X fab 3d printer

DWS Systems | Additive manufacturing

DWS Systems | Additive manufacturing|

XFAB 2500HD |

XFAB 3500HD |

028J Plus |

029JL2 |

029X |

029XC |

XPRO S |

XPRO SL |

XPRO Q |

|

XFAB 2500PD |

XFAB 3500PD |

029JL2 |

029X |

029XC |

XPRO S |

XPRO Q |

DFAB |

LFAB |

|

XFAB 2500SD |

XFAB 3500SD |

029JL2 |

029X |

029XC |

XPRO S |

XPRO SL |

XPRO Q |

JEWELLERY & FASHION

DENTAL LAB & CLINIC

MANUFACTURING & DESIGN

MANUFACTURING & DESIGN

JEWELLERY & FASHION

DENTAL LAB & CLINIC

Proseguendo la navigazione, accetti l'utilizzo dei cookies di questo sito. Per maggiori informazioni consulta l'informativa..

CHIUDI

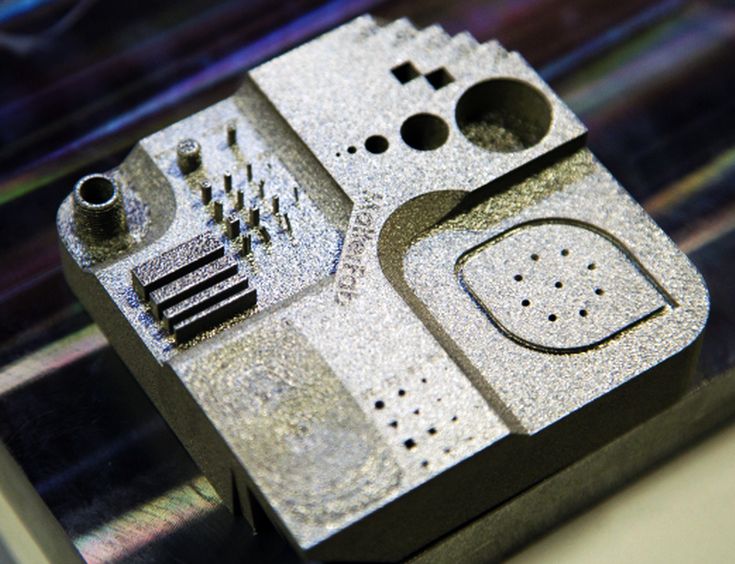

Wafer Level Packaging and 3D Integration

3D Integration and Wafer-Level Packaging

Heterogeneous 3D integration of semiconductor components is a main driver within the microelectronics industry towards higher integration complexity, enhanced system performance and economies of scale. Our technology offering of 3D integration and wafer-level packaging methods enables solutions for system integration of analog/mixed-signal integrated circuits , sensors and MEMS. These components are essential for the next-generation microelectronics products of our customers in the key markets automotive, industrial, medical and mobile communication.

Micro-Transfer-Printing technology enables 3D heterogeneous integration through vertical stacking of chips in a wafer-level process. These stacked components might originate from different source materials and manufacturing technologies, such as integrated circuits from different CMOS nodes, compound semiconductors, etc. As such, Micro-Transfer-Printing is a disruptive technology from which many novel applications will benefit.

As such, Micro-Transfer-Printing is a disruptive technology from which many novel applications will benefit.

Through-silicon vias are electrical interconnects between the front and back sides of a wafer. Our unique technology provides a TSV solution that is fully

integrated with our CMOS technologies and thereby enables innovative and cost-effective assembly concepts for analog/mixed-signal integrated circuits and sensors. Avoiding electrical connections on the top surface increases the effective chip area for sensor applications and enables a physical separation of electrical signals from the front side, for example in microfluidic devices.

CMOS–MEMS integration: Each sensor or actuator requires an integrated circuit for the processing of electrical input or output signals. For selected types of MEMS sensors and actuators, we offer solutions that are monolithically integrated with appropriate analog/mixed-signal CMOS nodes. We leverage the fact that X-FAB is at home in both worlds – CMOS and MEMS.

Our long-time experience with different wafer-level bonding techniques has enabled us to produce many types of sensors. In addition, we use wafer bonding for packaging chips, which generally reduces packaging costs, but can also add functionality, for example for capping microfluidic channels.

Our engineers love to develop challenging technologies together with our customers to come up with new integrated semiconductor solutions. Wafer-level packaging and 3D integration are among the specialties X-FAB focuses on.

Dr. Steffen Leopold, Technical Director BU MEMS

Micro-Transfer-Printing – Heterogeneous integration

Micro-Transfer-Printing (µTP) is an approach for the heterogeneous integration of microscale electronic devices on non-native substrates by means of stamp pick-up and printing procedures.

Advantages / Features:

- Parallel IC integration: highly efficient process

- Superior alignment accuracy

- Solutions for System-in-Package integration of CMOS, MEMS, wide-bandgap and photonic devices

Benefits:

- Heterogeneous integration – effective combination of different semiconductor materials

- Simultaneous “pick and place” of large amounts of chiplets

- Optimal use of expensive wafer materials

Our offering:

- Industry-first pilot line for the integration of smart systems by µTP

- Technology development and manufacturing solutions for heterogeneous system integration of CMOS, MEMS, wide-bandgap and photonic devices

- Dedicated process solutions to enable transfer printing of ASICs manufactured in our 180 nm CMOS node

Micro-Transfer-Printing – Application examples

ASIC integration enabling System-in-Package solutions

We offer a dedicated process solution for the heterogeneous integration of ASICs, using our XT018 SOI technology. Such printable SOI ASICs exhibit uniquely small feature sizes in both their lateral dimensions and their height. Along with the superior alignment accuracy and the scalability of a wafer-scale process, this technology unlocks a great potential for System-in-Package (SiP) solutions for many applications, including power management devices, radio frequency (RF) amplifiers, micro LED drivers and medical sensors. A special feature of transfer printing is the possibility to integrate chip arrays in a straightforward way.

Heterogeneous integration of GaAs Hall plates for magnetic sensors

For the heterogeneous combination of highly sensitive GaAs Hall plates with robust and reliable CMOS sensor ASICs and logics, a valuable process integration can be achieved by µTP. Print-ready GaAs Hall plates can thus be integrated directly on CMOS ASICs, allowing minimal package sizes and sensitivities up to five times higher than for state-of-the-art Si-based sensors.

Optical filters for photosensitive sensors

The integration of optical filters by µTP allows a more efficient use of expensive filter materials, as filter chiplets from one donor wafer can be used to populate multiple sensor wafers. It is also possible to integrate several different bandpass filters on one particular sensor ASIC.

µLED integration for ambient car lighting

As with the integration of Hall plates, µTP offers the possibility to integrate µLEDs directly on the LED driver ICs. This allows minimal package sizes to be achieved, reducing costs for our customers.

Printed Si photonics for life science and data center applications

For the integration of active photonic devices like µLEDs, lasers, photodiodes and modulators in passive waveguide circuits, µTP constitutes a very effective and highly precise integration technology. Thanks to the dense fabrication on four- and six-inch InP and GaAs donor wafers, the valuable active devices can be distributed over multiple target wafers with minimal displacements.

This process integration will particularly benefit life science and data center applications.

This process integration will particularly benefit life science and data center applications.Integrated compound semiconductor devices for power and RF applications

High-power, high-voltage and RF applications in particular will benefit from the integration of GaN high electron mobility transistors (HEMTs) and RF switches on reliable CMOS ASICs. As a wide-bandgap material, GaN offers superior performance to Si or SiC alternatives and can be used and integrated very effectively by µTP. Moreover, the removal of residual handle wafer material as well as very short metallization tracks improve the overall device performance.

3D interconnects – Through-silicon via

Through-silicon via (TSV) technology provides an innovative and efficient way to exploit the third dimension in wafer- and die-level 3D integration.

Advantages / Features:

- Vertical electrical connection (via) that passes completely through a silicon wafer or die

- High-performance interconnect techniques used as an alternative to wire bonding and flip chip to create 3D packages and 3D integrated circuit

- Substantially higher interconnect and device density and shorter length of connections compared to alternatives such as package-on-package

Benefits:

- Enables various packaging and form factor solutions

- Optimizes package form factor by avoiding wire bonds

- Improves front-side sensor access for light, gas, sound and liquid

- Enables stacking of chips for System-in-Package

- Allows tiling of image sensor chips

- Enables wafer-level chip-scale packaging (WLCSP)

Our offering:

- “TSVlast” process option for use in conjunction with our CMOS, CMOS sensors and MEMS technologies on 200 mm wafers

- "Low-density” TSV process to replace or augment top-side pads and wire bonding by bottom-side pads and a metal redistribution layer (RDL)

- Our TSV technology may be complemented by industry standard wafer- or die-level assembly methods like under-bump metallization (UBM) and solder ball placement.

3D packaging – Wafer bonding

Wafer bonding and wafer-level packaging (WLP) refer to various techniques for bonding two or more wafers together.

Advantages / Features:

- Direct, anodic, eutectic, glass frit and adhesive polymer bonding

- Used to form buried cavities, glass pedestals, protective covers and optical windows

- Silicon or glass wafers

- Eight- or six-inch silicon and glass caps

- Single or top and bottom caps

- Stack height up to 6 mm

- Wafer-level chip-scale packaging (WLCSP) used instead of traditional assembly techniques

Benefits:

- Same size of packaged device as ASIC device

- Possibility to test, characterize and stress devices in final packaging at wafer level

- Reduction of cost of packaging per chip

- Possibility to have controlled atmosphere (gas and pressure) in packaged device

Our offering:

- Wide range of wafer bonding experience and capabilities on eight-inch and six-inch wafers

- Processes available for direct, anodic, eutectic, glass frit and adhesive polymer bonding

- Wafer capping, optical windows, cavity formation, WLCSP

- In-production, open-platform processes featuring direct, anodic and glass frit wafer bonding

- Numerous customer-specific process developments completed

- Compatibility with MEMS wafer processing

- Combination of different materials with additional functionality

Contact

For more information, please contact us:

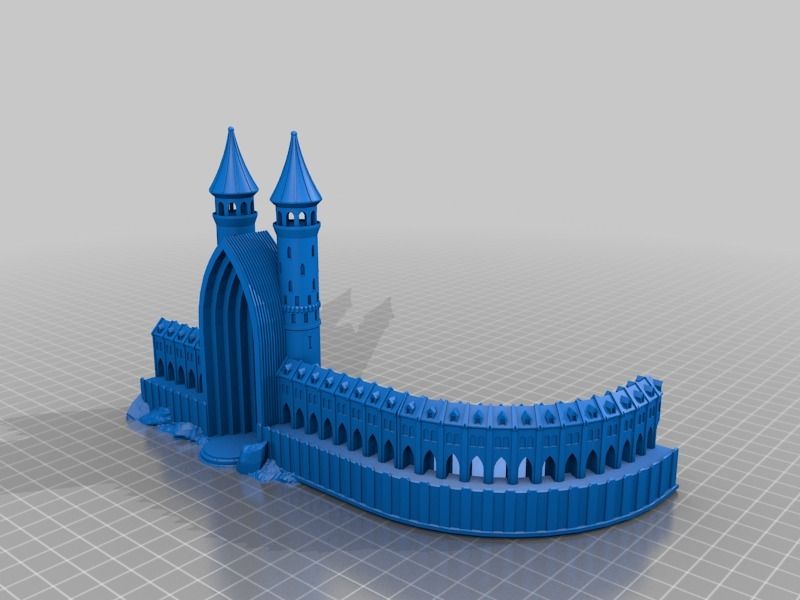

Fairy tale character Fox – 3D model

Fairy tale character Fox - 3D model

670. 00 ₽

00 ₽

File format: STL.

Error present: no errors detected.

Quantity of item Fairy tale character Fox – 3D model

-

Description

General information

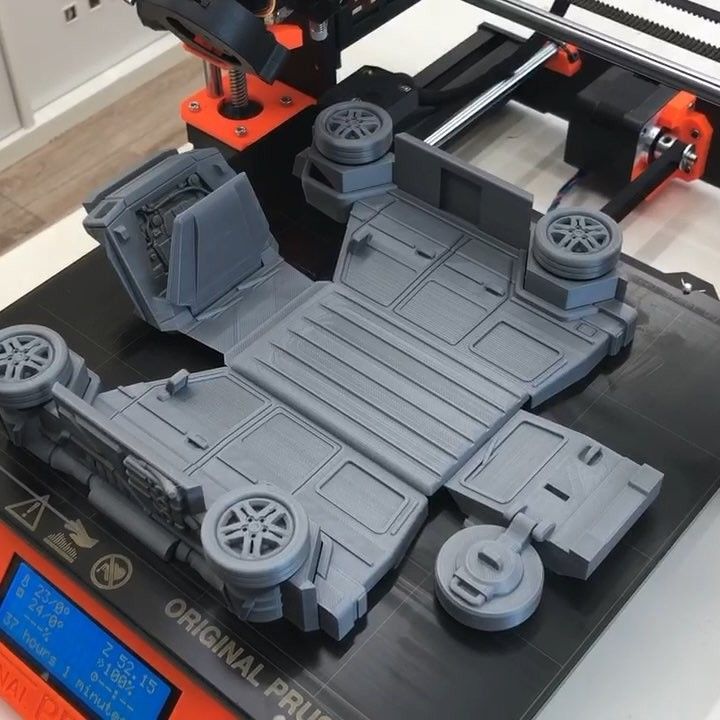

Character model from Fox fairy tales. The model is designed to receive a physical layout on a 3D printer.

File size - 11.2 MB. nine0007

Format - STL.

Overall dimensions of the model - 500 mm x 487 mm x 731 mm.

Payment and download

Payment for goods can be made by bank card or through an account for legal entities by placing an order on the website. Product images are actual and fully match the 3D model. After payment you will receive an e-mail with a link to download the model. You can always download a 3D model in your account on our website.

Please note that the purchase of the model for the purpose of resale is prohibited. Studia3D is a registered trademark that takes care of its own copyrights! nine0034

Where can I apply the 3D model?

First, this model was developed for a 3D printer.

If you buy this 3D model, you can print the downloaded file on a 3D printer. The printed model can be useful for use in mock-up business or as a souvenir. Secondly, this model can be used for any CNC machine, because the principles for developing 3D models for a 3D printer and other CNC machines do not differ significantly. Similarly, this model can be used for milling. Thirdly, this model can be used to implement 3D modeling projects. For example, you can use it in the 3Ds MAX program or similar software. In conclusion, I would like to note that using our models, you will not encounter polygon mesh problems or similar problems. nine0007

If you buy this 3D model, you can print the downloaded file on a 3D printer. The printed model can be useful for use in mock-up business or as a souvenir. Secondly, this model can be used for any CNC machine, because the principles for developing 3D models for a 3D printer and other CNC machines do not differ significantly. Similarly, this model can be used for milling. Thirdly, this model can be used to implement 3D modeling projects. For example, you can use it in the 3Ds MAX program or similar software. In conclusion, I would like to note that using our models, you will not encounter polygon mesh problems or similar problems. nine0007 Model check

All models are quality tested for compliance with the requirements and internal regulations. First of all, the polygonal mesh is fully stitched in the models. In addition, the model is single and does not allow multiple components. The number of polygons is optimally matched to the features of the model. The model does not contain inverted normals.

The model is scalable. Check the overall dimensions before using the model. After that, we use several professional programs to check the models: Netfabb, Materialize and Meshmixer. As a result, detailed verification allows our customers to use 3D models for any task without additional negative questions. We like to give only the best quality, because it is used for big projects! nine0007

The model is scalable. Check the overall dimensions before using the model. After that, we use several professional programs to check the models: Netfabb, Materialize and Meshmixer. As a result, detailed verification allows our customers to use 3D models for any task without additional negative questions. We like to give only the best quality, because it is used for big projects! nine0007 -

Reviews (0)

Only registered customers who bought this product can post reviews.

-

More offers

No more offers for this product!

-

Questions

General

No requests yet.

Related products

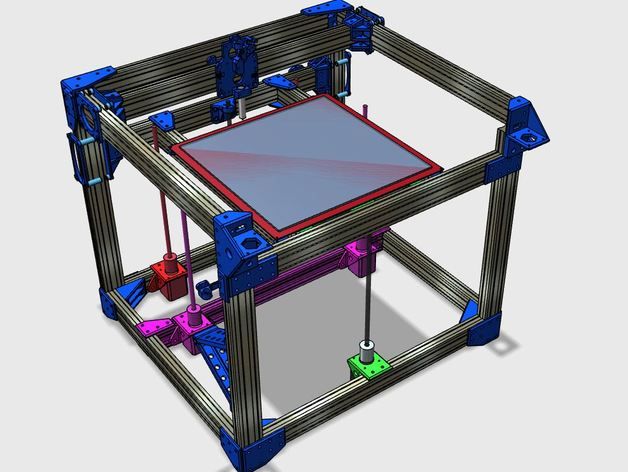

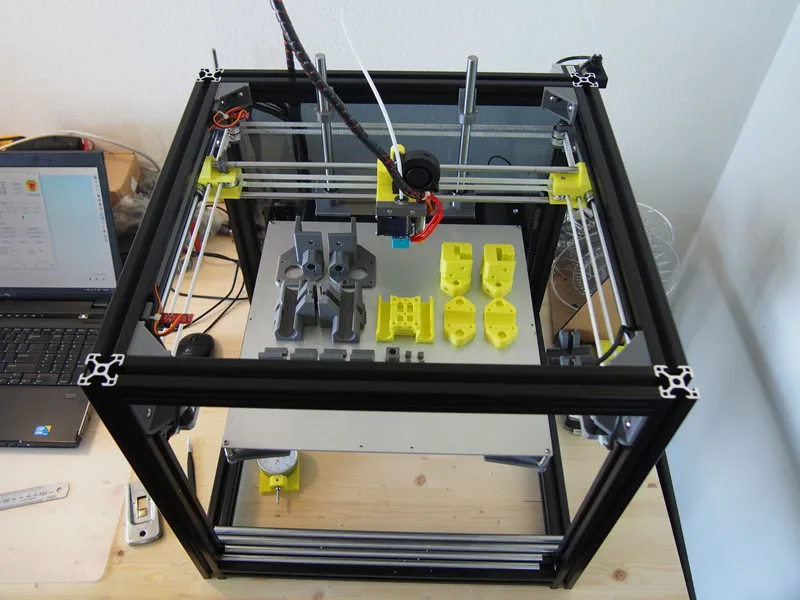

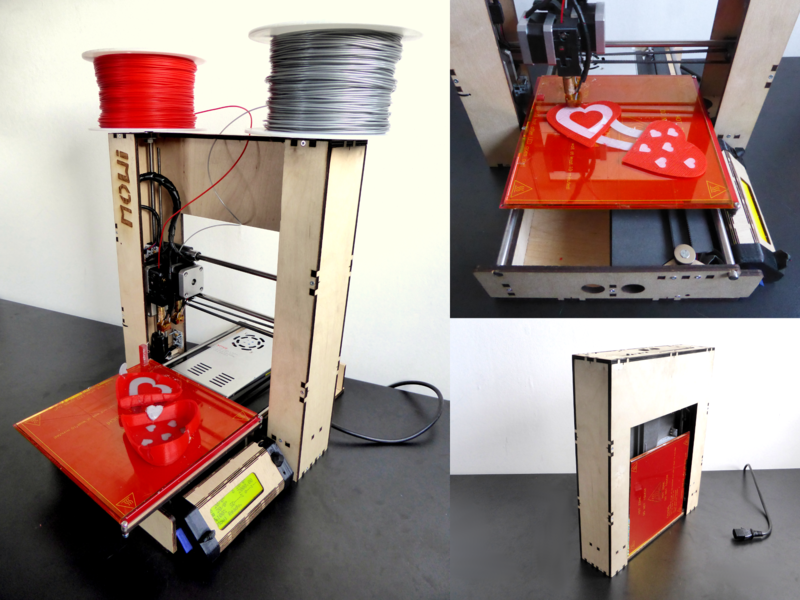

endless, for printing ceramics, with non-standard kinematics and other interesting models / Collections of goods from Aliexpress and not only / iXBT Live

Is there an endless printer? You will be surprised to get a 3D printer in your use, in which the movable table is a conveyor and provides continuous printing and printing of long (really long) models. What about unusual kinematic printers? Or options that have a certain “zest”, for example, a mix extruder for mixing plastic colors. I tried to pick up the models that are relevant for the current day, including an unusual printer for printing with ceramic clay. nine0007

What about unusual kinematic printers? Or options that have a certain “zest”, for example, a mix extruder for mixing plastic colors. I tried to pick up the models that are relevant for the current day, including an unusual printer for printing with ceramic clay. nine0007

Creality 3D PrintMill CR-30 Infinite 3D Printer

Get Price

Probably one of the most controversial printers for commercial printing. A special conveyor table ensures continuous printing of models, including large and long models. The Creality 3D PrintMill CR-30 allows you to print in a continuous flow by simply scrolling the table and providing a new place for new models. The specification says so - the working field is 200 x 170 x infinity. nine0007

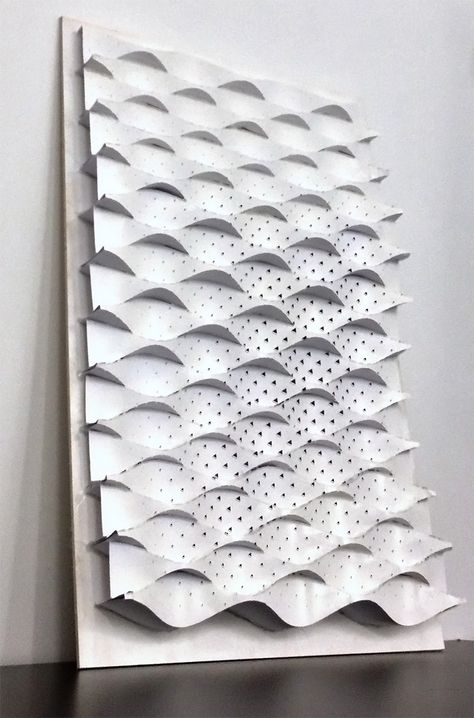

Tronxy Moore 1 3D printer for ceramic models

Ask for price

Extremely unusual Moore 1 3D printer from Tronxy. It is this model that can print clay products. The principle of printing is similar to FDM - this is a layer-by-layer application of material, but clay acts as a material, and a special mechanism for supplying prepared clay acts as an extruder. After printing and initial drying, the models can be baked in a microwave or muffle furnace. Ceramics can be additionally coated with glaze, obtaining an original result. nine0007

After printing and initial drying, the models can be baked in a microwave or muffle furnace. Ceramics can be additionally coated with glaze, obtaining an original result. nine0007

Geeetech A30T 3D printer for color models

Get price

Geeetech A30T 3D printer provides printing in three plastic colors at once. The kit includes holders for three coils of plastic at the same time. A special 3-in-1 extruder ensures that plastics are mixed in the right proportions. The working field is an impressive 320 x 320 x 420 mm, which gives a certain scope for creativity. Geeetech Color Mixer proprietary software is used to manage and prepare programs. nine0007

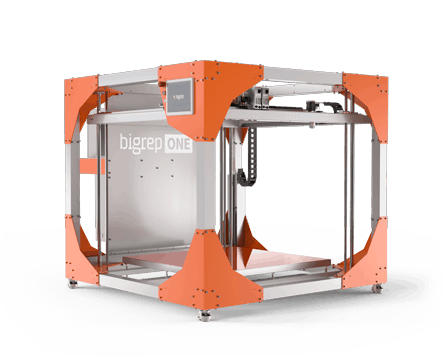

FYSETC VORON V2.4 fixed table 3D printer with CoreXYZ kinematics

Get price

One of the top DIY kits currently available. The FYSETC VORON 3D printer is distinguished not only by the presence of a belt in XY, but also by attention, a belt drive with gearboxes in Z. Such kinematics ensures maximum smoothness of the movement of the print head, eliminating all sorts of negative consequences on the model (does not “ring”, does not “thread” and etc. ). The table is fixed, which makes it possible to print complex models without the risk of tearing off the surface. Please note, the link is only not a complete 350 x 350 x 350mm build kit, this is not a finished printer. nine0007

). The table is fixed, which makes it possible to print complex models without the risk of tearing off the surface. Please note, the link is only not a complete 350 x 350 x 350mm build kit, this is not a finished printer. nine0007

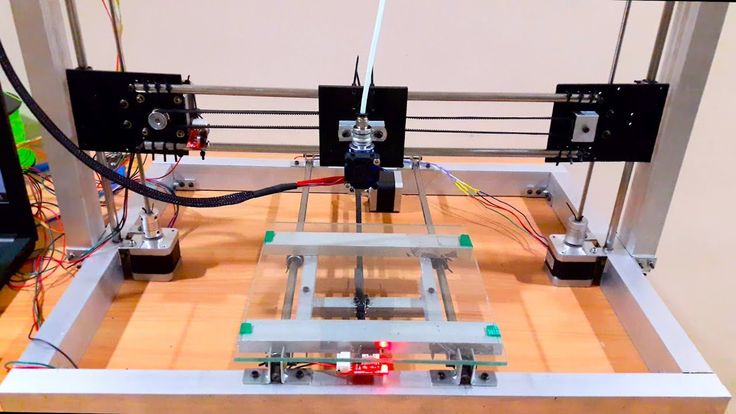

Scara Arm 3D printer with polar coordinates

Get price

One of the most complex kinematic schemes for printing is implemented in Scara Arm 3D printers. A complex system of motorized linked arms moves the print head to create a pattern. Unlike previous printers, Scara Arm 3D uses a polar coordinate system. The declared print area for the model at the link is 200 x 200 x 150 mm.

KINGROON KP3S Minimalist 3D Printer

Ask for price

A great option for those who are just getting acquainted with 3D printing. The KINGROON KP3S printer won't take up much desk space or hit your pocket hard. It is an entry-level model with a console version. I note that the model on the link is equipped with linear rails (MGN12), quiet drivers, and an extruder with titanium nozzles, which is quite good for such a price. Area available for printing: 180 x 180 x 180 mm.

Area available for printing: 180 x 180 x 180 mm.

Watch for discounts and promotions. Aliexpress offers coupons as part of the next sale. Such 3D printers can be a help in learning and instill in a child the skills of 3D modeling. Save this collection for yourself, recommend to your friends! You can find other tests and reviews of smart gadgets and technology, as well as selections at the links below and in my profile. nine0007

News

Publications

Newentor Q5 home weather station with external sensors needed to monitor the temperature in several rooms at once. For example, in each a separate room of an apartment or a private house. I bought...

Immediately after the KZ AS16 Pro, which is rather controversial in terms of setting, I suggest considering a new, much more successful model from the same manufacturer. CCA HM20 have a classic already hybrid circuit made of...

Good afternoon! Today, it seems to me, an interesting review should turn out, because the period of ownership of the watch in question is decent.