Laser scanning 3d printing

How to Choose the Best 3D Scanner to Use With Your 3D Printer

3D scanning has an important place at the beginning and end of 3D fabrication workflows. Engineers, product designers, and researchers use 3D scanners as a faster and more efficient way to start constructing digital models, whether by incorporating existing designs via reverse engineering, digitizing hand-sculpted clay designs, or referencing the exact shape of the human body.

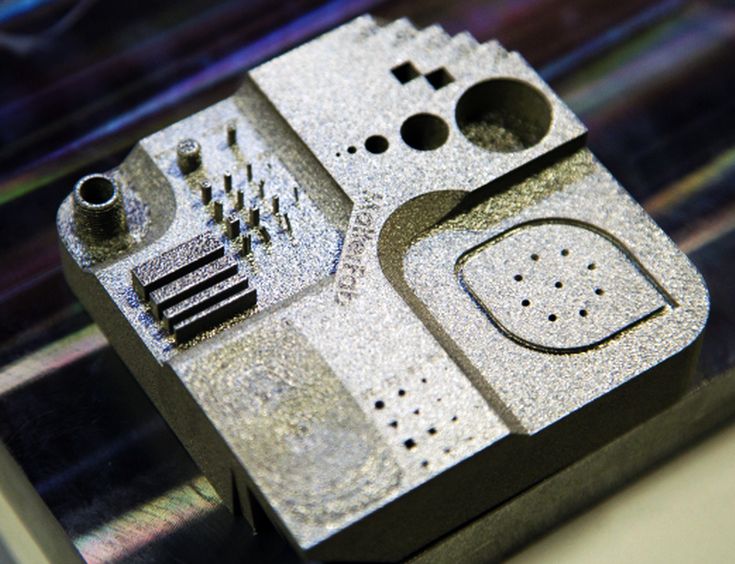

After fabrication, 3D scanning can support quality control and help to verify the accuracy of a 3D printed part, or, after the part has been used, a scanner can reveal how it’s performed—a scan of a deformed part can show you where to reinforce the design in the next revision.

With such a wide range of product options from handheld 3D scanners to desktop 3D scanners, it can be difficult to choose the best 3D scanning system that’s right for your application and budget. In this post, we explore the most important factors to consider when purchasing a 3D scanner and showcase some of the key applications that are empowered by combining 3D scanning and 3D printing.

White Paper

3D scanning and 3D printing workflows can be applied to replication and restoration, reverse engineering, metrology, and more. Download our white paper to explore these applications and learn how to get started.

Download the White Paper

There are multiple scanning technologies currently on the market, all offering their own advantages and weaknesses.

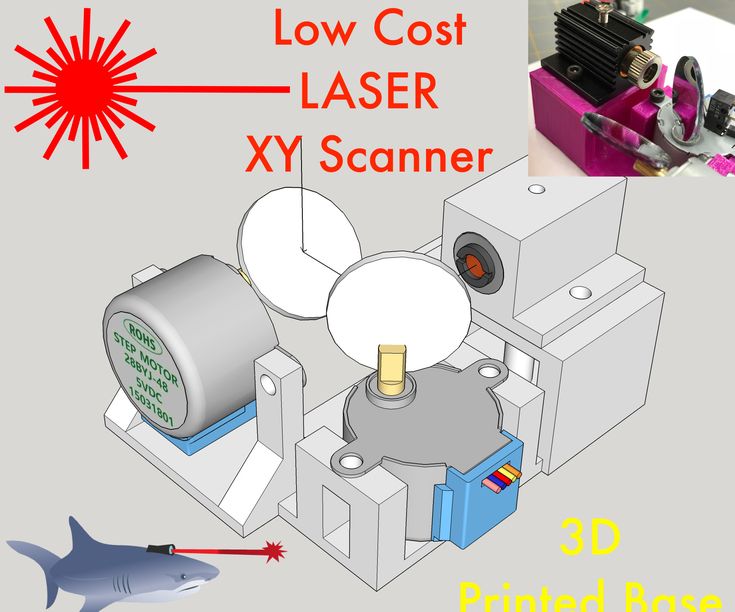

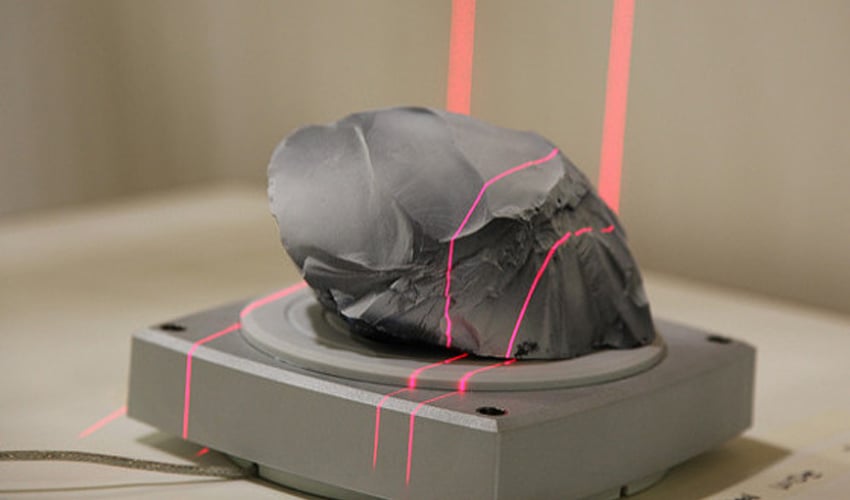

Laser triangulation uses light projected onto the object to take up to millions of measurements (dots) per second. The light reflected from the dots back into the scanner’s sensor to help it capture the geometry of the object. These types of scanners are often the most accurate, and are great for highly detailed parts that have opaque surfaces.

Laser triangulation scanners do have limitations. For example, this technology is not used in most portable scanners because the laser dots need to project from a stable source, and the source has to be kept a close distance from the scanned object. Laser triangulation scanners don’t always work on transparent or shiny surfaces either. Typically, they require reflective markers to be applied onto the object, which need to be removed after use and can be an obstacle depending on the object being scanned.

Laser triangulation scanners don’t always work on transparent or shiny surfaces either. Typically, they require reflective markers to be applied onto the object, which need to be removed after use and can be an obstacle depending on the object being scanned.

Finally, the laser dots can be harmful to human eyes, so it is important to use extra safety precautions when scanning body parts with a laser triangulation system, or to check with your scanner manufacturer to make sure the device is eye-safe.

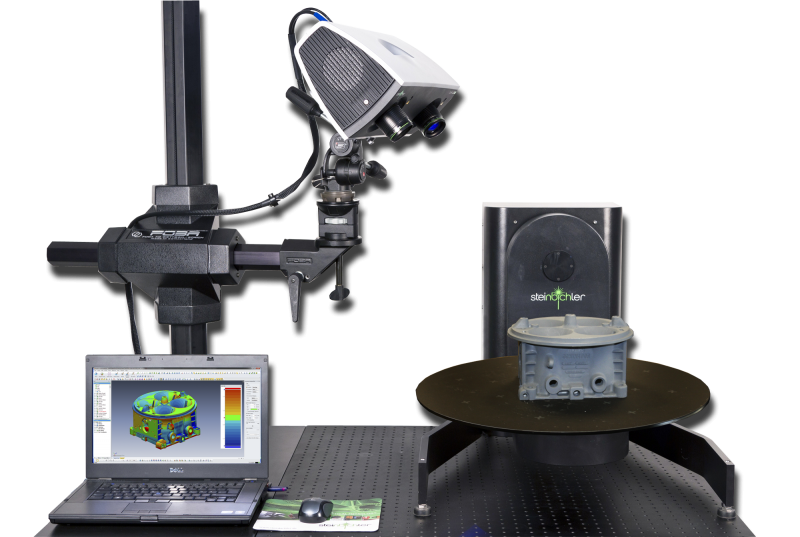

Structured light scanners (also known as white light scanners or blue light scanners) generally use a projector with two cameras at angles on either side. A pattern of light is projected and laid over the component being scanned, the cameras capture the ways in which the object deforms the light pattern, and then multiple images are integrated into a single 3D snapshot.

Structured light scanners are available in both stationary and portable format—the technology is the most commonly used process for handheld 3D scanners. Structured light scanners are far more common in medical applications, since it is safe to use on both humans and animals and excels when an object is not perfectly still. Traditional white light scanners have been slower to scan than laser triangulation scanners.

Structured light scanners are far more common in medical applications, since it is safe to use on both humans and animals and excels when an object is not perfectly still. Traditional white light scanners have been slower to scan than laser triangulation scanners.

Structured light scanning is the most commonly used technology in handheld 3D scanners.

Depth-sensing cameras project a field of dots in infrared (IR) to sample a 3D scene. Depth-sensing cameras are simple to use and are the least expensive scanning option, but their accuracy and resolution are low, and fine details are sometimes lost. Large objects may be captured with depth-sensing cameras, but accuracy declines with increased distance from the subject and at steeper angles to the camera.

Photogrammetry means the act of deriving precise measurements from photographs. It involves taking a set of overlapping photos of an object, building, person, or environment, and converting them into a 3D model using a number of computer algorithms. This is the most commonly used method when creating a 3D scan with a smartphone, since modern phone cameras are capable of capturing and combining a large numbers of photos. Photogrammetry should be considered the least expensive and least accurate method for creating 3D prints, and is not suitable for serious business applications.

This is the most commonly used method when creating a 3D scan with a smartphone, since modern phone cameras are capable of capturing and combining a large numbers of photos. Photogrammetry should be considered the least expensive and least accurate method for creating 3D prints, and is not suitable for serious business applications.

LiDAR (light detection and ranging) sensors can be found on some higher-end smartphones and tablets, such as the latest versions of the iPhone Pro and the iPad Pro. This has made the iPhone and iPad viable scanners for those with only occasional scanning needs, offering performance a step above devices that only have access to photogrammetry. Applications that generate 3D mesh files via your smartphone’s or tablet's camera should be seen as the floor for entry-level scanning; users should expect additional work in their CAD software to remove gaps in meshes and improve the 3D model for applications like sending it to a 3D printer. Smartphones use fewer light points when scanning objects, resulting in less detail than a true, stand-alone scanner. iPhones are good substitutes for scanners if you have significant CAD design ability or need to transfer basic models into a digital space.

iPhones are good substitutes for scanners if you have significant CAD design ability or need to transfer basic models into a digital space.

WEBINAR

Watch this webinar with Peel 3D to explore how to integrate 3D scanners into your 3D printing workflow to elevate your product development process.

Watch the Webinar Now

Scan accuracy varies considerably between scanner technologies, and higher accuracy generally comes at a higher cost. The required tolerances of your final part can be a helpful guide for determining your accuracy requirements for a 3D scanner.

| High Price, Highest Accuracy ($15,000 and more) | More Affordable, High Accuracy ($12,000 and under) | Low price, Low Accuracy |

|---|---|---|

| Zeiss T-Scan Hawk Scantech Simscan EviXscan Optima+ M Creaform HandyScan 307 Silver Series | peel 3d peel 1, peel 2 & peel 2-S FARO Freestyle 2 Polyga Compact S1 | iPhone Pro and iPad Pro Structure Sensor Matter and Form 3D Scanner V2 Revopoint POP |

With accuracy in the range of 0. 1 mm or better, laser and structured light scanners are a good fit for professional applications and alongside high-resolution 3D printers. Formlabs stereolithography (SLA) 3D printers (such as the Form 3+) produce parts at a similar accuracy, and with a similar printable area, to the scan volume of many desktop 3D scanners.

1 mm or better, laser and structured light scanners are a good fit for professional applications and alongside high-resolution 3D printers. Formlabs stereolithography (SLA) 3D printers (such as the Form 3+) produce parts at a similar accuracy, and with a similar printable area, to the scan volume of many desktop 3D scanners.

Besides the accuracy between measured points and their actual location, scanners also vary in terms of resolution, which is the distance between captured points at a given scan distance. This means that details on the scanned object that are smaller than the scanner’s resolution won’t be captured. For example, a highly accurate 3D scanner with a lower resolution might detect the general shape of jewelry on a statue, but not clearly show individual details on a ring or necklace. Depending on your project requirements, this may or may not be a dealbreaker.

An easy way to remember these metrics is: accuracy is the measurement error between the part and digital value. Resolution refers to the density of measurements.

Resolution refers to the density of measurements.

Accuracy can mean slightly different things depending on the manufacturer and 3D scanning technology. For example, the accuracy of handheld scanners depends on the distance to the subject and the quality of scan reconstruction, while desktop scanners have consistent accuracy within the constrained scan volume. If you are considering buying a 3D scanner for precise measurement, make sure to compare like to like.

In general, structured light scanning provides the best resolution and accuracy when compared to laser scanning. For some artistic use-cases for 3D scanning you may need a lot of detail, while overall accuracy is less important—especially if you don’t require your part to fit precisely with other parts in an assembly. In these cases, photogrammetry is an excellent low-cost option to explore.

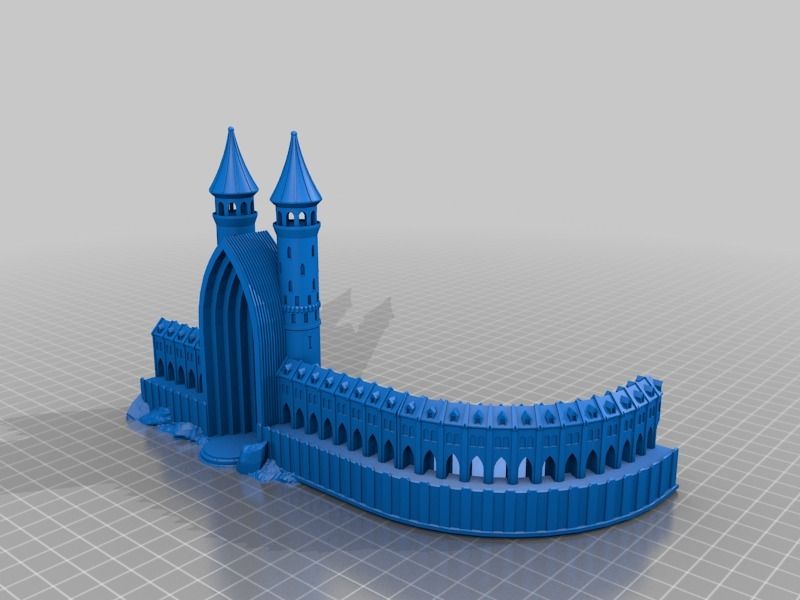

Both depth-sensing cameras and photogrammetry are a good solution for scanning large objects in order to create 3D printed scale models and also offer enough accuracy for capturing the shape of the human body.

Several entry-level laser scanners are available using technology similar to higher-end systems. These scanners are a great way to start replicating small objects at 1:1 scale. As one would expect, the accuracy of entry-level laser 3D scanners is lower than a high-end scanner, but they can easily provide enough detail to replicate small decorative objects and figures where accuracy is not critical.

If you only have occasional 3D scanning needs, digitization services can scan your object, as well as perform CAD translation and accuracy inspection.

The area that a 3D scanner can capture varies significantly between scanners. Find a scanner that fits your size and resolution requirements without too much overhead, as cost typically increases with scan volume.

Handheld scanners can be manually moved around the object and have fewer size constraints than desktop models. Most inexpensive handheld scanners can capture objects from the size of a basketball to an entire room. High-end handheld scanners have an even wider range, and fill the niche for all objects that require precise measurements, but cannot fit in a desktop scanner. Handheld scanners are also able to capture objects nearly instantaneously, which makes them well-suited for taking human measurements (where the subject is not perfectly still) for ergonomics and medical applications.

High-end handheld scanners have an even wider range, and fill the niche for all objects that require precise measurements, but cannot fit in a desktop scanner. Handheld scanners are also able to capture objects nearly instantaneously, which makes them well-suited for taking human measurements (where the subject is not perfectly still) for ergonomics and medical applications.

If the area of the model can’t be seen by the scanner, it will cause a gap in the model. You can automatically repair small missing sections with most scan software programs to create a 3D printable model. However, repaired holes are rarely accurate to the original object. For parts that demand close to perfect accuracy, auto-repair of gaps or holes will not be sufficient. Read our MeshMixer tutorial for advanced tips to edit and repair 3D files for 3D printing.

Many scanners use turntables to increase what the scanner can see. The sophistication of a scanner’s turntable affects how easily and completely the object is captured: some scanners have the ability to move the object around multiple axes, imaging the object from more angles. This feature is important when reverse engineering plastic parts with deep recesses and ribs, which are impossible to capture from a single angle.

This feature is important when reverse engineering plastic parts with deep recesses and ribs, which are impossible to capture from a single angle.

Scanners may rotate the object to capture occluded areas. Red regions are occluded and will be missing in the scan. Areas with deep relief are difficult for a single axis turntable to fully capture due to occlusion.

Cost concerns are straightforward; how much you are willing to spend on a scanner will reflect your business’s budget and how often the scanner is going to be used. Higher cost scanners will be able to capture small objects and create highly-detailed meshes that don’t require significant touch-ups in CAD software. Handheld scanners are also often on the higher end of the price range, due to their portable nature. The low-cost scanning market offers a wide range of options, but you have to know what to look for.

Use this flowchart to determine what scanner you need based on accuracy, scan volume, and budget.

Download the high-resolution version of this infographic here.

A 3D scanner expands the capabilities of a 3D printer, allowing you to replicate the shape of almost any object. Together, the two technologies create a powerful, digital workflow that can simplify and sophisticate processes in a range of industries.

The output from a 3D scanner is a mesh of triangles representing the surface of an object at a real-world scale. In some cases, the scan can be used directly to replicate objects without any CAD work. A hybrid workflow can also be powerful, where solid CAD models are combined with scanned 3D models. For example, customized ergonomics capture a physical imprint of a part of the human body, and integrate them with a mechanical design.

3D scanners are also valuable tools for measuring the accuracy of manufactured objects. Many factors affect 3D print accuracy, and metrology-grade 3D scanners provide a clear picture of how a material performs for demanding applications.

A variety of powerful workflows are enabled by combining a 3D printer and a 3D scanner:

- Reverse engineering to create replacement parts, products with custom ergonomics, and more.

- Replication and restoration of parts, especially in art and jewelry.

- Consumer audio for creating custom earpieces.

- Dental and medical applications, and how 3D scanning is enabling patient-specific workflows.

- Metrology to validate and measure the accuracy of manufactured objects.

Webinar

Watch this webinar for a detailed look at how to start using 3D scanning to improve part design and production when paired with reverse engineering CAD and 3D printing.

Watch the Webinar Now

3D scanners and 3D printers are essential parts of digital workflows across industries. Download our white paper or watch our webinar to get a detailed look into how to start using 3D scanning to improve part design and production and learn how to pair 3D printing and 3D scanning to empower a variety of workflows in engineering, product design, and more.

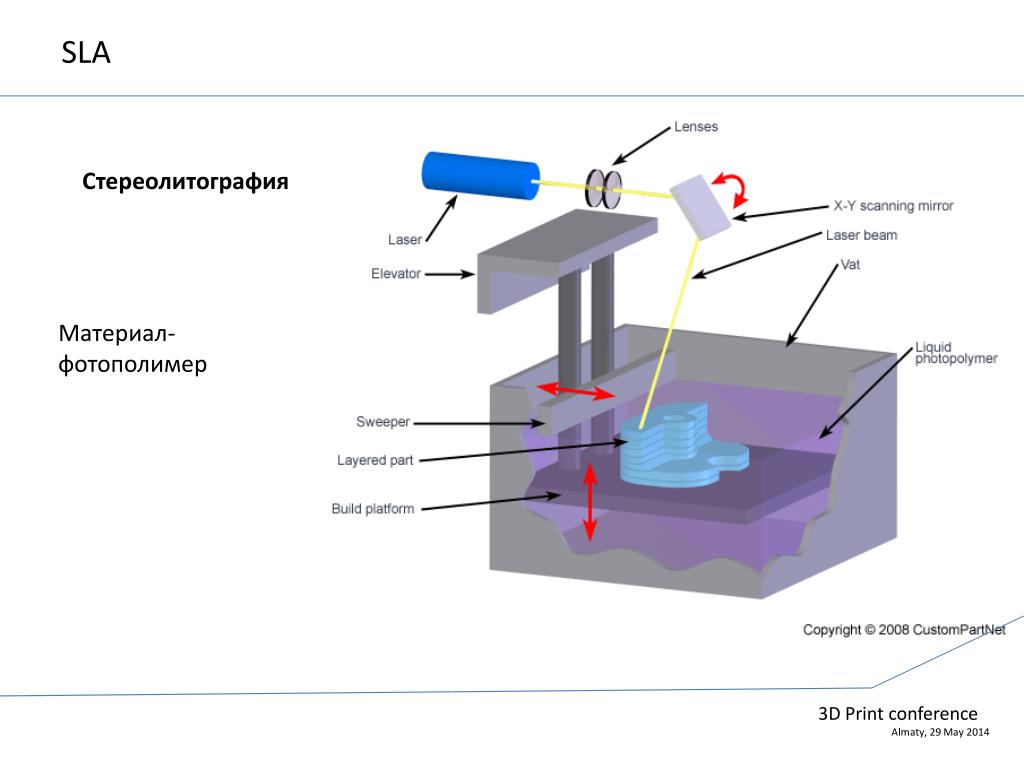

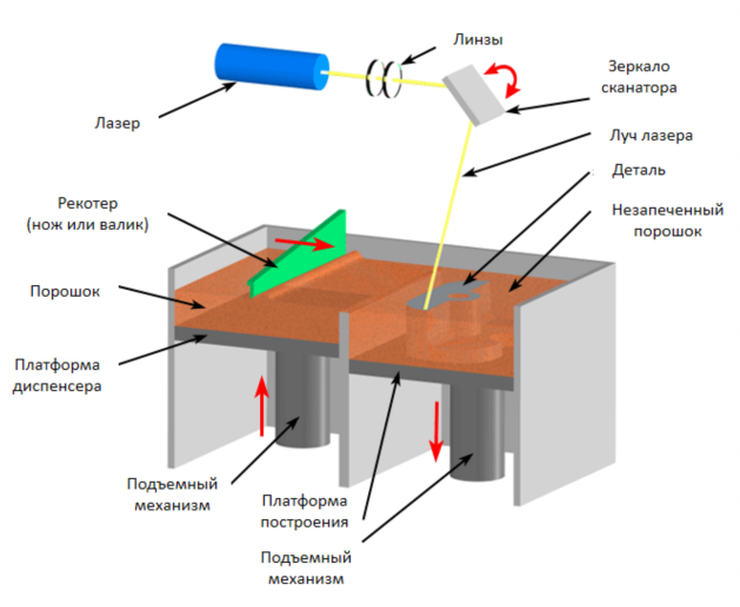

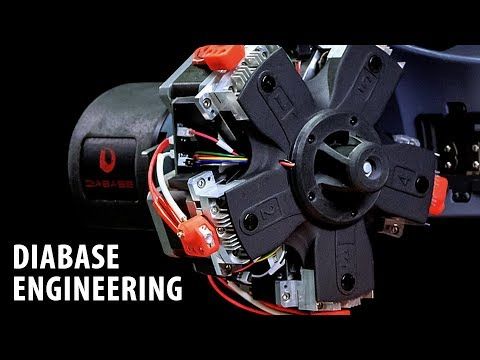

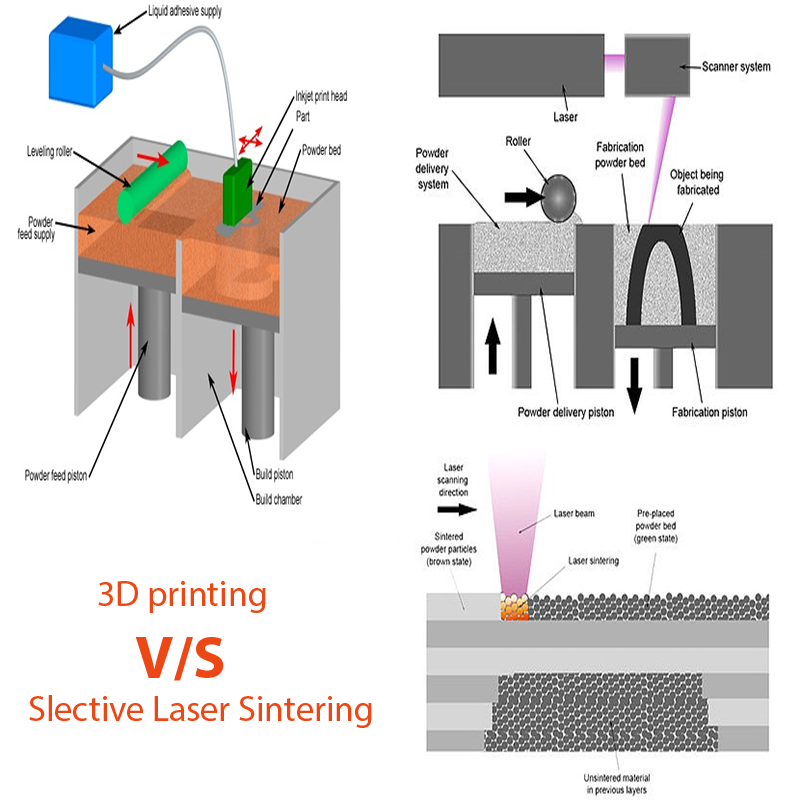

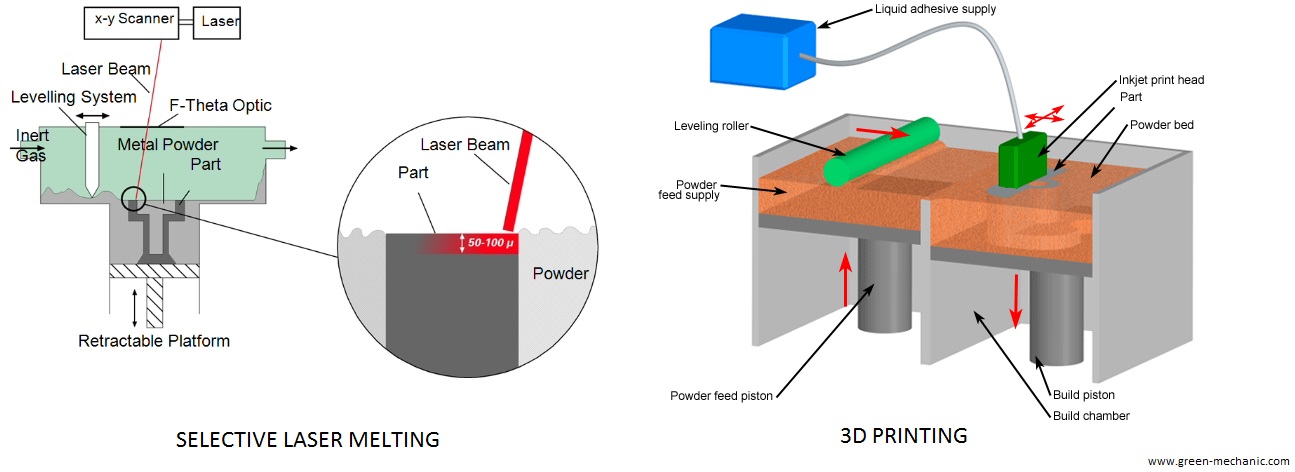

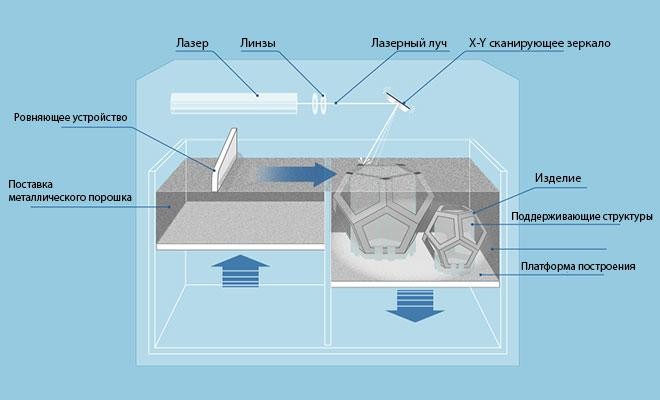

Learn more about the 3D printer side of the equation: get to know stereolithography (SLA) and selective laser sintering (SLS) 3D printing technologies and see Formlabs advanced 3D printing materials for yourself with a free sample 3D printed part.

Explore Formlabs 3D PrintersRequest a Free Sample Part

3D Scanners: What Are the Best Available Low-Cost Solutions?

Published on July 16, 2022 by Carlota V.

3D scanning is often used in the additive manufacturing (AM) sector to design a 3D model more easily than via modeling software. It captures data that is then transformed into a 3D model which can then be 3D printed. 3D scanners are based on two main technologies – laser triangulation and structured light – which will allow to obtain more or less precise details depending on the chosen device. Several affordable solutions, compared to professional scanners which are much more expensive, are available today to allow many users to bring their projects to life: whether you are a maker, a teacher or an industry leader, on of these low cost 3D scanners is bound to suit your needs! Easy to handle and transport, we have chosen some 3D scanners under $8,000 (€7,000), sorted by increasing price.

3D Scanner 2.0 from XYZprinting

Taiwanese manufacturer, XYZprinting, currently offers 5 scanners, though today we will focus on one of their more low-cost 3D scanners, the portable and high-resolution 3D Scanner 2.0. With a wider scanning range than its younger sibling the 1.0 A, the scanner can scan objects that are 5 x 5 x 5 ~ 100 x 100 x 200 cm using an Intel® RealSense™ Camera. The scan resolution is also superior to the 1.0A, between 0.2 and 1.5 mm with an operating range ranging from 25 to 60 cm. The manufacturer also provides XYZScan Handy, a scanning and post-editing software to edit your models after scanning. The product is lightweight measuring 41 x 157 x 61 mm with a weight of 238 g. It is available from €199.

Structure Sensor from Occipital

The Structure Sensor solution adds precise 3D vision to your mobile device, enabling 3D scanning among other features. The only equipment you will need for this 3D scanner to work is an iPad, then once you have downloaded the app Skanect Pro, it will work instantly.![]()

The new version of this device is smaller than the last, 109mm x 18mm x 24mm, and weighs about 65 g. It is recommended to use it on a 0.3 m to 5m scanning range. Some other features on this device include indoor mapping and virtual reality gaming! The Structure Sensor retails for $527, making it a low-cost scanner when compared to many other options.

POP 3D Scanner from Revopoint

The Revopoint POP is unique among 3D scanners as it has the distinction of being part of the highest crowdfunded campaign for a 3D scanner in Kickstarter, raising more than $2.28 million USD. It was developed by Revopoint, a company founded in 2014 by a group of young doctors and researchers from MIT, Kent University and other higher education institutions when they decided to focus on developing easy-to-use and cost-effective 3D scanners. It is safe to say that they certainly succeeded with their POP 3D scanner.

A binocular structured light 3D scanner that uses infrared as its light source, the Revopoint POP is a full-color scanner with an accuracy of up to 0. 3mm, texture scan and an 8Fps scanning speed. It has a number of interesting features, including the fact that it is easy to use outdoors because of it’s portable and can be powered by a power bank. With a cost of the scanner of only $549 in USA and about $599 in Europe, it is one of the most affordable options on our list, all while still being an effective, precise, high-resolution scanner. Not to mention, it can be used by a variety of users, as it supports four OS platforms – Windows, Android, Mac and iOS.

3mm, texture scan and an 8Fps scanning speed. It has a number of interesting features, including the fact that it is easy to use outdoors because of it’s portable and can be powered by a power bank. With a cost of the scanner of only $549 in USA and about $599 in Europe, it is one of the most affordable options on our list, all while still being an effective, precise, high-resolution scanner. Not to mention, it can be used by a variety of users, as it supports four OS platforms – Windows, Android, Mac and iOS.

Creality CR-Scan 01

Known for its affordable desktop 3D printers, manufacturer Creality has also developed a low-cost 3D scanner, the CR-Scan 01. Weighing only 1.91 kilos, this portable scanner is easy to handle and offers a scanning area of 536 x 378 mm. You will be able to scan your objects with an accuracy of up to 0.1 mm and export them in stl or obj format. Several scanning modes are offered, either manual or on a turntable. It is currently available from 589 €.

SOL 3D Scanner from Scan Dimension

This scanner was developed by Scan Dimension, based in Denmark, and is essentially a hybrid solution. It uses a combination of laser triangulation and white light technology to 3D scan real-life objects. The SOL 3D scanner can provide a resolution of up to 0.1 mm. The 3D scanning process is automated and you can choose between a near and far scanning mode.

The SOL 3D scanner also includes software to simplify your entire workflow. In a few steps you will be sending your 3D model to your 3D printer. This is a solution meant for makers, hobbyists, educators and entrepreneurs who may not have the most experience with 3D scanners but still want to achieve great results with a relatively low cost. The SOL 3D scanner retails for $699.

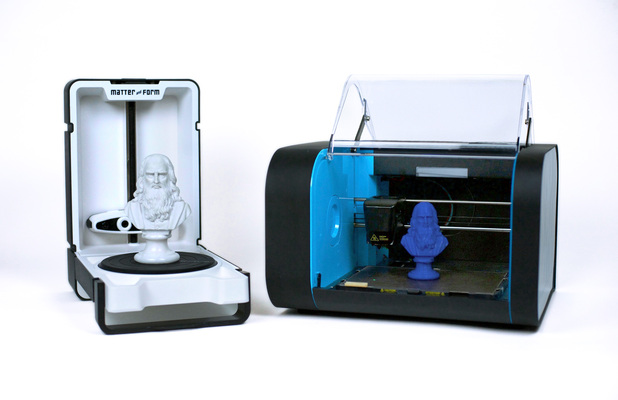

V2 from Matter & Form

The Matter and Form 3D Scanner V2 is a desktop 3D scanning solution manufactured by Matter & Form, a company founded in 2013. This company has made it its mission to develop and distribute affordable, high-resolution 3D scanners. With the V2, it has achieved that mission: the 3D scanner is available from $750 and is capable of producing high-quality scans with an accuracy of up to 0.1 mm. It weighs 1.71 kilograms (3.77 lbs) and has a height of 35.5 cm (13.5 in) and a width of 21 cm (8.25 in). The slim and foldable design allows the device to fit on small desks. The V2 allows scanning of objects with a maximum height of 25 cm (9.8 in) and a diameter of 18 cm (7.0 in). Windows and Mac scan files are supported, with multiple export options for 3D printing as well.

With the V2, it has achieved that mission: the 3D scanner is available from $750 and is capable of producing high-quality scans with an accuracy of up to 0.1 mm. It weighs 1.71 kilograms (3.77 lbs) and has a height of 35.5 cm (13.5 in) and a width of 21 cm (8.25 in). The slim and foldable design allows the device to fit on small desks. The V2 allows scanning of objects with a maximum height of 25 cm (9.8 in) and a diameter of 18 cm (7.0 in). Windows and Mac scan files are supported, with multiple export options for 3D printing as well.

RangeVision NEO

The NEO 3D scanner from the manufacturer RangeVision is an entry-level device with two 2-megapixel cameras, which works using Structured Light Scanning (SLS) technology. With an automatic scan mode, the scanner is suitable for all those who have little experience in digitizing objects. The SLS-3D scanner can capture objects from 30mm to 1200mm with a precision of 0.05mm, with 3D scans created using RangeVision software. Also included is a turntable and tripod, which make scanning easier for the user. According to the manufacturer, the NEO’s scans are suitable for reverse engineering, 3D modeling, historic preservation and, of course, 3D printing. The RangeVision NEO is available from around €2,190, making it one of the few low cost desktop 3D scanners available.

Also included is a turntable and tripod, which make scanning easier for the user. According to the manufacturer, the NEO’s scans are suitable for reverse engineering, 3D modeling, historic preservation and, of course, 3D printing. The RangeVision NEO is available from around €2,190, making it one of the few low cost desktop 3D scanners available.

Calibry, the low-cost 3D scanner, from Thor3D

Thor3D is a Russian manufacturer that is behind the Calibry portable 3D scanner. Based on structured light technology, it integrates a touch screen so that the user can follow the points it captures in real time. It offers accuracy down to 0.1 mm and is capable of scanning objects from 30 cm to 10 meters long. Black and glossy surfaces can be easily scanned and exported in stl, obj, ply or WRML formats. Finally, the Calibry is fast and convenient, capable of scanning up to 3 million points per second and weighing only 900 grams. It is available from 4,990 euros.

EINSCAN H from Shining 3D

The EinScan H is one of the most advanced versions of portable 3D scanners developed by the Chinese manufacturer Shining3D. Based on the hybrid structure light technology of LED and invisible infrared light, the EinScan H is able to perform human face scans more comfortably and without emitting strong light. It also incorporates a full-color camera and a large field of view for a truly impressive final quality of the models, ready for processing in just a few minutes. Its high resolution of 0.25 mm and data accuracy down to 0.05 mm make this a good choice in the market considering the price/performance ratio. In addition, it stands out for its light weight of almost 700g and intuitive user interface. The base price of this model is $5000 and you can get more information on the manufacturer’s website.

Eva Lite from Artec 3D

Artec 3D, based in Luxembourg, offers the Eva Lite as its cheapest option for 3D scanning. This professional scanner is specialized in the digitization of complex geometries, such as the human body, and is therefore increasingly used in the medical field. It works on the basis of structured light technology and, although it does not have the ability to capture colours and textures like most scanners of the brand, it has an accuracy of 0.5 mm.

This 3D scanner works with the software package Artec Studio. Artec Studio is a powerful tool for an optimized 3D scanning process. This software is able to perform, assemble and repair 3D scans. It is currently available at a price of $9,800. You can find more information HERE.

Any other low cost 3D printing scanners you think should be on this list? Let us know in a comment below or on our Facebook and Twitter pages! And remember to sign up for our free weekly Newsletter, to get all the latest news in 3D printing send straight to your inbox! For more 3Dnatives articles about 3D scanners, click HERE.

3D scanning of any objects. Affordable prices. RF and CIS

3D scanning of any complexity

35% discount when ordering from 10 objects

Small objects

from 2 mm to 300 mm

- Price

- 5000 ₽ for 1 object

- Timing

- 1 day nine0004

- Precision

- 10 micron

40% discount when ordering from 10 objects

Medium-sized objects

from 150 mm to 5 meters

- Price

- 5000 ₽ for 1 object

- Timing

- 1 day

- Precision

- from 30 microns

Large objects

from 3 meters

- Price

- from 35 000 ₽ for 1 working day nine0004

- Timing

- 1 day

- Precision

- is determined by the formula

3D scanning for civil and industrial design

- We work with any object nine0083 Departure of a specialist throughout Russia

details

Important Information

- How can I tell if my scanned item is small, medium, or large?

- If your object fits into 2 categories at once, focus on the scanning accuracy that you need.

Our specialist will always help you - call +7 (495) 223 01 21 or write to [email protected] - How to choose 3D scanning equipment?

- Our specialist will select a 3D scanner specifically for your task, based on the size of your object and the required scanning accuracy.

Don't worry about it 🙂

Ready to discuss all your questions!

Fill out the form or call +7 (495) 223 01 21

Request a call

Additional services

Reverse engineering (reverse engineering)

leave a request more

Quality control and part geometry. Metrological analysis, measurement of wear and deformation

leave a request more

Industrial design development

leave a request more

BIM modeling

leave a request more

3D modeling

leave a request more

3D printing

leave a request more

Examples of our work

The most interesting orders of our clients in various industries

see all works

- nine0084

Obtaining a 3D support bearing

- #3D scan

more details

Mercedes car scan for video tour

- #3D scan

more

Aircraft 3D scan

- #3D scan

more details

NURBS modeling of rubber car mats

- #3D modeling

more details

3D modeling and control of deviations of the mechanism body part

- #3D modeling

more details

3D simulation of lifting unit

- #3D simulation

more details

3D Jewelry Stencils

- #3D Print

more details

3D print car headlight

- #3D print nine0087

- #3D printing

- #BIM modeling

- #BIM modeling nine0087

- #BIM modeling

- #Plastic molding

- #Measurements

- #Measuring work

- #Measuring work

- mechanical engineering, fabrication of complex structures and parts

- aviation, space industry, ship and automotive industry

- medicine and dentistry

- construction and architecture

- defense industry

- science and education

- jewellery, etc.

- the easiest way to create 3D copies of a physical object

- high measurement speed

- high fidelity to the original design and reproduction of the smallest details of the product

- the ability to transfer and save data not only about the shape and size of an object, but also about its texture and color

- significant savings in time, physical and material resources

- photo of object from different angles

- dimensions and weight of object

- laser 3d scan target parts

- expected result

- the product and the scanner do not contact each other

- efficiency of work regardless of external factors, illumination level

- high precision result

- the ability to work with products of any complexity

more details

3D printing of a combine part from casting wax

more

BIM model for restoration of a cultural heritage site

more

BIM model for church restoration

details

Construction control of a building in Khimki

more details

Fork production

more details

Measurements of the facade of the fashion house Dior

details

Scanning the interior of the apartment

more details

Scanning a church in the Tver region to obtain data for restoration

details

Our clients

Aluminum and alumina production

Russian state company. Operator of the Russian railway network

Operator of the Russian railway network

Manufacture of combat and civil aircraft. Flight personnel training

Russian airline. Domestic and international passenger air transportation

R&D in the field of nanotechnology, robotics, space activities, ammunition

Design and manufacture of equipment for thermal, nuclear and hydroelectric power plants

Defense enterprise. Military-technical cooperation of the Russian Federation with foreign partners

Russia's leading underwater shipbuilding design bureau

Design, manufacture and after-sales service of aircraft

Development and production of complexes, systems and communications equipment for the Armed Forces of the Russian Federation

Leading university of the Upper Volga region

Engineering university. One of the nine backbone universities in Russia

Leading enterprise in Russia for the production of metal superstructures of bridges

Russian instrument-making concern. Production of electronic equipment for the Russian Navy

Production of electronic equipment for the Russian Navy

Creation of equipment for control systems of aviation and rocket technology, as well as for gas and oil pipelines

The largest research institute in the country, solving problems of defense, scientific and national economic importance

Development, manufacture and maintenance of engines for the aerospace industry

Development , production, testing, operation support, maintenance of aviation equipment

Creation and maintenance of the aerospace defense system in the interests of the security of the Russian Federation

Leading Russian developer of gas turbine engines for military and civil aviation

Manufacture of equipment for post-harvest processing, drying and storage of grain

3D scanning technology

3d scanning is the process of creating a three-dimensional copy of a real object, or digitizing it, using a special device - a 3D scanner. Today, there are many ways and settings for creating a digital model of objects. nine0005

Today, there are many ways and settings for creating a digital model of objects. nine0005

3D scanners make it easy to 3D scan even the smallest details from a wide variety of materials.

Basic scanning methods

There are currently two main 3D scanning methods: contact and non-contact.

Non-contact 3D scanners can scan both small and large objects such as buildings or monuments. They are divided into photogrammetric, laser and 3D devices using structured white light technology. The non-contact 3D scanning method involves the use of laser and light beams, allowing you to scan fragile objects without damaging them. nine0005

Applications

3d scanning is popular in a wide range of industries due to its versatility and simplicity. Key industries that use 3D scanning include:

A variety of 3D scanners allows manufacturers to choose exactly the device that will fully fit the purpose and size of the production tasks. Some 3D scanners are designed to digitize only small objects, while others are suitable for measuring buildings, structures and building structures. nine0005

3D scanning advantages

The main advantages of 3D scanning include:

3D scanning: price

The calculation of the price for 3D scanning is formed after determining the scope of work and is compiled individually for each project.

To calculate the exact price of the scanning service, you need to send us photos and dimensions of the object of measurement, as well as the purpose of the scan results, by e-mail. You can find the full list of required information here.

If you need 3d scanning services for your product, you can write to us at [email protected], call:

+7(495)223-01-21 or leave an online application.

Order service

3D scanning of parts and objects in St. Petersburg

3D scanning of parts and objects in St. Petersburg3D Studio

3d scanning is a technology for obtaining a high-precision model of a multi-profile object without mechanical contact. 3d scanning of an object is applicable for parts of any size. Detailing of a 3D image is increased by increasing the analyzed points of the scanned object. nine0005

3D printing

Ready 3d image can be obtained in any supported format, after which computer data processing can be performed. Scanning 3d models is beneficial in that it allows you to process not only different objects, but also plants, animals, people. Read more about human scanning here...

Scanning 3d models is beneficial in that it allows you to process not only different objects, but also plants, animals, people. Read more about human scanning here...

The resulting 3d image can be printed on a 3d printer. For printing, special materials are used, selected taking into account the expected results. A photograph printed on a 3d printer is a material object suitable for use in many areas. nine0005

Where

appliesMost often, scanning with a 3d scanner is used in the following areas of production and industry:

production of souvenirs

products

medicine

production of jewelry

products

development of computer games

writing of various programs

instrument making

industry

materials

3d scanning details: technology features

The process of 3D scanning of parts is simple: a special device highlights the object, after which its 3D model appears on the monitor display.

Before starting work, the part must be prepared: remove dirt and dust, perform matting, apply reference points. In the program used by the scanning device, the scans are stitched together into a complete model. The result is a model in stl format (the surface of the part, consisting of a large number of triangles). At the final stage, the result of the 3D modeling process is processed, after which the work can be called completed. nine0005

3d laser scanning

Laser 3d scanning is used in various areas of production and industry. Using a high-precision laser, it is possible to create three-dimensional models of any shape and size. In our studio in St. Petersburg, an order for laser 3d scanning of the following types is available:

parts of details for subsequent engineering copying

copying of an artistic detail (sculpture, fencing element, bas-relief)

creation of scans of architectural objects (skirting boards, moldings, balusters)

3D modeling using laser scanning of boats, motorcycles, cars

creation of scans of tuning objects

creation of scans of jewelry, stones

The price for this type of 3d scanning is set taking into account the shape, dimensions of the object and the complexity of the preparatory procedures. To determine the cost of 3d scanning of objects, the client provides the following data:

To determine the cost of 3d scanning of objects, the client provides the following data:

What is the advantage of using laser scanning technology for 3D models:

Equipment used

3D scanner is the main equipment required for 3d scanning of objects. For work, we use only the most modern models of scanners from a trusted manufacturer. This equipment makes it possible to obtain high-precision 3D models of objects of almost any size.

3D PRINTING SCAN MODELING and MILLING DURALUMINUM nine0005

Let's make your dream at affordable prices!

MaterialPlasticPhotopolymerPolyamideMetalDuralumin Quantity1 piece up to 25 pieces up to 100 pieces up to 1000 pieces1000+ pieces Dimensions up to 2cm*2cm*2cmup to 20cm*20cm*20cmup to 34cm*34cm*34cmover 34 cmAdvantages of cooperation with our company

democratic tariffs for all types of services in St. Petersburg

Petersburg

work is performed by experienced highly qualified professionals

use of special high-precision equipment (scanners, printers)

promptness in the provision of services

possibility of field service

strict adherence to established rules, high-quality preparation of the part before scanning

Ordering services in St. Petersburg

In our studio in St. Petersburg, you can order services for the creation of three-dimensional scans of objects (including field scans). We also print the received scans. Over the years of our activity, we have served a huge number of clients, many of whom have become permanent, which indicates the high quality of work. We take orders of any complexity at a favorable cost, constantly improve our skills in the field of three-dimensional modeling, do our best to improve the quality of service and meet all customer needs. nine0005

The cost of scanning 3D objects in St.