3D metal printing research

Researchers Uncover How to 3D-Print One of the Strongest Stainless Steels

A microscopic image of 3D-printed 17-4 stainless steel. The colors in the left-side version of the image represent the differing orientations of crystals within the alloy.

Credit: Q. Guo/University of Wisconsin-Madison

For airliners, cargo ships, nuclear power plants and other critical technologies, strength and durability are essential. This is why many contain a remarkably strong and corrosion-resistant alloy called 17-4 precipitation hardening (PH) stainless steel. Now, for the first time ever, 17-4 PH steel can be consistently 3D-printed while retaining its favorable characteristics.

A team of researchers from the National Institute of Standards and Technology (NIST), the University of Wisconsin-Madison and Argonne National Laboratory has identified particular 17-4 steel compositions that, when printed, match the properties of the conventionally manufactured version. The researchers’ strategy, described in the journal Additive Manufacturing, is based on high-speed data about the printing process they obtained using high-energy X-rays from a particle accelerator.

The new findings could help producers of 17-4 PH parts use 3D printing to cut costs and increase their manufacturing flexibility. The approach used to examine the material in this study may also set the table for a better understanding of how to print other types of materials and predict their properties and performance.

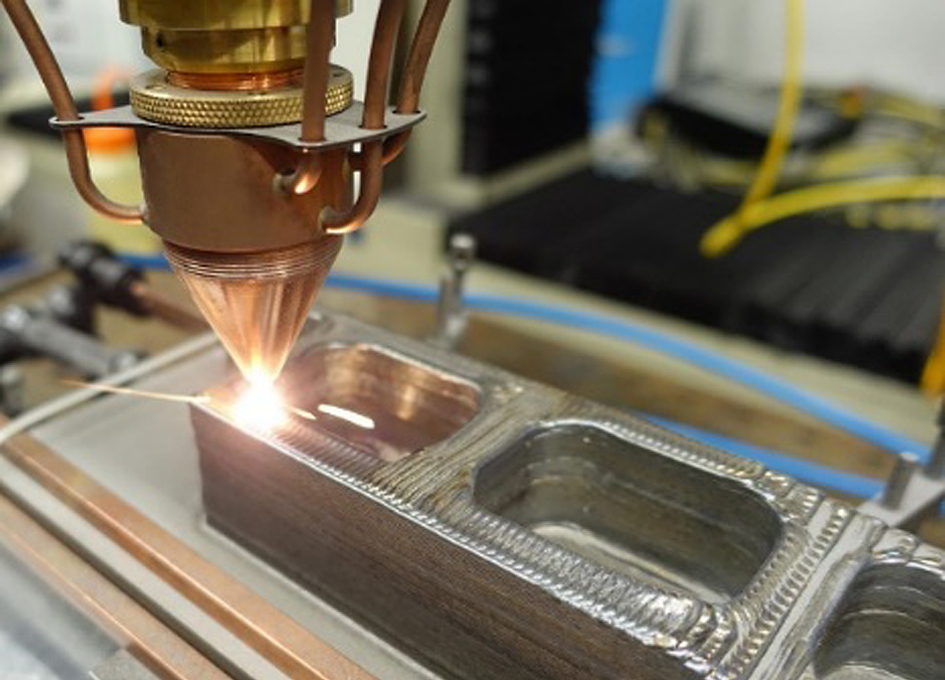

Despite its advantages over conventional manufacturing, 3D-printing of some materials can produce results that are too inconsistent for certain applications. Printing metal is particularly complex, in part because of how quickly temperatures shift during the process.

“When you think about additive manufacturing of metals, we are essentially welding millions of tiny, powdered particles into one piece with a high-powered source such as a laser, melting them into a liquid and cooling them into a solid,” said NIST physicist Fan Zhang, a study co-author. “But the cooling rate is high, sometimes higher than one million degrees Celsius per second, and this extreme nonequilibrium condition creates a set of extraordinary measurement challenges.”

“But the cooling rate is high, sometimes higher than one million degrees Celsius per second, and this extreme nonequilibrium condition creates a set of extraordinary measurement challenges.”

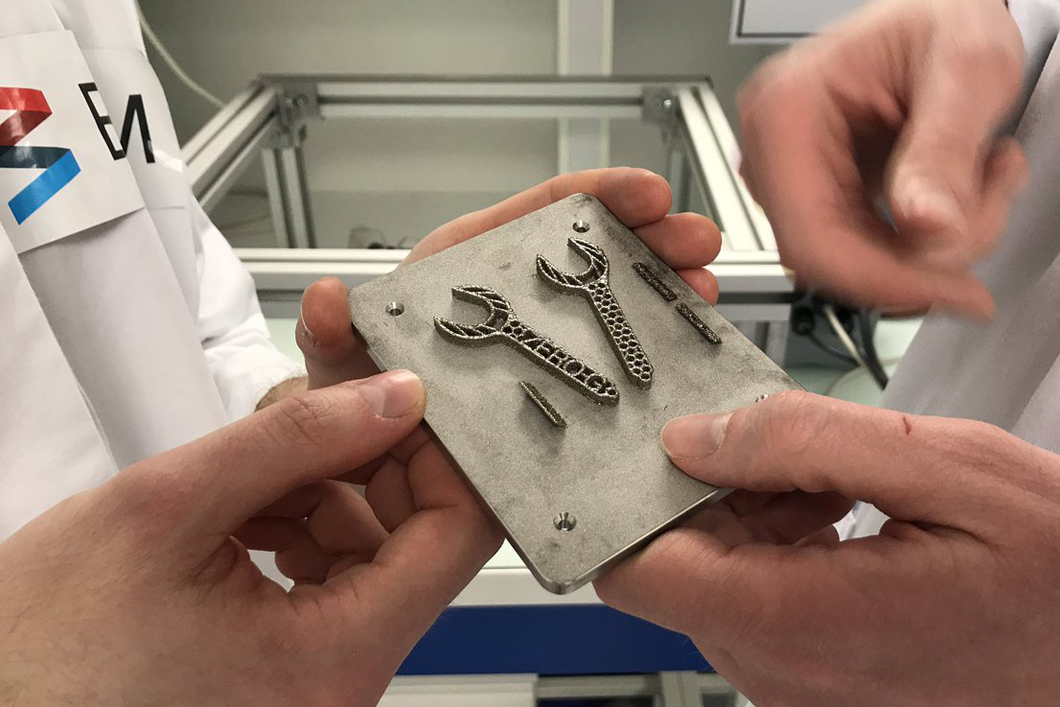

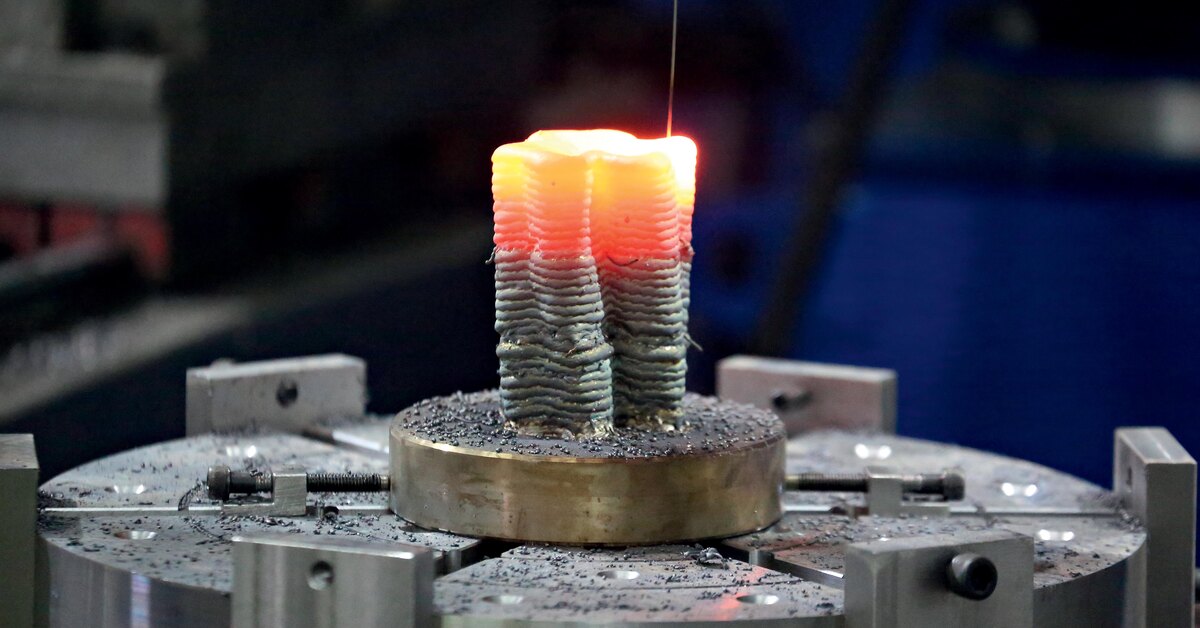

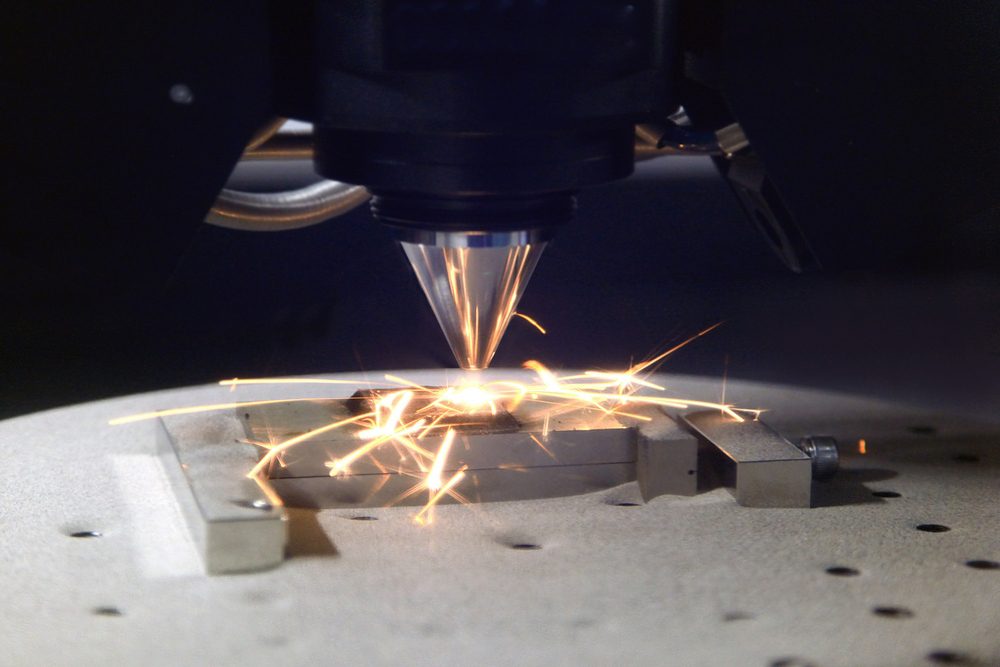

3D Printing with a Laser and Metal Powder

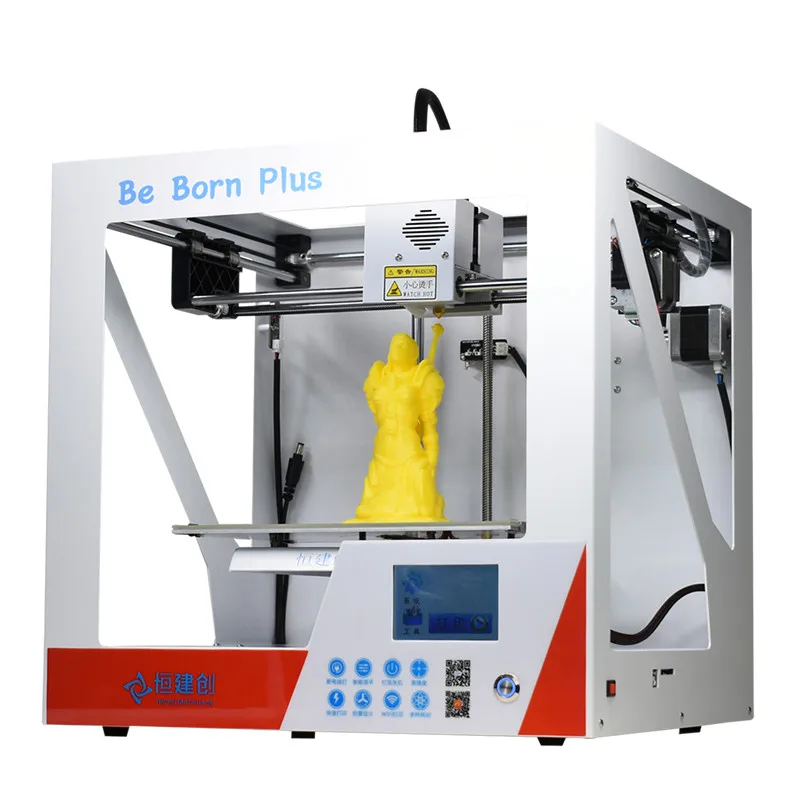

A 3D printer of the laser powder-bed fusion type, in action. Laser powder-bed fusion adds successive layers of metal powder and then uses a laser to melt each layer into place on the part being created.Because the material heats and cools so hastily, the arrangement, or crystal structure, of the atoms within the material shifts rapidly and is difficult to pin down, Zhang said. Without understanding what is happening to the crystal structure of steel as it is printed, researchers have struggled for years to 3D-print 17-4 PH, in which the crystal structure must be just right — a type called martensite — for the material to exhibit its highly sought-after properties.

The authors of the new study aimed to shed light on what happens during the fast temperature changes and find a way to drive the internal structure toward martensite.

Just as a high-speed camera is needed to see a hummingbird’s flapping wings, the researchers needed special equipment to observe rapid shifts in structure that occur in milliseconds. They found the right tool for the job in synchrotron X-ray diffraction, or XRD.

“In XRD, X-rays interact with a material and will form a signal that is like a fingerprint corresponding to the material’s specific crystal structure,” said Lianyi Chen, a professor of mechanical engineering at UW-Madison and study co-author.

At the Advanced Photon Source (APS), a powerful light source at the Department of Energy's Argonne National Laboratory, the authors smashed high-energy X-rays into steel samples during printing.

The authors mapped out how the crystal structure changed over the course of a print, revealing how certain factors they had control over — such as the composition of the powdered metal — influenced the process throughout.

While iron is the primary component of 17-4 PH steel, the composition of the alloy can contain differing amounts of up to a dozen different chemical elements. The authors, now equipped with a clear picture of the structural dynamics during printing as a guide, were able to fine-tune the makeup of the steel to find a set of compositions including just iron, nickel, copper, niobium and chromium that did the trick.

The authors, now equipped with a clear picture of the structural dynamics during printing as a guide, were able to fine-tune the makeup of the steel to find a set of compositions including just iron, nickel, copper, niobium and chromium that did the trick.

“Composition control is truly the key to 3D-printing alloys. By controlling the composition, we are able to control how it solidifies. We also showed that, over a wide range of cooling rates, say between 1,000 and 10 million degrees Celsius per second, our compositions consistently result in fully martensitic 17-4 PH steel,” Zhang said.

As a bonus, some compositions resulted in the formation of strength-inducing nanoparticles that, with the traditional method, require the steel to be cooled and then reheated. In other words, 3D printing could allow manufacturers to skip a step that requires special equipment, additional time and production cost.

Mechanical testing showed that the 3D-printed steel, with its martensite structure and strength-inducing nanoparticles, matched the strength of steel produced through conventional means.

The new study could make a splash beyond 17-4 PH steel as well. Not only could the XRD-based approach be used to optimize other alloys for 3D printing, but the information it reveals could be useful for building and testing computer models meant to predict the quality of printed parts.

“Our 17-4 is reliable and reproducible, which lowers the barrier for commercial use. If they follow this composition, manufacturers should be able to print out 17-4 structures that are just as good as conventionally manufactured parts,” Chen said.

Paper: Q. Guo, M. Qu, C.A. Chuang, L. Xiong, A. Nabaaa, Z.A. Young, Y. Ren, P. Kenesei, F. Zhang, and L. Chen. Phase transformation dynamics guided alloy development for additive manufacturing. Additive Manufacturing. Published online Aug. 2, 2022. DOI: 10.1016/j.addma.2022.103068

Manufacturing, Additive manufacturing, Sustainable manufacturing, Materials and Metals

What is the Future of Metal Additive Manufacturing?

Published on June 8, 2022 by Madeleine P.

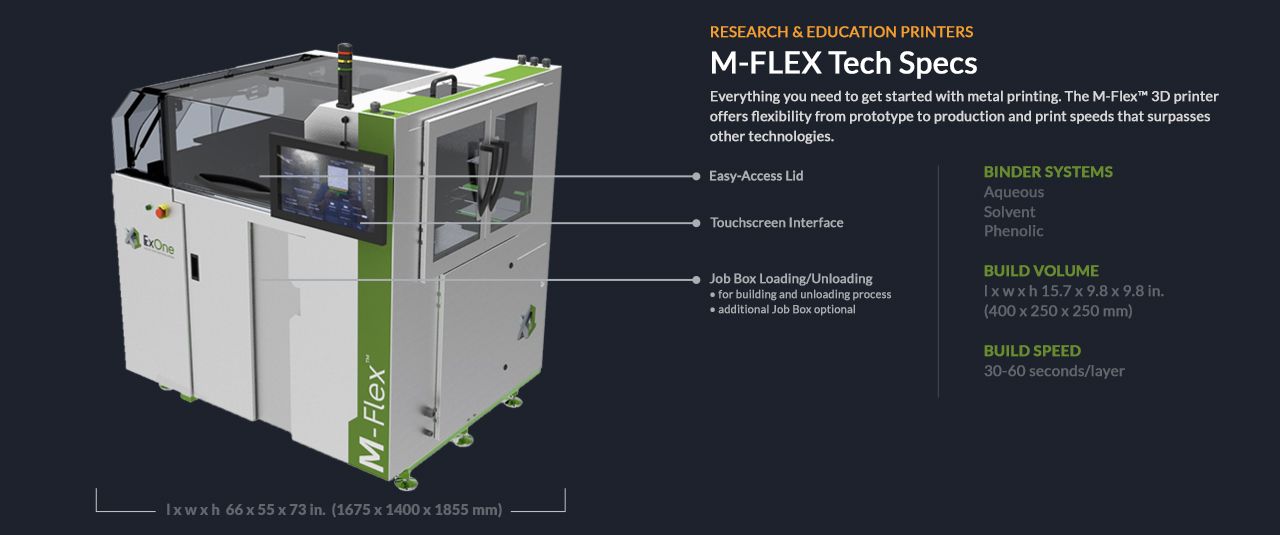

Earlier this year, research firm IDTechEx published a report on metal additive manufacturing, estimating that its value would reach $18.5 billion within 10 years, showing a gradual recovery of the market. As part of this study, the firm conducted an analysis of the future of the metal additive manufacturing market by comparing the different processes that exist, seeking to understand the major trends in the sector but also possible future sources of revenue. Powder bed processes, concentrated energy deposition (CED), wire extrusion: which technology should you focus on? Where does the future of metal 3D printing lie?

Fourteen 3D printing processes were analyzed and compared in the IDTechEx study. Among them, there are of course the most well-known technologies such as Binder Jetting, DED, extrusion (whether with granules, paste or even filaments), laser powder bed fusion, but also less popular processes such as electrochemical deposition or cold spray. For each process, criteria such as print volume, accuracy, price of the machine and material, and necessary post-processing steps were compared, with the aim of evaluating strengths and weaknesses.

IDTechEx compared 14 metal 3D printing processes according to specific criteria (photo credits: IDTechEx)

Current Market Trends

As with many other technologies, price and build volume are two key factors to which users are particularly sensitive. Starting with the former, you probably know that metal powder is expensive, especially when it comes to uniform powder. This is a major barrier to entry for many companies, preventing them therefore from turning to powder processes, even though there are many on the market today. This is where we see a trend emerging: the development of extrusion technologies, more specifically the deposition of metal filaments – or rods – and granules. One example is manufacturers such as Meltio, who has developed a machine that combines two types of raw materials to lower the cost of a 3D printed part. More and more players specialized in FDM/FFF have also presented extruders capable of supporting metallic materials.

Of course, some processes are historically based on a raw material other than metal powder – DED comes to mind, for example, but also sand powder binding. The main disadvantage of these two technologies is the entry price of the machines on the market. If you look at the IDTechX comparison chart, you will see that these are the most expensive 3D printers. A user looking for a more economical solution probably would therefore tend to go for an extrusion solution.

The main disadvantage of these two technologies is the entry price of the machines on the market. If you look at the IDTechX comparison chart, you will see that these are the most expensive 3D printers. A user looking for a more economical solution probably would therefore tend to go for an extrusion solution.

If we now look at build volume, we see that the metal additive manufacturing market offers a wide range when it comes to size. Users can design smaller parts on laser melting machines for example, but also large components via processes like cold spray. So the trend is encouraging, users would not be held back by the volume currently on offer. As a result, they can expand the range of possible applications and thus increase the use of metal 3D printing.

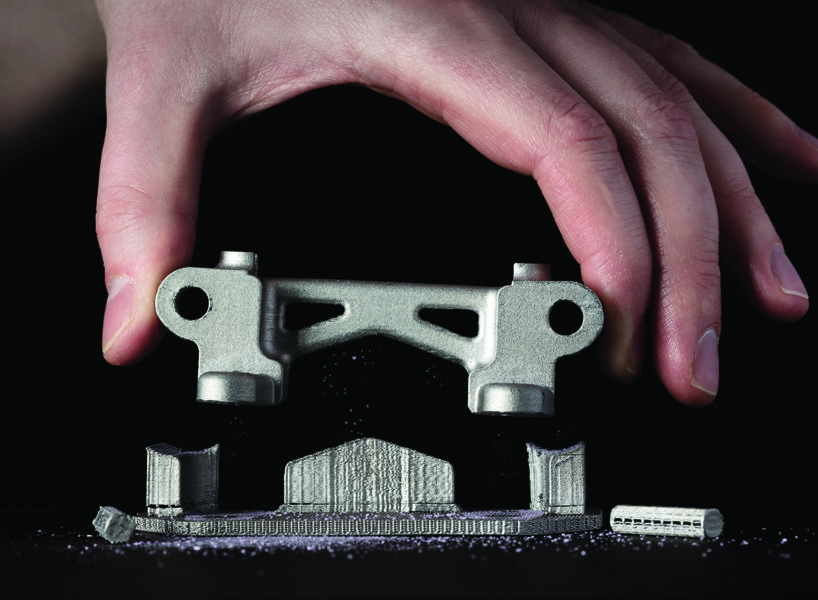

Current solutions allow the design of parts of varying sizes (photo credits: 3D Systems)

What is the Future of Metal Additive Manufacturing?

According to the results in the survey, it would seem that a metal 3D printer combining a relatively low entry price (or even with a lower raw material cost) with a large build volume would be a sensation for users. Mind you, when we talk about the price of the machine, we are talking about $500,000. Today’s solutions with a large printing volume cost several million dollars. In addition to this, the key properties of a metal 3D printer are surface finish and tensile strength: users want a solution that is capable of designing quality parts that meet the most demanding requirements.

Mind you, when we talk about the price of the machine, we are talking about $500,000. Today’s solutions with a large printing volume cost several million dollars. In addition to this, the key properties of a metal 3D printer are surface finish and tensile strength: users want a solution that is capable of designing quality parts that meet the most demanding requirements.

Finally, the IDTechX report shows that a balance must be struck between manufacturing speed and resolution. Current technologies often sacrifice one of the two – typically, good surface finish is favored at the expense of high material throughput. What if we could combine the two? If some polymer processes have been able to do this, such as Carbon’s DLS technology or EnvisonTec’s cDLM, why not metal additive manufacturing? This is what we will have to observe in the next few years: the combination of speed and resolution to go towards the production of finished parts in large series. In any case, you can be assured that we will certainly be keeping an eye on this! In the meantime, you can read the whole study HERE.

What do you think will be the future of metal additive manufacturing? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Lasercutting

How metal 3D printers work. Overview of SLM and DMLS technologies. additive manufacturing. 3D metal printing.

Metal 3D printing. Additive technologies.

SLM or DMLS: what's the difference?

Hello everyone, Friends! 3DTool is with you!

BLT metal 3D printer catalog

Selective laser melting ( SLM ) and direct metal laser sintering ( DMLS ) are two additive manufacturing processes that belong to the family of 3D printing using the powder layer method. The two technologies have much in common: they both use a laser to selectively melt (or melt) metal powder particles, bonding them together and creating a pattern layer by layer. In addition, the materials used in both processes are metals in granular form.

In addition, the materials used in both processes are metals in granular form.

The differences between SLM and DMLS come down to the basics of the particle bonding process: SLM uses metal powders with a single melting point and completely melts the particles, while in DMLS the powder consists of materials with variable melting points. nine0014

Specifically:

SLM produces single metal parts while DMLS produces metal alloy parts.

Both SLM and DMLS technologies are used in industry to create final engineering products. In this article, we will use the term "metal 3D printing" to summarize the 2 technologies. We will also describe the main mechanisms of the manufacturing process that are necessary for engineers to understand the advantages and disadvantages of these technologies. nine0002 There are other manufacturing processes for producing dense metal parts, such as electron beam melting (EBM) and ultrasonic additive manufacturing (UAM). Their availability and distribution is rather limited, so they will not be presented in this article.

nine0002 There are other manufacturing processes for producing dense metal parts, such as electron beam melting (EBM) and ultrasonic additive manufacturing (UAM). Their availability and distribution is rather limited, so they will not be presented in this article.

How 3D printing with SLM or DMLS metal works.

How does metal 3D printing work? The basic manufacturing process for SLM and DMLS is very similar.

1. The printing chamber is first filled with an inert gas (such as argon) to minimize the oxidation of the metal powder. It then heats up to the optimum operating temperature. nine0002 2. A layer of powder is spread over the platform, a powerful laser makes passes along a predetermined path in the program, fusing the metal particles together and creating the next layer.

3. When the sintering process is completed, the platform moves down 1 layer. Next, another thin layer of metal powder is applied. The process is repeated until the entire model is printed.

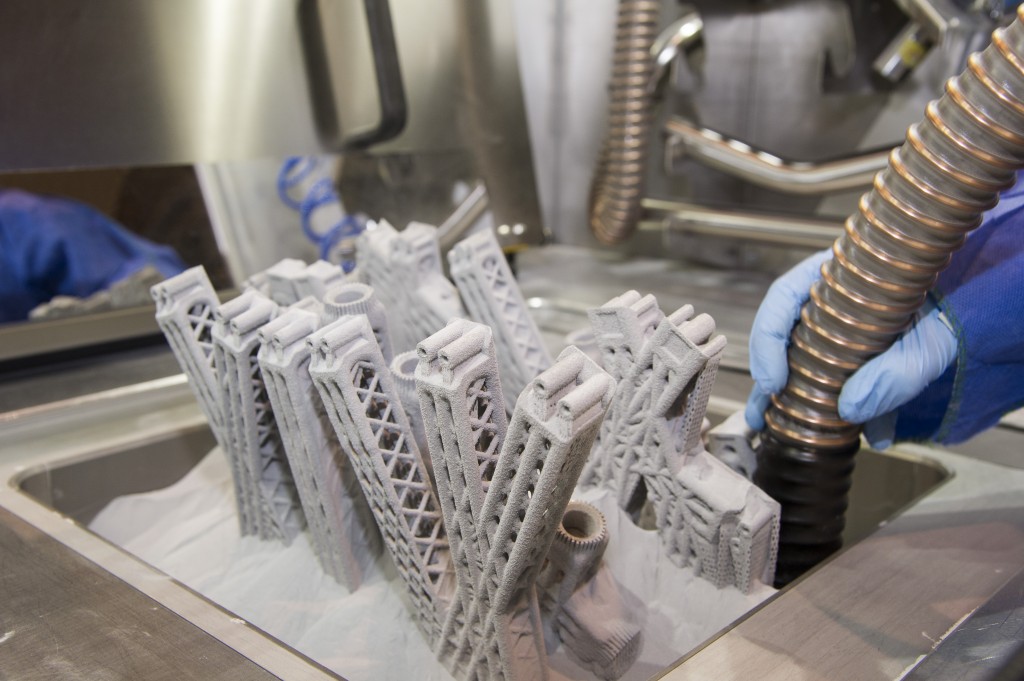

When the printing process is completed, the metal powder already has strong bonds in the structure. Unlike the SLS process, parts are attached to the platform via support structures. The support in metal 3D printing is created from the same material as the base part. This condition is necessary to reduce deformations that may occur due to high processing temperatures. nine0002 When the 3D printer's chamber cools down to room temperature, excess powder is removed manually, such as with a brush. The parts are then typically heat treated while they are still attached to the platform. This is done to relieve any residual stresses. They can then be further processed. The removal of the part from the platform occurs by means of sawing.

Scheme of operation of a 3D printer for metal.

In SLM and DMLS, almost all process parameters are set by the manufacturer. The layer height used in metal 3D printing varies from 20 to 50 microns and depends on the properties of the metal powder (fluidity, particle size distribution, shape, etc.). nine0002 The basic size of the print area on metal 3D printers is 200 x 150 x 150 mm, but there are also larger sizes of the working area. Printing accuracy is from 50 - 100 microns. As of 2020, metal 3D printers start at $150,000. For example, our company offers 3D metal printers from BLT.

The layer height used in metal 3D printing varies from 20 to 50 microns and depends on the properties of the metal powder (fluidity, particle size distribution, shape, etc.). nine0002 The basic size of the print area on metal 3D printers is 200 x 150 x 150 mm, but there are also larger sizes of the working area. Printing accuracy is from 50 - 100 microns. As of 2020, metal 3D printers start at $150,000. For example, our company offers 3D metal printers from BLT.

metal 3D printers can be used for small batch production, but the 3D printing capabilities of such systems are more like those of mass production on FDM or SLA machines. nine0002 The metal powder in SLM and DMLS is recyclable: typically less than 5% is consumed. After each impression, the unused powder is collected and sieved, and then topped up with fresh material to the level required for the next production.

Waste in metal printing, are supports (support structures, without which it will not be possible to achieve a successful result). With too much support on the manufactured parts, the cost of the entire production will increase accordingly. nine0002

With too much support on the manufactured parts, the cost of the entire production will increase accordingly. nine0002

Adhesion between coats.

3D metal printing on BLT 3D printers

SLM and DMLS metal parts have almost isotropic mechanical and thermal properties. They are hard and have very little internal porosity (less than 0.2% in 3D printed condition and virtually non-existent after processing).

Metal printed parts have higher strength and hardness and are often more flexible than traditionally made parts. However, such metal becomes “tired” faster. nine0014

3D model support structure and part orientation on the work platform.

Support structures are always required when printing with metal, due to the very high processing temperatures. They are usually built using a lattice pattern.

Supports in metal 3D printing perform 3 functions:

• They form the basis for creating the first layer of the part.

• They secure the part to the platform and prevent it from deforming.

• They act as a heat sink, removing heat from the model. nine0014

Parts are often oriented at an angle. However, this will increase the amount of support required, the printing time, and ultimately the overall cost.

Deformation can also be minimized with laser sintering templates. This strategy prevents the accumulation of residual stresses in any particular direction and adds a characteristic surface texture to the part.

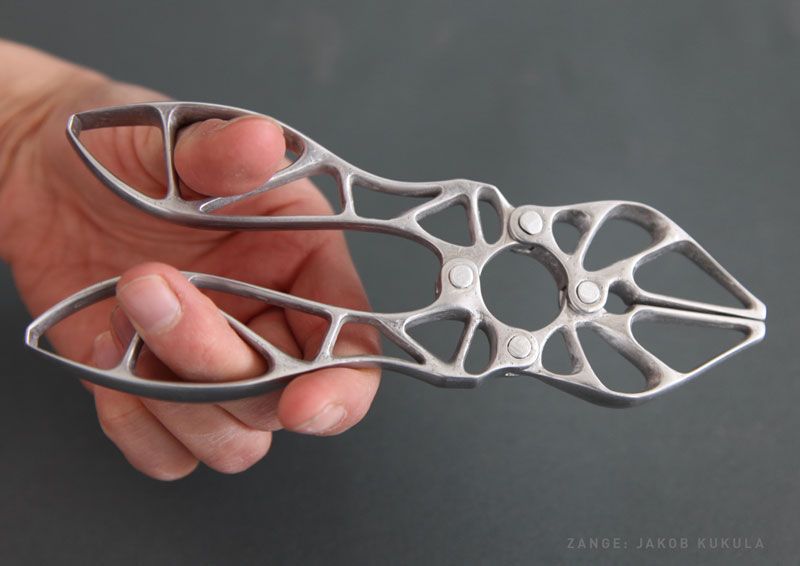

Since the cost of metal printing is very high, software simulations are often used to predict how a part will behave during processing. These topology optimization algorithms are otherwise used not only to increase mechanical performance and create lightweight parts, but also to minimize the need for supports and the likelihood of part distortion. nine0014

nine0014

Hollow sections and lightweight structures.

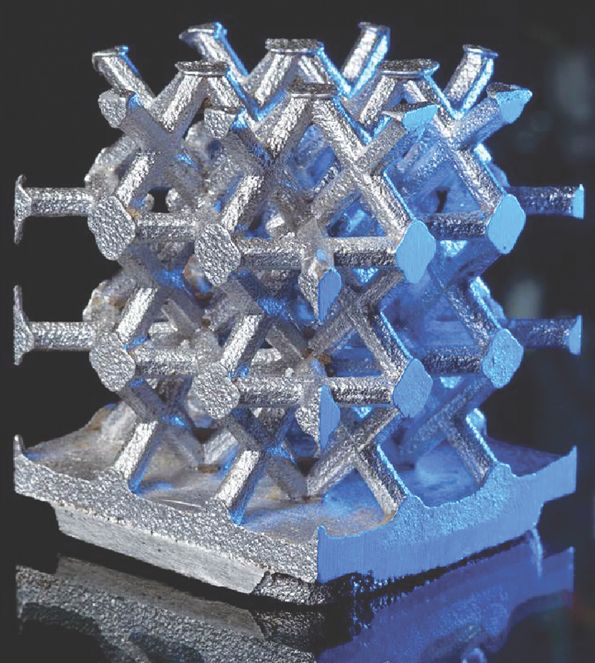

An example of printing on a BLT 3D printer

Unlike polymer powder melt processes such as SLS, large hollow sections are not typically used in metal printing as the support would be very difficult to remove, if at all possible.

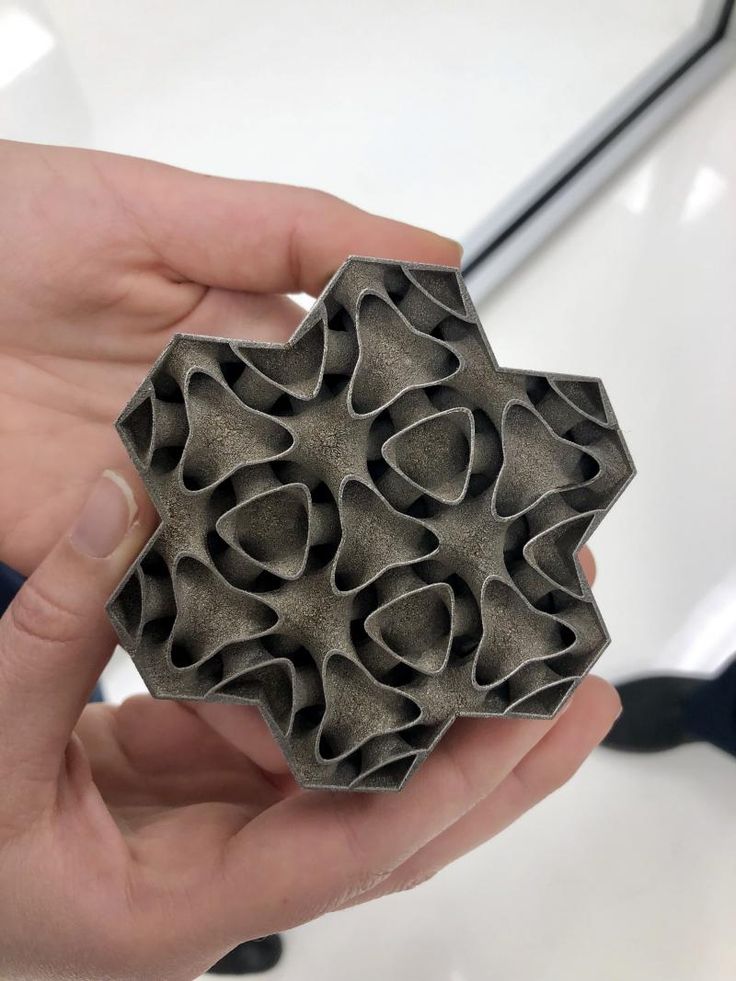

For internal channels larger than Ø 8 mm, it is recommended to use diamond or teardrop cross-sections instead of round ones, as they do not require support. More detailed recommendations on the design of SLM and DMLS can be found in other articles on this topic. nine0014

As an alternative to hollow sections, parts can be made with sheath and cores, which in turn are machined using different laser power and pass speeds, resulting in different material properties. The use of sheath and cores is very useful when making parts with a large solid section, as it greatly reduces printing time and reduces the chance of warping.

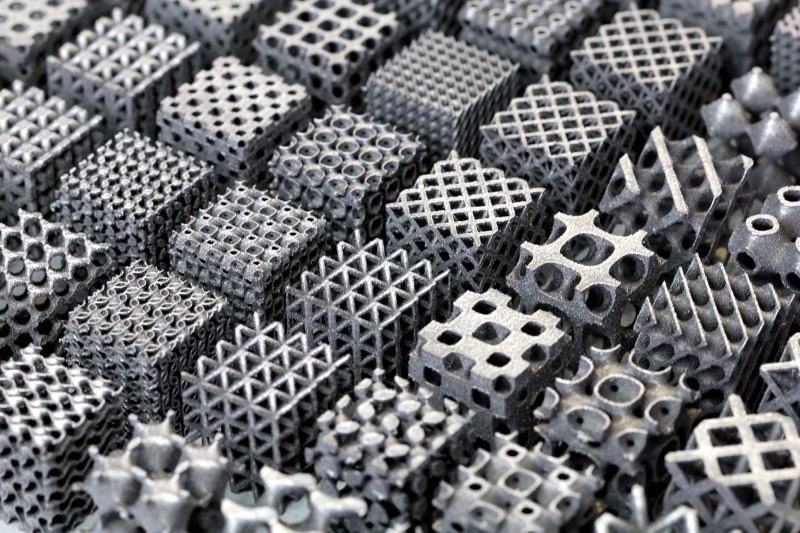

The use of a lattice structure is a common strategy in metal 3D printing to reduce part weight. Topology optimization algorithms can also help design organic lightweight shapes. nine0014

Consumables for 3D metal printing.

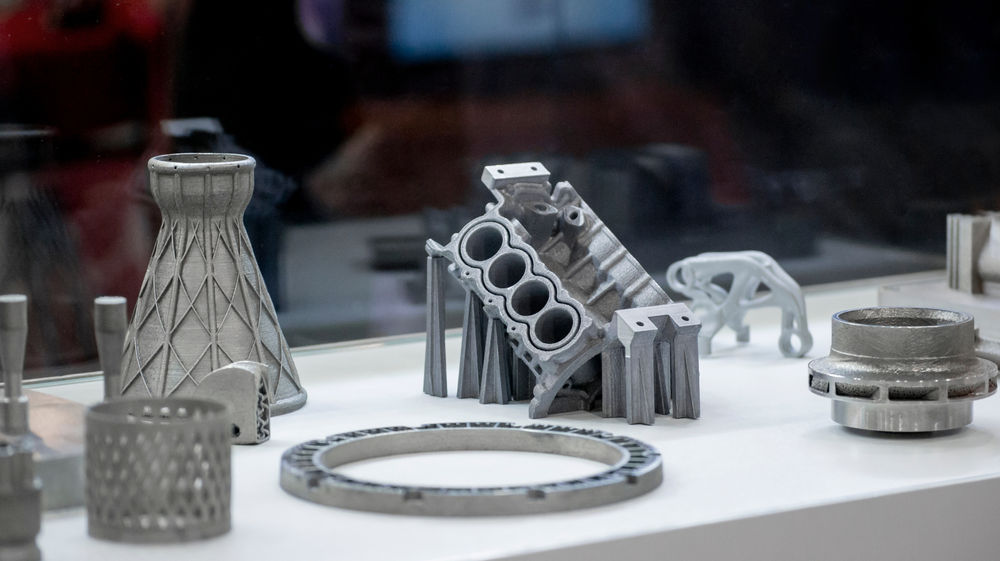

SLM and DMLS technologies can produce parts from a wide range of metals and metal alloys, including aluminum, stainless steel, titanium, cobalt, chromium and inconel. These materials meet the needs of most industrial applications, from aerospace to medical applications. Precious metals such as gold, platinum, palladium and silver can also be processed, but their use is of a minor nature and is mainly limited to jewelry making. nine0014

The cost of metal powder is very high. For example, a kilogram of 316 stainless steel powder costs approximately $350-$450. For this reason, minimizing part volume and the need for supports is key to maintaining optimal manufacturing cost.

The main advantage of metal 3D printing is its compatibility with high-strength materials such as nickel or cobalt-chromium superalloys, which are very difficult to machine with traditional methods. Significant cost and time savings can be achieved by using metal 3D printing to create a near-clean shape part. Subsequently, such a part can be processed to a very high surface quality. nine0002

Significant cost and time savings can be achieved by using metal 3D printing to create a near-clean shape part. Subsequently, such a part can be processed to a very high surface quality. nine0002

Metal post-processing.

Various post methods. treatments are used to improve the mechanical properties, accuracy and appearance of metal printed products.

Mandatory post-processing steps include the removal of loose powder and support structures, while heat treatment (heat annealing) is typically used to relieve residual stresses and improve the mechanical properties of the part.

CNC machining can be used for critical features (such as holes or threads). Sandblasting, plating, polishing, and micro-machining can improve the surface quality and fatigue strength of a metal printed part. nine0014

Advantages and disadvantages of metal 3D printing.

Pros:

1. Metal 3D printing can be used to make complex custom parts, with geometries that traditional manufacturing methods cannot provide.

Metal 3D printing can be used to make complex custom parts, with geometries that traditional manufacturing methods cannot provide.

2. Metal 3D printed parts can be optimized to increase their performance with minimal weight.

3. Metal 3D printed parts have excellent physical properties, metal 3D printers can print a wide range of metals and alloys. Includes difficult-to-machine materials and metal superalloys. nine0014

Cons:

1. Manufacturing costs associated with metal 3D printing are high. The cost of consumables is from $ 500 per 1 kg.

2. The size of the working area in metal 3D printers is limited.

Conclusions.

• Metal 3D printing is most suitable for complex, one-piece parts that are difficult or very expensive to manufacture using traditional methods, such as CNC.

• Reducing the need for building supports, will significantly reduce the cost of printing with metal. nine0002 • 3D printed metal parts have excellent mechanical properties and can be made from a wide range of engineering materials, including superalloys.

nine0002 • 3D printed metal parts have excellent mechanical properties and can be made from a wide range of engineering materials, including superalloys.

And that's all we have! We hope the article was useful to you.

Catalog of 3D printers for metal BLT

You can purchase metal 3d printers, as well as any other 3d printers and CNC machines, by contacting us:

• By email: [email protected]

• By phone: 8(800)775-86-69

• Or on our website: http://3dtool.ru

Also, don't forget to subscribe to our YouTube channel:

Subscribe to our groups in social networks:

In contact with

The current state of metal 3D printing in 2020

Metal printing as a form of 3D printing has grown over the past couple of years. Technology has made great strides in speed and material versatility, and many different technologies have been tried by a number of companies. While plastics are still the most popular materials used by companies and external services, metal-printed components are second only to resins, while both outperform ceramics. Needless to say, a lot has changed from just 5 years ago, so in this article, we're going to take a look at the specifics of how the metal printing industry is doing in 2020. nine0014

While plastics are still the most popular materials used by companies and external services, metal-printed components are second only to resins, while both outperform ceramics. Needless to say, a lot has changed from just 5 years ago, so in this article, we're going to take a look at the specifics of how the metal printing industry is doing in 2020. nine0014

Here are our key findings:

Industry Overview and Important Case Studies

Metallic printing has increased somewhat in use, increased market size, and attracted manufacturers. The rise in these statistics has been driven by an overall reduction in costs as well as increased awareness of the unique elements that 3D printing brings to the table. According to Grandview Research, the metal printing market was valued at $772.1 million in 2019, with a CAGR of 27.8% from 2020 to 2027. Similarly, Technavio's global market research suggests that the industry will grow by 1.59 between 2020 and 2024.billion dollars with an average annual growth rate of more than 26%. In any case, by both estimates, the industry looks pretty healthy.

In any case, by both estimates, the industry looks pretty healthy.

Greater design flexibility, low waste and cost-effectiveness have all contributed to this growth. Thanks to many important transactions in many manufacturing industries, there was a shift towards increasing the production of the final product, as a result of which more firms turned their attention to this technology. Laser systems and powders in particular have become a bit cheaper, but still quite expensive (which we'll talk about later in the materials section). nine0014

Image courtesy of Grandview Research

Adoption is on the rise, although much of it is through external parties and services rather than internal systems. According to a survey of 1,000 respondents, 36% of companies used metal components for 3D printing in 2018, up from 28% in 2017. This trend continues in the Sculpteo State of 3D Printing study, which found 45% of companies use metal as a material for 3D printing, with an additional 10% considering adding it to their own business in some way, be it external or internal. . nine0014

. nine0014

The 3D printing industry as a whole is developing rapidly, 3D printers are becoming faster, more reliable and more productive, and this also applies to metal printers. In terms of industries, the most notable are the automotive, medical, defense and aerospace industries. All of these industries are looking to use metal printing for rapid prototyping, end products, tools, and R&D. For example, rapid prototyping in the aerospace segment is expected to exceed US$105 million by 2026 for all materials combined. Aerospace companies mainly use 3D printing and metal printing technologies to minimize the cost of developing models and prototypes. nine0014

Specifically, NASA intends to 3D print more than 80% of its future rocket engines using metal systems. By the end of the year, it is expected to invest $3.5 billion in a plant to produce 100,000 fuel injectors per year for the aerospace giant's engines. The companies are making big deals with well-known aerospace firms, such as Velo3D donating their machines to SpaceX, and also announced that they raised $28 million in funding this April. nine0014

nine0014

The defense sector is another big player that is showing some interest from major 3D printing giants. The US Army commissioned 3D Systems to develop a prototype printer for them, mainly for the production of strong steel components and weapons. The commission was budgeted at US$15 million with a request to create objects up to 1×1 by 0.6 meters. The massive laser printer can process alloys designed to make bombs to destroy bunkers, so it is sure to be an important manufacturing system for the military. nine0014

In recent years, metal printing has also been widely used in the medical industry. Notable examples include 3D printed Stryker implants, including the 3D printed Tritanium TL Curved Posterior Lumbar Cage, which received FDA approval in March 2018. Similarly, Slice Mfg. Studios says each of its Arcam Q10 EBM machines can produce about 70 femoral acetabulums. cups every five days. Techniques such as EBM and SLM have also played a critical role in the very rapid development of specialized tooling, allowing hospitals to manufacture parts on site without long waiting times. nine0014

nine0014

The automotive industry has also released several breakthrough use cases. BMW is a strong player in terms of the scale and size of its 3D printing operation. Since 2010, a well-known automotive company has surpassed one million 3D printed parts (in all materials, not just metal). In terms of mass production, BMW plans to produce 50,000 components per year and 10,000 individual parts. Those parts include the i8 Roadster's roof bracket and window rail, and the entire M850i Coupe Night Sky Edition brake caliper. nine0014

Ford also works very well with 3D printing. Shortly before this year, Ford Performance printed what they say is the largest 3D printed metal automotive part of all time. The aluminum manifold inlet forms a complex mesh structure that would be impossible to manufacture using traditional manufacturing systems. On the other hand, the printers developed the part in five days. Overall, Ford's entire 3D printing operation saves them about half a million dollars a month. nine0014

nine0014

Volkswagen uses HP inkjet systems for thousands of parts and has announced plans to expand its functional parts additive manufacturing operations. Volvo, Volkswagen and Bugatti have been the main developers of this technology in recent years. They all use it to make tools, prototypes, and fixtures, but metal parts are especially important in end-use applications.

Technologies and materials

Image via HP

With the rise of technology, there are quite a few standouts in this sector. DMLS/SLM are currently the most heavily used, with most of the usage related to external services. Binder Jetting and Electron Beam Manufacturing are also key metal fabrication technologies with significant market share (40% and 28% of companies respectively). 50% of Sculpteo's respondents using metal printing tend to use selective laser sintering, inkjet welding, SLM/DMLS and inkjet printing with external services. They mainly use these technologies to offset equipment/maintenance costs. nine0014

nine0014

DMLS or SLM are probably the most commonly used technologies at the moment. The use of steel, aluminum and titanium makes it ideal for the aerospace, medical, dental and automotive industries. The main advantage that companies find in SLM over other manufacturing methods is the ability to produce lightweight complex functional metal structures at a relatively low cost.

Binder spraying is another popular technique, but it still has several barriers due to material availability. The most common alloys are stainless steels and tool steels such as 1.4404/316L or 1.4542/17-4 PH. Also, titanium alloys are available for Binder Jetting from companies like DIGITAL METAL, but they are not widely available. Nickel-based alloys, copper and bronze materials and carbides are currently under development. Aluminum alloys are fairly common other forms of 3D printing, but due to the general difficulties involved in sintering them, they are still under development when it comes to binder inkjet printing. nine0014

nine0014

Metal powders and resins have become cheaper, increasing the demand for technologies that use them. Metals used in 3D printing include aluminum, bronze, cobalt alloys, copper, gold, nickel alloys, palladium, platinum, silver, steel, titanium alloys, and tungsten. While steel and aluminum, along with their varieties, still dominate the metal printing space, there has been a notable increase for other metals (including precious metals). The rise in the use of precious metals may be due to the wider adoption of metal printing systems in the jewelry industry. nine0014

There are also noticeable differences between plastic and metal. Plastics are still the predominant materials, but metal parts are on the rise. From 2017 to 2018, the proportion of 3D printers using plastic dropped from 88% to 65%, but over the same period, metal usage rose from 28% to 36%. Systems are also becoming more powerful, with new technologies such as metal blasting and binder blasting speeding up production.

Future Forecasts and Obstacles to Adoption

IDTechEx predicts that the majority of annual revenue will come from inventory rather than printer sales and installations. In their IDTechEx Research forecasts, they also predict that the global metal 3D printing market will reach $19 billion by 2029.

Growing interest in the aerospace and defense industries is driving the development of more critical parts with metal systems. Many organizations such as NASA and the US Army have expressed interest in increasing their 3D printing volumes as they move forward. Many experts, including Digital Metal CEO Christian Lönne, look to Binder Jetting as a potential rising star of the future. Metal printing will become more popular due to their ability to use new geometries, reduced weight designs, fewer production steps, and greater production flexibility. nine0014

Automotive applications are expected to exceed US$240 million by 2026. It is expected that in Europe, in particular, by this period there will be a significant increase (more than 20%). EU Directive 2015/719, adopted by the EU Commission, obliges companies to minimize the weight of vehicles to improve fuel efficiency and control emissions. In theory, this should stimulate the development of the market for additive manufacturing and metal powders. The EU automotive sector also accounts for over 4% of their GDP. As a major automotive manufacturing region, this will have a positive impact on demand for 3D printing and additive manufacturing. nine0014

EU Directive 2015/719, adopted by the EU Commission, obliges companies to minimize the weight of vehicles to improve fuel efficiency and control emissions. In theory, this should stimulate the development of the market for additive manufacturing and metal powders. The EU automotive sector also accounts for over 4% of their GDP. As a major automotive manufacturing region, this will have a positive impact on demand for 3D printing and additive manufacturing. nine0014

As usual, the main obstacles to further implementation are dependence on existing systems, production time and money. In addition to the cost of materials, metals take a significant amount of time to produce the end products that companies desire. High lead times prevent most manufacturers from switching to additive manufacturing and prefer the traditional manufacturing process. Timing is a major issue in the adoption of 3D printing by major industries and companies within them, including many aerospace and defense companies, automotive companies, and electrical and electronics manufacturers.