Ideal room temperature for 3d printer

The proper working environment for your 3D printer

| EN | ES |

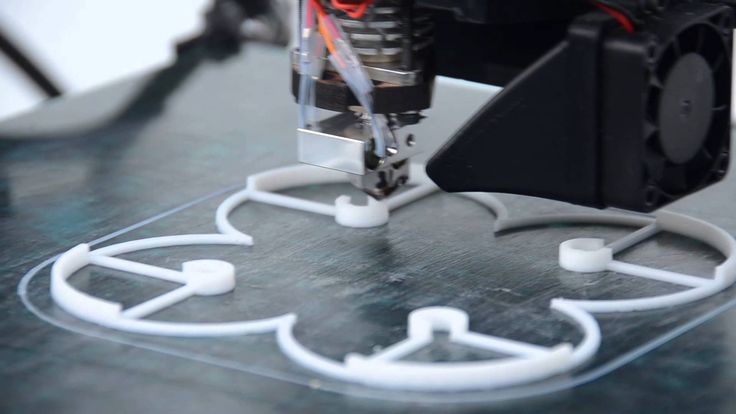

3D printers like other machines are subject to operating wear and tear and in turn to the environmental conditions where they are.

Installing your printer in an optimal environment improves its performance, maintains its useful life and that of the filaments, it also reduces the need to continuously perform certain maintenance operations.

Table of contents:

Environmental conditions for successful printing

The suitable area to install the printer

Environmental conditions for successful printing

The temperature, humidity, and ventilation affect both the mechanical and electronic elements of your printer as well as the print quality, so it is recommended to control these variables in order to avoid problems in the short and long term.

Room temperature

The place where you install the printer is recommended that it be between 15ºC and 30ºC to avoid problems that affect print quality. In very hot environments, material flow or shrinkage can be affected, leaving threads or bubbles on the piece surface.

A very cold environment can cause various problems such as:

- Warping: It is the total or partial lifting of the corners of the model in contact with the printing surface due to the contraction of the material, usually caused by a very sudden cooling during the printing process.

- Delamination or cracking: it is the separation of the intermediate layers of the model due to the stresses induced by the suddenness of the material.

Humidity

The humidity can damage the electronic components of the printer but affects the printing materials to a greater extent, for which it is recommended not to exceed 50% relative humidity and store them after use in a zip-lock bag or in the BCN3D Smart Cabinet

To properly store your filaments visit the following article:

How to handle and storage BCN3D filament

Ventilation

A well-ventilated environment allows easy temperature and humidity control. Make sure that the air can circulate in the room where your printer is and leave enough space with the walls.

Make sure that the air can circulate in the room where your printer is and leave enough space with the walls.

Avoid covering your printer especially the vents to ensure air circulation between the electronics element.

Proper ventilation of the environment around the printer also prevents the gases emitted by the filaments from accumulating during the printing process. These gases can have harmful effects on your health if they are constantly inhaled.

The right place to install the printer

In order to have easy access to the printer and to be able to perform routine and maintenance tasks comfortably, it is essential that the printer has sufficient space on all sides. In addition, it must be located on a solid and robust surface to absorb the vibrations generated during the normal operation of the printer.

Below you will find the articles with the specifications of the recommended place to install your device:

RELATED ARTICLES |

Can You 3D Print in a Cold or Hot Room? – Temperature Solutions – 3D Printerly

Getting the perfect 3D printing quality depends on many factors, the temperature is one of the main ones. Based on this, many people wonder whether you can 3D print in a cold or hot room. This article is going to answer exactly that so you have a better idea of your 3D printing capabilities.

Based on this, many people wonder whether you can 3D print in a cold or hot room. This article is going to answer exactly that so you have a better idea of your 3D printing capabilities.

You can 3D print in a cold or hot room as long as your 3D printer has the proper conditions, such as a constant printing temperature and the right kind of materials. If you try to 3D print ABS in a cold room, you are likely to run into massive warping problems, while PLA could be pulled off.

There are many more details that need to be discussed to get the real answer on 3D printing in a cold or hot room. Keep on reading to find out some key information on this topic.

If you are interested in seeing some of the best tools and accessories for your 3D printers, you can find them easily by clicking here (Amazon).

Can You 3D Print in a Cold Room or Cold Weather?

Monitoring temperature while printing is one important step you need to ensure. It can be hard to print in a cold environment hence you need to carefully monitor your environmental temperature while printing.

Different print materials require different optimum temperatures. When you print with ABS, you should keep the entire build area fairly hot to prevent warping. However, PLA is not as meticulous as ABS.

Which means that you can get some 3D prints in a relatively cold environment if you are printing with PLA. Users started to see printing issues with PLA at temperatures below 59°F (15°C).

The main thing you have to control is temperature fluctuations because large changes in temperature can definitely mess a print up. Warping occurs because print layers are cooling down too quickly, meaning they contract too much.

This is when you see corners of your print start to curl away from the print bed, which is bad for print quality and can even lead to prints getting knocked over because it decreases bed adhesion.

Once you control for temperature fluctuations, 3D printing in a cold room isn’t impossible, but it can definitely be difficult. I’m sure there are certain temperatures which are just too cold to operate successfully.

It will come down to how good your power supply is and your heated bed part’s ability to generate enough power to overcome the cooler environment.

Check out this video by Uncle Jessy who actually 3D printed outside in the snow to test out the theory!

Can You Resin 3D Print in a Cold Room?

Yes, it is possible to resin 3D print in a cold room if you keep in mind a few pointers. The resin won’t completely harden if the temperature falls too low if you ensure your workplace temperature stays stable at 75°F (24°C) and doesn’t fall below around the 68°F (20°C) mark.

The resin won’t completely harden if the temperature falls too low if you ensure your workplace temperature stays stable at 75°F (24°C) and doesn’t fall below around the 68°F (20°C) mark.

The operating temperature for a Formlabs resin 3D printer is 64-82°F (18-28°C).

You must ensure your resin is at room temperature if you want it to work fine. Try to keep your workplace temperature stable and make sure humidity level is not above 50 per cent.1

Hence, it is quite possible to get resin 3D print if you ensure a few important steps. By avoiding any temperature fluctuations and high humidity levels, it is possible to get resin 3D print in a cold room.

Cold is actually ideal for storing your resin because the lower temperatures reduce chemical reactions which mature the resin. Warming up your resin before use will get it going. Some resin shouldn’t be stored in environments which are too cool though.

Warming up your resin before use will get it going. Some resin shouldn’t be stored in environments which are too cool though.

You want to try avoiding storing your resin in temperatures below 50°F (10°C) or above 140°F (60°C).

Constant temperature is essential for successful prints. Temperature also has effects on how well your resin hardens from the light and cures with the help of UV. A high quality resin 3D printer will regulate the temperature inside the machine, as well as the curing chambers.

The Peopoly Maoi offers a heater for their printer which makes it much easier to resin 3D print in a cold environment.

Can You 3D Print in a Hot Room?

Most printing occurs efficiently under a hot environment however there is a certain limitation to the temperature.

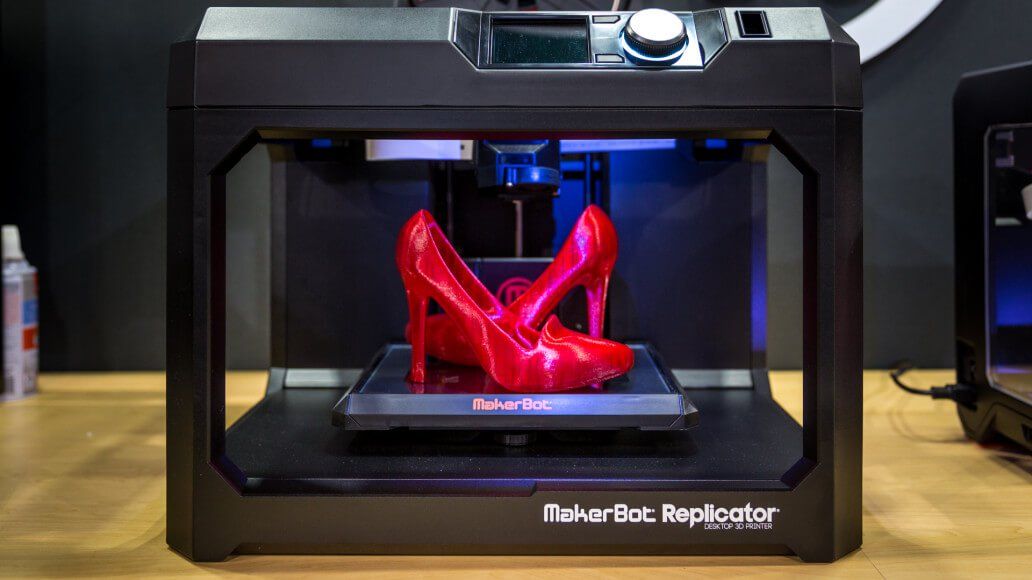

To allow a better working environment for the printer if your surroundings are hot is to install efficient cooling fans and even a cooler. For even better temperature regulation you can also place an air conditioner.

PLA is relatively easy to work with and is not that sensitive to temperature changes as compared to ABS.

You just want to make sure you don’t have an extremely hot operating temperature because that can mess up some prints, depending on the material.

Materials with a low glass transition temperature like PLA won’t do very well in a hot environment as it won’t harden in time. If you have strong cooling fans it may be able to print successfully, but it does make it harder.

However, regardless of the filament you use, you need to make sure at all times that the overall room temperature even in a hot room doesn’t exceed above 50 Celsius. Beyond this temperature, your prints can get messy and spoiled.

Moreover, your printer can overheat resulting in many other complications.

Can You Resin 3D Print in a Hot Room?

To allow resin 3D printing in a hot room you must observe consistent temperatures. Consistency in your workplace temperature is the key to perfect your resin printing in a relatively hot environment.

You can improve your resin printing by heating the resin in a water bath before starting the printing process. Most resins work best in the temperature range of 25-30°C.

By decreasing the heated bed temperature and using efficient fans for cooling, you can enable printing in a hot room. You should be able to regulate your temperature around 20°C.

3D Printing in a Hot Garage

Yes, it is possible for you to 3D print in a hot garage but for this, you need to have some accurate climate control facilities. By ensuring control over the operating temperature and its fluctuations you can successfully print in a hot room.

In hot garage temperatures, it shall be unlikely to print in PLA, as that specific temperature is way above its glass transition temperature. This therefore could never let it solidify.

But, for ABS it will be great and would also decrease warping. It will also improve surface finish.

Does Room Temperature Affect 3D Printing?

Regardless of the environment, you are working in, you should at all times, ensure stability in temperature. It is best advised to regulate the temperature around 68°F (20°C).

It is best advised to regulate the temperature around 68°F (20°C).

So, yes, room temperature surely has a huge effect on the printer’s performance, efficiency and longevity. No printer likes to work in an extreme climatic environment, whether it’s too cold or too hot.

Extreme high temperature can result in deformation of parts, whereas the cold temperature may result in warping between the print layers.

What is the Best Ambient Room Temperature for 3D Printing?

Technically speaking, there is no exact ambient room temperature for 3D printing. There isn’t actually an ideal ambient room temperature for the 3D printing. Rather a temperature range is to be kept in mind.

But the most foremost factor to practice is temperature stability. Hence, for good print output and overall performance, it’s best you maintain an optimum room temperature preferably around 62-68°F (17-20°C).

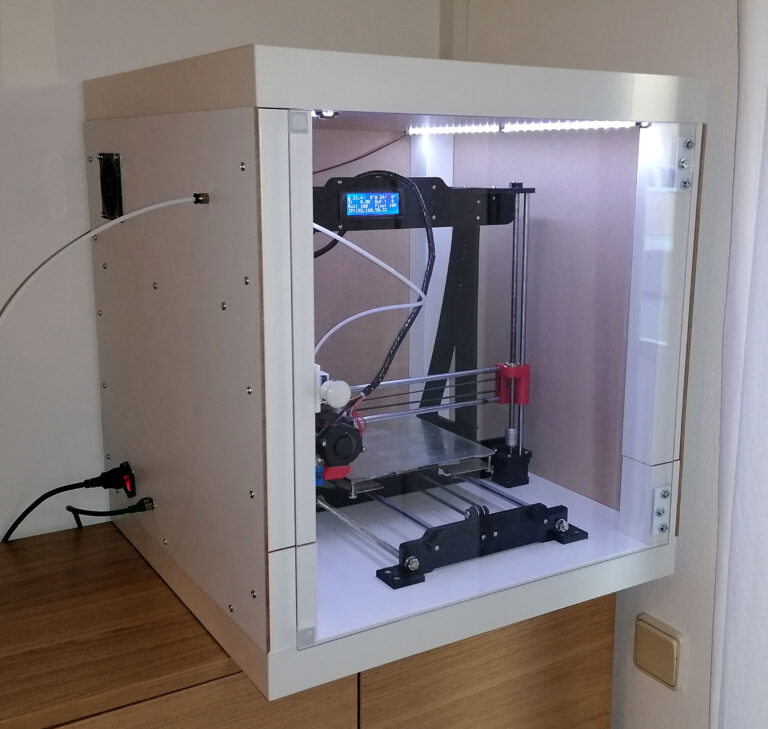

Should I Use a Heater for my Printer Enclosure?

If you are printing in a cold environment, it’s good to use a heater so that the overall workplace temperature is suitable for the printer to work in. Temperatures might fluctuate without a heater and hence spoil your printer’s performance.

Temperatures might fluctuate without a heater and hence spoil your printer’s performance.

So, you should place a heater to avoid the area from getting too cold. Extremely low temperatures can exist without there being no heater and this can result in your nozzle and filament getting spoiled.

How to Winterize your 3D Printer to Print in a Cold Room?

Printers might not be able to work in a very cold area, so you can install heating chambers for better results. It is also advised that you install wireless sensors which can monitor temperature and the humidity changes.

The main thing would be trying to increase your overall temperature in the cold room with a heater, or by using better insulation so the warm air doesn’t escape, and cold air doesn’t come in.

If you are having trouble with this, a heated chamber is going to be a lot more efficient compared to heating the whole room. It can be built out of many materials and there are guides on building DIY heated chambers that you can find on YouTube.

Furthermore, for a better printing experience you can also install carbon filters, and even an exhaust system which can filter out toxic fumes. Although you are working in a cold room, try to avoid your printer’s direct contact with sunlight.

This is suggested because, severe temperature fluctuations can prove to be really disadvantageous for the printer’s overall performance.

Apart from that, it is important that you store your materials and other supplies at room temperature and preferably in a vacuum free space.

Conclusion

Temperature regulation is a key step which can promise you a smooth printing experience. Other than that, the aforementioned guidelines will seem to be very effective if you practice them.

If you love great quality 3D prints, you’ll love the AMX3d Pro Grade 3D Printer Tool Kit from Amazon. It is a staple set of 3D printing tools that gives you everything you need to remove, clean & finish your 3D prints.

It gives you the ability to:

- Easily clean your 3D prints – 25-piece kit with 13 knife blades and 3 handles, long tweezers, needle nose pliers, and glue stick.

- Simply remove 3D prints – stop damaging your 3D prints by using one of the 3 specialized removal tools.

- Perfectly finish your 3D prints – the 3-piece, 6-tool precision scraper/pick/knife blade combo can get into small crevices to get a great finish.

- Become a 3D printing pro!

Optimal temperatures for 3D printing PLA, PETG, Nylon and TPU plastics

3DPrintStory 3D printing process Optimal temperatures for 3D printing with PLA, PETG, Nylon and TPU plastics

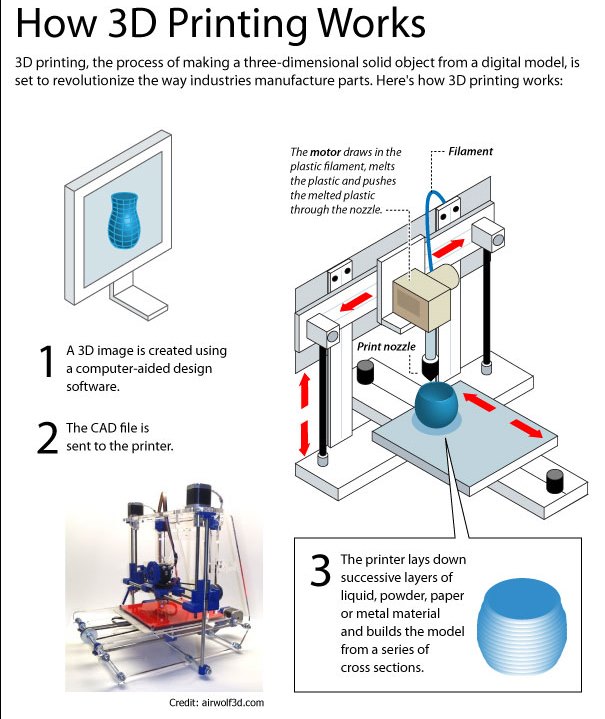

Although almost all 3D printing materials are thermoplastics, each has its own temperature requirements. The specificity arises from the fact that individual fibers differ greatly from each other in chemical composition. Some, like PLA, are made from starches, while others, like ABS, are oil-based.

The specificity arises from the fact that individual fibers differ greatly from each other in chemical composition. Some, like PLA, are made from starches, while others, like ABS, are oil-based.

The chemical composition of a thermoplastic directly affects its glass transition temperature, the temperature at which the material changes from a brittle filament to an extrudable elastic substance. It is this temperature that must be maintained for high-quality 3D printing. And since each material has a different glass transition temperature, each plastic must be used for 3D printing at a different extruder temperature.

In addition to a specific extrusion temperature, some materials require a specific hot bed temperature. When some fibers cool, they shrink and deform. The heated bed allows these plastics to cool more slowly during extrusion so that bending is minimized.

The heated layer also provides additional adhesion, ensuring that the first layer adheres well and the part does not separate from the base during 3D printing.

So 3D printing temperature is a very important parameter that differs depending on the material that is used.

Recommended temperature for 3D printing with PLA plastic

PLA is the most popular plastic in the world today. One of the reasons is undemanding to the conditions of 3D printing.

PLA prints best around 210°C, although it is very versatile and can work at 180 to 230°C. It doesn't require a heated bed to print, but if your 3D printer has one, set the bed temperature somewhere between 20 and 60° C.

When printing with PLA, make sure the cooling fans are on. PLA produces the best results when cooled properly.

Overall, PLA is very easy to use and doesn't require much tambourine dancing to be successful.

Recommended temperature for 3D printing with ABS

Until recently, ABS was the most widely used material for 3D printing. Then ABS lost to PLA in the battle for the lead. The main reason is the great difficulty during 3D printing.

ABS requires a slightly higher temperature to print successfully. The recommended nozzle temperature is between 210 and 250°C. A heated table with a set temperature between 80 and 110°C is required. This is because the ABS shrinks as it cools, and if the model cools too quickly, it deforms. For the same reason, the cooling fans must be turned off when printing ABS.

Recommended temperature for 3D printing PETG plastic

PETG is a relative newcomer to the 3D printing media market, combining many aspects of PLA and ABS.

It requires very high nozzle temperatures of 220 to 250°C. However, unlike ABS, PETG does not require a heated bed.

PETG prints best with blue masking tape on the table. Without it, the table must be heated to 50-75°C so that the extruded material will adhere well to the table on the first layer. And because this material doesn't flex like ABS, cooling fans can be turned on during 3D printing.

Although PETG is not as easy to use as PLA, it is much less demanding than ABS and is now the top of the list in popularity.

Recommended temperature for 3D printing Nylon with plastic

Nylon is another popular and interesting material, although it is more difficult to work with.

It requires a higher temperature than any of the other materials on the current list: 240 to 260° C is recommended. Required table temperature is 70 to 100° C. However, the glue stick layer is very important as Nylon suffers from adhesion quality problems first layer.

Nylon should not be printed with cooling fans as this will cause layer adhesion problems.

This material is also very hygroscopic, meaning it absorbs moisture from the air very actively. This significantly reduces the quality of 3D printing, so the nylon must be dried before printing or a quality thermal box must be used.

Nylon can be problematic at first, but once you learn how to print properly with this material, it will cover many of your questions and needs.

Recommended temperature for 3D printing TPU plastic

The flexible materials known as TPU are an unusual and sometimes very useful material, but very difficult to work with.

TPU is used at the same temperatures as PLA. Works best between 210 and 230°C with table temperatures between 30 and 60°C.

Because this material is very flexible, it can bend and stretch from the extruder gear to the nozzle itself. Therefore, it is important that the material is extruded slowly and without retract.

If these problems become noticeable, a slight increase in extruder temperature can help reduce any material distortion that could cause it to buckle.

Optimal table and hot end temperatures for 3D printing PLA

3DPrintStory 3D printing process Optimal table and hot end temperatures for PLA 3D printing

In an ideal world, there would be an ideal temperature where you could set up your 3D printer once and just hit the button to start 3D printing. But in reality, there is no ideal temperature for PLA plastics. And in order to get a good 3D printing result, you need to spend some time and effort.

But in reality, there is no ideal temperature for PLA plastics. And in order to get a good 3D printing result, you need to spend some time and effort.

PLA is quite forgiving when it comes to temperature, and as long as you don't deviate too much from the recommended 3D printing temperatures, the result will be good. What's more, PLA is a great way to get started in the world of 3D printing and experimentation, as it's easier to use than, for example, ABS or PETG.

One important thing to keep in mind when checking suitable temperature ranges is that different brands and even colors of PLA plastics can have different optimal 3D printing temperatures.

Optimal temperature range for hot end

As mentioned above, it would be nice to know one temperature for printing PLA materials, but in fact there is none. There is a recommended range within which you need to adjust the nozzle temperature of your 3D printer. For PLA plastics, the recommended hot end temperature range is 190° C to 220° C.

If during 3D printing you notice that the layers do not adhere to each other, you can increase the temperature within the above recommended range. On the other hand, hot end cooling can improve the quality of 3D printing. If the extruder is too hot, the PLA filament can become very soft and brittle. This results in the model being printed with visual defects.

3D printer hot end temperature symptoms

Another indicator that the hot end is too hot is if your 3D printer is not printing bridges well. This could mean that the plastic is so hot that it doesn't have time to cool down enough. If the hot end is too hot, your 3D models will look "dirty" and "tarnished". Lowering the temperature can help with this.

Meanwhile, if the 3D model does not adhere well to the table, then this may be a sign of insufficient hot end temperature. A cold hot end can also make it difficult to form good corners on your 3D models.

One of the best ways to achieve the ideal hot end temperature is to experiment. By slowly adjusting the temperature, increasing or decreasing, you will gradually find the optimal temperature for your 3D printer and plastic.

By slowly adjusting the temperature, increasing or decreasing, you will gradually find the optimal temperature for your 3D printer and plastic.

Heads from different manufacturers and different colors also affect the optimum temperature of the hot end. For example, a black PLA spool can print well at around 215°C, while a similar blue PLA spool from the same manufacturer will perform well at 210°C. Even small temperature differences can make a big difference in the quality of your 3D models.

Best 3D Printing Table Temperature Ranges

Heated tables have a huge impact on 3D printing quality. Although they are not available on all 3D printers, for those where they are installed, the temperature must also be adjusted correctly. While the recommended bed temperature for PLA 3D printing is 70°C, this does not always work perfectly. There are recommendations for a heated table temperature range of 55°C to 70°C for PLA plastic. So the temperature of the table as well as the hot end should be adjusted to your own realities.

Signs of incorrect 3D printer table temperature

The most obvious sign that your table temperature is too low is that your 3D models are not sticking to it. If they don't stick well, you can raise the temperature a little. A warmer 3D printer bed can help soften the plastic, allowing it to better grip at the base of the model. Just be careful not to overheat the table or you'll run into an elephant's paw problem. In short, this effect is manifested in the fact that the first few layers melt under the weight of the 3D model.

The "elephant leg" is especially strong, especially when the 3D model is very heavy, as there is more pressure on it. This annoying side effect can be easily fixed by lowering the temperature of the 3D printer bed a bit. Again, don't overdo it and don't set the temperature too low. Measure is needed everywhere!

Ambient

Ambient can also affect PLA print temperatures. If, for example, a cool breeze is blowing from the window, you can increase the temperature of the hot end and the 3D printing table by a couple of degrees. Air conditioning vents can also lower the temperature of 3D printing.

Air conditioning vents can also lower the temperature of 3D printing.

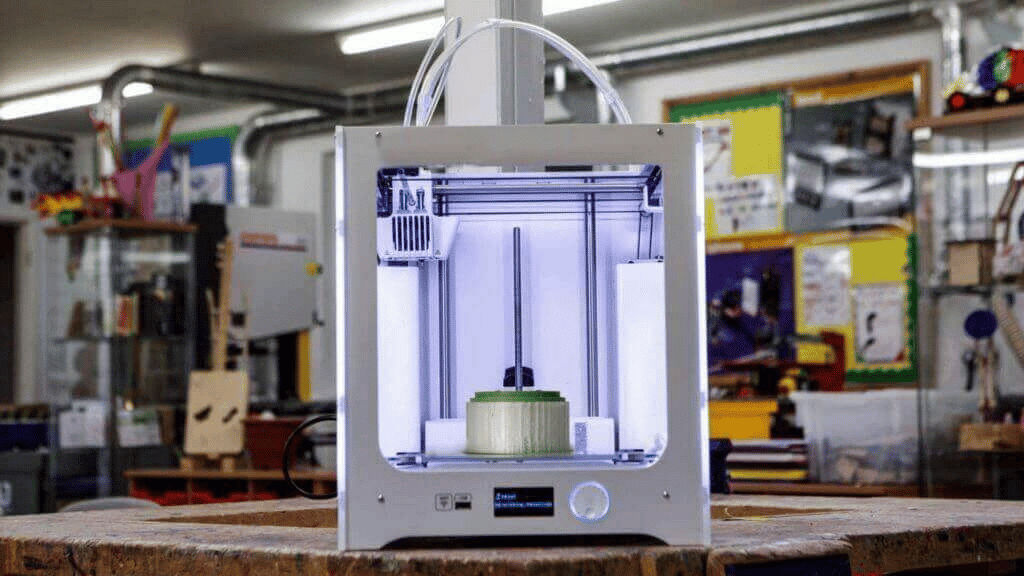

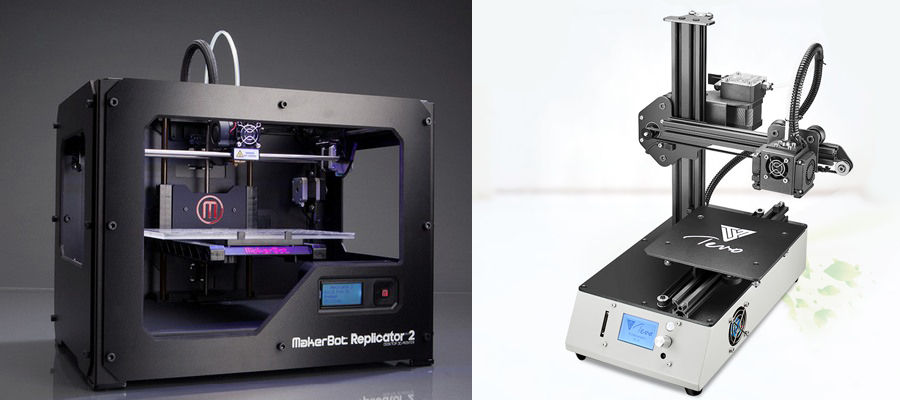

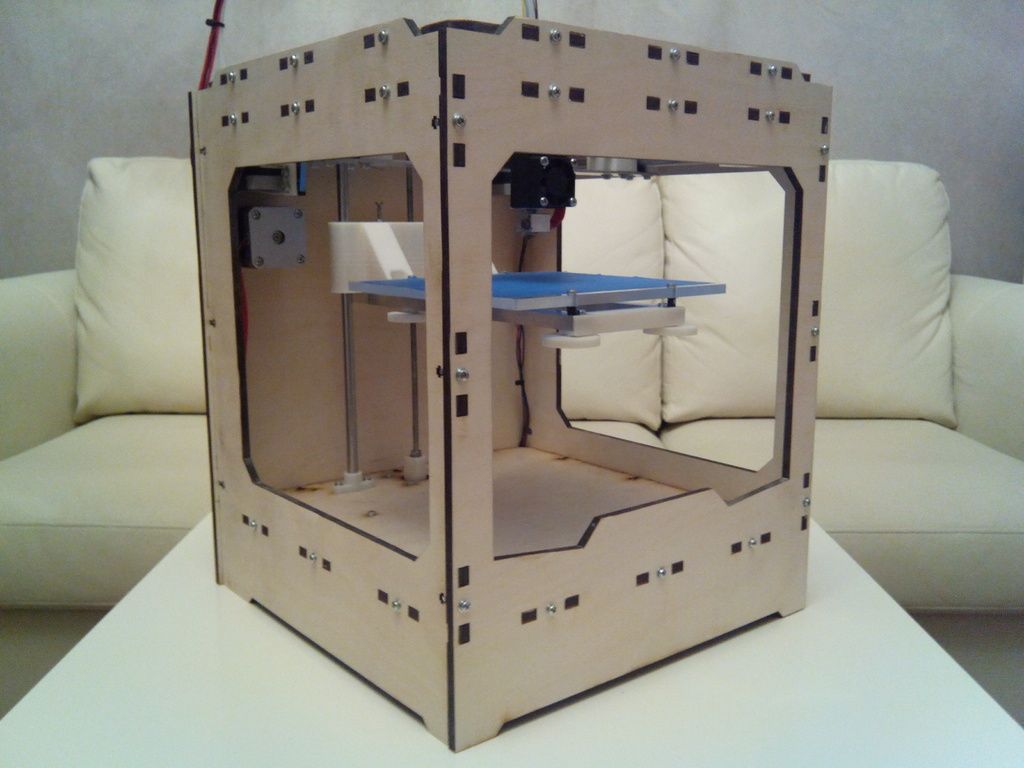

To minimize the impact of external factors, we strongly recommend making an enclosure for your 3D printer. When it comes to temperature, the case serves two purposes: keeping the outside temperature from affecting your 3D models, and keeping the heat inside.

There are quite a few 3D printer case designs available in the public domain, so feel free to google it or make your own. As materials for the case, plywood, plexiglass and fasteners are often used, which are printed on the same 3D printer.

How to find the optimal temperature settings for a 3D printer?

It's been mentioned before, but again: the best way to determine the temperature of the table and hot end is trial and error in your specific environment, with your 3D printer, your plastic, and where the 3D printer is standing during printing . If you find that your products are uneven, reduce the temperature of the hot end a little.