below. nine0003

nine0003

Unboxing the Creality Ender 3

As noted, the Creality Ender 3 is a fairly compact 3D printer and the box is true to size. When the 3D printer arrived, the box even caused some surprise due to its compactness.

When we unpacked the Creality Ender 3, we found that all parts and tools were neatly tucked away in the packing foam.

In addition to the 3D printer parts that we'll cover in the next assembly section, here's what the Creality team provided in the box:

- USB stick (with instructions, test models)

- Various tools such as wrenches, hex keys and a small screwdriver

- White PLA plastic sample

- Nozzle cleaning tool

- Wire cutters

- Plastic cable ties

- Multiple nozzles

For a 3D printer that costs less than $200, we were happy to see accessories such as additional nozzles and a nozzle cleaner included in the kit. Once we've dug every last detail out of the cardboard box, it's time to start the long-awaited build process of the Creality Ender 3.

Creality Ender 3 Assembly

The manufacturer claims that the Creality Ender 3 does not need to be fully assembled, as the individual components are already assembled, but don't be fooled - this 3D printer will require a lot of effort before you can start 3D printing. Compared to the Creality CR-10, which also comes partially assembled, the Ender 3 will take longer to assemble.

The assembly process is described in detail in the small booklet that came with the 3D printer, and contains only 12 steps. It seems simple enough, but there were some steps that lacked detail and explanation, which stretches the build time somewhat. If we take into account both the assembly of the 3D printer and the calibration of the table, it will take a beginner about 1-2 hours to do all this. nine0003

To simplify the task, you can break the assembly process into the following parts: frame assembly, X-axis assembly, belt installation, assembly of the main components of the 3D printer and electrical connections, wiring.

The first step is to assemble the frame together with a pair of 20 x 40 aluminum profiles, which will be attached to the frame with two screws on each side. If you turn the base on its side, then it will be easier to assemble the frame. The base of the Creality Ender 3 has pre-drilled holes for attaching aluminum profiles. nine0003

After that, step 2 - attach the power supply and LCD screen to the base. Again, this is a simple step, which is stated quite well in the instructions. But the next steps can already cause some difficulties.

Once the LCD and power supply are attached to the base, the next step is to mount the Z limit switch and Z motor on the left side of the frame. You also need to install two more components - the Z limit switch and the Z axis motor. The Z limit switch must be installed on the side of the vertical stand, exactly 32 mm from the bottom of the Creality Ender 3 base. As it turned out later, this is an important step, because installing the limit switch switch too high or too low will result in an inability to adequately calibrate. Therefore, we strongly recommend not to be lazy and use a ruler at this step. nine0003

Therefore, we strongly recommend not to be lazy and use a ruler at this step. nine0003

The Z-axis motor is attached directly to the pre-installed bracket on the back of the left upright. The lead screw is lubricated with grease, so be careful not to remove it during installation. Also be sure to loosen the bearings when installing the Z axis motor as the rail will not work properly if they are too tight.

The next step is to assemble the X-axis. This can also be tricky. Why? Well, there are two racks in the kit with the same exact dimensions, but only one of them has six pre-drilled holes. And that's the one you'll need for the X-Axis. The left mount includes both the X-Axis motor and the extruder motor, as well as a weird QR code to a Facebook page that seems a bit out of place on the Creality Ender 3's frame.0003

Starting from the open side of the X-pillar, you will need to slide the portal into place with the wheels up and down. The wheels should slide smoothly back and forth along the rail. If this is not the case and the wheels are not properly installed, you will have to fiddle with the eccentric nut behind the bottom wheel until it snaps into place. Next up is assembling the mounting bracket and belt tensioner, both of which are mounted on the right side of the beam.

If this is not the case and the wheels are not properly installed, you will have to fiddle with the eccentric nut behind the bottom wheel until it snaps into place. Next up is assembling the mounting bracket and belt tensioner, both of which are mounted on the right side of the beam.

At this point, it starts to feel like we have a real 3D printer in our hands, but only after installing the GT2 belt on the X axis. At each end of the pre-measured tape there is a clamp that will be placed in the slots under the extruder carriage. nine0003

To install the belt on the Creality Ender 3, you need to carefully roll the extruder carriage over the belt, which will slide the belt under the wheel into the empty space. Do the same procedure for the second wheel, placing the other end of the belt under the bottom bracket. There is a belt pulley at each end of the X-axis, which will keep the extruder moving smoothly.

There were some issues with the length of the strap, but we won't go into that now, but will mention them in the next section. The last step is to put all the pieces together and attach the material holder to the top of the frame. nine0003

The last step is to put all the pieces together and attach the material holder to the top of the frame. nine0003

Creality Ender 3 design

As mentioned above, the Creality Ender 3 has a minimalist design made popular by the company's crown jewel: the CR-10. However, the latest version of the Chinese manufacturer has a smaller amount of workspace and is more compact. Compactness is also ensured by the fact that the control panel with an LCD monitor is attached directly to the 3D printer, and is not taken out separately as a separate module, as it was before. Placing the motherboard directly below the printer avoids the spaghetti of wires and cables and gives the Ender 3 3D printer an elegant look. nine0003

The Creality Ender 3 is equipped with V-slot rollers that run along the aluminum profiles for smooth movement during 3D printing. For the most part, the design is solid and compact, but there are a few pitfalls.

The most egregious problem in the design of the Creality Ender 3 is the slight but annoying wobble of the 3D printing table. This may be a small defect of the 3D printer we got, but in fact, the stability of the 3D printer table is an important aspect, so keep in mind. nine0003

This may be a small defect of the 3D printer we got, but in fact, the stability of the 3D printer table is an important aspect, so keep in mind. nine0003

The portal-style open frame design offers a wide range of customization and add-on options, so you'll definitely have plenty of room to upgrade this 3D printer.

The X-axis belt that came with the assembly kit was too long, causing it to be under tension. The toothed belt has golden metal plugs at the ends, which is certainly convenient for installation, but only if it is of the correct length. So I had to tinker a little with its installation before we got decent 3D printing results. You can see in more detail the difference between the belt with good tension and the one offered in the kit in the section "First 3D printing on Creality Ender 3". nine0003

The Creality Ender 3 has a well-designed extruder system that uses a narrow bore Bowden extruder to aid in 3D printing with flexible plastics. The material supply system is efficient, but it is quite difficult to initially feed it into a narrow opening.

The table calibration process (which, by the way, is done manually) is also well thought out. There are really big and really easy to turn knobs at every corner of the 3D printing table on the Creality Ender 3, which makes the manual calibration process as convenient as possible. nine0003

The Creality Ender 3 control panel offers a wide range of settings. When working with the control panel, you will probably encounter minor freezes. Otherwise, the LCD display is a welcome addition to the Creality Ender family and is easy to navigate.

There are several useful features that are missing. The main one is the possibility of extruding the thread. When changing material, there is no efficient way to remove the previous material from the nozzle, and being able to extrude filament directly from the control panel would solve this problem. nine0003

Last but not least, a quick note about the noise level of the Creality Ender 3. You will definitely hear the mechanical purr of this 3D printer if you leave the door to the next room open, so keep that in mind.

First 3D print with the Creality Ender 3

Time to get to the fun part: 3D print with the Creality Ender 3!

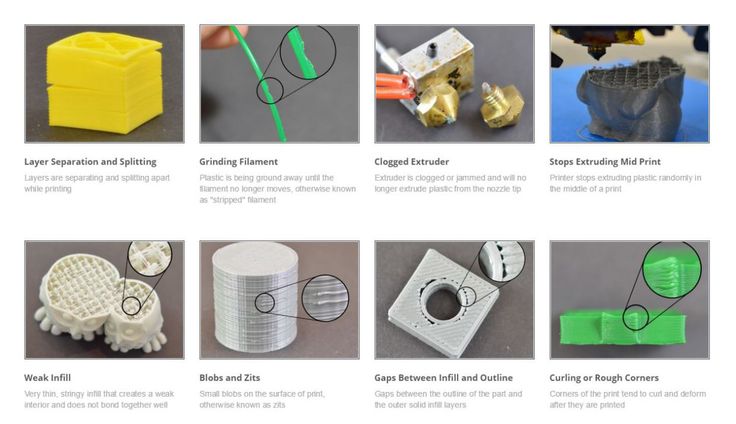

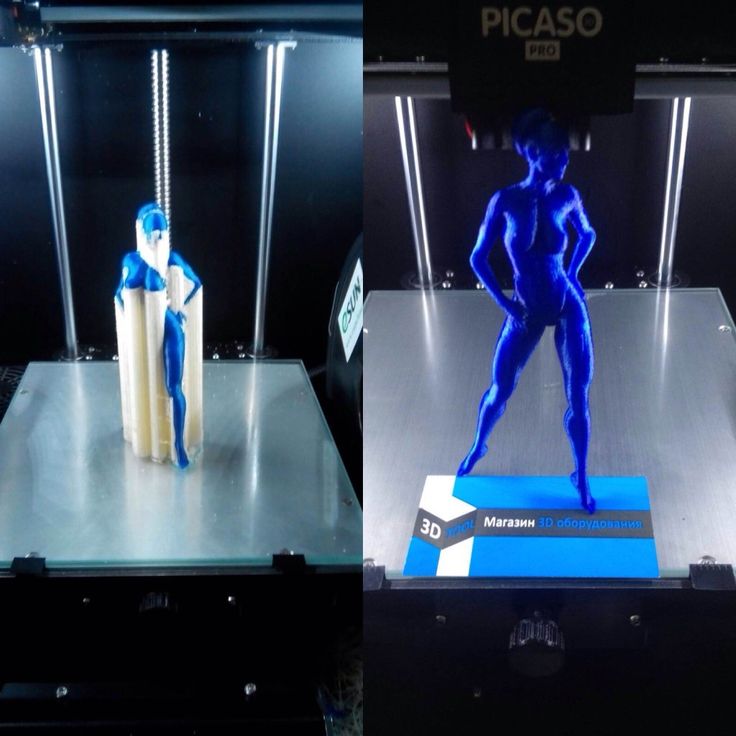

There have been several failed prints and subsequent adjustments before you get a perfectly working 3D printer. Benchy was used to set up the 3D printing, but you can consider other 3D models for test 3D printing. Matterhackers Black PLA was used for printing. nine0003

As you can see below, the first attempt was... well... interesting to say the least. The second attempt ended with a full-fledged boat. The 3D printer did a good job with the ridges and overlap, but there was a subtle wave pattern on the surface. At this stage, the problem with the length of the belt along the X axis was revealed. The final Benchy turned out to be almost flawless even with a layer height of 0.15 mm. Our third attempt gave amazing quality and passed almost all the tests set by 3DBenchy. On the first layer, signs of an elephant leg appeared, but the explanation for this most likely lies in the not ideal calibration of the table of the tested Ender 3.

Wanting to add some variety to the first collection of prints, it was decided to choose a more functional item for the next model - a carabiner. Unexpected adhesion problems. After playing around with the temperature of the table and its calibration, in the end they added glue and the problem went away.

Tests with PLA are completed, we are moving to a higher temperature material - ABS plastic. Used Green ABS from CCTREE. For tests, a 3D model of Flexi Rex, a small but flexible dinosaur with several joints, was chosen. For the most part, the 3D printing was successful, but there was a small crack between the layers on the dinosaur's head. But this is probably not so much a matter of Ender 3 as of the quality of the material. nine0003

After normal calibration and fixing the tension of the Creality Ender 3 belt, the result began to please and even surprise. There was another ambitious attempt to 3D print the Waving Groot using colorFabb Corkfill wood-mix plastic. The 3D printing was left overnight, and in the morning it turned out that the print had failed almost at the very end. It's a shame, of course, although the surface of the model was excellent, especially for such a difficult material for 3D printing.

The 3D printing was left overnight, and in the morning it turned out that the print had failed almost at the very end. It's a shame, of course, although the surface of the model was excellent, especially for such a difficult material for 3D printing.

Further 3D printing on Creality Ender 3

After successfully 3D printing with PLA (despite the Groot print failing), we decided to up the ante and try 3D printing with more exotic materials. The second round of printing experiments on the Ender 3 began with colorFabb nGen Flex, a semi-flexible material developed in collaboration with Eastman Chemical Company.

The first 3D printed model was the Cute Octopus SD Card Holder, a useful little model that can hold six SD cards and two MicroSD cards. We expected the semi-flexible material to be a little more difficult, but in the end we were pleasantly surprised by the quality, which we immediately achieved on the first test. The model had a little ductility (which is to be expected from flexible plastic) and the model came out just fine. nine0003

nine0003

The next stage of bold experiments was to print a 3D model. Well, what could be better than a test print in gray color than the insidious and beer-burping robot Bender from the beautiful Futurama animated series? The model consists of six different parts that are glued together. Not only are these models larger than the previous ones, but the Creality Ender 3 had to print them with flexible plastic in one setup. It seemed like an adequate way to test the capabilities of this 3D printer, and once again it exceeded our initial expectations. nine0003

Even without the support material, we were able to print every part of the Bender model without error. Again, the right leg and antenna on the top of the head have some minor layering issues. But overall the model turned out pretty good and once we glued it all together we had a fantastic Bender model.

The next test we did was with pink ABS filament made by CCTree. Thinking about what would work with this light pink material, we ended up with the majestic Crystal Cluster. And the Creality Ender 3 did struggle with ABS at first. nine0003

And the Creality Ender 3 did struggle with ABS at first. nine0003

It took about five or six attempts for the material to get a good grip on the 3D printer table and not deform, but again glue came in handy. The result is a great product. Despite some difficult angles, the surface quality of these crystals was almost flawless.

Everyone involved in 3D printing knows the favorite test of 3D printers: 3DBenchy. We printed one for our review of the Creality Ender 3, but decided to rock the boat a little... Well, what better than a Benchy stand that looks like a rough sea. nine0003

It just so happens that this model was perfect for our next material, Rigid.ink's clear blue PETG plastic. And the Creality Ender 3 did a great job with PETG as you can see in the photo above.

Finally, it was decided to give wood 3D printing another chance with another Waving Groot model. This time, the Creality Ender 3 made it to the top of the character's head before the clog occurred.