3D printed gun stl file

DEFCAD

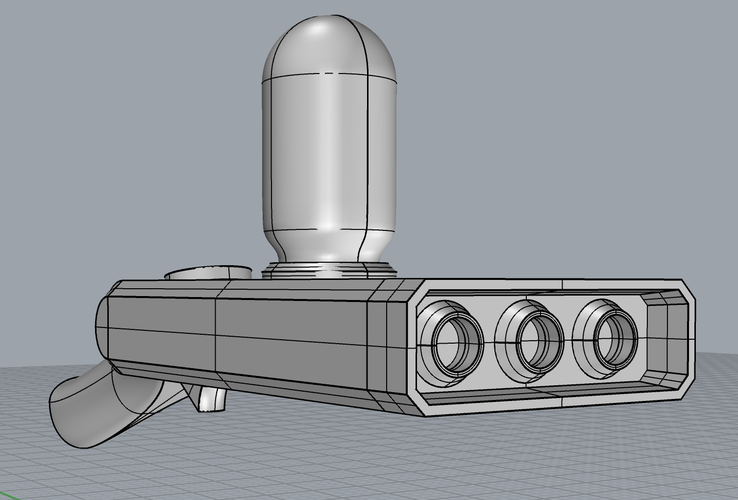

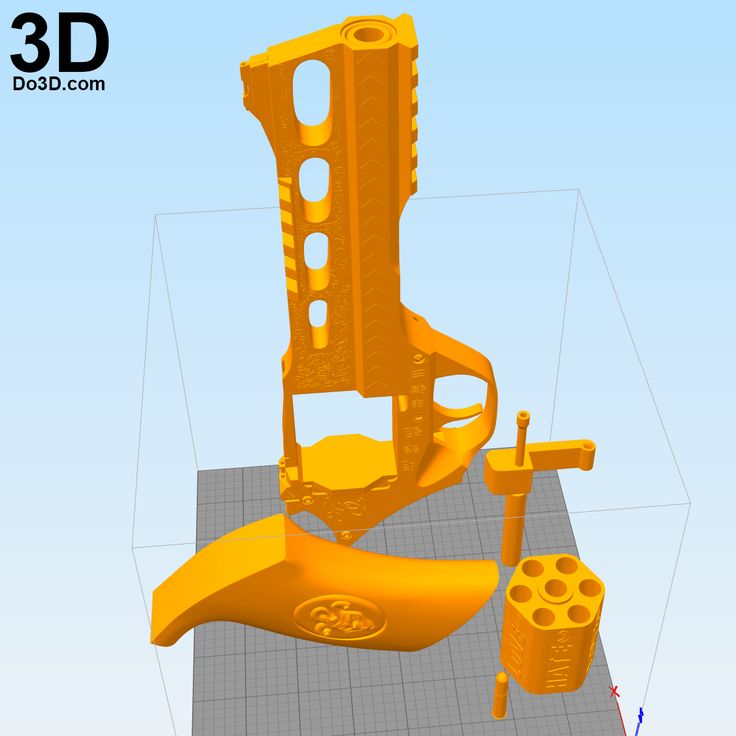

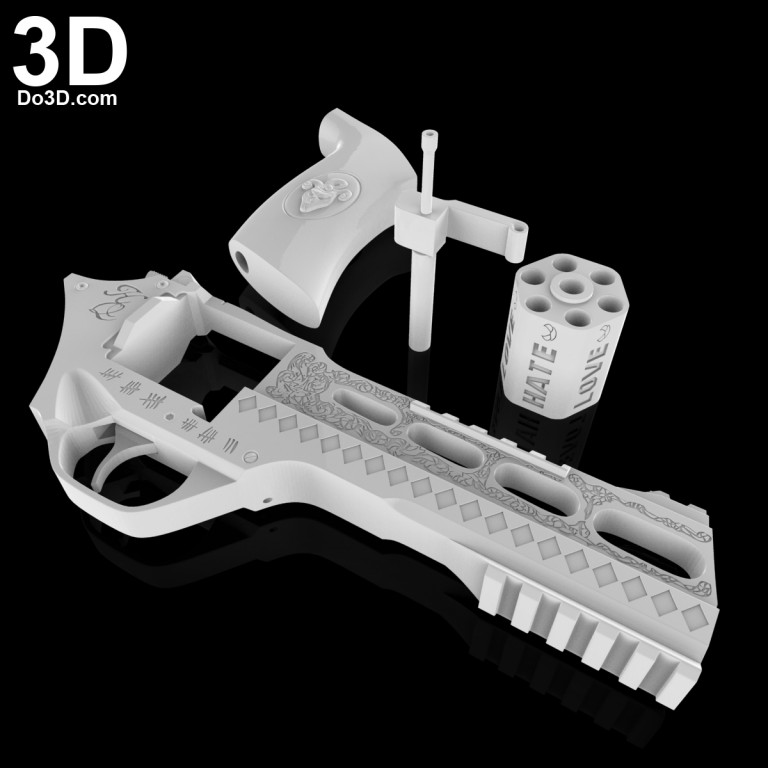

King Cobra 9

Newest release from Derwood and Mussy - the world's most advanced 3D-printed gun

Access Today

4.44

Rating based on 46 reviews.

4.22

Rating based on 100 reviews.

4.52

Rating based on 69 reviews.

3.93

Rating based on 57 reviews.

4.59

Rating based on 29 reviews.

4.29

Rating based on 73 reviews.

4.47

Rating based on 15 reviews.

5

Rating based on 10 reviews.

5

Rating based on 9 reviews.

3.84

Rating based on 25 reviews.

4.78

Rating based on 9 reviews.

4.50

Rating based on 2 reviews.

4.86

Rating based on 14 reviews.

5

Rating based on 2 reviews.

4.25

Rating based on 4 reviews.

4.25

Rating based on 87 reviews.

2.85

Rating based on 13 reviews.

3.74

Rating based on 73 reviews.

3.96

Rating based on 22 reviews.

4.25

Rating based on 20 reviews.

4.73

Rating based on 15 reviews.

4.35

Rating based on 43 reviews.

4

Rating based on 4 reviews.

4.48

Rating based on 25 reviews.

4.08

Rating based on 13 reviews.

5

Rating based on 6 reviews.

5

Rating based on 1 reviews.

4.50

Rating based on 4 reviews.

4.05

Rating based on 200 reviews.

5

Rating based on 18 reviews.

4.67

Rating based on 6 reviews.

3.93

Rating based on 15 reviews.

3.85

Rating based on 13 reviews.

4.23

Rating based on 13 reviews.

4. 50

50

Rating based on 2 reviews.

4.92

Rating based on 12 reviews.

4.44

Rating based on 46 reviews.

4.22

Rating based on 100 reviews.

4.52

Rating based on 69 reviews.

3.93

Rating based on 57 reviews.

4.59

Rating based on 29 reviews.

4.47

Rating based on 15 reviews.

5

Rating based on 10 reviews.

5

Rating based on 9 reviews.

4.50

Rating based on 2 reviews.

4.86

Rating based on 14 reviews.

3.96

Rating based on 22 reviews.

4.25

Rating based on 20 reviews.

4.73

Rating based on 15 reviews.

4.35

Rating based on 43 reviews.

4

Rating based on 4 reviews.

5

Rating based on 18 reviews.

4.67

Rating based on 6 reviews.

3.93

Rating based on 15 reviews.

3.85

Rating based on 13 reviews.

4.23

Rating based on 13 reviews.

4.50

Rating based on 2 reviews.

4.92

Rating based on 12 reviews.

4.71

Rating based on 7 reviews.

4.14

Rating based on 29 reviews.

4.11

Rating based on 9 reviews.

4.33

Rating based on 82 reviews.

4.43

Rating based on 37 reviews.

3.81

Rating based on 41 reviews.

4.29

Rating based on 17 reviews.

4

Rating based on 23 reviews.

3.86

Rating based on 14 reviews.

3.63

Rating based on 38 reviews.

3.73

Rating based on 22 reviews.

5

Rating based on 2 reviews.

3.70

Rating based on 27 reviews.

5

Rating based on 2 reviews.

4.25

Rating based on 4 reviews.

4.25

Rating based on 87 reviews.

2.85

Rating based on 13 reviews.

3.74

Rating based on 73 reviews.

4.48

Rating based on 25 reviews.

4.08

Rating based on 13 reviews.

5

Rating based on 6 reviews.

5

Rating based on 1 reviews.

4.50

Rating based on 4 reviews.

4.05

Rating based on 200 reviews.

4.90

Rating based on 10 reviews.

4.42

Rating based on 26 reviews.

4.33

Rating based on 3 reviews.

5

Rating based on 2 reviews.

4.67

Rating based on 3 reviews.

5

Rating based on 2 reviews.

4.67

Rating based on 3 reviews.

2

Rating based on 1 reviews.

4. 50

50

Rating based on 2 reviews.

3.78

Rating based on 18 reviews.

5

Rating based on 1 reviews.

4.04

Rating based on 52 reviews.

5

Rating based on 8 reviews.

2.89

Rating based on 63 reviews.

2.40

Rating based on 15 reviews.

3.95

Rating based on 21 reviews.

5

Rating based on 2 reviews.

4.67

Rating based on 21 reviews.

4.90

Rating based on 10 reviews.

5

Rating based on 2 reviews.

3.84

Rating based on 25 reviews.

4.78

Rating based on 9 reviews.

4.75

Rating based on 4 reviews.

5

Rating based on 4 reviews.

4

Rating based on 4 reviews.

3.75

Rating based on 4 reviews.

4.25

Rating based on 8 reviews.

4.82

Rating based on 11 reviews.

5

Rating based on 1 reviews.

4.71

Rating based on 7 reviews.

3.33

Rating based on 6 reviews.

4.67

Rating based on 3 reviews.

4.25

Rating based on 4 reviews.

4

Rating based on 1 reviews.

5

Rating based on 2 reviews.

4.17

Rating based on 6 reviews.

3.20

Rating based on 10 reviews.

3.67

Rating based on 3 reviews.

4.50

Rating based on 2 reviews.

4.33

Rating based on 3 reviews.

4

Rating based on 1 reviews.

5

Rating based on 3 reviews.

5

Rating based on 4 reviews.

1.60

Rating based on 5 reviews.

2.83

Rating based on 12 reviews.

3.50

Rating based on 8 reviews.

5

Rating based on 2 reviews.

5

Rating based on 1 reviews.

5

Rating based on 2 reviews.

4.67

Rating based on 3 reviews.

3.17

Rating based on 24 reviews.

4.78

Rating based on 9 reviews.

2.33

Rating based on 24 reviews.

5

Rating based on 5 reviews.

4

Rating based on 1 reviews.

5

Rating based on 2 reviews.

4.46

Rating based on 80 reviews.

2.50

Rating based on 8 reviews.

3

Rating based on 5 reviews.

4.46

Rating based on 13 reviews.

5

Rating based on 2 reviews.

5

Rating based on 4 reviews.

4.86

Rating based on 7 reviews.

4.60

Rating based on 5 reviews.

5

Rating based on 2 reviews.

3.60

Rating based on 5 reviews.

5

Rating based on 1 reviews.

5

Rating based on 1 reviews.

5

Rating based on 4 reviews.

2

Rating based on 7 reviews.

3.11

Rating based on 9 reviews.

5

Rating based on 1 reviews.

3.40

Rating based on 5 reviews.

3.40

Rating based on 5 reviews.

4

Rating based on 7 reviews.

1.64

Rating based on 11 reviews.

4.29

Rating based on 7 reviews.

4.29

Rating based on 73 reviews.

5

Rating based on 15 reviews.

5

Rating based on 6 reviews.

4.50

Rating based on 2 reviews.

4.50

Rating based on 2 reviews.

5

Rating based on 2 reviews.

4.67

Rating based on 3 reviews.

4

Rating based on 4 reviews.

5

Rating based on 2 reviews.

5

Rating based on 2 reviews.

5

Rating based on 4 reviews.

5

Rating based on 1 reviews.

5

Rating based on 2 reviews.

5

Rating based on 3 reviews.

4.67

Rating based on 3 reviews.

4.50

Rating based on 4 reviews.

4.50

Rating based on 2 reviews.

5

Rating based on 1 reviews.

4.50

Rating based on 2 reviews.

5

Rating based on 1 reviews.

5

Rating based on 1 reviews.

5

Rating based on 1 reviews.

4.50

Rating based on 2 reviews.

3.40

Rating based on 5 reviews.

1.80

Rating based on 5 reviews.

4.50

Rating based on 2 reviews.

5

Rating based on 2 reviews.

5

Rating based on 2 reviews.

5

Rating based on 2 reviews.

5

Rating based on 1 reviews.

5

Rating based on 1 reviews.

1.75

Rating based on 4 reviews.

2

Rating based on 7 reviews.

4.67

Rating based on 3 reviews.

2.25

Rating based on 4 reviews.

2.50

Rating based on 4 reviews.

2

Rating based on 5 reviews.

5

Rating based on 1 reviews.

2.25

Rating based on 4 reviews.

1

Rating based on 4 reviews.

1.80

Rating based on 5 reviews.

5

Rating based on 2 reviews.

4.67

Rating based on 3 reviews.

4.33

Rating based on 3 reviews.

5

Rating based on 1 reviews.

5

Rating based on 1 reviews.

1.75

Rating based on 4 reviews.

2.25

Rating based on 4 reviews.

2.50

Rating based on 4 reviews.

2

Rating based on 5 reviews.

5

Rating based on 1 reviews.

2.25

Rating based on 4 reviews.

1

Rating based on 4 reviews.

5

Rating based on 2 reviews.

4.33

Rating based on 3 reviews.

2

Rating based on 4 reviews.

2

Rating based on 5 reviews.

2

Rating based on 4 reviews.

5

Rating based on 1 reviews.

5

Rating based on 1 reviews.

3

Rating based on 2 reviews.

5

Rating based on 1 reviews.

3.50

Rating based on 2 reviews.

5

Rating based on 1 reviews.

1.80

Rating based on 5 reviews.

4.67

Rating based on 3 reviews.

1

Rating based on 1 reviews.

3.33

Rating based on 3 reviews.

4.67

Rating based on 3 reviews.

4.33

Rating based on 3 reviews.

1.80

Rating based on 5 reviews.

2

Rating based on 4 reviews.

1.80

Rating based on 5 reviews.

2

Rating based on 4 reviews.

2

Rating based on 4 reviews.

2

Rating based on 4 reviews.

2

Rating based on 4 reviews.

2

Rating based on 4 reviews.

2

Rating based on 4 reviews.

1.80

Rating based on 5 reviews.

2

Rating based on 4 reviews.

2

Rating based on 4 reviews.

1.80

Rating based on 5 reviews.

2

Rating based on 4 reviews.

4.50

Rating based on 4 reviews.

3.50

Rating based on 8 reviews.

1

Rating based on 1 reviews.

2.33

Rating based on 3 reviews.

2.33

Rating based on 3 reviews.

3.25

Rating based on 4 reviews.

2

Rating based on 4 reviews.

4.67

Rating based on 3 reviews.

5

Rating based on 2 reviews.

2

Rating based on 4 reviews.

3.33

Rating based on 6 reviews.

2.33

Rating based on 3 reviews.

5

Rating based on 1 reviews.

5

Rating based on 2 reviews.

2.33

Rating based on 3 reviews.

2.33

Rating based on 3 reviews.

3.67

Rating based on 3 reviews.

4.67

Rating based on 3 reviews.

5

Rating based on 2 reviews.

4.71

Rating based on 7 reviews.

2.83

Rating based on 12 reviews.

4.67

Rating based on 3 reviews.

5

Rating based on 2 reviews.

5

Rating based on 2 reviews.

4.67

Rating based on 3 reviews.

4.50

Rating based on 2 reviews.

3

Rating based on 3 reviews.

5

Rating based on 2 reviews.

4.50

Rating based on 2 reviews.

4.50

Rating based on 2 reviews.

5

Rating based on 1 reviews.

2

Rating based on 7 reviews.

4

Rating based on 4 reviews.

3.67

Rating based on 3 reviews.

5

Rating based on 2 reviews.

5

Rating based on 1 reviews.

5

Rating based on 1 reviews.

5

Rating based on 1 reviews.

4.67

Rating based on 3 reviews.

4

Rating based on 4 reviews.

5

Rating based on 1 reviews.

5

Rating based on 1 reviews.

4.50

Rating based on 4 reviews.

4.50

Rating based on 2 reviews.

5

Rating based on 2 reviews.

4.50

Rating based on 2 reviews.

5

Rating based on 2 reviews.

4.67

Rating based on 3 reviews.

5

Rating based on 2 reviews.

4.50

Rating based on 2 reviews.

4.50

Rating based on 2 reviews.

5

Rating based on 2 reviews.

5

Rating based on 4 reviews.

5

Rating based on 6 reviews.

5

Rating based on 1 reviews.

5

Rating based on 3 reviews.

DEFCAD Newsletter:

Subscribe to the DEFCAD newsletter

×Legality, Models, & STL File Kits

Modern 3D printers have enormous capabilities. They can print products of almost any complexity.

Until quite recently, it was difficult to even imagine that a plastic weapon could shoot. However, it is already possible to make a 3d printed gun.

So, here in this article let’s know about 3d printed guns.

Contents

- 1 What Are 3D-Printed Guns?

- 2 Beginnings Of 3D Printed Guns

- 3 Legal Issues Of 3D Printed Guns

- 4 How Dangerous Are 3D Printed Guns?

- 5 3D Printed Gun STL/Print Files

- 6 5 Best 3D Printer For Gun Parts

- 6.1 ANYCUBIC Mega-S New Upgrade 3D Printer

- 6.2 FOKOOS 3D Printer Odin-5 F3 Foldable 99% 3D Printer

- 6.3 R QIDI TECHNOLOGY 3D Printer

- 6.4 Voxelab Aquila 3D Printer

- 6.5 Comgrow Official Creality Ender 3 3D Printer

- 7 FAQ 3D Printed Guns

- 7.

1 Should We Be Afraid Of Fully Plastic Guns?

1 Should We Be Afraid Of Fully Plastic Guns? - 7.2 Can 3D Printers Be Used For Gun Parts?

- 7.3 Is It Illegal To 3d Print A Gun?

- 7.4 How Much Does It Cost To A 3D Print Gun?

- 7.

A 3D printed gun is a pistol that is made by a 3D printer. Many people might think that can guns be made by 3D printers?

Well Yes, this can be true. All parts were printed on an FDM printer only the trigger is made of metal.

Modern 3D printers are capable of printing any CAD model, and such firearm models have been available for over 10 years. If in previous years their printing required professional skills, now almost any user can master them.

With a 3D printer and a finished model, it became quite possible to print a gun. Another thing is that such “creativity” is punishable by the laws of most countries.

Beginnings Of 3D Printed Guns

The very first additive pistol was the Liberator. This iconic weapon appeared in 2013. It is completely printed on a Stratasys Dimension SST 3D printer, and its cost is about $10.

This iconic weapon appeared in 2013. It is completely printed on a Stratasys Dimension SST 3D printer, and its cost is about $10.

The drawings of this device were freely available. The disadvantages of this weapon were that it gave a lot of misfires, and was only capable of one shot. The shortcomings have been eliminated in the improved Lulz Liberator model. This plastic pistol is capable of firing up to 8 shots.

Now the drawings are removed from free access. And the distribution and printing of Liberator are prohibited by law, although you can find a photo of it without problems.

Despite all the prohibitions and restrictions, the evolution of 3D-printed firearms is moving at a great speed. The beginning was laid by the single-shot plastic pistol Liberator of the American K. Wilson, which appeared in 2013. It had a simple design and was chambered for 380 ACP.

Already after 10-12 shots, this weapon fell into disrepair. However, the very possibility of printing firearms served as an impetus for the development of the idea. The author of the first pistol himself founded the Defense Distributed company, which began to actively improve the technology.

The author of the first pistol himself founded the Defense Distributed company, which began to actively improve the technology.

One of the ways to increase the durability of weapons was to increase the number of their barrels.

At the beginning of 2014, the Japanese Y. Imura makes a 38 caliber Zig Zag pistol. He was able to fire up to 6 shots non-stop. The author of the weapon was recognized as a criminal and convicted.

The next step was the production of a six-shot revolver by J. Patrick in 2015. The PM522 Washbear has been shown in action on YouTube.

The weapon was noticeably safer for the shooter compared to previous versions but still allowed to fire only a few dozen rounds.

The first semi-automatic pistol for a 9 mm bullet appeared in 2016 under the name Shuty-MP1.

It was developed by a handicraft gunsmith who hid under the pseudonym Derwood. It wasn’t exactly a plastic weapon.

The author used some metal parts from factory pistols – a barrel, a firing pin, a bolt, and several springs. This made it possible to ensure a rate of fire of more than 46 rounds/min.

This made it possible to ensure a rate of fire of more than 46 rounds/min.

However, when changing the store, the plastic case had to be cooled. In 2017, the same master proposed an improved model – Shuty AP-9.

The main contribution to the development of weapons printing technology on a 3D printer was made by Defense Distributed, which brought together a group of like-minded activists.

First, these enthusiasts won legal proceedings in the United States and obtained permission to 3D-print weapons, which greatly expanded their capabilities.

Secondly, they were able to organize a professional business with product testing and quality control. As a result, in 2018–19 they developed numerous models of a variety of firearms – from pistols to carbines.

They posted over 30 files for printing original gun parts. Most of them were plastic, and the metal parts were not made from purchased, ready-made elements, but from simple metal profiles (tubes, strips, etc.), which are sold in ordinary hardware stores. This made it possible to exclude the use of parts patented by gunsmiths.

This made it possible to exclude the use of parts patented by gunsmiths.

At the moment, the semi-automatic carbine FGC-9, developed on the basis of the Shuty AP-9, has become the pinnacle of “creativity” of Defense Distributed. At the same time, there is not a single factory part in it.

The barrel for the 9 mm cartridge is made of steel pipe using electrochemical processing.

Legal Issues Of 3D Printed Guns

The only country where firearms can be 3D printed is the United States. The Gun Control Act of 1968 is in effect here, giving Americans the right to make weapons, but only for personal use.

Only one limitation is put forward: it must be determined by metal detectors, that is, it must have a metal element.

In virtually all other countries, homemade weapons manufacturing and repair for any purpose is prohibited by law.

How Dangerous Are 3D Printed Guns?

Most experts agree that currently, printed weapons are more of an interesting toy. It is quite expensive and is designed to carry out only a few dozen shots.

It is quite expensive and is designed to carry out only a few dozen shots.

Moreover, such pistols are quite dangerous for the shooter himself with live ammunition, because they can explode in their hands.

However, the degree of danger cannot be downplayed. It is easier and cheaper for a “serious” criminal to buy illegal military weapons than to make them on a printer.

At the same time, there may be “enthusiasts” who, for their own interest, can make a pistol and try it out in action.

Such inadequate people represent an undoubted danger. In addition, the temptation is great for terrorists.

Metal detectors do not detect a plastic gun, which means that it is easier to carry it, for example, on an airplane.

3D Printed Gun STL/Print Files

The potential for 3D printing of firearms is far from exhausted. The expansion of equipment capabilities and the development of innovative materials indicate that in the near future such weapons may approach military weapons in terms of characteristics.

In the future – a significant increase in the resource and the provision of automatic firing.

Significantly increases the reliability of printed pistols and carbines SLS technology using metal powder. Such weapons already differ little from the factory metal models.

While it is very expensive, which significantly limits the application. However, over time, the material will become cheaper, which means it will become more affordable.

Printing firearms on a 3D printer has become a reality. Despite its extremely low performance and reliability, interest is growing in it. Experts predict that the printing of weapons will become widespread, and it is impossible to stop such production.

There comes a time when measures should be taken at the legislative level to establish effective control over this process.

5 Best 3D Printer For Gun Parts

The market for large format 3D printers aimed at the mass user and small businesses continues to grow.

This is because a large-format 3D printer is ideal for the research and development of products with rapid prototyping without the need to invest in full-scale industrial additive manufacturing.

Whether you’re a manufacturer looking to take on big projects or a small business looking for a professional device, we’ll help you find the large format 3D printer that fits your needs.

In the following list, we will share with you the best consumer 3D printers for gun parts. So, see below the 5 best 3D printers for gun parts.

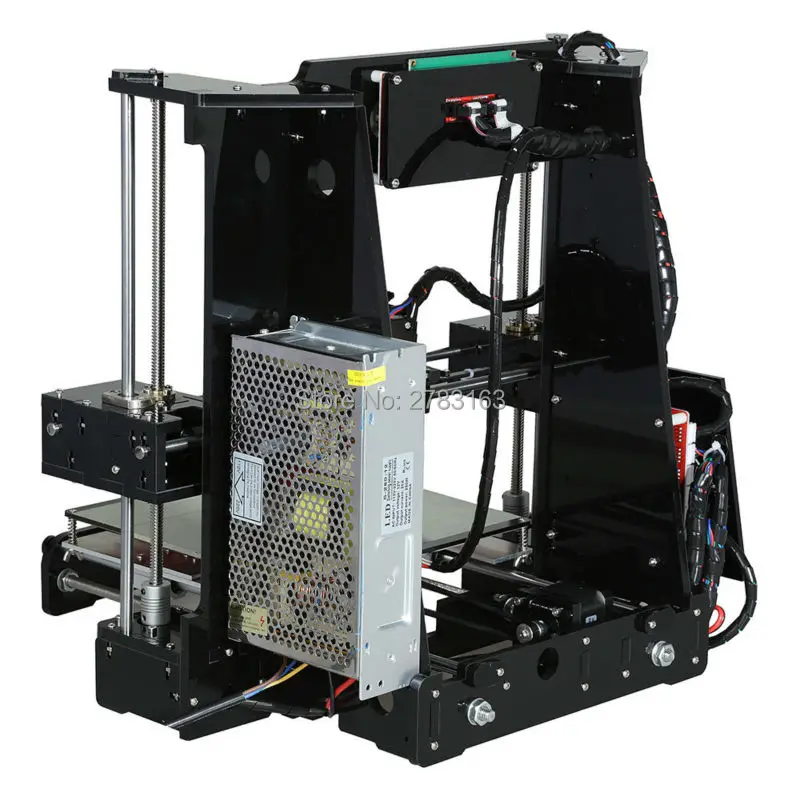

ANYCUBIC Mega-S New Upgrade 3D Printer

Thanks to the success of the popular budget model ANYCUBIC, several product versions have been created since its release, including the ANYCUBIC Mega-S New which shares the same open-body design and dual Z-axis to add stability to the printing process.

ANYCUBIC has really worked on the shortcomings of the Mega-S New Upgrade model design that makes the model more accurate, with a larger touch screen, an improved fan, and a silicone sleeve for better nozzle temperature control.

An impressive print volume of 330 x 330 x 400mm allows the ANYCUBIC Mega-S to outshine some of its competitors that cost ten times as much.

This is not to say that ANYCUBIC brand printers stand out from their more well-known competitors. We did not have the opportunity to test these models, but I would note that Creality products, the Ender 5 line, stand out in this segment.

In particular, the Ender 5 Plus model, which even slightly surpasses the ANYCUBIC Mega-S in terms of its working area, and is not inferior to it in all other parameters.

FOKOOS 3D Printer Odin-5 F3 Foldable 99% 3D Printer

The FOKOOS 3D Printer Odin-5 F3 is a very well-designed machine. The printer boasts proper cable management, the control box is located under the device, which adds stability and reduces the floor space occupied by the printer, while the equipment is easy to assemble and run.

Thanks to the use of some premium brand components, such as the Bondtech certified dual filament extruder, tube, ultra-quiet drivers that make the device noticeably quieter than others, and automatic alignment with the sensor, the printer is well equipped to perform its tasks.

And most importantly, it prints really reliably. This is a great deal with an affordable price, high print volume, and easy to use.

Expert commentary: a rather expensive model for the FOKOOS brand, famous for its budget models, and, despite many advantages, is in limited demand losing to more famous models on the market, there is no doubt about this printer and if your choice falls on it, it will not disappoint you.

R QIDI TECHNOLOGY 3D Printer

An impressive 3D printer with a print volume of 500 x 500 x 600 mm and dimensions of 850 x 770 x 875 mm.

It is constructed from aluminum and steel, features a dual Z-axis screw for improved accuracy, a touch control panel, and features print resume and filament end detection—important especially for large format printing.

R QIDI TECHNOLOGY 3D Printer with a 500x500x600 print area is a very budget option for a printer with such a working area. Other models with similar print areas are sold much more expensive.

If you really plan to print models of this size, I would advise you to consider more professional models. The printing of such objects requires a higher reliability of the printer’s design.

Voxelab Aquila 3D Printer

The Voxelab Aquila 3D Printer is one of the best 3D printers and one of the most competitive mainstream large format printers currently on the market. Offering a build area of 500 x 500 x 500mm, it helps make your biggest 3D printing dreams come true.

In our opinion, the leader is simple. It does exactly the job that justifies its price and yet is affordable enough to make worthwhile the various additions and improvements available through numerous mods and updates.

The most budgetary model with a large print area, but perhaps too simple for the end of 2020, the time of such models is running out and they are being replaced by more technically advanced printers, including those from the same Creality brand, in particular the models.

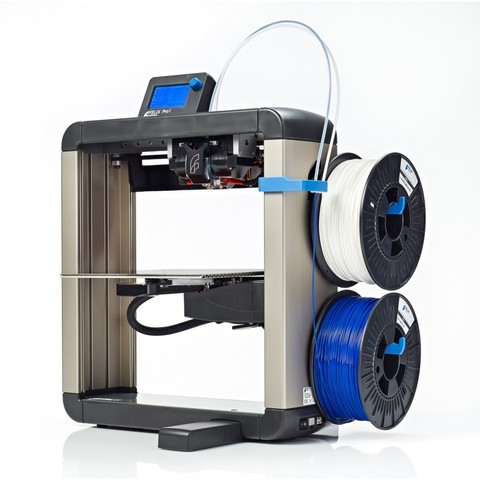

Comgrow Official Creality Ender 3 3D Printer

The Comgrow Official Creality Ender 3 3D Printer offers simplicity, affordability, and high build volume, making it a great option for professionals who want a gigantic printable area without spending too much.

While the print volume of 600 x 600 x 660mm is the device’s most notable feature, it’s not all that this large-format 3D printer has to offer.

The product includes a high-flow Volcano heating block, fully automatic platform leveling, 3D board, dual zone silicon print bed heater, PEI printable surface, and filament end sensor.

The company also offers optional upgrades such as a dual extruder, closed body, and other nozzle sizes.

While this 3D printer may seem expensive compared to some of the budget options on our list, the Comgrow Official Creality Ender 3 3D Printer makes every dollar invested.

FAQ 3D Printed Guns

Following are the most common questions on 3D printed guns.

Should We Be Afraid Of Fully Plastic Guns?

The question of how dangerous a weapon is printed on a printer is becoming increasingly relevant. Despite all the prohibitions, it is extremely difficult to control the spread of technology around the world.

The availability of 3D printers and the increase in their functionality make it possible to master the production of plastic guns at home.

Can 3D Printers Be Used For Gun Parts?

A few guns can be made primarily with a 3D printer. These completely 3D printed models are, as the term recommends, practically all plastic from printed parts.

Is It Illegal To 3d Print A Gun?

3D printing offers an abundance of development and opportunity and yet as with such countless mechanical progressions, the law is not ready for its belongings in its ongoing configuration.

In this way, 3D printing itself isn’t unlawful yet a portion of its ramifications may be particularly concerning protected innovation regulation.

How Much Does It Cost To A 3D Print Gun?

Assuming you as of now have a 3D printer and fundamental hand devices, it costs about $100 until the end of the apparatuses to fabricate the barrel, then, at that point, about $100 in provisions for each firearm after that.

Reference

- all3dp.com/1/3d-printed-gun-firearm-weapon-parts/

- thetrace.org/2021/02/3d-printer-ghost-gun-legal-liberator-deterrence-dispensed/

- aniwaa.com/guide/3d-printers/3d-printed-guns/

- vice.com/en/article/bvzak4/ghost-gun-glock-3d-printing

- stormreport.it/glock-stl.html

How the 3D printer industry turned into weapons, organs and spacecraft in a decade

The inventors imagined everything differently. How the 3D Printing Industry Became Used to Make Weapons, Organs, and Spaceships

Over the past decade, 3D printing has gone from a hobby for geeks to one of the most sought-after technologies in the world. It is used from the aerospace and military industries to medicine, design, construction and cosplay. Completely different from what the inventors of the technology in the 80s of the last century intended. We decided to recall how the eyewash cup has become a universal technology for the production of parts, weapons, and even internal organs.

It is used from the aerospace and military industries to medicine, design, construction and cosplay. Completely different from what the inventors of the technology in the 80s of the last century intended. We decided to recall how the eyewash cup has become a universal technology for the production of parts, weapons, and even internal organs.

https://unsplash.com/photos/UqCCSbAIaDU

Zmist

- 1 History of 3D printing

- 1.1 Different 3D printing technologies

2 technologies - 3 How 3D models began to be used in various fields

- 4 Bottom line: why they created and what they ended up with

The history of the emergence of 3D printing

In many sources, Charles (Chuck) is considered the father of 3D printing ) Halla, it was him on August 8, 1984 filed a patent for a technology called "Apparatus for creating three-dimensional objects using stereolithography (STL)". As often happens in the history of science, the discoverer was not the one who did it first, but the one who received funding in time and created a more universal technology. A few years before Charles Hull, several other scientists worked fruitfully in this area, but failed to get a patent, although they made significant progress.

As often happens in the history of science, the discoverer was not the one who did it first, but the one who received funding in time and created a more universal technology. A few years before Charles Hull, several other scientists worked fruitfully in this area, but failed to get a patent, although they made significant progress.

Course

Development in Java

Introduce the popular Java programming language at your hour, and earn $1000 per cob of career

REGISTER!

Japanese Hideo Kodama was one of the first to invent single-beam laser polymerization. Unfortunately, he failed to get a patent for the discovery.https://www.sculpteo.com/blog/2017/03/01/whos-behind-the-three-main-3d-printing-technologies/

Before Hull started experimenting in 1981, Dr. Hideo Kodama from the Municipal Industrial Research Institute in Nagoya described in the article a process during which "a solid model is made by exposing a liquid photopolymer to ultraviolet rays, <. ..> laying down transverse hardened layers." He was able to create some prototype parts, but never completed the patent specification, and over time he refused to develop the idea. And all because of the lack of funding!

..> laying down transverse hardened layers." He was able to create some prototype parts, but never completed the patent specification, and over time he refused to develop the idea. And all because of the lack of funding!

The second major claim to success in creating 3D printing was the experiments of three French engineers: Alain Le Mecho, Olivier de Witt and Jean-Claude Andre. In the dining room, they discussed creating a "fractal object" using a laser and a hardening polymer. But the first experiments failed and then, Jean-Claude Andre, a specialist from CNRS French National Center for Scientific Research , proposed building a model not from blocks, but layer by layer. In this way, they were able to create a prototype of a spiral staircase. Engineers filed a patent for the stereolithography process three weeks before the American Chuck Hull and received it at 1986 year. But CNRS and Alcatel, on the basis of which the research was carried out, did not see the prospects in stereolithography technology, so the patent was never used.

https://www.arsmathematica.org/is2013/

Let's go back to Charles Hull. He planned to use 3D printing technology in furniture production. Using ultraviolet rays, he wanted to prototype small parts for countertops. The management of the company where he worked approved Hull's initiative, provided him with a small laboratory and funded research. He described the whole process as follows: “ultraviolet light hits the surface of a container filled with liquid photopolymer, under computer control the beam “paints” each layer on the surface of the liquid, causing the photopolymer to turn into a solid.”

Description of the first stereolithography project filed by Charles Hull for a technology patent.

https://patents.google.com/patent/US4575330?oq=4%2c575%2c330

At the same time, Autodesk's Fusion 360 separates the computer model into thin layers that are printed in succession, solidifying as the model is built. One night, Hull's experiments resulted in a complete 3D model. He pulled his wife out of bed and proudly showed her... a black eyewash cup. It was he who became the world's first "official" 3D model made using STL technology, and at 1986 Charles Hull received a patent for his discovery. The inventor's next step was to set up 3D Systems in Valencia, California and expand the patents to include different starting materials and continue to commercialize the process.

One night, Hull's experiments resulted in a complete 3D model. He pulled his wife out of bed and proudly showed her... a black eyewash cup. It was he who became the world's first "official" 3D model made using STL technology, and at 1986 Charles Hull received a patent for his discovery. The inventor's next step was to set up 3D Systems in Valencia, California and expand the patents to include different starting materials and continue to commercialize the process.

Photo 1:

The same eyewash cup that became the first 3D model in 1983

Charles Hull (second from left) and the 3D Systems team in Valencia

3dsystems.com/our-story

A Canadian investor believed in the technology, and as soon as the company was able to launch a commercial 3D printer on the market in 1988 - model SLA-1, car manufacturers, medical institutions and aerospace companies are interested in it. Today, 3D Systems, led by Chuck Hull, continues to play a leading role in the 3D printing technology market, and Hull himself was inducted into the National Inventors Hall of Fame in 2014 for his achievements.

https://www.3dsystems.com/our-story

Miscellaneous 3D printing technologies

Nearly the same time as Hull, University of Texas at Austin student Carl Deckard came up with an alternative 3D printing technology called selective laser sintering, or SLS. While working with a TRW machine that made parts for oilfields, Deckard realized that productivity could be increased by reducing the number of castings.

Carl R. Deckard and Dr. Joe Beeman with one of the first SLS deviceshttps://3dprintingindustry.com/news/carl-deckard-the-inventor-of-sls-passes-away-166853/

About two and a half years he needed to develop technology that would allow the machine to produce parts without casting. Carl Deckard filed a patent for SLS in 1987 and received it in 1989. The main difference between his technology and stereolithography is the material at which the laser is directed: instead of a polymer (resin), Descartes acted on a free-flowing powder, turning it into a solid. Thanks to the support of Professor Joe Birman and investors who believed in the project, Desk Top Manufacturing (DTM) Corp. was born. But it took more than 20 years for SLS printing to become financially affordable for the average consumer.

Thanks to the support of Professor Joe Birman and investors who believed in the project, Desk Top Manufacturing (DTM) Corp. was born. But it took more than 20 years for SLS printing to become financially affordable for the average consumer.

https://en.wikipedia.org/wiki/Selective_laser_sintering#/media/File:SLS_schematic.svg

But the most affordable printing technology was born in a garage from engineer Scott Crump's desire to make a frog figurine for his daughter. In the late 1980s, Crump mixed candle wax with polyethylene and used a hot glue gun to make a three-dimensional frog. This is how the first model was made using FDM - technology of layer-by-layer deposition using molten plastic.

In 1989, together with his wife Lisa Crump, who strongly urged her husband to turn the discovery into a business, they patented the FDM technology. In 1992, Scott created the first working FDM 3D printer. Soon the couple became co-founders of Stratasys, one of the modern leaders in the industrial 3D printer market. In less than a decade, three 3D printing technologies were born that changed the course of events: stereolithography (SLA), selective laser sintering (SLS), deposition deposition modeling (FDM).

In less than a decade, three 3D printing technologies were born that changed the course of events: stereolithography (SLA), selective laser sintering (SLS), deposition deposition modeling (FDM).

https://www.tctmagazine.com/additive-manufacturing-3d-printing-news/exclusive-stratasys-scott-crump-3d- printing-legacy/

When the tipping point and mass adoption of the technology occurred

Despite the fact that in the 1980s several inventors made a breakthrough with the discovery of stereolithography and other types of 3D printing, until the early 2000s, the technology did not receive widespread. First, the cost and scale of the equipment: for a long time, only the automotive and aerospace industries could afford to buy equipment for the production of three-dimensional parts. Secondly, the first 3D models were fragile, limited in shape and materials from which they were created, so for a long time the wider adoption of 3D printing seemed futile.

Until the RepRap (Replicating Rapid Prototyper) project appeared in 2005. Dr. Adrian Bauer of the University of Bath came up with the idea for a 3D printer to reproduce its own open source parts. In 2006, for the first time, scientists successfully reproduced a part for a "child" printer on a "parent" one.

All plastic parts for the machine on the right were made on the machine on the left. Adrian Bauer (left) and Vic Olliver (right) are members of the RepRap project.https://stringfixer.com/files/704541002.jpg

The first such printer under the name Darwin was released in 2007. Then came Mendel, Prusa Mendel, and Huxley, all named after evolutionary biologists. Over the next few years, RepRap was able to reproduce more than 50% of the details. This technology not only made it possible to use 3D printers more without global restrictions to test future replicas of the original devices, but also save on production processes.

This resulted in the Prusa MK3 or Lulzbot Mini 2. Both machines use a lot of printed parts and their manufacturers provide STL files for download. It was no longer necessary to rely on expensive parts made on commercial 3D printers. Every year the number of replicas that were created with the help of "parent" printers, and then "child" printers, grew and in 2008 exceeded one hundred.

Both machines use a lot of printed parts and their manufacturers provide STL files for download. It was no longer necessary to rely on expensive parts made on commercial 3D printers. Every year the number of replicas that were created with the help of "parent" printers, and then "child" printers, grew and in 2008 exceeded one hundred.

https://threedpr.com/lulzbot-mini-2-vs-prusa-mk3/

Not only engineers and scientists were interested in making 3D printing accessible for all. In 2009, the Kickstarter crowdfunding platform was launched, where dozens of companies and individuals raised money for projects to create mass-produced and inexpensive 3D printers.

Many of the ideas have remained as descriptions on the site, while others have received phenomenal support on Kickstarter. For example, to create the “first true consumer 3D printer”, a group of startups asked for $50,000 in aid, and ended up raising a record $3,401,361. And in 2014 they introduced the Micro, a compact printer that runs on PLA polylactide is a biodegradable, biocompatible, thermoplastic, aliphatic polyester whose monomer is lactic acid or ABS acrylonitrile butadiene styrene - belongs to the styrenic polymer family and shares many properties with polystyrene .

And in 2014 they introduced the Micro, a compact printer that runs on PLA polylactide is a biodegradable, biocompatible, thermoplastic, aliphatic polyester whose monomer is lactic acid or ABS acrylonitrile butadiene styrene - belongs to the styrenic polymer family and shares many properties with polystyrene .

https://www.kickstarter.com/projects/m3d/the-micro-the-first-truly-consumer-3d-printer

It's time for desktop printers. By this time, the main patent for FDM technology had expired, and in 2009 the guys from Marketbot fulfilled the dream of many self-taught engineers. The D.I.Y. sets are released to the market. open source for anyone who wanted to create their own 3D printers and models. Following this, the company opens the Thingiverse online library, where users can upload and download ready-made files for 3D printing. To this day, Thingiverse remains the largest repository and online community in the industry.

How 3D models began to be used in various fields

In parallel with the attempt to make 3D printing as accessible as possible for all users, biotechnologists have learned to use 3D printing to create viable cell-based models. The dream of any transplant doctor is that there is no need to look for tissues or organs from a suitable donor.

The new technology would make it possible to grow a 3D model from the patient's own cells and, over time, would have to fully take root in the body. The first patent for bioprinting was received by Organovo. Using the NovoGen MMX apparatus, the company “grows” skin, heart, and blood vessel tissues. During a TED talk, surgeon Anthony Atala showed the beginnings of a project to grow a kidney on a 3D printer. He believes that one day such experiments will lead to the fact that we will no longer need donors.

About 90% of people in need of a transplant are waiting for a kidney. Therefore, scientists aim to recreate this particular organ. The structure of a kidney on a 3D printer is created in seven hours, but due to the complexity of the structure, it is still too early to talk about a full-fledged printed organ.

The structure of a kidney on a 3D printer is created in seven hours, but due to the complexity of the structure, it is still too early to talk about a full-fledged printed organ. https://www.ted.com/talks/anthony_atala_printing_a_human_kidney

More than in medicine, military structures of different countries became interested in the possibilities of 3D printing technology. By investing multi-million dollar budgets in various developments, the ministries of defense and private military corporations have at their disposal: the SULSA 9 drone0047 Southampton University Laser Sintered Aircraft , hulls for drones, missiles, R.A.M.B.O.

Photo 1:

Aerospace engineers at the University of Southampton designed, built and in 2011 flew the world's first "printed" aircraft.

https://phys.org/news/2011-07-southampton-world-aircraft.html

Photo 2:

R.A.M.B.O. consists of 50 individual 3D printed parts, excluding springs and fasteners. This is a modified M203 grenade launcher with a pistol grip.

This is a modified M203 grenade launcher with a pistol grip.

https://all3dp.com/3d-printed-grenade-launcher-rambo/

In 2021, the US military entered into a deal with the non-profit organization ASTRO America, which is to develop the largest 3D printer capable of creating monolithic cases from metal for combat vehicles. The technology of monolithic hulls has already proven to be resistant to damage, while the military wants to speed up and reduce the cost of converting vehicles through 3D printing.

Individuals are also not far behind. Several scandalous cases in America have long been known, for example, Texan Cody Wilson is selling a CNC milling kit called Ghost Gunner 3 for $ 2.5 thousand. The technology allows you to turn raw aluminum into an untraceable small arms, and its creator proudly says that that sells 55 units weekly. Cody Wilson shows the world's first working 3D model of the Liberator pistol he created in 2013.

https://slate.com/technology/2018/08/the-latest-ruling-about-3d-printed-guns-misunderstands-the-technology. html

html

It is difficult to overestimate the contribution of 3D modeling to architecture and construction. Surely Chuck Hull did not think that it was possible to print an entire building at home while he was trying to “layer” the first eyewash glass. But residential buildings, which were created from parts printed on a 3D printer, no longer surprise anyone. The first residential building in the EU was the Milestone project. Designers from Saint-Gobain Weber Beamix created a boulder-shaped room to experiment with the shape of the model and expand the creative possibilities of designers.

Photo 1, 2:

The concrete structure is visually indistinguishable from the houses formerly occupied by the Dutch couple who received the keys to Milestone.

https://www.designboom.com/architecture/project-milestone-first-3d-printed-concrete-house-europe-eindhoven-netherland-completion-04-30-2021/

But the most surprising thing seems to be the possibility that three-dimensional models will be mass-produced right in space. NASA has successfully delivered an improved Made in Space Manufacturing Device (ManD) 3D printer to the ISS on the Redwire Regolith Print (RRP) spacecraft. Scientists want to know if the printer can work in zero gravity and use regolith 9 as a feedstock0047 soil rock on the moon to create future colonies. If successful, the scientists also hope to solve the problem of sarcopenia, loss of muscle mass and functionality in microgravity.

NASA has successfully delivered an improved Made in Space Manufacturing Device (ManD) 3D printer to the ISS on the Redwire Regolith Print (RRP) spacecraft. Scientists want to know if the printer can work in zero gravity and use regolith 9 as a feedstock0047 soil rock on the moon to create future colonies. If successful, the scientists also hope to solve the problem of sarcopenia, loss of muscle mass and functionality in microgravity.

Redwire Regolith Print Complex, consisting of the Redwire additive manufacturing facility, printheads, wafers, and lunar regolith simulation feedstock.

Bottom line: why they created it and what they ended up with

The scientific world never ceases to amaze: a whole industry was born from a technology that could speed up the work in furniture production, or the desire to create an original toy for a daughter. From a technology only available to the military, automotive giants and NASA, 3D printing has moved into the category of things where a child can use a pen and plastic rods to create a three-dimensional figure of the Eiffel Tower.

Global changes have taken place in just 30 years. We say “everything” because, in the context of the history of scientific discoveries, it seems like a grain of sand. We hope that future generations will use new discoveries in 3D printing to improve living conditions and conquer space, and not another, even more powerful weapon.

3D printing weapons, 3d printer for printing weapons

Turch December 13th, 2014

3D printing and 3D prototyping are synonyms for the production of physical objects according to a three-dimensional layout made in any graphic editor. This allows you to create structures of any complexity and work out internal details that are impossible to perform on modern equipment.

Types of 3D prototyping technologies:

- Extrusion is a method in which the material is first melted and then extruded in the desired proportions, determined by a given program.

- Granulation is a method in which material particles are glued together or sintered under the influence of high temperature.

- Lamination is the application of thin layers of material on top of each other and subsequent cutting (as on a lathe).

- Photopolymerization - the process of polymer curing when exposed to a laser beam.

Regardless of the application of any of the existing technologies, the basic principle remains the same. Application of material ball by ball in three planes (X, Y, Z axis). 3D printing can be used in any field, as it allows you to create an object from scratch. It is enough to load its virtual layout.

3D printing materials weapons

Since 3D printing technology has a very wide scope, the materials are also quite diverse:

- Polylactide

- Petroleum products (plastic, nylon).

- Metal powder.

- Mixture of plastic and wood (wood fibre).

- Polycaprolaton.

- Polypropylene.

- Acrylic.

- Gypsum and others.

Polylactide

Equipment for 3D printing of weapons

A machine that converts a virtual model, by the method of ball-and-stick application of material, into a real object is called a 3D printer. It can be used at home (desktop) and commercially (industrial). The cost varies from 1,000 to 1,000,000 US dollars. Also, for each technology, a separate model of the device is provided.

Weapons on a 3D printer

The idea to print military weapons on a 3D printer first appeared in the United States of America.

In May of this year, a video appeared on the Internet in which a man shoots from a printed model of a Liberator pistol. It was 25-year-old Cody Wilson, head of Defense Distributed, which promotes the idea of universal availability of 3D weapons.

Using a 3D printer, they printed firearms, and uploaded files about the work done to the worldwide network. Defense Distributed employees have already made magazines that hold more cartridges for the AR-15s rifle and the legendary Kalashnikov assault rifle (AK-47 modification). Also on their account is the manufacture of the lower part of the receiver, in which the bolt of a self-loading rifle AR - 15 is placed. You can attach the barrel and magazine to it, having received a finished weapon without any problems. No authorization is required to purchase parts in the USA. Now work is underway on a 3D printout of the entire rifle. In doing so, Cody and his team dealt a major blow to the American gun control debate. The discussion began in December, after twenty children and six adults were killed by assassins at a junior high school in Connecticut. The vast majority of Americans rallied to support government reform. This is a thorough check that will make it difficult for criminals to obtain weapons. However, this did not prevent Mr. Wilson from obtaining a federal license to manufacture and sell firearms.

Defense Distributed employees have already made magazines that hold more cartridges for the AR-15s rifle and the legendary Kalashnikov assault rifle (AK-47 modification). Also on their account is the manufacture of the lower part of the receiver, in which the bolt of a self-loading rifle AR - 15 is placed. You can attach the barrel and magazine to it, having received a finished weapon without any problems. No authorization is required to purchase parts in the USA. Now work is underway on a 3D printout of the entire rifle. In doing so, Cody and his team dealt a major blow to the American gun control debate. The discussion began in December, after twenty children and six adults were killed by assassins at a junior high school in Connecticut. The vast majority of Americans rallied to support government reform. This is a thorough check that will make it difficult for criminals to obtain weapons. However, this did not prevent Mr. Wilson from obtaining a federal license to manufacture and sell firearms.

More serious developments in the field of printing firearms on a 3D printer are being carried out in Austin, Texas. The project is led by Eric Macler, coordinator at Solid Concepts, a 3D printing company.

Erik Machler

Ten industrial 3D printers are installed at the Austin plant. Solid Concepts received a federal license to manufacture weapons, and now, using direct metal laser sintering technology, produces the Browning 19 pistol.eleven". Making a pistol takes up to 35 hours. Depending on which printer and materials are used. More than 1,000 shots have already been fired from the first printed pistol, Solid Concepts, while the company has created a second version of the Browning 1911 model.

Solid Concepts isn't going to mass-produce the gun because they can't sell it in a way that makes a profit. While many 3D printers cost around $1,000, Solid Concepts says hobbyists can't make the stainless steel gun they make. Since their machines cost between $600,000 and $1 million, industrial conditions are needed here. The devices consume more electricity than can be obtained in residential areas. In addition, the printers use inert gases that are not commercially available. So this is a technology for commercial production.

Since their machines cost between $600,000 and $1 million, industrial conditions are needed here. The devices consume more electricity than can be obtained in residential areas. In addition, the printers use inert gases that are not commercially available. So this is a technology for commercial production.

The first cases of arrests for making weapons on a 3D printer have already appeared. So, a Japanese citizen Yoshimo Imuro was detained by local law enforcement agencies for carrying military weapons, which he printed on a 3D printer. During a search of his home, 5 weapons were found, two of which were combat. The court sentenced Imuro to two years' imprisonment. The detainee said that he himself developed the technology for creating a pistol, and downloaded the drawings on the Internet. The man also said that he purchased a 3D printer from an online store for 60,000 Japanese yen. This corresponds to 600 US dollars. Also, according to experts, weapons made in this way can be dangerous not only for those against whom it is used, but also for the shooter himself.