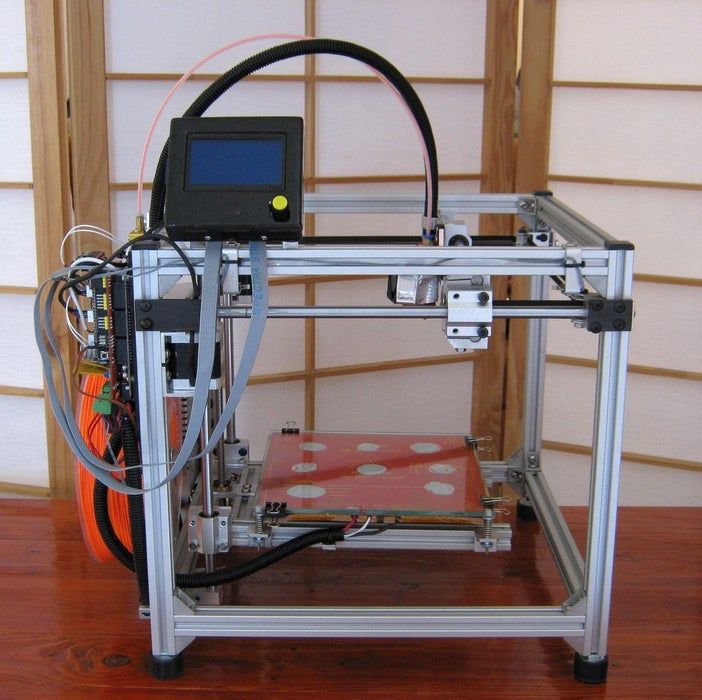

Xyz 3d printer parts

XYZ da Vinci Mini 3D Printer

The da Vinci Mini offers a perfect entry point for beginners and students to explore 3D printing, thanks to simplified controls and a user-friendly workflow process.

- One touch button process for quick 3D printing

- Auto calibration provides instant bed leveling

- Small footprint, yet robust build volume

- Bundled with XYZmaker and XYZware

- Built-in Wi-Fi for connecting to the home, office, or classroom

- Accommodates safe, non-toxic PLA filament

Read the full description below

Notes from the Workshop:

With the XYZprinting STEAM program, students and beginners can quickly get acclimated to 3D printing in science, technology, engineering, math, and the arts.

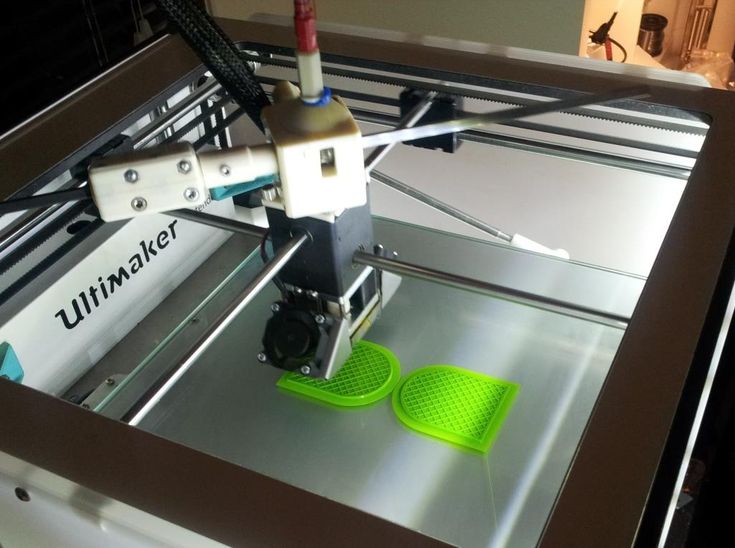

XYZprinting’s da Vinci Mini is part of its Beginning line of products, ideal for young makers, students, and part-time hobbyists who require an easy and affordable way to get started with 3D printing. Using a seamless, one-touch control process, the da Vinci Mini features an automatic filament loading system, color coded indicator lights, and a simplified overall workflow for beginners. With its intuitive auto-calibration system, the da Vinci Mini performs instant bed leveling prior to each 3D print. It can connect wirelessly to computers in homes, offices, and classrooms, reducing the need for USB cable clutter.

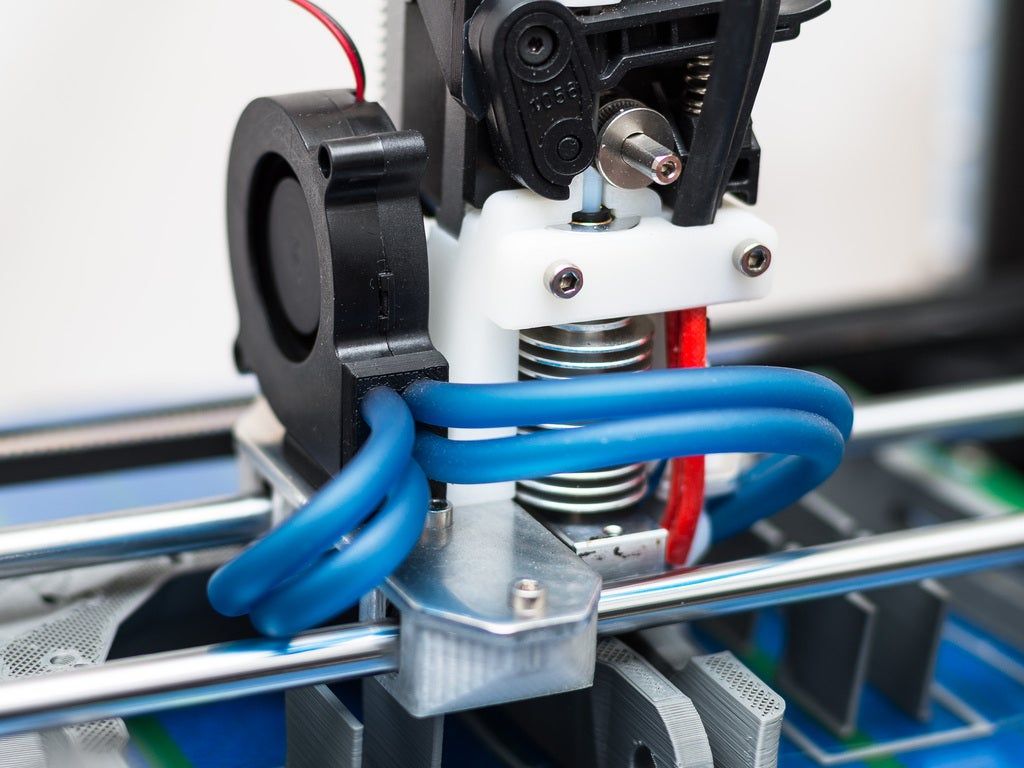

Made with a rigid plastic housing and supported by steel components, the da Vinci Mini 3D printer offers a stable, vibration-free extrusion process in order to ensure accuracy. The aluminum build plate helps promote surface adhesion in order to prevent warping and curling. All of the printer’s precision components have been carefully designed to ensure consistent and trouble-free 3D printing.

The da Vinci Mini’s build area measures 5.9” x 5.9” x 5.9”, allowing it to work with objects such as toys, small prototypes, jewelry, and more. The external drive system pushes filament toward the single extruder hot end, simplifying the process for beginners. The color coded LED interface changes according to the 3D printing conditions, providing a new way for users to interpret heating, printing, or potential filament feeding issues.

The color coded LED interface changes according to the 3D printing conditions, providing a new way for users to interpret heating, printing, or potential filament feeding issues.

Important information about print material (filament) – again, in a positive way

- To be noted if print material is limited (e.g. only custom PLA spools).

- To be noted if the variety of print materials is impressive.

Anything else notable

- The da Vinci Mini 3D printer uses proprietary filament rolls from XYZprinting, making them safe for younger consumers, students, and casual hobbyists.

- XYZprinting PLA filaments are non-toxic and free of heavy metals; extensively tested for safe and reliable 3D printing.

- XYZmaker and XYZware are bundled with the da Vinci Mini, providing streamlined 3D modeling and slicing capabilities that are easy and intuitive for classrooms.

- Can go into more technical information about the print chamber size, extruder model or temperatures, print bed material.

Feel free to include actual specs (e.g. 17 microns, 12”, etc.)

Feel free to include actual specs (e.g. 17 microns, 12”, etc.)

The da Vinci Mini 3D printer is capable of printing between 100 micron (0.1 mm) and 400 micron (0.4 mm). Users should be aware that the finer the resolution, the slower the overall print speed.

The da Vinci Mini is available in two colors, orange and black, and red/yellow/blue. The red, yellow, blue color scheme is designed to complement the atmosphere of younger classrooms.

XYZprinting is a leading provider of affordable desktop 3D printers for homes, offices, and schools. Backed by a variety of 3D printers and accessories, the company strives to make 3D printing affordable and accessible to the masses.

| Technique | Additive Manufacturing |

|---|---|

| Printer Type | FDM (Fused Deposition Modeling) |

| Filament Compatibility | PLA (Polyactic Acid) |

| Construction | Plastic, Aluminum |

| Printer Weight | 22. 7 lbs 7 lbs |

| External Dimensions | 20” x 18” x 15.5” (508 mm x 457 mm x 394 mm) |

| Print Bed | Aluminum Plate |

|---|---|

| Print Bed Max Temp | Non-Heated |

| Extruder Configuration | Single Extruder |

| Extruder Max Temp | 230 Degrees Celsius (446 Degrees Fahrenheit) |

| Motor | NEMA |

| Build Area | 5.9” x 5.9” x 5.9” (150 mm x 150 mm x 150 mm) |

|---|---|

| Build Volume (Approximate) | 205 cubic inches (3.36 Liters) |

| Layer Thickness Minimum | 100 microns (.1 mm) (Variable) |

| Layer Thickness Maximum | 400 Microns (.4mm) (Variable) |

| Input File Type | .STL |

|---|---|

| System Compatibility | Windows |

| Software Compatibility | XYZ Maker, XYZWare, XYZ printing STEAM |

| Power Compatibility | 100 – 240 VAC, 50 – 60hz |

|---|---|

| Manufactured In | Thailand |

Vendor: XYZ Printing

Source Graphics | XYZ

XYZprinting Industrial 3D Printers

Dedicated to bringing ideas to life

Watch Video

Create High Performance Printed Parts with Lowest Cost of Ownership

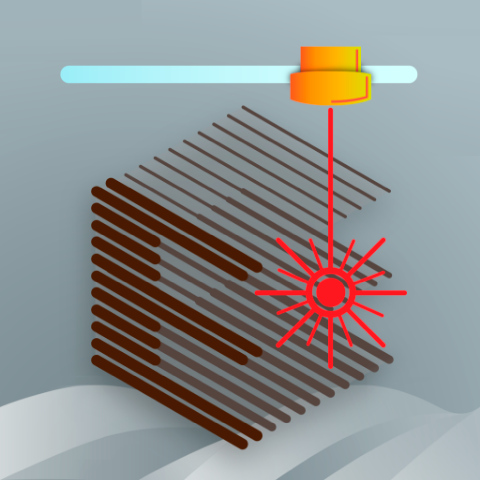

Selective Laser Sintering technology (SLS) has long been the platform of choice for producing 3D printed part with tough, durable mechanical properties. Until now most users outsourced these parts due to high cost of machine acquisition. The MfgPro230 xS brings this capability to every prototyping user at an unprecedented value.

Until now most users outsourced these parts due to high cost of machine acquisition. The MfgPro230 xS brings this capability to every prototyping user at an unprecedented value.

- Build Volume: 9 x 9 x 9 inch

- Layer Thickness: 0.08 mm / 0.1 mm / 0.15 mm / 0.2 mm

- Build Speed: Up to 20 mm / hour

More Information

Produce 3D printed parts with tough, mechanical, and thermal properties

The MfgPro236 xS with polyamide 6 (PA 6) powder expands the range of rapid prototyping applications to higher temperatures, especially in the automotive and electronic industrials. Upgrade printing speed up to 22 mm per hour with shorter cooling time, the MfgPro236 xS spares less printing time and delivers high-quality parts you need.

- Build Volume: 9 x 9 x 9.8 inch

- Layer Thickness: 0.

06 mm / 0.08 mm / 0.1 mm / 0.15 mm / 0.2 mm / 0.3 mm

06 mm / 0.08 mm / 0.1 mm / 0.15 mm / 0.2 mm / 0.3 mm

- Build Speed: Up to 22 mm / hour

More Information

Watch Video

Watch Video

High Productivity Color Part Platform

The PartPro350 xBC offers cutting edge printhead technology that delivers industry leading color part productivity. With speeds up to 18 mm per hour for a fully loaded build volume, the PartPro350 xBC is 150% faster than other color binder technologies.

- Build Volume: 8.7 x 13.8 x 7.9 inch

- Layer Thickness: 0.10 mm

- Build Speed: Up to 18 mm / hour

More Information

High-Resolution Parts in Minutes

A digital micromirror device is used to reflect and focus ultraviolet light (UV) on the surface of the photosensitive resin polymerized in a layer-by-layer manner. And UFFTM Technology enables high throughput 3D printing.

And UFFTM Technology enables high throughput 3D printing.

- Build Volume: 4.5 x 2.5 x 4.0 inch

- Layer Resolution: 25 / 50 / 100 micron (Material dependent)

- Light Source: UV LED λ 405 nm

More Information

Watch Video

Watch Video

High resolution for those small parts where accuracy and details are critical.

A digital micromirror device is used to reflect and focus ultraviolet light (UV) on the surface of the photosensitive resin polymerized in a layer-by-layer manner.

- Build Volume: 2.5 x 1.6 x 4.7 inch

- Layer Thickness: 25 / 50 / 100 micron

- Light Source: UV LED λ 405 nm

More Information

Accelerate Ideas

Advanced laser scanning technology. The linear laser scanning system delivers groundbreaking quality and reliability with comparison to legacy galvo mirror systems.

The linear laser scanning system delivers groundbreaking quality and reliability with comparison to legacy galvo mirror systems.

- Build Volume: 5.9 x 5.9 x 7.8 inch

- Layer Thickness: 25 / 50 / 100 / 200 micron

- Light Source: UV Laser λ 405 nm

More Information

Watch Video

Watch Video

Designed for Ease of Use and High Performance

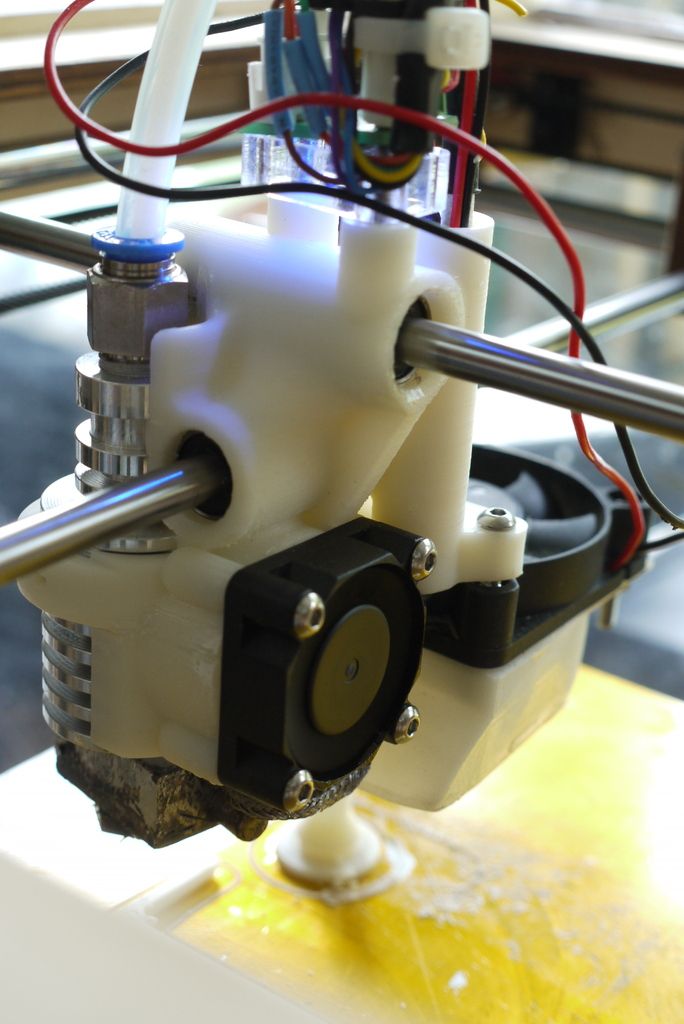

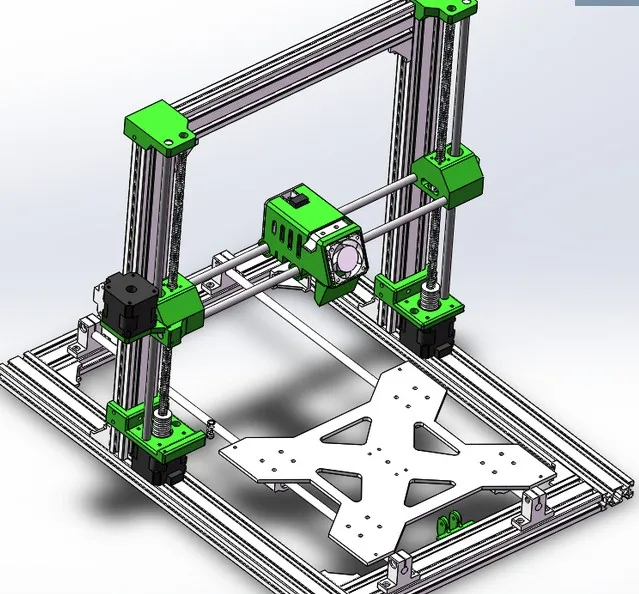

The pro grade XYZprinting PartPro300 xT FFF 3D printer is designed for rapid prototyping of high performance parts. It is compatible with multi advanced material such as Carbon Fiber, Metallic, and water-soluble materials which allows it to provide the needs of material characteristics requirements.

- Build Volume: 7.7 x 10.6 x 11.8 inch or 11.6 x 11.8 x 11.

8 inch

8 inch

- Layer Resolution: 50 - 700 micron

- Build Speed: 300 mm/s

More Information

Performance 3D Printers for High Quality Parts

XYZprinting Industiral 3D printer PartPro200 xTCS is an innovative full-color FFF (Fused Filament Fabrication) desktop 3D printer that integrates 3D printing, 3D scanning and laser engraving function into one machine allowing changing the way you work.

- Build Volume: 7.2 x 7.2 x 5.9 inch or 7.9 x 7.9 x 5.9 inch

- Layer Thickness: 100 - 400 mm

- Build Speed: 180 mm/s

More Information

Watch Video

Read more about XYZ Printing's first color FDM 3D printer

Reviews

Good afternoon dear colleagues.

We, iGo3D Russia, are the official distributor of XYZprinting products in the Russian Federation and the countries of the Customs Union, and today we will tell you about another significant step in the development of FDM 3D printing technologies.

XYZ Printing takes the technology lead this time.

They were the first to announce a desktop FDM 3D printer with full digital gamut!

We present you: ' da Vinci Color '

How does it work?

The 3D printer uses a unique ink module with CMYK color profile and ink cartridge system. And together with the printer, proprietary software is used for processing, painting and preparing models for printing.

Technically, the da Vinci Color is sort of a hybrid between an inkjet and a 3D printer.

A word about XYZMaker software

This 3D modeling software has a large set of objects and editing tools that you can combine and use with each other to create stunning designs. XYZmaker has the function of combining with the da Vinci series 3D printer from XYZprinting, being at the same time a slicer.

XYZmaker has the function of combining with the da Vinci series 3D printer from XYZprinting, being at the same time a slicer.

Solution for designers and print-to-order.

da Vinci Color is a powerful and economical solution for small business owners. Thanks to the use of PLA filament as the main consumable material, you end up with a ready-made, color model that does not need post-processing. This 3D printer will fit perfectly into any custom 3D printing service, as it significantly saves time in the production of a full-color product.

Also, one of the interesting innovations is the platform: EZ-Removable Print bed .

This is a special, sandwich-like, flexible design designed to make it easier to remove the finished model.

So, the main features:

- The first FDM 3D printer with full color printing capability

- Print area size: 200x200x150 mm, unheated table

- 0055 Nozzle diameter: 0.

4 mm

4 mm - Supported materials: PLA, 3D-Color-inkjet PLA, Tough PLA, PETG

- Latest technology printing platform .

- Layer thickness 100 - 400 microns

- Print speed 30-120 mm/s

- Automatic calibration

- Friendly interface from software to color LCD on board by XYZ Printing - XYZ Printing Color

.

Your iGo3D team

Our social media groups:

YouTube

Vkontakte

Facebook

Instagram

Follow author

Follow

Don't want

9

More interesting articles

3Dtool

Loading

16.09.2022

859

2

Follow author

Follow

Don't want

Hello everyone, Friends! 3DTool is with you!

What to do if the task is to scan.

..

.. Read more

0

Subscribe to the author

Subscribe

Don't want

In this article we will talk about another device from FlyingBear - FlyingBear Reborn 2. Pro...

Read more

nk.xcfg

Loading

05/10/2016

38159

117

Follow author

Follow

Don't want

“A good tester won't even launch the app.” (heard at work) Based on real...

Read more

The Iron Man suit and the stop-motion revolution

XYZ Media

A technology that has already impacted industry and medicine is now changing cinema.

One of the most difficult tasks in filmmaking is the creation of objects important to the plot, whether they be weapons, figures for animation, complex mechanisms and futuristic costumes.

All this requires the right material. Usually objects are created manually, which takes a lot of time and money and often brings inconvenience in operation.

3D printing could be the solution. This technology has already been used in cinema and there is every indication that it will significantly affect the industry in the future.

Author: Mark Tyutyunnik

What is 3D printing?

3D printing (additive manufacturing, AM) is the construction of three-dimensional objects from models created in CAD (computer-aided drawing programs) or other 3D digital models.

It is not necessary to draw up drawings for future objects on your own, you can download already developed 3D models - for example, here. Then you need to cut the model into thin layers (using special programs for slicing), in accordance with which the material will be superimposed during printing. By uploading the file with the model to the printer (via an SD card, flash drive or Wi-Fi), even a beginner can print the object.

Additive manufacturing has greatly influenced the development of a wide variety of industries. It is used in the creation of weapons, the construction of buildings, the development of medicines and in other areas.

Gradually, this technology was adopted in the cinema.

The benefits of 3D printing are many. Firstly, the production of objects is carried out quickly and efficiently. Secondly, very complex objects can be made using this technology, which eliminates additional assembly steps and provides more freedom for designers.

Another advantage of additive manufacturing is the variety of materials. Printer manufacturers offer a set of sources, but the user always has the opportunity to mix different substances and even simulate ceramics or metal.

How 3D printing works

One of the most important parts of 3D printing is the scanner .

It collects the physical data of an environmental object or (volume, texture and color) to create a digital model.

It collects the physical data of an environmental object or (volume, texture and color) to create a digital model.

There are two main types of 3D scanners: contact and non-contact. The former explore the object through physical contact. The second is to collect radiation from the target object using a laser, structured light, photogrammetry, or optical coordinate measurement.

SLS technology is used to manufacture machine parts and objects with complex geometry. It helps to achieve high strength and precision. A roller rolls the powder, consisting of 50 micron diameter nylon spheres, onto a platform, and the printer heats it up to sintering temperature. Then, with the help of a laser, these spheres are sintered layer by layer until the necessary detail is obtained.

BigRep ONE brand printers are mainly used in cinema. A build chamber with a volume of >1m3 simplifies the additive manufacturing of large-scale objects.

The fast speed and convenience of this production is possible thanks to the camera, which creates large life-size parts and allows you to directly monitor the process. When NeoMetrix Technologies released a video of the development of a functioning car on the BigRep ONE printer, the reason for the technology's popularity in film production was perhaps obvious.

The use of 3D printing in animation

Laika Entertainment has pioneered the full scale application of technology in film. The company has resorted to additive manufacturing to provide naturalistic facial animation for stop-motion dolls. The idea was to take puppet "acting" to the next level.

When working on The Nightmare Before Christmas, director Henry Selick used hand sculpting and the usual replacement of faces - first they shot the head with one facial expression, and in the next frame they replaced it with another. But the range of emotions with this approach turned out to be very meager.

When producing Coraline in the Land of Nightmares, Selick wanted the main character to be able to show as many subtle expressions as possible. That is why the director decided to conduct an experiment using 3D printing.

When producing Coraline in the Land of Nightmares, Selick wanted the main character to be able to show as many subtle expressions as possible. That is why the director decided to conduct an experiment using 3D printing. Leading additive manufacturing industry advocate Brian F. McLean Visual effects specialist for Coraline, Paranorman, Family of Monsters and Kubo: The Legend of the Samurai. He has probably the most experience with 3D printing in the film industry today.

In Coraline, McLean used traditional stop-motion animation and combined it with new techniques. Additive manufacturing has been used to create facial expressions of characters with thousands of details. The specialist used three Objet printers, with the help of which the animators developed about 20 thousand facial areas that could convey more than 200,000 facial expressions.

The image above clearly shows the line of alignment of the upper and lower parts of the face, which was removed in post-production.

Using traditional methods, this amount of work would have taken about 30 years, but thanks to 3D printing, it turned out much faster.

Using traditional methods, this amount of work would have taken about 30 years, but thanks to 3D printing, it turned out much faster. It is even more difficult to imagine how many years Paranorman would have taken to produce. The animators used about 40 thousand different facial elements to expand the emotional range. Each of the 40,000 elements was put into a special face library. Thanks to their combination, Norman alone had about 1.5 million facial expressions. Each short half-minute episode required about 250 different expressions for one character.

About 56,000 faces were printed for "The Monster Family", which were divided into two main areas: eyebrows and mouth.

Each of the options had special names, such as "raised eyebrows" or "pursed lips." Combining them, McLean got the unique expression he needed.

According to McLean, the aim of the rapid prototyping department was "to push stop motion into uncharted territory.

" This idea reached its peak in The Monster Family, where they tried to touch every muscle of the face, and the heads were printed specifically for one frame and were no longer used in the production of the cartoon.

" This idea reached its peak in The Monster Family, where they tried to touch every muscle of the face, and the heads were printed specifically for one frame and were no longer used in the production of the cartoon.

McLean credits lead texture artist Tori Bryant for finding a way to recreate the nuances of coloring layouts by hand using additive manufacturing. She figured out how to compensate for the lack of color calibration on the printer and found that applying traditional drawing and coloring techniques to digital models resulted in a more believable result.

McLean has also used 3D printing on Laika's latest two projects: Kubo: The Legend of the Samurai and Lost Link. The scale increased again - only the main character could have 48 million facial expressions. In addition, when creating both cartoons, PolyJet 9 technology was used.0204 , with the help of which painted the printed objects in the required colors.

3D printing in big-budget movies

Disney pioneered the use of 3D printing in feature films - Jason Lopez (Legacy Effects specialist who worked with Marvel Studios from Iron Man 2 to Guardians of the Galaxy 2 ”) using this technology greatly accelerated the creation of the Iron Man suit. First, experts scanned the body of Robert Downey Jr. - this was necessary to make wearing the suit more comfortable - and then printed armor fragments on Objet Geometries from various materials. Rubber was used for action scenes and fast movements, and metal for close-ups.

For Thor: Ragnarok, Hela's helmet was designed by José Fernandez, costume designer at Ironhead Studios, using this technology. It used SLS (laser sintered nylon powder) with the addition of reinforced carbon fiber so that the headgear was not heavy.

3D printed synthetic materials such as nylon have also been used in the development of other Disney projects: Queen Ramonda's headdress from Black Panther; Kylo Ren costume, shining chrome stormtrooper armor, some parts of Rey's staff, C3PO droid as a costume for actor Anthony Daniels from The Force Awakens, Interpol car from The Muppets 2.

Disney is again the first to apply new technologies, as it was with virtual production or the first “animation” of an actor using a mockup.

Additive manufacturing is also used by Sony Pictures Entertainment, Universal Pictures and Warner Bros.

Rapid prototyping for 007: Skyfall produced an Aston Martin DB5 and a one-third life-size helicopter specifically for the explosion scene, which proved to be significantly cheaper than any other method.

Stratasys printers were used to design armor for the 2014 RoboCop remake.

A The red stripe on the visor was printed using a transparent photopolymer material.

The Apollo 11 spacecraft for Man on the Moon was also recreated using large scale printers - it was created using BigRep ONE V3.

Weta Workshop, a special effects and props company, used this technology to design helmets, sword hilts, spears and axes for the Hobbit trilogy. Animatronics engineer Rob Sheeney has stated that using 3D printing is beneficial as it is more economical and less time consuming.

Then, in 2012, Weta Workshop also tested large-scale printers.

How 3D printing will change cinema

Cinematographer Victor Marin (Young Americans) believes that this technology will play an increasingly important role in the future. He recommends combining methods, instead of replacing traditional ones with innovative ones.

Julia Koerner (helped with 3D printing for the Black Panther designers) also calls for a combination of these methods. She sees the benefits of additive manufacturing in creating really complex and detailed structures that can't be created with traditional methods. In his work, Koerner tries to combine traditional methods with progressive ones.

Gilles-Alexandre Deschaux, creator of stop-motion short Chase me :

“3D printing is already widely used in the film industry, from stop-motion films to big American blockbusters and commercials.

3D printing is often used to create decorative items and props, but not only there. At the development stages, it is used to promote new individual projects and conceptual solutions.

According to Pinewood Studios 3D supervisor Jet Cooper, the possibilities of this technology are already “incredible”, because if you want, you can even scan someone's face with all the wrinkles and pores.

Jet Cooper, Pinewood Studios 3D Supervisor:

“Voxeljet has the biggest printers. Their maximum format: 4000 mm x 2000 mm x 1000 mm. This is the largest printer in the world as far as I know. We have a 1060mm x 500mm x 600mm resolution printer at Pinewood. Anything over this size, we print in parts and then put them together.

3D printing is used to create props, and the metal coating of the material makes it strong and durable. But the Germans are working on a new material - epoxy resins, which are as strong as stone. They are extremely hard.

"

" 3D printing is developing rapidly and is becoming cheaper every time, especially when compared to traditional methods or the use of computer graphics. Perhaps the day is not far off when handmade props and scenery will almost cease to be used in films - they will be replaced by cheaper and faster “printed” counterparts.

Like this article?

WANT TO GET THE BEST ARTICLES

FROM XYZ ONCE A WEEK?

Subscribe to the XYZ newsletter

By clicking on the button, you agree to the terms of data processing

How physics was used to create animations in Star Wars Jedi: Fallen Order.

About creating physical animations for Star Wars Jedi: Fallen Order and the problems that game designers faced. There are 3 ways to adjust the animations in the game for physics.

How Unreal Engine is used in movies

The game engine Unreal Engine 4 is being used in movies. For example, in The Mandalorian they created virtual objects right on the set.

Learn more