Monoprice 3d printer troubleshooting

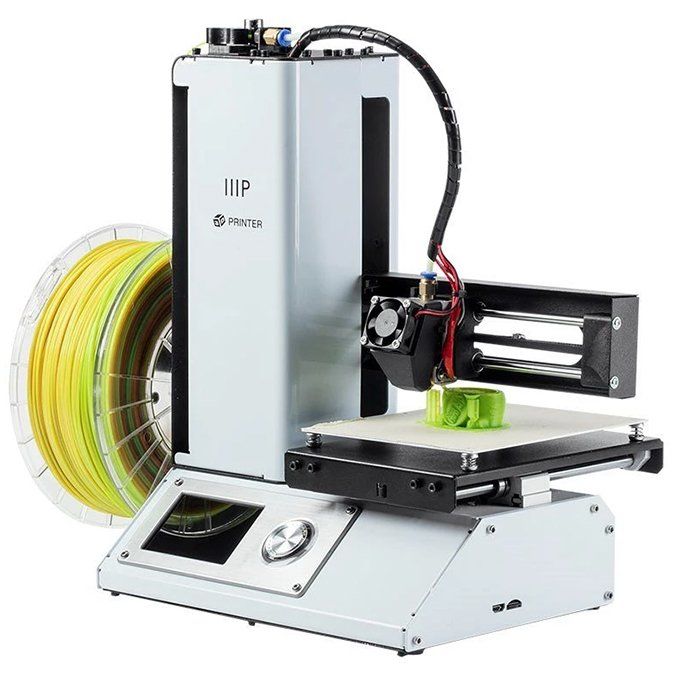

Monoprice Maker Select Mini — Fargo 3D Printing

We’ve noticed some common questions asked about the Monoprice Maker Select Mini that revolve around the same issues. This page goes through the most common solutions to these problems.

Let’s get started.

Under Extrusion/No ExtrusionWhen there’s no filament coming out of the nozzle or filament is “curling” out of the nozzle. Your printer isn’t supplying the amount of plastic asked for.

Troubleshoot It

Issues with Heating and Temperature RegulationYour printer is receiving “Heating Failure” codes or it doesn’t seem to be retaining heat.

Troubleshoot It

Stepper Motor Not WorkingYou’re noticing your stepper motors aren’t running, or running but not operating.

Troubleshoot It

Bed Stopped HeatingThe bed plate on your printer isn’t heating like it should.

Troubleshoot It

The LCD Screen or the SD Card is not WorkingYou’re having any amount of issues with your LCD screen or SD card.

Troubleshoot It

The Axis Does Not MoveIf the axis on your printer isn’t moving, there are a few solutions to this problem.

Troubleshoot It

Stuttering/Step SkippingYour printer is stuttering at the same location of each layer, or your printer is shifting layers.

Troubleshoot It

Axis CrashesIf your axis is crashing, there are a few solutions and steps to take.

Troubleshoot It

Extruder Stops Mid-PrintYou notice that your prints are failing part-way or about a half-hour into the printing process.

Troubleshoot It

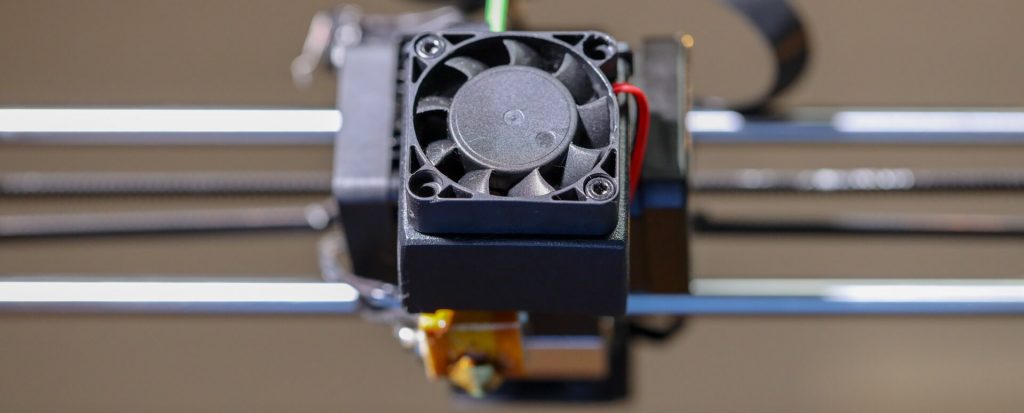

Under Extrusion/No ExtrusionCheck the Front Extruder Fan

The front fan may not be spinning, may be missing blades, spinning slowly, or mounted incorrectly. Visibly check for any of these issues. Also check to ensure that the fan is getting 12 volts of power at max fan speed. If it is not, it is spinning slowly. The fan will need to be replaced or remounted.

Visibly check for any of these issues. Also check to ensure that the fan is getting 12 volts of power at max fan speed. If it is not, it is spinning slowly. The fan will need to be replaced or remounted.

Hobbed Gear is Clogged

A piece of filament may be stuck in the teeth of the hobbed gear. If this is the case, use a wire brush or toothpick to clean out the teeth. This gear may also be worn down and may need to be replaced.

Filament Path is Blocked

There are several places that the filament path could clog. The thermal barrier tubing or the nozzle could be clogged. If you cannot easily unclog the hot end, you may need to replace part or all of your hot end.

Poor Quality or Bad Filament

You may be using filament that is of low quality or has irregularities in its shape. This can slow the flow of filament or can stop it altogether. Try using a different spool of filament and see if the problem is still present. You can also measure the amount of filament that is extruded with calipers to ensure that the stepper motor is extruding the correct amount. Fargo 3D Printing sells 3D-Fuel brand filament, whose quality we vouch for.

Fargo 3D Printing sells 3D-Fuel brand filament, whose quality we vouch for.

Print Temp is Too Low

Your printer may be printing at a temperature that is too low for your filament. Try increasing the printing temp to the maximum temperature or above the recommended temperature range.

Bowden Tubing is Pinched or Clogged

The Bowden tube directs the filament from the stepper motor to the hot end. If the turns sharply or is clogged, this restricts the flow of filament. Visibly check to see if the tubing is making sharp turns or has filament stuck inside of it.

Issues with Heating and Temperature RegulationFaulty Thermistor

Run a pre-heat. If your printer is not displaying that it is heating up, but you observe that the heater block is heating up, then the thermistor is most likely faulty. Check to make sure that the thermistor wire is not cut or damaged, then replace the thermistor.

Faulty Heater Cartridge

Run a pre-heat. If the heater block does not heat up, then the heater cartridge is most likely faulty. Check to make sure the wire to the heater cartridge is not cut or damaged, then replace the cartridge.

If the heater block does not heat up, then the heater cartridge is most likely faulty. Check to make sure the wire to the heater cartridge is not cut or damaged, then replace the cartridge.

PID Settings Incorrect

PID settings control how much power is sent to the heater cartridge. Over time, these settings can change and may need to be reset.

Missing or Damaged Ceramic Tape

Check the ceramic tape. If it is torn or missing it may be causing irregular heating or heat creep. If this is the case, replace the ceramic tape.

Stepper Motor Not WorkingCheck Stepper Motor Connections

Check all connections from the motherboard to the stepper motor to ensure they are not loose, cut, or damaged.

Faulty Stepper Motor

Your stepper motor may be damaged or defunct. To check, unplug the stepper motor and plug it into an axis that you are sure works. If the motor still does not work, then it needs to be replaced.

Faulty Motor Cable

First, check to ensure that the stepper motor works (previous step). If the motor works, then either the cable or the stepper driver is faulty. To check the cable, test the resistance on the wire leading to the motherboard. If the wire is damaged or cut, this cable will need to be replaced.

If the motor works, then either the cable or the stepper driver is faulty. To check the cable, test the resistance on the wire leading to the motherboard. If the wire is damaged or cut, this cable will need to be replaced.

Faulty Stepper Drivers

First, check to ensure that the stepper motor works and that the motor cable is not faulty (previous two steps). If the motor works and the cable is functioning, then the stepper motor driver is faulty, and your motherboard will need to be replaced.

Bed Stopped HeatingCheck Connectors

The connectors from the print bed to the motherboard may have melted or may be charred. If this is the case, your printer may have smoked or started to smell before your print bed stopped heating. To check the connectors, open the electronics case and see if the connectors for the heated bed are melted or charred black. If so, your motherboard will need to be replaced.

Check Wiring

To check the wiring, open the electronics case and make sure the wires for the print bed are plugged in and undamaged. If they are, check the resistance on these wires. If the wires are damaged or cut, they will need to be replaced.

If they are, check the resistance on these wires. If the wires are damaged or cut, they will need to be replaced.

Check Voltage

To check the voltage to the print bed, open the electronics case and pre-heat the print bed. Use a volt meter to ensure that the bed is getting 12V. If it is, then either the wiring or the bed itself is faulty and will need to be replace. If the bed is not getting 12V, then the motherboard is faulty and will need to be replaced.

The LCD Screen or the SD Card is not WorkingThe LCD screen has dead pixels

Replace the LCD screen.

The LCD screen does not light up

Replace the LCD screen.

The SD card does not read

Replace the motherboard.

The Selector wheel does not work

Replace the selector wheel board.

The Axis Does Not MoveFaulty Pulley

The pulley may be worn. Check the pulley to see if it spins smoothly and check to ensure no teeth are missing. If the pulley is damaged or worn, replace the pulley.

If the pulley is damaged or worn, replace the pulley.

Loose Belt

Check the tightness of the belt. If it is too loose, the pulley may not turn the belt. In this case, tighten the belt.

Loose Set Screw

Check the set screw on the pulley. If this is loose, the motor will spin without spinning the pulley. To fix, tighten the set screw.

Faulty Stepper Motor or Stepper Driver

Check Troubleshooting Chart for Stepper Motor Not Working.

Rough Axis Movement

Turn the axis by hand and observe if there are any rough spots. If so, find out why.

Stuttering/Step SkippingCheck Stepper Motor Connections

Check all connections from the motherboard to the stepper motor to ensure they are not loose, cut, or damaged.

Check the Axis Rotation

Turn the axis by hand and observe if there are any rough spots. If so, find out why.

Faulty Stepper Motor, Cable, or Drivers

Check the Troubleshooting Chart for Stepper Motor Not Working.

Out of Place End Stop

The end stop may be out of place or mounted incorrectly. Check the mount bracket to see if it is bent or missing screws. You may need to replace the bracket or remount it.

Faulty End Stop

The end stop may be damaged. If so, replace.

Check Wiring

Check the wires to the end stop to see if they are cut or damaged. Also check the resistance of the wires. If they are damaged or broken, replace the wires.

Extruder Stops Mid-PrintCheck Front Fan

The front fan may not be spinning, may be missing blades, spinning slowly, or mounted incorrectly. Visibly check for any of these issues. Also check to ensure that the fan is getting 12 volts of power at max fan speed. If it is not, it is spinning slowly. The fan will need to be replaced or remounted.

Check Fan Shroud

Your fan shroud may be missing. If so, replace it.

Check PTFE Liner

The PTFE liner may be black or burnt. If this is the case, it needs to be replaced.

If this is the case, it needs to be replaced.

Poor Quality or Bad Filament

You may be using filament that is of low quality or has irregularities in its shape. This can slow the flow of filament or can stop it altogether. Try using a different spool of filament and see if the problem is still present. You can also measure the amount of filament that is extruded with calipers to ensure that the stepper motor is extruding the correct amount.

Hobbed Gear is Clogged

A piece of filament may be stuck in the teeth of the hobbed gear. If this is the case, use a wire brush or toothpick to clean out the teeth. This gear may also be worn down and may need to be replaced.

Dropped Temperature

The hot end may suddenly drop in temperature. Watch your temperature to see if the temperature drops rapidly by twenty or more degrees or if it drops gradually. If the drop is quick, there may be faulty wiring, a faulty heater cartridge, or a faulty thermistor. To troubleshoot these problems, check the Troubleshooting Chart for Issues with Heating and Temperature Regulation. If the drop is gradual, then your parts fan may be spinning too fast or your ceramic insulation may be damaged or missing.

To troubleshoot these problems, check the Troubleshooting Chart for Issues with Heating and Temperature Regulation. If the drop is gradual, then your parts fan may be spinning too fast or your ceramic insulation may be damaged or missing.

Monoprice 3D printer not printing? - 3D Printers - Talk Manufacturing

Hamsammie

#1

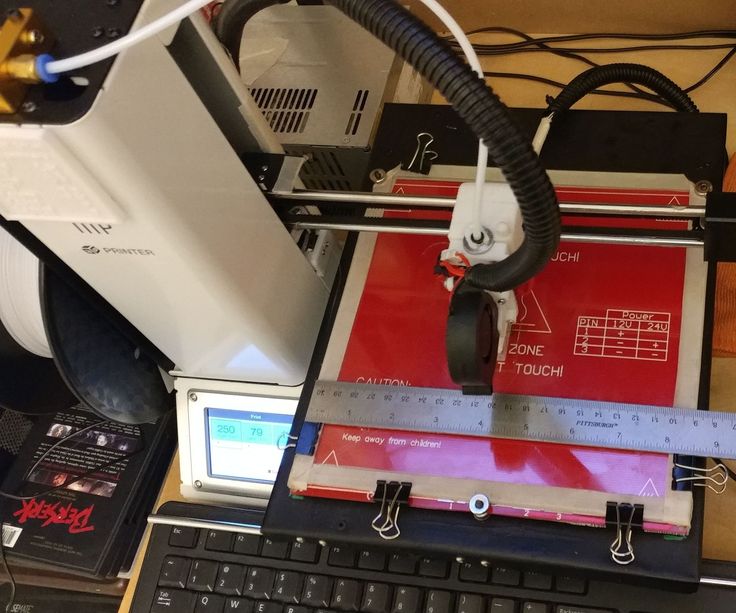

I got a monoprice 3D printer for christmas and I’m having trouble even making it past the test cat. My boyfriend removed the tape on the platform so we botched a good bit of the provided filament. After we fixed the tape issue we started our print and things went great until we ran out of filament. We cleaned it out and started working with the new one. The base started to print but the extrusion stopped coming out. I’ve cleaned the head, tried removing the extrusion, clipping it, and tried it again, I tried preheating it too but nothing seems to work. Is there any insight as to what we’re doing wrong?

Is there any insight as to what we’re doing wrong?

CalSchilling

#2

Which printer is it exactly? I have the Monoprice Dual. Can you see the motor spinning? Does it sound like it is skipping? Have you cleaned the extruder nozzle? I had a chunk of PVA stuck in mine once that refused to get out.

1 Like

EvilsWay

#3

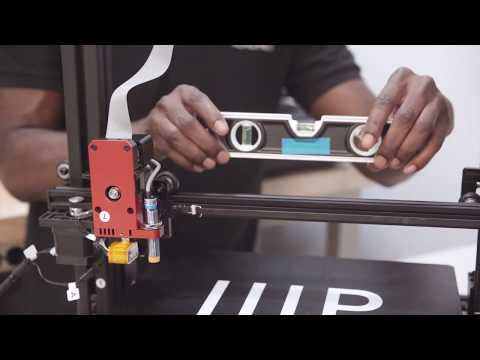

What are your print settings? Do you hear a clicking or knocking sound from the extruder? if the only thing you have tried to print is the test cat, then I would suspect the bed is not at the proper height, and you’re not extruding well, creating a clog. What are you using to calibrate bed height?

What are you using to calibrate bed height?

1 Like

Just3D

#4

what printer and when you say tape are you referring to the buildtak surface?

1 Like

petersawiris

#5

The provided filament really sucks in my opinion, get yourself some good PLA such as Hatchbox from amazon, Also I like to print around 230 degrees Celsius.

One last thing, when you feed the new filament into the extruder run out a few inches of it before beginning the print, this ensures the extruder is full of filament and no air pockets

1 Like

ChrisBuildsStuf

#6

Have you taken the fan off to see if the new filament is extruding? This printer has given me some issues with adding or changing filaments.

1 Like

cj5fpv

#7

Sam,

Glad you made the jump into the 3D printing hobby! It’s fun once you get a hang of a few things. I as well started on a Monoprice printer.

Be sure to check this link: https://www.simplify3d.com/support/print-quality-troubleshooting/

Hopefully this helps!

1 Like

Damani_Kofi_Ada

#8

It’s probably clogged. Happens sometimes when changing spools.

Heres a video on clearing the hot end that helped me.

https://m.youtube.com/watch?v=Pgsq297zdAs

1 Like

Hamsammie

#9

Thank you! This will definitely be helpful!

Hamsammie

#10

Thank you! I am going to keep this one handy.

Hamsammie

#11

I’m not too savvy with this type of thing. I’m honestly afraid i’d break it. Thank you for the insight though, i’ll bring it up to him and see if maybe we can take a look at that.

Hamsammie

#12

Hatchbox is actually the kind we’re trying to work with now! It’s glow in the dark, so I don’t know if that makes a difference. We’ll try a higher heat setting and see if that helps. Thank you!

Hamsammie

#13

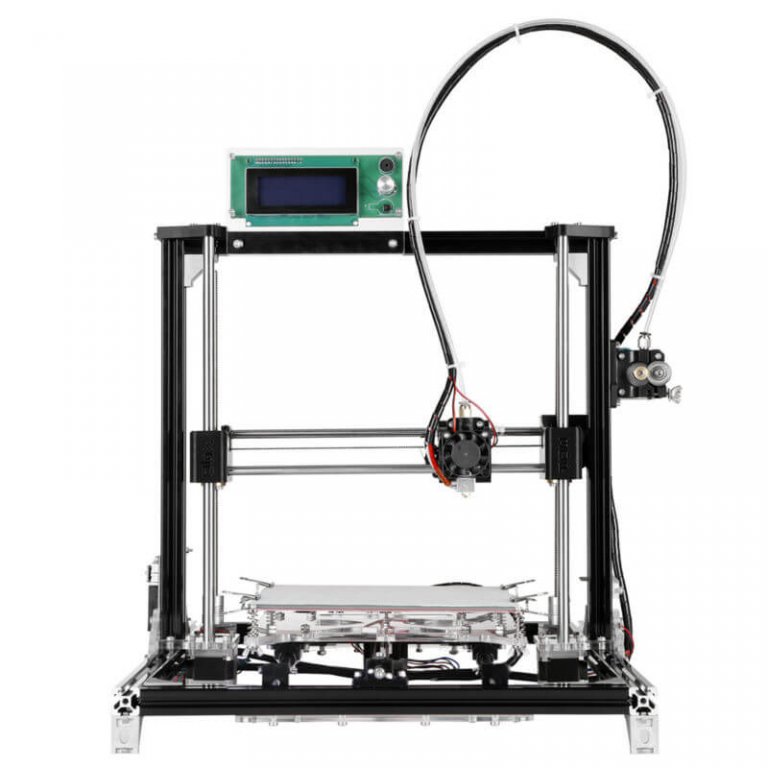

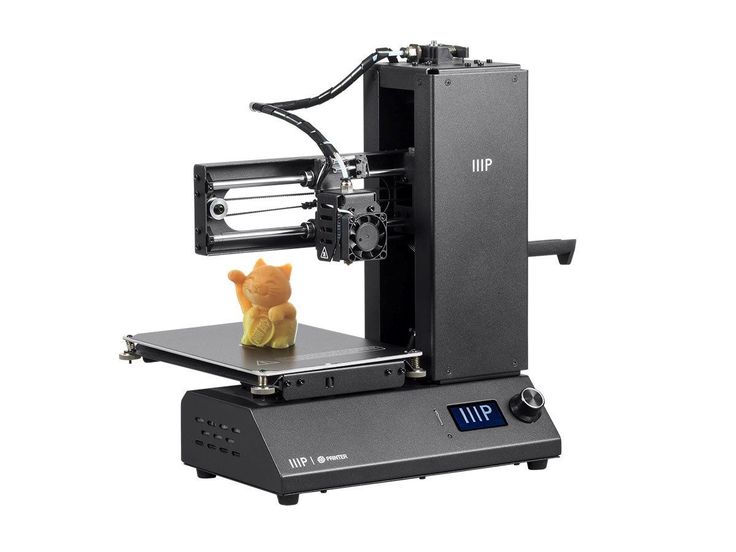

I’m not 100% sure, the box said monoprice and it has IIIP on the front of the device. The printing plate came with something like a large piece of masking tape over it. It was pulled off while setting up and after a few botched attempts we looked at the manual and realized it was supposed to be there. Per the instructionsame we replaced it with masking tape and it seemed to work fine up until the original filament ran out.

The printing plate came with something like a large piece of masking tape over it. It was pulled off while setting up and after a few botched attempts we looked at the manual and realized it was supposed to be there. Per the instructionsame we replaced it with masking tape and it seemed to work fine up until the original filament ran out.

Hamsammie

#14

I’m not 100% certain of the model, it just says IIIP on the front of the device. There is no visible motor that I can see, but when trying to print it does make a clicking noise that was not present the first try. We tried cleaning it last night at the recommendation of a friend but haven’t gotten a chance to test it yet. Hopefully it will work!

Hamsammie

#15

The settings we are using are straight out of the box. We did start printing the test cat with the original filament and what did print turned out perfectly. We are hearing a clicking noise from the extruder as it tries to pull the filament through.

We did start printing the test cat with the original filament and what did print turned out perfectly. We are hearing a clicking noise from the extruder as it tries to pull the filament through.

Damani_Kofi_Ada

#16

Yea it’s the MP Select Mini aka the Malyan M200. And that noise is a jam.

1 Like

Joseph_Lenox

#17

Just fyi, blue painters tape tends to work better than the cheaper manilla. If this isn’t the mini then you can look into Printbite (mutley3d.com) or pei as an alternative surface.

1 Like

EvilsWay

#18

Follow the instructions for clearing a jam linked above, slow down your print speed, raise your temperature 5°, and calibrate bed height with a thick sheet of paper.

1 Like

OTHERAREAS

#19

Definately remove the fan and manulally unclog jam. Realy easy only a couple screws dont be afraid

doakley42

#20

im having this same problem let me know if you get this fixed please.

next page →

Answers to troubleshooting questions, page 4

- Control issues with new printer prevent table alignment process I recently built my first 3D printer from a kit, my build went fine without any issues, but now I'm struggling to properly level my table.

My LCD screen…

My LCD screen… - PLA print problem first 3mm Ender 3 Pro I have tried adjusting printer settings with different nozzle temperatures(190-210°C)/table (0-60°C), fan speed (0-100%), Cura and Slicer settings, but nothing worked...

- Y-min stay triggered I have a FLSUN i3 220x220x240 with: LCD Display Year 2004 (RepRap Discount Smart Controller) MKS-gen-L-v1.0 printer board running Marlin firmware 2.0…

- Poor adhesion on new layer - Monoprice mini select My Monoprice Mini Select v2 has poor adhesion when the print head goes to lay a new layer on the table, as seen in the photo. Does anyone have a solution for this?

- Printing from card not showing up on new card SKR mini e3 v1.2 I'm new with a 3 month old Ender 3 Pro, my first. I bought, installed and downloaded a new SKR Mini E3 V1.2 mobo. The LCD panel lit up as usual with no problems. I chose "print from card" which...

- FabPro 1000 makes flat little discs? I'm just getting started with 3D printing and have a FabPro 1000 (primarily for miniatures).

I tested this by trying to print a few things, but every time it was a disaster: …

I tested this by trying to print a few things, but every time it was a disaster: … - Filament is almost impossible to remove Most people complain that the filament does not stick to the plate, but mine is the opposite. At first it was very good. When I removed the magnetic table, the project came off easily, but within a few...

- How to Resume an Unfinished Project I was printing a box lid on my Ender 3 pro printer. But I don't know why he stopped printing and moved aside when this happens in finished prints. It happened at midnight and I...

- Replicator Mini Homing Loop I have 2 problems with my Replicator mini. the first problem is that at random times i will do something on the computer, like tell the printer to upload a file or start...

- RAMPS 1.4 LED 2 blinks when trying to warm up the table On my i3 clone I was trying to add an Anycubic i3 Ultrabase to my RAMPS 1.4 board, and after adding the necessary configurations to the Marlin firmware, I can heat up the table.

The problem is that he is very…

The problem is that he is very… - First diagonal filament 3D print Just bought a Creality Ender 3 yesterday. Installed it and ran a test print of a dog. Photo below. I used the sample filament that came with the printer. I'm not 100% what it is, but...

- Gaps/holes in 3D printing walls I'm new to 3D printing, recently bought an Ender 5 Pro. I'm trying to print with 1.75mm PLA but the results are very poor unfortunately. When I got there after leveling the table, I got a decent result…

- Very unusual diagonal edging Edit #2 The title has changed again to better reflect the nature of the question. I installed the Z axis motor on top of the frame to alleviate any misalignment that might occur. Z Axis…

- Troubleshooting Filament Slippage on MakerBot 5 I run a high school 3D printer lab and we have several MakerBot 5th generation printers. On one of them, I had significant problems with "thin" prints and .

..

.. - Nozzle crashes into print after changing filament Recently watched a YouTube video about using Cura to change G-code to pause at a certain height to change filament (using Ender 3 Pro). The first time I did this...

- Getting the Turnigy Fabrikator Mini V2 up and running I recently bought a used Turnigy Fabrikator Mini V2, which I can tell is a rebrand of the Malyan M100. After the first few prints, I noticed that my prints were very...

- Anet A8 moves down to the chunk, destroying it, just before the printer is set to terminate Hopefully someone can help me figure out what's going on with my printer. I printed a couple of pieces and they printed great. But for some reason the printer goes down in chunks from time to time...

- Thermal runaway fires when temperature rises while recharging I've noticed interesting behavior on my Ender 3 with SKR Mini E3 motherboard and Marlin 2.0.x bugfix firmware.

(otherwise all other equipment is fully stocked) After…

(otherwise all other equipment is fully stocked) After… - How do I fix bulging first layers of print? The bottom 1-6 layers of my prints always stick out like an enlarged elephant foot effect. I have tried all the fixes for the elephant leg but to no avail. I use: XYZprinting DaVinci Jr 1.0…

- Error when trying to upload firmware to cr-10 I had trouble uploading Th4DUF_R2 firmware to CR-10. I have already successfully flashed the bootloader with Arduino, but when I try to upload the bootloader I get this error: avrdude: ser_open():…

- Ender 3 distance between nozzle and table changes in Y direction After I leveled my Ender 3, the distance between nozzle and table seems fine at both ends, but moving the table along the Y direction shows it increases and decreases by a factor of three times,…

- Ender 3 y-axis stretched (I don't believe it's a layer offset) I'm having a weird problem today and was looking for some help.

Out of the six Ender 3s I manage at my college, one of them seems to stretch the y-axis of all the prints I…

Out of the six Ender 3s I manage at my college, one of them seems to stretch the y-axis of all the prints I… - Troubleshooting Help: Wavy/Lifting Lines Can someone help me troubleshoot? It seems to stick to the table but not very well as the lines are somewhat wavy or rising. Is it related to adhesion? Or maybe...

- Random underpressure on Ender 3 (don't know what to do anymore!) I have an Ender 3 that I bought in December 2018. Now I have a problem with underextrusion that I don't know how to solve. I tried everything: changed the nozzle, changed the PTFE, changed the filament,…

- Why doesn't PLA print stick to the table? Plastic: Same Matterhacker PLA (filament I use every day) Printer: Anycubic i3 Mega (the one I use every day) Slicer: Ultimaker Cura 4.2.1 I don't know what is causing this...

- The printer makes errors on the right half of the print but not on the left I am a total newbie having problems with the Monoprice Maker select v2 printer.

The left half of my prints looks fine, but the right half always gets confused. When I watch him type...

The left half of my prints looks fine, but the right half always gets confused. When I watch him type... - Z axis is limited to 15mm at height I have a Prusa i3 and I have a problem with my Z axis. It stops at 15mm even if the object to be printed is larger than that. Could you please help me solve this problem? …

- Inconsistent vertical walls on Robo 3D R1+ I'm trying to fix a problem with my 3D printer (Robo 3D R1+). It can no longer print vertical walls well. Here is a picture of what it looks like: The walls are very inconsistent.…

- AnyCubic Chiron moves in Y direction I have AnyCubic Chiron and sometimes the table does not move properly. This leads to displacement of the prints and destruction of the seal. I spent a lot of time watching it and noticed that when it is...

- Anycubic i3 Mega Layer Offset My Anycubic I3 Mega shifts each layer a small distance, causing the straight model to lean towards it at an angle.

For example, this white round drop should have had a straight cylindrical ...

For example, this white round drop should have had a straight cylindrical ... - Hotend won't support temperature Last month I got the Anycubic Predator and after fixing a few mechanical issues I was able to get it to print decently well. The only major modification I made...

- Printing paused while printing I got a new CR-10S 3D printer (I got it for Christmas). It was printing just fine until yesterday, I was doing a print and it randomly stopped, it didn't restart by itself, I...

- 3D printer extruder not heating up I am facing some problem with my 3D printer device. The table seems to heat up without any problems, however the hot end does not heat up! Can you help me identify what is...

- Ender 3 BLTouch fails in many ways My newly installed BLTouch probe regularly fails ABL properly. There seem to be 3-4 failure modes: The probe controls some points, but partially fails, with .

..

.. - Filatech PETG Print with E3Dv6 Hypercube Clone fails after 3 smooth coats I recently got Filatech PETG filament to print on my E3Dv6 Hotend clone hypercube printer. The first 3 layers for each print are pretty good, but the 4th layer doesn't stick and my prints... Printrun/Pronterface Slic3r 1.3.0 Windows 10 Arduino Mega+RAMPS 1.4 Marlin 1.1.9Prusa i3 -- Hephestos BQ with the following modifications: Power supply 450W (from 230V…

- Odd dots when printing line I tried to print an "improved" calibration cube and noticed that the printer was stacking dots instead of a solid line. This was right after turning off my extruder motor and adjusting…

- Anycubic i3 Mega Incorrect Heated Bed Temperature Reading It's been about a month since I started using the Anycubic i3 Mega and everything was going great, but today I left it alone to print 3DBenchy and it suddenly stopped in the middle…

- E-steps reset somehow, how could this happen History After installing a direct drive extruder (E3D Hemera) on my CR-10S, I calibrated the E-steps to give adequate extrusion; transition from ~95 steps/mm to ~390 steps/mm.

…

… - Test print comes out spongy I got the Anycubic Chiron yesterday. I went through the alignment procedure and I think the level test print came out well, so I printed a 20mm calibration cube and benches. Both of them came out with some...

- Wavy lines on 1st layer only I get wavy lines on first layer only in both x and y directions the same. First layer 0.4 mm with 0.4 mm tip. The remaining layers are 0.2 mm. I tried changing the Z offset from -1.2 to 0…

- How to solve this extrusion problem? I used this model at 100% infill for extrusion testing: The printer is an old printer bot that I converted to a Clipper so I'm doing some tests to make sure...

- Best way to fix ABS corner curl on a closed Prusa style printer with a PEI heatbed? I'm trying to set up a closed (custom case) Prusa i3 style printer for ABS, but I'm having a lot of trouble getting the corners of the parts to not curl.

Detailed technical...

Detailed technical... - Squealing noise when moving z-axis down I had my Prusa i3 clone for about two years and it always made a screeching sound when the z-axis moved down. I have tried many solutions to this problem such as lubricating the z-bars, printing a new top...0005

- Ender 4 printer stalling problem in the middle of printing I'm looking for suggestions on what could be causing my printouts to stall in the middle of printing. I cut with Ultimaker Cura 3.6. Some prints work fine and others randomly stop...

- BLTouch Deploys and then immediately retracts during homing I just bought a Creality CR10 Max (this is my 9th printer, 3 of my others are creality and they all have BLTuch). I have only done probably 5 prints on this machine since I bought it,…

- Print failed and looks charred I started printing on my Monoprice Select v2 and let it run. I print with Dikale PLA at 200°C and 60°C extruder temperatures.

My initial layer speed is 30mm/s and then 60mm/s. Although...

My initial layer speed is 30mm/s and then 60mm/s. Although... - What is causing this "stringing" and can my seal recover from it? This is what it looks like This is a model universe of things links It looks like it couldn't print the edge, but that happened many hours after the margin was printed. This didn't happen with my 1st attempt...

- Z-banding help Monoprice MP Select Mini 3D Printer V2 . Here is what my printed part of the fan looks like: These printers are known for their Z lead screw assembly (M4 bolt and nut), so I...

- Why did the print fall off the raft? I just set up a refurbished MP Select Mini V2 and tried to print the manufacturer's included test file, cat.gcode , from the included SD card. I printed in PLA (I think;…

- …

- 3

- 4

- 5

- …

- >>

8 Best Enclosed 3D Printers of 2022 (All Price Ranges)

Enclosed 3D printers prevent cold air from entering the print, causing warping or other problems. For basic materials like PLA, 3D printer cases don't matter much, but for more complex materials like ABS and Nylon, they will save you time and time again.

For basic materials like PLA, 3D printer cases don't matter much, but for more complex materials like ABS and Nylon, they will save you time and time again.

Most cheap 3D printers are open 3D printers - they do not have a frame or housing (sometimes you can buy them separately) and print in the open. Almost all 3D printer kits like the Ender 3 and CR-10 are open source 3D printers.

However, this can cause problems. ABS, a widely used material for 3D printers, warps if it is not cooled slowly. In addition, closed 3D printers allow you to keep hot and dangerous parts of the 3D printer away from your hands and others. This is especially important for kids, which is why indoor 3D printers are some of the best 3D printers for kids.

Contents

- Best indoor 3D printers under a thousand dollars

- Flashforge Adventurer 3 Lite — cheapest indoor 3D printer

- Monoprice Voxel — budget indoor 3D printer

- QIDI Tech X-Pro great 3D printer — with case for 0

- Flashforge Creator Pro 2 is the best low cost IDEX printer

- BIBO 2

- Best indoor 3D printers for consumers

- Dremel 3D45

- Raise3D E2

- Best 3D printers in the upper price range with housings

- Raise3D Pro2

- Ultimaker S5 (with housing kit)

- Buyer's Guide - What to look for

- Benefits of closed 3D printers

- Top closed questions

Flashforge Adventurer 3 Lite is the cheapest indoor 3D printer

- Price: approximately $339

- Assembly volume: 150 x 150 x 150 mm

Flashforge Adventurer 3 Lite is a compact and quiet, fully enclosed beginner printer that provides friction-free printing. Printer setup is minimal other than a well-managed five-point calibration process, making it the best choice for beginners or students looking to start printing without the hassle.

Printer setup is minimal other than a well-managed five-point calibration process, making it the best choice for beginners or students looking to start printing without the hassle.

It is almost identical to the Adventurer 3, except for the built-in camera and thread runout sensor. These minor features do not detract from the simple typing experience.

In addition to a sleek, closed design, the Flashforge Adventurer 3 Lite has everything you need to handle tough materials like ABS: a flexible heated bed with a maximum temperature of 100°C and a maximum nozzle temperature of 240°C. With these features, you can also work with more exotic heat-sensitive materials such as metal, wood, and more.

It also has a wide range of connectivity options, including Wi-Fi and remote print monitoring thanks to FlashForge's 3D Cloud Print technology. The build volume of 150 x 150 x 150mm results in a narrow printable area, which is one of the few gripes I had when evaluating the Flashforge Adventurer 3 Lite. You won't have much luck printing bulky and tall parts, but this is easy to fix by printing in batches.

You won't have much luck printing bulky and tall parts, but this is easy to fix by printing in batches.

It is also worth noting that the filament compartment located on the side of the printer, while practical, is not intended for all types and brands of filament. You may need an external holder if your chosen third party filament is not suitable.

Key points:

- Closed chamber

- Reliable, beginner-friendly printer

- Wi-Fi connectivity

- Materials: PLA, ABS, heavy duty PLA, PLA Color Change, metal-filled, wood and high speed PLA

Monoprice Voxel - Budget Indoor 3D Printer

- Price: $449

- Assembly volume: 150 x 150 x 150 mm

The cheapest indoor 3D printer we recommend, the Monoprice Voxel is one of the best 3D printers for beginners. It's very easy to set up (within 10 minutes!), easy to operate with a touch screen, can print over WiFi, and comes with 8GB of onboard storage for 3D printer files. It comes with several 3D models in files, as well as some materials to get you started, so you can go from unboxing to printing in minutes.

It comes with several 3D models in files, as well as some materials to get you started, so you can go from unboxing to printing in minutes.

If you're new to 3D printing and aren't too tech-savvy, assisted leveling reduces the experience to a simple click. It also comes fully assembled, so you won't need any DIY skills, which is surprising considering most printers in this price range are 3D printing kits. It can also connect to Polar Cloud, allowing you to manage and control your printer remotely, and even do so for multiple printers at the same time.

Key points:

- Cheap indoor 3D printer

- Beginner Friendly

- WiFi Printing and Touch Screen on an Inexpensive Device

- Materials: ABS, PLA, PETG, Flexibles

QIDI Tech X-Pro is a great 3D printer with a $500 case

- Price: $500

- Assembly volume: 230 x 150 x 150 mm

One of last year's most popular low-cost 3D printers, the Qidi Tech X-Pro offers reliability, precision, dual extrusion and an efficient closed area print, all for $500.

The layer thickness starts from 0.05 mm, the printer can print at speeds from 30 to 150 mm/s - although at such high speeds the print quality deteriorates noticeably. The printer is Mac and Windows compatible and can print over WiFi, USB or Ethernet.

Flexible, removable plate allows for easy removal of prints with minimal damage, and comes with Qidi Tech's own QidiPrint 3D Slicer. Overall, this is one of the best indoor 3D printers under $500.

Highlights:

- Large 4.5" touchscreen for ergonomic printing

- Flexible assembly plate

- WiFi printing and dual extrusion for $500

- Materials: ABS, PLA and PETG

Flashforge Creator Pro 2 is the best low cost IDEX printer

- Build volume: 200 x 148 x 150 mm

A well-equipped update to the classic Creator Pro, the Flashforge Creator Pro 2 offers all the benefits of a case with features you don't expect to see in the $600-$700 range. We see it as an ideal second printer for manufacturers who have already completed their initial training on a budget FDM kit and are now looking for something more versatile and feature rich.

We see it as an ideal second printer for manufacturers who have already completed their initial training on a budget FDM kit and are now looking for something more versatile and feature rich.

While the Flashforge Creator Pro 2 has a solid, well-made sealed chamber suitable for both ABS and PLA thanks to its removable acrylic top cover, it's the independent dual extruder system that sets it apart from other top-rated sealed 3D printers.

The IDEX System is almost unheard of at this price point, giving manufacturers the flexibility to work with specular prints, duplicate prints, dissolvable support structures, and even print multiple materials or colors at the same time. It is suitable for complex prints with vertical overhangs or is the perfect tool to help the teacher to release as many student-designed prints as quickly as possible.

These two centerpieces aside, Flashforge Creator Pro 2 completes the offering with a touch interface, 200 x 148 x 150mm volume and compatibility with PLA, Pearl PLA, ABS, ABS Pro, PVA and HIPS materials.

It's worth noting that Flashforge made the wrong choice by tying the Creator Pro 2 to its own FlashPrint slicer. It does its job well enough, but doesn't have the versatility of an open source software suite like Cura. This isn't necessarily the deciding factor, especially for those new to 3D printing or educators who want simple software and pre-loaded settings specifically tuned to work with the Creator Pro 2 right from the start.

Highlights:

- Inexpensive independent system with two extruders

- Fully enclosed print chamber

- Materials: PLA, Pearl PLA, ABS, ABS Pro, PVA and HIPS

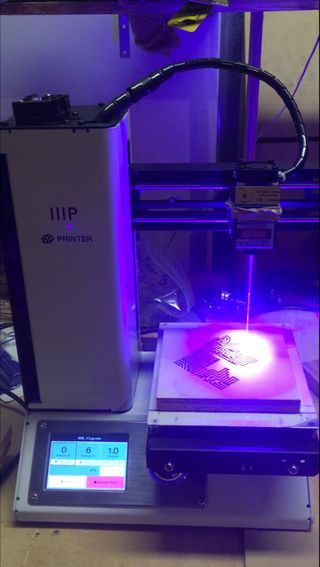

BIBO 2

- Price: $679

- Assembly volume: 216 x 187 x 160 mm

The Bibo 2 printer, with character and affordable for hobbyists, offers 50 micron precision, dual extrusion and WiFi printing, all for less than $1,000.

Although this closed 3D printer is not an IDEX printer, it still offers copy printing modes for printing two identical objects at the same time. It features an easy-to-use touch screen - which isn't a given in this price range - and has a low-filament detection feature to avoid spoiling prints.

It features an easy-to-use touch screen - which isn't a given in this price range - and has a low-filament detection feature to avoid spoiling prints.

In addition to the ABS and Nylon efficient 3D printer body, Bibo is built in a stable and durable aluminum frame, minimizing unwanted vibrations that can slightly affect print performance and quality. Overall, this is a great indoor 3D printer for the price, and it can also come with a laser engraver kit.

Highlights:

- WiFi printing, dual extrusion and touch screen, all for just over $500.

- Minimum layer height 50 microns

- Claims it can print polycarbonate but also says max temperature is 270C

- Materials: PLA, ABS, HIPS, flexible filaments, PETG, nylon, PC, carbon fiber

- Best Indoor 3D Printers for Consumers

Best Indoor 3D Printers for Consumers

Dremel 3D45

- Price: $1,599

- Assembly volume: 254 x 152 x 170 mm

Accurate, versatile and ideal for teaching 3D printing in schools, the Dremel 3D45 builds on nearly a century of Dremel manufacturing experience. Accuracy down to 50 microns, WiFi, USB or Ethernet cable connectivity, Mac and Windows compatibility, and iPad compatibility make the Dremel Digilab 3D45 the perfect addition to any school or business prototyping environment.

Accuracy down to 50 microns, WiFi, USB or Ethernet cable connectivity, Mac and Windows compatibility, and iPad compatibility make the Dremel Digilab 3D45 the perfect addition to any school or business prototyping environment.

The heated plate allows you to print on nylon and Eco-ABS, while the built-in HD camera provides convenient remote control of the print progress, which is easily done using cloud-based 3D printing software.

If you have any problems, Dremel's USA support team is here to help. Overall, this is a solid and accurate indoor 3D printer that offers good volume and results for the price.

Highlights:

- Efficient automatic leveling system

- Highly rated customer support

- Universal

- Materials: PLA, PETG, Eco-ABS, Nylon

- Price: $3,499

- Assembly volume: 330 x 240 x 240 mm

Raise3D Large Enclosed 3D Printer adds to IDEX's already impressive range of dual extruder 3D printers. The extruders of IDEX 3D printers can move independently of each other, which greatly increases the speed and efficiency of printing, especially when printing multiple identical or identical parts.

The extruders of IDEX 3D printers can move independently of each other, which greatly increases the speed and efficiency of printing, especially when printing multiple identical or identical parts.

Raise3D E2

The E2 printer has two main modes:

Mirror mode: 3D printing simultaneously prints reversed mirrored versions of your model, such as the sole of a shoe for the left and right foot.

Duplicating mode: uses both extruders synchronously, printing two identical objects at the same time and doubling the printing efficiency.

The E2 3D printer case keeps heat inside and everything else outside. If the door is opened during printing, the process is immediately suspended so that no one is burned or injured by the extruder or the heated layer. The E2 is also equipped with an efficient air filtration system that removes melted plastic particles and odors, as well as filament end sensors and power-off recovery functions.

Key points:

- Build volume is reduced to 295 x 240 x 240 mm when using the dual extruder

- Useful "Mirror" and "Duplicate" modes

- Built-in security measures

- Materials: PLA, ABS, HIPS, PC, TPU and TPE, PETG, nylon, PP, ASA, PVA, glass-filled filaments, metal-filled, carbon-fiber and wood-filled.

- Price: $3,999 / $5,999

Build Volume: 305 x 305 x 300 (605) mm

Top-of-the-range 3D printers with housings

Raise3D Pro2

A true workhorse full-body 3D printer, the Raise3D Pro2 series offers incredible precision, material compatibility, great workflow and many other key features.

The standard Pro2 already has a very large build area, while the Pro2 Plus extends the z-axis range to parts up to 605mm high. The extruders can reach temperatures of 300C for even the toughest materials such as PC, and the dual extruders enable efficient printing with support for soluble materials as well as multi-color 3D printing.

With a minimum layer height of 0.01mm, Pro2 3D printers can print incredibly sharp and finely detailed details. Swap out the nozzle for a smaller nozzle and focus on the small details to get a fantastic finish. The built-in camera makes it easy to control prints, while the 7-inch touch screen provides data and an easy-to-use overall workflow.

Key points:

- Build volume with dual extruder: 280 x 305 x 300 mm

- A complete printer: accurate, reliable, closed, versatile.

- Materials: PLA, ABS, HIPS, PC, TPU, nylon, ASA, PETG, PVA, glass, carbon fiber, wood.

Ultimaker S5 (with housing kit)

- Price: $5,995

- Assembly volume: 330 x 240 x 300 mm

The Ultimaker S5 is capable of printing industrial grade parts with layer resolution down to 20 microns. An enclosed 3D printer that becomes even more efficient and safer with the S5 Pro kit, the S5 delivers reliable and repeatable dual extrusion with amazing precision, even with abrasive filaments such as glass and carbon fiber.

Although Ultimaker manufactures its own filaments, the S5 is open and can be used with any 2.85mm filament. It prints over WiFi as well as other methods and can be monitored remotely using the built-in camera.

When you purchase the S5 Pro Bundle, you get access to 24/7 automated material handling, air filtration and heat control for 6 filaments, as well as an Air Manager that further encloses the 3D printer.

Highlights:

- Excellent accuracy and print quality

- Reliable and efficient in many materials

- Pro Bundle makes it even more efficient indoor 3D printer

- Materials: PLA, CPE, NYLON, ABS, glass, carbon fiber, PC, PVA, PP, TPU

Ultimaker s5 with optional pro kit including housing, air filter and filament storage

Buyer's guide - what to look for

Fully or partially enclosed chamber

Partially enclosed chamber printers are a bit of an oddity because they don't provide ideal printing conditions with either of the two main filament types, ABS and PLA. However, they provide an extra layer of security, which is useful for educational institutions or those with children. We recommend a fully enclosed chamber if you plan to print with ABS, and an open chamber if you choose PLA as your media. If you are going to print with ABS and PLA, choose an enclosed printer with removable covers.

However, they provide an extra layer of security, which is useful for educational institutions or those with children. We recommend a fully enclosed chamber if you plan to print with ABS, and an open chamber if you choose PLA as your media. If you are going to print with ABS and PLA, choose an enclosed printer with removable covers.

Stock Volume

Build Volume is the printable area available to you on a closed printer. In other words, it is a measure of the size and type of prints you can make. If you are planning on making large prints or multiple copies, we recommend high volume printers such as the Ultimaker S5.

Material Compatibility

The enclosed 3D printer is designed to be compatible with a wider range of media types by being able to maintain higher temperatures around prints and keep cold air out. ABS is the most common type of material for sealed chambers, but you will also find printers that can work with nylon, PC, and other heat-sensitive materials. PLA can also be used if the printer covers are removable as this material requires cooler ambient temperatures for best results.

PLA can also be used if the printer covers are removable as this material requires cooler ambient temperatures for best results.

Heated bed

Given that the purpose of a closed chamber is to provide a stable thermal environment for printing with more complex materials such as ABS, a heated bed is a must. It helps provide an additional source of heat directly below the print, which promotes layer adhesion and slows down the cooling rate, thus avoiding unwanted defects such as warping and curling.

Connectivity

Connectivity defines how you interact with the printer, whether it's sending cut prints or fine-tuning settings. An SD card reader is more or less standard, as is USB in many cases, but for ease of use, there's nothing better than a Wi-Fi connection and thus cloud printing and monitoring.

Layer resolution

Layer resolution indicates the smallest layer height that can be printed. Choose a printer with a lower layer resolution for parts with more detail, such as 20 microns on the Ultimaker S5. On a closed FDM printer, 100 micron layer resolution is relatively standard and allows for a wide range of detail.

Choose a printer with a lower layer resolution for parts with more detail, such as 20 microns on the Ultimaker S5. On a closed FDM printer, 100 micron layer resolution is relatively standard and allows for a wide range of detail.

Filters

If you're buying a closed chamber, your plan is most likely to include ABS printing. ABS not only has an unpleasant odor, but also emits potentially harmful fumes. A printer equipped with filters, carbon or HEPA, helps to extract the most toxic elements from the fumes. In addition, we also recommend working with ABS in a well-ventilated area.

Touch screen

For convenience, we recommend an enclosed touch screen 3D printer. After all, we're all used to scrolling and swiping on our phones, so it makes sense to want the same functionality and familiar interface when working with a 3D printer. Most modern printers come with a touch screen as standard.

Price

Closed printers tend to increase in price as you pay for additional production and design. But thanks to the ever-increasing popularity of the budget category, enclosed camera printers are more affordable than ever before. You can easily buy a reliable indoor 3D printer for less than $400. Naturally, if you have the budget, new professional-grade printers that cost thousands of dollars also hit store shelves every year.

But thanks to the ever-increasing popularity of the budget category, enclosed camera printers are more affordable than ever before. You can easily buy a reliable indoor 3D printer for less than $400. Naturally, if you have the budget, new professional-grade printers that cost thousands of dollars also hit store shelves every year.

Benefits of Enclosed 3D Printers

Better ABS and Nylon 3D Printing

Enclosures can cool parts more slowly and maintain a more stable and higher temperature in the build chamber. This reduces buckling and splitting during the printing process.

Much safer

3D printer housings keep hot parts such as the nozzle and heated bed away from children if you have a family at home or if 3D printing is done in schools.

Quieter

The closed area keeps noise out, making them ideal quiet 3D printers. The enclosures keep out the buzz and hum of the printing process, which is a real boon if you're typing at home or in confined spaces with poor acoustics that can amplify noise levels.

Stronger and more durable

Enclosed 3D printers typically feature a sturdy four-walled cubic design that keeps vibrations and other factors from degrading print quality.

Noise Reduction

Enclosures help reduce noise by reducing hum and hum during printing, which is a real boon if you're printing at home or in confined spaces with poor acoustics that can amplify noise levels.

Drawbacks of Enclosed 3D Printers

More Expensive - 3D printers with enclosures are more expensive than open FDM printers. The logic here is obvious: manufacturers are forced to spend more money on raw materials and the assembly process, which invariably reflects on consumers.

Maintenance and Troubleshooting Difficulty - Due to the enclosed design, maintenance of an enclosed 3D printer is much more difficult. Cleaning, replacing, troubleshooting or upgrading parts is much more of a hassle than an open design 3D printer.

FAQ

What is the 3D printer case for?

Enclosures help improve print performance by keeping hot air in and cold air/draughts out. For heat sensitive materials such as ABS, a stable higher temperature environment is critical for proper layer adhesion and reduced chance of warping, curling and other problems. Likewise, the shroud helps prevent dust and dirt from getting on printer parts and the print itself; this is essential for successful printing as contamination can affect adhesion and print quality.

Are closed 3D printers safer? Why?

Yes. The housing shields hot and moving parts from prying fingers and hands, reducing the chance of injury compared to open design printers where all parts are exposed and easily accessible. Whether you live with children or work in an educational setting with younger students, an enclosed 3D printer will give you peace of mind. In addition, filters, often installed in enclosed printers, remove toxic elements from the fumes.