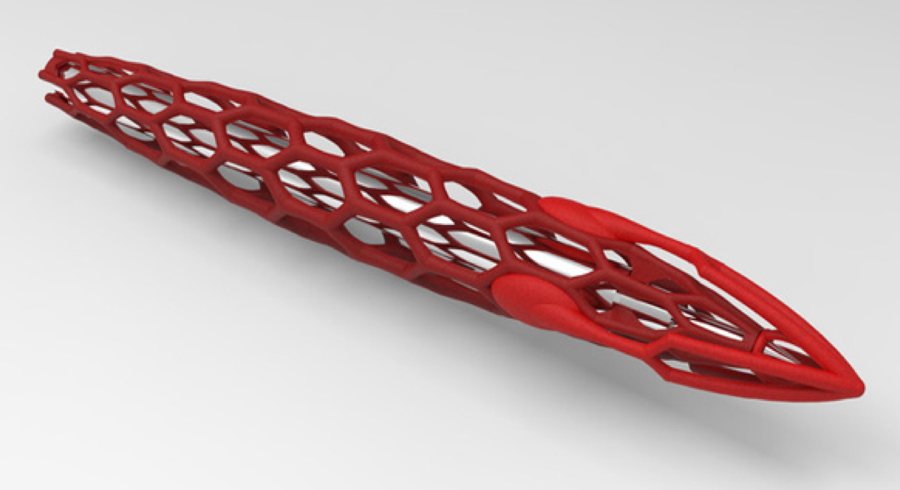

3D printed pen molds

▷ resin pen blank molds 3d models 【 STLFinder 】

KWS Star Pen Blank Molds

thingiverse

Also, check out my other pen blank molds - V1 - https://www.thingiverse.com/thing:4548223 V2 - https://www.thingiverse.com/thing:4549184 V3 (Anchor) - https://www.thingiverse.com/thing:4821799 If you have any questions or ideas for other designs...

resin pen blanks

thingiverse

resin moulds for pen blanks

LarryDNJR Segmented Pen Blank Resin Casting Mold 1

thingiverse

HOW TO MAKE A 3D PRINTED SEGMENTED MOLD RESIN CAST PEN BLANK By Thomas Walter, 2018 Having the proper settings for printing these molds is critical. Use nozzle temperature in the higher end of the range to keep the filament from stringing and...

Pen Blank

thingiverse

UPDATED! ... This is a 1" x 1" x 6" pen blank The area for the resin is now .75" x .75" x 5.75

pen.blank

thingiverse

2.5in x .75in x .75 pen blank

Pen Blank

myminifactory

This is used when making a pen with a pen kit. Usually wood or resin is used.

Nora Valkyrie Resin Molds

thingiverse

So, I went to my first con over the weekend and got a few resin casts. (Which are beautiful.)

... I may have been inspired.

These are to be printed in TPU filament, which is very flexible and easy to get the casts out.

...

Based on Nora Valkyrie...

(Which are beautiful.)

... I may have been inspired.

These are to be printed in TPU filament, which is very flexible and easy to get the casts out.

...

Based on Nora Valkyrie...

PEN BLANK

thingiverse

This is a pen blank design I whipped up in fusion 360 to start getting accustomed to the software. I am fully aware this is not a creative design but it was me getting some basics down in fusion. ...thank you for taking a look.

blank pen

thingiverse

Customized version of http://www.thingiverse.com/thing:45576 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=45576 Instructions Using the following options: pen_length = 130 font_spacing = 0. 81 word = font_scale = 2.1

81 word = font_scale = 2.1

blank pen

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=148722 Instructions Using the following options: tip_diameter = 4 object = 1 font_scale = 2.1 pen_thickness = 7 word = lid_length = 30 font_spacing = 0.81 tolerance = 0.2 helper_tabs = 0...

Blank Pen

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=148722 Instructions Using the following options: helper_tabs = 1 lid_length = 30 tip_diameter = 4.3 pen_thickness = 7 tolerance = 0.26 inner_length = 125 font_spacing = 0.7 word = inner_diameter...

blank pen

thingiverse

http://www. thingiverse.com/apps/customizer/run?thing_id=148722 Instructions Using the following options: tip_diameter = 4 object = 1 font_scale = 2.1 pen_thickness = 7 word = lid_length = 30 font_spacing = 0.81 tolerance = 0.2 helper_tabs = 0...

thingiverse.com/apps/customizer/run?thing_id=148722 Instructions Using the following options: tip_diameter = 4 object = 1 font_scale = 2.1 pen_thickness = 7 word = lid_length = 30 font_spacing = 0.81 tolerance = 0.2 helper_tabs = 0...

blank pen

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=148722 Instructions Using the following options: word = lid_length = 30 inner_length = 125 pen_thickness = 7 helper_tabs = 0 inner_diameter = 3.4 object = 1 font_scale = 2.1 font_spacing = 0.81...

Gisi 3d Printed Resin Pen Molds

thingiverse

.175 layer height or finer

Print with infill at 15%. Rotate till opening is at the top.

Print at 100% scale

Please feel free to print for personal use or to share. ... Do Not print and sell.

Rotate till opening is at the top.

Print at 100% scale

Please feel free to print for personal use or to share. ... Do Not print and sell.

Round Coaster Set - Resin Molds

myminifactory

... be used as a mold to pour epoxy resin in. The coasters are super easy to print, without any supports. I have included the individual files seperately. Happy printing! :) I will add some pictures of my resin coasters when they are done. ...:)

Coaster set round - Resin Molds

thingiverse

A round coaster set with different patterns I've designed in Fusion360. . ..They could be used as a mold to pour epoxy resin in.

The coasters are super easy to print, without any supports.

Happy printing! ...:)

..They could be used as a mold to pour epoxy resin in.

The coasters are super easy to print, without any supports.

Happy printing! ...:)

resin pen mould

thingiverse

1/8" hex resin pen mould

pen blank clown fish

thingiverse

Clown fish pen blank.

ECG PEN BLANK

thingiverse

This is half of a blank to be casted in resin and turned into a beautiful custom pen. ...Great for healthcare workers and the like!

Pen Blank(Angled Lines)

thingiverse

Basic pen blank with angled lines.

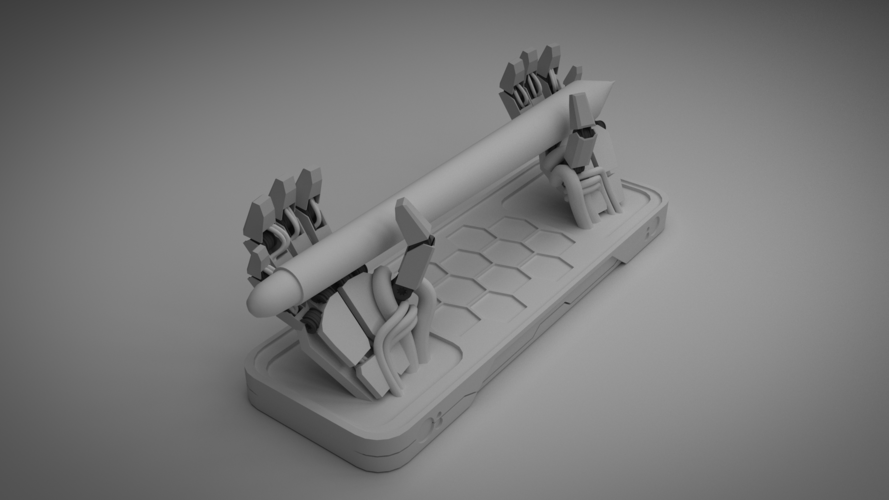

Pen Blank Centre Finder

thingiverse

Simple centre finder for pen blanks. ... Two models 35x35mm & 25x25mm

Pen Blank Center Marker

thingiverse

Mark the center of 3/4in pen blank. ... Print @ 2650%

pen blank sanding jig

thingiverse

Pen blank sanding jig for harbor freight belt/disk combo

Pen Blank holder

thingiverse

Simple pen blank holder after turned, if you have multiple pieces to assemble, this will keep slim line pens and one piece pens in line with each other so you can mass produce pens fast.

Reverse Pen Blank Mold

thingiverse

This is a reverse pen blank for silicone pen blanks. the cavities are 0.8 x 0.8 x 5 inches. I printed at 50% infil, but not sure if that's all that necessary. ... Trying to get multiple uses before having to reprint if possible.

Piling Pen blank

thingiverse

first attempt at a pen blank in tinkercad. 1x1x5. No print settings yet. if you print let me know how it works for you, and don't forget to tip. ...

Pen Blank Saw Jig

thingiverse

I needed a way to cut pen blanks with a hand saw. I have only cut a few, and the saw is damaging the print, so I'm considering it sacrificial. ABS or PETG may last longer. ...The 120pct version is scale up 120% in the Y and Z direction to fit larger...

I have only cut a few, and the saw is damaging the print, so I'm considering it sacrificial. ABS or PETG may last longer. ...The 120pct version is scale up 120% in the Y and Z direction to fit larger...

Pen Blank Vise

thingiverse

I bought a Milescraft 1318 Drillmate https://www.milescraft.com/product/drillmate/, and wanted a better way of holding a pen blank (with a clamp) while I drilled it. Holding just the blank would make it harder to keep it perpendicular, as well as the...

pen_blank_fixed_banana

thingiverse

This is a Pen Blank for 7mm Desk Pen Kit. You might have to sand down the end of the brass barrel a little bit.

Then it will fit perfect.

This thing was made with Tinkercad. ...Edit it online https://www.tinkercad.com/things/7J1PtdMrQjv

Pen Blank Drilling Guide

thingiverse

Jig to help hold pen blanks vertically for drilling the barrel hole. ...Designed for the Bessy drill press vise: https://www.homedepot.com/p/BESSEY-4-in-Drill-Press-Vise-BV-DP40/205023096) Requires three 1/4" diameter rare-earth magnets ...

How to Easily 3D Print a Resin Mold – Printing It 3D

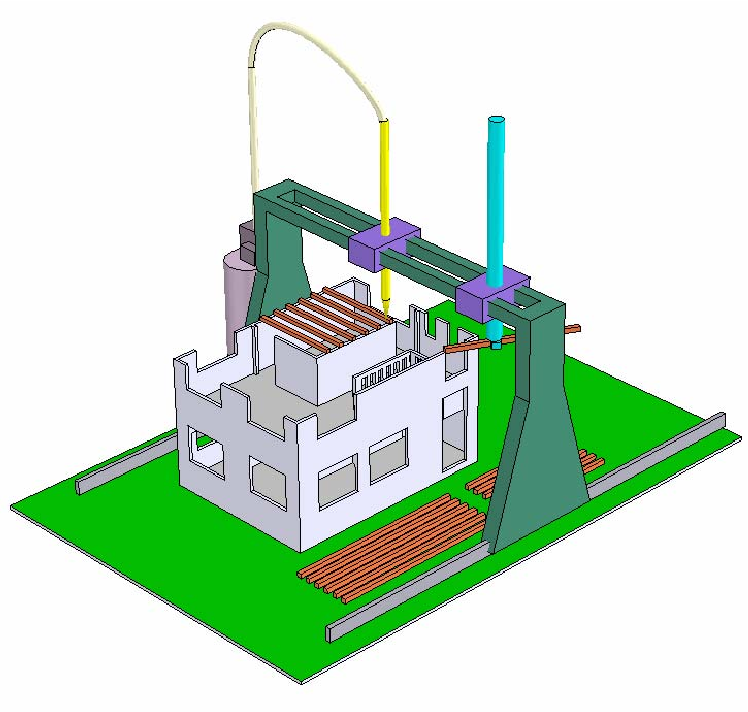

3D printers can only print particular objects at a fixed speed with certain filaments. However, if you want to speed up the production process and make molds with your 3D printer, doing so is simple, fun, and affordable.

Here’s how to easily 3D print a resin mold:

- Choose your mold design and prep your filament.

- Design your mold in a CAD program.

- Slice your mold.

- Print the mold.

- Prepare your mold for casting.

- Get some epoxy resin.

- Mix and pour your resin.

- Allow for full curing.

- Remove your object from the mold.

- Post-process your cast.

So, let’s go through the steps together and talk about the easiest ways to make resin molds. I’ll give you some pro tips and suggestions along the way so that you can make molds for any design with almost any 3D printer.

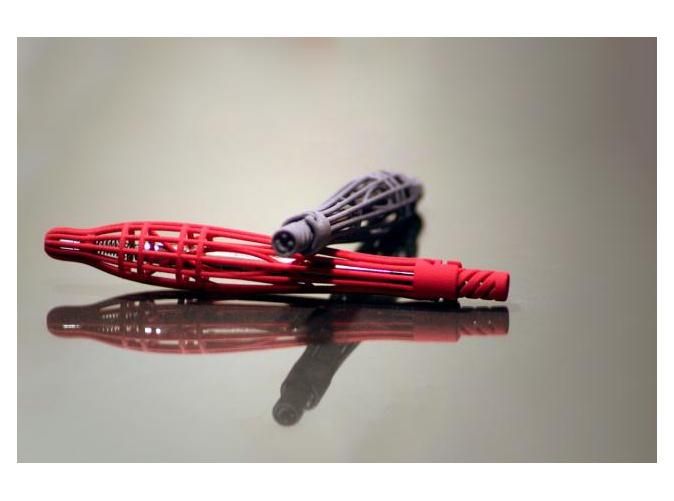

1. Choose Your Mold Design and Prep Your Filament

Before you jump right in and start designing, you will need to plan out what kind of mold you want to make.

When you make a mold, there needs to be that is flexible enough to release your cast from the mold. Resin in itself is rigid and unforgiving, so you will need either a flexible casting material or a flexible mold to make this work.

When 3D printing, you can either make a flexible mold from your filament that you can cast resin into or make a resin mold that you can cast flexible silicone or plastics into.

Usually, your printer can make this decision for you. If you have a standard FDM printer, you will need to make a flexible mold to pour the resin into. So, to make a mold durable and bendable enough to withstand the epoxy, you will need to use a filament such as a flexible TPU.

I use this Overture TPU Filament (available on Amazon.com) to make my resin molds for pen turning, jewelry making, and model making, and it has held up after many uses. I highly recommend it for anyone who isn’t sure what filaments will hold up best.

If you have a resin 3D printer, you can make a resin mold to pour plastics such as polypropylene, polyethylene, and TPE into.

For this tutorial, I’ll walk you through making a flexible mold for casting resin. That said, if you only have a 3D resin printer, I highly recommend trying out injection mold printing. With the injection mold technique, the molds usually last much longer and can make very intricate designs without too much post-processing.

With the injection mold technique, the molds usually last much longer and can make very intricate designs without too much post-processing.

For an entertaining and helpful tutorial on how to create an injection mold with a resin 3D printer, check out this video from The CrafsMan Steady Crafting on Youtube, which will walk you through the entire process:

2. Design Your Mold in a CAD Program

Once you know what you want to make and have the filament you need, it’s time to open up your favorite CAD program and get designing.

You can either make a two-part injection mold or an open-faced mold when you design your mold. Open-faced molds are best for objects that sit on a flat base, while injection molds are better for castings that need to have details across all sides.

To start, design a solid block with 100% infill to keep the mold strong. Then, create the object you want to make the hollow part of the mold with and set it to 0% infill to make a negative model.

Combine the rectangle and your object, ensuring that the rectangle is wide and tall enough to encompass it.

If you’re making an open-faced mold, cut down the edges, leaving only a thin wall between the hollow mold and outside your model. Trimming down thick edges will make it easier to pop the cured resin out of the mold later.

If you are making an injection mold, make sure to add a fill hole so that you can add your resin to it after printing.

One of the most important processes you need to do when designing your model on your CAD software is to make the mold watertight. Failing to solidify the 3D print will cause the resin to fuse with the TPU, destroying the mold and your casting. So, don’t forget to make it watertight!

To help keep your mold watertight and minimize layer lines, you may want to print your mold in as high a resolution as possible. That way, you will have less post-processing, and your finished cast will have more delicate details.

That way, you will have less post-processing, and your finished cast will have more delicate details.

3. Slice Your Mold

Once you have designed your mold, it’s slicing time. Slicing will help you ensure that your mold is as detailed as possible and allow you to cut your mold into segments for certain types of casting.

Process your 3D print through a slicer and cut your mold in half if making an injection mold. If you aren’t making an injection mold, your model should be ready to send over to the printer for processing!

4. Print the Mold

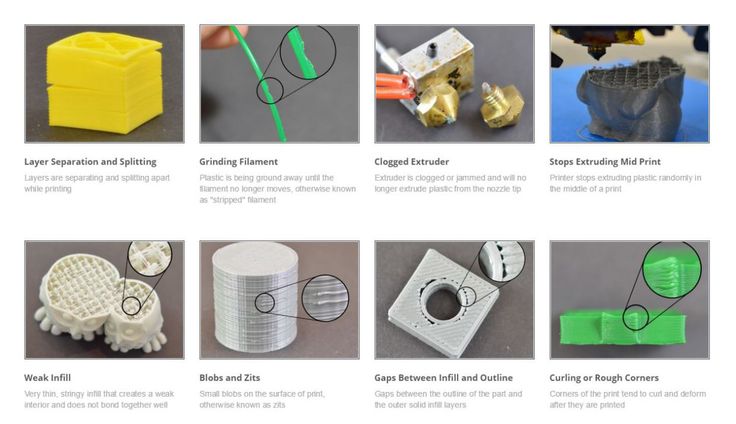

During printing, there are some extra steps you can take to ensure that the mold comes out just right:

- Turn up the temperature by 5º C (9º F) to help with adhesion

- Turn up the flow rate a bit to melt the layers together, reducing layer lines.

Following these tips won’t ensure a foolproof print, and you may still have to monitor your printer to ensure that these adjustments work for you and your filament, but they do usually result in a more seamless and durable mold.

Once your print is finished, please remove it from the print bed and inspect it for holes and failed spots. If you see any mistakes in the interior of the casting surface, you may have to reprint the mold.

If there are visible layer lines, you can either leave them or lightly sand them out with fine-grit sandpaper. However, you can always sand out the lines on your finished cast, which may be easier if you have a detailed or complex mold.

5. Prepare Your Mold

Epoxy resin is sticky, durable, and hard when cured, which is why it is crucial to use a mold-release material such as this PVA Mold-Release Spray (available on Amazon.com). This mold-release spray is gentle enough to use on TPU, while other demolding agents could damage the mold or not work at all on the filament.

TPU is durable and flexible enough to ensure you get a clean casting, but only if you use a mold-releasing agent. If you don’t, you could risk ripping your mold when removing your cured resin, obliterating the TPU.

If you’re in a pinch, you can use some common household items such as canola cooking spray or vaseline to prime your mold. However, these demolding agents never work quite as well as the real thing, and they could add extra bubbles or an uneven surface to your resin.

Whatever you use, do not be sparing with the releasing agent. Coat your mold until it looks like it could drip, and be sure to apply plenty into every nook and cranny, where the resin will probably grab onto your mold during the curing process.

In addition, if you are using an injection mold or split mold, now is the time to clamp your mold together. You can use two pieces of wood, metal plates, books, cardboard, or anything else you have lying around to serve as a stiff back for your mold. Then, you can clamp the pieces together.

6. Get Some Epoxy Resin

Not all resins are made equally, which is something I’ve learned from experience. Generally, cheap resins have curing problems, yellow quickly, or have insanely large bubbles that are challenging to get rid of. So, you will want some epoxy that you can be sure will cure well.

So, you will want some epoxy that you can be sure will cure well.

Some of my favorite resins to work with when making professional-grade casts (which are all available on Amazon.com) are:

- Counter Culture DIY Culture Cast

- Amazing Clear Cast Resin.

- JANCHUN Crystal Clear Epoxy.

These are all resins I rely on for my castings, and they have worked the best for my TPU molds. That said, there are plenty of others out there, so feel free to look for the one that will work best for you.

7. Mix and Pour Your Resin

It is almost time for casting, but before you go wild with the pouring, there are some things you should know about pouring epoxy resin.

Resin is not food-safe (unless otherwise specified), and it is a highly toxic substance. Once it is fully cured, it bonds to itself, creating a shell between you and the poisonous plastics, but in liquid form, it emits harmful lung-damaging vapors and can burn your hands when you touch it.

All this to say – you need protection when working with resin. Always wear:

- Gloves

- Goggles

- A safety mask or respirator

- Long-sleeve clothes

It is best to work in an area with plenty of ventilation when pouring and to mix the resin. To keep air moving and push away the toxic fumes of the epoxy, open your windows and turn on some fans.

Make sure to cover the surface you are working on with something you don’t mind messing up.

I use this Hosonsen Vinyl Tablecloth (available on Amazon.com) for all of my resin work, and it’s so durable that it’s lasted me for years through all of my crafting and DIY adventures. Resin won’t soak through this tablecloth, ensuring that anything underneath will be protected from those inevitable drops of epoxy that fall during pouring.

Now, it’s mixing time! Mix your epoxy resin using the instructions on the label, and be careful to get the measurements right. If you don’t mix it properly, you could end up with par-cured resin that still emits toxic vapors and has a sticky surface, or you could end up with cracks and unsightly bubbles. Then, you can add any colorants or additives to the resin.

Then, you can add any colorants or additives to the resin.

When you are ready, pour your resin into the mold slowly, trying not to create additional bubbles.

Optionally, you can use a heat gun on its lowest setting to pop some of the bubbles in the resin. However, it would be best to do so sparingly – the TPU might warp or melt under too much heat.

8. Allow for Full Curing

Now, you will have to wait for your resin to cure. Most resins cure within 24 hours, but it is usually best to wait a bit longer, especially if your cast is large or has a solid interior.

I usually recommend waiting an additional 24 hours (remember, patience is a virtue) on top of the time that your resin label indicates, just in case things are still wet. If you remove your cast before it is fully hardened, you will probably ruin it, forcing you to repour and waste materials (and money).

9. Remove Your Object From the Mold

Once your resin is fully cured, carefully remove it from the mold, slowly peeling the cast off. If you go too quickly, you risk ripping the mold that you spent so long designing and printing, so be careful.

If you go too quickly, you risk ripping the mold that you spent so long designing and printing, so be careful.

Once your resin is de-molded, you should clean the mold, removing any debris or crispy resin bits left behind. You can use a dish detergent and a cloth or sponge to clean the TPU out. However, make sure to be gentle, and never use your usual dish sponge to clean something with resin on it.

10. Post-Process Your Cast

You might notice that your casting has layer lines or other flaws in it, which is typical for 3D printed molds. To remove these defects and ridges, all you have to do is sand them out.

Before sanding, make sure to wear your safety gear. Resin dust is just as toxic as liquid resin, and inhaling it could permanently damage your lungs.

To sand your resin:

- Wet your resin object.

- Use coarse to medium grit wet/dry sandpaper to buff off the edges.

- Repeat the process with medium-grit sandpaper and then again with fine-grit sandpaper.

- Buff your resin with a damp buffing cloth or microfiber cloth until it shines.

- If you want to polish, you can use a resin polishing compound and your buffing cloth to finish your piece.

For an example of how to sand out your resin and some fantastic tips, check out this tutorial from ResinObsession:

Final Thoughts

From start to finish, 3D printing a reusable TPU mold for casting resin is no more challenging than making any other model with CAD software. While using the mold does take some extra steps and know-how, you’ll never go back to buying silicone molds once you get the hang of it. With 3D printing, you have the power to cast anything you could ever want!

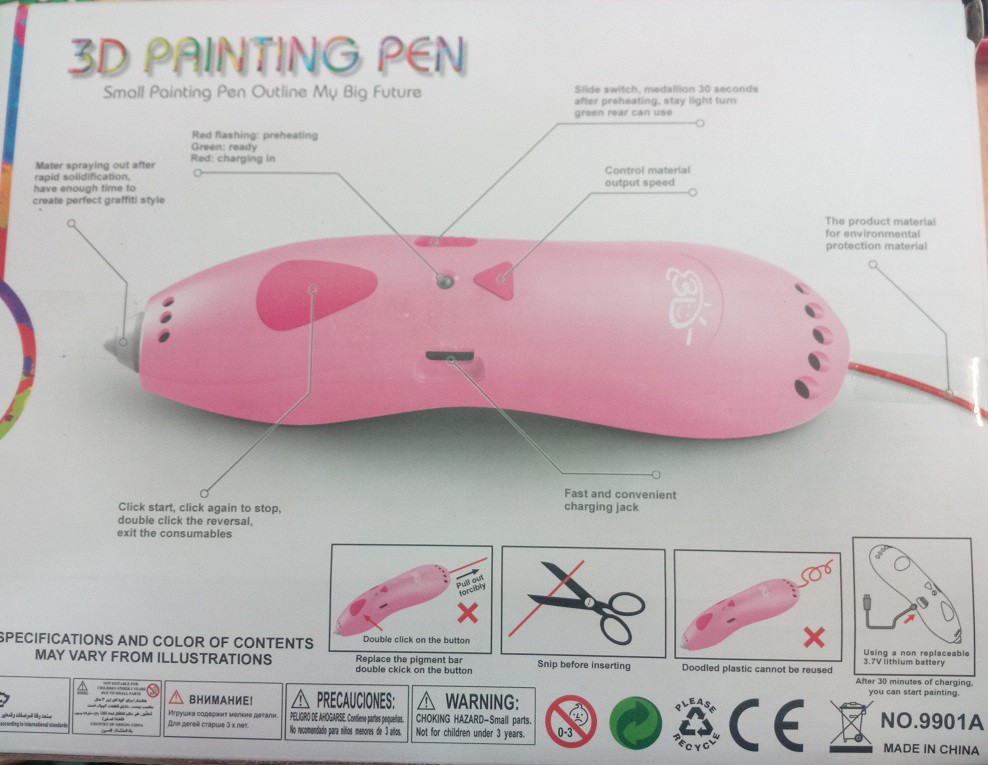

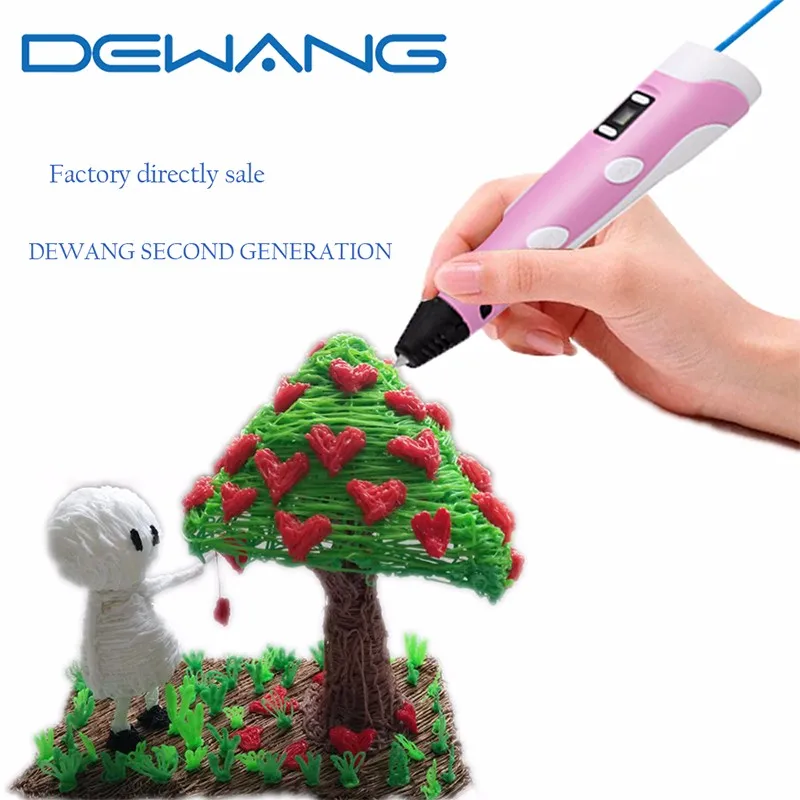

How does a 3D printing pen work?

For many manufacturers, a need or desire for something often leads to the question, "Print or buy?" And while 3D printing has come a long way, it's far from completely eliminating the need to buy items. So where do you draw the line?

So where do you draw the line?

In this article, we will look at when to print something on a 3D printer and when not. The answer depends on a number of factors, including the part itself, the equipment needed to make it, what it's made of, the quality required, and how much time you're willing to spend. You need to take all of these factors into account when choosing between 3D printing a part or simply buying a finished version. nine0003

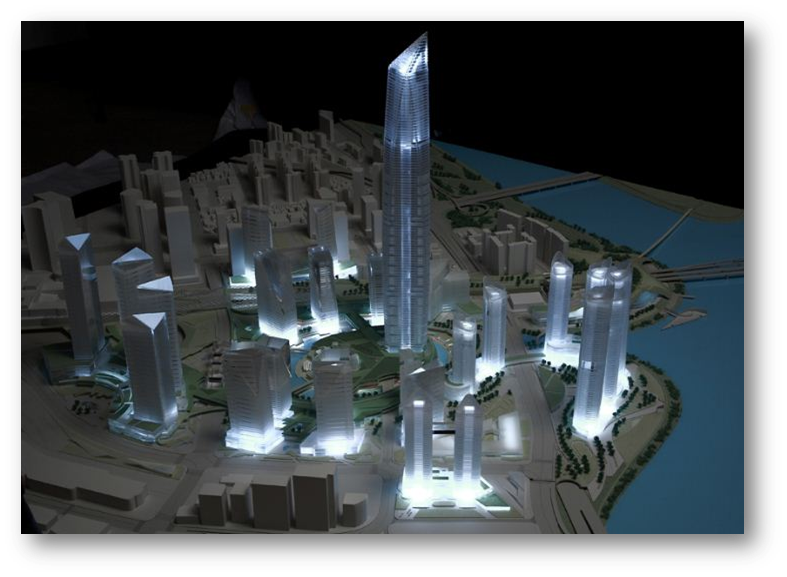

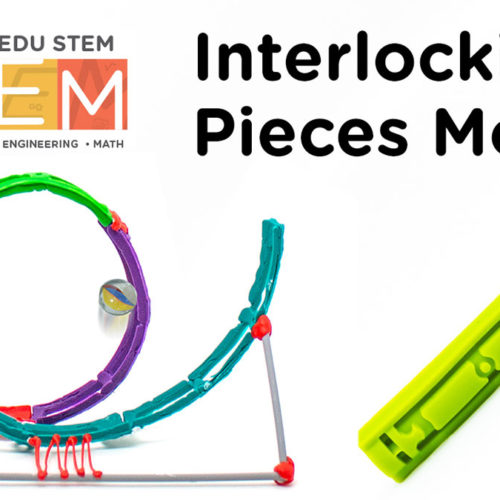

You may also consider other factors such as customization and certain design elements. For example, 3D printing has been beneficial to the dental industry, as custom 3D printed tooth molds based on 3D scans can be very accurate. Another example is some aircraft parts with complex internal geometries that are easy to print but difficult to create using other manufacturing techniques.

Both of these examples are very expensive to 3D print, but they have other advantages. In some cases, despite the cost, 3D printing may be a more appropriate manufacturing method, so more than just price should be considered. Here we'll look at some of the things to think about when you're deciding whether to print a part or just buy it. nine0003

Here we'll look at some of the things to think about when you're deciding whether to print a part or just buy it. nine0003

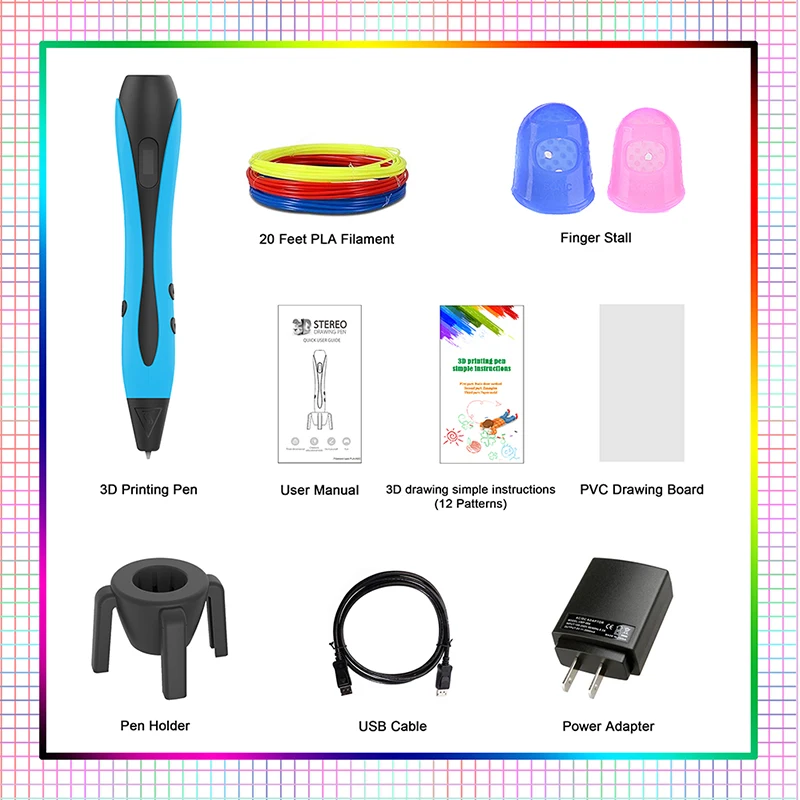

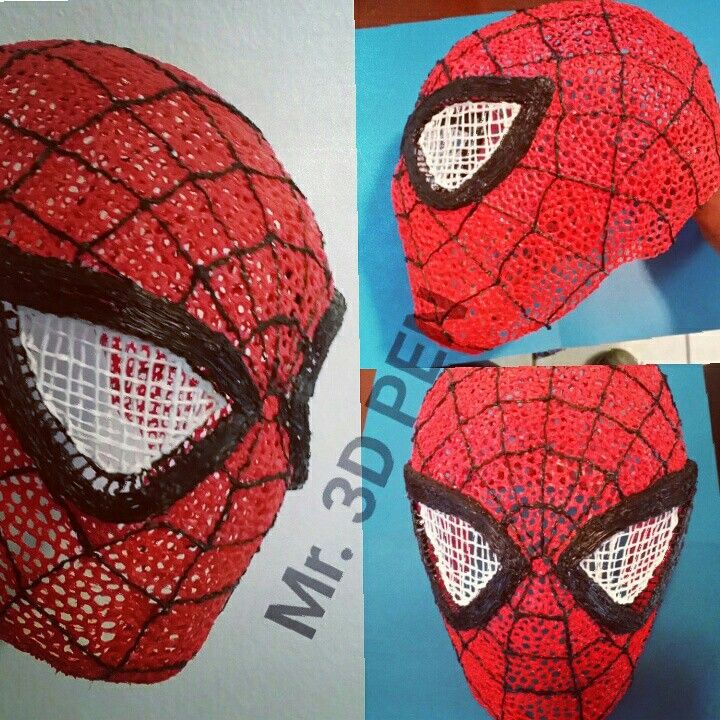

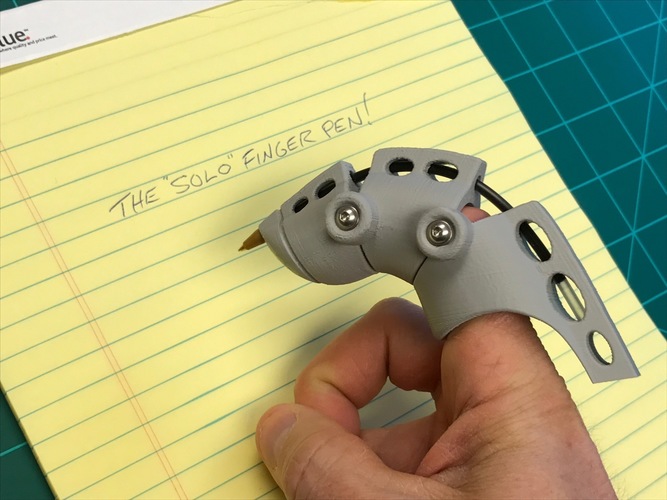

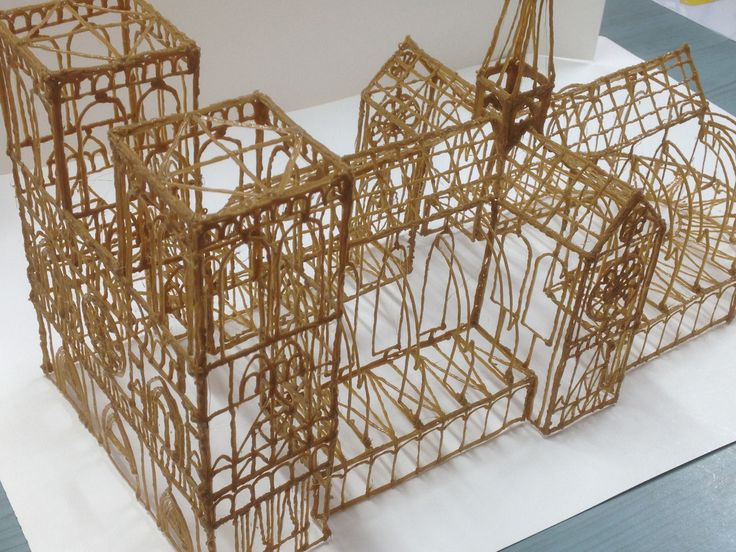

Here are a few cases where a 3D printing pen is preferred over a 3D printer:

- Develop freestyle hand drawings of items and free sketch concept designs

- Realizing imaginary models instead of trying to create them in CAD software

- Teaching children the basics of 3D printing

- Visualizing ideas early in product concept development (even before prototyping)

- Inexpensively play with 3D technology

After seeing some of the key concepts of 3D printing pens, we hope you can see how a 3D pen can be a toy, a tool, or both! In the end, it depends on the pen you're using and who's using it.

The 3D pen can be a serious tool when it comes to studying, drawing or product development. On the other hand, it is a toy when used for crafts, drawing, and general entertainment. nine0003

To summarize the article, I would say that a 3D pen is a worthwhile purchase, especially for making adjustments and filling in blemishes on your 3D prints. This is a nice addition to a 3D printer that gives you a little more room to fix finished objects.

This is a nice addition to a 3D printer that gives you a little more room to fix finished objects.

This is great fun for all the kids around you and, of course, for yourself! Friends and family would love to see the idea of creating something instantly in front of them, so I would recommend getting yourself a 3D pen. nine0003

Click "Like" and get only the best posts on Facebook ↓

Share on Facebook

Share on VK

Share on OK

Share on Twitter

Share on Google Plus

9003interest Share on 9003interestUseful

Model overview, All about 3D pens

Myriwell RP400A and Tiger 3d Round One -

performance comparison

The 3D pen has undoubtedly become a unique and useful gift for a child or an adult in recent years. 3D pen perfectly develops and entertains.

In our article, we objectively compare two models, the most convenient 3D pens for drawing with plastic for both children and adults.

All about 3D pens

The most comfortable 3D pen

nine0002With a wide variety of 3D pens on the market, it is very difficult to choose a 3D pen that is guaranteed to be comfortable for you and your children. We have been selling 3D pens for several years and have accumulated a lot of experience in drawing with 3D pens and have collected a lot of opinions and feedback from children and adults, which pen, in their opinion, is considered the most convenient and reliable. Our opinion and the opinion of our customers coincided. Most of the respondents confidently answered that the Myriwell Stereo Graffity Pen RP400A 3D pen can be called the most convenient for a child and an adult. nine0003

All about 3D pens

State of the art 3D pen

The 3D pen industry has not stood still and has been actively developing. The Chinese company Myriwell has become the forerunner of this development. In less than three years, the company's engineers have developed and commercialized four generations of 3D pens. In each of the following, radically improving ergonomics, the quality of components and materials, reliability, reducing the weight of the 3D pen and much more. Doing everything to ensure that the 3D pen is easy to use, especially for children, because. children are the main consumers. nine0003

In each of the following, radically improving ergonomics, the quality of components and materials, reliability, reducing the weight of the 3D pen and much more. Doing everything to ensure that the 3D pen is easy to use, especially for children, because. children are the main consumers. nine0003

All about 3D pens

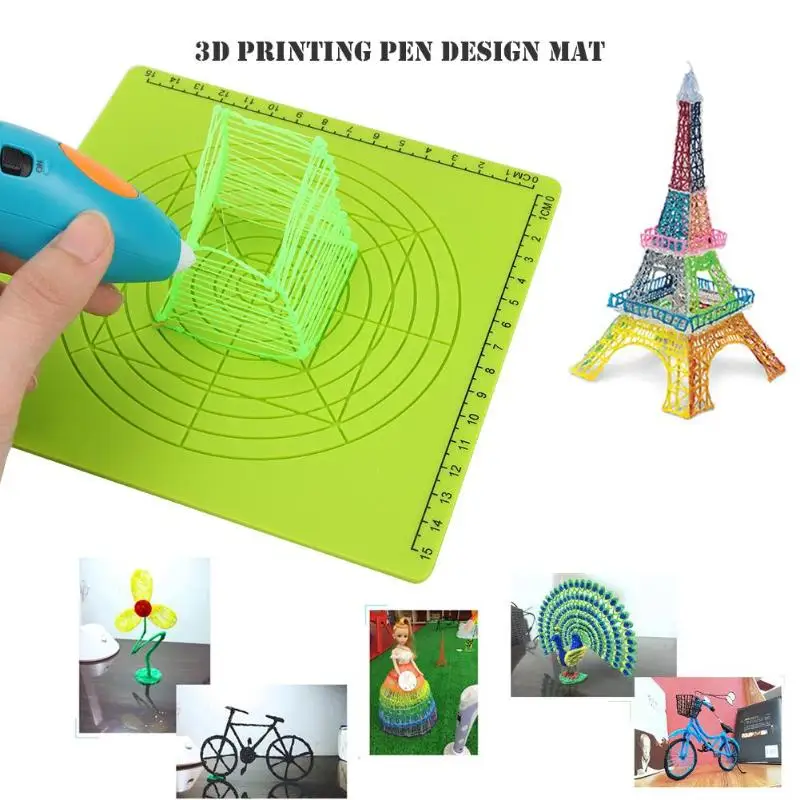

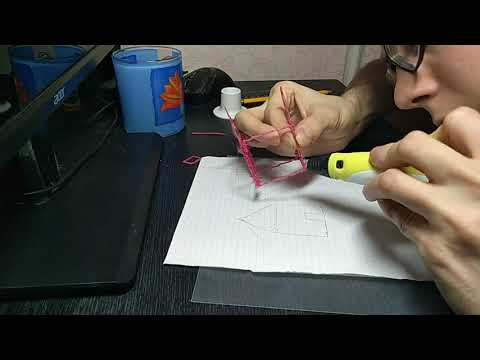

How to draw with 3D pen

Drawings drawn with pencils, felt-tip pens, or paints, in most cases, remain in the albums, at best, you hang the drawing in a frame on the wall. A 3D pen allows you to make voluminous and bright drawings that can take place not only on the wall or in an album, but are also guaranteed to decorate a room, a Christmas tree. Draw and create three-dimensional drawings for any holiday. nine0003

All about 3D pens, Overview of

modelsMyriwell RP100A and Myriwell RP100B model comparison

Myriwell RP100A and RP100B 3D pens are the first models in the Myriwell 3D pens line. Simplicity of design, convenience for children and adults, affordable price allow us to say with confidence that Myriwell RP100A and RP100B 3D pens are the most popular on the Russian market. At first glance, 3d pens are very similar. The same shape, buttons, print head, mains power supply and plastic loading mechanism are really the same, but in all other respects the pens are different. nine0003

At first glance, 3d pens are very similar. The same shape, buttons, print head, mains power supply and plastic loading mechanism are really the same, but in all other respects the pens are different. nine0003

All about 3D Pens, Instructions

Repair 3D pen

Every 3D pen user, sooner or later, faces the problem when the 3D pen does not feed the plastic filament. The motor runs, but the feed does not go. Such a breakdown is caused by the fact that the plastic thread was fully loaded into the handle, which, according to the instructions, is not recommended.

If your pen does not feed plastic, does not load new thread, then we advise you to watch this video for cleaning and repair:

Instruction video showing how to repair Myriwell RP400A 3D Pen

3D printing news

Vincent van Gogh's printed ear made from living tissue and DNA

We have already seen a lot of human tissue printed in the 3D bioprinting process. Such technology in the long term promises to eliminate many ailments, restore damaged organs for implantation, and actually provide all sorts of "replacement" body parts. nine0003

Such technology in the long term promises to eliminate many ailments, restore damaged organs for implantation, and actually provide all sorts of "replacement" body parts. nine0003

All about 3D pens

The cheapest 3D pen

The3D pen is a new plastic drawing device aimed at both children and adults. The principle of operation of a 3D pen is quite simple. The 3D pen mechanism feeds the plastic filament into the heating head (extruder) where it melts to a predetermined temperature and is extruded to the surface and hardens very quickly. Thanks to this, your child can draw like a regular pencil or felt-tip pen, but with a 3D pen, his imagination is not limited to paper and a sketchbook. With a 3D pen, you can draw on any surface (glass, wood, plastic or plain paper). nine0003

All about 3D pens, Overview of

modelsVideo Review of Myriwell RP600A 3D Pen

Myriwell RP600A 3D pen is very easy and fun to draw, the convenience and light weight will be very good for both adults and children. It is convenient to use the main function buttons. The architecture of the 3D pen is adapted to work with both right-handed and left-handed people,

It is convenient to use the main function buttons. The architecture of the 3D pen is adapted to work with both right-handed and left-handed people,

Myriwell RP600A 3D pen has a RETRACT function. As soon as the supply of plastic stops, the motor pulls back a thread of excess plastic, and now it does not flow out of the nozzle. You no longer have to remove excess material and the quality of the product will not suffer! nine0003

All about 3D pens, Overview of

modelsVideo Review of Myriwell RP800A 3D Pen

A new model of 3D-pens from Myriwell - RP800A which is very easy and pleasant to draw, convenience and light weight will be appreciated by both adults and children. It is convenient to use the main function buttons. 3D pen architecture adapted to work with both right-handed and left-handed people,

All about 3D Pens, Instructions

Manual for 3D pen Myriwell RP800A

- Connect the power adapter to AC power and the 3D pen power socket (or use a USB cable to connect to an external battery that delivers more than 2A). When the OLED screen lights up, it means that the pen is ready for use.

When the OLED screen lights up, it means that the pen is ready for use.

- Press the filament loading button, the pen will start to heat up and the green LED will light up. After approximately 40 seconds, the green LED will stop flashing, indicating that the pen is ready to load filament. nine0003

Duplicator i3

Install glass on Wanhao Duplicator i3 3d printer

Many of those who decide to buy a Duplicator i3 3d printer, soon after purchasing it, think about installing glass on the print platform. You can learn from the experience of many who have decided to do this, on forums and reviews on the Internet. We recommend buying borosilicate glass of the right size for your 3d printer's print platform.

nine0002 Model overviewVideo review of 3D printer Flashforge Dreamer

Flashforge Dreamer 3D printer from Flashforge, a large Asian company, has already established itself in the American and European markets as one of the best 3D printers for professional and household tasks. Attractive design, fully enclosed housing, high-quality materials and reliable components, coupled with intuitive controls and software in Russian, make the Flashforge Dreamer 3D printer a relatively inexpensive, professional tool for creating the most complex 3D models

Attractive design, fully enclosed housing, high-quality materials and reliable components, coupled with intuitive controls and software in Russian, make the Flashforge Dreamer 3D printer a relatively inexpensive, professional tool for creating the most complex 3D models

Model overview

3D Printer Review UP! Mini

3D printers have long ceased to be expensive, bulky and noisy devices used only in industrial production, various institutions and large companies. Printing and modeling three-dimensional objects at home no longer requires high costs and in-depth knowledge. There are a lot of types of 3D printers now: self-assembly kits, expensive European and American 3D printers, high-precision 3D printers with a large print area, for jewelers and dentistry, etc. But among all the models available and with stable high print quality, there are not so many. One of them, compact and elegant - 3D printer UP! mini. nine0003

3D printers

20 amazing things created with a 3D printer

If you can print in 2D, can you print in 3D? Well, the technology is already here.