Inkredible 3d printer

INKREDIBLE Bioprinter - 3D Cell Culturing

Learn more

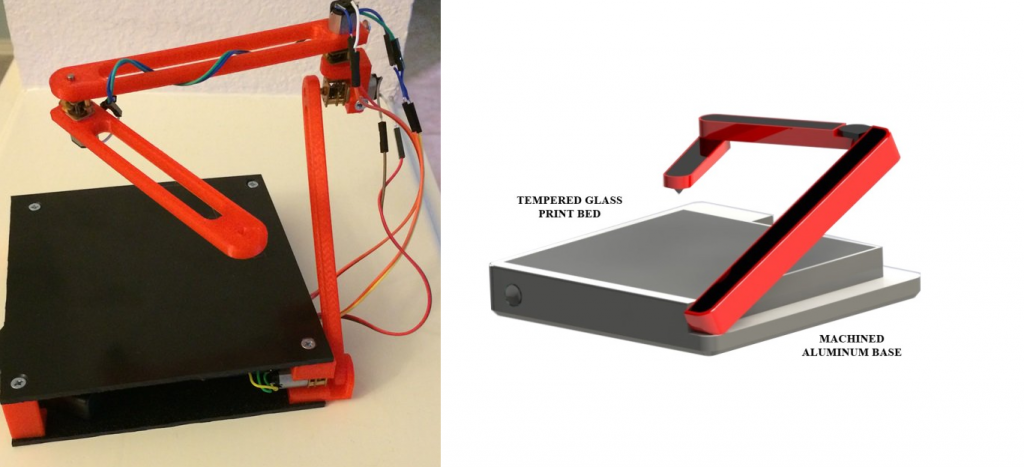

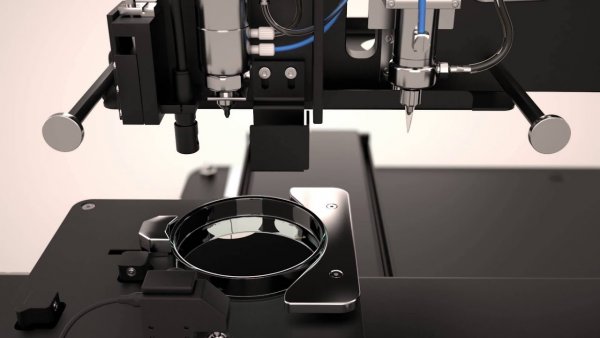

This bioprinter system launched an industry and can also launch your research to the next level. Small but mighty, the INKREDIBLE bioprinter system offers basic dual head pneumatic extrusion in a standalone unit.

Get a quote

SKU: S-10002-001 Categories: Bioprinters, Extrusion bioprinters Tag: Extrusion Bioprinters

- Description

Description

Easily fabricate 3D constructs consisting of up to two cell types and bioinks just using the built in UI (or through a connected computer). With built in photocuring modules, you also have full control to rapidly crosslink your constructs during or after the bioprinting process. The INKREDIBLE easily fits in any standard biosafety cabinet to ensure a clean bioprinting environment with your cells or work from your benchtop to develop your own bioinks and optimize your construct geometries. Compatible with G-Code for full control over printing workflows.

- Two printheads for 3 mL cartridge (non-temperature controlled)

- Built in photocuring module (365 nm by default, 405 nm available upon request)

- Compatible with standard petri dishes, multi wellplates

- Precise positioning in X, Y, and Z

- For more advanced bioprinting capacities, check out the BIO X or INKREDIBLE+

See products listed below for a full-list of compatible ready-made bioinks

You may also like…

-

CELLINK RGD

Based on CELLINK Bioink, CELLINK RGD bioink provid...

€179–

€749 -

CELLINK START

CELLINK START is a water-soluble gel used as a sac...

€53–

€96 -

CELLINK A-RGD

CELLINK A-RGD bioink offers the same 3D environmen.

€475 ..

..–

€1,199 -

Chitoink

Chitoink is the first ever commercialized chitosan...

€99–

€349 -

CELLINK START Sterile

CELLINK START is a water-soluble gel used as a sa...

€109–

€199 -

CELLINK Bioink

CELLINK Bioink is composed of non-animal derived p...

€375–

€1,099 -

CELLINK XPLORE

CELLINK XPLORE is a non-sterile ink designed for d...

€149–

€199 -

START X

With a new and improved formulation, CELLINK START...

€72–

€229 -

CELLINK START (50 mL)

CELLINK START is a water-soluble gel used as a sac.

€109 ..

..

CELLINK's $5,000 3D Bioprinter - 3D Printing Industry

0Shares

This is the time for 3D bioprinting. Incredible things are, literally, taking place in this amazing sector. Literally, because the new INKREDIBLE bioprinter developed by Swedish startup CELLINK, is going to be presented next September 8th at the TERMIS World Congress, hitting the market at the “incredible” price point of $5,000.

This is the “magic” price point that is generally considered to set the difference between the industrial and professional spheres and the prosumer/consumer target. This does not mean that we are going to be 3D printing biological tissues at home anytime soon, but there is little doubt that the bioprinting sector is following many of the same market dynamics as “traditional” 3D printing. A commercially available $5,000 bioprinter – along with other similar products such as the BioBot1 – pave the way to the idea of 3D bioprinting services, catering to the needs of bioengineers and bioengineering students (and biodesigners?) just like 3D printing services cater to the needs of designers, architects and engineers.

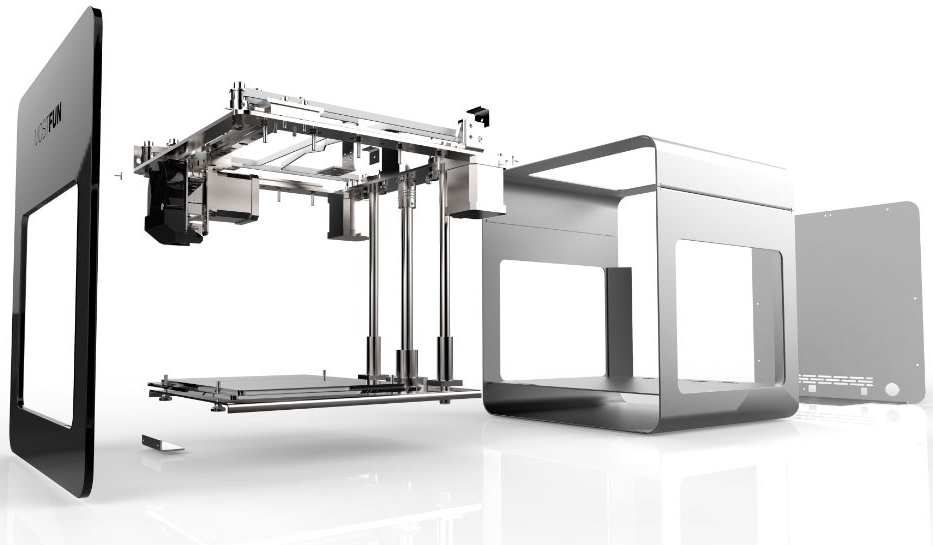

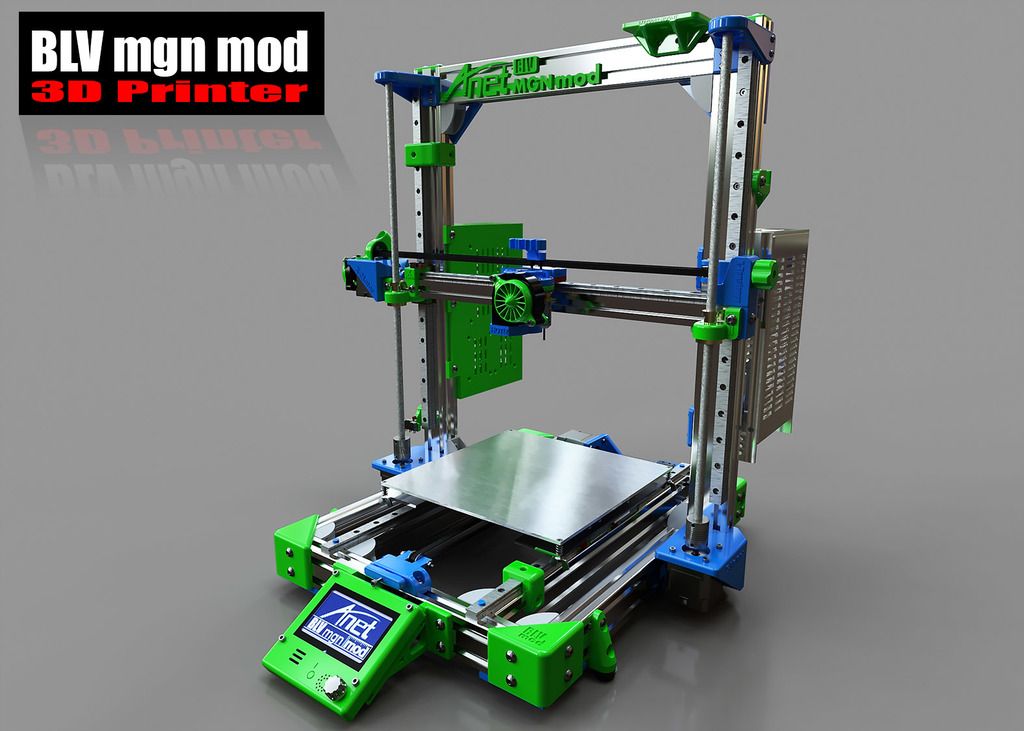

Getting back to the INKREDIBLE 3D printer, it even looks like a standard FFF desktop 3D printer. “It employs a pneumatic extrusion 3D printing process which is known to be less harmful to the cells”, Erik Gatenholm, director of operations (and co-founder of CELLINK with R&D Engineer Ivan Tournier), explains. Like several other commercial bioprinters it comes in two versions, the INKREDIBLE and the INKREDIBLE+; both have standard dual extrusion, with the more expensive model offering other advanced research features and coming in at $9,000.

CELLINK started developing the 3D printer as they were testing out their CELLINK consumables for bioprinting. “As we tried out so many different bioprinters, we realised there were so many small features that were missing, or that could have been done differently or could have been done better,” Erik says. “So, we brought in Hector Martines, who has a PhD in tissue engineering and has been working with 3D printers and bioprinting for a long time. He was immediately enthused by our project, so we began working together.”

He was immediately enthused by our project, so we began working together.”

There are three features that, as Erik stressed, make this 3D printer truly incredible. First of all, it has clean chamber technology. This means that the chamber inside which the bioprinting takes place is an almost sterile, CGMP environment. “It has a highly filtered air flow with positive pressure created inside the chamber so it reduces contamination and particle count inside the printing area basically down to zero. This is absolutely amazing and it means that researchers can print right on the benchtop.” Erik also assured me that up to 98% of cells are alive when using their own bioink on their 3D printer, which would be an “incredible” result.

The second feature, already mentioned, is the standard dual extrusion, which has been introduced in order to enable all models to bioprint skin tissue. The third feature is the printer’s digital pressure sensors. “We’ve seen that many of the bioprinters in the market today have problems with regulating pressure,” Erik explains. “So, making it digital means that you have an accurate reading of what pressure you’re using because you need this kind of accuracy when you’re working to publish your research results.”

“So, making it digital means that you have an accurate reading of what pressure you’re using because you need this kind of accuracy when you’re working to publish your research results.”

Although CELLINK makes its own consumable, the INKREDIBLE bioprinter is open to any materials, even those produced internally at research facilities and universities. “We offer ionic solutions; however, many researchers use UV-curable biomaterials and they will be able to use those in our 3D printer, as well.” In fact, another very important piece of news is that CELLINK is also announcing two new “bioconsumables”: CELLINK+, an improved CELLINK for chondrogenic differentiation, and CELLINK A, which is an alginate-based bioink that many researchers have been asking for.

What are the prospects for this new technology? As said, CELLINK and other companies like BioBots are lowering the costs of entry into the bioprinting research industry, so, who knows, we might soon see 3D bioprinting services pop up all over the world. Erik agrees that the possibility exists. “Some universities have similar facilities and researchers are already basically paying for access by the 3D bioprinted model. Today,” Erik adds, “many universities prefer to have their own bioprinters in-house.” CELLINK is not comparing its 3D printer to higher-end models, such as EnvisionTEC’s or RegenHU’s. The company targets a different market niche, one that will be able to enter this market and then move on to the higher-end machines as their research progresses.

Erik agrees that the possibility exists. “Some universities have similar facilities and researchers are already basically paying for access by the 3D bioprinted model. Today,” Erik adds, “many universities prefer to have their own bioprinters in-house.” CELLINK is not comparing its 3D printer to higher-end models, such as EnvisionTEC’s or RegenHU’s. The company targets a different market niche, one that will be able to enter this market and then move on to the higher-end machines as their research progresses.

As the technology gains adoption, 3D bioprintable model databases – a sort of “Organiverse” (don’t bother, it is already registered) – might also appear. “It is definitely something we have begun working on internally,” says Erik. “We’d like to be able to launch a library for our customers so that they can download the desired 3D tissue models they need.” Similarities with the 3D printing industry do not end here.

I remember when colorFabb announced their partnership with raw polymer material manufacturer Eastman. Well CELLINK has also just signed a partnership with Rooster Bio a large hMSC (stem) cell manufacturer. “The biofabrication field has been limited in access to easy-to-use cells, and easy-to-use biomaterials for emerging 3D bioprinting applications,” said Rooster Bio’s CEO Jon A. Rowley. “CELLINK is a leading provider of biomaterials specifically formulated for bioprinting. Collaborating with CellInk, RoosterBio is excited to jointly bring to market first-in-class kits enabling end users to quickly access sufficient stem cells for experiments, and simple protocols for high fidelity mixing and printing of living cellular bioinks. These complementary technologies will accelerate the 3D Bioprinting field towards rapid therapeutic translation.” It all sounds even more credible now.

Well CELLINK has also just signed a partnership with Rooster Bio a large hMSC (stem) cell manufacturer. “The biofabrication field has been limited in access to easy-to-use cells, and easy-to-use biomaterials for emerging 3D bioprinting applications,” said Rooster Bio’s CEO Jon A. Rowley. “CELLINK is a leading provider of biomaterials specifically formulated for bioprinting. Collaborating with CellInk, RoosterBio is excited to jointly bring to market first-in-class kits enabling end users to quickly access sufficient stem cells for experiments, and simple protocols for high fidelity mixing and printing of living cellular bioinks. These complementary technologies will accelerate the 3D Bioprinting field towards rapid therapeutic translation.” It all sounds even more credible now.

Davide Sher

Davide was born in Milan, Italy and moved to New York at age 14, which is where he received his education, all the way to a BA. He moved back to Italy at 26 and began working as an editor for a trade magazine in the videogame industry. As the market shifted toward new business models Davide started working for YouTech, the first iPad native technology magazine in Italy, where he discovered the world of additive manufacturing and became extremely fascinated by its incredible potential. Davide has since started to work as a freelance journalist and collaborate with many of Italy’s main generalist publications such as Corriere della Sera, Panorama, Focus Italy and Wired Italy: many of his articles have revolved around the different applications of 3D printing.

As the market shifted toward new business models Davide started working for YouTech, the first iPad native technology magazine in Italy, where he discovered the world of additive manufacturing and became extremely fascinated by its incredible potential. Davide has since started to work as a freelance journalist and collaborate with many of Italy’s main generalist publications such as Corriere della Sera, Panorama, Focus Italy and Wired Italy: many of his articles have revolved around the different applications of 3D printing.

10 Incredible Things 3D Printers Can Do Today

It's been more than thirty years since Chuck Hull invented the first 3D printer in 1983. Since then, the idea of printing objects on a machine has gone from fantasy to reality, opening up new possibilities for every field, from science to art.

3D printing may still be evolving, but the technology has grown exponentially over the last thirty years, both in terms of volume and utility of printable objects. And you know, it's not just stuff-dryuki and toys. nine0003

And you know, it's not just stuff-dryuki and toys. nine0003

It's easy to be skeptical about 3D printing, which is still slower, more expensive and less efficient than traditional manufacturing. But if we focus on a few of the technology's remaining drawbacks, we won't be able to see how far 3D printing has already come.

Here are ten of the most incredible objects that you can already print.

Contents

- 1 Parts of the body

- 2 Pizza

- 3 Chocolate

- 4 Clothing

- 5 Musical instruments

- 6 Cars

- 7 Weapons

- 8 Drones

- 9 Toys for adults

- 10 3D printers

Ears, Kids, blood vessels, leather and bones-leather and bones-leather and bones-leather and bones-leather and bones-leather and bones-leather and bones-leather and bones-skin and bones-leather and bones-leather and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones.

all of this was successfully printed. Instead of the usual plastics associated with 3D printing, medical bioprinters use a gel-like substance made from cells. Except for the bones, which are based on ceramic powder. nine0003

all of this was successfully printed. Instead of the usual plastics associated with 3D printing, medical bioprinters use a gel-like substance made from cells. Except for the bones, which are based on ceramic powder. nine0003 Advances in 3D bioprinting mean that doctors will one day be able to provide every patient with a perfectly matched bone fragment, skin flap or kidney. The kidneys, by the way, are already there, but not yet working.

And while bioprinters can't print whole human limbs, plastic printers can already print artificial limbs for less than $100 in just a couple of hours.

Pizza

This NASA project is quite edible. The organization has begun funding 3D printed food to feed astronauts in space. Usually 3D printers work with one material cartridge. A food printer prints from several cartridges at once, containing materials like dough, cheese or sauce. nine0003

Chocolate

If you replace ordinary plastic in a 3D printer cartridge with melted chocolate and give it the ability to write futuristic monograms on cupcakes and chocolates, a real paradise for the sweet tooth will begin. You can print or paint whatever you draw on the computer and then eat it.

You can print or paint whatever you draw on the computer and then eat it.

Chocedge is one of the first multi-thousand dollar exclusive chocolate printers. However, 3D printing of sweets is fiercely competitive. In January, Hershey and 3D Systems announced a partnership to create all kinds of printed candies. If a company replaces its workers with 3D printers, it will greatly streamline the workflow. nine0003

Clothing

3D printed clothing may not be available in stores yet, but it already exists. Model Dita Von Teese wears the first fully 3D printed dress made especially for her.

For ordinary people, 3D printing can mean an incredible level of personalization of clothes, up to having your own tailor, literally. A 3D printer will be able to print clothes for any body. On the other hand, if you don't have a figure like Dita, you may just not be ready yet. nine0061

Musical instruments

It is now possible to create functional musical instruments completely 3D printed. The commercial realm already has the Odd 3D guitar, which promises a unique look and top class acoustics. MIT lab researcher Amit Zoran has printed a fully working flute. The German company EOS has printed a polymer violin.

The commercial realm already has the Odd 3D guitar, which promises a unique look and top class acoustics. MIT lab researcher Amit Zoran has printed a fully working flute. The German company EOS has printed a polymer violin.

The only problem is that 3D printed musical instruments don't sound as good as traditional ones. Violinist Joanna Vronko played a regular violin and a printed one at a concert in Amsterdam, and it became clear that the audience liked it better. nine0003

Cars

The Urbee 2 looks more like a bean than a car. But in fact, this is the first car made from 3D printed parts.

The three-wheeled car is cheaper and uses less fuel than any other car on the market, but the 23-horsepower engine (with batteries) allows it to reach incredible speed. The creators of Urbee 2 want to get the car on American roads within two years, but they still have a little work to do. The car, for example, does not comply with US traffic regulations at the moment. nine0003

nine0003

Weapons

Perhaps the most controversial thing to print is firearms. The first model was called the Liberator and was designed by 26-year-old Cody Wilson. Now, just about anyone with a 3D printer and an internet connection can download and print their own plastic handgun. But just because it's made of plastic doesn't mean it's safe.

Even though the Liberator exploded when the FBI decided to unseal it, Wilson uploaded a video of him successfully shooting himself. In general, it will soon be banned at the legislative level. nine0003

Drones

What about 3D printed drones flying through the skies?

Researchers at the University of Southampton have developed SULSA, an unmanned aerial vehicle that can be mass-produced in 3D printing. Its top speed is 150 km/h and it can stay in the air for a total of 30 minutes.

The drone can be assembled from plastic in 10 minutes without the use of screws or other fasteners. The result is an absolutely quiet aircraft. nine0003

The result is an absolutely quiet aircraft. nine0003

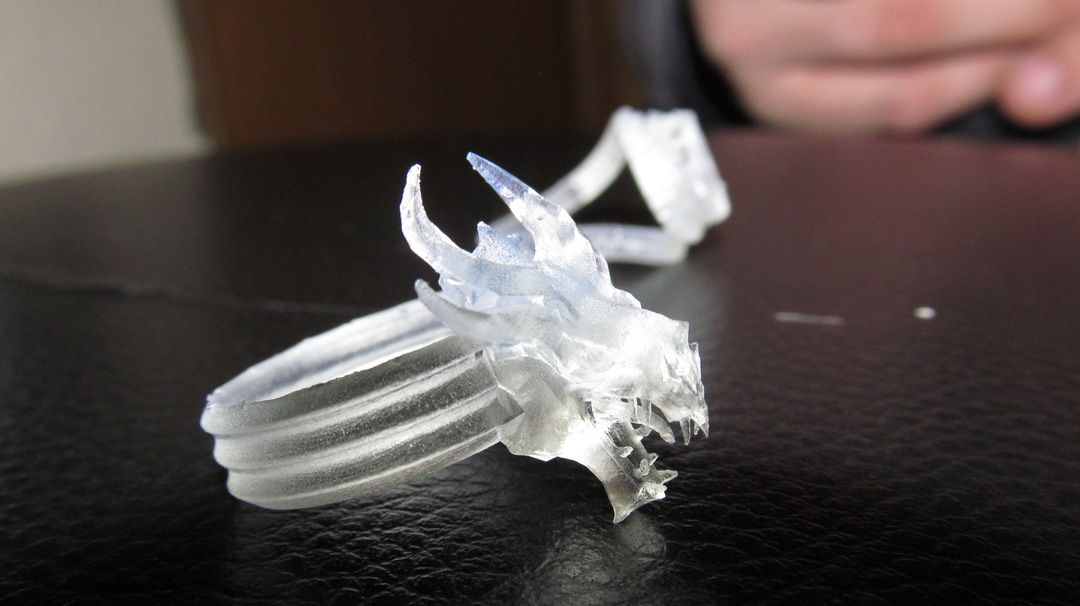

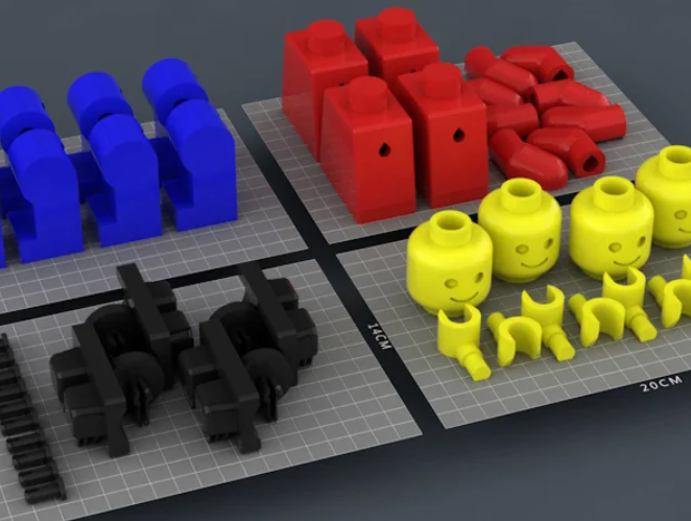

Toys for adults

And of course, one of the first things people started doing with the advent of 3D printers was sex toys. The industry is already giving out dildos, vibrating sleeves and other accessories. Some of them are highly personalized.

It was possible to predict what all this would lead to. After all, we all know what people started using the Internet for.

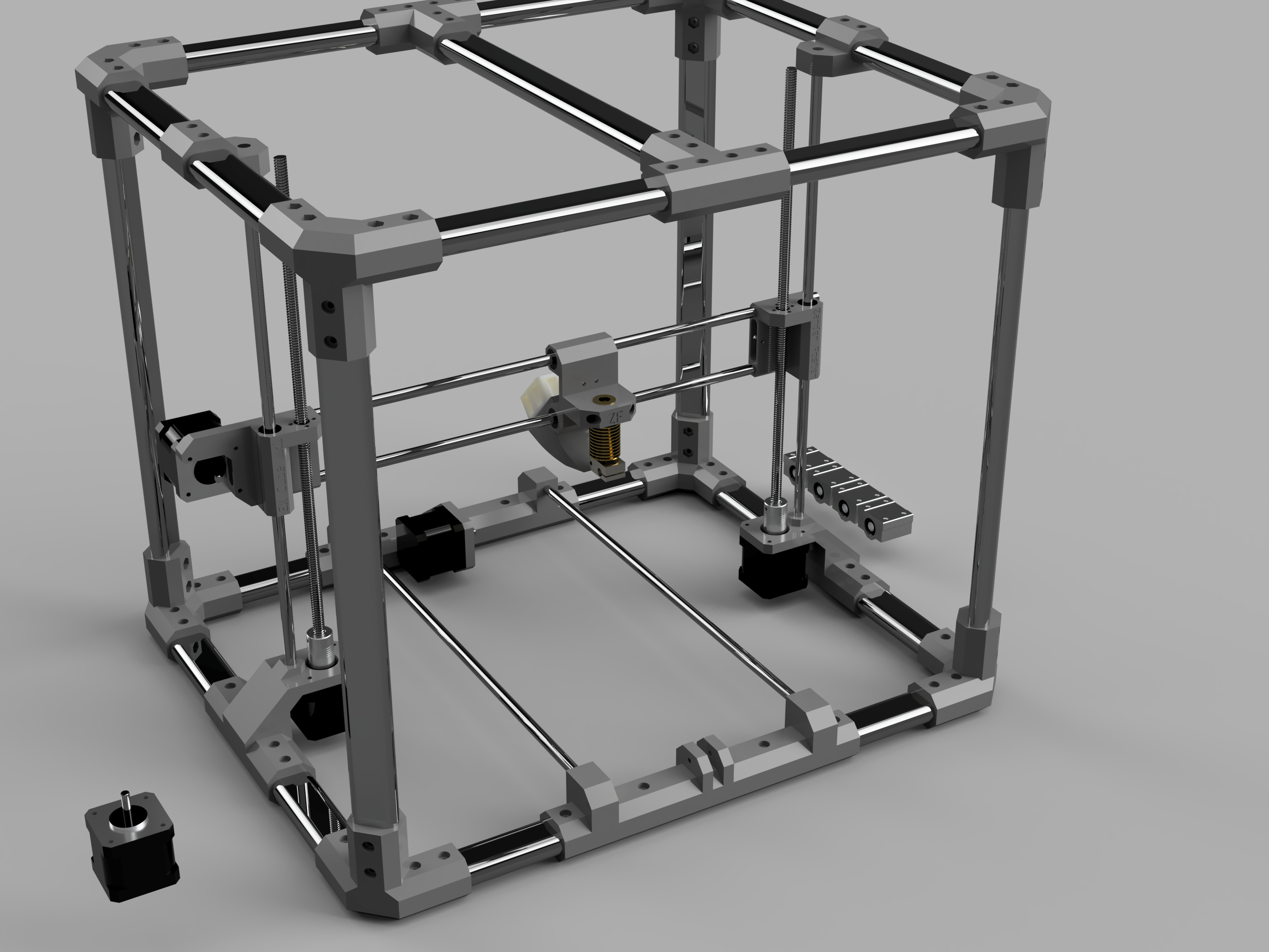

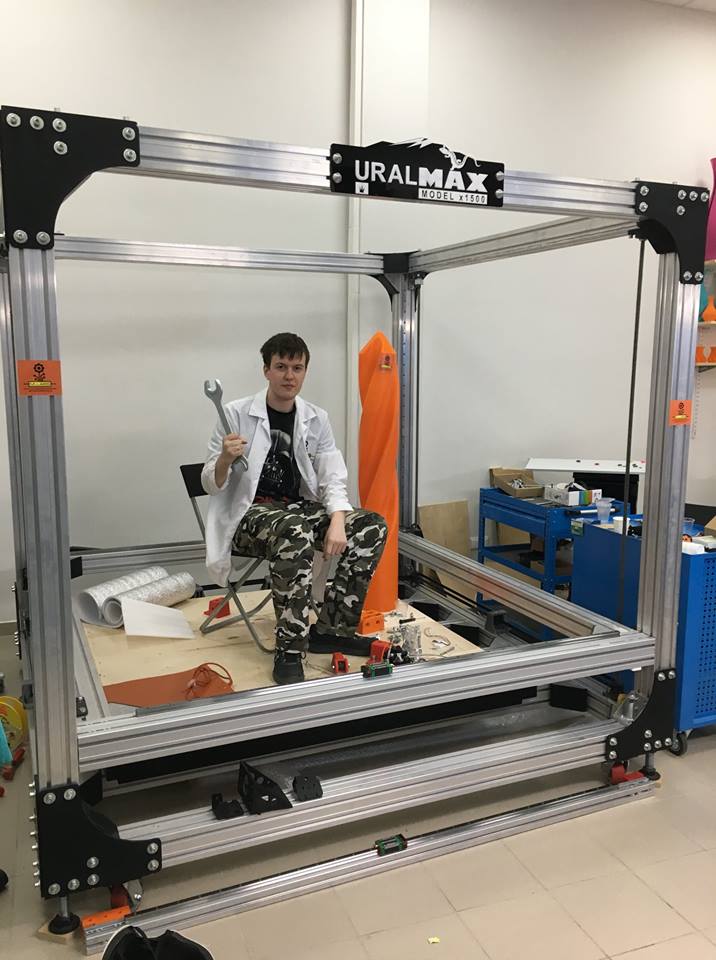

3D printers

In fact, a 3D printer can also print on a 3D printer. With the advent of such an opportunity, we closed the circle. RepRap is an open source printer that does just that. Open source means you can print and assemble all the parts with ease. You just need to buy the device itself (500-600 dollars) and a program for printing, and then you can give all your friends a printer. nine0003

TOP 10 incredible things that can be printed on a 3D printer

One gets the feeling that everything once created by human hands is now more efficiently and better produced using computers. And the 3D printer is the best proof of that. Based on a computer model and with the help of special software, the thinnest layers of material are sprayed, whether it be plastic, porcelain, clay, rubber, or titanium powder, and then, using heat, these layers are fused together. Thus, a new object is created. nine0003

And the 3D printer is the best proof of that. Based on a computer model and with the help of special software, the thinnest layers of material are sprayed, whether it be plastic, porcelain, clay, rubber, or titanium powder, and then, using heat, these layers are fused together. Thus, a new object is created. nine0003

3D printers have been around for about 30 years, and we're just one step away from creating the magic food-producing boxes mentioned in the movie Star Trek . In recent years, the methods used to create various marvels of technology have become more cost-effective. And more and more engineers inspired by this fact create things that bring invaluable benefits to humanity.

The range of items that can be created with a 3D printer is amazing. But in order to realize how far progress has come, you can simply make an online request to buy a 3D printer. There are quite a few options waiting for you. Be sure to take a look at printer related products. For example, online giant Amazon. com offers you over 1,000 different printer gadgets. Pay attention to the 10 cheapest and most affordable 3D printers for purchase. nine0003

com offers you over 1,000 different printer gadgets. Pay attention to the 10 cheapest and most affordable 3D printers for purchase. nine0003

Agree that we used to use the online store in the shortest possible time to get the desired thing. And now, in such a store, you can buy a product that can create another product.

So let's take a look at 10 incredible things that can be printed on a 3D printer.

10. Amazing Guitar

Produced from selective laser fused nylon powder, this 3D printed guitar by musician Olaf Diegel can be yours for as little as $3,500. nine0113 A smaller version of the guitar designed by the printer is available for $3000 . Digel himself says that when designing, he was inspired by the idea of \u200b\u200bcreating the perfect instrument in the style of heavy metal.

9. Earth's crust

Phys.org reported on a team of soil scientists at University Albertay in the UK who are using 3D printing to investigate how the world works underground. For some time, using 3D scanning, they created a computer model of the earth, which allows for a detailed analysis of the structure of the soil. nine0003

For some time, using 3D scanning, they created a computer model of the earth, which allows for a detailed analysis of the structure of the soil. nine0003

3D printing, in turn, has taken things even further. Now, with such a real model, they can put bacteria and other microorganisms in there to study their movement, nutrition, and any other actions.

8. Crime scene

As you know from numerous police TV series and computer games, the most important job of a forensic scientist is to keep the crime scene intact. Apparently, the progress of 3D technologies will be able to significantly help forensic scientists in their work .

The police does not remain aloof from the achievements of scientific and technological progress. Most recently, the police department of the city of Roswell, New Mexico, USA, distinguished itself by purchasing a device that helps in solving crimes. This device is a network of 3D scanners that, when placed at a crime scene, form a detailed model of the entire space.

It turns out a recreated picture of the crime with all the details and details, with exact dimensions, with a correction of a few millimeters. A smaller model, made to scale, can be printed and presented in court. nine0003

7. Medical models

Today, expensive models are often used to study the structure of bone tissue and human structure. To make them, first, models of the bones themselves are created in several stages, then everything is coated with a gel-like composition to simulate skin.

3D printing simplifies this process: using a 3D scanner, you can create the structure of the bone tissue of any patient, which greatly facilitates the task of doctors in making a diagnosis. nine0106

6. Embryo model

Some 3D technology companies use ultrasound to enable expectant parents to look at a photo of their baby. Now, the company " 3D Children " offers expectant mothers and fathers to acquire a 3D model of the fetus. The price for this model varies depending on the size. From a tiny 5cm model for $200 to a 20cm baby for $800.

From a tiny 5cm model for $200 to a 20cm baby for $800.

5. Dentures

This item could not but appear in this list. With the advent of increasingly sophisticated technologies, it has become possible to do absolutely incredible things in the field of prosthetics. Hand prostheses are becoming more and more common due to the ease and affordability of the process of recreating limbs.

But phenomena such as the replacement of an entire human skull are no longer science fiction. Scientists have created a bionic ear using plastic and silver nanoparticles. nine0113 Such an ear hears even better than a human ear . True, they have not yet come up with a way to attach such an ear to a person.

4. Microscopic fireballs

Apparently, size is not an issue when it comes to 3D printing. Researchers at the Vienna University of Technology decided that they were already bored with creating analogues of objects in the size of the original, with incredible accuracy.

Then they developed a new kind of 3D printer that can create objects with the same precision, but at a smaller or minimal scale. nine0113 They made a tiny model of a racing car with nanometer precision.

3. Stem cells

The topic of stem cells has always been quite controversial, and is still very sensitive for some people. The stem cell is a " pure " cell, without content, but with unlimited possibilities - it can become any cell in the human body.

In Scotland, home of the cloned sheep Dolly, researchers have created a cellular printer that can print viable stem cells. The process involves two parts of a mixture called "b ionic " - a nutrient fluid called the cell medium, and the stem cells themselves. The main goal of the team working on this is the creation of whole organs.

2. Meat

Currently, several companies are working on the creation of synthetically printed meat, which has a good chance of success. In 2012, companies with the talking name " Modern Meadows ”, $350,000 was provided for further development in this area.

In 2012, companies with the talking name " Modern Meadows ”, $350,000 was provided for further development in this area.

More recently in Germany, a company called " Biozoon " created a special product for older people with eating problems.

1. Lunar Homes

The European Space Agency (ESA ) is seeking collaboration with architects to explore the feasibility of using a 3D printer to create a viable building material for building lunar homes. nine0003

Summarizing the construction of lunar houses, we can highlight the advantages of 3D printing on the Moon:

- The ability to build artificial structures on the Moon, without the need to send building materials from Earth.

- A possible way to erect buildings capable of supporting human life on any planet that humans can reach.

Disadvantages of 3D printing on the Moon:

- It's sad that shipping companies won't buy spaceships to deliver packages from Earth.

Learn more