Storing 3d printer filament

How to Store 3D Printer Filament and Keep it Dry

(Image credit: Tom's Hardware)Storing filament for your 3D printer is a very personal matter. Some people like to display unwrapped rolls like books on a shelf, while others keep their stock locked away in moisture controlled Tupperware. Which is right?

Both, actually.

If you only print with PLA, store it in a low humidity environment and move through your stock rather quickly, keeping your rolls unwrapped is fine. But if your workshop is in a garage – or you work with more advanced filaments like TPU and nylon – moisture will become a problem.

Why Moist Filament is a Problem

It defies logic, but filament that has absorbed moisture can get brittle, bubbly or stringy. In extreme cases, it will steam and hiss as the filament is heated. Check out this short video from Maker’s Muse who was printing PLA during a record rainy Australian summer.

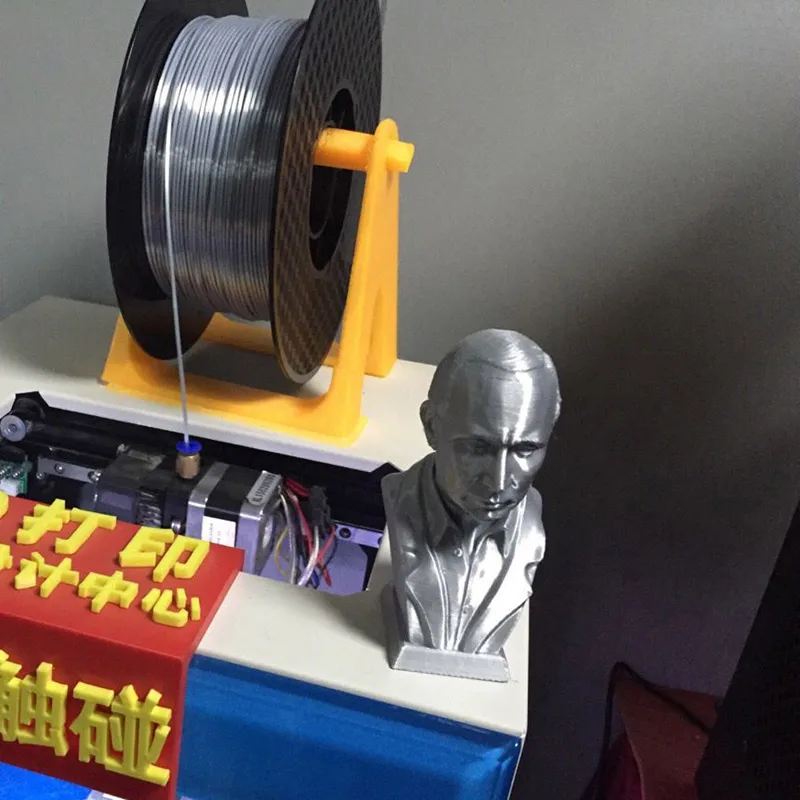

Given enough time, moisture will eventually seep into PLA. For example, this roll of yellow PLA was left unwrapped for about 6 months and is now stringy.

All 3D printing filaments are created from blends of hygroscopic polymers that are capable of trapping moisture. This leads to brittleness, stringing and failed prints. However, some types of filament are less susceptible to water damage than others. PLA is fairly resistant to moisture and may print perfectly fine after years in the open air, provided that it’s being stored in a room with fairly dry conditions.

Nylon, TPU and even PETG are an entirely different matter. When some of these filaments are left unwrapped for even 24 hours, they can pick up enough moisture to cause a failure.

Below, we’ll show you several ways to keep your filament safe and organized. We also have instructions on how to dry out filament that’s absorbed moisture so you can use it again effectively.

Shelves for Open Filament Storage

If you want to display your filament out in the open, and don’t mind risking moisture damage, you’ll need to buy sturdy shelving that can handle the load. One option is a custom-made wall rack, like this one from RepKord. The design is free to download from PrusaPrints.org and is made of 3D printed or laser cut parts and metal conduit pipe available at any hardware store.

One option is a custom-made wall rack, like this one from RepKord. The design is free to download from PrusaPrints.org and is made of 3D printed or laser cut parts and metal conduit pipe available at any hardware store.

The rack cradles spools between two lengths of pipe to prevent them from rolling. It can be made as long as you like to hold any amount of filament.

(Image credit: RepKord)Courtney Blum from Filament Stories goes one step further with a filament bunker. She converted a basement closet into a climate controlled storage unit for over 500 rolls of assorted filament, all organized by color. A dehumidifier constantly pulls moisture from the room, and hygrometers on the shelves let her know that every spool is cozy and dry. Tension rods keep the spools from rolling off the shelving.

(Image credit: Courtney Blum)Fight Filament Moisture with Desiccant

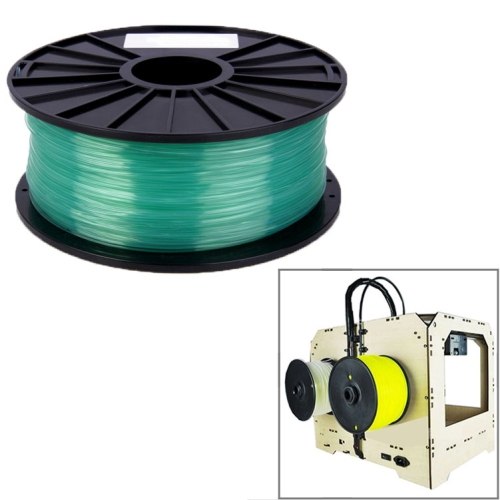

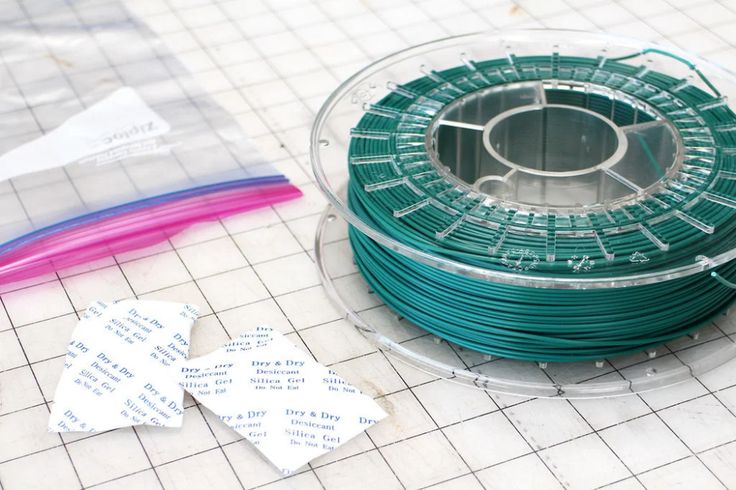

Desiccant is a drying agent that attracts and traps moisture. Silica gel is a common desiccant you’ll find tucked inside boxes of filament, electronics and just about any product that needs to stay dry during shipping.

You can reuse desiccant packs that shipped with your filament, but I would suggest trying color changing Dry & Dry . Each pack contains color changing beads to let you know when the silica is moist and needs to be dried out again.

I opened a pack of Dry & Dry and exposed half of it to water to show the color beads at work. The yellow beads are dry, the dark green beads are wet.

(Image credit: Tom's Hardware)Silica gel can be dried in the oven and used over and over again. Simply place the packets on a cookie sheet and bake at 200°F for 30 minutes to 2 hours.

One gram of Dry & Dry can protect 120 cubic inches, so a cereal box sized container would only need 3 grams to keep it dry.

Five DIY Containers for Filament Storage

- Method 1: Keep filament in the original package.

If you’re lucky, your filament came in a resealable bag, so check both ends for a zip lock before randomly hacking the package open. When you’re done, return the spool to its original bag with a fresh silica pack.

When you’re done, return the spool to its original bag with a fresh silica pack.

- Method 2: Use ordinary kitchen zip bags.

Many rolls– especially those on cardboard spools– will fit in a one gallon zip lock food storage bag. Don’t use the one’s with sliders, the opening isn’t wide enough. Thick plastic 1KG spools may need a larger “jumbo” bag.

- Method 3: Keep spools in plastic cereal boxes.

Cereal boxes are designed to keep moisture out, so they’re perfect for holding single spools. It’s a more expensive option than plastic bags, but if you want your shelf to look fabulous – and can afford the extra $8-10 a box for storage – this is a great looking option.

This 18.5 cup box I found at Walmart is wide enough to hold a full 1KG spool. If you’re ready for a little DIY, you can add a spool holder and PTFE connector to use this as a dry box while you print.

- Method 4: Use vacuum bags to reseal filament.

When you really want to keep the moisture out, vacuum seal your spools.

eSun makes a complete vacuum sealing kit for filament. It comes with thick plastic zip bags equipped with a valve and a hand pump for removing air. You get enough bags, silica gel packs and humidity monitoring cards to seal 15 spools.

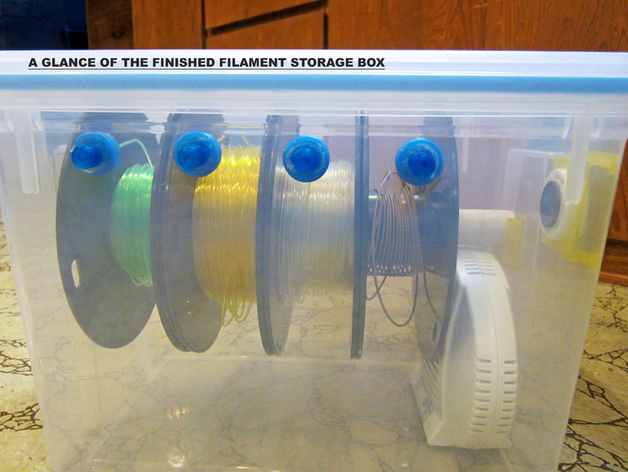

- Method 5: Plastic tubs for mass storage.

Cheaper than individual boxes, a large storage box with a gasket can keep several spools dry. Large tubs are great for storing filament in closets, garage shelving or stuck in the corner of your workshop.

This 72 quart tub held 16 full 1KG spools, making it a bit awkward to carry.

Dry Out Damaged Filament

Moisture damaged filament can be saved with a little help from a drier. Some sources suggest using your kitchen oven. However not all ovens can maintain the proper temperature and risks melting your entire roll.

However not all ovens can maintain the proper temperature and risks melting your entire roll.

DIY Filament Dryer

Taulman3D posted directions for a great DIY dryer made from a 5 gallon bucket, a trouble light and dowel rods. Holes are drilled into the bucket for the rods, ventilation and cord access. The company uses this bucket hack in its own lab and say it can dry two spools overnight.

Buy a Filament Dryer

You can purchase a ready-made dryer from several sources online. I own the Sunlu FilaDryer S1 , which can dry one roll at a time in about 6 hours. The Sunlu dryer has a temperature range from 35c to 55c, which isn’t hot enough for nylon, but can handle most hobby-level filaments.

(Image credit: Tom's Hardware)If you need to dry nylon filament, try the Print Dry Pro , which reaches 75c.

Drying Times for Common Filaments

| PLA | 50c | >3 hours |

| PETG | 50c | >3 hours |

| ABS | 55c | >3 hours |

| TPU | 55c | >4 hours |

| ASA | 55c | >4 hours |

| Nylon | 75c | >12 hours |

Desiccants can be dried at 65c for at least 3 hours.

Professional Filament Storage Option

(Image credit: RepKord)If you want something more classy than a tote box, there’s the RepBox. It can hold six 1kg spools (or 12 half kg spools) in a sealed case that sits next to, underneath, or hung on the wall above your printer.

The RepBox has individual holes for each spool to feed through, allowing you to print directly from the sealed box. It’s also a popular option for tangle free Multi Material printing. Starting at a pricey $149, boxes come in wood finishes, clear acrylic and can be customized with your logo.

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing.

Topics

3D Printing

Filament Storage For 3D Printing: Your How-To Guide

Filament storage poses a big problem for 3D printing enthusiasts. Incorrect storage results in moisture from the air making its way into your filaments, which as you’ll see soon – is bad news. Read on for your guide to storing filaments correctly so that you don’t end up losing money on filaments that give you low-quality prints.

Read on for your guide to storing filaments correctly so that you don’t end up losing money on filaments that give you low-quality prints.

Before we get into filament storage, a brief note is needed on what happens to poorly stored filaments.

Filaments used for 3D printing purposes are polymers, meaning they can be broken down in a process known as hydrolysis. As a result of moisture from the air coming into contact with your filaments when they are poorly stored, the polymer breaks down when it’s heated at the point of extrusion, rendering the filament weakened.

Any parts printed with this “wet” filament will not look as polished or pristine as you want them to. Furthermore, “wet” filament necessitates a higher temperature for proper extrusion. The likes of nylon, polycarbonate, and copolyester filaments are very susceptible to the occurrence of hydrolysis when they become wet and are heated.

3D printing filaments tend to be hygroscopic, which is a fancy way of saying they easily absorb moisture. So, the storage problem comes down to avoiding contact with humid air. The rest of this article focuses on how you’ll achieve this dry environment for your filaments.

So, the storage problem comes down to avoiding contact with humid air. The rest of this article focuses on how you’ll achieve this dry environment for your filaments.

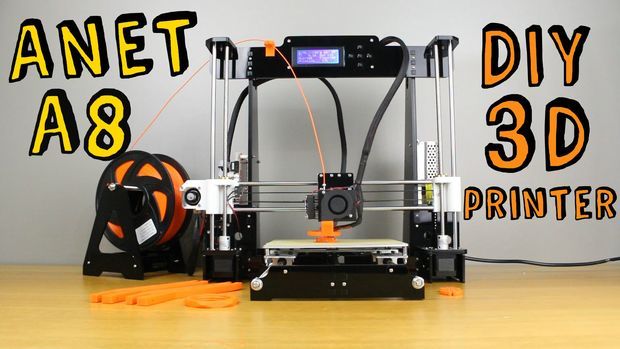

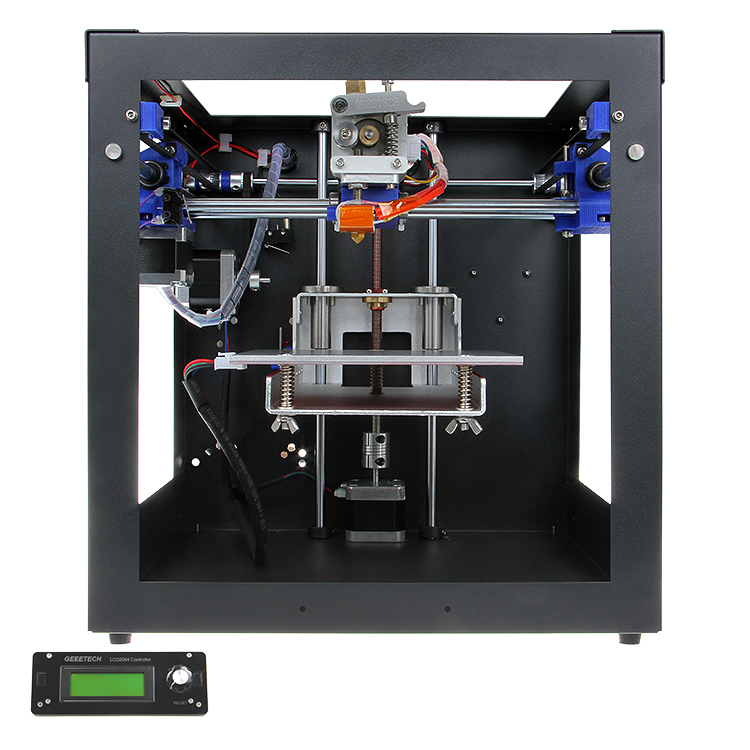

Hint: the below image is a prime example of how not to store your filaments. The truth is that leaving them out in the open pretty much guarantees contact with moisture, which could ruin the printed product.

Vacuum Bags

There are many storage solutions available for your filaments but a significant proportion are either expensive, impractical, or too time-consuming. As a hobbyist, you want to keep things as cheap and simple as possible.

Enter the humble vacuum. Or to be more specific; vacuum bags. High-quality vacuum bags provide an air-free environment for your filaments. You’ll want to purchase bags that have a vacuum valve for sucking the air out. Additionally, you’ll need to go for bags with a double-zipper mechanism for maximum impermeability to air. Creating an air-free environment in the bags is as easy as using a normal household vacuum cleaner on them to suck the air out.

You’ll fit about 4 filament spools in one vacuum bag. Packets containing six bags are available for roughly $20. This should be more than enough for any 3D printing hobbyist. In summary, this is a cheap and easy solution to the issue of filament storage and one that you should consider.

Pro tip. With vacuum bags, some moisture inevitably remains inside the bag. No vacuum is absolute, although the amount of moisture remaining is often close to negligible. To ensure you get rid of any remaining moisture, use some silica gel beads. Nearly everyone is familiar with these. They come in small packets with goods such as trainers and food products because they are amazing at absorbing moisture. Simply place the packets of silica beads inside the vacuum bags alongside your filament. These silica gel dry packs tend to be relatively cheap, with 20 bags on Amazon selling for roughly $10.

Another bonus tip is to use filament clips when storing your spools in vacuum bags. The end-points of filaments can be pretty sharp and easily pierce a hole in the vacuum bags, exposing the filament to the moist air you’re trying to protect it from. Filament clips are cheap and not using them would be equivalent to taking a really unnecessary risk.

The end-points of filaments can be pretty sharp and easily pierce a hole in the vacuum bags, exposing the filament to the moist air you’re trying to protect it from. Filament clips are cheap and not using them would be equivalent to taking a really unnecessary risk.

Dry Box

Another great solution to creating a moisture-free environment for filament storage is a dry box. These cabinets provide the kind of low-humidity environment that is perfect for filament storage. The technology works through a electronic dehumidifier system that constantly dehumidifies the interior of the box. As a result, you’ll limit the contact that your filament has with humid air to practically nothing. For you, this means stronger, more reliable prints.

Storage Boxes

Transparent storage boxes with sealed lids present another great way to store your 3d printing filaments correctly. The idea behind the sealed lids is that no new moisture can reach the filament from outside. The need for transparency arises from a practicality perspective. If you cannot see inside the boxes, you’ll never know what filament is inside which boxes.

If you cannot see inside the boxes, you’ll never know what filament is inside which boxes.

In terms of size, you’ll want to aim for something big enough to stack a few spools of at least 20 cm in diameter. A good base size to aim for is something of roughly 40 cm in length and 30 cm in width. The height depends on how many filament spools you plan to stack but around 40 cm should be fine.

Dehumidifiers

The one issue with storage boxes is the need to reduce the humidity of the air that remains inside the box once you place the filament in it. To solve this conundrum, you can purchase a dehumidifier. One could forgive you for thinking that this solution already lacks practicality. But fret not; dehumidifiers require no batteries or cords to operate. And they are completely renewable. In other words, they are the very definition of practical.

A good dehumidifier should set you back as little as just $15-20 on somewhere like Amazon. Check out the Eva Dry E-333 for a good example. These dehumidifiers need to be renewed approximately once every month. To renew your dehumidifier, simply plug it into a power outlet when the silica gel beads change color. Most dehumidifiers come with a color indicator that helps you identify when it needs renewing.

These dehumidifiers need to be renewed approximately once every month. To renew your dehumidifier, simply plug it into a power outlet when the silica gel beads change color. Most dehumidifiers come with a color indicator that helps you identify when it needs renewing.

Like with the vacuum bags, silica gel beads are used to absorb moisture. Since you’ll fit a maximum of around 5 or 6 spools in each box, two storage boxes and two dehumidifiers should be enough for most people’s needs. The fact that your dehumidifier is renewable offsets that initial investment. When you are sure that your dehumidifier is fully charged, simply place it inside the storage box with the indicator facing outside the box.

If you want to get fancy, or you’re having trouble checking what color the beads are on your dehumidifier, you can purchase some humidity indicator cards. Ultimately, this step is not necessary but it can be helpful for easily gauging the humidity level. Simply place the cards inside your box and you’re all set.

Oven-Drying

So far we’ve looked at some cheap and practical solutions for storing filaments. But it also makes sense to address the issue of drying filament that is already saturated with moisture. Printing with moist filament means using filament that is weaker and inconsistent than normal. In other words, it’s likely to ruin the quality of your printed product.

To dry your filament, you can use that all-around useful appliance–the household oven. More specifically, you’ll need a fan oven because this kind of oven distributes air evenly throughout the interior. The even flow of air means that warm air constantly circulates around the spool.

A crucial factor to consider when deciding whether your filament is suitable for oven-drying – is the Glass Transition Temperature (Tg) of the material. This is the temperature region where the polymer changes from a hard, glassy material to a soft, rubbery material.

PLA, for example, has a Tg of just 60 degrees Celsius, making it unsuitable for oven-drying unless your oven doesn’t have a minimum heat setting. On the contrary, other filament types like ABS has a Tg of 100 degrees. The important thing if you decide to dry any filament is to research that filament’s glass transition temperature. If it’s around 80 degrees or higher, it should be fine in there for an hour at 60-70 degrees. If the Tg is less than 80 degrees Celsius, you can try to dry the filament at a lower temperature of around 30-40 degrees Celsius, but perhaps leave it in there for longer.

On the contrary, other filament types like ABS has a Tg of 100 degrees. The important thing if you decide to dry any filament is to research that filament’s glass transition temperature. If it’s around 80 degrees or higher, it should be fine in there for an hour at 60-70 degrees. If the Tg is less than 80 degrees Celsius, you can try to dry the filament at a lower temperature of around 30-40 degrees Celsius, but perhaps leave it in there for longer.

Summary

When 3D printing filament absorbs moisture from the air around it, the following issues can occur:

- The filament becomes brittle and more prone to breakage

- The extruding temperature increases

- The filament loses its tensile strength

- There’ll be steam or bubbling once the filament passes through the hot end of the extruder, leading to an undesirable finish

To store filament correctly so that it doesn’t come into contact with moist air, you have three practical and relatively cheap options:

- Use double-zipped vacuum bags with a valve for sucking the air out with a standard vacuum cleaner.

Place silica gel beads inside the bags to absorb any remaining moisture.

Place silica gel beads inside the bags to absorb any remaining moisture. - Store your filament spools in transparent storage boxes with sealed lids. Use a cheap renewable dehumidifier to absorb any remaining moisture inside the boxes.

Any filament that you suspect has come into contact with moist air needs to be dried out in the oven.

Using the above guide, you should be able to store your filament correctly from now on and improve the quality of your 3D prints.

Proper storage of filament

3D printer filament requires special storage conditions. For the most common PLA, ABS, PETG and TPU filaments, the main requirement for storage is the absence of humidity. Also important is the absence of dust and solid particles during storage of the thread. Let's take a closer look!

What's so dangerous about humidity?

Most materials used in FDM 3D printing can be considered hygroscopic, meaning that they absorb water molecules rather than repel them. This does not mean that the plastic filament will act like a sponge, but if you leave it outdoors, the print quality will deteriorate. Even what may be considered relatively low environmental humidity can damage the filament through a cumulative effect.

This does not mean that the plastic filament will act like a sponge, but if you leave it outdoors, the print quality will deteriorate. Even what may be considered relatively low environmental humidity can damage the filament through a cumulative effect.

Storing the filament in an airtight container is a must to prevent absorption of moisture from the air, but it is even better to use airtight containers or containers with a desiccant (silica gel). See the end of this article for more information on silica gel.

How do you know if your filament is wet and needs to be dried? The answer to this question can be found in our other article about drying the filament

Need for storage

Leaving the filament in the open air, solid particles and dust begin to settle on its surface. These small “contaminants” can lead to reduced print quality, and sometimes they even cause the nozzle to clog during printing.

Often, replacing or cleaning the nozzle on some printer models causes problems. Avoid getting dust on the filament. All this can be achieved by simply storing the filament in closed containers or other places protected from airborne particles. Also use a dust filter (see Add-ons section at the end of the article), through which the filament slides during the printing process and traps “dirt” particles before they enter the extruder.

Avoid getting dust on the filament. All this can be achieved by simply storing the filament in closed containers or other places protected from airborne particles. Also use a dust filter (see Add-ons section at the end of the article), through which the filament slides during the printing process and traps “dirt” particles before they enter the extruder.

Best filament storage solutions

Below are FDM storage solutions.

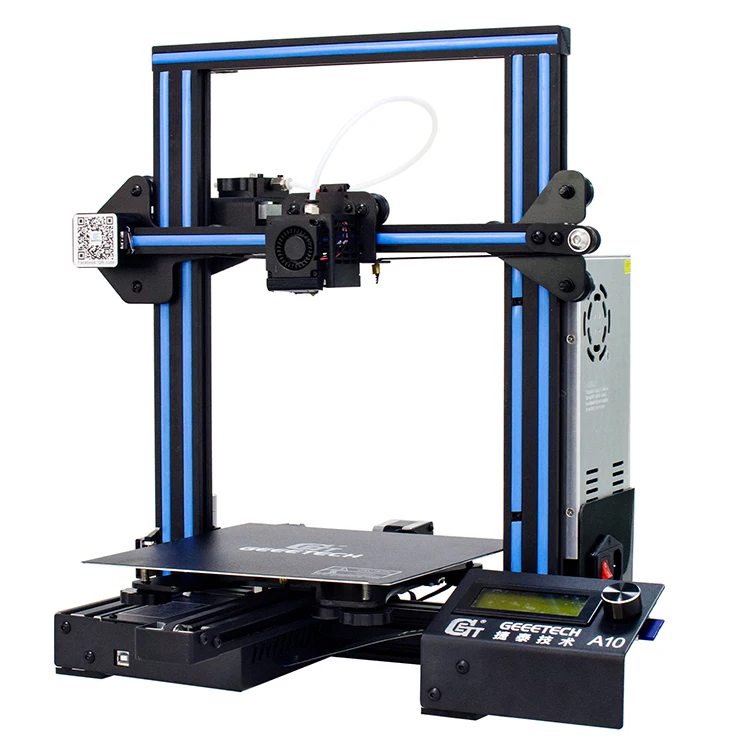

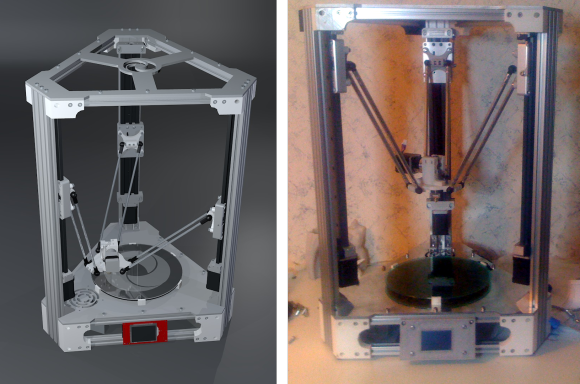

Specialized box

This box usually holds two spools at once, which is very convenient when printing with two plastics at once.

Universal specialized container for storage and supply of filament. This solution is not just a plastic box, but also various sensors, a screen for displaying temperature and humidity inside the box.

Boxes are available both for one reel and for two reels of 750 g each, sometimes a 2 kg reel can be placed there. In some models, for convenience, special rollers on bearings are provided that allow the spool to rotate freely when it is used in printing.

These units often have a pair of 100 gram silica gel bags installed rather than heating elements.

Prices for ready-made solutions vary and you can find the perfect option for yourself.

Drying cabinet

The adjustable shelves of this cabinet can be adapted to any size and volume of filament spools.

Dry cabinets - the new player in filament storage. Generally they are intended for professional cameras and other photographic equipment that can be damaged by moisture, but they are also sold for other moisture-sensitive items. Why not use it for 3D printer filament?

Available in sizes from 30 to 125 liters, dry cabinets are very reminiscent of wine coolers with their glass doors and elegant appearance, a big plus for those who love aesthetics and beauty. The digital screen tells you the temperature and humidity inside the cabinet, these parameters can be changed by yourself.

Of course, such a cabinet is expensive, but with the right configuration of the shelves it can hold a lot of reels with plastic and maybe even a couple of wine bottles will fit in there.

Storage box lite

This is a cheaper version of the filament storage box than the specialized box. Only one coil can be placed in such a box. Equipped with a battery-powered temperature and humidity sensor. The LCD screen allows you to get information about the storage conditions inside the box.

The box has a long teflon tube for connecting to the printer, a place at the bottom of the silica gel container and a very tight lid. Such a single storage of coils allows you to quickly get the necessary container with the necessary material during printing and put it into printing. This use will prevent moisture and other particles from getting onto your print media.

Vacuum box

This filament storage container takes a distinctly different approach to storing reels. The container itself is designed for long-term storage, and not for actively drying the filament or feeding it into the printer, as other options do.

The box is made of durable plastic, which is able to withstand certain loads when pumping out air. Equipped with 4 durable, plastic latches and a valve in the middle of the lid. The valve is designed to pump air out of the container using a special pump.

These containers are very airtight and can safely store your roll of plastic for a long time. You can also put a bag of silica gel inside. The only downside is the price.

There are cheaper options, but they are already without such powerful latches.

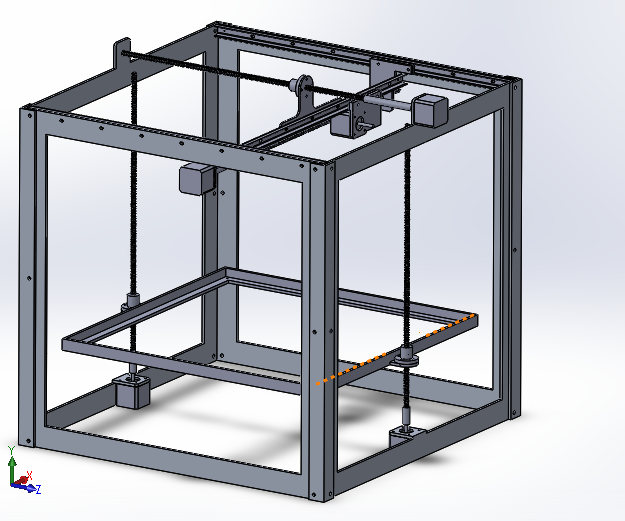

DIY

Now, let's look at options that you can make yourself. Some are a little more complex and functional, while others are quite light and affordable.

DIY box (Source: RichRap via Thingiverse)

This solution is perfect for storing filament if you want to do it yourself. All ready-made solutions practically do not differ from this option, the only difference is the appearance.

This DIY box uses a reptile heating mat at the base, placed on the bottom of the box, and includes silica gel sachets. A temperature and humidity sensor is installed that monitors indicators inside the box.

3D components are available on the Thingiverse build page. You can use REC

plastic to print them. The remaining components will need to be bought separately and it is better to take a pair at once, it will be cheaper and you will have more space to store the plastic spools.

As a result, you will get a great cheap box with good features.

Airtight Roll Container

Generally made specifically for pet food, but also great for storing lots of plastic spools. If you think that you have too many spools of plastic and not a single container can cope with such a volume, then you are mistaken! This is not only a huge container, but it is also on 4 swivel wheels. It will be extremely easy and convenient to move it. Tightness at a height, because. it was developed to store food, and as we know, food is also hygroscopic.

Tightness at a height, because. it was developed to store food, and as we know, food is also hygroscopic.

A large amount of silica gel can be put on the bottom, which will completely get rid of moisture inside the box. The only disadvantage of such huge boxes is that when you need to get the coil that lies at the bottom, you will have to get all the coils lying above first.

Affordable price for this amount of usable space inside.

Zip Lock Bags

Resealable bags have always been a popular storage item for filament. Such bags are made of more durable and thicker plastic, so that moisture does not penetrate into the inside of the bag. A good zip lock, when properly closed, will ensure tightness.

Even though the pouches are not as strong as a box and you certainly can't print directly from the pouches, they do the job just as well as any other sealed container. Only one coil is placed in such a package. But at a completely low price for such a package, you can buy a lot of them and use them for a long time.

But at a completely low price for such a package, you can buy a lot of them and use them for a long time.

There are also zip bags with an indicator strip that will show the humidity inside the bag

Vacuum storage bags

Many of us are familiar with vacuum storage bags. Most popular for storing and transporting clothes and the like, these bags work with either a hand pump (often included) or a household vacuum cleaner (for faster air extraction). A simple solution with a valve, just put the coil (you can have several) in a bag and pump out the air - that's it.

It is of course recommended to add silica gel before pumping out all the air, but this is not always necessary.

These bags are available in different sizes and opacity (transparent and opaque). In opaque bags, it is best to put plastic that is affected by the sun's rays.

The price for such packages is low

OPTIONS

Clamp / Filament End Holder

One of many Filament Clamps available on Thingiverse (Source: aliendagwood via Thingiverse)

go there will be an overlap. So if your filament spool doesn't have a hole around the edge (REC spools do) to secure the free end, or the free end doesn't quite reach the hole, try printing this accessory. A small clip fits onto the outer rim of the spool and securely holds the end of the filament. Download here

So if your filament spool doesn't have a hole around the edge (REC spools do) to secure the free end, or the free end doesn't quite reach the hole, try printing this accessory. A small clip fits onto the outer rim of the spool and securely holds the end of the filament. Download here

Dust filter

Dust is known to be the enemy of 3D printing. To avoid dust accumulating on the surface of the rod, you can print a small capsule into which a sponge or piece of cloth is inserted and when the rod passes through this capsule, all the dust remains outside the extruder. You can also download it on Thingiverse

Silica gel

In general, silica gel is a dried gel formed from supersaturated solutions of silicic acids. It absorbs moisture very well.

Most often, silica gel is found in portion packs from 5 to 500 grams. The bags themselves contain silica gel balls, the size of the balls is from 2-4 mm.

Sometimes there are options without bags, there are just balls and you pour them into the right place in the right amount.

Color indication. Most dehumidifiers on the market have a color indication function. This means that as the silica gel becomes saturated with water, the color will gradually change from, say, blue to orange or orange to green, depending on the type of silica gel.

3D Filament Storage - Top 5 Tips!・Cults

It's no surprise that the quality of 3D printing filament can make a big difference in the quality of your prints. That is why there has been much debate about how best to maintain and store the thread.

However, no one argues about the main enemy of 3D filament - moisture.

There are countless stories on the Internet about manufacturers finding their new threads damaged by moisture in the air. It is important to note that some threads are more sensitive to moisture than others. For example, PLA, PVA carrier material, nylon and ABS are particularly sensitive to moisture in the air.

- 1) Thread breakage: Some threads are more sensitive to moisture in the air because they are made of materials that absorb water easily. For example, PLA plastic is biodegradable and is made from natural resources such as corn or rice. While it's much better for the environment than other plastics, it also means that under the right conditions, it breaks down into carbon dioxide, water, and methane. Humid conditions and ultraviolet radiation accelerate the degradation of the filament, which weakens it and causes inconsistent or poor-quality prints.

On his blog, RepRage talks about an experiment in which scientists tested how long PLA takes to absorb water. They compared the weight of the thread before and after it was immersed in water for 30 days, and it turned out that it absorbed up to 60 ml of water! If you live in the tropics, you may want to store your floss in an airtight place so it doesn't absorb water from the air. Nylon is also highly absorbent and soaks with water as early as 18 hours after exposure to wet conditions.

-

2) Printer jams/nozzles: A side effect of filament absorbing water is that it increases in diameter and weakens the surface of the filament. When you insert it into the printer, it may cause a nozzle jam. Just as rice expands when you boil it in water, so does this filament expand and eventually become unusable because it cannot pass through your printer properly. In extreme cases, it can even mess up your hot end. If you think that the thread has absorbed moisture, it is recommended to measure its diameter.

-

3) Poor quality 3D printing: When water is absorbed into the filament and heated by the 3D printer for extrusion, the water combines with the heat to form steam (you will hear a hissing sound when steam is generated). This results in bubbles as the filament exits the hot end and an uneven print surface.

- 4) Weak thread and breakage: The more water gets on the thread, the higher the risk of thread breakage. While water weakens the filament, the real problem comes when you heat up the wet filament while running it through the hot end of the 3D printer.

Studies show that printing with wet material reduces its durability by 33%!

Studies show that printing with wet material reduces its durability by 33%!

Of course, how much moisture will affect the filament depends on the type of filament you are using. PET and ABS are not as sensitive to moisture absorption as nylon or PLA. However, it does not hurt to store all threads in a water-free environment.

There are conflicting opinions about the ideal moisture level for your filament, but 10-15% moisture should be safe. Of course, you don't have to spend tons of money on fancy dehumidifiers and filament protection systems. Many manufacturers have taken to creating their own filament storage kits, such as Stephen Hall and his airtight filament container. Here are some simple and inexpensive tips that we recommend:

- 1) Use desiccants to absorb moisture: The most effective and documented desiccant to keep the filament dry is silica gel. These are small, absorbent gel sachets found in shoe boxes and vitamin bottles. You can buy quartz beads that change color to indicate that the beads have passed a certain amount of water.

When the beads change color, you can put them in the oven for 3 hours at 120°C and they will return to their original color and you can use them again. To store the gel, place it in any container with air holes or slots. You can 3D print one or more tinkers by using empty plastic containers and drilling small holes in them.

When the beads change color, you can put them in the oven for 3 hours at 120°C and they will return to their original color and you can use them again. To store the gel, place it in any container with air holes or slots. You can 3D print one or more tinkers by using empty plastic containers and drilling small holes in them.

Rice is also a mild dehydrator and can absorb small amounts of water. If anyone has ever dropped their phone in water, you may have heard of the trick of putting it in a container of rice. It really helps! However, for this purpose, it is not as effective as silica gel in absorbing moisture from the air. If you live in a humid climate, we recommend using silica.

-

2) Use vacuum bags: These bags differ from Ziploc bags in that they have a hole in which you can insert a vacuum cleaner tip to suck out all the air. No air = no moisture or other elements that will ruin the quality of your prints! To use the thread, you need to take it out of the bag and close it again.

Make it even more effective by adding a few packs of silica gel to your bag!

Make it even more effective by adding a few packs of silica gel to your bag! -

3) Sealed pails or containers: These are an alternative to vacuum bags that can range from pet food containers to large pails available at any hardware store. There are lids with built-in dehydrators, called gamma lids, that you can also get at the hardware store. According to a conversation on the RepRap forum, 5 gallon buckets can hold 4 1kg spools of filament.

-

4) Do not store the thread for more than 12 months: Naturally, the quality of the thread deteriorates over time, no matter what measures you take to protect it from moisture. It's best not to store too much floss unless you intend to use it within the next year.

-

5) Store in a dry cabinet: There are dry cabinets and dehumidifiers on the market that work, but we recommend drying the simpler solution first.