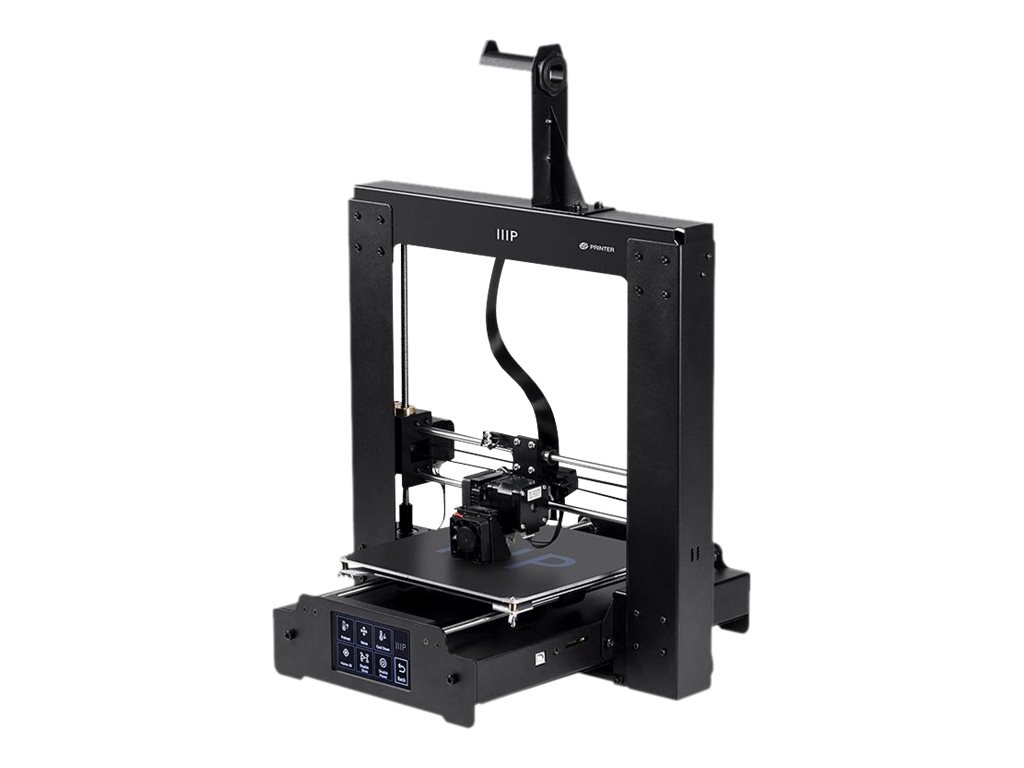

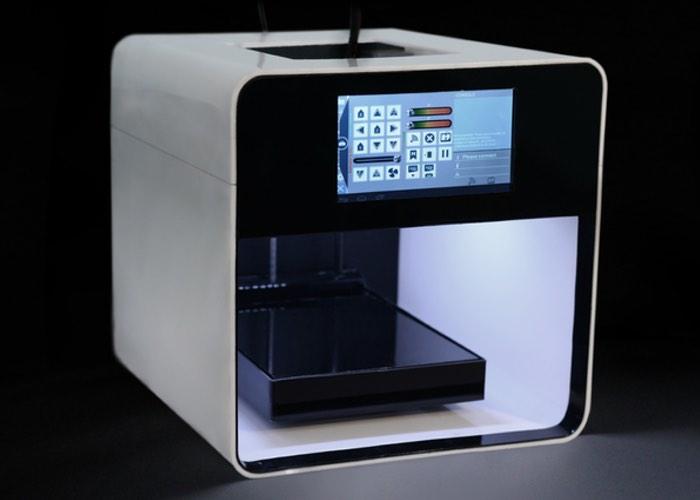

Mono select 3d printer

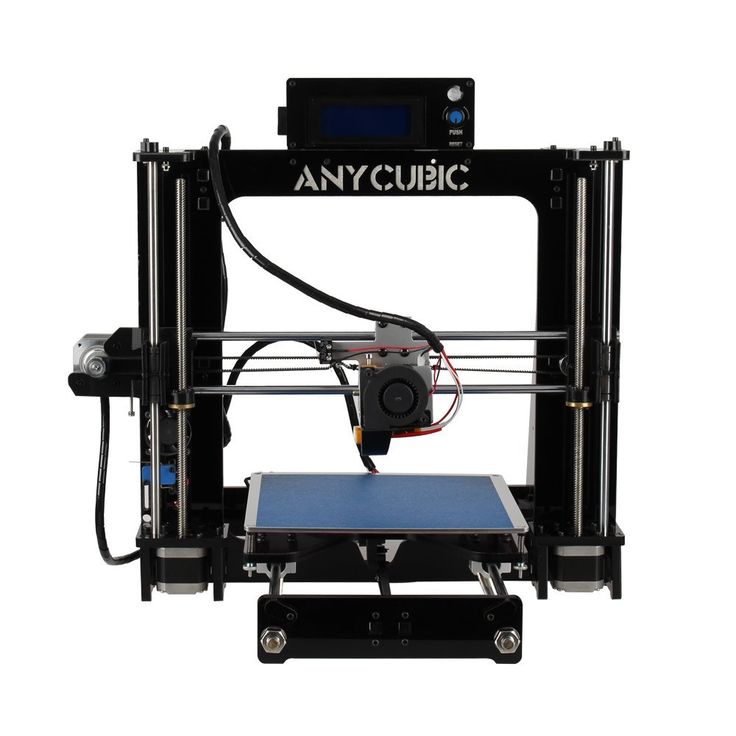

Monoprice Select Mini Review 2022

We reviewed and tested the Monoprice Select Mini 3D printer, and here's why we liked it so much! You'll want this budget 3D printer too after reading this!

By Justin Evans

4

See Price

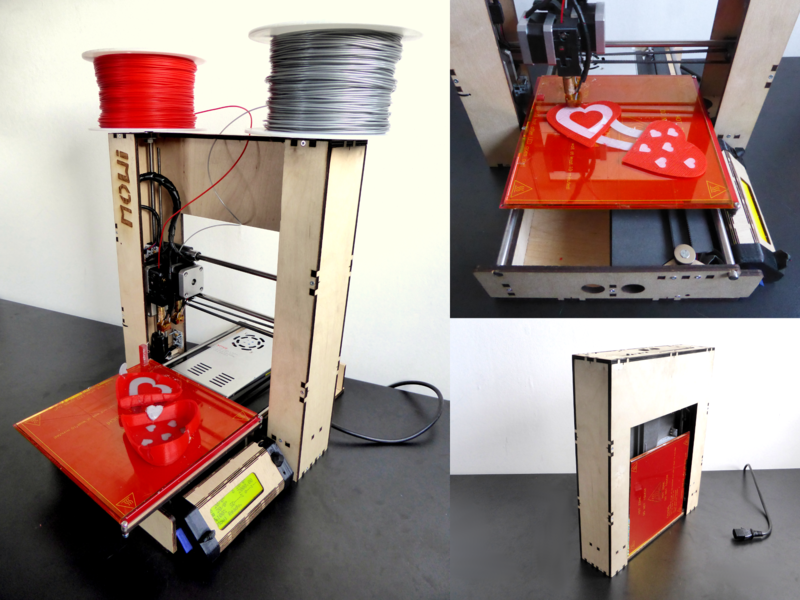

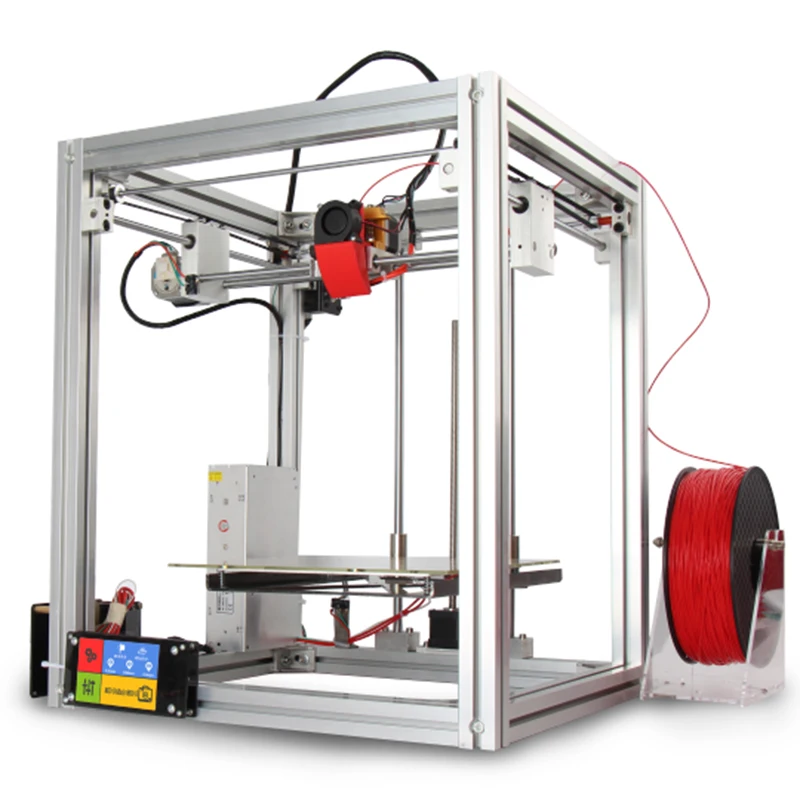

Let’s say you’re in the market for a budget 3D printer. It’s tough: there are models that are vastly overpriced, models that have to be manually assembled from parts, and some that simply aren’t good enough to justify even a very low price. What if you saw a printer far less expensive than the rest? Would you trust it?

Maybe you should. We’re talking, of course, about the Monoprice Select Mini. It’s an absolutely tiny printer designed for people looking to explore the world of 3D printing, without breaking the bank. So how does it hold up? Let’s find out!

| Filament Diameter | 1. |

| Extruders | 1 |

| Supported Materials | PLA, ABS, HIPS, PVA, TPU |

| Connectivity | USB, SD Card |

| Printing Speed | 55mm/s |

| Build Volume | 4.7 x 4.7 x 4.7” |

Table of ContentsShow

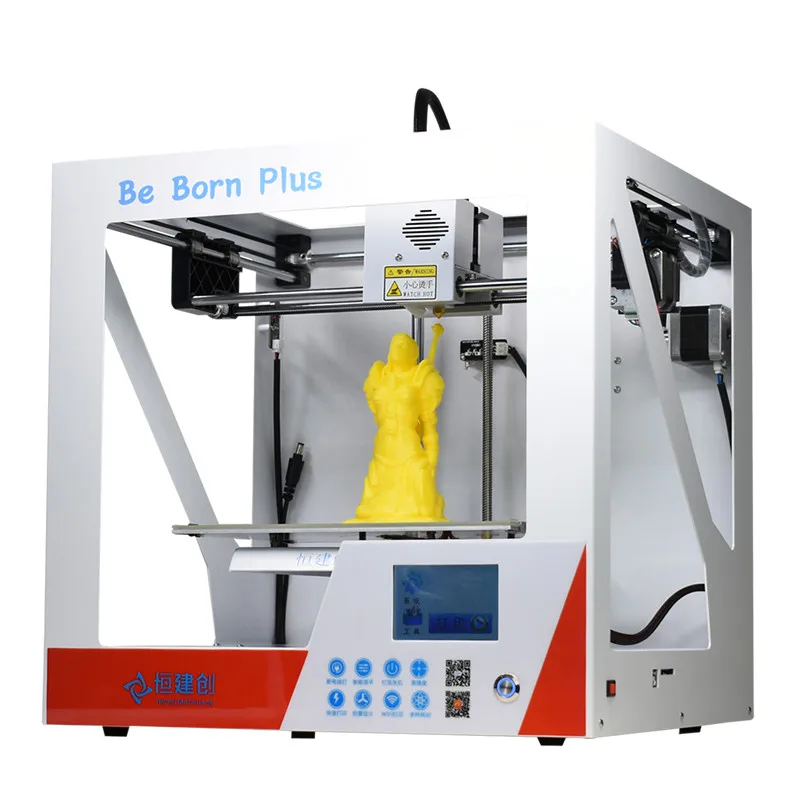

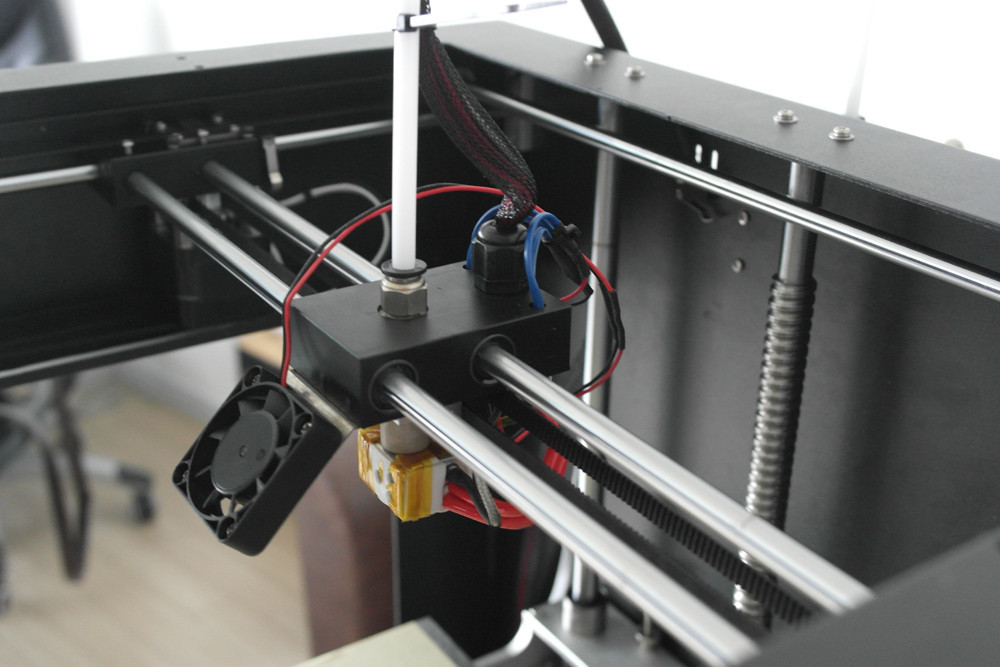

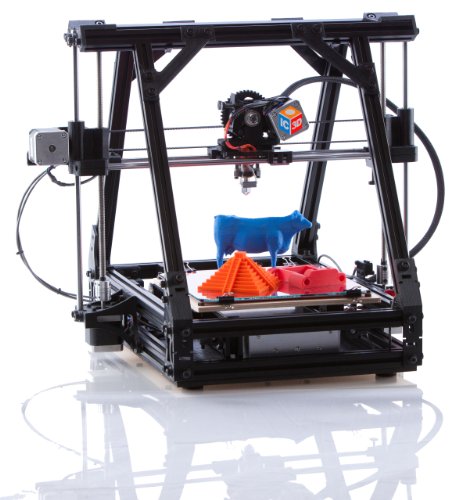

Design

This printer’s design is about as simple as they come. It has a single extruder, and prints onto a heated bed. The build area is, as you’d expect, fairly small – roughly the size of a can of Coke. Still, this is about average for a printer in this price range, so there are no complaints on this front.

Since this printer is designed for beginners, we were pleased to see that it ships fully assembled and pre-calibrated. In fact, thanks to the four-post leveling system, you shouldn’t have to calibrate it too often. Instead, you can focus on the fun part: actually printing things.

You can control this printer either with a PC or directly, using the built-in screen to select models for printing. There’s also a USB port and SD card slot, and the printer actually includes a USB stick with models so you can get printing right away.

Printing

The first thing you should know is that the Select Mini is slow. Its top speed is about half as fast as its rivals, and worse, it tends to fail when running even at that. You’ll be far better served with a slow and steady approach. This seems to create the most consistent, high-quality models.

Now, bear in mind that this is a budget 3D printer. Despite this, we found its prints come out looking pretty good! Sure, you can still see the layers, and intricate details aren’t replicated all that well, but with a little patience (and post-processing), you’ll find you can actually do quite a lot with the Select Mini.

Budget 3D printers tend to have one characteristic in common: lack of versatility. You can expect to print with PLA, maybe ABS too, at best. Incredibly, the Monoprice Select Mini supports both of these materials, as well as HIPS, PVA, and TPU. It’s not even limited to using a proprietary filament, so you can really go wild.

Incredibly, the Monoprice Select Mini supports both of these materials, as well as HIPS, PVA, and TPU. It’s not even limited to using a proprietary filament, so you can really go wild.

Features

Part of this printer’s appeal is its simplicity. As such, it doesn’t have many advanced features to speak of. Rather, it tries to make things as easy for new users as possible. Take software, for instance: it works with Cura, Repetier, Simplify3D, and most other popular modeling or slicing programs.

As you grow more comfortable using a 3D printer, you might want to add some upgrades. The Select Mini is perfect for this, since its inner workings are easily accessible, and its firmware easily flashed. In fact, we’ve found guides for everything from changing the hot end to adding wireless functionality.

If you’ve used a 3D printer before, it’s unlikely that this model will blow you away. It’s aimed at beginners and has a price point to match, after all. However, if you’re completely new to printing and just want something to tinker with as you learn, there are a few models better than this one.

Cost

So how much do you think this printer costs? Brace yourself – it actually retails for around $190, making it among the cheapest 3D printers we’ve seen. Now, it’s not available directly from Monoprice anymore since they’ve released the Mini v2 for the same price. However, it can still be picked up by third-party retailers.

The freedom to use third-party filament means you can keep your material costs down. Evidently, if you want to print often, this will increase to some degree, but since there’s no support for exotic filaments, things shouldn’t get too out of hand.

This printer is perfectly priced and has enough versatility to corner the low-end market. Frankly, we’re amazed that this isn’t the go-to recommendation for people looking to get into 3D printing for the first time.

Support

Despite its low prices, Monoprice offers a 30-day money back guarantee on all its printers. Once you’ve committed to keeping the unit, a year-long limited warranty takes effect. This is pretty good coverage, especially since there’s no risk of breaking anything during assembly.

This is pretty good coverage, especially since there’s no risk of breaking anything during assembly.

On the other hand, Monoprice only offers basic troubleshooting tips and 3D printing tutorials in its support section. You can use the ticket system, email, phone, or live chat to get more detailed help. Our only issue is that the returns link only works on some pages, throwing an error on others.

Honestly, this level of support was unexpected. Too often, low-end 3D printers try to sell their product and then wash their hands of it. That’s clearly not the case with Monoprice, and for that, we applaud them.

B9 Creator Review

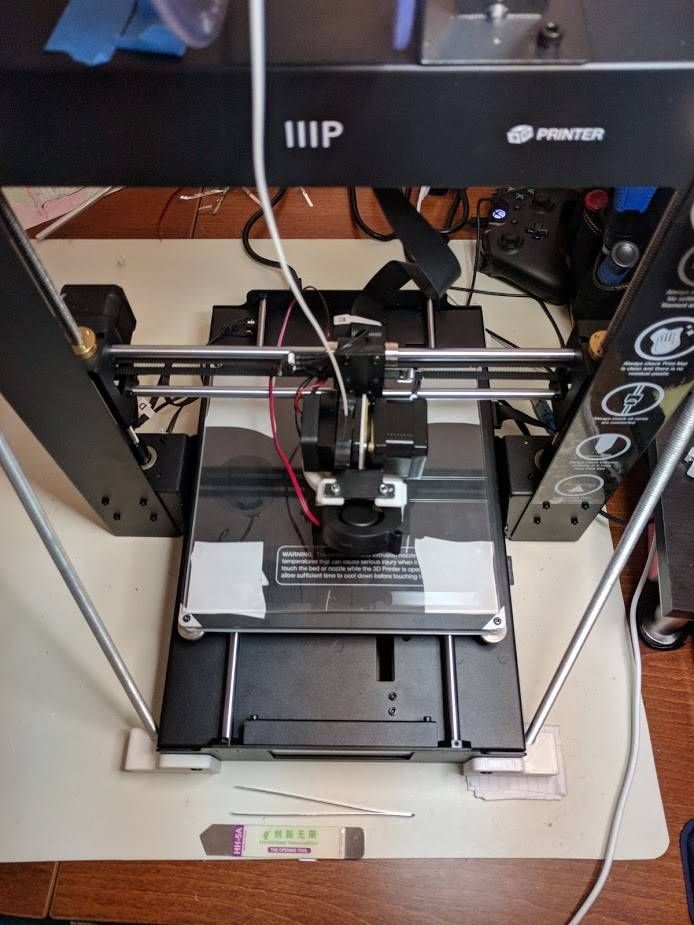

Monoprice Select Mini 3D Printer

| Brand | Monoprice |

| Machine type | 3D Printer |

| Technology | FDM (Fused Deposition Modeling) |

| Materials | PVA, PLA, ABS, Wood PLA, Copper PLA, PETG |

| Website | http://www. monoprice.com/ monoprice.com/ |

| Average Price | $199.00 |

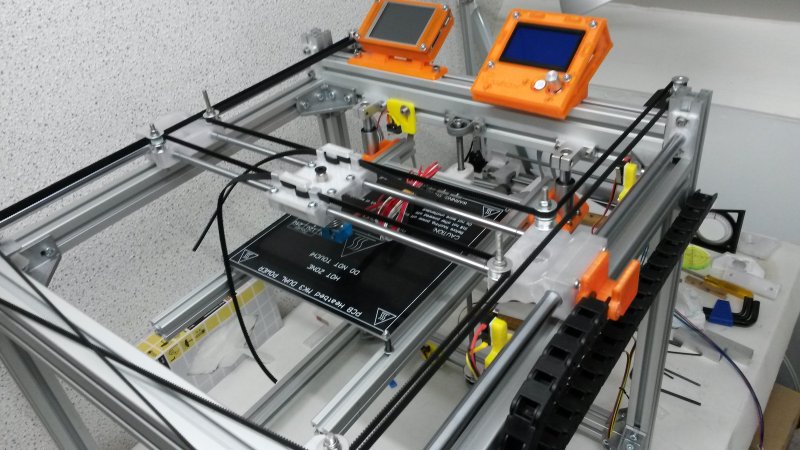

Too often, getting a low-cost 3D printer means getting a box of ill-fitted parts with poorly written and incomplete documentation. You end up spending hours on the internet, searching forums and asking for help to get the printer assembled and operating properly.

That isn't how Monoprice operates and this 3D printer is a perfect example! This printer not only comes fully assembled, it has already been calibrated at the factory. All you have to do is perform a quick check to verify that the print bed is still leveled, in case it shifted during shipping, then load the included MicroSD™ card, load some filament, and start printing the preloaded model. Nowhere else will you find a 3D printer ready to print out of the box at such a low price!

All Filament Types: The heated build plate and wide range of extruder temperatures allow this printer to work with any type of filament, from basic filaments, such as ABS and PLA, to more advanced materials, such as conductive PLA, wood and metal composites, or dissolvable PVA.

Compact Desktop Design: Featuring a small footprint and basic, open frame design, this 3D printer is compact enough for any desk.

Ready to Print: Unlike most other low-cost 3D printers, this printer ships fully assembled and has already been calibrated at the factory. We even include sample PLA filament and a MicroSD™ card with preinstalled models, so you can start printing right out of the box!

Features:

- Heated aluminum build plate nozzle cooling fan for printing all filament types

- Fully assembled and factory calibrated so you can start printing right away

- Complete kit with sample PLA filament, bed scraper, and MicroSD™ card with preloaded model files

- Micro USB and MicroSD card connectivity

- PC and Mac® compatible

- Compatible with Cura, Repetier, and other software

What's in the Box:

- MP Select Mini 3D printer

- Filament rack

- AC power adapter

- AC power cord

- Micro USB cable

- MicroSD™ card

- Plastic bed scraper

- Bed leveling hex wrench

- Sample PLA filament

3D Printing Technologies - FDM, FFF, SLA, DLP, PolyJet, CJP, SLS, SLM

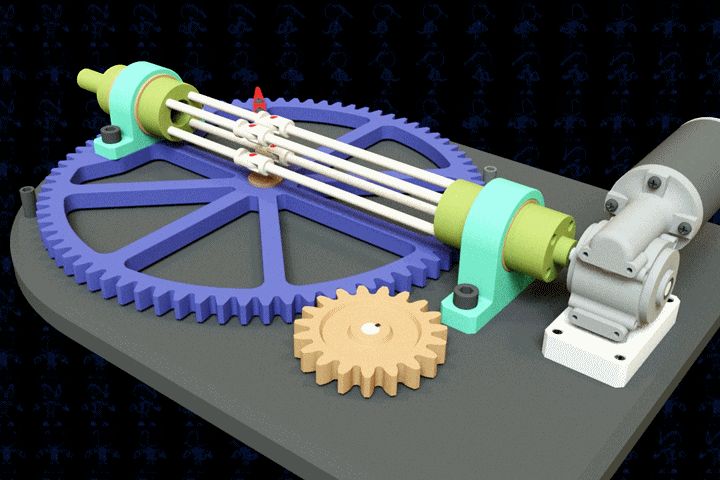

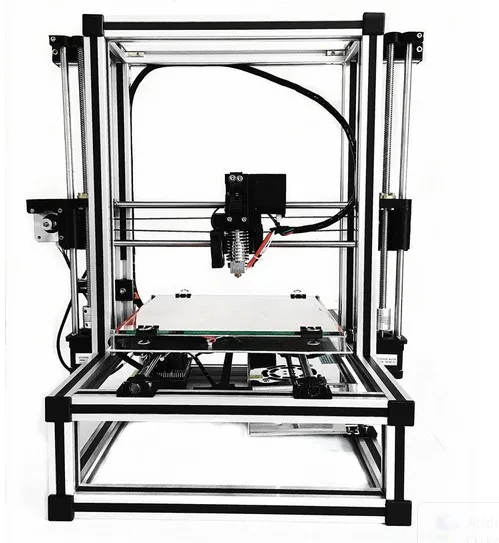

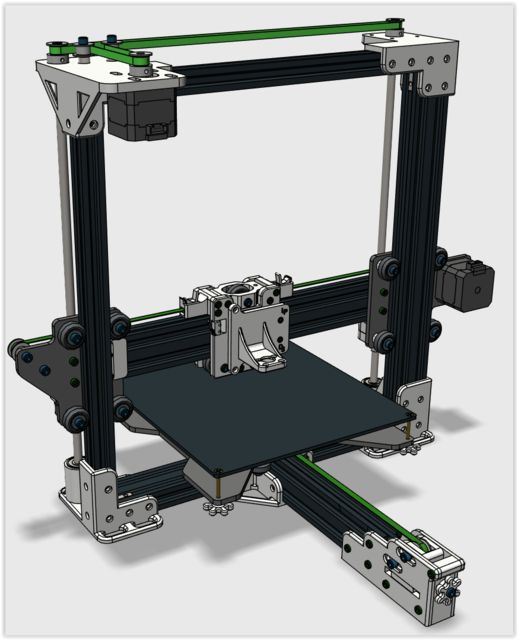

FUSED DEPOSITION MODELING PRINT TECHNOLOGY – + FDM

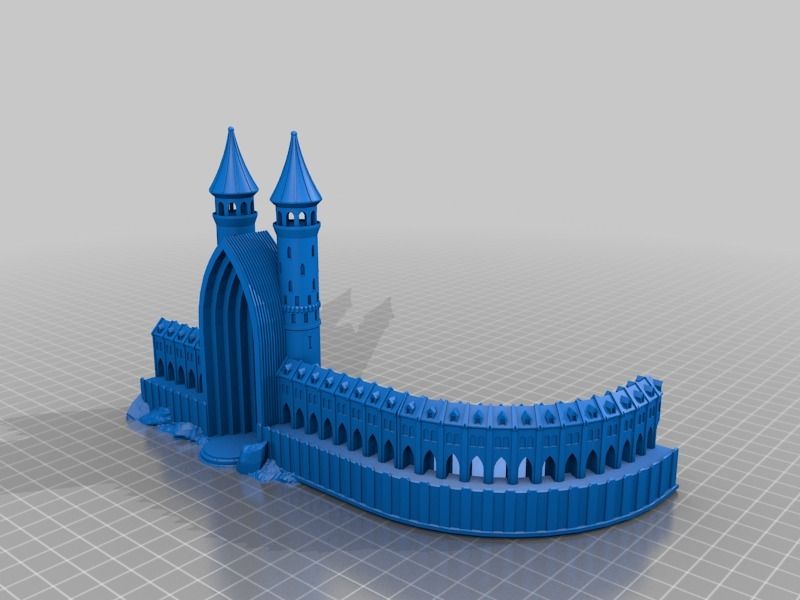

One of the most popular, simple and cheap 3D printing technologies is Fused Depsition Modeling. The technology was invented more than 20 years ago and implemented by Stratasys, and still it remains the most popular. The principle of building a prototype using this method is simple and clear. The simulated 3D object in STL format is transferred to the 3D printer software. After placing the model in a virtual working chamber (automatically or manually), cutting the model into horizontal layers, the 3D printing process begins. The extruder print head melts the filament, laying down layer by layer according to the model data. If necessary, before starting printing, auxiliary structures (supports) are automatically or manually placed on a virtual 3D model, which, after printing, can be removed with a special solution or manually. nine0007 There are many types of equipment that print using this technology. They differ in terms of accuracy, the number of print heads, the size of the working platform, the presence or absence of a closed working chamber, consumable options, etc. There are models that support the ability to use different materials when printing.

The technology was invented more than 20 years ago and implemented by Stratasys, and still it remains the most popular. The principle of building a prototype using this method is simple and clear. The simulated 3D object in STL format is transferred to the 3D printer software. After placing the model in a virtual working chamber (automatically or manually), cutting the model into horizontal layers, the 3D printing process begins. The extruder print head melts the filament, laying down layer by layer according to the model data. If necessary, before starting printing, auxiliary structures (supports) are automatically or manually placed on a virtual 3D model, which, after printing, can be removed with a special solution or manually. nine0007 There are many types of equipment that print using this technology. They differ in terms of accuracy, the number of print heads, the size of the working platform, the presence or absence of a closed working chamber, consumable options, etc. There are models that support the ability to use different materials when printing. There are also industrial FDM 3D printers and personal ones.

There are also industrial FDM 3D printers and personal ones.

The following materials can be used in FDM 3D printing: nine0005

- ABS

- PLA

- SBS plastic

- Nylon

- Polycarbonate

- HIPS support material

- PVA support material

- PETG plastic

- FLEX rubber-like plastic

- RUBBER plastic with rubber properties

The most popular materials are ABS and PLA. Products printed using FDM technology are characterized by elasticity, strength and stable physical characteristics, depending on the selected material. The construction accuracy varies from 0.027mm to 1mm. As a rule, the printed object has a layered (ribbed) surface, the severity of which depends on the thickness of one layer. This effect can be eliminated by post-processing with chemicals or grinding. nine0007 The advantages of FDM 3D printing technology include sufficient speed and ease of manufacture of products, safety, high accuracy, a wide choice of materials, as well as ease of use and maintenance of equipment. In addition, consumables for printing in this way are affordable. All this together makes this technology the most highly competitive and affordable in economic terms.

In addition, consumables for printing in this way are affordable. All this together makes this technology the most highly competitive and affordable in economic terms.

FDM 3D printing technology can be used for rapid prototyping and even small series production. Depending on the selected consumable material, this technology can be used to create parts of mechanisms, toys, interior items, jewelry, souvenirs and much more. The use of high-strength engineering thermoplastics makes it possible to apply this 3D printing method to products used in the aerospace industry. nine0007 Our company has several 3D printers working on this technology. You can order high-quality 3D printing using FDM technology from us with any of the available materials and in any available color option. We guarantee you the quality and efficiency of order execution of any degree of complexity.

To order 3D printing using FDM technology, you need to send us a file in STL format. Trust our professionalism and take advantage of the most affordable 3D printing.

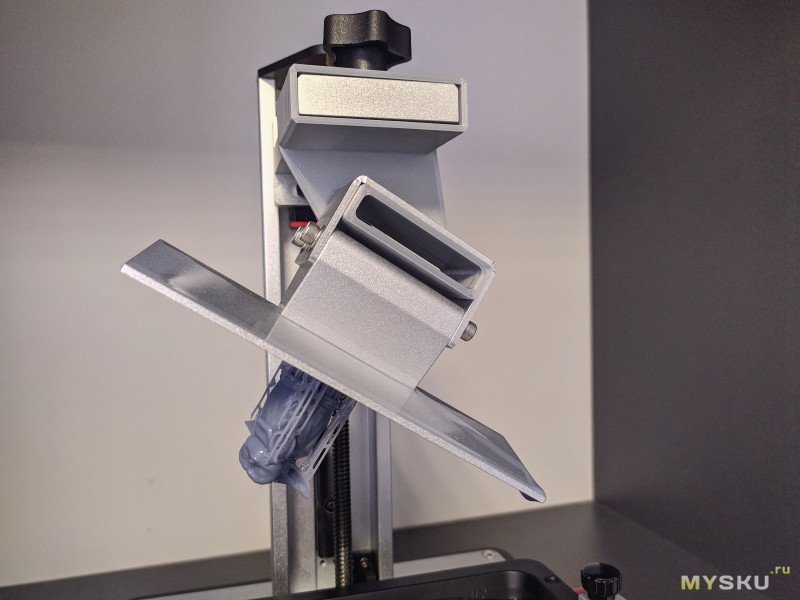

STEREOLITHOGRAPHY PRINT TECHNOLOGY – + SLA

SLA 3D printing technology or laser stereolithography is based on the layer-by-layer curing of a liquid photopolymer under the action of a laser beam. The technology was invented in 1986 by Charles W. Hull, who founded 3D Systems, which manufactures 3D printers that print using this technique.

Photopolymer, which in this case acts as a consumable, is a resinous substance that changes its properties under the influence of ultraviolet radiation - it polymerizes and hardens. In this case, the wavelength and time of exposure to radiation will depend on the environmental conditions and the specific material. nine0007 The principle of building a model using laser stereolithography technology at the initial level is similar to any other - the modeled object in STL format is loaded into the 3D printer software, placed in a virtual working chamber and cut into layers. Photopolymer resin is poured into a special container. It contains a working platform on which the part will be built. Initially, the working platform is set so that it is covered with the thinnest layer of photopolymer (0.05-0.13 mm). This will be the size of the layer when printed. Then the laser is turned on, it irradiates the areas that will later become parts of the finished product. As a result of irradiation, the material hardens and the working platform sinks to the extent of the layer. The algorithm repeats again until all programmed layers are exhausted. Then the finished product is immersed in a special bath, into which a composition is poured to remove excess elements. And at the end, the product is again irradiated so that it gains maximum strength. nine0007 Stereolithography, like most other 3D printing technologies, requires support. After printing is completed, they are removed manually.

Photopolymer resin is poured into a special container. It contains a working platform on which the part will be built. Initially, the working platform is set so that it is covered with the thinnest layer of photopolymer (0.05-0.13 mm). This will be the size of the layer when printed. Then the laser is turned on, it irradiates the areas that will later become parts of the finished product. As a result of irradiation, the material hardens and the working platform sinks to the extent of the layer. The algorithm repeats again until all programmed layers are exhausted. Then the finished product is immersed in a special bath, into which a composition is poured to remove excess elements. And at the end, the product is again irradiated so that it gains maximum strength. nine0007 Stereolithography, like most other 3D printing technologies, requires support. After printing is completed, they are removed manually.

The main advantages of stereolithography technology are the highest precision and the ability to create the smallest and thin-walled objects. The technique is distinguished by easy post-processing of products and their almost perfect surface. The disadvantage of this technology is the impossibility of using several materials at once. Color printing is also not possible. The properties of the model and its color will determine the initial characteristics of one photopolymer. In addition, the cost of such printing and equipment is not cheap. nine0007 Due to the fact that stereolithography allows you to get a model of almost any degree of complexity, the main scope of this 3D printing is research. And due to the highest accuracy and detail, this technique is used in medicine, in particular in dentistry. Also, printed models are in demand in art, jewelry, museum work and restoration. There are photopolymers that can be used to print molded models. The model printed on a 3D printer, in this case, is poured with molding sand and placed in an oven for annealing at a temperature of 1000 degrees. As a result, the polymer burns out without leaving a trace, and the resulting form can be used for pouring metal under vacuum.

The technique is distinguished by easy post-processing of products and their almost perfect surface. The disadvantage of this technology is the impossibility of using several materials at once. Color printing is also not possible. The properties of the model and its color will determine the initial characteristics of one photopolymer. In addition, the cost of such printing and equipment is not cheap. nine0007 Due to the fact that stereolithography allows you to get a model of almost any degree of complexity, the main scope of this 3D printing is research. And due to the highest accuracy and detail, this technique is used in medicine, in particular in dentistry. Also, printed models are in demand in art, jewelry, museum work and restoration. There are photopolymers that can be used to print molded models. The model printed on a 3D printer, in this case, is poured with molding sand and placed in an oven for annealing at a temperature of 1000 degrees. As a result, the polymer burns out without leaving a trace, and the resulting form can be used for pouring metal under vacuum. As the metal cools, the mold breaks and the metal part is removed. nine0007 In our company you can order 3D printing using SLA technology. We have in our arsenal professional 3D printers using this technology and a wide range of photopolymer resins with various characteristics for 3D printing. We guarantee you high quality and prompt execution of the order. To order 3D printing using the laser stereolithography method, you need to provide us with a file in STL format.

As the metal cools, the mold breaks and the metal part is removed. nine0007 In our company you can order 3D printing using SLA technology. We have in our arsenal professional 3D printers using this technology and a wide range of photopolymer resins with various characteristics for 3D printing. We guarantee you high quality and prompt execution of the order. To order 3D printing using the laser stereolithography method, you need to provide us with a file in STL format.

Get the most out of high-precision and highly detailed stereolithographic 3D printing. nine0007

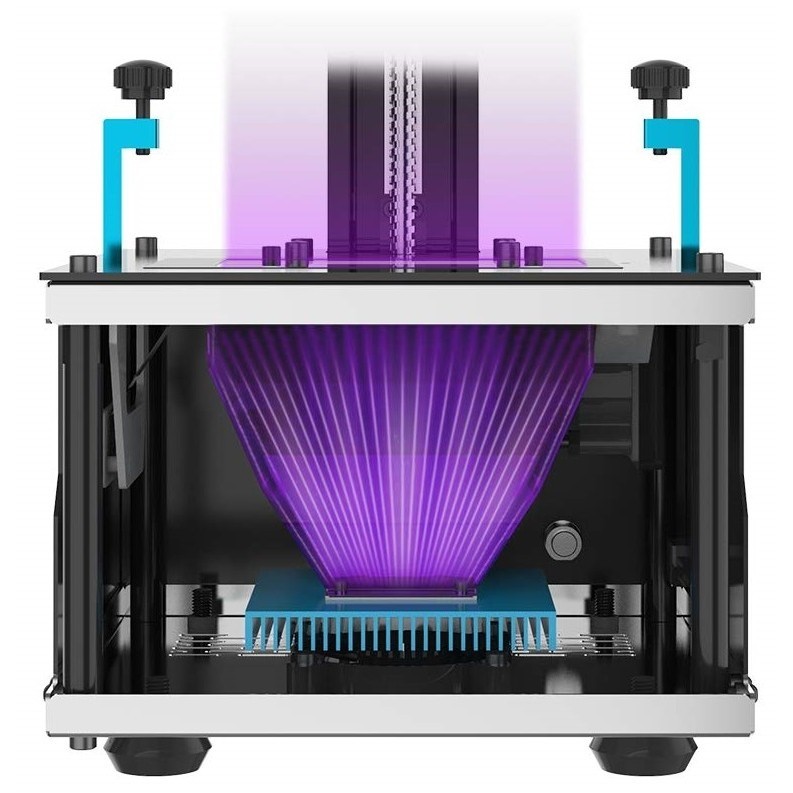

DIGITAL LIGHT PROCESSING PRINT TECHNOLOGY – + DLP

DLP 3D printing is one of the most accurate and fastest 3D printing methods. It is based on the technology that Larry Hornbeck invented for multimedia projectors. The peculiarity lies in the use of a special mirror matrix. Each individual pixel of this matrix is a microscopic mirror. nine0007 DLP stands for Digital Light Processing, which means "Digital Light Processing". Thus, this technology is one of the varieties of photopolymer 3D printing and photopolymer resin is used as a consumable. This resin is irradiated with projected light from the LEDs and hardens. The technology is very similar to stereolithography. However, with SLA 3D printing, each layer is, as it were, loomed with laser beams. And in DLP technology, the layer is completely projected onto a photopolymer using the same matrix with micromirrors, that is, this method is more like stamping. Thus, while maintaining the highest accuracy of 3D printing, it was possible to significantly increase its speed. At the moment, the speed of DLP printing is several times higher than FDM, SLM and SLA printing. For this reason, the DLP 3D printing technique is one of the most promising. nine0007 The thickness of one layer when printing using DLP technology is 10-15 microns, which is basically similar to the indicators for SLA 3D printing technology.

nine0007 DLP stands for Digital Light Processing, which means "Digital Light Processing". Thus, this technology is one of the varieties of photopolymer 3D printing and photopolymer resin is used as a consumable. This resin is irradiated with projected light from the LEDs and hardens. The technology is very similar to stereolithography. However, with SLA 3D printing, each layer is, as it were, loomed with laser beams. And in DLP technology, the layer is completely projected onto a photopolymer using the same matrix with micromirrors, that is, this method is more like stamping. Thus, while maintaining the highest accuracy of 3D printing, it was possible to significantly increase its speed. At the moment, the speed of DLP printing is several times higher than FDM, SLM and SLA printing. For this reason, the DLP 3D printing technique is one of the most promising. nine0007 The thickness of one layer when printing using DLP technology is 10-15 microns, which is basically similar to the indicators for SLA 3D printing technology. For comparison, the FDM method implies a minimum thickness of at least 50 microns.

Since DLP printers are the main competitors of SLA printing, their application is about the same. They can print products for dentistry, jewelry, complex designs and even souvenirs. The technology is also in demand in the research area.

Photopolymers used in 3D printing with this method are diverse, and you can choose a material with the desired characteristics. For example, there are materials that mimic the properties of ABS plastic, hard engineering plastics, and even rubber. However, it is important to know that in some cases, under the influence of light, photopolymer products can crack and become brittle. This technology implies the impossibility of using several materials at once. Color printing is also not possible. The properties of the model and its color will determine the initial characteristics of one photopolymer. nine0007 However, there is also a drawback to DLP technology - as in the case of SLA 3D printers, the cost of equipment is very high, as in principle the price of photopolymers. Not every, even a large company, can afford such a 3D printer.

But this does not mean at all that you will not be able to take advantage of the speed and advantages of DLP printing, because you have the opportunity to order 3D printing on such a 3D printer in our company. To do this, you just need to provide us with an STL file with the desired model. We guarantee you prompt execution of the order and high quality. nine0007 Enjoy high-quality, fast, high-precision DLP printing.

PRINT TECHNOLOGY LED DISPLAY – + LED

One of the varieties of DLP 3D printing technology is LED 3D printing. That is, this method is based on the same digital light processing (as Digital Light Processing stands for). However, in devices for LED 3D printing, instead of a mirror chipped matrix, there is an LED display that immediately highlights a whole layer on the material, like a kind of light stamp. Using an LED display allows you to increase the speed of 3D printing. So it takes about 10-15 minutes to 3D print 2.5 cm along the Z-axis, and it's really fast. Although the print speed in any case will directly depend on the thickness of one layer. nine0007 As a consumable material, a photopolymer resin is used, which polymerizes under the action of ultraviolet light, that is, it changes its qualities, passing from a semi-liquid state to a solid one. There are many options for photopolymers, among which there are materials that, after the polymerization process, imitate the characteristics of solid, including engineering plastics. There are also those that are very similar to classic rubber after hardening, that is, they have the same strength and elasticity indicators. You can also choose biocompatible photopolymers. When choosing a material for printing, you should be guided by the technical characteristics and scope of a particular photopolymer. nine0007 Like any other photopolymer 3D printing, LED technology is characterized by the highest precision and detail.

The thickness of one layer is only 10-15 microns. With its help, you can print thin-walled products, objects with complex geometry. Photopolymers practically do not shrink and do not change their geometry after hardening, and this is also an advantage, especially when it is necessary to print anatomically accurate models. The DLP LED 3D printing technology itself, although it provides for a layer-by-layer method for creating a model, still does not differ in pronounced layering of the finished model. The surface is almost perfectly smooth, requiring no additional processing. nine0007 If complex objects are printed, support must be used. They can be set in automatic or manual mode immediately before printing during the positioning of the model in the virtual working chamber. These supports are subsequently removed manually.

The thickness of one layer is only 10-15 microns. With its help, you can print thin-walled products, objects with complex geometry. Photopolymers practically do not shrink and do not change their geometry after hardening, and this is also an advantage, especially when it is necessary to print anatomically accurate models. The DLP LED 3D printing technology itself, although it provides for a layer-by-layer method for creating a model, still does not differ in pronounced layering of the finished model. The surface is almost perfectly smooth, requiring no additional processing. nine0007 If complex objects are printed, support must be used. They can be set in automatic or manual mode immediately before printing during the positioning of the model in the virtual working chamber. These supports are subsequently removed manually.

LED technology implies the impossibility of using several materials at once. Color 3D printing is also not possible. The properties of the finished prototype and its color will determine the initial characteristics of the photopolymer used. nine0007 The field of application of LED 3D printing is basically the same as the field of use of DLP printing, since this technology is, in fact, its improvement. The technology is in demand in the production of hearing aids and earmolds, in dentistry and orthodontics, as well as in jewelry. Due to the high accuracy and detail of 3D objects printed using this technology, products will also be in demand in the field of research and engineering activities.

nine0007 The field of application of LED 3D printing is basically the same as the field of use of DLP printing, since this technology is, in fact, its improvement. The technology is in demand in the production of hearing aids and earmolds, in dentistry and orthodontics, as well as in jewelry. Due to the high accuracy and detail of 3D objects printed using this technology, products will also be in demand in the field of research and engineering activities.

LED 3D printer is very expensive. However, this does not mean that its benefits are not available to you. You can order 3D printing using LED technology in our company. We offer you a large selection of photopolymer resins for printing and guarantee the high quality of models, in full compliance with the provided STL-file, and the prompt execution of the order. nine0007 Take full advantage of LED technology with our help.

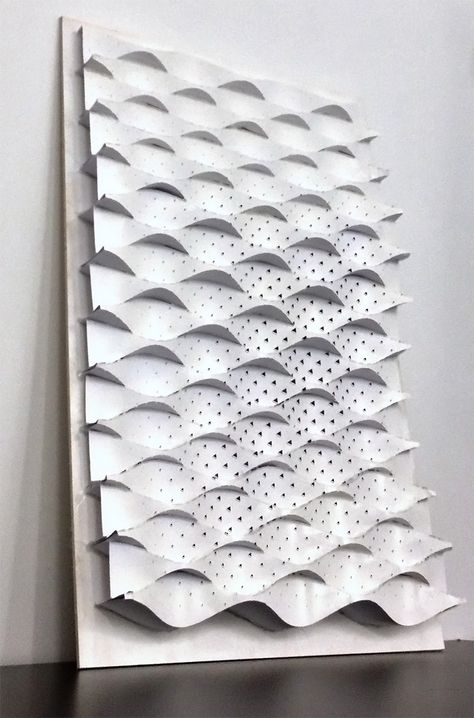

POLYJET PRINT TECHNOLOGY – + PJ

PolyJet is a revolutionary 3D printing technology that is a powerful tool for high performance additive manufacturing. The technique was invented and patented by Stratasys. The operation of a PolyJet 3D printer is very similar to a conventional, well-known inkjet printer, but printing is carried out not on paper and not with simple ink, but on a special substrate in the chamber, and an acrylic-based liquid photopolymer acts as a material. nine0007 The PolyJet-enabled 3D printer is equipped with a special print head with nozzles. There can be several printheads, which allows you to print faster and even prototyping several objects at once. The printing process is carried out by dosed deposition of a photopolymer. One layer of 16 microns is sprayed at a time. Then this layer is exposed to an ultraviolet lamp and the photopolymer turns into a hard plastic. After that, the working platform with the substrate is lowered, and the algorithm is repeated again. When printing complex geometric shapes, a support material is used. For this technology, a special gel-like material has been created, which is easily removed with plain water or hands.

The technique was invented and patented by Stratasys. The operation of a PolyJet 3D printer is very similar to a conventional, well-known inkjet printer, but printing is carried out not on paper and not with simple ink, but on a special substrate in the chamber, and an acrylic-based liquid photopolymer acts as a material. nine0007 The PolyJet-enabled 3D printer is equipped with a special print head with nozzles. There can be several printheads, which allows you to print faster and even prototyping several objects at once. The printing process is carried out by dosed deposition of a photopolymer. One layer of 16 microns is sprayed at a time. Then this layer is exposed to an ultraviolet lamp and the photopolymer turns into a hard plastic. After that, the working platform with the substrate is lowered, and the algorithm is repeated again. When printing complex geometric shapes, a support material is used. For this technology, a special gel-like material has been created, which is easily removed with plain water or hands. nine0007 A key feature of PolyJet 3D printing technology is the ability to use multiple materials in one print run. At the same time, there are models of 3D printers that can mix photopolymers in various proportions, obtaining a variety of composite materials with certain characteristics. Also, this technology is characterized by the possibility of complex color reproduction. That is, it is possible to use color printing, the palette of which includes about 1000 colors and shades. In fact, it is the only additive manufacturing technology that supports these capabilities. nine0007 Other advantages of the method include: high printing speed, high accuracy and detail, perfect surface and generally excellent quality of printed objects. In addition, a wide range of materials allows you to create objects of almost any kind. More than 100 different photopolymer resins can be used as a base, mixing of which allows obtaining materials from transparent to completely opaque, from hard to elastic and rubbery.

nine0007 A key feature of PolyJet 3D printing technology is the ability to use multiple materials in one print run. At the same time, there are models of 3D printers that can mix photopolymers in various proportions, obtaining a variety of composite materials with certain characteristics. Also, this technology is characterized by the possibility of complex color reproduction. That is, it is possible to use color printing, the palette of which includes about 1000 colors and shades. In fact, it is the only additive manufacturing technology that supports these capabilities. nine0007 Other advantages of the method include: high printing speed, high accuracy and detail, perfect surface and generally excellent quality of printed objects. In addition, a wide range of materials allows you to create objects of almost any kind. More than 100 different photopolymer resins can be used as a base, mixing of which allows obtaining materials from transparent to completely opaque, from hard to elastic and rubbery. This is truly a new standard for realism in the most complex prints. PolyJet technology allows you to achieve perfect surface smoothness and imitate any even the most subtle texture. The camera of the PolyJet 3D printer is quite large, but if you need to print a large object, then it can be broken into parts, which are then simply glued together. nine0007 The only disadvantage of the technology is its high cost. The equipment is very expensive, and photopolymer resins are not cheap. But this does not mean that you cannot use this technology, because you have the opportunity to order 3D printing using PolyJet technology in our company. In a short time, we will implement your project on our own 3D printer. All you need is to provide us with the STL file.

This is truly a new standard for realism in the most complex prints. PolyJet technology allows you to achieve perfect surface smoothness and imitate any even the most subtle texture. The camera of the PolyJet 3D printer is quite large, but if you need to print a large object, then it can be broken into parts, which are then simply glued together. nine0007 The only disadvantage of the technology is its high cost. The equipment is very expensive, and photopolymer resins are not cheap. But this does not mean that you cannot use this technology, because you have the opportunity to order 3D printing using PolyJet technology in our company. In a short time, we will implement your project on our own 3D printer. All you need is to provide us with the STL file.

PolyJet 3D printing technology is truly limitless. nine0007

COLOR JET PRINTING TECHNOLOGY – + CJP

Color inkjet 3D printing - CJP (ColorJet Printing) technology - a patented technique invented by 3D Systems. It consists in layer-by-layer gluing and coloring of the powder gypsum composite. 3D printing of this type is based on a technique called 3DP, which is its improvement. nine0007 3D printing by this method is based on the use of two materials: base and binder. To create the base layer, a consumable of the main type is used. It consists of gypsum mixed with a polymer. And the binder is used for gluing and staining the layers.

It consists in layer-by-layer gluing and coloring of the powder gypsum composite. 3D printing of this type is based on a technique called 3DP, which is its improvement. nine0007 3D printing by this method is based on the use of two materials: base and binder. To create the base layer, a consumable of the main type is used. It consists of gypsum mixed with a polymer. And the binder is used for gluing and staining the layers.

ColorJet Printing 3D printer has two cameras. A gypsum composite is poured into one of them, and the second chamber is used to remove excess material. The model is "grown" in layers. A special roller distributes a thin layer of material on the working platform. The print head applies the adhesive and colors the main consumable particles. All this is carried out in accordance with the loaded mathematical 3D model. The working surface is lowered by the amount of the layer (0.1016 mm), and the roller again applies a layer of gypsum composite powder, and so on until the model is printed to the end. nine0007 ColorJet Printing technology has a relatively low cost of printed models. Its advantage is the absence of the need for supports, since the non-glued material will act as supporting structures. In addition, the material that was not used during printing can be reused. It turns out that this method of additive manufacturing is waste-free.

nine0007 ColorJet Printing technology has a relatively low cost of printed models. Its advantage is the absence of the need for supports, since the non-glued material will act as supporting structures. In addition, the material that was not used during printing can be reused. It turns out that this method of additive manufacturing is waste-free.

The CJP technology is the only one that uses the CMYK printing color palette. This palette includes 390 thousand colors and shades. The material is dyed during the gluing of the layer, resulting in details with excellent color reproduction.

The accuracy of building a model by this method is very high, the minimum printed element has dimensions of 0.1-0.4 mm. The thickness of the walls of the prototype, which will not collapse under their own weight, is 0.102-0.089 mm.

Models printed using ColorJet Printing technology have a typical gypsum rough surface, characterized by a high degree of hygroscopicity. The strength of the models is average. However, finished models are easy to sand, paint and glue. To improve the characteristics of the model and protect them from moisture, you can cover the surface with varnishes, waxes, resins, as well as all kinds of fixatives. nine0007 The technology can be used for 3D printing of architectural models, product presentations, souvenirs, miniatures, etc. Despite the fact that the products are of low strength, they allow you to visually evaluate the prototypes.

However, finished models are easy to sand, paint and glue. To improve the characteristics of the model and protect them from moisture, you can cover the surface with varnishes, waxes, resins, as well as all kinds of fixatives. nine0007 The technology can be used for 3D printing of architectural models, product presentations, souvenirs, miniatures, etc. Despite the fact that the products are of low strength, they allow you to visually evaluate the prototypes.

CJP 3D printer has impressive dimensions and is quite expensive, despite the fact that the cost of printed prototypes is low, not everyone can afford such pleasure. In our company, you can order 3D printing using ColorJet Printing technology. We guarantee you prompt execution of the order and full compliance of the prototype with the modeled object. All you need is to provide us with an STL file with a 3D model. nine0007 Take advantage of CJP 3D printing technology with our help and appreciate all its advantages in practice.

SELECTIVE LASER SINTERING PRINT TECHNOLOGY – + SLS

Selective, that is, selective, laser sintering is a 3D printing technology that was created back in 1979. However, for a long time it was not available to the market until DTM was created in 1996. In 2001, 3D Systems bought this company, and in 2014 the patent expired, and now this technology is available to a wide range of consumers. nine0007 The SLS 3D printing technique consists in the fact that the material is heated by a laser beam until the particles are sintered, that is, not completely. As a result, the model turns out not to be solid, but as if “sintered” from individual tiny particles. If we consider the structure under magnification, then individual particles of the material will be visible, as if glued to each other.

However, for a long time it was not available to the market until DTM was created in 1996. In 2001, 3D Systems bought this company, and in 2014 the patent expired, and now this technology is available to a wide range of consumers. nine0007 The SLS 3D printing technique consists in the fact that the material is heated by a laser beam until the particles are sintered, that is, not completely. As a result, the model turns out not to be solid, but as if “sintered” from individual tiny particles. If we consider the structure under magnification, then individual particles of the material will be visible, as if glued to each other.

The operation of a 3D printer that prints using SLS technology is as follows. Powder material is poured into the chamber. A 3D model in STL format is loaded into the software. The working platform is exposed and a thin layer of material (thickness about 120 microns) is applied to it, leveled with a roller. The laser sinters the powder particles according to the loaded model. After the layer is completed, the platform is lowered and a new layer of material is applied. The procedure will be repeated until the very last layer is completed. nine0007 Since there is unused material in the working chamber, the need for supports simply disappears, because complex and overhanging parts will be supported by unused material. This allows you to get models of any, even very complex geometry.

After the layer is completed, the platform is lowered and a new layer of material is applied. The procedure will be repeated until the very last layer is completed. nine0007 Since there is unused material in the working chamber, the need for supports simply disappears, because complex and overhanging parts will be supported by unused material. This allows you to get models of any, even very complex geometry.

Powder polymers, metals and their alloys, ceramics, glass, composite materials can be used as consumables. But in any case, the material must be in powder form. Due to the fact that the power of laser radiation can be adjusted, the degree of melting of the material can change, and, accordingly, the strength and uniformity of the structure of the resulting model. Currently, the most popular material for 3D printing using SLS technology is polyamide. This is a versatile powder material that can be used in almost any field. If powdered metal is used for printing, it is preheated to make printing faster and easier. nine0007 As a result of 3D printing, models are obtained with a surface that requires processing, in particular grinding. Models made of polyamide are sensitive to moisture, so they must be coated with a protective compound, such as moisture-resistant paint, if outdoor use is planned.

nine0007 As a result of 3D printing, models are obtained with a surface that requires processing, in particular grinding. Models made of polyamide are sensitive to moisture, so they must be coated with a protective compound, such as moisture-resistant paint, if outdoor use is planned.

Selective laser sintering shows excellent results when used in small-scale production, as well as for the manufacture of master models. This 3D printing technology is in demand in the aerospace industry, in manufacturing, etc. nine0007 The disadvantages of SLS 3D printing technology are the high cost of equipment. In addition, the powder material is potentially harmful to the human body, so a separate room with air conditioning and an air filter is equipped for such 3D printers. All this imposes difficulties for additive manufacturing using this technique. But this does not mean that you cannot take advantage of the possibilities of selective laser sintering technology, because our company provides professional 3D printing services on such equipment. You can order 3D printing using SLS technology from us. All you need is to provide us with a file with a 3D model in STL format. We guarantee you high quality printing in full accordance with the provided 3D model. nine0007

You can order 3D printing using SLS technology from us. All you need is to provide us with a file with a 3D model in STL format. We guarantee you high quality printing in full accordance with the provided 3D model. nine0007

SELECTIVE LASER MELTING PRINT TECHNOLOGY – + SLM

Selective (selective) laser melting - SLM is a 3D printing method from a mathematical CAD model, which is used to create 3D objects by melting metal powders. For this, high-power lasers are used.

Using this technology, it is possible to create precise metal parts that will later be used in various units and assemblies, including non-separable structures that change their geometry during use. This type of printing is becoming more and more widespread, because the parts created by this method are in many ways superior in their mechanical and physical characteristics to products produced by traditional methods. nine0007 The advantages of 3D printing using SLM technology are: the ability to solve the most complex production problems, including in the aerospace industry, where parts and assemblies have a hard load and serious requirements are imposed. Also, SLM printing is used in experimental and scientific and technical activities, where it is possible to significantly reduce the R&D cycle, because the most complex mechanisms and products can be created without serious equipment.

Also, SLM printing is used in experimental and scientific and technical activities, where it is possible to significantly reduce the R&D cycle, because the most complex mechanisms and products can be created without serious equipment.

The technology also allows you to print objects with internal cavities, which can significantly reduce the weight of products. nine0007 The essence of the method lies in the layer-by-layer application of metal powder on a special heated platform and its subsequent processing with a high-power laser, in accordance with the CAD model. The working chamber of the 3D printer, where the melting process itself takes place, is filled with argon or nitrogen. The choice of gas will depend on which consumable is selected for printing. Inert gas will be mainly consumed in preparation for printing, when the chamber is purged, because it is necessary to achieve conditions so that the percentage of oxygen in the chamber is no more than 0.15%. This is a necessary condition in order to avoid the oxidation of metals. Consumables can be: powdered metals and alloys. It can be tool or stainless steel, titanium and its alloys, aluminum, platinum, gold, as well as cobalt-chromium alloys. nine0007 The model is fused layer by layer. After the printing of the prototype is completed, it is removed from the chamber with the working platform and separated from it mechanically. In the future, it may require processing, because the surface of the product may not be ideal. However, the product will be very strong and uniform in structure, similar to cast.

Consumables can be: powdered metals and alloys. It can be tool or stainless steel, titanium and its alloys, aluminum, platinum, gold, as well as cobalt-chromium alloys. nine0007 The model is fused layer by layer. After the printing of the prototype is completed, it is removed from the chamber with the working platform and separated from it mechanically. In the future, it may require processing, because the surface of the product may not be ideal. However, the product will be very strong and uniform in structure, similar to cast.

One of the advantages of the technology is its economy and non-waste. After all, unsintered material can be reused. The thickness of one layer is 20-100 microns. Thus, SLM 3D printing is a very precise and highly detailed additive manufacturing technique. nine0007 The cost of 3D printers using this method is very high. And in general, their operation is by no means a simple matter, requiring special conditions. But you have a great opportunity to use 3D printing using selective laser fusion technology with the help of our company. All you need is just to order 3D printing using this technique in our company. To do this, you need to provide us with an STL file with a CAD model for printing.

All you need is just to order 3D printing using this technique in our company. To do this, you need to provide us with an STL file with a CAD model for printing.

Take advantage of the innovative method of creating high-precision metal products - SLM printing. nine0007

ELECTRON BEAM MELTING PRINT TECHNOLOGY – + EBM

One of the most reliable metal 3D printing methods is EBM printing or electron beam melting. This is an additive manufacturing technology that is used to create high-strength, comparable to cast, metal products. Pure (without impurities) metal powder acts as a consumable. Printing is carried out in a vacuum chamber, which minimizes the oxidation of the material, such as pure titanium. nine0007 Electron beam melting is very similar to SLS 3D printing technology, that is, selective laser melting. However, it does not use powerful lasers, but electron emitters, which serve as sources of powerful energy used to melt metal. So-called electron guns fire high power electron beams that fuse metal powder. The method is similar to other 3D printing methods - the layering of consumables. A layer of metal powder is applied, and electron beams, following the contour of the model, fuse the material. Then the algorithm is repeated again until all layers are created and a finished three-dimensional object is obtained in accordance with the mathematical 3D model. nine0007 As a result of such 3D printing, a high-density metal model is obtained, and the porosity of the structure is absent. This means that additional processing by the method of firing for a strong fusion of the material in the model is not required. And the model itself will have high strength characteristics initially, that is, it will not differ in any way from cast products.

So-called electron guns fire high power electron beams that fuse metal powder. The method is similar to other 3D printing methods - the layering of consumables. A layer of metal powder is applied, and electron beams, following the contour of the model, fuse the material. Then the algorithm is repeated again until all layers are created and a finished three-dimensional object is obtained in accordance with the mathematical 3D model. nine0007 As a result of such 3D printing, a high-density metal model is obtained, and the porosity of the structure is absent. This means that additional processing by the method of firing for a strong fusion of the material in the model is not required. And the model itself will have high strength characteristics initially, that is, it will not differ in any way from cast products.

Electron beam melting is printed at high background temperatures of 700-1000 degrees Celsius. This avoids a strong temperature difference between the already cooled printed layer and the fresh hot layer. Therefore, printed parts will not suffer from residual mechanical stress. This is how the highest possible strength of EBM-printed products is achieved. nine0007 This 3D printing technology is used to create high-precision titanium prostheses and implants, such as hip and knee implants, skull parts, etc. Titanium combines strength and biocompatibility.

Therefore, printed parts will not suffer from residual mechanical stress. This is how the highest possible strength of EBM-printed products is achieved. nine0007 This 3D printing technology is used to create high-precision titanium prostheses and implants, such as hip and knee implants, skull parts, etc. Titanium combines strength and biocompatibility.

EBM printing is also used in the aerospace industry. With the help of this technology, load-bearing structural elements of various devices (aircraft, rockets), as well as parts of their engines, are printed. For this purpose, strong and light powder metals are used. nine0007 EBM printing equipment is very expensive. However, you can order 3D printing using the technology of electron beam melting of powder metal. We are ready to fulfill your order in the shortest possible time, and we guarantee the high quality of printed products, in full accordance with the provided STL file.

Take advantage of high-precision and high-strength metal 3D printing - electron beam melting (EBM).

File types for 3D modeling and 3D printing

Almost everyone knows what types of files are used to save images: PNG, JPG, BMP, TIFF and others. But what about volume models? It would seem that we are adding a third dimension, but the file size is often smaller than even the image of the same model. In this article, we will tell you everything you need to know about files for storing models and even more: conversion methods, features of each type of file, and the file format for 3D printing. nine0005

3D model storage features

Unlike images, the voxel (voxel - volumetric pixel) storage method has not taken root in the world of 3D models. Only a few craftsmen use it when creating games or in scientific research. This is due to the history of the emergence of three-dimensional graphics: unlike the appearance of photography, three-dimensional graphics were originally created on a computer, and were used for animation. Voxels are much more difficult to animate, so they began to use the polygon storage method instead: the entire model consists of many polygons - triangles that have three points. It's like creating sculptures out of paper - by putting together a lot of flat pieces, you can get something voluminous and even smooth. nine0005

It's like creating sculptures out of paper - by putting together a lot of flat pieces, you can get something voluminous and even smooth. nine0005

Dolphin Polygon Model

Although this method of saving as polygons cannot be called raster, these methods have much in common: the impossibility of increasing the quality, the direct relationship between the quality and file weight, ease of editing. This is the most practical format for saving and using models in 3D printing, but not the only one. Next, we will look at the most popular formats for storing 3D models. nine0005

Universal 3D Model File Formats

In fact, there are as many different methods for storing 3D models as there are for storing photos and videos. But there are also universal formats that, although with some restrictions, can be opened in almost any program.

STL

Contrary to misconceptions, STL was not originally intended for artistic modeling. It was developed by the Albert Consulting Group and was intended for an early 3D printing method - stereolithography. Hence the name of the file - STereoLithography. After some time, the company openly published the format and since then it has gained immense popularity. nine0005

It was developed by the Albert Consulting Group and was intended for an early 3D printing method - stereolithography. Hence the name of the file - STereoLithography. After some time, the company openly published the format and since then it has gained immense popularity. nine0005

The STL format is widely used due to the simplicity of its structure: polygons (facets) and their normals. The former are needed to set the surface, and the latter to indicate where the outer side of the polygon is located. Therefore, this format can be considered the most universal.

Comparison of CAD model and STL model

Due to the fact that the model is defined using many triangles, it is impossible to accurately define curved surfaces, because this would require an infinite number of triangles, and therefore an infinite data store. But when used in 3D printing, this minus is not so important, since the accuracy specified using triangles is higher than the printing accuracy. nine0005

nine0005

OBJ

This format is very similar to STL, but differs in the ability to apply textures, set the material and store other information. Therefore, OBJ can be called an extended version of STL and is mainly intended for artistic modeling programs such as Blender, Autodesk Maya, 3Ds Max, Meshlab and others.

OBJ model processing in Blender

STEP

Now we are moving on to the engineering side of 3D modeling, because STEP is the only format that can be opened in any engineering modeling program and freely edited with the tools built into the program. STEP was originally developed as a world standard format for storing products on a computer, and was intended for a complete development cycle of a part. That is why all serious engineering modeling and physical simulation programs can work with this format. A distinctive feature of STEP is its high accuracy: the model is created with tools that allow you to set curves using formulas. Therefore, the precision in this format is infinite: no matter how much you increase it, the curved line will remain a curve, and will not become a lot of straight lines. nine0005

Therefore, the precision in this format is infinite: no matter how much you increase it, the curved line will remain a curve, and will not become a lot of straight lines. nine0005

Creating a model in CAD SolidWorks

To create models in STEP format, CAD (Computer-Aided Design) is used. Thanks to the ISO standard, all CAD programs can work in this format. But not all data is freely transferred from one program to another via STEP. For us, the most important thing is the transfer of model geometry, and simulations, material and other data that the STEP format does not store are of secondary importance. nine0005

Proprietary sizes

This category includes file formats that can only be opened in one program - in which the files were created. They are intended only for storing projects, often they cannot be used in 3D printing. An exception is the Ultimaker Cura slicer, which has the ability to add plug-ins that allow you to open files of programs such as Inventor, Siemens NX, Solidworks and others directly from the slicer.

Engineering programs

As mentioned earlier, these programs are called CAD. Since this software is often intended for production, they also have a common file format (STEP). Some programs, often produced by one company, allow you to work in a common ecosystem. For example, in many of Autodesk's engineering software, format compatibility can be found: Fusion 360 can open a file created in Inventor. But with this method of opening, some information about the product will still be lost, for example, information about the physical simulations performed. Therefore, if the part is not developed to the end, you should not move it between different programs. nine0005

Arts programs

This category includes programs created for visualization: animation, special effects, creation of figures and models for video games. Unlike the previous case, chaos reigns in artistic modeling programs. Each program has its own format, and the general STL format limits the functionality of each program to the simplest tools. But this is enough to create models that will later be printed on a 3D printer, since only the geometry of the model is important. nine0005

But this is enough to create models that will later be printed on a 3D printer, since only the geometry of the model is important. nine0005

Gcode - format for 3D printing

Actually Gcode is more than just a file format. It is a separate programming language. But instead of executing commands by a computer, commands in this language are executed by a 3D printer. Initially, this language was developed for complex CNC machines, and a 3D printer is one of the simplest representatives of this type of device. Unlike previous formats, gcode can be easily edited manually, thereby giving commands to the printer directly, bypassing the computer. With this, you can create macros that make it easier to work with a 3D printer. You can read more about working with the gcode language and creating macros in an article on our website. nine0005

3D model file format conversion

If you have a need to move the model between programs for 3D modeling, then you should determine in which group the program is from where and where you want to move the model.