What to look for in a good 3d printer

6 Things You Should Know Before Buying a 3D Printer

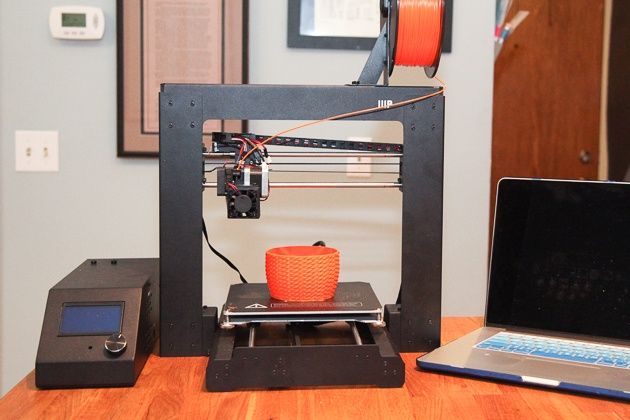

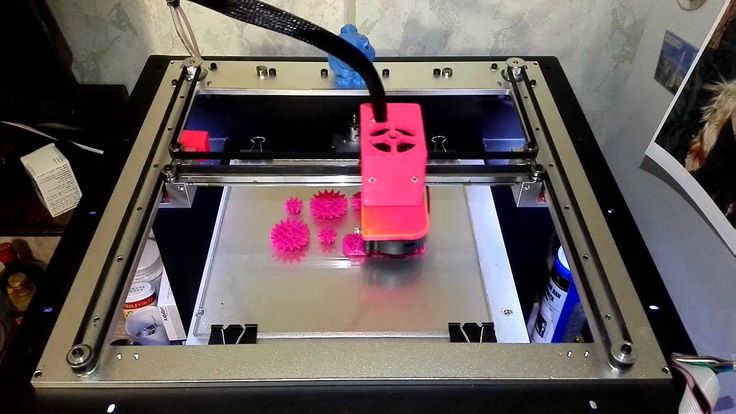

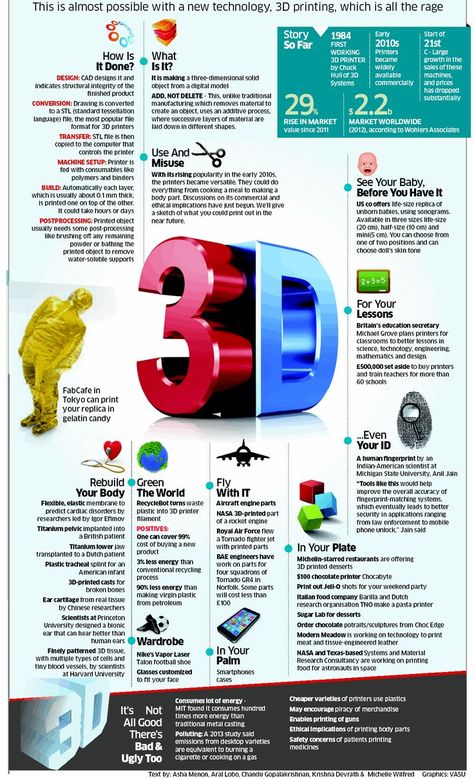

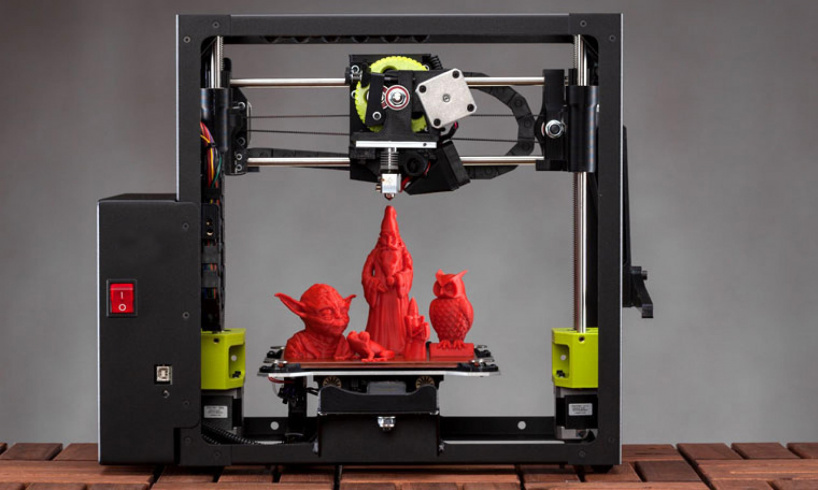

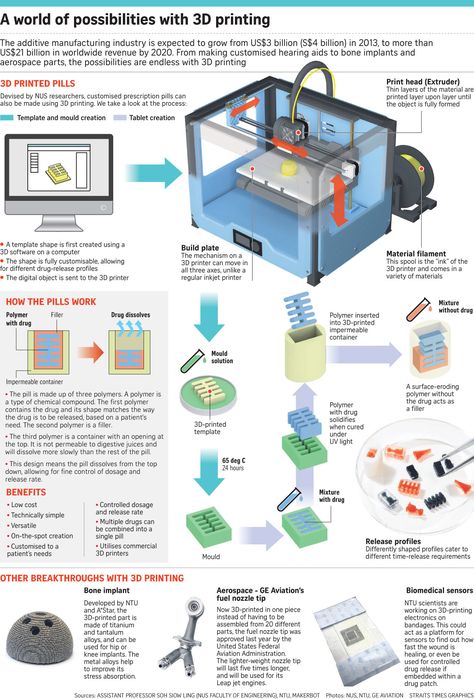

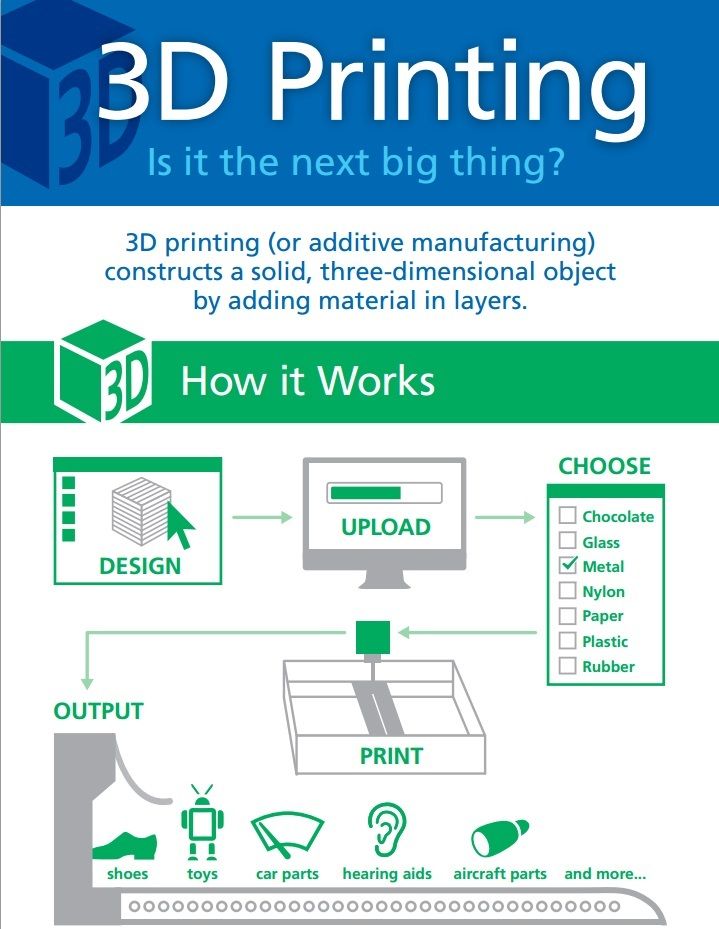

When you learn about the many functions a 3D printer can perform, you can get pretty excited about getting one. 3D printers are fancy because of the many models you can get to print with them; figurines, smartphone cases, and an endless list of things.

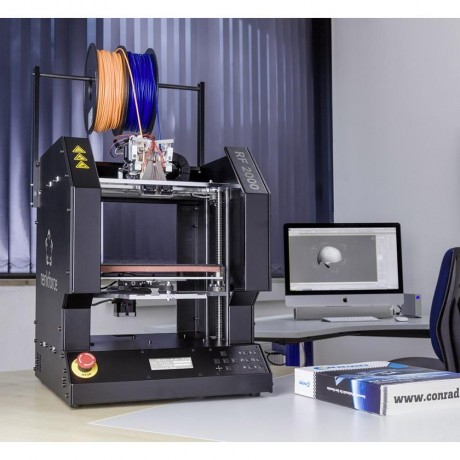

There are different specifications of 3D printers, and they vary according to size, function, and technology. So, before you buy a 3D printer, read this article to learn things you should know about 3D printers.

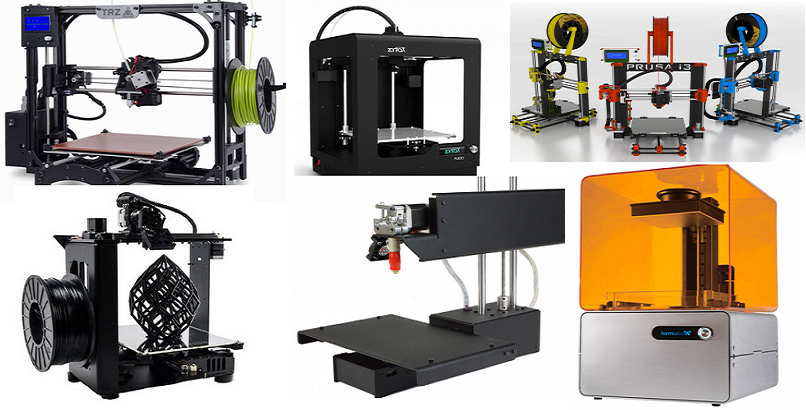

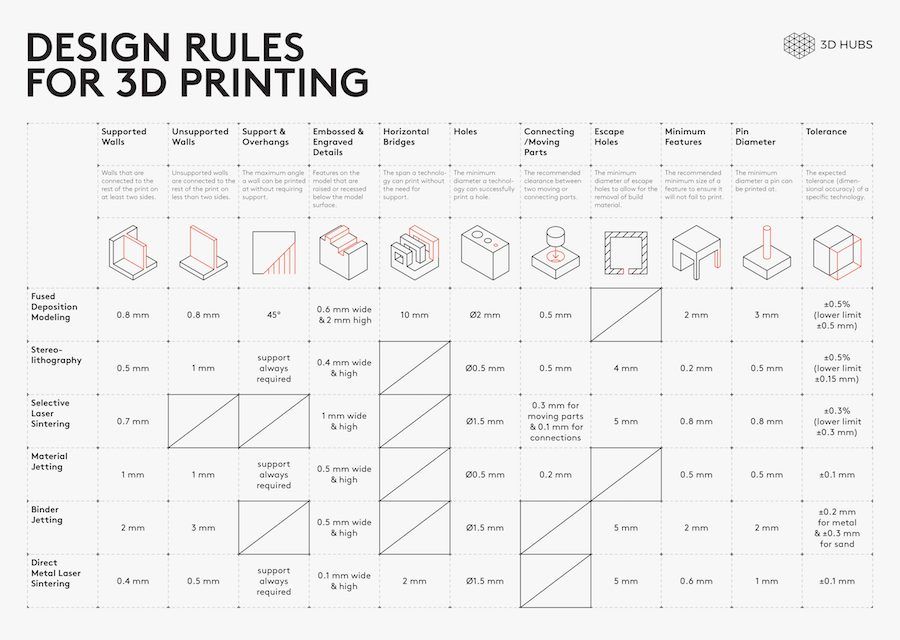

1. Types of 3D Printers

Before buying a 3D printer, you should know the types of 3D printers that are available.

Fused Deposition Modelling (FDM) Printers

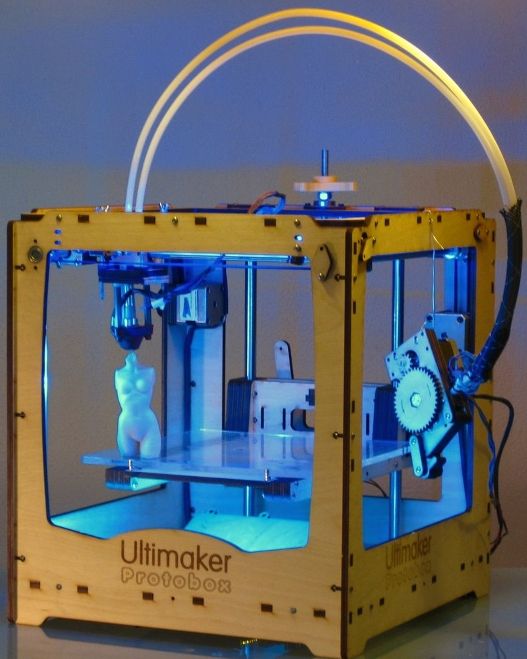

FDM technology was first developed by S. Scott Crump in the late 1980s and later commercialized in 1990. Fused Filament Fabrication (FFF) is an equivalent term for FDM created to give a phrase that is legally unimpeded in its use.

In order to create an object with an FDM printer, the files have to be in a computer-aided design (CAD) format which must be converted to a set-up that a 3D printer can understand, in most cases the STL design. These printers use both modeling materials and support materials. The modeling material constitutes the concluded object while the support material holds up the object during printing.

These materials take the form of a thermoplastic filament which is uncoiled and directed through an extrusion nozzle. The nozzle then melts the filaments and places them on a build platform or base. The build platform and nozzle are regulated by a computer which helps generate the X, Y, and Z coordinates to be adapted during printing. The nozzle moves vertically and horizontally over the base forming a thin layer of plastic which after cooling hardens and binds the layer beneath it. The base is then lowered to enable the formation of the next plastic layer, this process continues until the whole design is complete.

The final part of the printing using the FDM technology is removing the object from the printer once it is complete. This is done by soaking the object in a detergent and water solution or by breaking off the support base by hand. To improve the appearance, the object can be painted, sanded, or lacquered as desired.

To improve the appearance, the object can be painted, sanded, or lacquered as desired.

Stereolithography (SLA)

The SLA printing process creates a model by illuminating a UV light beam on resin or any other photosensitive liquid to harden the area and create the desired model. This method makes the object of higher quality than that of FDM printed objects.

SLA printing uses similar technology to other minor 3D printing processes like Digital Light Processing (DLP) and LCD.

Selective Laser Sintering (SLS)

The SLS printing model also uses a process similar to that of SLA. However, the only difference is that SLS uses lasers instead of Ultraviolet light beams and powders instead of photosensitive liquid. The laser melts and fuses the powder to create a solid model.

SLS printing process is the 3D printing process that can print metal objects and models.

2. Your Budget

When you know about the price of 3D printers and the cost of running them, you might reconsider getting one. However, do not panic; you can get a 3D printer for as low as 180 EUR- a simple model like Creality’s Ender 3.

However, do not panic; you can get a 3D printer for as low as 180 EUR- a simple model like Creality’s Ender 3.

The FDM printer price ranges from 500 to 1500 EUR, while an SLS price ranges from 6000 to 18,500 EUR. Here you can get the best price from best buy 3D printers.

Note that the cost of the 3D printer does not cover all the materials you will need to print the models and objects. The cost of the material varies directly with the cost of the 3D printer. The prices of filaments change regarding the materials that were used in their production.

So, do not just consider the initial cost of getting the 3D printer; consider the subsequent amount you will need to 3D print objects. Spare parts are very affordable, and the price of 1 kg of the most popular filaments is around 20 EUR. With 1kg of filament, you can print a huge amount of 3D products. The consumption of filament depends on several different factors, so it is difficult to determine the exact number of models you can make with 1000g of material. Consumption is affected by model fullness, layer thickness, product size,…

Consumption is affected by model fullness, layer thickness, product size,…

3. Features

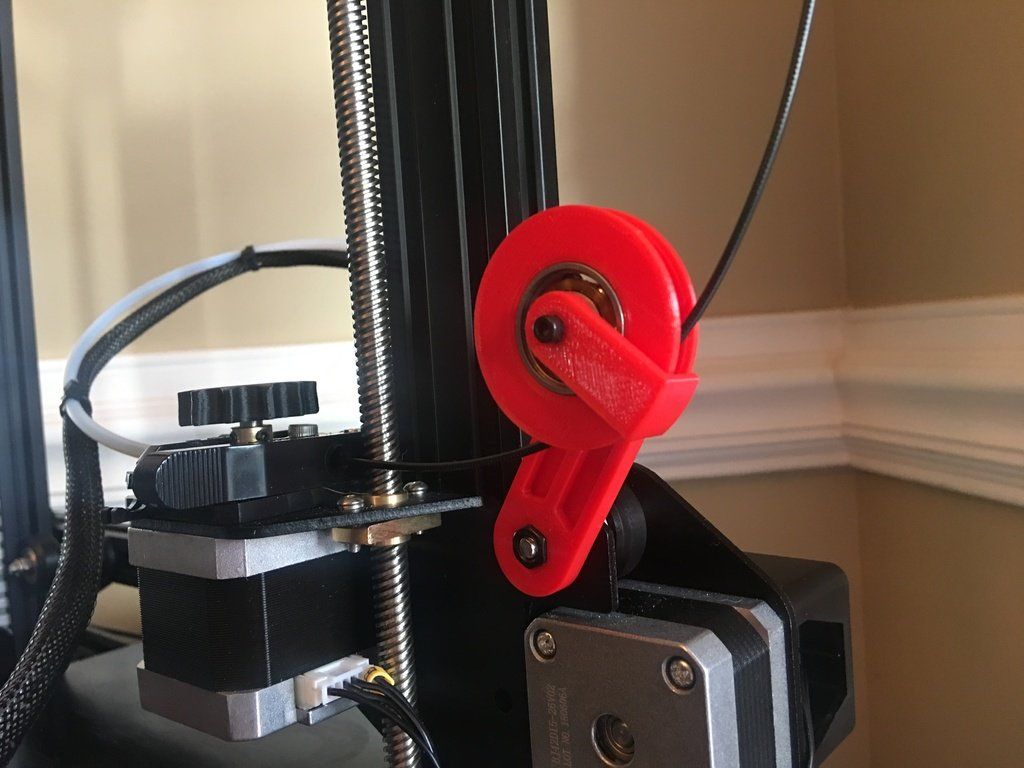

When you decide what type of printer you would like to get, you should check out the features you want your printer to have. Some FDM printers can cool the nozzle when you are done printing, and some other printers can move the nozzle away after printing to prevent overheating or the production of excess filament.

Apart from these safety features, be sure to check for other features like:

- type of plate,

- touchscreen interface,

- build volume,

- print bed size,

- sensor filament,

- bed leveling,

- how many extruders have,

- Does it have a direct drive extruder or a Bowden tube system,

- Wi-fi connection,

- Diameter of filament (1,75mm or 2,85mm), …

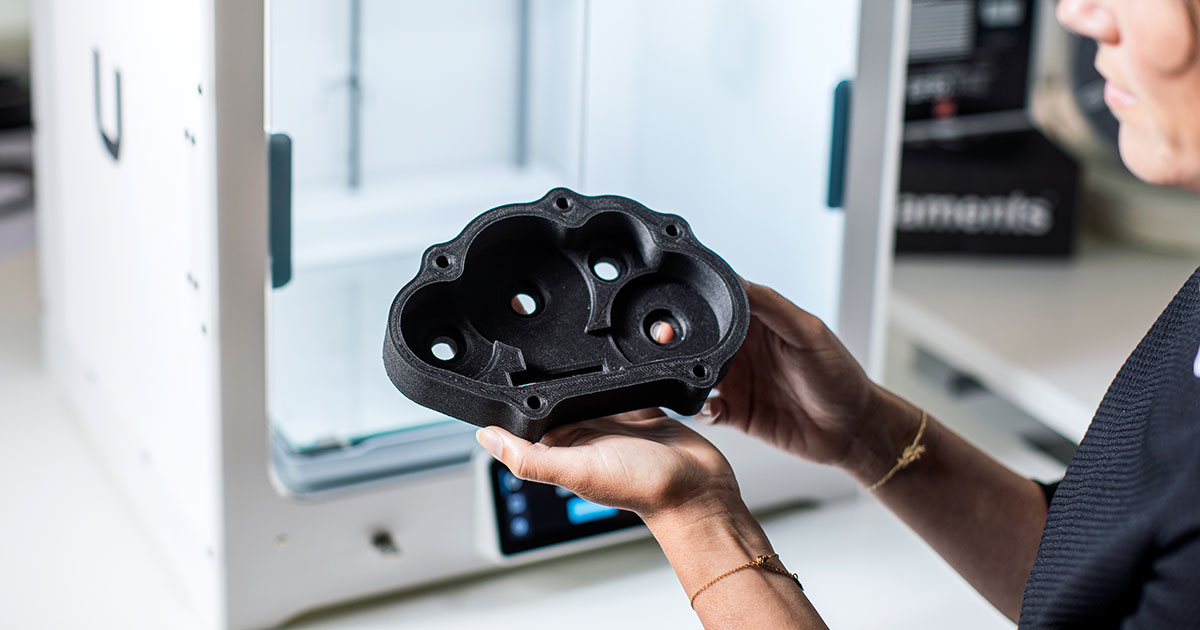

4. End Result 3D model/ Which 3D material is best to use?

What you intend to print will determine the type of material and the 3D printer you will use. Each type of 3D printer has different kinds of material it supports. 3D filaments are very different from each other in their properties. If you want beautiful, aesthetically pleasing filaments, then SILK or PLA will be the right choice for you. However, if you need a strong and light filament, you will print the PAHT filament with carbon fiber. It is important to know the properties of the materials with which you will 3D print;

Each type of 3D printer has different kinds of material it supports. 3D filaments are very different from each other in their properties. If you want beautiful, aesthetically pleasing filaments, then SILK or PLA will be the right choice for you. However, if you need a strong and light filament, you will print the PAHT filament with carbon fiber. It is important to know the properties of the materials with which you will 3D print;

PLA FILAMENT (Polylactic Acid)

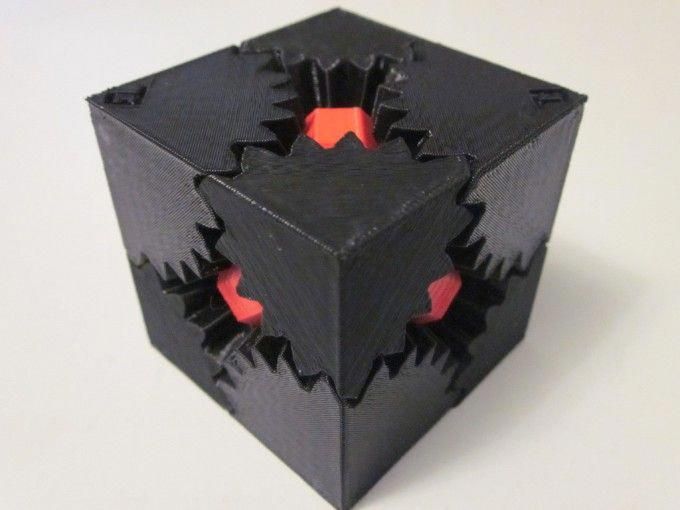

PLA filament is one of the most popular materials in the 3D world. It is used to create household items, figures, vases, phone accessory cases, holders, and home plastic materials. You can get it in full and transparent colors, with the addition of wood (PLA WOOD), glitter (PLA glitter), a special pearl gloss (PLA Pearl), …

Pros

- It is eco friendly and biodegradable

- It cools quickly, which prevents model warping

- Suitable for non-heated print beds and adhesives

Cons

- It has a low melting point which sometimes causes models to deform when you subject them to high heat.

- It is not suitable for making joints or interlocking parts.

ABS FILAMENT (Acrylonitrile Butadiene Styrene)

ABS filament is also a type of plastic made from petroleum-based substances. It is known for being flexible and strong. It is suitable for outdoor products because it can withstand harsh conditions.

Pros

It is very adaptable, making it easy to use to create joints and interlocking parts.

It does not deform when subjected to high heat because it has a high melting point.

Cons

Its high melting point makes it cool slowly and can cause model warping.

It emits fumes that can be dangerous to one's health.

PETG filament (Polyethylene Terephthalate Glycol)

PETG is a thermoplastic polyester modified with glycol. It has a combination of PLA’s ease of use and ABS durability. It is used to make mechanical components, food containers, and water bottles. If you need a hard, strong piece and you are deciding between PLA and PETG filament, choose PETG and you will not be disappointed. In addition to its durability, it is also important to mention that is made of eco-friendly materials, as it is one of the few filaments that can come into contact with food. However, always ask the manufacturer for a food safety certificate.

If you need a hard, strong piece and you are deciding between PLA and PETG filament, choose PETG and you will not be disappointed. In addition to its durability, it is also important to mention that is made of eco-friendly materials, as it is one of the few filaments that can come into contact with food. However, always ask the manufacturer for a food safety certificate.

Pros

- It is FDA-approved that it is suitable for edible consumption containers.

- It does not cause model warping

- It is heat and water-resistant

- It has good electrical properties

Cons

- It is not biodegradable

- It is more expensive

5. Goals

This is also one of the most important factors to consider before buying your 3D printer. Your goal will determine the type of 3D printer to get, the features it should have, and what filaments should you use.

It is important to think about the conditions in which you will use the printer. Outdoor use might require the printer to be waterproof and UV-resistant. And if you want it for indoor use, it must fit into your home. It is important to consider that if you are going to print ABS filament you will smell it during printing since it has a specific odor and is not the safest choice for your bedroom or your kids’ room.

Outdoor use might require the printer to be waterproof and UV-resistant. And if you want it for indoor use, it must fit into your home. It is important to consider that if you are going to print ABS filament you will smell it during printing since it has a specific odor and is not the safest choice for your bedroom or your kids’ room.

When deciding where a 3D printer will be placed, you need to think about what print size suits you; how big do you want your 3D printed items to be? If you are looking to print small items such as figurines, phone accessories, car accessories, useful items for your home, etc. you can look at the Ender 3 or Ender 5 series printers. However, if you need larger models, the CR-10 series will be right for you, as it offers a larger print area and consequently larger prints. The CR-10 MAX printer is considered one of the largest on the market, offering prints up to 450 x 450 x 470 mm.

6.

Safety

Safety You should look out for safety features before getting your 3D printers, primarily if you use them in your home or areas accessible to children. 3D printers work with heat, and you will need to take extra care to avoid bad burns.

Some 3D printers have enclosures around the print areas, while some take the nozzle away once you pause or stop printing.

Safety also extends to how environmentally friendly the 3D printer is. Some 3D printers use materials (like ABS plastics) that produce fumes. This type of 3D printer might not be suitable for indoor use or in a place that is not well-ventilated.

In addition, know what material is suitable for specific products. If you want to produce kitchenware or consumables containers, you must ensure the material is food-safe. Note that an FDM-type 3D printer can collect bacteria with its porous surfaces, making it unsafe for food containers.

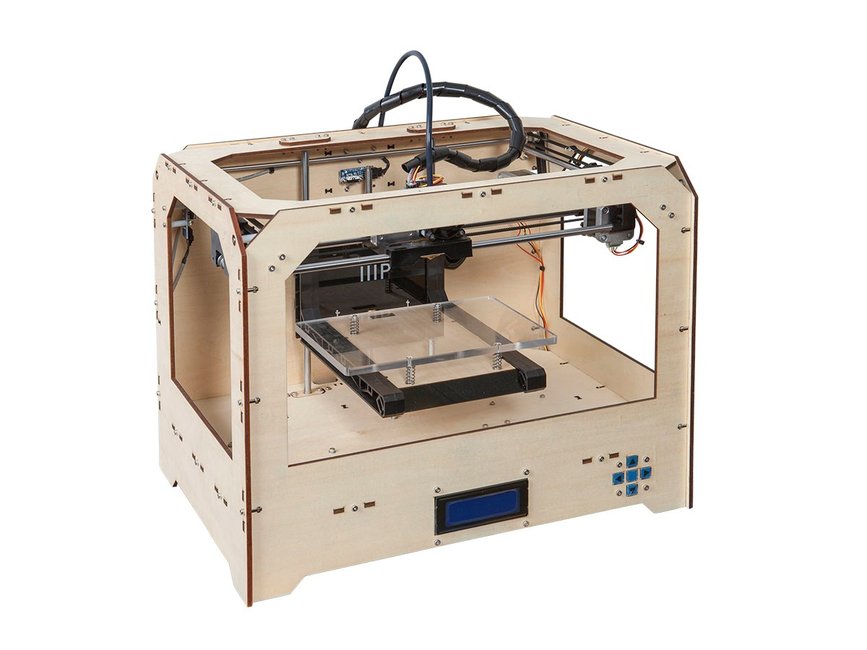

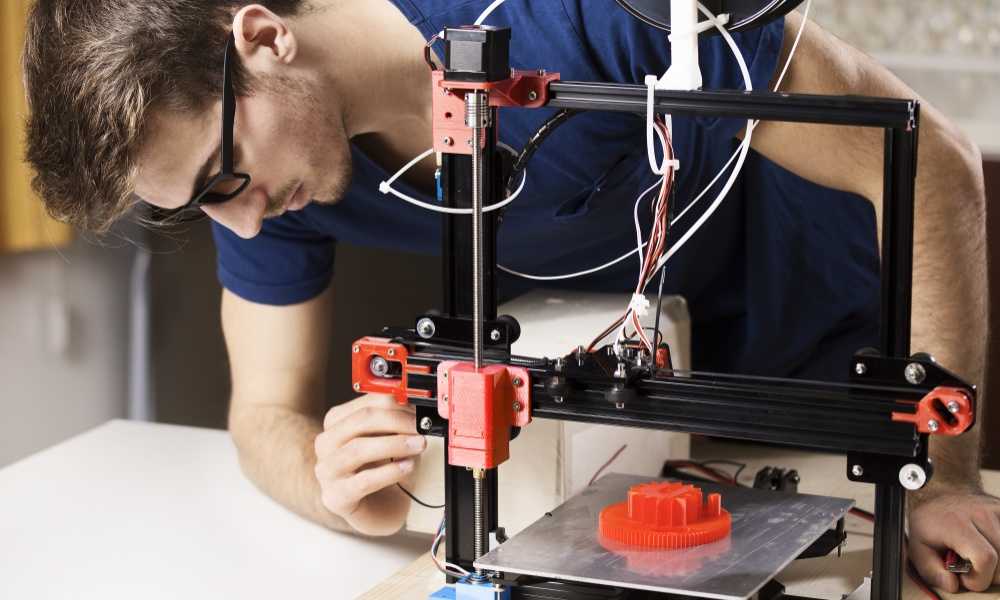

Building vs. Buying a 3D Printer

3D printing technology leaves a chance for you to be a 3D printer maker or creator. You do not necessarily have to buy a 3D printer because you can build one for yourself. And even though making a 3D printer might be more time-consuming and hectic, it is cheaper than buying a new one.

You do not necessarily have to buy a 3D printer because you can build one for yourself. And even though making a 3D printer might be more time-consuming and hectic, it is cheaper than buying a new one.

If you decide to go with building your 3D printer, you can get the 3D printer kits where you will find an instruction manual, or you can check online to find available tutorial videos. When building your 3D printer, it is better to use a combination of videos and instruction manuals so that you do not make mistakes.

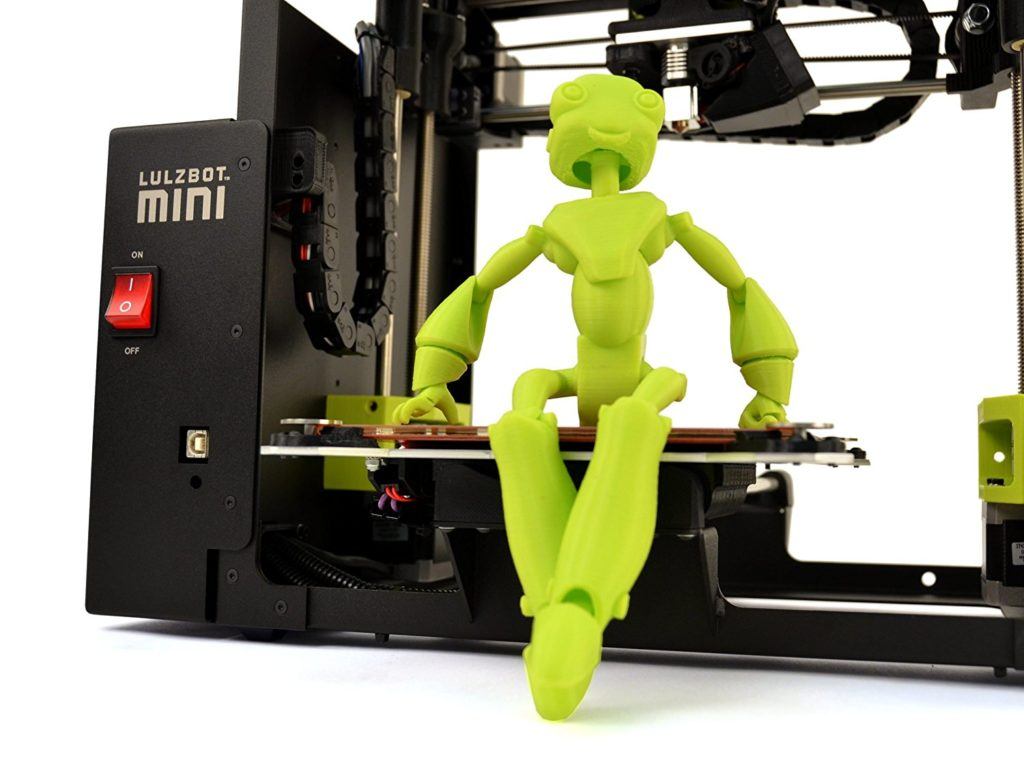

And if you do not have the time or energy to do this, get a pre-assembled 3D printer. The 3D printers you can buy these days usually come with a few parts that need to be assembled. It is definitely easier and less time-consuming, so if you can’t wait to start with 3D printing, is best to buy a 3D printer.

Extra Tips for Getting a 3D printer

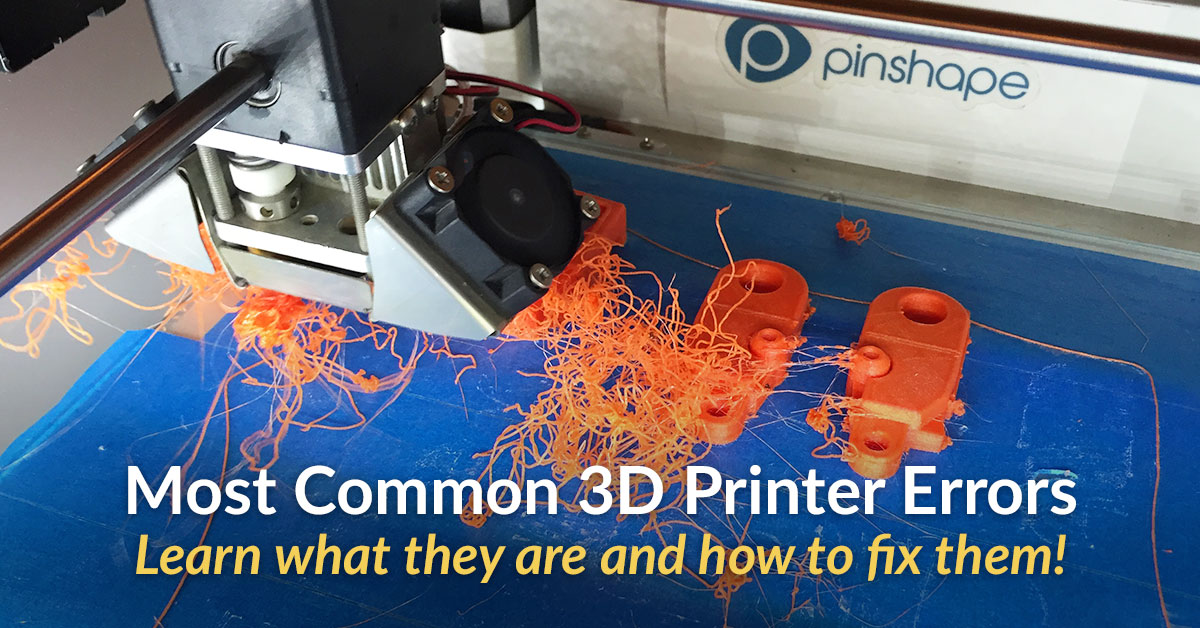

Get an Auto-levelling 3D printer.

If you are into the 3D printing service, it is better to go for an auto-leveling 3D printer rather than a manual-leveling one. Manual leveling requires pre-leveling knowledge and a few DIYs. And in cases where the print bed is not leveled, it can cause scratch marks on the prints, poor adhesion, and nozzle clogging.

Manual leveling requires pre-leveling knowledge and a few DIYs. And in cases where the print bed is not leveled, it can cause scratch marks on the prints, poor adhesion, and nozzle clogging.

Get a decent filament.

The level of quality of your final product is of the essence. If you want to get the best final product, do not go cheap on the filament, as it determines how well the final product will be.

Conclusion

Getting a 3D printer requires your money and attention; you need to pay attention to the details to get the appropriate one for the intended purpose. Consider what you want to print, look out for the features you want in it, and determine if the quality of the final 3d model presents what you want.

Follow these tips diligently, and you will choose the 3D printer you want and need.

10 Things You Should Know Before Buying 3D Printers

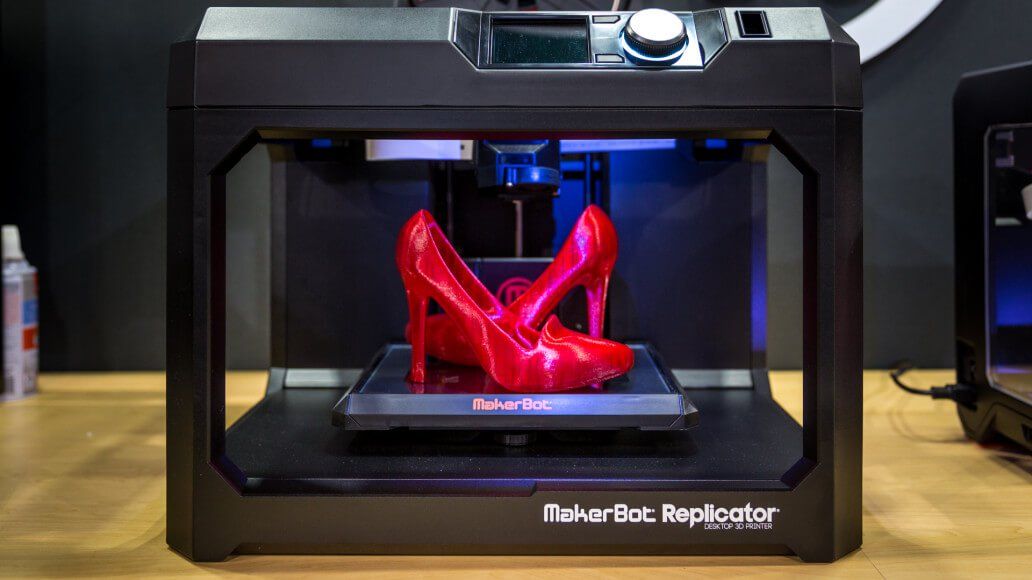

So you have decided to buy yourself a 3D printer after hearing about the amazing things it can build. You want to get started on printing models of your own a custom phone case, cosplay materials, figurines, musical instruments – the possibilities are endless.

You want to get started on printing models of your own a custom phone case, cosplay materials, figurines, musical instruments – the possibilities are endless.

Hold your horses, there are a few things you need to know before diving into the world of 3D printing.

There are a lot of 3D printers on the market today that have varying specifications, which in turn cater to different demands.

On top of that, there are technicalities about 3D printing that you really should look into. To help you decide on which printer to make your first, we have complied a list of 10 things you need to know before you buy a 3D printer.

10 Cheap and Affordable 3D Printers to Buy

10 Cheap and Affordable 3D Printers to Buy

There was a time when 3D printers were a novelty - but not anymore. You see hundreds of... Read more

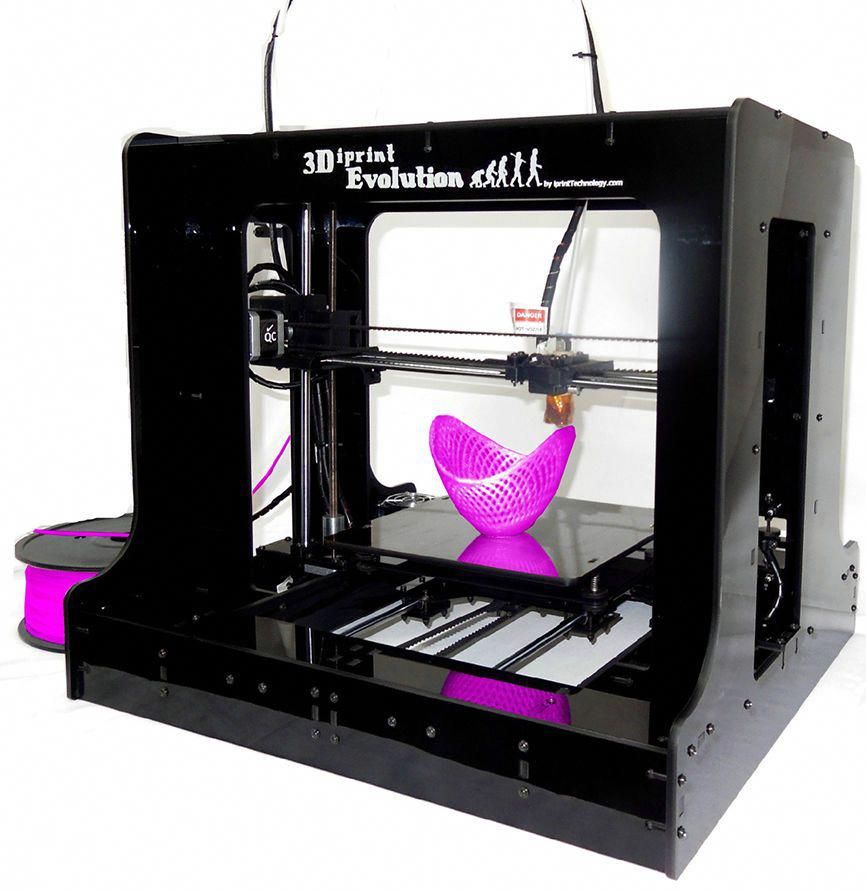

1. Types of 3D printers

3D printing is a broad term that covers the technologies required for producing physical materials. The one you probably heard of in the media and the most popular among hobbyists is the one that uses Fused Deposition Modeling (FDM).

The one you probably heard of in the media and the most popular among hobbyists is the one that uses Fused Deposition Modeling (FDM).

Fused Deposition Modeling (FDM)

FDM is an additive process, where a model is created by heating and extruding plastic, pieced together layer by layer.

Most of the 3D printers referred in this post works on FDM, as they are more widely available and easy to find.

There are 2 other types of 3D printing available: Stereolithography and Selective Laser Sintering (SLS). They are much more expensive compared to FDM.

Stereolithography

Stereolithography also uses the additive process but instead of extruding plastics, the process utilizes an ultraviolet light beam to harden a model from a pool of photosensitive liquid.

This allows for a higher quality printout.

Selective Laser Sintering (SLS)

SLS is similar to stereolithography, except that the process involves lasers and powders instead of UV light beams and liquid. A laser is used to melt the powder, creating a layer of the printed material.

A laser is used to melt the powder, creating a layer of the printed material.

This allows some models to print metal objects, which is not possible in the other two processes.

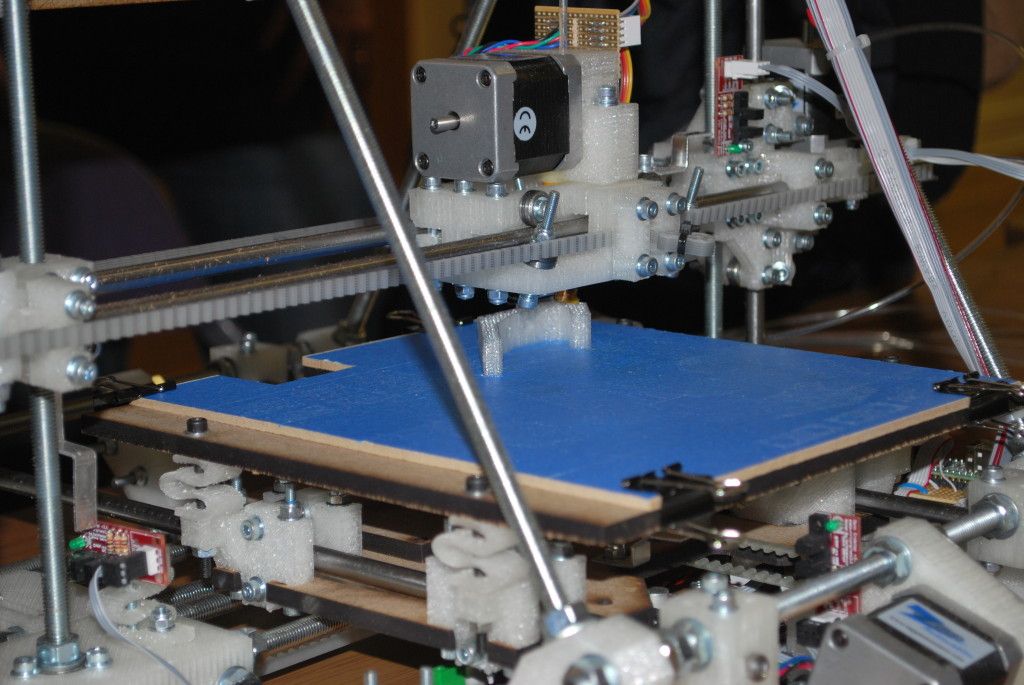

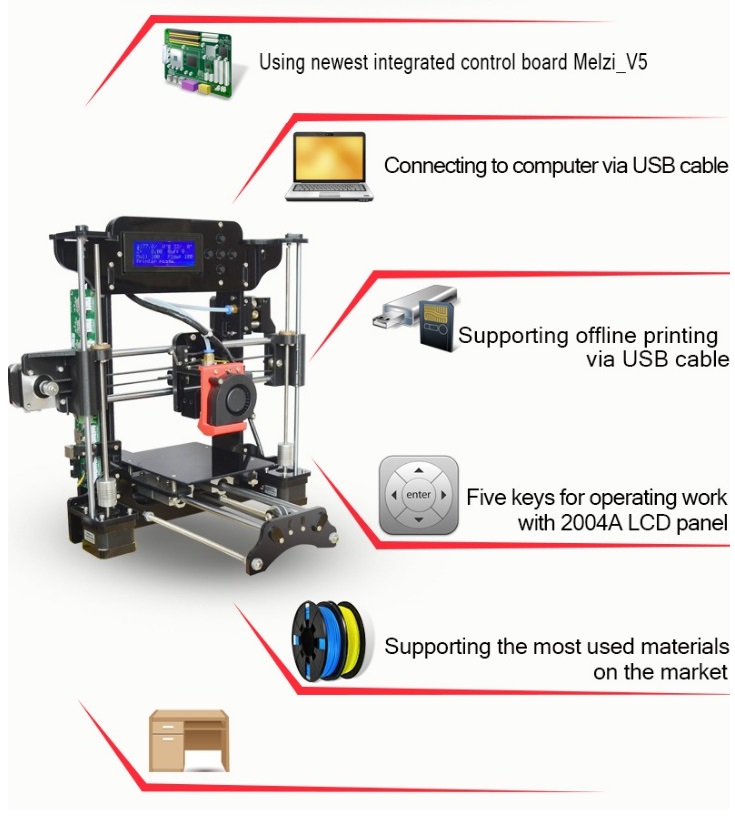

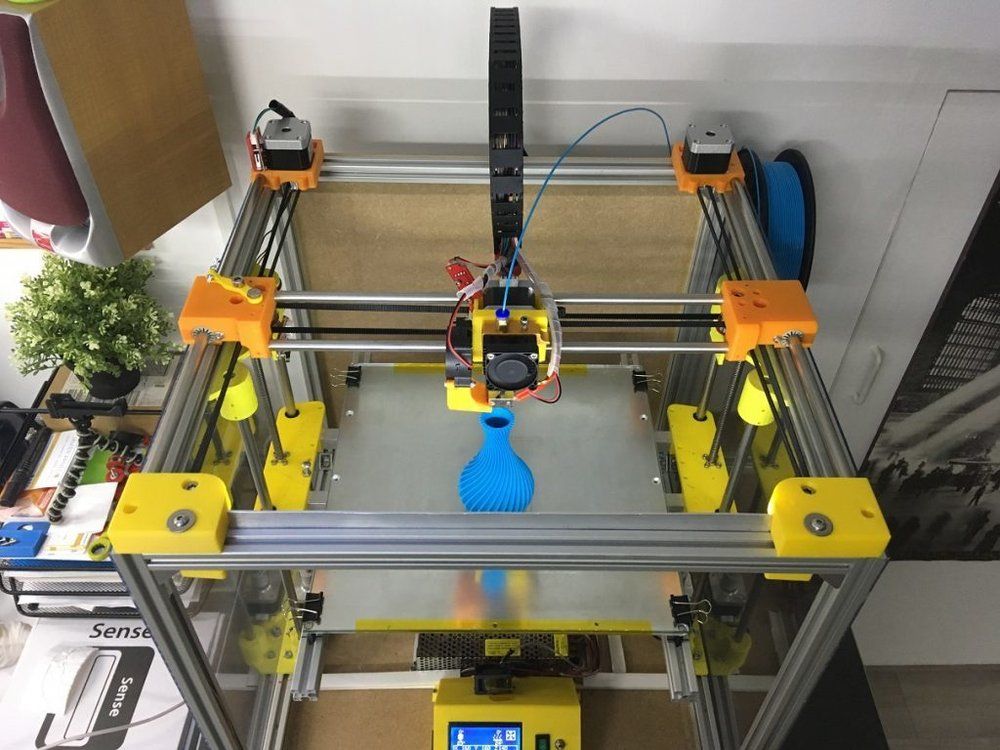

2. Build Your Own Or Buy One

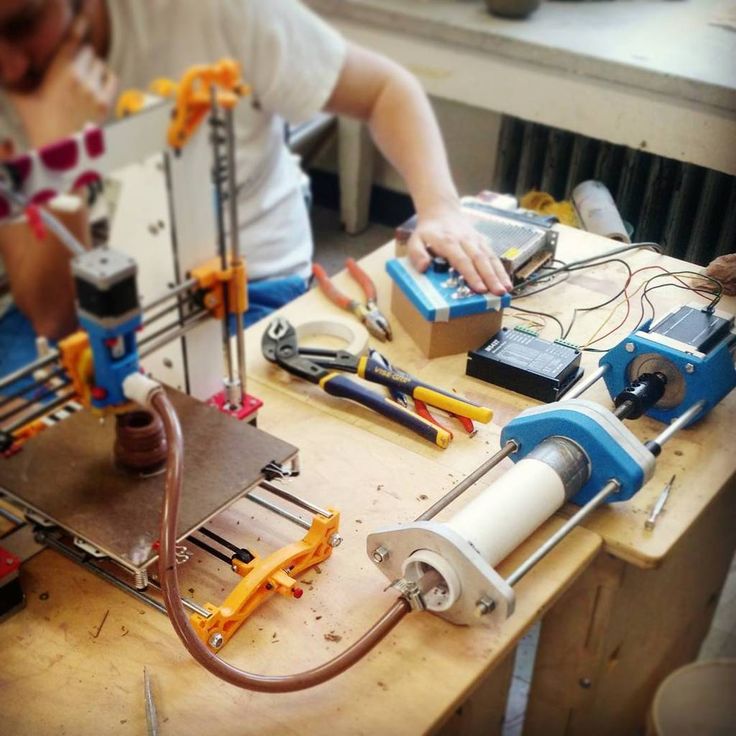

The 3D printing community is one made of creators and makers, so it makes sense that many people would like to try their hand in building a 3D printer on their own.

There are building instructions and 3D printer kits available online if you decide to go with this route.

Building your own printer can be cheaper than buying one but if you don’t have the time, you could always buy a pre-assembled printer.

Your final decision will depend on whether you are interested in tinkering with the technology, or just want to start printing right away.

3. Price

One of the main factors that can help turn 3D printers mainstream is their market price. Prices depend mainly on the quality of the output.

In general, the higher-quality ones tend to go above $1000; professional printers can even go above $2000, e.g. the MakerBot series. But if you are just dipping your toes in 3D printing, you can start with simple models that go for as low as $100.

With rising popularity and heavy competition, the prices of printers will only go down while the quality improves. Note that these printers do not come with the materials you require to print your products.

You will need to separately acquire the materials as different products may require different materials.

4. Materials used to print

The two materials required for 3D printing are Poly Lactic Acid (PLA) and Acrylonitrile Butadiene Styrene (ABS). Both are thermoplastics that will become soft and malleable when heated, frozen when cooled.

They are sold as 1kg (2.2lbs) spools of filament, priced in the $30 range.

Let’s take a look at the good and bad of both materials.

Poly Lactic Acid (PLA)

PLA is a type of plastic that is derived from corn starch, excellent for beginners to start dabbling with. Also great for creating small, simple household items. Other characteristics include:

- Biodegradable and environmentally sound

- Cools quickly, which prevents problems with model warping

- Available in both solid and translucent colors, gives printed objects a glossy look

- Disadvantage: Its low melting point may cause models to deform under high heat

- Disadvantage: It is difficult to work with if you require joints and interlocking parts

Acrylonitrile Butadiene Styrene (ABS)

ABS is a petroleum-based plastic that is a popular choice because of its strength and flexibility – think Lego bricks (which can be made using 3D printers, if you didn’t know).

- Its flexibility makes creating interlocking pieces easier to create and work with.

- It also has a higher melting point, so your creations will be less likely to deform under high heat.

- Disadvantage: It takes longer to cool compared to PLA; models are susceptible to warping.

- Disadvantage: It emits fumes during printing (more on this below).

How to Choose

You need to know which material is suitable for your final product. From there you can choose which type of printer you should buy. It is important to know that not all printers can accept both materials – some will work with only either one type.

When it comes to filament size – 1.75mm or 3mm in diameter – it doesn’t factor much into the end quality. More popular printer brands go with 1.75mm so it is recommended that you start with that.

5. Safety

When it comes to 3D printing, there are a few safety issues to take note.

Playing With Heat

The most important thing to remember is that you are working with heated plastics. Extruders, plastics and in some printers, the print bed itself can get very hot and can cause bad burns if you are not careful.

Extruders, plastics and in some printers, the print bed itself can get very hot and can cause bad burns if you are not careful.

Some printers have no enclosure around the print area; practice extra caution with these printers.

Beware of Fumes

It is important to keep your 3D printer in an well-ventilated room. During the printing process, expect fumes to be emitted, particularly when you use ABS plastics.

These fumes are reported to be rather overwhelming although there is little to no research that states the impact they have on general health.

Still, it is best to take the necessary precautions, particularly if you will be using 3D printers a lot.

Food-Grade Plastic

3D printers can be use to create many types of household items, including kitchenware. Both ABS and PLA are generally food safe but if there are additives added in, those additives may not be.

Another major concern is that products created with FDM-type 3D printers have porous surfaces on which bacteria can collect in.

You can coat the object to make it safer to use but it is best to limit the usage of 3D printed kitchenware.

6. Quality

To produce high quality 3D printed products, you need to take note of two things: print resolution and print speed.

Print resolution refers to the level of detail the printer can get, measured in microns – the smaller it is, the higher level of detail in the objects you can create.

Print speed measures how fast the printer can move its extruder – the higher the print speed, the faster it will print.

Note that other features may affect the print speed, such as the acceleration and deceleration of the printer, which helps prevent the printer from shaking.

In the end though, the best way to gauge the quality of a printer is to look at its output. You can look at photos, available online, of the final output of 3D printers before buying.

7. Obtaining A 3D Model

When it comes to getting a 3D model, there are two routes: you can create it yourself or download a pre-made model blueprint from the Internet.

If you intend to create your own model, there are a variety of software, both free and commercial, that will help you bring your creation into the real world. If you like, you can even learn 3D modeling.

Learning to model in a computer is a difficult task that will take time and effort to truly get used to. Fortunately, for those who are short on time, there are websites that provide 3D models of many different items, made by enthusiasts from all over.

A quick google search can probably yield you the item that you’re looking for.

8. STL Files

The STL file (STereoLithography) is the standard file format that you will use to print your 3D model into a physical object.

The file can be generated using most CAD programs so if you are building your own 3D models, chances are the software you are using can output one.

Basically inside an STL file is the information needed to produce a 3D model. The model itself is broken down to a series of triangles and a list of their XYZ coordinates is used by the printer to create the physical object, layer by layer.

9. Slicing Software

Once you have an STL file of the model you want to print, you will have to put them through a slicing software. What slicing does is that it “tells” your printer how to print your model.

It provides instructions on the number of layers needed, the starting position of the printer and the parts of the model that should be solid or hollow.

There are a number of software to help you with this although some software come with the printer. A good example would be MakerBot’s MakerWare.

10. Community

The great thing about a new tech trend is that there is almost always an online community devoted to it. It is no different with 3D printers.

Check online for a community of people who own a particular brand, to get more insight and answers to questions you may have about the ins and outs of that printer.

If the community is small or worse, nonexistent, the lack of users should raise a red flag about that particular brand.

All you need to make a sound investment is to read up more about that brand and its competitors so you know what you are getting into.

One of the main factors that can help turn 3D printers mainstream is their market price. Prices depend mainly on the quality of the output.

In general, the higher-quality ones tend to go above $1000; professional printers can even go above $2000, e.g. the MakerBot series.

But if you are just dipping your toes in 3D printing, you can start with simple models that go for as low as $100.

With rising popularity and heavy competition, the prices of printers will only go down while the quality improves.

Note that these printers do not come with the materials you require to print your products. You will need to separately acquire the materials as different products may require different materials.

4. Materials used to print

The two materials required for 3D printing are Poly Lactic Acid (PLA) and Acrylonitrile Butadiene Styrene (ABS). Both are thermoplastics that will become soft and malleable when heated, frozen when cooled.

Both are thermoplastics that will become soft and malleable when heated, frozen when cooled.

They are sold as 1kg (2.2lbs) spools of filament, priced in the $30 range.

Let’s take a look at the good and bad of both materials.

Poly Lactic Acid (PLA)

PLA is a type of plastic that is derived from corn starch, excellent for beginners to start dabbling with. Also great for creating small, simple household items. Other characteristics include:

- Biodegradable and environmentally sound

- Cools quickly, which prevents problems with model warping

- Available in both solid and translucent colors, gives printed objects a glossy look

- Disadvantage: Its low melting point may cause models to deform under high heat

- Disadvantage: It is difficult to work with if you require joints and interlocking parts

Acrylonitrile Butadiene Styrene (ABS)

ABS is a petroleum-based plastic that is a popular choice because of its strength and flexibility – think Lego bricks (which can be made using 3D printers, if you didn’t know).

- Its flexibility makes creating interlocking pieces easier to create and work with.

- It also has a higher melting point, so your creations will be less likely to deform under high heat.

- Disadvantage: It takes longer to cool compared to PLA; models are susceptible to warping.

- Disadvantage: It emits fumes during printing (more on this below).

How to Choose

You need to know which material is suitable for your final product. From there you can choose which type of printer you should buy.

It is important to know that not all printers can accept both materials – some will work with only either one type.

When it comes to filament size – 1.75mm or 3mm in diameter – it doesn’t factor much into the end quality. More popular printer brands go with 1.75mm so it is recommended that you start with that.

5. Safety

When it comes to 3D printing, there are a few safety issues to take note.

Playing With Heat

The most important thing to remember is that you are working with heated plastics. Extruders, plastics and in some printers, the print bed itself can get very hot and can cause bad burns if you are not careful. Some printers have no enclosure around the print area; practice extra caution with these printers.

Beware Of Fumes

It is important to keep your 3D printer in an well-ventilated room. During the printing process, expect fumes to be emitted, particularly when you use ABS plastics. These fumes are reported to be rather overwhelming although there is little to no research that states the impact they have on general health. Still, it is best to take the necessary precautions, particularly if you will be using 3D printers a lot.

Food-Grade Plastic

3D printers can be use to create many types of household items, including kitchenware. Both ABS and PLA are generally food safe but if there are additives added in, those additives may not be. Another major concern is that products created with FDM-type 3D printers have porous surfaces on which bacteria can collect in. You can coat the object to make it safer to use but it is best to limit the usage of 3D printed kitchenware.

Another major concern is that products created with FDM-type 3D printers have porous surfaces on which bacteria can collect in. You can coat the object to make it safer to use but it is best to limit the usage of 3D printed kitchenware.

6. Quality

To produce high quality 3D printed products, you need to take note of two things: print resolution and print speed.

Print resolution refers to the level of detail the printer can get, measured in microns – the smaller it is, the higher level of detail in the objects you can create. Print speed measures how fast the printer can move its extruder – the higher the print speed, the faster it will print. Note that other features may affect the print speed, such as the acceleration and deceleration of the printer, which helps prevent the printer from shaking.

In the end though, the best way to gauge the quality of a printer is to look at its output. You can look at photos, available online, of the final output of 3D printers before buying.

You can look at photos, available online, of the final output of 3D printers before buying.

7. Obtaining A 3D Model

When it comes to getting a 3D model, there are two routes: you can create it yourself or download a pre-made model blueprint from the Internet. If you intend to create your own model, there are a variety of software, both free and commercial, that will help you bring your creation into the real world. If you like, you can even learn 3D modeling.

Learning to model in a computer is a difficult task that will take time and effort to truly get used to. Fortunately, for those who are short on time, there are websites that provide 3D models of many different items, made by enthusiasts from all over. A quick google search can probably yield you the item that you’re looking for.

8. STL Files

The STL file (STereoLithography) is the standard file format that you will use to print your 3D model into a physical object. The file can be generated using most CAD programs so if you are building your own 3D models, chances are the software you are using can output one.

The file can be generated using most CAD programs so if you are building your own 3D models, chances are the software you are using can output one.

Basically inside an STL file is the information needed to produce a 3D model. The model itself is broken down to a series of triangles and a list of their XYZ coordinates is used by the printer to create the physical object, layer by layer.

9. Slicing Software

Once you have an STL file of the model you want to print, you will have to put them through a slicing software.

What slicing does is that it “tells” your printer how to print your model. It provides instructions on the number of layers needed, the starting position of the printer and the parts of the model that should be solid or hollow.

There are a number of software to help you with this although some software come with the printer. A good example would be MakerBot’s MakerWare.

10. Community

The great thing about a new tech trend is that there is almost always an online community devoted to it. It is no different with 3D printers. Check online for a community of people who own a particular brand, to get more insight and answers to questions you may have about the ins and outs of that printer.

It is no different with 3D printers. Check online for a community of people who own a particular brand, to get more insight and answers to questions you may have about the ins and outs of that printer.

If the community is small or worse, nonexistent, the lack of users should raise a red flag about that particular brand. All you need to make a sound investment is to read up more about that brand and its competitors so you know what you are getting into.

50 Cool Things to 3D Print / Sudo Null IT News

No ideas for 3D printing? Tired of worthless trinkets? Here is a list of 50 cool really useful things for 3D printing.

Like us, you're excited about the possibilities of 3D printing. But, unfortunately, the horizon is littered with trinkets, trinkets and other unnecessary things. We are in danger of being buried under a heap of useless rubbish.

Throw off the shackles of mediocrity! Let's create really useful things! Here is a list of cool things that you can make on a 3D printer right now..jpg) Prove to your family and loved ones that this wonderful technology can be used daily and in practice.

Prove to your family and loved ones that this wonderful technology can be used daily and in practice.

No access to 3D printer? No problem. Just upload your files to our 3D printing price comparison system and choose the best price, ONLINE!

Download from Myminifactory

Cool thing for 3D Press No. 29: Form for Snow.

Download from ThingiVerse

Cool 3D Printable Item #30: Wine Bottle Protector

Download from MyMiniFactory170004

Cool thing for 3D printing No. 31: Pocket ashtray

download from Myminifactory

Cool Press No. 32: Rod holder

3D Printable Cool Item #33: Apple Remote Stand

Download from MyMiniFactory

3D Printable Cool Item #34: Key Holder

Download with Myminifactory

Cool thing for 3D printing No. 35: Holder of cutlery for people with disabilities

download from Myminifactory

Current Press No. Cover wine bottle

Download from MyMiniFactory

Cool thing for 3D printing #37: Paper cup holder

download from Myminifactory

Cool thing for 3D printing No. 38: Case for blades

38: Case for blades

download from Myminifactory

Cool thing for 3D printing No. 39: Holder for children from MyMiniFactory

3D Printable Cool Item #40: Towel Rack

Download from MyMiniFactory

3D Printable Cool Item #41: Holder for a glass

Download with Myminifactory

Cool thing for 3D Press No. 42: Holder for a phone in the shower

Download from Myminifactory 9000

Twisting thing for 3D printing No. 43: Holder No. 43: Holder for beer glasses

Download from MyMiniFactory

Cool thing for 3D printing #44: MacBook Pro stand

download from Myminifactory

Cool thing for 3D printing No. 45: Protection for SD-Cart

download from Myminifactory

Cool thing No. 46: Bathrrics 0

Download from MyMiniFactory

3D Printable Cool Item #47: Ice Cream Cone Holder

Download from MyMiniFactory

Printable Cool Item #40016 shower set

download from Myminifactory

Cool Semit for 3D Press No. 49: Evacal separator

49: Evacal separator

Download with Myminifactory

Cool Press No. 50:

Download from MyMiniFactory

Want more exciting news from the world of 3D technology?

Follow us on social. facebook networks:

beginner's guide / Habr

The author of this post saw the first 3D model printed on a printer about 10 years ago. There was a meeting at a huge Russian advertising agency that was using the power of 3D printing to print demonstrations of a very expensive souvenir - it was to be made from copper, bronze, silver, and very small things from gold. The commercial director of the then company and I were twisting in our hands the future figurines and badges made of brown-gray-blue plastic, with sloppy burrs, “failures”, etc. It seemed to us the eighth wonder of the world - and when we were given the mock-ups for good, we were happy as children and already in the car joked that it would be cool to print pancakes, cakes and sausages on a printer. We have never been so close to predicting the future.

We have never been so close to predicting the future.

When the owner bought a 3D printer and you realized what hopelessness looks like

Today, 3D printers have become so affordable that almost everyone can buy their own just for fun (and we buy - we at Gearbest know better than anyone), for example, to print New Year's snowflakes or toys with a child, to make a model for work, an airplane for a hobby or elements for some incredible DIY. Moreover, often a 3D printer takes its place of honor next to a long-dead home printer, and the owner sometimes conscientiously thinks about finally printing something. Well, at least the Eiffel Tower and the Arc de Triomphe for my sister, who is passionate about French.

Such popularity is not surprising - 3D printers appear almost every week: affordable, with excellent consumables, multifunctional. And this trend will lead to one thing: printers will settle in everyone's home as a working tool, assistant, toy, training complex.

Looking forward to next generation 3D printers

The theory you need to understand what your 3D printer is like

Although the article is for beginners, it will not be possible to avoid terms - a long journey begins with the first step. Therefore, first of all, you need to ask what kind of printing technology a 3D printer has. Most hobby printers use a technology called "Fused Deposition Modeling" (FDM), aka "Fused Filament Fabrication" (FFF), aka "Plastic Jet Printing" (PJP). The printing technology is simple and straightforward: layers of plastic (rarely another material) are superimposed on each other and form the figure that you have modeled. That is, the product, as it were, is made up of many horizontal sections formed from plastic, which is extruded from a hot nozzle (the plastic thread melts) and freezes immediately after extrusion.

There are also SLA printers, in which printing occurs due to the fact that the resin interacts with a laser and hardens as the shape is created. These printers print ultra-precise and detailed products.

These printers print ultra-precise and detailed products.

The base material for DIY home printing is colored plastic, most commonly sold as filament on spools (rarely in short lengths). But, as we remember from the school chemistry course, plastic is also different and each type of material has its own properties of strength, brittleness, transparency, plasticity, etc. Most often, the material is called ABS filament or PLA filament. And these are not just acronyms.

ABS plastic is quite impact resistant and durable, does not break when bent. It is called by the first letters of the components: acrylonitrile (up to 35%), butadiene (up to 30%), styrene (up to 60%). It is a non-toxic and safe material that can be handled in the presence of children. However, in the open sun and frost, plastic can lose its appearance.

PLA (polylactide) is an extremely thermoplastic polyester that is more brittle and less durable than ABS. Completely environmentally friendly and biodegradable. PLA is made from corn or sugar cane. This type of plastic holds its shape well and has good friction, so if you're building something with moving parts, look into PLA.

PLA is made from corn or sugar cane. This type of plastic holds its shape well and has good friction, so if you're building something with moving parts, look into PLA.

Roughly divided, ABS is more for professionals, and PLA is more for beginners.

What other materials are available?

- Stainless - An alloy of stainless steel and bronze. Very cool material, but not used in amateur 3D printers.

- Wood is a blend of recycled wood and polymer. Products from a good, expensive thread of this kind look like wood and are pleasant in the hands. Printing with such a thread is no more difficult than the others.

- Resin is an expensive material with a high degree of smoothness, precision, excellent texture. Products may become cloudy from sunlight.

- Nylon is a popular material for 3D printing, but is more commonly used in industry and medicine.

When choosing materials, pay attention to the size of the spool and the diameter of the filament - they must meet the specifications of your printer.

- Printable area - in other words, the volume of a figure that can be printed on a 3D printer. This value is usually specified in cubic centimeters or as a ratio of depth, height and width in mm.

- Print speed is an important parameter that determines how fast the nozzle gives off the molten filament (mm per second). Good speed is not always worth rejoicing at - sometimes it comes at the expense of print resolution. Also, the speed is affected by the print material and the structure of the model itself that you are trying to make.

- Layer resolution - essentially the thickness of the layer: high resolution - thin layers, almost imperceptible relief, smooth product; low resolution - rough work with thicker layers. Often, 3D printers provide the user with the option to choose a resolution.

Layer thickness 50, 100 and 200 microns - there is a difference, of course. The material is melted in the nozzle and extruded from it (printed). In addition to the nozzle, the extruder includes a filament feed mechanism, a temperature sensor and a cooling system (in normal models). If the printer has one extruder, then the print is pretty monotonous - one color at a time. But two or more extruders allow you to combine colors and materials. Printers with a dual nozzle per extruder are rare, expensive - at home this is an overkill.

In addition to the nozzle, the extruder includes a filament feed mechanism, a temperature sensor and a cooling system (in normal models). If the printer has one extruder, then the print is pretty monotonous - one color at a time. But two or more extruders allow you to combine colors and materials. Printers with a dual nozzle per extruder are rare, expensive - at home this is an overkill.

In extrusion, a thermoplastic filament is extruded as a molten material and this very material is deposited along the X and Y coordinates, and the object itself is “formed” along the Z coordinate (hence 3D printing).

It is these programs that will help you design the model and generate the STL file.

It is these programs that will help you design the model and generate the STL file.

Autodesk Inventors Fusion

- Options - beautiful display, function buttons, material recognition, etc. - this is already a matter of taste and convenience, which, nevertheless, affects the price.

Well, separately it is necessary to say about the delivery model, which you will certainly meet even in this article - the concept of "Kit". Kit differs from Assembled in that the user must assemble the device on their own (DIY). There are many pluses: the main one is the pleasure of assembly and the opportunity to study the printer to the screw, the second is a significantly reduced price due to the compact delivery, also due to the fact that the manufacturer did not have to assemble and calibrate your 3D machine.

Alfawise U20 can be called a solid printer for beginners - on the one hand, it is simple and affordable ($ 299. 99, and with the GBAlfawiseU20 coupon $ 279.99 - only 50 coupons), on the other hand, it has everything to make the owner feel almost professional. What we get from this model: a working area of 300 x 300 x 400 mm (this is enough for most amateur requests and for some engineering ones), a solid aluminum frame, an extruder with a single 0.4 mm nozzle and the ability to heat up to 250 degrees (and this is already choice of material!), support for a memory card, convenient LCD screen, print speed from 20 to 150 mm / s, support for ABS, PLA, TPU (wear-resistant flexible material based on polyurethane). The printer weighs 12 kg, it will take up space on the table. And yes, this is the same DIY Kit, that is, you have to assemble the car yourself (not without fun!).

99, and with the GBAlfawiseU20 coupon $ 279.99 - only 50 coupons), on the other hand, it has everything to make the owner feel almost professional. What we get from this model: a working area of 300 x 300 x 400 mm (this is enough for most amateur requests and for some engineering ones), a solid aluminum frame, an extruder with a single 0.4 mm nozzle and the ability to heat up to 250 degrees (and this is already choice of material!), support for a memory card, convenient LCD screen, print speed from 20 to 150 mm / s, support for ABS, PLA, TPU (wear-resistant flexible material based on polyurethane). The printer weighs 12 kg, it will take up space on the table. And yes, this is the same DIY Kit, that is, you have to assemble the car yourself (not without fun!).

Another model that has become literally a classic for beginners in the field of 3D printing is the Anet A8 printer (price $145.99). This is a printer proven by the experience of many users, reliable as a Kalashnikov assault rifle and just as simple. What we have: a working volume of 220 x 220 x 240 mm (this is not very much), support for a bunch of materials, including “wood”, nylon and glowing threads, support for SD cards, a print speed of 100 mm / s and a very modest but informative LCD -display. Good sweet Anet in that you can find almost any information and any user experience on it. The popularity of the model plays into her hands (or whatever she has ...).

What we have: a working volume of 220 x 220 x 240 mm (this is not very much), support for a bunch of materials, including “wood”, nylon and glowing threads, support for SD cards, a print speed of 100 mm / s and a very modest but informative LCD -display. Good sweet Anet in that you can find almost any information and any user experience on it. The popularity of the model plays into her hands (or whatever she has ...).

For comparison, let's take an expensive 3D printer - Creality3D CR-X, which is currently on pre-order for $ 789.99. And it really differs from the listed models. First of all, it is a large workspace 300 x 300 x 400 mm, resolution 50-400 microns, 4.3' touchscreen. Well, the main feature is support for printing in two colors due to the dual extruder and working with PETG, an impact-resistant material with almost no smell and no shrinkage. The printer comes with a set of tools, has a siliconized working platform (the chances of getting burned are almost zero) and a dual cooling system. As you can see, the difference is obvious.

As you can see, the difference is obvious.

By the way, in the world of 3D there are MFPs, as well as in the world of printing printers. Typically, 3D MFPs include cameras for remote print monitoring, conventional printers, scanners, and more.

What do you need to decide before ordering your 3D printer?

You can buy an extra mobile phone “to see what the shell is”, a couple of external drives, headphones out of curiosity and even a second DVR, but buying a 3D printer out of the blue is a dubious story: it’s big, takes up a lot of space, costs normal money and in general requires a responsible approach and awareness that it will need kilometers of consumables (fortunately, mostly inexpensive). It's almost like with a cat - you take it once and for all. But not because it is difficult to resell if something happens, but because you get attached to the soul.

Your house will be filled with cuteness and funny figurines

So, what you need to decide.

- Budget. 3D printers cost anywhere from $150 to several thousand dollars. Accordingly, decide how much you are willing to spend, how much consumables you will have to purchase. Choose a printer according to your goals, but do not try to save money at any cost - if you decide to take 3D printing seriously, some important functions may not be enough in an inexpensive model.

- Your projects. What are you going to do? How busy will your printer be (for example, one thing is rare crafts for school or clubs, another is servicing the production of hand-made gifts and gizmos for making money)? What materials will you need?

- Materials needed and their properties - ask about materials and supplies, make a list and calculate the amount of threads you will need. If your project involves some kind of commercial component, consider the fact that the delivery of materials will take some time. Be sure to check if the selected printer supports the required types of plastic.

- Multi-color printing - if you need multiple colors, you need a printer with multiple extruders, which is another price point.

- Printing goals usually determine the size of the printer you need. If you are just going to “play around” or buy a toy for a child, then it is better not to bother and choose a compact printer with a small working volume. This will be quite enough for just for fun.

For example, there is a very nice model Alfawise X6A. Firstly, it is stylish and looks somewhat better than the usual "skeletons", and secondly, it has a very compact working area - 220 x 220 x 220 mm. At the same time, it is open to any experiments and supports ABS, HIPS, PC, PLA, PVC, Wood materials, has a print speed of 20 to 150 mm, a good print resolution of 0.06 to 0.4 mm, supports SD and USB, is equipped with great working display. And at the same time, its total dimensions are 41.5 x 40.8 x 44.5 cm - that is, it will simply take a corner on the desktop. This is a really compact home model. And it only costs $289.99 (with coupon GBX6A - $285.99).

This is a really compact home model. And it only costs $289.99 (with coupon GBX6A - $285.99).

- Place for the printer - most often a desktop or any stable surface. However, we would recommend not to choose completely clogged premises (if it is an apartment, not a garage). The fact is that working with hot plastic involves a certain smell (the intensity depends on the material) and the room must be ventilated.

- Your experience with 3D printing will determine the time from plugging in to the first result in your hands (it's an indescribable feeling to hold the first figurine made!). You need to get comfortable with technology, with the appropriate software, with memory cards, working with a PC, etc. However, for a modern person, such tasks are a matter of a very short time.

- Who else will use a 3D printer. If your peer (brother, sister, friend, colleague) joins you, then this is one thing and you can share responsibility for the condition and operation of the printer.

If this is your curious teenager, then it is better to work with the printer together, and choose a model that is more stable and reliable.

If this is your curious teenager, then it is better to work with the printer together, and choose a model that is more stable and reliable.

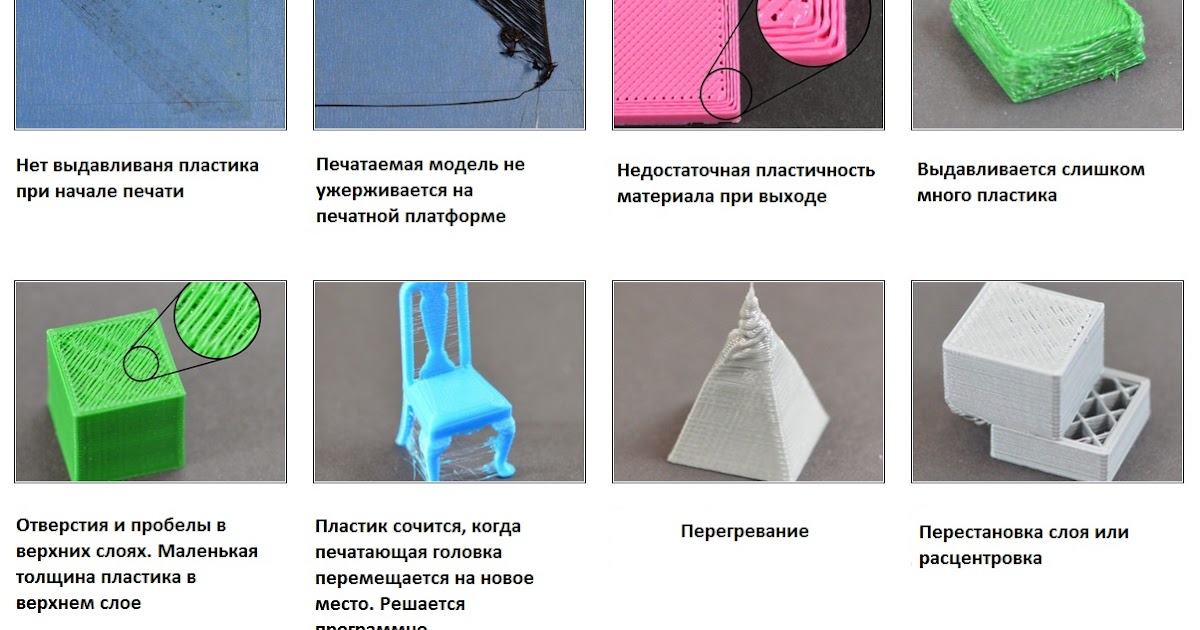

- Get ready to process models. Alas, there is no perfection in the world (although the TEVO Little Monster Delta 3D Printer DIY Kit seems so to us - just look at this design!) And you will have to work with a file, nail scissors and knives of various stripes to bring the figure to perfection. It is often necessary to remove excess threads, sagging, protrusions, etc. from finished products.

For the first level user of a 3D printer, this information will be really useful, much more useful than numerous videos with the “magic” of printing. The fact is that the printer itself is just a tool and you create the main magic - with your imagination, skill, taste. But that the process is exciting is a fact. Even if the models are from the Internet, even if the material is the most inexpensive, and the printer is not fancy. Because the nature of creatine works wonders for each of us.

Because the nature of creatine works wonders for each of us.

If you have special tips that can complement the article, please write in the comments - as Habr's experience shows, comments often give +500 to the usefulness of the publication. Let's explore the wilds of 3D printing together!

A few more models that we really like:

- Alfawise U20 - $299.99 ($279.99 with GB-$20OFF coupon) - support for many filament materials, screen, speed 20 - 150 mm/s.

- Alfawise U10 - $439.99 ($429.99 with coupon GBU10EU) - large displacement, 4 materials, print speed 10 -150 mm/s, high precision

- Anet E12 - $279.99 ($269.99 with coupon GBE12) - high resolution, 3 filament materials, print speed 40-120 mm/s, same indestructible Anet model, but with a large working area

- Creality3D CR-10 - $389.99 - very quick to assemble DIY Kit, excellent print detail

- Creality3D CR-10S4 - $599.

Learn more

You can change the pattern of the inner pallet if you wish.

You can change the pattern of the inner pallet if you wish.  Print it out and give it to your grandmother. She will appreciate this gesture.

Print it out and give it to your grandmother. She will appreciate this gesture.  " Do you have such a business card? Find her a pair in the form of this business card holder, printed in its entirety (yes, already with a hinged lid). Instructions for adding a custom logo are included.

" Do you have such a business card? Find her a pair in the form of this business card holder, printed in its entirety (yes, already with a hinged lid). Instructions for adding a custom logo are included.

It is especially suitable for kitchen plants. The next time you buy fresh herbs for cooking, transplant them into this neat device and they'll stay fresh all week long.

It is especially suitable for kitchen plants. The next time you buy fresh herbs for cooking, transplant them into this neat device and they'll stay fresh all week long.  It’s great if you have water limits set in the height of summer.

It’s great if you have water limits set in the height of summer.  28: Protection for disk

28: Protection for disk