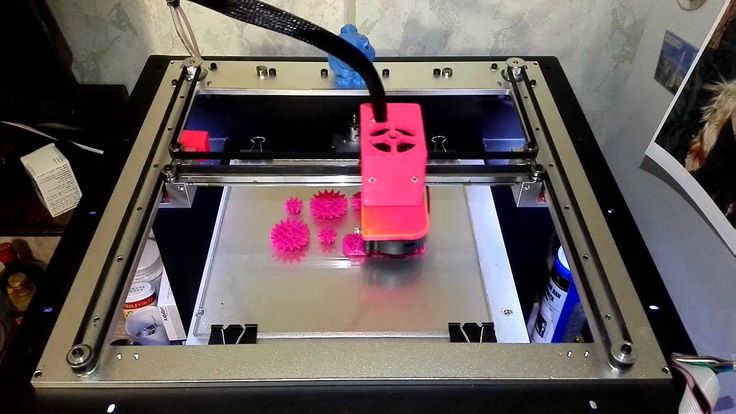

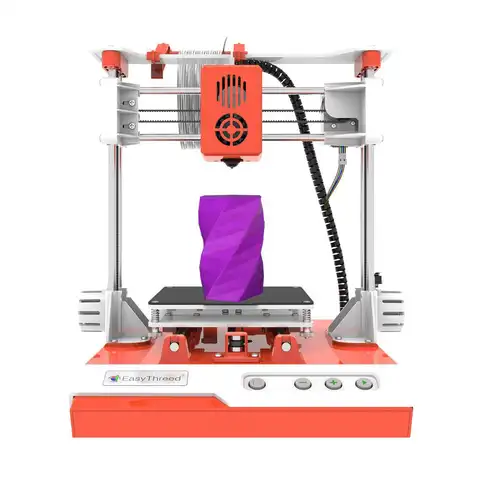

Little 3d printer kit

The 8 Best Mini 3D Printers in 2023 (ALL Price Ranges!)

Advances in 3D printing have created more accurate and faster 3D printers that are smaller and cheaper than ever before, leading to the current range of mini 3D printer options that can fit on your desktop. Many of these affordable 3D printers cost just a few hundred dollars, take up little space, and can produce fantastically accurate plastic parts.

Therefore, we’ve ranked some of the best small 3D printers around, listing their main advantages, so you can choose which best suits your 3D printing needs.

Budget Mini 3D Printer

4.3

Amazon here

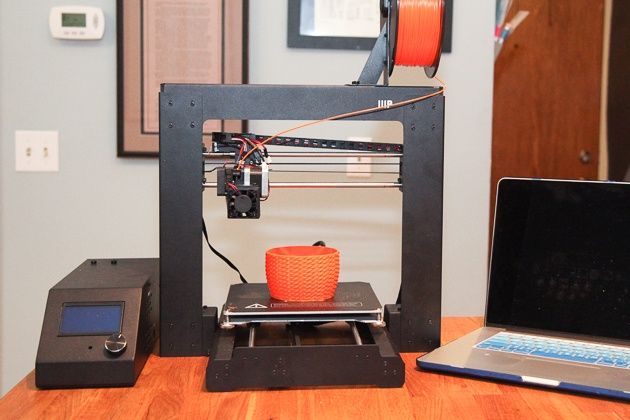

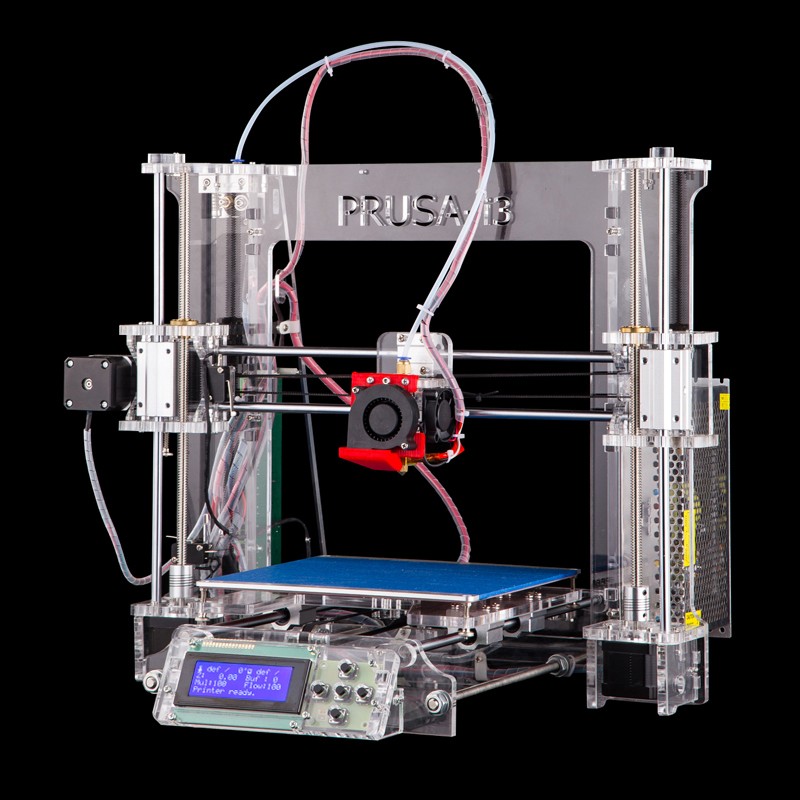

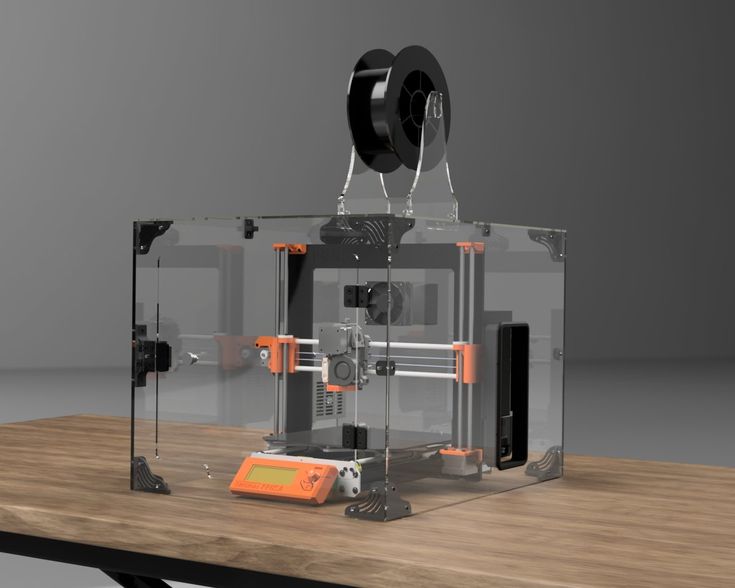

Best Mini 3D Printer Kit

4.7

Budget Resin Pick

4.5

Around $200 if on sale

Amazon here

- If you’re a beginner to 3D printing, you may also want to check out our guide to the best 3D printers for beginners

- We also have a ranking of the best 3D printers for kids

- We also have a ranking of the best resin 3D printers

Best Mini 3D printers

| Name | Build Volume(mm) | Price | Where to buy | Alternative purchase option |

|---|---|---|---|---|

| LABISTS Mini X1 | 100 x 100 x 100 | $150 | Amazon here | |

| Monoprice Select Mini V2 | 120 x 120 x 120 | $219 | Amazon here | |

| Monoprice Mini Delta | 110 x 110 x 120 | $190 | Amazon here | |

| Flashforge Finder / Finder Lite | 140 x 140 x 140 | $250 / $299 | Finder Lite on Amazon here | Finder on Amazon here |

| Elegoo Mars 2 Pro | 115 x 65 x 150 | $250 | Elegoo here | Amazon here |

| Flashforge Adventurer 3 / 3 Lite | 150 x 150 x 150 | $369 / $449 | Amazon here | |

| XYZprinting Da Vinci Mini W+ | 150 x 150 x 150 | $209 | Amazon here | |

| Prusa Mini | 180 x 180 x 180 | $39 | Prusa Store here |

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Best Mini 3D printers (under 150mm cubed build volume)

LABISTS Mini X1 3D printer — Smallest 3D printer in the world?

- Small 3D printer price: $140 — Available on Amazon here

- Build volume: 100 x 100 x 100 mm

- Print speed: 40mm/s

Pros

Compact size.

Easy to assemble as it comes in just a few parts.

Accurate and provides a smooth surface finish.

Cons

It’s pretty basic.

The complete miniature 3D printer and a great 3D printer for kids to try out 3D printing, the LABISTS Mini 3D printer is tiny, basic, and cheap.

With a tiny 3D printing volume of just 100 x 100 x 100 mm it can fit almost anywhere, and the lack of an enclosure makes it even easier to fit in even the most crowded households. Though a 3D printer kit, the LABISTS Mini X1 3D printer comes in just a few parts, and shouldn’t take more than a few minutes to get print-ready if you follow their assembly video shown below.

Despite the tiny size and low price, the Mini X1 3D printer offers up to 50-micron accuracy and surprisingly smooth surface finish, though it can only print PLA.

It comes with some PLA filament to get you started, and with the simple interface and lack of complex features, is an ideal 3D printer for beginners and kids to get acquainted with 3D printing. It comes with its own easy-to-use 3D slicer, and is also famed for being quiet — able to print at under 60db.

This could quite possibly be the smallest 3D printer you can buy commercially, so if you’re just dipping your toe into 3D printing, this could be the one for you.

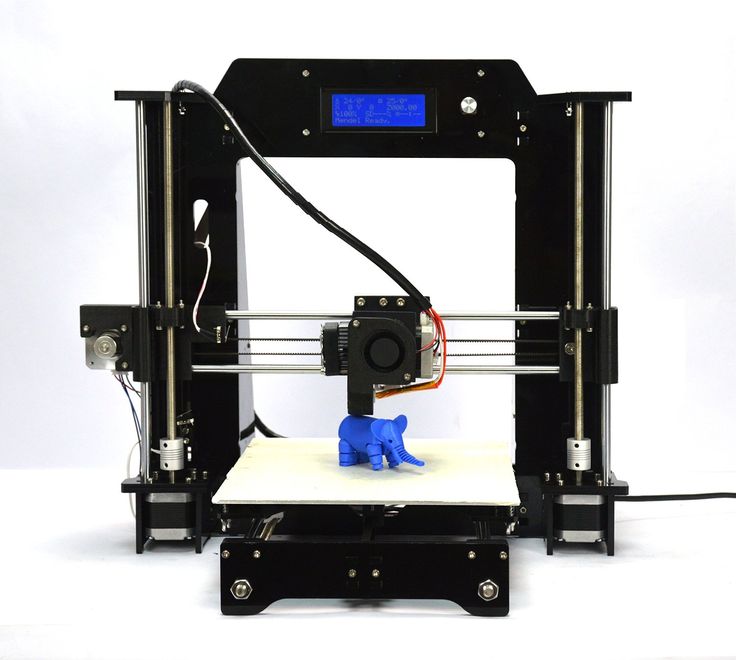

Monoprice Select Mini V2 — Mini Monoprice 3D printer

- Mini 3D printer price: $219 — Available on Amazon here

- Build volume: 120 x 120 x 120 mm

- Print speed: 55m/s

Pros

Versatile and compact.

Good entry-level 3D printer for beginners.

Cons

Not suitable for larger objects.

The Monoprice Select Mini V2 is another popular mini 3D printer by successful technology manufacturer Monoprice, and an effective yet portable 3D printer priced at just $200. It’s the ideal entry level 3D printer, coming with no fancy extra features. You just get the printer, some filament to get you started, and some pre-installed 3D printer models.

It’s the ideal entry level 3D printer, coming with no fancy extra features. You just get the printer, some filament to get you started, and some pre-installed 3D printer models.

- To download your own 3D printer models, check out our list of the best sites for STL files

We recommend the Select Mini V2 for producing small parts such as 3D printing 28mm miniatures or other tiny 3D prints. It’s not well suited for larger parts, but for those you should check out our large 3D printer ranking or our yearly best 3D printer recommendations.

Overall, the Select Mini V2 is a versatile, compact 3D printer that surprisingly can still print materials like ABS, PVA and wood filament; and for the price tag, is a fantastic introductory 3D printer.

Monoprice Mini Delta — delta mini 3D printer

- Mini 3D printer price: $180 — Available on Amazon here

- Build volume: 110 x 110 x 120 mm

- Print speed: up to 150mm/s

Pros

Fast for such a compact design.

Sturdy and durable.

The aluminum and steel frame anchors make it precise and prevent any vibrations.

Cons

Can’t work with flexible filaments.

With a small 3D printing build volume of just 110 x 110 x 120 mm, the Monoprice Mini Delta really lives up to its name as a mini printer. The Monoprice Mini Delta is the only delta 3D printer on our small 3D printer buyer’s guide, allowing it to print very fast for such a compact machine, at up to 150mm/s. It is almost certainly the fastest 3D printer in its size range.

Despite the low weight and high speed, this small home 3D printer is built to be sturdy and durable: the aluminium and steel frame anchors it down to ensure print quality is precise and prevent any vibrations from affecting your model’s surface finish.

The Mini Delta is a tiny 3D printer but still features a heated bed, so 3D printing ABS and other filaments should be no problem with the right print settings.

The Monoprice Mini Delta is also very precise, at up to 50 microns, and unlike most delta printers comes fully assembled rather than as a 3D printer kit. As a result, it’s a great 3D printer for beginners, and extremely simple to operate and print with – you can even print via WiFi, a rare feature on small, inexpensive printers.

As a result, it’s a great 3D printer for beginners, and extremely simple to operate and print with – you can even print via WiFi, a rare feature on small, inexpensive printers.

Flashforge Finder / Finder Lite

- Price: Finder Lite = $250 — Available on Amazon here / Finder = $299 — Available on Amazon here

- Europe: Available on 3DPrima Europe here

- Build volume: 140 x 140 x 140 mm

Pros

Built to be quiet.

Can print PLA, TPU, and copper PLA.

Includes auto-leveling and calibration.

Cons

The bed is not heated which can cause warping.

The original Flashforge Finder was a big success, becoming as highly rated as the best-selling Creator Pro. The new Finder Lite has the same tiny 140 x 140 x 140 mm build volume, but has costs $50 less due to the lack of WiFi 3D printing feature.

The Flashforge Finder Lite is built to be quiet, can print PLA, TPU and copper PLA, and comes with a few popular 3D printer models to get you started on your 3D printing journey. Flashforge’s patented nozzle has been upgraded, and the feeder tube and extruder have been improved to prevent jams and improve your prints’ surface finish.

Flashforge’s patented nozzle has been upgraded, and the feeder tube and extruder have been improved to prevent jams and improve your prints’ surface finish.

The Lite version comes with all the latest features you have come to expect from a small 3D printer costing around $300, including auto leveling and calibration, a large 3.5 inch touchscreen, and a removable build platform which makes removing your printed models easier than ever. Overall, it is another great mini 3D printer for those with little space or those who just want to start small.

Elegoo Mars 2 Pro — great small 3D printer (for resin)

- Mini 3D printer price: $250 — Available at Elegoo store here / Available on Amazon here

- Build volume: 115 x 65 x 150 mm

- Print speed: 22.5mm/hour

Pros

High resolution for a great price.

Solid and durable metal construction.

Cons

Build volume is relative small compared to other FDM printers.

The original Elegoo Mars is one of the best-selling resin 3D printers of the last few years, and now Elegoo have released the Mars 2 Pro, with a number of key upgrades.

Though a good build size for an LCD 3D printer, most desktop makers creating tabletop miniature 3D prints would still consider the build volume small, especially compared to FDM printers.

Several key upgrades are built into the Elegoo Mars 2 Pro, including improved precision via the improved Z-axis linear guide-way structure, leading to smoother layers with less obvious layer lines. The Mars Pro is also made safer by the silicone seal that can be placed on the printer’s cover to prevent any resin leaking, which could otherwise cause safety issues.

It’s a lightweight and compact 3D printer that can produce tiny 3D prints with extraordinary accuracy – our best 3D printer for miniatures guide recommends it too – and ideal for those who want precise parts and have the skills to handle a resin printer. You can read more in our full Elegoo Mars 2 Pro review.From our Elegoo Mars 2 Pro unboxing and testing

Flashforge Adventurer 3 / 3 Lite

- Price: $369 for Adventurer 3 Lite — Available at Flashforge here / Available on Amazon here

- Adventurer 3 price: $449 — Available at Flashforge here / Available on Amazon here

- Build volume: 150 x 150 x 150 mm

- Print speed: best at around 50mm/s

Pros

Reliable and beginner friendly.

WiFi connectivity included.

Can print PLA, ABS, Ultra Strong PLA, PLA color Change, Metal-Filled, Wood, and High Speed PLA.

Cons

Proporietary nozzle assembly is pricey.

A reliable mini 3D printer with a closed build chamber, the Flashforge Adventurer 3 Lite is for those who don’t mind spending a bit extra (as compared with the Mini Delta or Maker Select) for better print conditions and better ABS 3D printing.

With a minimum layer height of 50 microns, it’s perfect for 3D printing miniatures and other small models. The closed chamber means that ABS and other filaments will warp less, and all these extras come in a compact 3D printer costing under $500.

The 150 x 150 x 150 mm build volume is small, but we would not consider this a tiny 3D printer – most day-to-day projects should be printable with ease, or can be broken up into a few separate prints and stuck together. The nozzle is easily switchable, for example if you want to print faster with a larger nozzle, and overall it is a reliable and low-cost small 3D printer with a closed chamber for effective 3D printing.

It’s $80 cheaper than the Adventurer 3, with the only noticeable differences is that the Lite version doesn’t have the HD camera that the Adventurer 3 has. It’s your choice whether this affects your choice, but we’ve included links to both above to make things easier for you.

XYZprinting Da Vinci Mini W+ — good small 3D printer under $300

- Small 3D printer price: $209 — Available on Amazon here

- Build volume: 150 x 150 x 150 mm

- Print speed: maximum 120mm/s

Pros

Simple to use.

Reliable and precise.

WiFi printing, saving you time and hassle.

Cons

Difficult to use third party filaments.

XYZprinting not only make some of the most popular small FDM 3D printers around, but are also famed for their industrial 3D printers, including their MfgPro230 xS SLS 3D printer. Their most successful small-scale 3D printer, the Da Vinci Mini, is inexpensive, simple to use, and reliable – you can trust it to get the job done.

With a precision of 100 microns for each layer printed, you can be sure of a quality 3D print even for the low price. It can print PLA and PETG and can also be upgraded to 3D print metallic and carbon PLA blends with XYZ’s hardened steel nozzle.

A major advantage is WiFi printing, a feature that not many mini 3D printers have, saving time and hassle from continuously removing and inserting SD cards and USBs from your laptop to the printer. The Da Vinci Mini 3D printer’s ability to level itself makes it perfect for beginners looking to start small, and overall it’s a great introductory printer – though be careful as it is very difficult to use third party filaments, so you may be restricted to XYZprinting’s own-brand PLA.

Best Small 3D printers (under 200mm cubed)

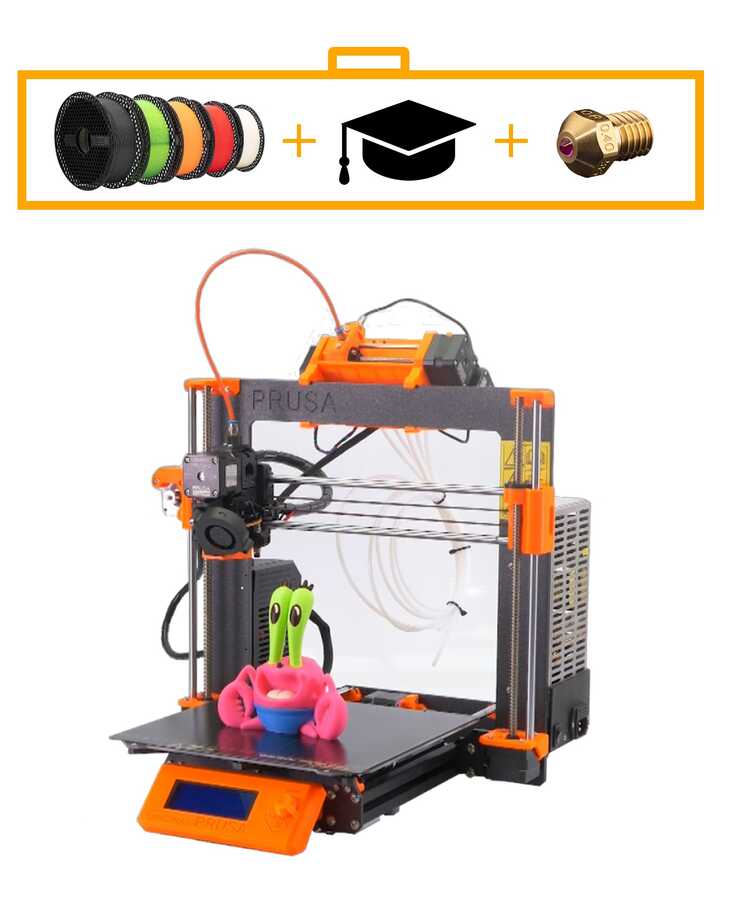

Prusa Mini — best small 3D printer

- Price: $399 — Available on Prusa Store here

- Build volume: 180 x 180 x 180 mm

Pros

Reliable and durable, like all prusa printers.

Very fast with speeds up to 200mm/s.

Cons

Less sturdy gantry system than most Cartesian printers.

The Prusa MK3S+ is too large to consider for a small 3D printer ranking, but the Prusa Mini 3D printer offers most of the benefits, in a smaller package.

With a 180 x 180 x 180 mm max build volume, it’s a portable 3D printer that can fit on most desktops, but it can still calibrate itself, with the same 0.05mm precision that the MK3S+ has.

Some differences are that the Prusa Mini needs to be upgraded to have the filament sensor, and it can’t heat up to quite the same extruder temperatures. But you can still 3D print standard PLA and ABS, as well as PETG, flexibles and ASA.

The Mini comes with Prusa’s own PrusaSlicer 3D slicer, and if you run into any problems, you can speak with Prusa’s support team 24/7. Overall, it’s a great lower cost RepRap 3D printer for great quality, reliable prints at a lower price.

If you liked this ranking, you may also want to view:

- Our guide to the best FDM 3D printers

- Our guide to the best dual extruder 3D printers

- Our guide to the best large scale 3D printers

- Our 3D pen buyer’s guide

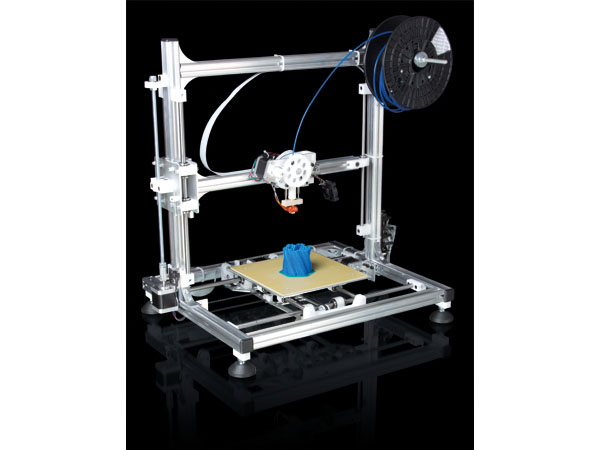

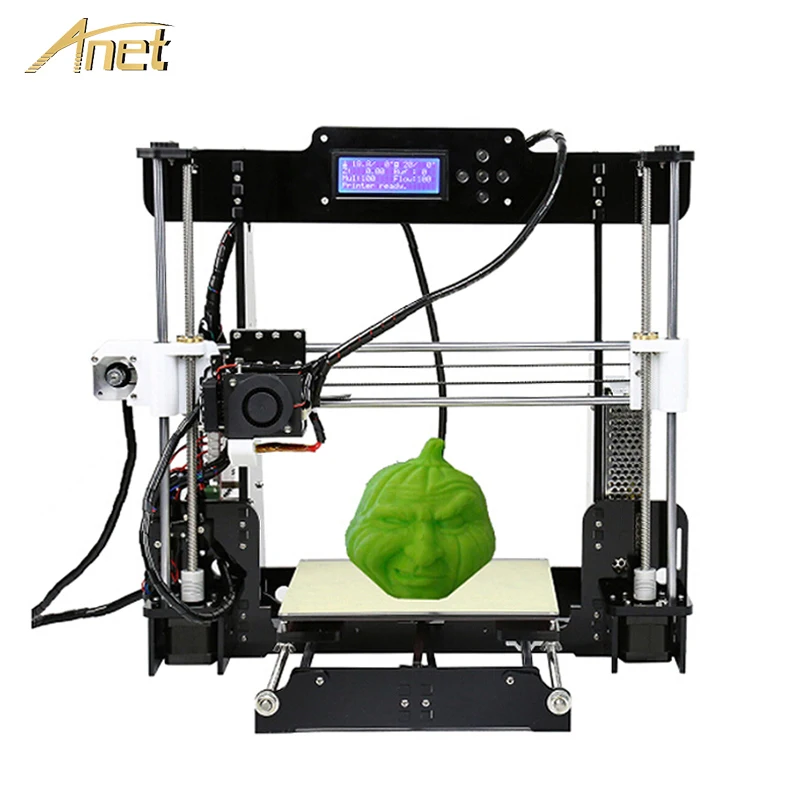

Best DIY 3D Printer Kits & Build Plans 2022

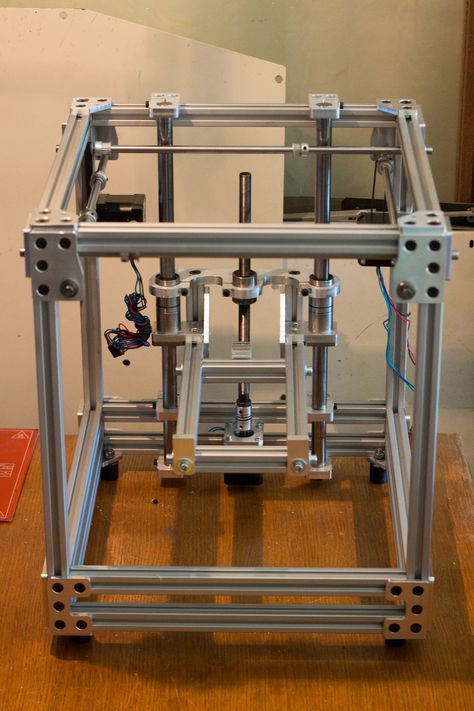

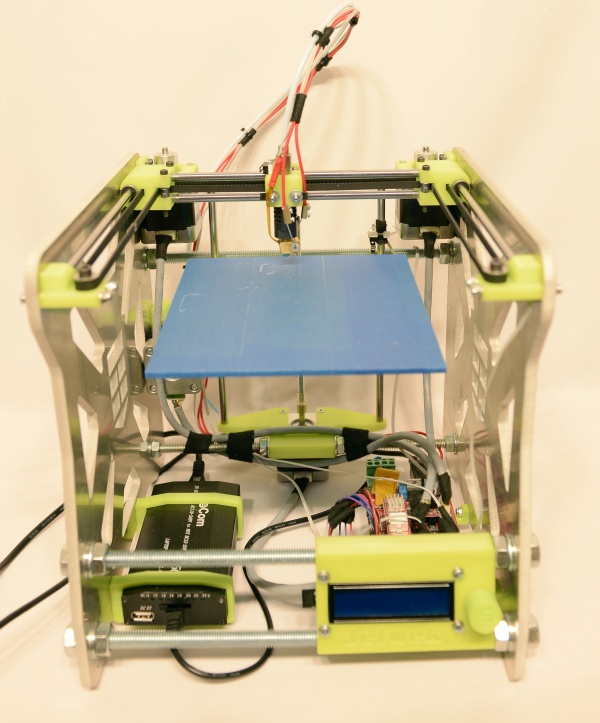

Building your own DIY 3D printer can be an affordable option to get started 3d printing as well as a learning experience as one gets familiar with the mechanics or the nuts and bolts of a 3D printer. You learn how it works and how to fix it when it breaks. Building a 3d printer is more challenging than buying a completely assembled machine that’s ready to print. In this article, we review the best DIY 3d printers and list some of the options available. Here’s a guide for the list of considerations when planning your 3d printer build.

You learn how it works and how to fix it when it breaks. Building a 3d printer is more challenging than buying a completely assembled machine that’s ready to print. In this article, we review the best DIY 3d printers and list some of the options available. Here’s a guide for the list of considerations when planning your 3d printer build.

- Documentation & Assembly Guides

- DIY Kits vs Pre-Assembled 3D Printers

- Self-Source Parts vs DIY Kits

- Documentation

- Community

- Build Volume

- 3D Printer Kinematics

Table Of Contents

- DIY 3D Printer Build Advantages

- DIY 3D Printer Build Disadvantages

- DIY 3D Printer Kits vs Pre-Assembled Printers

- Complete 3D Printer Kits vs Open Source Build Plans

- Self-Source Parts

- Advantages of Building Your Own 3D Printer

- Challenges In Building Your Own 3D Printer

- Open-Source 3D Printers & Build Plans

- 3D Printer Kits vs Pre-Assembled

- Complete 3D Printer Kits

- Self Sourced DIY 3D Printer Plans

- Railcore II 300ZL

- Pros & Cons

- Hypercube Evolution – H.

E.V.O.

E.V.O. - Voron 2.4

- Rat Rig V-Core 3

- The Evolution of The RepRap Project

- Self-Source Parts vs DIY Kits

- Cantilever Bed vs 3-point Bed Leveling

- Lead Screw vs Ball Screw vs Belt Drive

- Lead Screw vs Belt

- Lead Screw Pitch & Required Torque

- Build volume

- Rods vs Linear Rails

- White Knight: DIY Conveyor Belt 3D Printer

- Best Large DIY 3D Printers 2023

- Modix BIG-40

- Raise3D Pro2 Plus

- BigRep – STUDIO G2

- Piper 2: Piper 3D Printers Made From Conduit Pipe

- Gantry 3D Printer Design – Reducing Moving Mass

- Large Scale 3D Printing vs Batch Printing

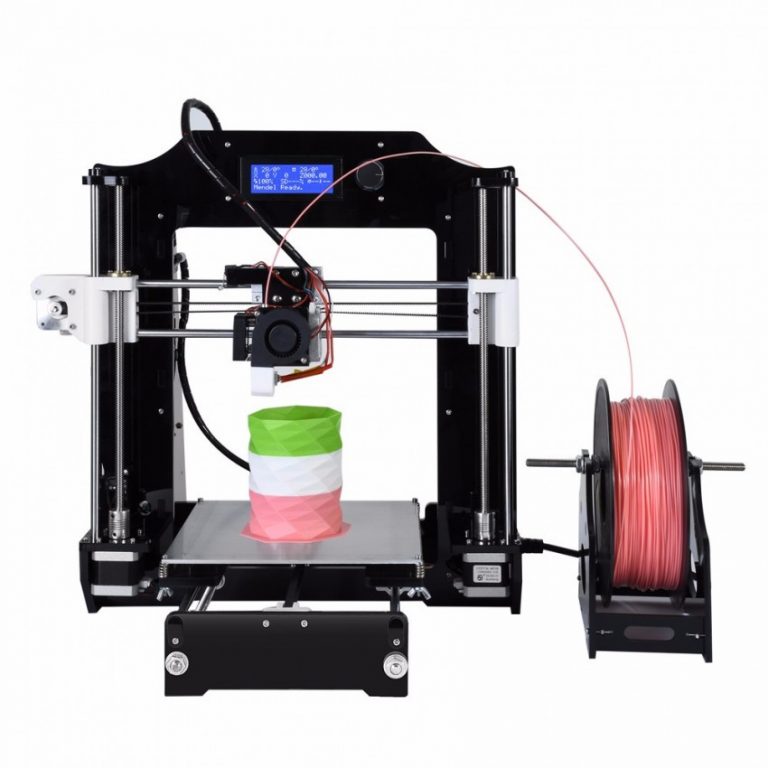

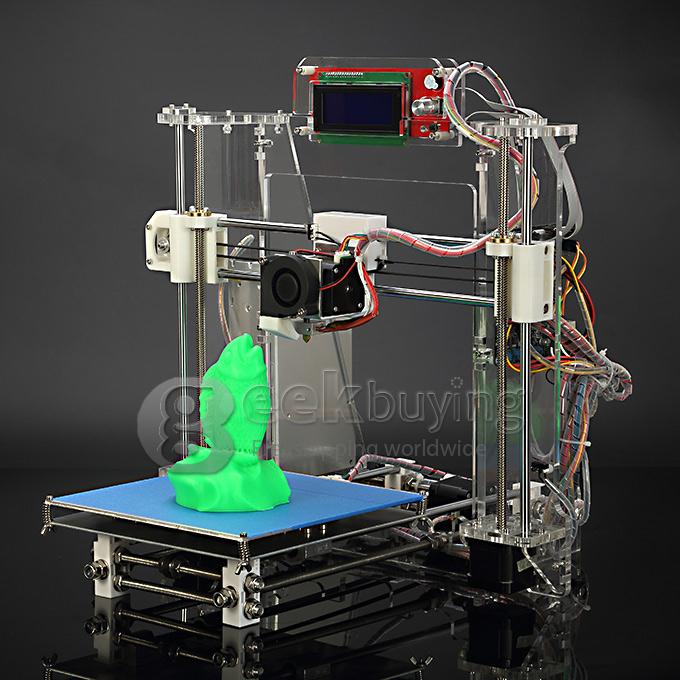

DIY 3d printer plans make it easier to get started and are a great option for beginners who want to learn how the mechanics work. The kits usually come with everything you need such as tools, parts, and instructions which take out some of the guesswork when building your printer.

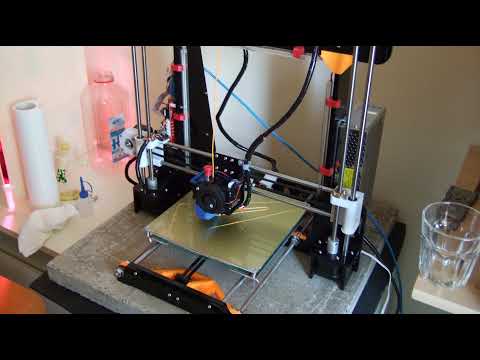

Building a printer can be challenging and time-consuming. There are many things that can go wrong, so it’s important to have some experience with building or repairing electronic devices before starting this project. Also, you may not have all the parts you need, which could lead to delays in printing.

DIY 3D Printer Kits vs Pre-Assembled PrintersThere are pros and cons to each option. If you choose a kit, it’s important to consider how much time you have for assembly, the difficulty level of the project, your budget, versatility options (e.g., build volume or filament types supported), and the quality of the community support.

Complete 3D Printer Kits vs Open Source Build Plans

While many printer designs are available in complete kits some open source designs are currently still self-sourced, meaning that builders will have to source individual 3d printer parts and get it all together which results in complexity as some parts may take long to receive and increases the chance that one might order the wrong part number. With that said, is the price still about the same depending on extruder options print size.

With that said, is the price still about the same depending on extruder options print size.

A common option is to source all your own parts. This can be more affordable, but it takes more time and effort to find compatible parts and can be difficult depending on experience level. The advantage of this approach is that you can customize your printer to fit your needs.

Advantages of Building Your Own 3D PrinterThere are several advantages of building your own DIY printer:

- -You learn how the machine works and can troubleshoot problems on your own.

- It can be more affordable than buying a pre-assembled printer.

- You can customize your printer to fit your needs.

- The community is usually very helpful and supportive.

DIY Printer Build

Challenges In Building Your Own 3D Printer

There are also some disadvantages of building your own printer:

- It can be more challenging than buying a pre-assembled machine.

- There’s a higher chance of something going wrong during the build process.

- You may not have all the parts you need, which could lead to delays in printing.

The best DIY printer for your needs depends on your level of experience, budget, and goals. We hope this article provides some helpful advice for choosing the right printer kit for you. Happy building

Open-Source 3D Printers & Build Plans

Documentation is important when choosing a 3d printer to build or buy and effects overall user experience. Poor documentation can lead to downtime as users assemble or troubleshoot their machine to get it printing. Look for kits or build plans that are well documented and comprehensive for your skill level. Good documentation will also include tips and tricks for getting the best 3d prints, troubleshooting common problems that you may experience.

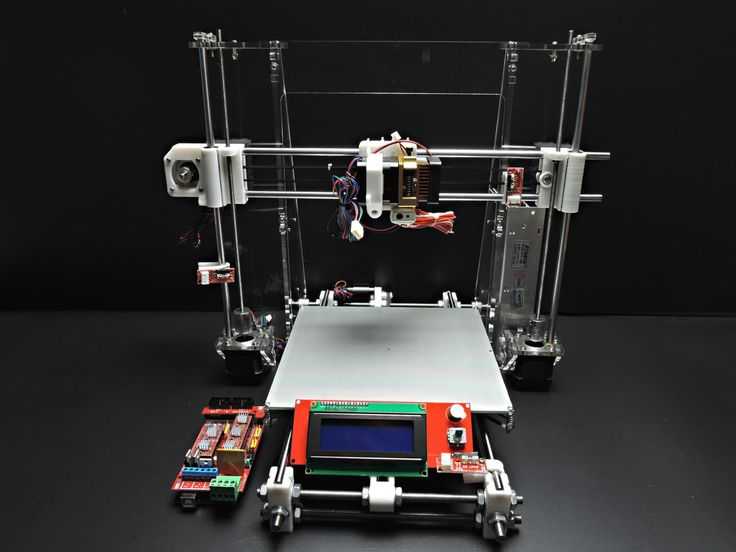

3D Printer Kits vs Pre-AssembledWhen it comes to the Best DIY kit printers, there are many options. The advantages of a pre-assembled machine is that they usually come with some documentation and have been assembled by someone else so you can trust in them being functional machines already. This makes them less complicated than self sourced kits and more appealing to beginners.

The advantages of a pre-assembled machine is that they usually come with some documentation and have been assembled by someone else so you can trust in them being functional machines already. This makes them less complicated than self sourced kits and more appealing to beginners.

If you’re not comfortable with sourcing your own parts from various suppliers, there are also pre-assembled printers available. These machines come with everything or almost everything to assemble a working machine, including all of the screws and tools needed.

Complete 3d printer kits make it easier to get up and running rather than sourcing all the parts yourself from different suppliers with different shipping dates or quality. It is also a great way of saving money on shipping which can be quite costly when buying small amounts of parts.

The downside of a pre-assembled machine is that they can be more expensive than DIY kits, lack upgradability, and might not have the best quality control.

When sourcing your own parts for a printer there are a few things you need to take into account: what type of printer do you want to build, what parts do you need and where can you source them from.

The best 3d printer kits give a great range of options depending on performance needs and budget. Beginners can start off with an unassembled diy kit which is less expensive than pre-assembled machines.

Railcore II 300ZLThis is a pre-assembled machine that comes with an excellent build guide and video tutorial. It uses a CoreXY motion system which gives it good print quality and speed. The kit can be sourced from different sellers, or you could buy the fully assembled machine directly from Printed Solid.

The kit can be sourced from different sellers, or you could buy the fully assembled machine directly from Printed Solid.

Each of these kits have their own pros and cons, so it’s important to do your own research before settling on a printer. For example, the Rat Rig V-Core uses a corexy kinematics which is known for its speed and accuracy, but can be more difficult to calibrate.

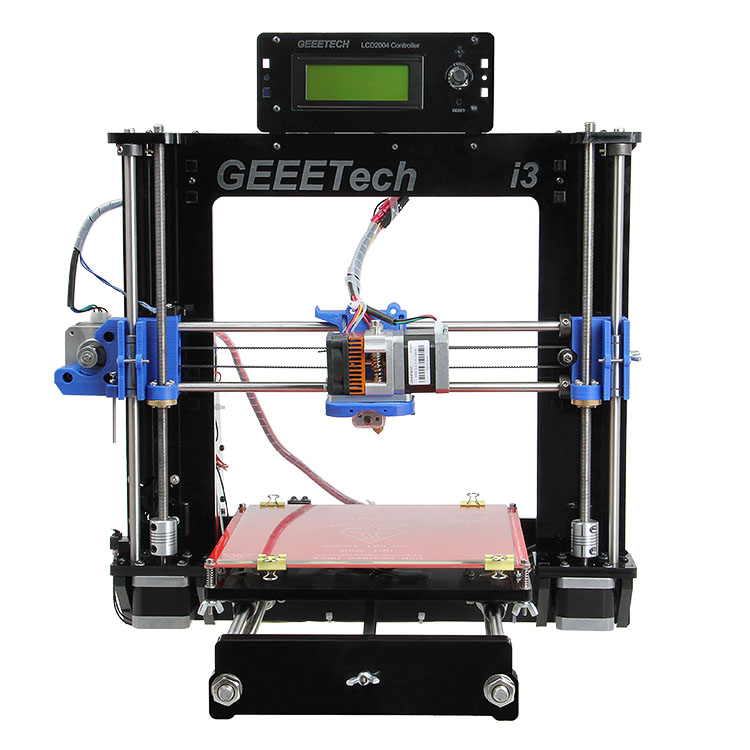

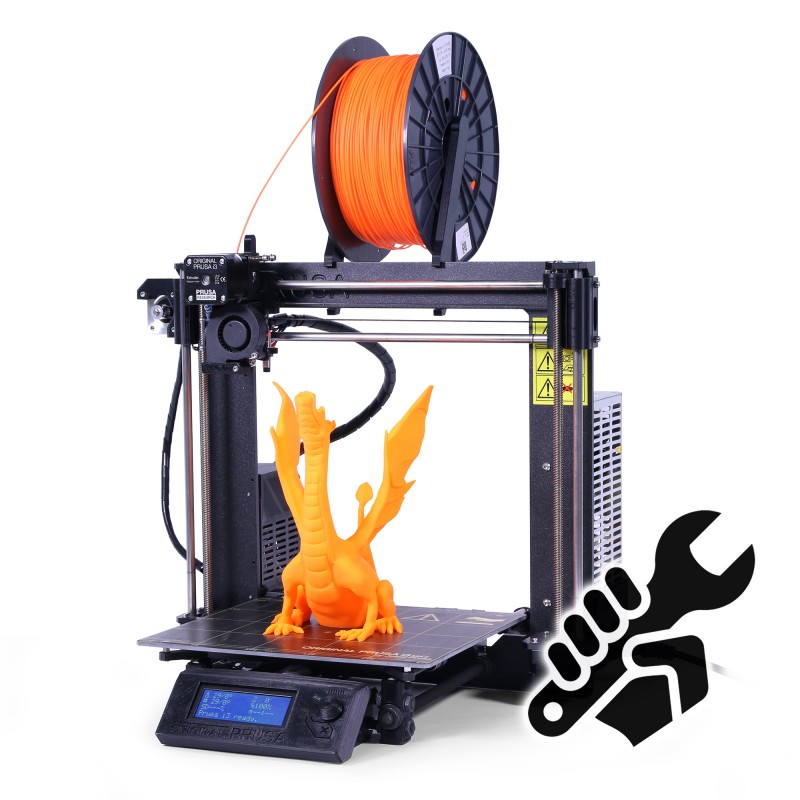

Original Prusa i MKS+

This kit is based on the popular Original Prusa i MKS printer and comes with an excellent build guide. It’s a great option if you want to get started right away with minimal assembly.

Hypercube Evolution – H.E.V.O.This kit is a great option for those looking for an upgradeable machine. It comes with a variety of parts that can be swapped out or upgraded as needed.

Voron 2.4This open source design is great for experienced builders and offers good print quality and speed.

When sourcing your own parts, it’s important to do your research and decide which seller to use and consider shipping rates.

Rat Rig V-Core 3The Rat Rig V-Core 3 is a great option for those looking for a specific size or options as kits can be configured for specific needs or price. The complete printer kit comes in a range of options with a well documented build guide and instructions. The V-core 3 uses the CoreXY motion system which offers good print quality and speed. The v-core 3 kit can be purchased from the Rat-Rig website, or could be self sourced.

The Evolution of The RepRap Project

Self-Source Parts vs DIY KitsWhen sourcing your own parts, there are a few things to take into account: what build volume is needed and type of parts to use which is usually related to how much you’re willing to spend.

There are a range of options for extruders and electronics, so it’s important to decide on the features you need. If you want a machine with high resolution, then you will need more precise parts which can be expensive.

If you want a machine with high resolution, then you will need more precise parts which can be expensive.

Cantilever Bed vs 3-point Bed Leveling

While many of the original DIY 3d printers used cantilever beds to lift the print bed or build plate constrained POM wheels or smooth rods. The newer 3d printer designs use linear rails and have adopted more functional mechanisms such as belted z-axis, and non-planar 3d printing concepts such as 3-point bed leveling or tilting print beds. Although the simplicity of older Reprap 3d printers were less technical and easier for newbies, the increasing number of options and features can easily be adopted from corexy design platform to another, which has exponentially inspired contributors as they work to identify or fix potential issues or increase overall print volume.

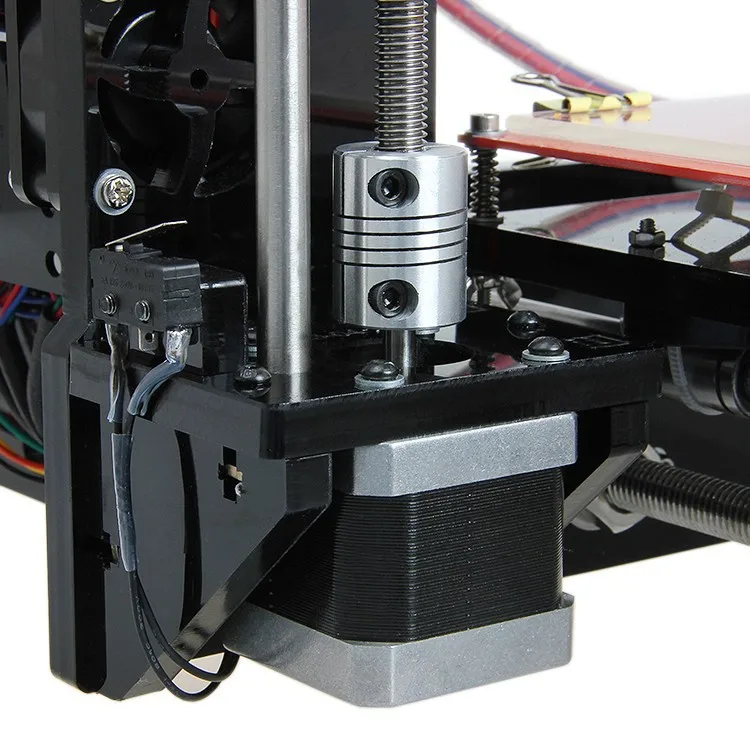

Lead Screw vs Ball Screw vs Belt DriveMechanical components and kinematics are critical to the functionality and can compromise speed or quality. Lead screw which is commonly used to drive the z-axis or lift the print bed is known for backlash but backlash can be eliminated using anti backlash nuts or may not be an issue due to gravity. Lead screw pitch and lead is critical for speed and precision. Issues with speed, resonance, artifacts can be a challenge in any 3d printer build but can be reduced by travel speed and acceleration but is compromised with slower travel speed the longer it takes to print an object.

Lead screw which is commonly used to drive the z-axis or lift the print bed is known for backlash but backlash can be eliminated using anti backlash nuts or may not be an issue due to gravity. Lead screw pitch and lead is critical for speed and precision. Issues with speed, resonance, artifacts can be a challenge in any 3d printer build but can be reduced by travel speed and acceleration but is compromised with slower travel speed the longer it takes to print an object.

Quality lead screws and ball screws cost much more but cheap lead screws can have tolerance issues. Longer ball screws may wobble at a distance and need support and rigidity. Although backlash is mostly a problem in XY-axis movements while the z-axis is the preloaded weight of the bed and gravity.

Lead Screw Pitch & Required TorqueLead screws are similar to a gear. When the pitch changes the lead and torque needed to drive the system changes as well. Most 3D printers use 1/16 or 1/32 microstepping but the resolution of 3d printed plastic can only be so precise. Larger motors have more inductance and need more voltage to reach the same RPM. Increasing the step rate for the reduced travel rate of the drive, a higher voltage stepper driver and supply may be needed to reach ideal motor performance.

Most 3D printers use 1/16 or 1/32 microstepping but the resolution of 3d printed plastic can only be so precise. Larger motors have more inductance and need more voltage to reach the same RPM. Increasing the step rate for the reduced travel rate of the drive, a higher voltage stepper driver and supply may be needed to reach ideal motor performance.

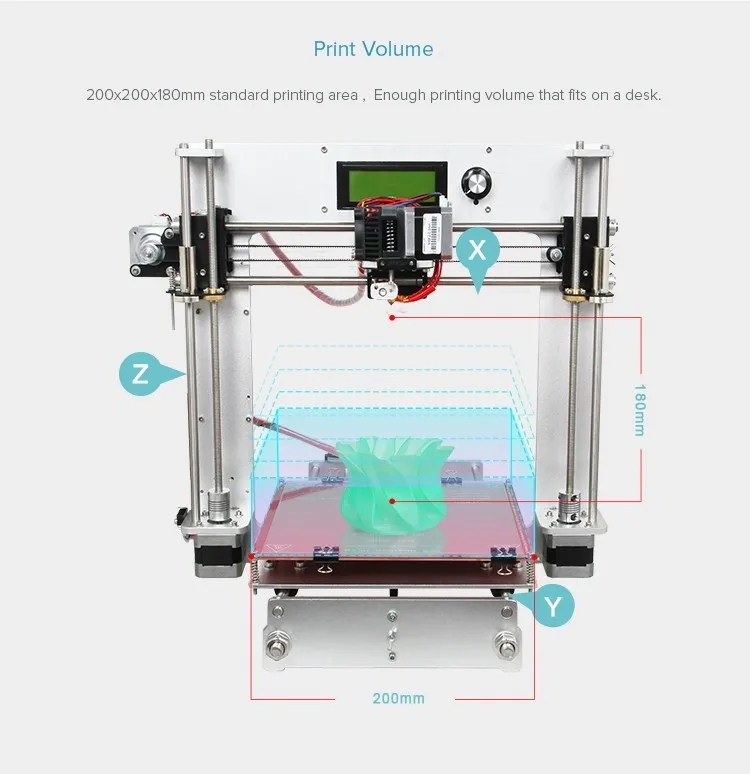

Build volume

Build volume refers to the print bed size which dictates the maximum size of 3d printed objects.

Rods vs Linear Rails

Many of the earlier 3d printers were designed around cheaper mechanical parts such as carbon rods or stainless steel smooth rods which were once commonly used and recommended. As the cost of linear rails become cheaper and cheaper due to the economy of scale and increasing number of buyers and large volume production of manufactures and suppliers. 8mm steel rods and linear bearings are slowly being somewhat phased out but still used on cheap kits found on Aliexpress.

White Knight: DIY Conveyor Belt 3D Printer

The White Knight 3D Printer is a belt printer designed by Carl from NAK3DDesigns. The Unlimited Z-Axis has a large build area for continuous 3d printing.

Best Large DIY 3D Printers 2023

Large scale 3d printers are becoming more accessible to the average user as open-source designs continue to improve. One challenge of large scale 3d printing is bed leveling and layer adhesion Deciding on a large 3d printer to build or buy is a balance between price and reliability. In this section, we review and list the best large scale 3d printers available.

Large-scale 3d printing is increasing in demand as 3d printing becomes more accessible. Large scale printers allow users to 3d print large objects that would otherwise be constructed from multiple smaller printed objects from smaller machines.

Modix BIG-40

- Made In Israel

- Build Volume 400 × 400 × 800 mm

- Price $5,000

Modix specializes in large format 3D printers that are available in DIY self-assembly kits, which is a much more affordable 3d printer compared to the larger commercial 3d printers on the market.

The Modix BIG-40 is an industrial grade machine that uses a dual-zone heated bed and a PEI print surface with auto bed leveling and an enclosure option.

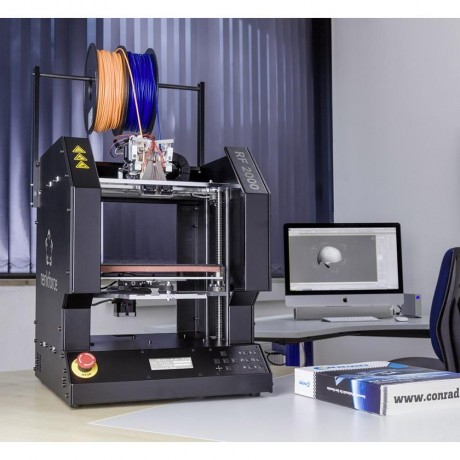

Raise3D Pro2 Plus

- Made In US

- Build Volume 305 × 305 × 605 mm

- Price $5,999

- Extruder/Hotend Dual Extruder

Raise3D is known for their high quality 3d printers that are made in the USA. The Pro2 Plus is the latest release which offers the largest build volume compared to their other Raise3D models.

The Pro2 Plus has a 305 mm x 305 mm x 605 mm build area and reaches temps up to 300°C which allows users to expand their range of materials to print with.

BigRep – STUDIO G2

Made In Germany

Build Volume 500 × 1000 × 500 mm

Price $60,000

The BigRep STUDIO is a large format 3d printer designed to print engineer grade materials and uses dual extrusion ruby nozzles for abrasive materials. The large machine is equipped with a dual filament chamber with each chamber independent controlled temperature environments and features a touchscreen interface and the BigRep BLADE software.

Piper 2: Piper 3D Printers Made From Conduit Pipe

Piper 2: Piper 3D Printers Made From Conduit Pipe.Piper 2 by Piper 3D Printers is a open source corexy DIY 3d printer design made from conduit pipe.

see Piper 3D Printers

see Midwest RepRap DIY 3D Printer Festival

Gantry 3D Printer Design – Reducing Moving Mass

Many earlier 3d printers kinematics use the classic “bed-slinger” design that originated from the early Reprap designs. As 3d printer builders and designers gradually pushed the limits of scalability, the classic y-axis traveling bed kinematics became more problematic. Although there are large scale 3d printers that work fine with this mechanical arrangement, they are often using industrial grade hardware such as linear rails and ball screws driven with high end servo motors to maintain print head position at all times, print beds that travel laterally, typically along the Y-axis.

While a simple and cheap solution for kinematics that works for countless desktop 3D printers, this potentially poses a challenge to a large-format 3D printer in that it’s putting a lot of moving mass on one of the two main axes engaged in travel during printing. A large moving mass consisting of the print bed, the carriage it’s riding on, and the increasing weight of the print being deposited on it means greater inertia to overcome with each direction change in that axis.

The timing belt tightness and the linear guides may be rigid enough to handle the inertia, but the frequent direction changes can leave artifacts such as ghosting on 3d printed objects. Not only this, a print that has poor adhesion to the print bed, moving vigorously back and forth through the Y-axis, can risk the success of the print.

These problems are not an issue for large-format 3D printers which use a static bed setup that is stationary and moving only through the Z-axis layer changes. While the motion system is more complex it can maintain the mechanical advantage compared to “bed-slinging” designs.

Large Scale 3D Printing vs Batch PrintingLarge volume 3d printers can be considered as a great solution for batch printing, or alternate to multiple smaller 3d printers. A typical sized object or print job can be arranged and stacked for mass production. However, a print farm can complete a large quantity run or job quicker than a single object 3d printed as a batch of 3d printed objects are spread across a number of machines and can decrease the number of failed prints. Failed prints are isolated to a single machine without affecting the rest or potentially ruining the entire job.

Failed prints are isolated to a single machine without affecting the rest or potentially ruining the entire job.

Like this:

Like Loading...

Tools needed to maintain the 3D printer

3DPrintStory Reviews Tools needed to maintain a 3D printer

Building a 3D printer from scratch is hard enough, not to mention trying to assemble it without the right tools. Below we highlight some of the most common 3D printer repair and assembly tools.

Below we highlight some of the most common 3D printer repair and assembly tools.

Caliper

Calipers are used to measure the distance between opposite sides of an object. Although used in many industries, including medicine and woodworking, modern calipers in mechanical engineering are often Vernier calipers that offer a high degree of accuracy compared to purely mechanical options. The included digital dials and scales can display measurements to the nearest thousandth of a millimeter/inch.

Screwdrivers/Hex Keys

The 3D printer is made up of complex individual parts that are held together with a variety of materials and fasteners. In matters of assembly and repair of a 3D printer, screwdrivers and hex keys are crucial. Be sure to stock up on a flat head screwdriver as well as a set of hex wrenches of various sizes. Due to the huge number and variety of mounts, most 3D printers use metric mounts, but this statement is not an unshakable truth, anything can happen, there are a lot of manufacturers of desktop 3D printers.

Hex keys are simple and small hex head screwdrivers that are very cheap in cost. So it is convenient for both manufacturers and consumers, who can purchase a set of hexagons of various sizes for a small amount and use it not only for a 3D printer, but in general in everyday life.

Wrenches

Although there are dozens of wrenches, each with a specific purpose, for those who work with a 3D printer, hex keys, socket wrenches, spanners and adjustable wrenches will be the most useful.

Due to the large number of fasteners used in 3D printers, manipulating in tight spaces and applying a lot of force without moving the entire wrench arm is key. To do this, hex keys have a relatively small footprint, and socket wrenches allow you to securely tighten fasteners without swinging the entire socket wrench arm (and likely avoid damaging the 3D printer frame). Adjustable wrenches have the same backlash as adjustable pliers, allowing precise control of fasteners in tight spaces. keys like these will be useful for working in and around the 3D printer's extruder.

keys like these will be useful for working in and around the 3D printer's extruder.

Wire strippers/wire crimps, soldering iron

Often included in the same tool, wire strippers and wire crimps are used to strip wires and connect crimp connectors, respectively. While any pliers with sharp inside jaws can strip the wire, the process is more difficult than using a good wire stripper. Similarly, sharp-tipped pliers can be used to terminate crimp connectors at the ends of wires, although this requires more skill and patience than using crimp pliers.

3D printers often include dozens of wires, and having clean connections between various electronic devices ensures they last a long time. Along the same lines, a soldering iron may sometimes be required when assembling and maintaining the printer. However, solder joints can serve as replacements for crimp connector bodies, although the solder joint is not as flexible/modular if changes need to be made.

Please note that most solders cannot withstand the temperature of a 3D printer's hot end. Crimp connectors should only be used in areas of the printer that can become very hot. This applies to the greatest extent to the connections of the heating element and the hotend thermistor.

Crimp connectors should only be used in areas of the printer that can become very hot. This applies to the greatest extent to the connections of the heating element and the hotend thermistor.

Pliers

When building your basic 3D printing tool kit, don't overlook a good pair of pliers. They will definitely come in handy for scraping off excess filament from the hotend and bed, or for fixing parts of a 3D printer and attaching wires. Due to the extreme temperatures around the hot end, you should never manually adjust components under the X carriage while the printer is heating up or cooling down. Pliers (and to some extent wrenches and screwdrivers) will allow you to manipulate the hot parts of a 3D printer without getting burned.

Lubrication

With many moving axles, bearings and carriages, a 3D printer is nothing more than a finely tuned dynamic machine. It is very important to properly lubricate the parts with a few drops of machine lubricant. Silicone-based compounds or those containing PTFE are best for protecting the rods, bearings, and bushings that allow the printer to print. Lubricant and timely maintenance of the mechanics of a 3D printer will definitely help protect your brainchild from unnecessary and unpleasant breakdowns.

Silicone-based compounds or those containing PTFE are best for protecting the rods, bearings, and bushings that allow the printer to print. Lubricant and timely maintenance of the mechanics of a 3D printer will definitely help protect your brainchild from unnecessary and unpleasant breakdowns.

Spirit level

A simple water level can help calibrate the 3D printer bed, X carriage and frame components. Mostly used during assembly. It can also be used to check the alignment of parts after a long period of use or during troubleshooting.

Cable Ties (Cable Ties)

Fully assembled 3D printers rarely require additional cables, but do-it-yourself 3D printers and printers assembled from scrap materials and assemblies will require adequate cable management. In addition, many 3D printer parts use cable ties as structural elements - again, with the exception of most prefabricated assemblies.

Material spool holder

A clean material feed to the 3D printer is very important as it helps to maintain the integrity of the extruder and the mobility of the extruder carriage. It also prevents jamming during long 3D prints where it is simply not possible to be present during the entire print. So if your 3D printer did not come with a holder for a spool of material, you definitely need to make it yourself.

It also prevents jamming during long 3D prints where it is simply not possible to be present during the entire print. So if your 3D printer did not come with a holder for a spool of material, you definitely need to make it yourself.

10 Benefits of a 3D Printer: Save Time and Money

Until recently, 3D printing was viewed as something completely new. The technology was underdeveloped, the hardware was too expensive for widespread use. But only a few years have passed, and the situation has changed radically. Not only did more and more 3D printers begin to appear in stores, but also some enthusiasts began to assemble this equipment themselves.

1. Economy

Although large-scale projects with thousands of 3D printed parts are not cheap, it still turns out to be much more profitable than other technologies. Many manufacturers use 3D printing for small runs or for prototyping. Plastic can also be used for injection molding, but casting small batches can require expensive equipment. But even in this case, manufacturers can produce cast 3D parts several times cheaper than using aluminum.

But even in this case, manufacturers can produce cast 3D parts several times cheaper than using aluminum.

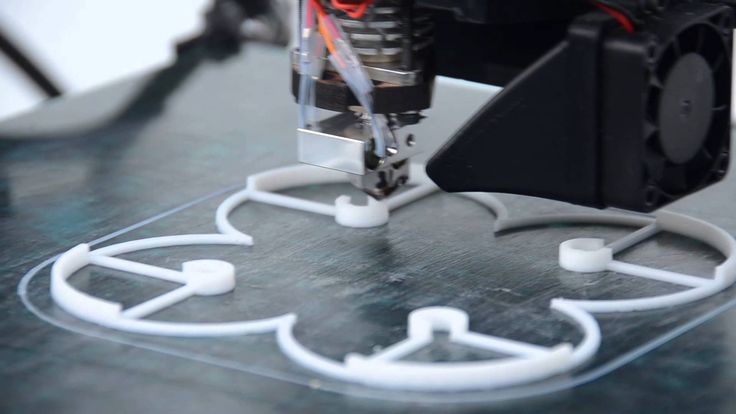

Prototype parts printed on Prusa i3 Bizon 3D printer, layer height 0.1mm, PLA material

Compared to traditional production methods, the entire process can take weeks or days, and most products are printed in hours. Some manufacturers have even begun to make parts to order, which has also allowed them to optimize their warehouse capacity and resource management scheme, making them more flexible. With this new approach, the manufacturer does not need to store every single part or component, they can simply be printed as needed and immediately put into action.

Miniature parts printed by Wanhao Duplicator 7 photopolymer 3D printer, layer height 0.5mm, photopolymer resin material

It not only affects the reputation of the company in its industry, insufficient technical control can lead to injury to employees and customers.

Since 3D printing uses a completely different production method than most machine tool operations, the process has significantly fewer weaknesses and flaws overall.

Since 3D printing uses a completely different production method than most machine tool operations, the process has significantly fewer weaknesses and flaws overall.

Model printed on Picaso Designer X PRO 3D printer, 0.2 mm layer, ABS materials, HIPS

4. Less waste

The press is gaining more and more support in the form of supporters of the "green" movement. Because 3D printing produces significantly less waste than traditional processing, the technology is more environmentally friendly while reducing costs. 3D printing has even made its way into the textile industry, allowing clothing and prototypes to be printed.

Hercules Strong 3D printed yacht steering parts. Details printed in 15 hours with a 0.5 mm nozzle and a layer height of 0.3 mm at a speed of 60 mm/s.

5. Greater customization

3D printed products are also highly customizable. Parts can be printed not only with light plastic, some next-generation models may also have a metal coating. As a result, objects are not only aesthetic, but also functional. In addition, they can acquire thermal and chemical resistance. The existing metallization method can also be used for plastic.

As a result, objects are not only aesthetic, but also functional. In addition, they can acquire thermal and chemical resistance. The existing metallization method can also be used for plastic.

Functional parts printed on Hercules. Material ABS, nozzle diameter 0.5 mm, layer height 150 µm, filling 100%. The model consists of 3 parts: the body and 2 halves of the latch, after printing and processing, the parts were glued together with acetone.

6. Customer Availability

If some craftsmen set up small mechanical workshops, for example, in garages, then most of us cannot afford such a luxury. 3D printing allows you to bring a significant part of the manufacturing process directly into the home, made possible by the availability of user-grade 3D technology. While it turns out to be quite expensive for one-off projects, the price of 3D printers and consumables is dropping rapidly.

Technical wing caps in REC RUBBER or REC FLEX. The models are printed on a Prusa i3 Steel 3D printer.

The models are printed on a Prusa i3 Steel 3D printer.

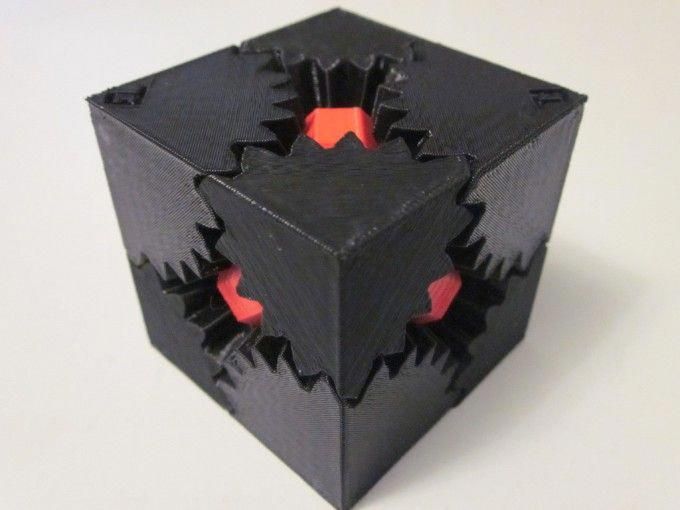

7. High complexity

In most cases, when it comes to complex parts and elements, the manufacturing process imposes certain limitations. Techniques used in casting and finishing objects may not be subtle enough for sophisticated design details. 3D manufacturing processes make it possible to realize almost any design solution, regardless of its complexity, and in a reasonable time. This not only eliminates the extra assembly steps required by traditional methods, but also provides more freedom to create future-proof designs.

Printing large parts from the engine layout on a Zenit 3D printer

8. Fewer risks

While there are inherent risks associated with these new technologies, in terms of day-to-day business, 3D printing risks are significantly lower than with traditional manufacturing methods. Not only is 3D printing much cheaper when it comes to testing a new design or product, the printed prototypes themselves can stir up investor and customer interest and get them to decide whether to proceed with mass production of a product, whether it is worth the time and effort required.

Printing miniature model on Wanhao Duplicator i3 3D printer

9. Variety of materials

The materials used in modern 3D printers are much more diverse than most raw materials in traditional production methods. 3D printing also provides the ability to mix different substances, a luxury that is not always available with conventional methods. Although many 3D printer manufacturers offer their own, very limited set of sources, 3D printers can work not only with original materials, allowing you to simulate ceramics, metal, glass and more.

Printing samples in different materials: PEGT, ABS-PC, PLA, SBS on Wanhao D6 3D printer

The manufacturer not only needs to clearly understand what the customer wants, the manufacturer must also be able to explain what he himself can. Drawings, diagrams, diagrams are all good, of course, but there is nothing better than a real prototype that you can hold, look at and study.