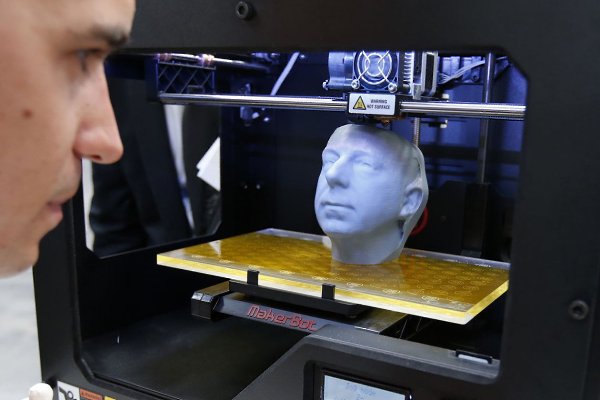

Watch a 3d printer work

How 3D Printers Work | Department of Energy

This week we’re celebrating the launch of a new series on Energy.gov: How Energy Works.

Three years ago, printing three-dimensional objects at home might have sounded like a thing out of The Jetsons. But in just a few short years, 3D printing has exploded -- shifting from a niche technology to a game-changing innovation that is capturing the imagination of major manufacturers and hobbyists alike.

3D printing has the potential to revolutionize manufacturing, allowing companies (and individuals) to design and produce products in new ways while also reducing material waste, saving energy and shortening the time needed to bring products to market.

What is 3D printing?

First invented in the 1980s by Chuck Hull, an engineer and physicist, 3D printing technology has come a long way. Also called additive manufacturing, 3D printing is the process of making an object by depositing material, one tiny layer at a time.

The basic idea behind additive manufacturing can be found in rock formations deep underground (dripping water deposits thin layers of minerals to form stalactites and stalagmites), but a more modern example is a common desktop printer. Just like an inkjet printer adds individual dots of ink to form an image, a 3D printer only adds material where it is needed based on a digital file.

In comparison, many conventional manufacturing processes -- which have recently been termed “subtractive manufacturing” -- require cutting away excess materials to make the desired part. The result: Subtractive manufacturing can waste up to 30 pounds of material for every 1 pound of useful material in some parts, according to a finding from the Energy Department’s Oak Ridge National Lab.

With some 3D printing processes, about 98 percent of the raw material is used in the finished part. Not to mention, 3D printing enables manufacturers to create new shapes and lighter parts that use less raw material and require fewer manufacturing steps. In turn, that can translate into lower energy use for 3D printing -- up to 50 percent less energy for certain processes compared to conventional manufacturing processes.

In turn, that can translate into lower energy use for 3D printing -- up to 50 percent less energy for certain processes compared to conventional manufacturing processes.

Though the possibilities for additive manufacturing are endless, today 3D printing is mostly used to build small, relatively costly components using plastics and metal powders. Yet, as the price of desktop 3D printers continues to drop, some innovators are experimenting with different materials like chocolate and other food items, wax, ceramics and biomaterial similar to human cells.

How does a 3D printer work?

Additive manufacturing technology comes in many shapes and sizes, but no matter the type of 3D printer or material you are using, the 3D printing process follows the same basic steps.

It starts with creating a 3D blueprint using computer-aided design (commonly called CAD) software. Creators are only limited by their imaginations. For example, 3D printers have been used to manufacture everything from robots and prosthetic limbs to custom shoes and musical instruments. Oak Ridge National Lab is even partnering with a company to create the first 3D printed car using a large-scale 3D printer, and America Makes -- the President’s pilot manufacturing innovation institute that focuses on 3D printing -- recently announced it was providing funding for a new low-cost 3D metal printer.

Oak Ridge National Lab is even partnering with a company to create the first 3D printed car using a large-scale 3D printer, and America Makes -- the President’s pilot manufacturing innovation institute that focuses on 3D printing -- recently announced it was providing funding for a new low-cost 3D metal printer.

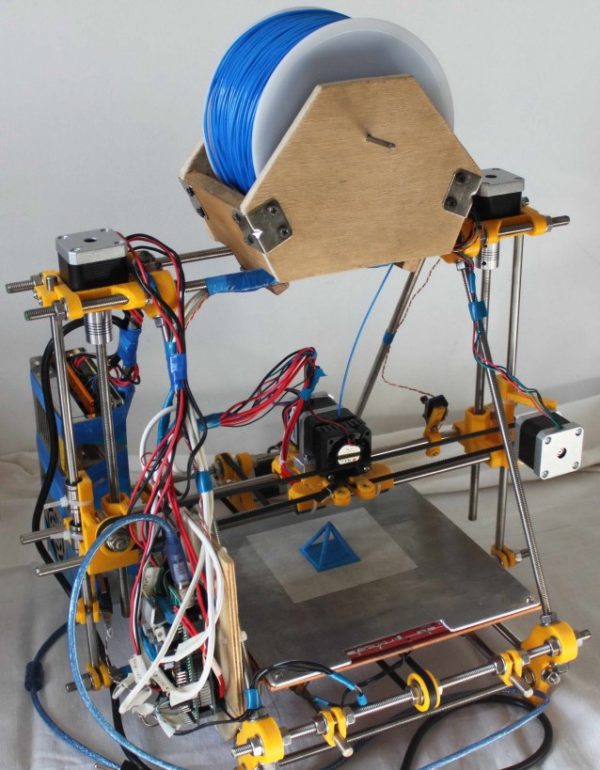

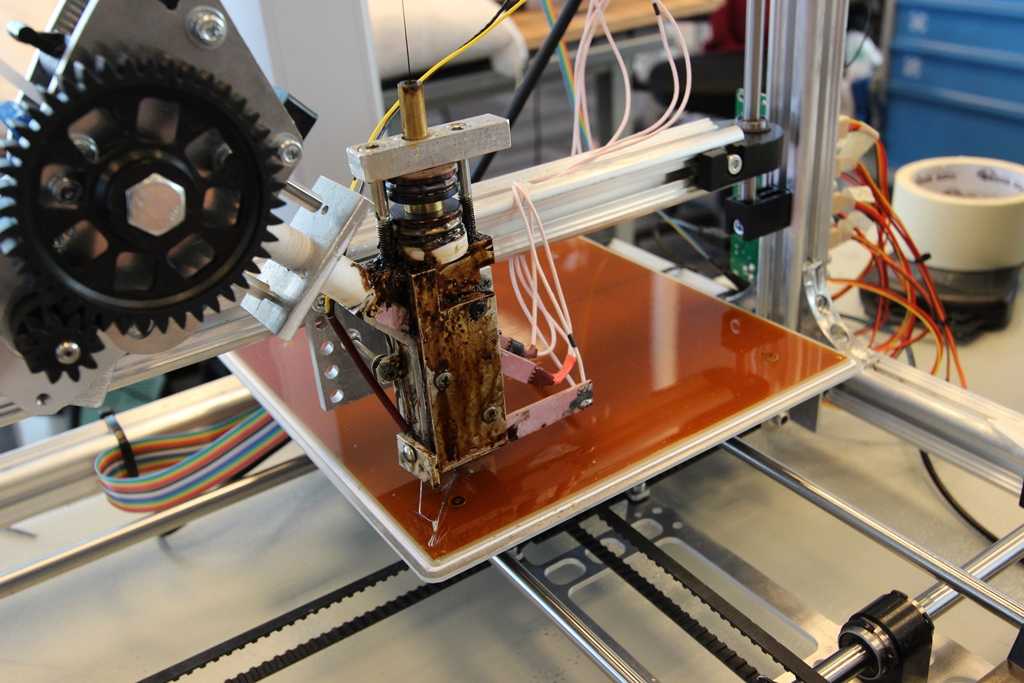

Once the 3D blueprint is created, the printer needs to be prepared. This includes refilling the raw materials (such as plastics, metal powders or binding solutions) and preparing the build platform (in some instances, you might have to clean it or apply an adhesive to prevent movement and warping from the heat during the printing process).

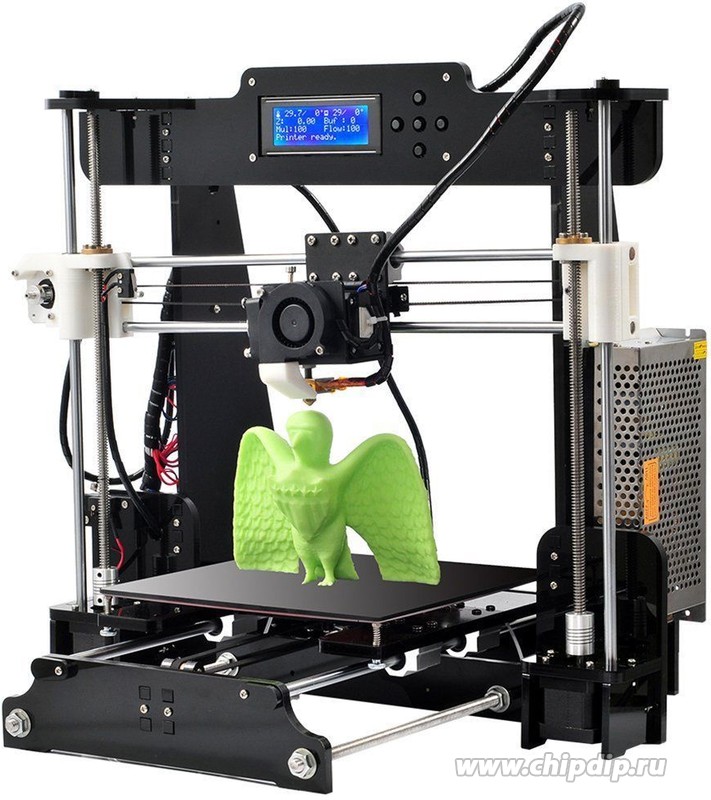

Once you hit print, the machine takes over, automatically building the desired object. While printing processes vary depending on the type of 3D printing technology, material extrusion (which includes a number of different types of processes such as fused deposition modeling) is the most common process used in desktop 3D printers.

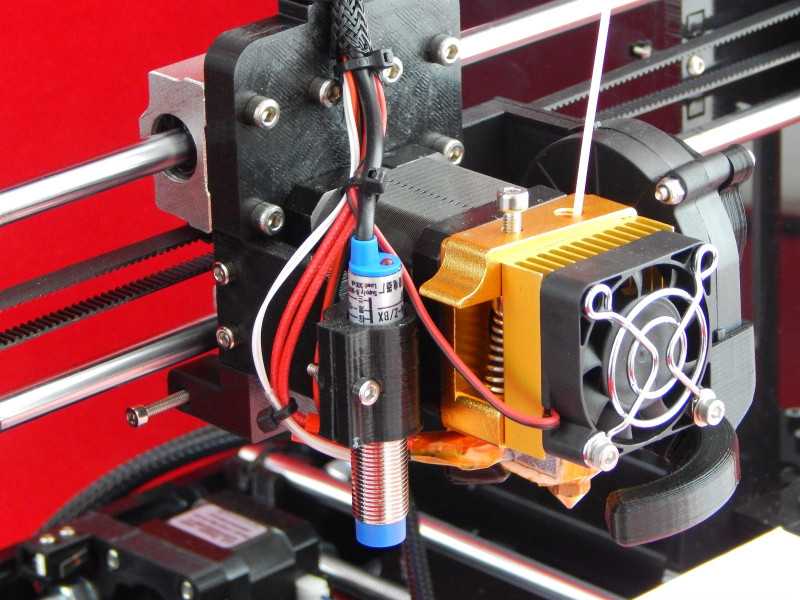

Material extrusion works like a glue gun. The printing material -- typically a plastic filament -- is heated until it liquefies and extruded through the print nozzle. Using information from the digital file -- the design is split into thin two-dimensional cross-sections so the printer knows exactly where to put material -- the nozzle deposits the polymer in thin layers, often 0.1 millimeter thick. The polymer solidifies quickly, bonding to the layer below before the build platform lowers and the print head adds another layer. Depending on the size and complexity of the object, the entire process can take anywhere from minutes to days.

After the printing is finished, every object requires a bit of post-processing. This can range from unsticking the object from the build platform to removing support structures (temporary material printed to support overhangs on the object) to brushing off excess powders.

Types of 3D printers

Over the years, the 3D printing industry has grown dramatically, creating new technologies (and a new language to describe the different additive manufacturing processes). To help simplify this language, ASTM International -- an international standards organization -- released standard terminology in 2012 that classified additive manufacturing technologies into seven broad categories. Below are quick summaries of the different types of 3D printing (with material extrusion explained in the previous section).

To help simplify this language, ASTM International -- an international standards organization -- released standard terminology in 2012 that classified additive manufacturing technologies into seven broad categories. Below are quick summaries of the different types of 3D printing (with material extrusion explained in the previous section).

- Material Jetting: Just like a standard desktop printer, material jetting deposits material through an inkjet printer head. The process typically uses a plastic that requires light to harden it (called a photopolymer) but it can also print waxes and other materials. While material jetting can produce accurate parts and incorporate multiple materials through the use of additional inkjet printer nozzles, the machines are relatively expensive and build times can be slow.

- Binder Jetting: In binder jetting, a thin layer of powder (this can be anything from plastics or glass to metals or sand) is rolled across the build platform.

Then the printer head sprays a binding solution (similar to a glue) to fuse the powder together only in the places specified in the digital file. The process repeats until the object is finished printing, and the excess powder that supported the object during the build is removed and saved for later use. Binder jetting can be used to create relatively large parts, but it can be expensive, especially for large systems.

Then the printer head sprays a binding solution (similar to a glue) to fuse the powder together only in the places specified in the digital file. The process repeats until the object is finished printing, and the excess powder that supported the object during the build is removed and saved for later use. Binder jetting can be used to create relatively large parts, but it can be expensive, especially for large systems. - Powder Bed Fusion: Powder bed fusion is similar to binder jetting, except the layers of powder are fused together (either melted or sintered -- a process that uses heat or pressure to form a solid mass of material without melting it) using a heat source, such as a laser or electron beam. While powder bed processes can produce high quality, strong polymer and solid metal parts, the raw material choices for this type of additive manufacturing are limited.

- Directed Energy Deposition: Directed energy deposition can come in many forms, but they all follow a basic process.

Wire or powder material is deposited into thin layers and melted using a high-energy source, such as a laser. Directed energy deposition systems are commonly used to repair existing parts and build very large parts, but with this technology, these parts often require more extensive post processing.

Wire or powder material is deposited into thin layers and melted using a high-energy source, such as a laser. Directed energy deposition systems are commonly used to repair existing parts and build very large parts, but with this technology, these parts often require more extensive post processing. - Sheet Lamination: Sheet lamination systems bond thin sheets of material (typically paper or metals) together using adhesives, low-temperature heat sources or other forms of energy to produce a 3D object. Sheet lamination systems allow manufacturers to print with materials that are sensitive to heat, such as paper and electronics, and they offer the lowest material costs of any additive process. But the process can be slightly less accurate than some other types of additive manufacturing systems.

- Vat Photopolymerization: Photopolymerization -- the oldest type of 3D printer -- uses a liquid resin that is cured using special lights to create a 3D object.

Depending on the type of printer, it either uses a laser or a projector to trigger a chemical reaction and harden thin layers of the resin. These processes can build very accurate parts with fine detail, but the material choices are limited and the machines can be expensive.

Depending on the type of printer, it either uses a laser or a projector to trigger a chemical reaction and harden thin layers of the resin. These processes can build very accurate parts with fine detail, but the material choices are limited and the machines can be expensive.

Creating a country of Makers

While 3D printing isn’t new, recent advancements in the technology (along with the rise in popularity of sites like Esty and Kickstarter) have sparked a creative manufacturing renaissance -- where anyone with access to a printer is a manufacturer and product customization is nearly unlimited.

3D printers and other manufacturing technologies are turning consumers into creators -- or makers of things. This movement, often called the Maker Movement, is helping spur innovation and creating a whole new way of doing business. Products no longer have to be mass manufactured -- they can be made in small batches, printed on the spot or customized for an individual’s unique needs.

This new way of thinking is also trickling down into the classroom through access to 3D printers. Students aren’t limited to imagining cool, new ideas -- they can make them a reality, and it’s inspiring them to go into STEM (science, technology, engineering and math) fields. To educate students about additive manufacturing and the potential it holds, the Energy Department, Oak Ridge National Lab and America Makes donated almost 450 3D printers to teams competing in the FIRST Robotics competition this year.

The rise of the Maker Movement -- embraced by both the young and old -- represents a huge opportunity for the United States. It can create a foundation for new products and processes that can help revitalize American manufacturing. To celebrate this potential, President Obama hosted the first White House Maker Faire -- allowing innovators and entrepreneurs of all ages to show what they’ve made and share what they’ve learned.

The future of 3D printing

Additive manufacturing isn’t just impacting the Maker Movement, it’s also changing the way companies and federal agencies do business.

Companies are turning to additive manufacturing to build parts that weren’t possible before -- an example that many point to is GE’s use of 3D printers to create fuel nozzles for a new jet engine that are stronger and lighter than conventional parts -- and federal agencies are exploring ways to use the technology to better meet their missions. The U.S. Department of Health and Human Services created the NIH 3D Print Exchange to better share biomedical 3D-printable models across the medical community while NASA is exploring how 3D printing works in space.

Yet, this is just the tip of the iceberg when it comes to additive manufacturing’s potential. For manufacturers, additive manufacturing will enable a wide range of new product designs that can increase industry competitiveness, lower industry energy consumption and help grow the clean energy economy.

From helping fund America Makes, a public-private partnership designed to make the U.S. the leader in 3D printing, to establishing the Manufacturing Demonstration Facility at Oak Ridge Lab, the Energy Department is providing companies with access to 3D printing technologies and educating them -- and future engineers -- about the technology’s possibilities. To ensure the technology moves forward, the Department’s National Labs are partnering with industry to create new 3D printing technology. Lawrence Livermore National Lab recently announced a collaboration to develop new 3D printing materials, hardware and software, and Oak Ridge National Lab is partnering to develop a new commercial additive manufacturing system that is 200 to 500 times faster and could print plastic components 10 times larger than today’s commercial 3D printers.

To ensure the technology moves forward, the Department’s National Labs are partnering with industry to create new 3D printing technology. Lawrence Livermore National Lab recently announced a collaboration to develop new 3D printing materials, hardware and software, and Oak Ridge National Lab is partnering to develop a new commercial additive manufacturing system that is 200 to 500 times faster and could print plastic components 10 times larger than today’s commercial 3D printers.

As the prices drop and the technology becomes faster and more precise, 3D printing is poised to change the way companies and consumers think about manufacturing -- much in the same way the first computers led to the rapid access to knowledge that we now take for granted.

To learn more about the Energy Department’s 3D printing work, visit the Advanced Manufacturing Office’s website.

Is It Now Possible To 3D-Print A Mechanical Watch Movement?

Written by Ashley Sandeman and edited by Ariel Adams

The first time I saw a Star Trek replicator, I knew I had to have one. And high on the list of objects I’d like to print at home is my own mechanical watch.

And high on the list of objects I’d like to print at home is my own mechanical watch.

Advertising Message

But despite all the promises of 3D printing technology, miniaturizing metallic parts at a watchmaking scale has remained elusive. Hopes, however, remain high as the technology in question is evolving rapidly. Cracking the shell of the 3D-printed metal mechanical watch movement could forever change the economics and power bases of today’s luxury wristwatch industry.

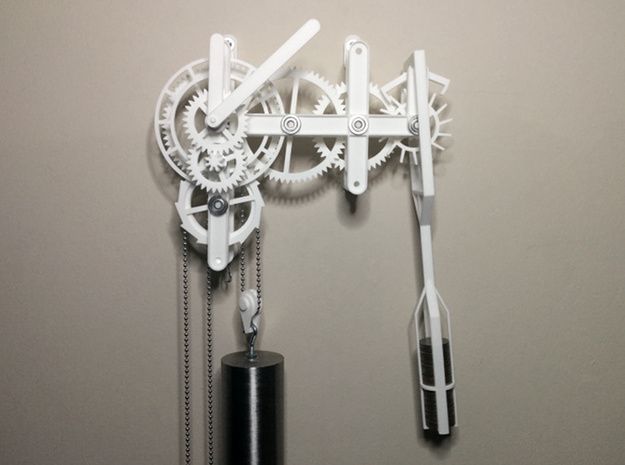

Photo Credit: SSPopov

Back in 2014, I became excited by the work of watchmaker and software engineer Nicholas Manousos, who 3D-printed the Tourbillon 1000%. Printed in PLA (Polylactic acid) plastic at a ten-fold size increase of a normal tourbillon, this was part of a larger project to produce a fully functioning movement. It was later abandoned due to technical challenges.

In 2016, Christoph Laimer gave us further hope. He 3D-printed a tourbillon pocket watch at 98mm in diameter that ran for about 30 minutes using a consumer-grade printer.

Advertising Message

More recently, Panerai used the 3D printing technique DMLS (Direct Metal Laser Sintering) on the case of the Luminor Marina – 44mm (PAM01662). This makes Panerai one of the few companies to take 3D printing to production. Elsewhere, we’ve seen 3D Printing used for rapid prototyping in R&D departments at IWC, A. Lange & Söhne, Parmigiani, and the R&D Q-Lab at Roger Dubuis. Admittedly, these uses are not related to internal watch movements or mechanisms. Rather, they are mostly decorative or helpful in the context of testing new product designs.

Over the same recent timeframe, the most visible miniaturization of consumer technology means smartphones can now replace laptops. And your smartwatch can replace some functionality of your phone. So, with all these advancements, why isn’t anyone able to solve the challenge of 3D printing a fully metallic watch? The answer comes down (ironically) to accuracy and precision.

And your smartwatch can replace some functionality of your phone. So, with all these advancements, why isn’t anyone able to solve the challenge of 3D printing a fully metallic watch? The answer comes down (ironically) to accuracy and precision.

The layperson might think 3D printing a watch is straightforward. You take a CAD model of the watch, feed it into a machine, and out pops your product. No more Rolex shortages, right? But while we can print basic parts at home in rough plastic, it’s more complicated when it comes to precise metal parts. And with regard to 3D printing, the frontier has moved beyond plastic. Certain forms of metal can now be 3D-printed, as well — which is where real watchmaking comes in.

Timepiece aficionados often forget that beneath the dial, a movement’s components make up the majority of parts in a watch — which typically number in the hundreds of — if not several hundred — parts). Precision intolerance is one of the major reasons we haven’t seen printed movements yet. The current landscape of commercial and industrial 3D printing machines simply aren’t suited for the tiny sizes and near-perfect tolerances even the most basic of mechanical watch movements require. In many ways, the industrial machine that the traditional watch industry built to mass-produce precision parts is a key component in its longevity. Much of the know-how remains tightly guarded at companies in Switzerland. For example, there are only a handful of companies that can produce their own regulation system balance springs. The Swatch Group’s Nivarox is among the few companies that can mass-produce them — and they still don’t have very many competitors.

The current landscape of commercial and industrial 3D printing machines simply aren’t suited for the tiny sizes and near-perfect tolerances even the most basic of mechanical watch movements require. In many ways, the industrial machine that the traditional watch industry built to mass-produce precision parts is a key component in its longevity. Much of the know-how remains tightly guarded at companies in Switzerland. For example, there are only a handful of companies that can produce their own regulation system balance springs. The Swatch Group’s Nivarox is among the few companies that can mass-produce them — and they still don’t have very many competitors.

To help understand the 3D printing precision gap, I sat down with British watch designer, aerospace engineer, and expert in 3D printing, Gregg Cowell. Cowell has undertaken this challenge over the past three years and answered using his pictured prototype watch to illustrate. The watch was produced using production-level manufacturing equipment across four different locations in the UK.

His watch (pictured within this article) demonstrates what different 3D printing techniques can achieve (and not necessarily mainstream tastes). The case is produced under high-resolution laser titanium melting. Cowell has taken his prototype further, printing a single interlinked bracelet using a coarser powder mixture under a standard resolution titanium laser method. Meanwhile, the bracelet clasp is produced in steel using binder jetting, as printing titanium is prohibitively difficult at the scale of the clasp. Finally, the high-finish rhodium dial is produced using a mixture of old and new technology called lost wax casting.

The different techniques are important, maximizing the product definition of each part. For example, Lost wax casting was used on the dial of Gregg’s watch because it produces a better finish than laser sintering. Similarly, the DMLS process used to produce the Luminor Marina case isn’t suitable for the precision parts of movement manufacture because where laser melting is used, it produces tiny surface bubbles that must be removed after printing. The difficulty comes in manufacturing highly finished parts small enough and strong enough to withstand the forces generated by the movement. There are new and experimental miniaturizing processes, such as MICA Freeform, but this focuses on sizes too small to replicate traditional escapements. Cowell has produced a metallic escapement fork but has been unable to achieve a tolerance for it to operate in a working movement.

The difficulty comes in manufacturing highly finished parts small enough and strong enough to withstand the forces generated by the movement. There are new and experimental miniaturizing processes, such as MICA Freeform, but this focuses on sizes too small to replicate traditional escapements. Cowell has produced a metallic escapement fork but has been unable to achieve a tolerance for it to operate in a working movement.

An easy way to improve 3D printing precision is to simply make a finer writing instrument. In 2014 the hefty size of the Manousos Tourbillon 1000% was dictated in part by the nozzle width-limitations of the printer and the tolerances required to make it function without ripping off gear teeth. Manousos wasn’t able to achieve the needed tolerance precision with 3D-printed plastic until working at 1000% of the original metal movement’s size. Cowell likewise believes traditional escapement designs are ill-suited to manufacture given the current limitations and capabilities of current printing technology.

Photo credit: Marina Grigorivna

As watch lovers, we can only speculate that applicable 3D printing experts over at the larger watch brands have all come to similar conclusions about how 3D printing currently can’t do much for them. Today, 3D printing technology isn’t well-suited to the lilliputian part size-needs of traditionally manufactured watches. That said, the tolerance of 3D-printed metal (in combination with some finishing processes) might be a welcome addition to the construction of watch cases and other structural elements.

I asked Alessandro Ficarelli — Product Development Director at Panerai — why the brand chose a 3D-printed component for a case construction part for the PAM01662, and also what developments we can expect to see next from the Panerai Laboratorio di Idee. Here is what he said [edited]:

“3D printing technologies are often used for prototyping since the quality level normally reached by the printed material is not sufficient for production parts. “Panerai, after a long development phase … started with the improvement of the powders used as raw material and ended with the configuration of the entire 3D printing process. [Panerai] managed to achieve a quality of the printed material without equal. This material has no porosity; its behavior is perfect through all the printed part and makes it possible to produce technically and aesthetically perfect components, meeting the very high standards of Panerai. Looking at the future, we will further explore the universe of more durable, eco-friendly materials to ride the new sustainable challenges of tomorrow.”

“Panerai, after a long development phase … started with the improvement of the powders used as raw material and ended with the configuration of the entire 3D printing process. [Panerai] managed to achieve a quality of the printed material without equal. This material has no porosity; its behavior is perfect through all the printed part and makes it possible to produce technically and aesthetically perfect components, meeting the very high standards of Panerai. Looking at the future, we will further explore the universe of more durable, eco-friendly materials to ride the new sustainable challenges of tomorrow.”

This final statement refers to Panerai’s 2020 developments of the eco-sustainable basalt-fiber composite material Fibratech™ and the new EcoPangaea™ composite. It points toward another change we’ve seen since 2014: the rise of company eco-credentials and the environmental awareness of consumers that are driving innovation and sales. But that is another story altogether that aBlogtoWatch has also been covering.

In 2018, Roger Dubuis CEO Jean-Marc Pontroué was quoted in the South China Morning Post as saying there was a “high likelihood” we would see 3D printed movement parts in its watches by 2019. That date has passed, and Pontroué is now CEO of Panerai. I asked current Roger Dubuis CEO Nicola Andreatta if he could expand on the comments of his predecessor, but for now, Roger Dubuis is making no comment.

Photo credit: Moreno Soppelsa

Unless that comment comes in the form of a product, it looks unlikely we’re on the verge of a 3D printing revolution in the mechanical watchmaking world. Like many industries, material developments in watchmaking are increasingly used to highlight environmental awareness. 3D printing is not as cool these days as saving the planet. But it is probably technology we need if we are ever going to get off this planet.

Relatively modest consumer demand for luxury 3D printed products makes it unlikely that many brands will invest in vanity 3D-printed watch case materials today. Consumers will spend a premium on products that apparently have some connection with earth-friendly sustainability — even if there is no direct evidence those products actually result in net gains for ecological impact reduction.

Consumers will spend a premium on products that apparently have some connection with earth-friendly sustainability — even if there is no direct evidence those products actually result in net gains for ecological impact reduction.

Photo credit: Marina Grigorivna

The current nerdy unsexy view on 3D printed components, from a pop culture perspective, makes it hard to imagine that established luxury watchmakers will be striving to press the boundaries of 3D printing technology, especially when the security of machined movements is under no threat from the market or driven forward by consumer pressure.

Watchmakers all seem to agree that if one could 3D-print metal watch parts it would be a game-changer — not merely in being able to mass-produce parts in a new way but also to solve some old problems while answering new ones. The vintage and restoration market will fundamentally change when brand new parts (that have the potential to again ask the question of what is “vintage”) for old watches can be produced out of relative thin air, and then simply polished to perfection. Creatives would also love the new level of design freedom afforded by an ever-expanded set of structural part opportunities. A 3D-printed part could easily befuddle even the most complicated of computer-controlled cutting (CNC) machines. What the CNC machine has on 3D printing today is, again, precision. Given the incredible promise to the watch industry afforded with the eventual availability of precision 3D-printed parts, the technology’s advent is worth watching out for.

Creatives would also love the new level of design freedom afforded by an ever-expanded set of structural part opportunities. A 3D-printed part could easily befuddle even the most complicated of computer-controlled cutting (CNC) machines. What the CNC machine has on 3D printing today is, again, precision. Given the incredible promise to the watch industry afforded with the eventual availability of precision 3D-printed parts, the technology’s advent is worth watching out for.

Ashley Sandeman has loved watches since getting a Casio TS-100 at age six. Now a little older, he helps businesses deliver strategy and writes about watches, lifestyle, and fiction. He sometimes still wears the TS-100, and anything else he can. Connect with Ashley on LinkedIn.

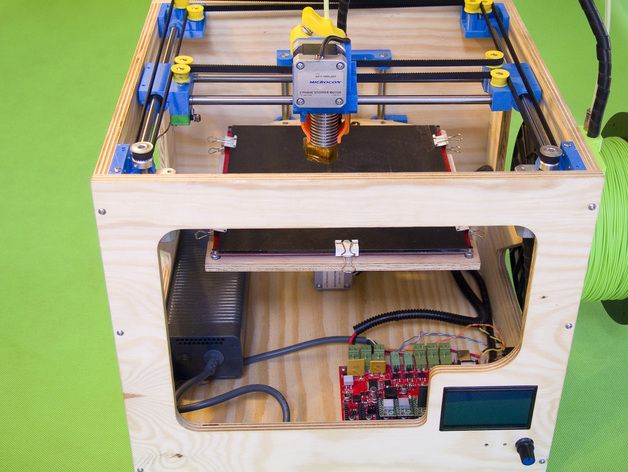

How a 3D printer works, what can be printed on a 3D printer

The 3D printer is a technology that allows you to create real objects from a digital model. It all started in the 80s under the name "rapid prototyping", which was the goal of the technology: to create a prototype faster and cheaper. A lot has changed since then, and today 3D printers allow you to create anything you can imagine.

A lot has changed since then, and today 3D printers allow you to create anything you can imagine.

Contents:

- What is 3D printing?

- How does a 3D printer work?

- What can be printed?

The 3D printer allows you to create objects that are almost identical to their virtual models. That is why the scope of these technologies is so wide.

What is 3D printing?

3D printing is an additive manufacturing process because, unlike traditional subtractive manufacturing, 3D printing does not remove material, but adds it, layer by layer—that is, it builds or grows.

- In the first step of printing, the data from the drawing or 3D model is read by the printer.

- Next is the sequential overlay of layers.

- These layers, consisting of sheet material, liquid or powder, are combined with each other, turning into the final form.

With limited production of parts, 3D printing will be faster and cheaper. The world of 3D printing does not stand still and therefore there are more and more different technologies competing with each other on the market. The difference lies in the printing process itself. Some technologies create layers by softening or melting the material, then they provide layer-by-layer application of this same material. Other technologies involve the use of liquid materials, which acquire a solid form in the process under the influence of various factors.

The world of 3D printing does not stand still and therefore there are more and more different technologies competing with each other on the market. The difference lies in the printing process itself. Some technologies create layers by softening or melting the material, then they provide layer-by-layer application of this same material. Other technologies involve the use of liquid materials, which acquire a solid form in the process under the influence of various factors.

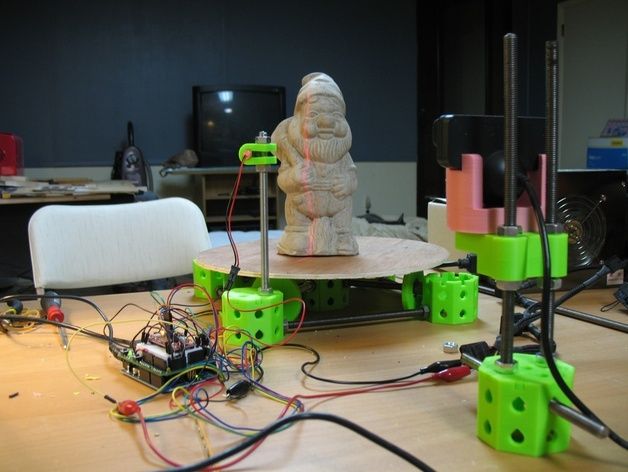

In order to print something , you first need a 3D model of the object, which you can create in a 3D modeling program (CAD - Computer Aided Design), or use a 3D scanner to scan the object you want print. There are also easier options, such as looking for models on the internet that have been created and made available to other people.

Once your design is ready, all you need to do is import it into the Slicer, a program that converts the model into codes and instructions for a 3D printer, most of the programs are open source and free. The slicer will convert your project into a gcode file ready to be printed as a physical object. Simply save the file to the included SD card and insert it into your 3D printer and hit print.

The slicer will convert your project into a gcode file ready to be printed as a physical object. Simply save the file to the included SD card and insert it into your 3D printer and hit print.

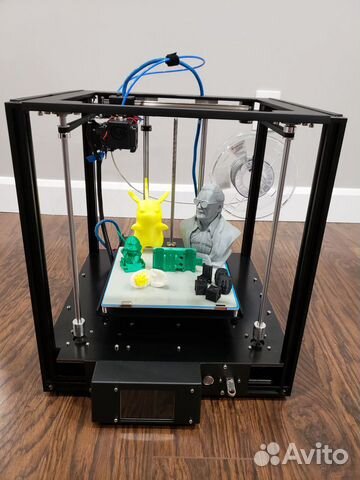

The whole process can take several hours and sometimes several days. It all depends on the size, material and complexity of the model. Some 3D printers use two different materials. One of them is part of the model itself, the other acts as a prop that supports parts of the model hanging in the air. The second material is subsequently removed.

How does a 3D printer work?

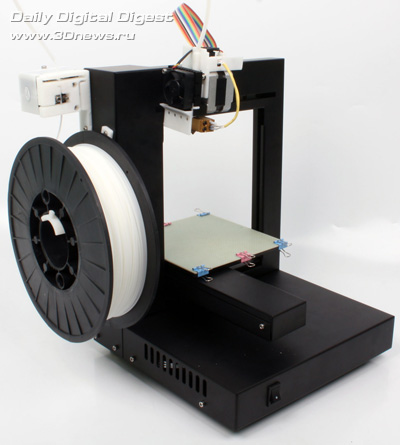

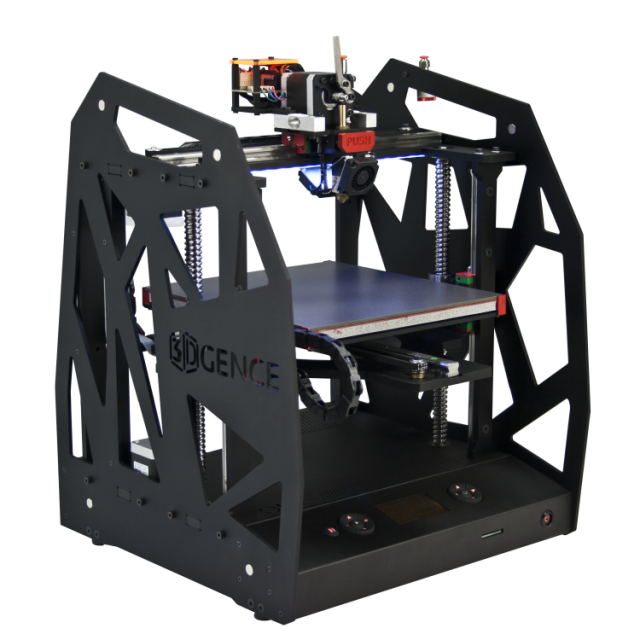

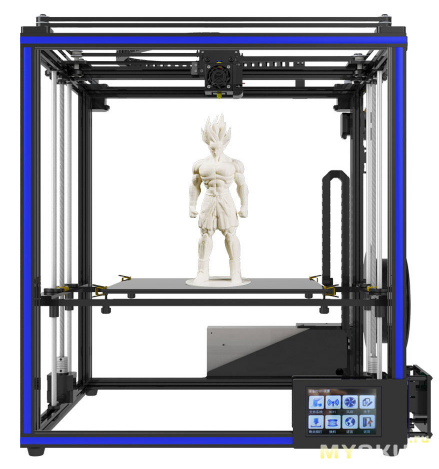

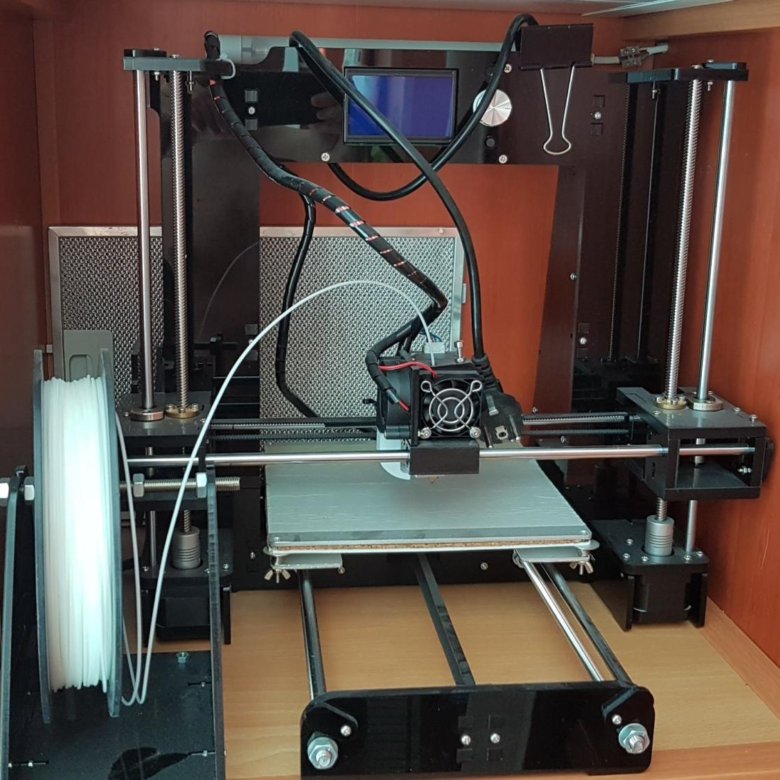

Although there are several 3D printing technologies, most create an object by building up many successive thin layers of material. Typically desktop 3D printers use plastic filaments (1) which are fed into the printer by the feeder (2) . The filament melts in the print head (3) which extrudes the material onto the platform (4) creating the object layer by layer. Once the printer starts printing, all you have to do is wait - it's easy.

Once the printer starts printing, all you have to do is wait - it's easy.

Of course, as you become an advanced user, playing with the settings and tweaking your printer can lead to even better results.

What can be 3D printed?

The possibilities of 3D printers are endless and they are now becoming a common tool in fields such as engineering, industrial design, manufacturing and architecture. Here are some typical use cases:

Custom Models

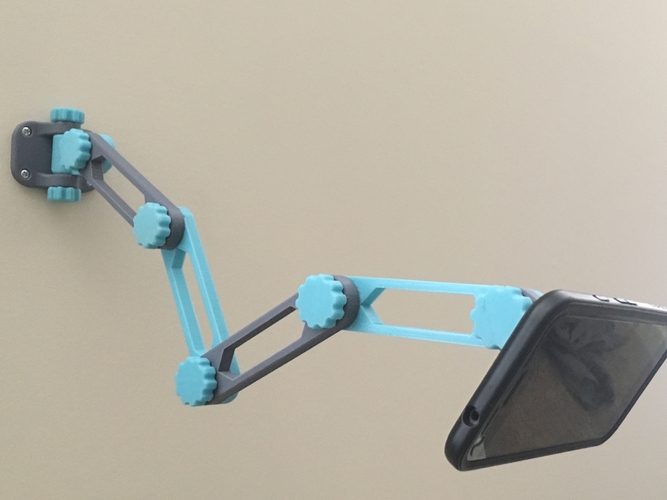

Create custom products that perfectly fit your needs in terms of size and shape. Do something that would be impossible with any other technology.

Rapid Prototyping

3D printing allows you to quickly create a model or prototype, helping engineers, designers and companies get feedback on their projects in a short time.

Complex geometry

Models that are hard to imagine can be easily created with a 3D printer. These models are good for teaching others about complex geometry in a fun and useful way.

Cost reduction

The cost of 3D printing end-use parts and prototypes is low due to the materials and technology used. Reduced production time and material consumption as you can print models multiple times using only the material you need.

How to choose and buy a 3D printer? →

The Complete Guide to Stereolithographic (SLA) 3D Printing

Stereolithographic (SLA) 3D printing is gaining immense popularity due to its ability to produce highly accurate, isotropic and waterproof prototypes and models with fine details and smooth surfaces from various modern materials.

This comprehensive guide explains how SLA printing technologies work, why thousands of professionals use them today, and how this 3D printing technology can be useful in your work.

White Paper

Download our white paper to find out how SLA printing works, why thousands of people use it today, and how this 3D printing technology can help your work.

Download white paper

The development of 3D printing technology continues to influence how companies approach prototyping and manufacturing. This technology is becoming more accessible, and equipment and materials are developing in accordance with the possibilities and requirements of the market. That's why today designers, engineers and others are integrating 3D printing into workflows at all stages of development.

This technology is becoming more accessible, and equipment and materials are developing in accordance with the possibilities and requirements of the market. That's why today designers, engineers and others are integrating 3D printing into workflows at all stages of development.

3D printing is helping professionals across industries reduce recruitment costs, accelerate iteration, streamline manufacturing processes, and even discover entirely new business models.

Stereolithography 3D printing technology has evolved significantly. In the past, resin 3D printers were monolithic and costly, requiring skilled technicians and costly service contracts to operate. Today's small desktop printers are highly flexible and produce industrial-quality products at a much lower cost.

Stereolithography is a type of additive manufacturing. It is also known as photopolymerization in the bath or 3D printing using polymer resin. Devices that use this technology have a common principle of operation: under the influence of a light source (laser or projector), a liquid polymer turns into a solid plastic. The main differences are in the location of the main components such as the light source, work platform and resin tank.

The main differences are in the location of the main components such as the light source, work platform and resin tank.

See how stereolithography 3D printing is done.

Stereolithographic 3D printers use light-sensitive curable materials called "polymers". When stereolithographic polymers are exposed to specific wavelengths of light, short molecular chains join together causing the monomers and oligomers to polymerize into either rigid or flexible patterns.

Graphical representation of the main mechanisms of stereolithographic 3D printing.

Models printed on SLA printers have the highest resolution and accuracy, the sharpest detail, and the smoothest surface of any 3D printing technology, but the main advantage of this method is its versatility.

Materials manufacturers have developed innovative formulas for stereolithographic polymers with a wide range of optical, mechanical and thermal properties similar to standard, engineering and industrial thermoplastic resins.

Comparison of stereolithographic 3D printing with two other common plastic modeling technologies: Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS).

Sample

Experience the quality of 3D stereolithography for yourself. We will send a free sample of the printed model directly to your office.

Request a Free Print Sample

Learn how to go from design to 3D printing with a Form 3 3D printer. Watch this 5-minute video to learn the fundamentals of using the Form 3 printer, from software and materials to processes printing and post-processing.

Use any CAD software or 3D scan data to design the model and export it to a 3D print file format (STL or OBJ). All printers based on SLA technology work with software that allows you to set print parameters and separate the digital model into layers. After the settings are complete, the model preparation software sends instructions to the printer via a wireless or cable connection.

More advanced users can design directly for SLA technology or, for example, print models with voids to save materials.

After a quick check of the settings, the printing process starts. The printer may run unattended until printing is complete. In printers with a cartridge system, material is replenished automatically.

Formlabs' online Dashboard allows you to remotely manage printers, resins, and employee access.

After printing is completed, models should be rinsed with isopropyl alcohol to remove resin residue from their surface. After the washed models have dried, some materials require final polymerization, a process that ensures the best possible strength and stability of the parts. Finally, remove the support structures from the models and sand down the remaining traces of the supports for a clean finish. Models produced with SLA technology can be machined, primed, painted or assembled depending on the intended use.

The final polymerization is particularly important for functional polymer resins used in engineering, dentistry and jewellery.

Engineers, designers, fabricators and others choose stereolithography 3D printing because it provides excellent detail, smooth surfaces, superior model fidelity, isotropy, and water resistance. In addition, it allows you to work with various materials.

Because 3D printing creates models layer by layer, the strength of finished parts can vary depending on the orientation of the part relative to the printing process: the X, Y, and Z axes will have different properties.

Extrusion-based 3D printing processes such as deposition filament modeling (FDM) are anisotropic due to a special approach to creating different layers during the manufacturing process. This anisotropy limits the application of FDM technology or requires additional changes in the design of the model to compensate for it.

Check out our detailed guide comparing FDM vs. SLA 3D printers to see how they differ in terms of print quality, materials, application, workflow, speed, cost, and more.

SLA 3D printers to see how they differ in terms of print quality, materials, application, workflow, speed, cost, and more.

Stereolithographic 3D printers, on the other hand, allow the production of highly isotropic models. Achieving detail isotropy relies on a number of factors that can be tightly controlled by integrating the chemical composition of materials with the printing process. During printing, the components of the polymers form covalent bonds, but when creating subsequent layers, the model remains in an "immature" state of partial reaction.

In its immature state, the resin retains polymerizable groups that can form bonds between layers, giving the model isotropic and waterproof properties after final curing. At the molecular level, there are no differences between the X, Y, and Z planes. This results in models with predictable mechanical characteristics critical for applications such as jigs and fixtures and finished parts, as well as functional prototyping.

SLA printed parts are highly isotropic compared to FDM parts.

Due to its isotropic nature, stereolithographic printed models, such as this jig for Pankl Racing Systems, can withstand directional loads during the manufacturing process.

SLA printed objects are continuous, whether they are solid or have internal channels. Watertightness is important when it is necessary to control and predict the impact of air or liquid flows. Engineers and designers are using the water resistance of stereolithography printers for air and fluid flow applications in the automotive industry, biomedical research, and to test the design of parts in consumer products such as kitchen appliances.

OXO relies on the water resistance of stereolithographic printed models to create durable working prototypes of air and fluid products such as coffee makers.

Stereolithographic 3D printing is used to produce precise, reproducible components in a variety of industries, including dentistry and manufacturing. In order to produce accurate models during the printing process, many factors must be strictly controlled.

In order to produce accurate models during the printing process, many factors must be strictly controlled.

The quality of stereolithographic 3D printing is between standard and precision machined. SLA has the highest tolerance compared to other commercial 3D printing technologies. Learn more about tolerances, accuracy and precision in 3D printing.

The heated resin tank combined with the closed working environment provide virtually the same conditions for every model. The higher accuracy also depends on the lower printing temperature compared to thermoplastic-based technologies in which the raw material is melted. Because stereolithography uses light instead of heat, it prints at close to room temperature and models are not subject to thermal expansion and contraction.

Dental example (comparing a scanned component to an original CAD model) demonstrating the ability to maintain tight tolerances for an entire stereolithographic model.

LFS stereolithography 3D printing involves an optic in a Light Processing Unit (LPU) that moves along the x-axis. parabolic mirrors so that it is always perpendicular to the plane of the platform, so it always moves in a straight line, ensuring maximum precision and accuracy. This allows consistency to be achieved as the size of the equipment increases, for example, when working with a large-sized Formlabs Form 3L stereolithography printer. The LPU also uses a spatial filter, which forms a clear laser spot.

parabolic mirrors so that it is always perpendicular to the plane of the platform, so it always moves in a straight line, ensuring maximum precision and accuracy. This allows consistency to be achieved as the size of the equipment increases, for example, when working with a large-sized Formlabs Form 3L stereolithography printer. The LPU also uses a spatial filter, which forms a clear laser spot.

The characteristics of the individual materials also play an important role in ensuring the reliability and reproducibility of print results.

Formlabs Rigid Resin has a high green modulus, or modulus of elasticity, before final polymerization, allowing you to print very thin models with high precision and reliability.

Stereolithography printers are considered the best 3D printers due to the smooth surface of the produced models, the appearance of which is comparable to parts produced by traditional methods such as machining, injection molding and extrusion.

This surface quality is ideal when a perfect finish is needed and also helps reduce post-processing time because these models are easy to sand, polish and paint. For example, large companies like Gillette use stereolithography 3D printing to create finished products such as razor handles in their Razor Maker platform.

Large companies such as Gillette use stereolithography 3D printing to create finished products such as razor handles in their Razor Maker platform.

The z-layer height is often used to determine the resolution of a 3D printer. On Formlabs stereolithographic 3D printers, it can be adjusted from 25 microns to 300 microns to trade off speed and print quality.

FDM and SLS printers typically print Z-axis layers between 100 and 300 microns wide. At the same time, a part printed with 100 micron layers on an FDM or SLS printer is very different from a part printed with 100 micron layers on an SLA printer. Models printed on a stereolithographic printer have a smoother surface immediately after printing, because their outer walls are straight, and each new printed layer interacts with the previous one, smoothing out the effect of the stairs. When printed on an FDM printer, layers are often visible in models, and the surface of models printed on an SLS printer has a grainy structure due to sintered powder.

Models printed on a stereolithographic printer have a smoother surface immediately after printing, because their outer walls are straight, and each new printed layer interacts with the previous one, smoothing out the effect of the stairs. When printed on an FDM printer, layers are often visible in models, and the surface of models printed on an SLS printer has a grainy structure due to sintered powder.

In addition, the stereolithography printer can print fine details: the Form 3 laser spot size is 85 microns, while industrial SLS printers have a laser spot size of 350 microns, and FDM-based devices use nozzles with a diameter of 250– 800 microns.

Models printed on FDM printers often show layer lines and may have inaccuracies around complex features. Models printed on stereolithography printers have sharp edges, a smooth surface, and almost imperceptible layer lines.

The advantage of SLA polymers lies in a wide range of formulations offering a variety of characteristics: they can be soft or hard, contain additives such as glass and ceramics, or have special mechanical properties such as high bending temperature under load or impact resistance. Materials can be designed for a particular industry, such as dentures, or have properties close to those of final materials to create prototypes that can be tested and run under stress.

Materials can be designed for a particular industry, such as dentures, or have properties close to those of final materials to create prototypes that can be tested and run under stress.

Ceramic Resin can be 3D printed with a stone-like texture and then fired to create a ceramic product.

In some cases, it is this combination of versatility and functionality that is leading businesses to adopt polymer-based 3D printing in-house. After solving existing problems through the use of a certain functional polymer, other applications are usually quickly discovered. In this case, the printer becomes a tool for discovering the various properties of various polymers.

For example, hundreds of engineers in the Design and Prototyping group at the Advanced Manufacturing Equipment Research Center (AMRC) at the University of Sheffield have access to 12 stereolithographic 3D printers and various construction materials that they use in numerous research projects for these partner companies like Boeing, Rolls-Royce, BAE Systems and Airbus. They printed High Temp Resin washers, brackets, and a mounting system for a sensor that must operate in high temperature conditions, and used Durable Resin to create complex spring components for a material handling robot as part of a composite manufacturing automation system.

They printed High Temp Resin washers, brackets, and a mounting system for a sensor that must operate in high temperature conditions, and used Durable Resin to create complex spring components for a material handling robot as part of a composite manufacturing automation system.

AMRC engineers have access to 12 stereolithographic 3D printers and various construction materials, allowing them to create custom-designed parts for a variety of research projects, such as brackets for a stacking robot (above) and mounts for an environmental sensor. high temperature (below).

Material selection

Need help choosing a material for 3D printing? Our new interactive materials wizard will help you make the right material decision based on what you're going to use it for and the properties you care most about in our growing range of polymers.

Get material recommendations

Stereolithographic 3D printing makes it easier for businesses across industries to innovate. Such industries include engineering, manufacturing, dentistry, healthcare, education, entertainment, jewelry, and audiology.

Such industries include engineering, manufacturing, dentistry, healthcare, education, entertainment, jewelry, and audiology.

Rapid prototyping with 3D printing enables engineers and developers to turn ideas into working proofs of concept, transform concepts into high-quality prototypes that look and work like final products, and take products through testing phases to launch into mass production.

Find out more

By creating the necessary prototypes and 3D printing special tools, molds and production aids, manufacturing companies can automate production and optimize workflows at a much lower cost and in much faster time than traditional manufacturing. Thus, production costs are reduced and defects are prevented, quality is improved, assembly is accelerated and labor productivity is increased.

Find out more

Digital Dentistry reduces the risks and uncertainties associated with human error, enabling consistent quality and precision at every step of the workflow, and improving patient care. 3D printers can produce a range of high quality custom products at low cost, providing exceptional fit and reproducible results.

3D printers can produce a range of high quality custom products at low cost, providing exceptional fit and reproducible results.

Learn more

3D printers are multifunctional tools for creating immersive learning and research environments. They stimulate creativity and introduce students to professional-level technology, enabling the implementation of the STEAM method in the fields of science, technology, art and design.

Learn more

Affordable, professional-grade desktop 3D printers help clinicians create medical devices that meet individual needs and improve patient outcomes. At the same time, the organization significantly reduces time and money costs: from laboratories to operating rooms.

Learn more

High resolution printed physical models are widely used in digital sculpting, 3D character modeling and prop making. 3D-printed models have been featured in animated films, video game characters, theatrical costumes, and even special effects for blockbuster films.

Learn more

Professional jewelers use the power of CAD and 3D printing to rapidly prototype, customize jewelry to customer specifications and produce large batches of blanks for casting. Digital tools allow you to create dense, highly detailed models without the tedious, error-prone production of stencils.

Learn more

Hearing professionals and hearing care labs use digital workflows and 3D printing to simplify the production of high-quality custom and hearing aids, as well as to mass-produce behind-the-ear hearing aids, hearing protectors, special earmoulds and headphones .

Find out more

Many companies are starting to use 3D printing technology through service bureaus and laboratories. Outsourcing can be a great solution when the need for 3D printing is infrequent or you need to do one-off jobs using materials that have unique properties or produce special models. Service bureaus can also provide advice on various materials and offer additional services such as design or improved finishes.

The main disadvantages of outsourcing are the high cost and duration of production. Often, outsourcing becomes a step on the way to in-house manufacturing as needs grow. One of the main advantages of 3D printing is its speed compared to traditional production methods. But it is noticeably reduced when the delivery of the model produced by the involved organization takes several days or even weeks. As demand and production capacity increase, the costs of outsourcing are rising rapidly.

With the increasing availability of industrial-quality 3D printing today, more companies are opting to immediately bring 3D printing into their facility, vertically integrating it into existing workshops or labs, or providing printers to engineers, designers, and other professionals who benefit from digital transformation. projects into physical models or are engaged in the production of products in small batches.

Compact desktop stereolithography 3D printers are an excellent solution for rapid model production. Depending on the number of parts needed and the volume of prints, the investment in a compact 3D printer can pay for itself in just a few months. In addition, compact appliances allow you to purchase just the amount of equipment you need to run your business and scale your production by adding more units as demand grows. Using multiple 3D printers also allows you to print models from different materials at the same time. And when the need arises for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue.

Depending on the number of parts needed and the volume of prints, the investment in a compact 3D printer can pay for itself in just a few months. In addition, compact appliances allow you to purchase just the amount of equipment you need to run your business and scale your production by adding more units as demand grows. Using multiple 3D printers also allows you to print models from different materials at the same time. And when the need arises for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue.

INTERACTIVE

Try our interactive ROI tool to see how much time and money you can save by printing with Formlabs 3D printers.

Calculate your savings

High production speed is an important reason to buy a desktop 3D printer. When working with a print bureau, there are delays related to the speed of production, communication and delivery. A desktop 3D printer like the Form 3 delivers models in hours, allowing designers and engineers to print multiple parts a day. This contributes to faster iterations and significant time savings in product development, as well as rapid testing of mechanisms and assemblies, avoiding costly tool changes.

This contributes to faster iterations and significant time savings in product development, as well as rapid testing of mechanisms and assemblies, avoiding costly tool changes.

Purchasing a desktop 3D printer saves a lot of money by eliminating bureau services and traditional processing methods, as their cost rises sharply with demand and production volumes.

For example, the production engineer and others at Pankl Racing Systems used stereolithographic 3D printing technology to produce products on a tight schedule. This allowed them to independently manufacture custom-designed jigs and other small-sized components for the production line. While stereolithography was initially viewed with skepticism, this technology proved to be an ideal solution to replace the machining of a number of tools. In one of the cases, it made it possible to reduce the manufacturing time of conductors by

By 3D printing custom-designed jigs, Pankl Racing Systems has significantly reduced both order preparation time and production costs.

Learn more