Can you 3d print meat

What is 3D Meat, How is it Made, and What are its Benefits?

From pasta to chocolate and now 3D-printed meat, 3D-printed food is becoming increasingly popular. And while there is resistance against 3D-printed meat, the practice is here to stay.

With an increasing number of people adopting vegan, flexitarian, or vegetarian eating practices, coupled with the rising issues with livestock, alternative options that taste like meat are gaining in popularity.

In this guide, we’ll answer questions like what is 3D meat and explore the concept in greater depth.

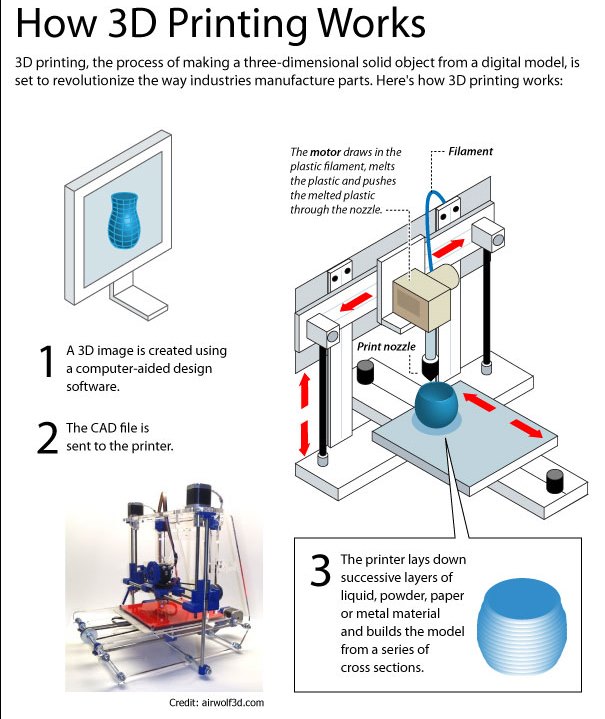

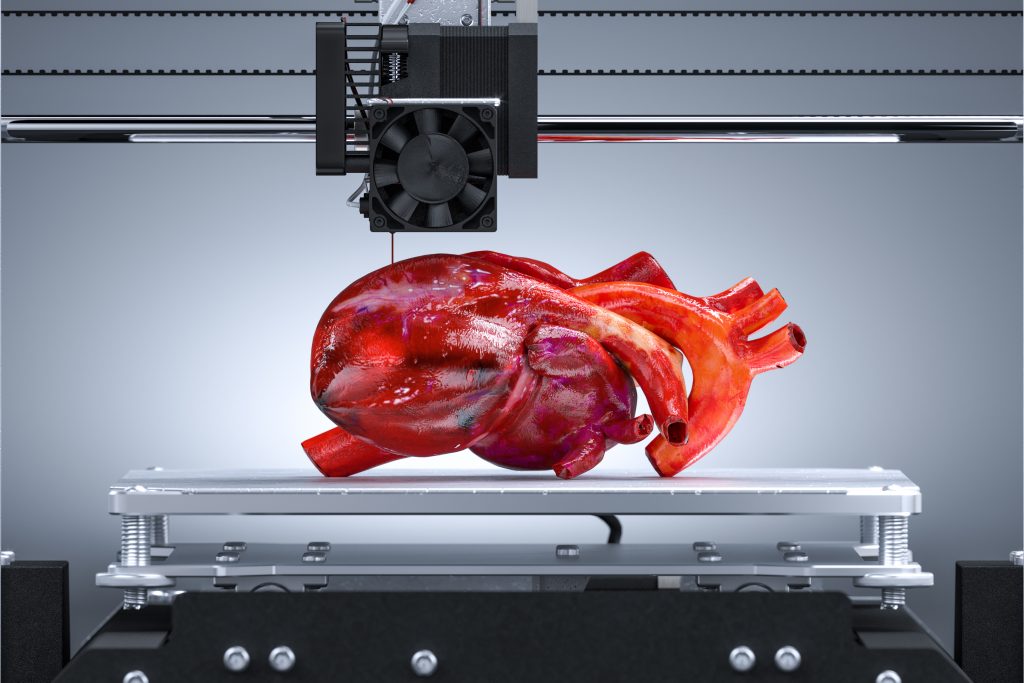

What Is 3D Meat?3D meat or 3D printed meat is a type of cultured or created meat made using 3D printers and additive manufacturing techniques, along with artificial intelligence and material science.

One approach involves feeding the printer cultured animal cells that are ‘printed’ into meat-like forms. Think of a regular printer, but instead of ink, you feed it a viscous consumable material, and you can eat the final product.

Note that 3D printed meat is only the process of producing the meat—it must still be cooked before it can be consumed. The 3D printing process only involves printing or projecting the material onto a surface in the desired shape.

Now that we’ve defined 3D meat, let’s see what 3D food and 3D meat are made from.

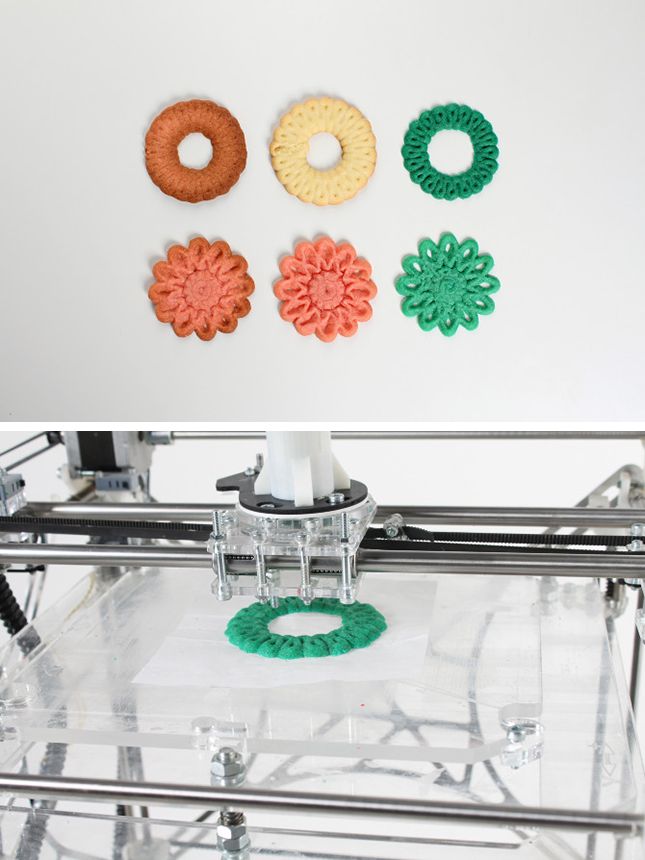

What Is 3D Food Made Of?3D food can be made using any ingredient as long as it adheres to the printing technique used. Some of these techniques include:

- Extrusion-based printing

- Selective laser sintering

- Hot-melt and room-temperature extrusion

- Inkjet printing

- Binder jetting

- Multi-printhead and multi-material printing

Most 3D food involves the following ingredients:

- Puree

- Mashed potatoes

- Jelly

- Cheese

- Frosting

- Chocolate

- Sugar

- Chocolate powder

- Protein powder

- Sauces (ketchup, pizza, hot sauce, mustard, etc.

)

) - Colored food ink

For 3D-printed meat, this list of ingredients can include plant-based ingredients such as peas, chickpeas, beetroot, etc., or cultured animal cells.

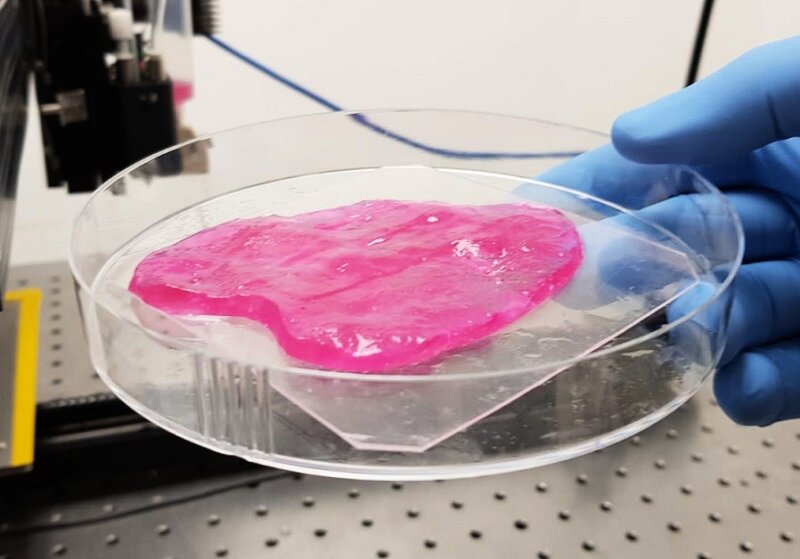

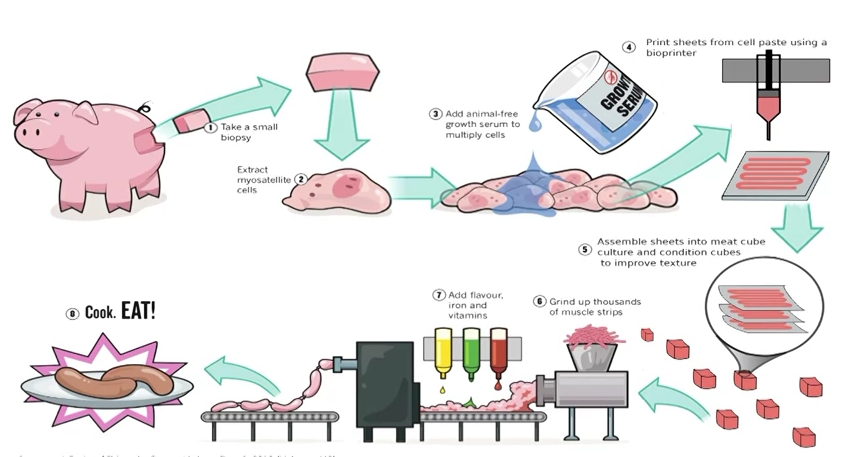

How Is 3D Printed Cultured Meat Made?Lab-grown cultured 3D meat is produced using bovine stem cells from a cow or chicken egg. Also known as starter cells, these are isolated and grown in a bioreactor to produce a large quantity of biomass. The cells are then differentiated into edible tissue of muscle and fat cells that are printed into the meat we know and enjoy. Consumers can rest assured that this is an entirely harmless procedure.

This process is further broken down into steps that may differ based on the technology and company producing it.

Is 3D-Printed Meat Vegan/Vegetarian?3D-printed meat may or may not be vegetarian, depending on the ingredients used to ‘print’ it.

Some 3D-printed meat is made using plant-based ingredients such as soy, pea protein, beetroot, chickpeas, and coconut fat. While other varieties of 3D meat — also known as cultured meat — are made using animal cells.

While other varieties of 3D meat — also known as cultured meat — are made using animal cells.

While there is technically no ethical violation in eating printed meat made using cultured animal cells, some vegans and vegetarians might disagree.

At present, there is limited regulatory oversight involved in 3D printing food. But with an increasing number of vegans and vegetarians adapting to the idea of 3D-printed meat or cultured meat, regulation will follow soon.

Is 3D Meat Healthy?Here are some of the health benefits of 3D meat when compared to consuming livestock-based meats:

- Lower risk of cardiovascular disease

- Lower risk of diabetes

- Lower risk of certain types of cancer

- And more.

Nutritious Content in 3D Meats

The best thing about 3D meat is that it can be found in various nutritional constituencies. Depending on health conditions or dietary requirements, 3D meat can be made to cater to people with celiac disease, obesity, hypertension, diabetes, and more.

Since 3D meat is made of plant-based ingredients or cultured cells, its nutritional value is typically much higher than regular meat. These alt-meats provide more nutritious supplements without any harmful content, like unhealthy fats.

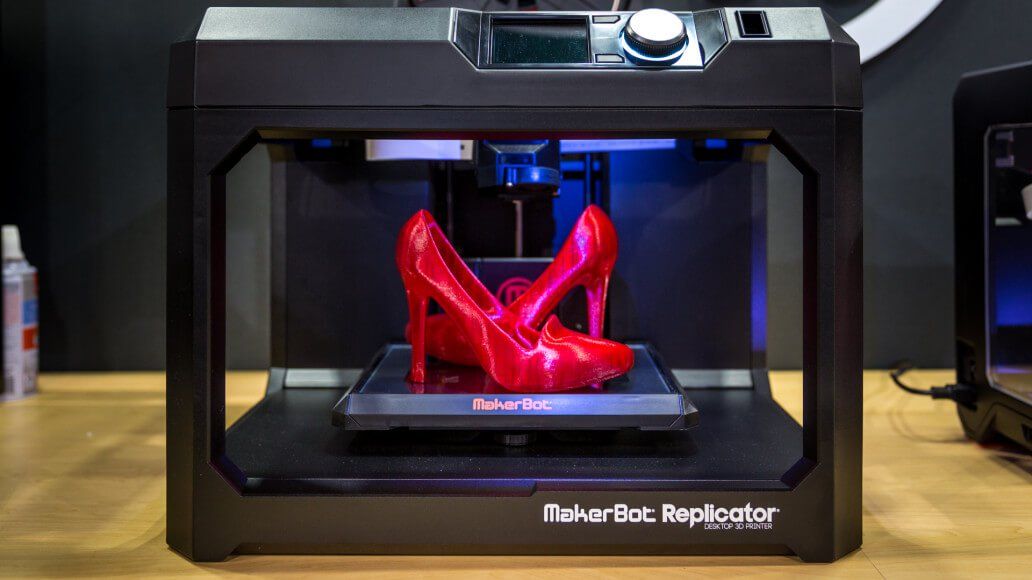

3D Meat: The Expenses InvolvedAt present, 3D printing meat can involve high cost of production, which makes the resulting product prohibitively expensive.

Commercial-grade 3D printers cost thousands of dollars. Every element must be top-grade, from the materials and filaments to the machine itself. And with a relatively small scale of production, this can mean incredibly high production costs overall.

The filaments used in 3D printers also require quite a bit of processing to make them safe for food production. Add to that the time spent learning how to handle these devices properly, and this endeavor becomes even more resource-intensive.

Using cheaper alternatives comes with safety risks and machine troubles—two things that must be avoided.

Yes, 3D meat is eco-friendly.

3D printing uses fewer resources to produce a cultured lab-grown piece of steak than the complex processes needed to make the real thing. More importantly, it doesn’t require raising livestock, slaughtering, or processing meat.

The process of 3D printing also allows for the use of meat by-products to print a steak, thereby reducing the amount of waste that goes out of restaurants.

3D printing also has a lower impact on the environment than other forms of meat processing and production practices.

Currently, the practice of printing meat is one of the best eco-friendly alternatives in the industry. Although, more work is required to make the process affordable for all types of enterprises and customers all over the world. Manufacturers of 3D printers must also find ways to match the production requirements of current food production methods.

In time, these improvements will make the 3D printing process and products an affordable and more environmentally friendly alternative to traditional meat sources.

Companies and scientists making 3D-printed meats have claimed that their products taste just like the real thing. But little data backs up this claim since 3D printed meat is not yet accessible for large-scale consumption.

The technology used to create 3D meat aims to recreate the muscle fibers of real meat and its juiciness. This may be as close to getting the taste and texture right.

One recent study attempted to use 3D printing to replicate prized Wagyu beef, with a focus on mimicking the original product’s unique marbling, tenderness, texture, and flavor. While no taste reports are available, getting Wagyu right is sure to be an important milestone in the 3D printed meat industry.

There is also a reluctance to taste lab-grown meat among Gen-Z. This implies the taste of cultured meat is still mainly a matter of perception and will need some getting used to.

Types of Alt-Meat That Can Be Created Using 3D PrintingAs 3D meat printing techniques continue to develop, various types of meat can be created. The popular options available to consumers currently include:

The popular options available to consumers currently include:

- Ground beef

- Burgers

- Lamb

- Kebabs

- Sausages

- And more.

There’s no limit on the type of alternative meats that can be produced using 3D printing.

Reasons to Use 3D Printing to Produce FoodCustomization Options

One reason to use 3D printing to produce food is that you can customize the food preparations and alter its taste, flavor, texture, appearance, and more. This helps to ensure better consumer satisfaction, as personalization leads to satisfaction.

Nutritious

3D-printed food is also more nutritious than regular food, thanks to the nutritional control that can be exercised in its production.

From personalized dietary requirements to elderly nutrition, one can control how much protein, sugar, vitamins, minerals, and fats go into 3D-printed food. One can also make softer food products for older adults that fulfill their nutritional requirements.

One can also make softer food products for older adults that fulfill their nutritional requirements.

Sustainability

While plenty of food is being produced to feed everyone in the world, doing so requires a vast amount of natural resources. This has increased the need for sustainable solutions in food production.

One such solution lies in entomophagy, or the consumption of insects. For example, crickets have long been known for their high protein levels. Capturing and processing these insects for consumption requires very few resources, especially compared to other animal protein sources.

While eating crickets as they are might seem strange, 3D printing makes the process more palatable. Using crickets as material for 3D-printed meat will lead to a delicious and nutritious meat alternative. This is one way to explore the sustainable production of food for mass consumption.

When 3D-printed meat becomes more common, it will require little in the way of transportation—an element of food production and distribution that consumes a lot of resources and accounts for tons of greenhouse gas emissions.

Reduction of Food Waste

Leftovers, bruised fruit, meat off-cuts, perishables—there’s no shortage of food waste in every step of the food production and distribution process. Over 1.3 billion tons of food waste is generated every year.

By using 3D printing technology, one can put consumable ingredients to good use and finally solve the global food waste problem.

Reproducibility

With 3D printing technology, consistency is much easier to achieve. These machines are fed recipes that they turn into the ideal product, be it pancakes or burger patties.

Space Exploration

3D food printing is also a great way to provide astronauts with nutritious food alternatives. The customization options are especially useful—these explorers will be able to prepare the meals that they want.

3D-printed food also has a longer shelf life in comparison to freeze-dried food. This means scientists can design space exploration journeys for longer periods without worrying about how long food can last in space.

3D meat is a smart alternative to traditionally-raised livestock in many ways.

Less Reliance on Livestock

For starters, it’s an obvious solution for those looking to reduce their reliance on livestock. This takes the pressure off the planet by reducing greenhouse gas emissions.

With growing climate change concerns, this makes a good case for why you should consider 3D printing to produce meat.

Healthier

3D-printed meat is also much healthier than traditionally sourced meat. You can customize nutrition content, flavor, texture, and other elements to suit the preferences and needs of your consumers.

Vegan and Vegetarian-Friendly

Another huge benefit of producing meat using 3D printing is that it allows manufacturers and restaurants to offer vegan, flexitarian or vegetarian customers delicious meat alternatives.

Better yet, these meat products also live up to the expectations of meat lovers, despite being made with plant-based ingredients.

De-Animalization

Even meat lovers have limits. And some animal parts, while technically edible, are often just thrown away as offcuts.

The solution? De-animalization of meat such as heart, tongue, liver, kidney, intestines, etc.

Typically, these parts would be removed from the meat product. But with 3D printing, they can be used to make more aesthetically pleasing ingredients that taste just as delicious.

Wrapping Up 3D MeatPreviously just an experimental research field, 3D printing food is now reaching new heights and expanding in popularity. With 3D-printed meat, we’ll soon be resolving the myriad problems caused by the cultivation and slaughter of meat using traditional methods.

Share this article:

How Does 3d Printed Meat Work? — Nikko Industries

The culinary industry has printed a range of edible objects from cakes to pizzas, but now they're taking on a much bigger undertaking.

The goal of 3D-printed meat is to solve three major issues: lowering greenhouse gas emissions, providing a sustainable protein supply for all consumers, and promoting a cruelty-free method of meeting meat demand. Let's take a peek at the food industry's cutting-edge technology.

It is not an exaggeration to state that the world has seen incredible advancements in alternative meat production technologies in the last two years. If phrases like "3D printed vegan meat" or "meat 3D printed in space" sounded like science fiction a decade ago, they are now not only feasible but are happening.

Given the world's environmental catastrophe and the rapid depletion of natural resources, sustainability is no longer merely a selling point, but a critical business strategy.

3D-Printed Meat— How Does it Work?

Generally speaking, 3D printing meat is similar to printing filament with a standard FDM 3D printer in that a viscous material is deposited onto a surface to generate a final product. This vision has come to life, specifically when it comes to 3D printing meat, thanks to a technology known as Proprietary Tissue Engineering Process.

This vision has come to life, specifically when it comes to 3D printing meat, thanks to a technology known as Proprietary Tissue Engineering Process.

This method works by isolating and growing bovine stem cells from a tissue sample until they reach an appropriate cellular mass.

Stem cells are formed into a bio-ink and then employed in a 3D bioprinter after they reach this mass.

You can then actually produce a steak and place it in an incubator to grow using a digital model of a steak structure. The cells finally differentiate into fat and muscle cells throughout this maturation period.

As bioprinting and cultivation technology progress, it will soon be hard to tell the difference between a steak that is virtually bioprinted and one that is not.

Newest Developments in the 3D-Printed Meat Sector

Finding the perfect meat substitute appears to be a puzzle. It's not only about the flavor of the meat, enthusiasts considering a switch to "3D-printed meats" will expect the same texture, softness, and odor.

More importantly, scientists believe that the specific composition of meat is responsible for the desire for it. It hasn't been simple recreating such powerful stimuli, but the results will continue to turn heads as the procedures improve and capital comes into the alternative meats business. As a result, an increasing number of companies have begun to invest in the creation of 3D printed beef alternatives in recent years.

Some choose to produce their meat filaments. Others prefer to develop a vegan filament that tastes and feels like a real steak. There are options for everyone, and these may soon be the selections in our grocery stores and butcher shops, replacing standard steaks and other meats. Let's have a look at some of the companies you might support in the future!

- Redefine Meat: selling printers, not steaks

Redefine Meat revealed the world's first plant-based Alt-Steak and began commercial testing last year at select high-end eateries. Alt-Steak products, which are made with Redefine Meat's patent-pending 3D meat printing technology, have the texture, flavor, and appearance of beefsteak and can be created at a low enough cost to allow for large-scale production.

Alt-Steak products, which are made with Redefine Meat's patent-pending 3D meat printing technology, have the texture, flavor, and appearance of beefsteak and can be created at a low enough cost to allow for large-scale production.

Redefine Meat was able to digitally imprint more than 70 sensory factors into its Alt-Steak products after conferring with prominent butchers, chefs, food scientists, and taste experts, including premium beef cuts' texture, juiciness, fat distribution, and even mouthfeel. Using Redefine Meat's Alt-Muscle, Alt-Fat, and Alt-Blood plant-based formulations, the company's patented industrial-scale 3D food printers layer by layer generate the Alt-Steak products.

Redefine Meat can make sustainable, high-protein, low-cholesterol steaks that appear, cook, and taste like beef by printing with several materials.

Redefine Meat's Alt-Steak products have been put to the test in several top chef restaurants. The company has also ramped up manufacturing of its 3D meat printers and alt-meat formulas, taking into account comments from high-level chefs and butchers. It's important to note that the company only intends to sell the technology and ingredients, not the meat itself.

It's important to note that the company only intends to sell the technology and ingredients, not the meat itself.

- Aleph Farms: cell-based 3D printed meat

Aleph Farms, an Israeli startup, is one of the forerunners in this emerging market. In 2018, it developed BioFarm, a scalable manufacturing 3D tissue engineering platform for cultivating whole-muscle steaks, and manufactured the world's first slaughter-free steak made from cow cells.

It opened a 65,000-square-foot plant at the Stratasys building in Rehovot earlier this year. It has expanded its cultivated meat portfolio by introducing a new cell-cultured collagen product line (due to hit the market in 2024) made from the cells of living cows, which eliminates the need to slaughter animals in the process.

It also discovered a system that simulates the natural process of muscle regeneration that occurs inside the cow's body, but in a controlled environment. Unlike plant-based 3D printed meat, this method uses bovine cells to mimic the flavor, texture, and appearance of meat.

Their novel method involves combining cells such as fat cells, muscle fibers, blood vessel cells, and others to create a bio-ink that can be used in 3D bioprinting.

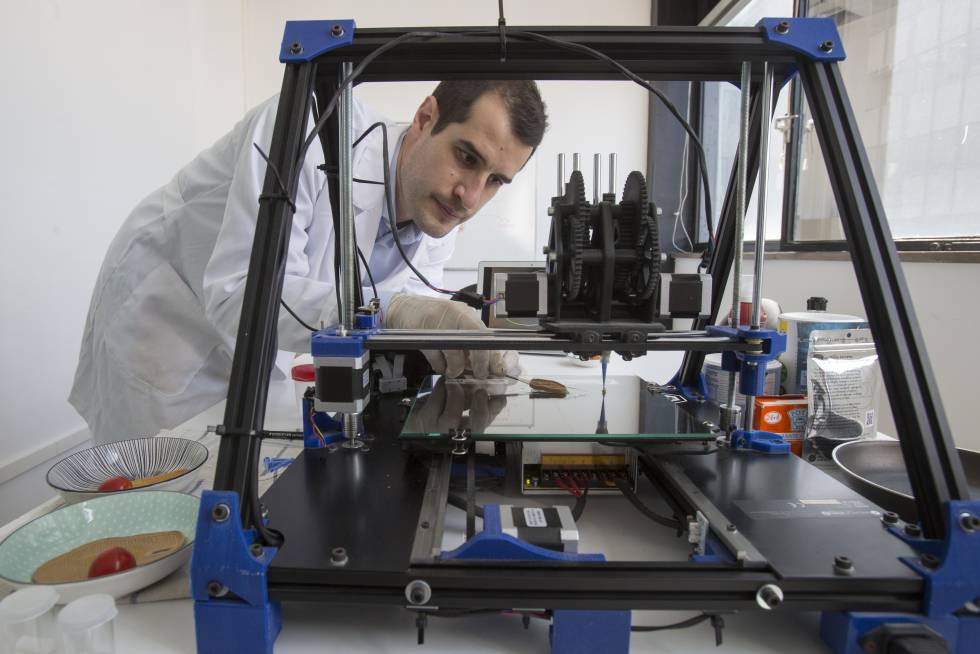

- NOVA MEAT: vegan and sustainable

This Spanish company is well-known for its 3D-printed vegan meat. NOVA MEAT's method essentially reorganizes the nanofibers from vegetable proteins so that they appear to be animal proteins.

They utilize a bioprinter to create a vegetarian filament consisting of peas, seaweed, and rice that has a meat-like taste and texture. The Barcelona-based business recently unveiled its 3D-printed pork skewer 2.0. The manufacturer employed a mixture of pea extract, rice extract, extra-virgin olive oil, brown seaweed extract, beet juice concentrate, and a natural scent to create it.

Through its technology, NOVA MEAT hopes to contribute to a more compassionate and sustainable global food system. Guiseppe Scionti, the company's CEO and co-founder, says the company is "tuning the flavorings and improving sustainability" by "trying alternative components (proteins, fibers, and oils). "

This technique has been proven to work with a wide range of ingredients which helps to preserve diversification and counter unsustainable cultivation and deforestation.

- MeaTech: production in large quantities

MeaTech is a newcomer to the competition for the best 3D-printed meat. This Israeli firm focuses on industrial 3D printing of meat. Starting with T-cells from an umbilical cord, it takes a new approach.

The company extracts several "inks" like muscle, fat, and structure, which are then 3D printed and incubated while growing. MeaTech's goal, like Aleph Farms', is to recreate the texture and composition of certain cuts of meat.

The company's goal, according to Sharon Fima, CEO and co-founder, is to generate units swiftly, one every few seconds, and to demonstrate that industrial-scale 3D printing of beef is possible.

Companies promising a revolution in meat production and consumption may have you wondering when their goods will leave the lab and "enter" your kitchen. According to some industrial companies, such as MeaTech, 3D printing meat is still in its early stages of development and will be ready for mass consumption in 2-3 years. So don't expect to find 3D-printed meat in your neighborhood store anytime soon.

Pros and Cons of a 3D-Printed Meat

It is perfectly fine to eat 3D printed meat as long as they've been cooked in a clean atmosphere with a suitable machine (as with any other kitchen). In addition to generating amazing-looking meals, 3D printed meat has the following advantages:

- Customizing meals

3D printed beef enables precise control of the variety and amount of minerals, vitamins, and calories in each meal. This could be particularly useful in hospitals, where restricted diets are more usual, and it allows for easy patient customization.

- Time-saving

The 3D meat printer has the brilliant idea of being self-contained. Only an operator is required to start the program and complete the final steps. Your teams will have more time to focus on other production activities because it prints autonomously in 3D.

In the kitchen, launching the 3D meat printer after the session and retrieving the created goods, ready to use for the following service, is an excellent scenario. As a result, the 3D meat printing step can be more simply incorporated into the implementation plan.

- Easy replication

It might be as simple as sending a digital file over the internet to share recipes. Only the same raw ingredients, printing settings, and suitable printing equipment would be required.

Drawbacks to 3D Meat Printing

With all of these fascinating benefits, we'd be remiss if we didn't mention that 3D printing food has certain drawbacks.

- Limited materials

It is currently impossible to print any material using a 3D printer. This restriction applies to both plastic and metal printers, as well as meat 3D printers. For starters, it has to do with printing technology. Not all substances containing fibers compacted into textiles (usually meats) can be 3D printed in their natural state.

- Size of the prints

The bulk of 3D printers, whether for commercial or home use, have restricted manufacturing capacities. With this technology, it's difficult to envision producing a meter-long 3D beef!

When you need to create a piece that is larger than the machine's printing volume, divide the design into many parts that can be combined by nesting or gluing. This necessitates additional labor during the finishing process to hide the seams between the parts.

The same constraint applies to 3D meat printers as it does to all other 3D printers.

- Post-processing

3D meat printing technology is sensitive, they are frequently destroyed during handling and post-processing of the food.

- It is inconvenient to use

The technique for 3D food printing needs high-voltage power, requires specialized equipment, and has parts that make it difficult to control or even use.

Why Print Meat?

The reasons for switching from regular meat to 3D printed meat are numerous.

To begin with, moving away from traditional slaughterhouses will significantly cut greenhouse gas emissions, which are a major contributor to global warming. The traditional meat business (together with agriculture) creates 9% of global greenhouse gas emissions, according to the Environmental Protection Agency. Printing meat is a positive start toward mitigating human-induced global warming.

Traditional slaughterhouses have also been criticized for being inhumane. When meat is printed, companies can meet the demand for their product without worrying about the ethics of meat production.

All clients, vegans and carnivores alike, are satisfied with 3D-printed meat. Producers can develop their product in a lab to mimic the texture and flavor of a real steak without using cows, or they can make a plant-based mixture to mimic the texture and flavor of a steak without using any tissue at all. Everyone is thrilled with 3D-printed meat: meat-eaters, environmental activists, and animals.

Conclusion

Many people wonder, as they do with any new technology, where it will all lead, both for the better and for the worst. It's crucial to be practical, even if it's thrilling.

3D printed foods, according to the creators of numerous meat 3D printing startups, might be a part of our daily life in only a few years. They plan to supply meat 3D printers to supermarkets in the coming years, with the possibility of selling them to the general public a few years later.

Food 3D printers capable of 3D printing pizzas can already be ordered online, thus this may potentially generate a market for entirely home-printed meats in the not-too-distant future.

How does a 3D printer steak taste? - such a question is no longer from the category of fantasy. Israeli startup Redefine Meat has learned how to 3D print steaks that look like real meat. In mid-February, the startup completed another round of funding to start shipping its printers around the world. According to the plan, the expansion was supposed to begin last year, but the pandemic prevented it: the startup intends to promote the product first through restaurants.

Many companies produce artificial meat from soy and pea protein, coconut fat, sunflower oil, natural colors and flavors. But even if they taste like real minced meat, they lack the main thing: the texture and look of the steak. Redefine Meat founder Eshkhar Ben-Shitrit figured out what to do with it. His printer prints three types of voxels, or millimetric three-dimensional pixels. Some copy muscle, others fat, others blood. Each stake consists of an example of 3 million voxels. By changing the recipe and collecting them in different sequences and proportions, you can reproduce tenderloin, ribeye, picanha and other types of steaks. And most importantly - they copy not only the taste, but also the type of meat, and even sensations. “A steak is basically muscle, fat and blood in a complex structure that affects how it feels in the mouth and how it is cooked. The taste depends on how the marbled veins of fat melt when you cook,” Ben-Shitrit told Israel21c online.

How Ben-Shitrit met cows

Ben-Shitrit grew up on a kibbutz where his mother ran a dairy farm. He loved meat since childhood. And at the age of 13, he learned how to cook the perfect steak when he went to work part-time at his uncle's restaurant in Tel Aviv in the summer.

He graduated with a law degree from the Hebrew University of Jerusalem, worked for a year and a half as a clerk of the Israeli Supreme Court, and in 2011 changed careers to become a product manager for Hewlett-Packard. Responsible for printing on cardboard boxes. His next job was at the Israeli company Highcon, specializing in cardboard packaging. In 2015–2017 he was its vice president of marketing.

So, Ben Shitrit loved meat. But when his first child was born, he was surprised to find that he could no longer eat beef. There were memories of his childhood on a dairy farm, where he saw firsthand how cows take care of their calves. Ben-Shitrit tried many meat substitutes, but none of them looked like a real steak. Then he had the idea to print meat on a printer to copy its texture. He quit and in February 2018 founded Jet-Eat, which was later renamed Redefine Meat.

“The company was engaged in R&D for almost two years before [in the fall of 2019] we first raised serious investments and recruited a team - in nine months the staff grew from 6 to 25 people,” Ben-Shitrit told Business Insider and last July . Now, judging by the information on the startup's website, it employs 36 people.

The startup developed its products in collaboration with scientists from the Israeli Institute of Technology Technion, using its laboratories for experiments. In September 2019The company received $6 million in seed funding from CPT Capital, a venture fund that also includes stakes in other artificial meat producers, Impossible Foods and Beyond Meat. In February of this year, Redefine Meat raised $29 million in a Series A round in which new investors joined CPT Capital - Losa Group, Sake Bosch, K3 Ventures.

1/5 cow per day

Redefine Meat already has something to boast about. Last June, the company officially unveiled the world's first plant-based 3D printed steak, then began testing its product in high-end restaurants in Israel, and Ben-Shitrit became a hero in the Israeli media with the phrase "We print steaks on a 3D printer ".

True, the fastest printer at his disposal prints about 6 kg of meat per hour. With three cartridges to recharge (artificial meat, fat and blood) and maintain the machine, on good days it produces about 90 kg of meat per day. Beef cows can weigh about half a ton, but meat can account for 60–70% of the total weight.

No meat in meat, no milk in chocolate

Not only meat becomes vegan. In mid-February, Nestle announced that it would launch the first vegan milk chocolate, called KitKat V. The product will roll out to several countries, including the UK, and if successful, will expand to other markets. It took about two years to develop the bar. The main problem was that soy and almond substitutes do not mix well with cocoa and sugar, and as a result, the desired creamy structure is not obtained. KitKat V replaced milk with rice mix. This is not the first product to replace animal ingredients. Last year, Nestle launched meat-free sausage, veggie ground meat, dairy-free ice cream, and animal food with insect protein and bean and millet meat protein substitutes.

The startup is currently completing the construction of the first production line, which will assemble a new printer model designed for 10 kg of meat per hour. “It’s not yet an industrial machine, we call it semi-industrial,” Ben-Shitrit told Business Insider.

Machines will be installed directly at customers' premises to enable them to sell fresh meat. The technology that Redefine Meat is developing could disrupt the global food supply chain, Ben-Shitrit shared his thoughts with The Times of Israel online edition. 3D printers that produce meat near the points of sale make it unnecessary to buy meat in other countries, he said.

Redefine Meat was supposed to hit restaurants late last year, but the coronavirus got in the way. During the pandemic, Redefine Meat signed contracts with several organizations interested in introducing artificial meat into the assortment. For example, in January of this year, Redefine Meat announced a strategic agreement with Israeli meat distributor Best Meister. The partner will supply not only to restaurants in Israel, but also to butcher shops. The agreement was signed after a blind tasting of alternative meats in Tel Aviv (both companies claim that it was the largest in the world - it was attended by about 600 people), which showed that 90% of meat eaters like fake meat. The company wants to conduct the same test with chefs in other countries and is preparing to enter markets in Europe, Asia and North America later this year. “This is a step towards becoming the world's largest alternative meat company by 2030,” Ben-Shitrit told The Times of Israel.

What the startup hopes for

Ben-Shitrit is going to sell his meat at the price of the real one. He believes that now is the best time to bring the product to market - many large meat companies are investing in meat alternatives for vegans, flexitarists, etc.

According to Euromonitor, global sales of meat substitutes reached $19.5 billion in 2018. In 2019, investment bank UBS predicted that the plant-based meat market would reach $85 billion by 2030. And Barclays named meat substitutes as the fastest growing segment of the food industry and estimated their market by 2030 at $ 140 billion. A large contribution to its popularity is the demand from people concerned about healthy eating, animal cruelty and climate change. Ben-Shitrit says that his equipment can in the future create analogues with the structure of chicken, pork, lamb and tuna. But he started with beef for two reasons. “Beef has the biggest business potential, it's the $500 billion industry, and it's the most environmentally damaging,” he told Food Ingredients First online. “In the beef category, there is a wide variety of products for which alternative meat is not used, mainly minced meat and sausages.” He says that the 20,000 liters of water and 25 kg of feed needed to produce 1 kg of meat is a terrible inefficiency and waste. In addition, the meat produced by his startup contains almost no cholesterol and boasts a high fiber content.

Media news2

Is advertising distracting? With a subscription you won't see it on the siteMeat for printing: how startups prepare steaks in a 3D printer :: RBC Pro

Pro Project partner*

TV channel

Pro

Investments

Events

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating Club

Research

Credit ratings

Franchises

Newspaper

Special projects St. Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Policy

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

Material section Main

Management · Global business trends

Articles Bloomberg

The global market for meat substitutes has already reached $14 billion. But so far, such products are more expensive than real pork or beef, and their texture is far from the original. Startups from Israel and Spain promise to solve both problems with a 3D printer0003

Photo: Baptiste Virot for Bloomberg Businessweek

The walls of the Redefine Meat laboratory in Rehovot, Israel are decorated with stucco moldings in the shape of different types of steaks, among which, of course, there are tibon and ribeye. There are books about meat on the shelves, and refrigerators are literally bursting with packages of minced meat and tenderloin, or something very similar to minced meat and tenderloin.

Technicians and researchers here are downright obsessed with their work. And no, the main goal of a startup is not at all to sell customers the perfect beef tenderloin. The company wants to create high-quality plant analogues. Redefine Meat is currently working on a 3D printer that, according to the creators, will be able to print steaks so juicy and full of flavor that even the most demanding meat eaters will not be able to distinguish them from real ones.