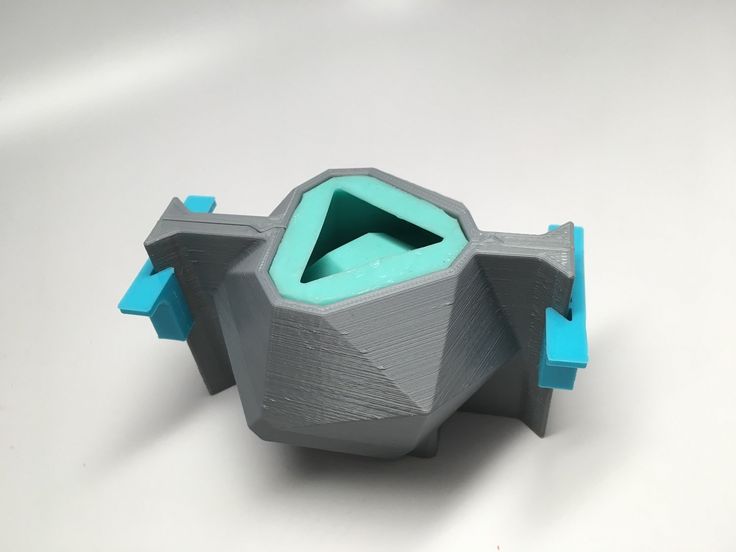

3D printed mold for silicone

Ultimate Guide to Silicone Molding for 3D Printing (Part 1)

Download the full Guide

as a PDF!

The simple post-processing techniques presented in this guide are an excellent way for professionals to create low-cost silicone molds, threaded inserts for enclosures, vacuum formed parts, and more.

Silicone molding is a powerful production method that, when combined with 3D printing, can allow you to make several copies of one product. You can also create a product in a material that is not supported by your 3D printer.

In this How To, we will show you some of the best practices associated with creating silicone molds around 3D printed parts.

Working time will vary depending on a number of factors. Creating a mold around our 3D printed part took us about 1.5 hours. Casting into our mold took about 15 minutes.

Supplies

3D printed mold box, hardware, vents & keys (read on for more info).

Master (the print you are molding)

Silicone

Resin and dye

Mixing cups

Mixing sticks

Mold release spray

Hot glue or cyanoacrylate glue

Funnel

Ex acto knife

Rubber bands, tape, or straps

Gloves

Respiratory mask

Eye protection

Need some of these products? We've curated an Amazon wish list for you.

Step 1: Choose a file to cast a mold around

Obtain a file that you would like to either make several of, or create in a material not supported by your printer.

We chose the cap to a perfume bottle to understand what the process would look like for a product development team attempting to produce several concept models of a prototype.

The next step is to create your mold box. This is the structure that will hold the silicone in place around your part when pouring. Your master will need to be suspended in this structure.

You can create mold boxes from:

Foam core board

Legos

3D printing

We chose to design and print ours as this method has a few benefits. Designing and 3D printing mold boxes allows you to:

Print in pour holes and vents

Easily calculate the volume of our mold

Create boxes that perfectly fit the parts you plan to create a mold of

Re-use mold boxes to create multiple molds

While 3D printing your mold box isn’t necessary, it provides you with a reusable customizable mold box that the other methods cannot produce.

Step 3: Prepare and Print

Because the silicone molding process is not very demanding on the 3D printed mold box or master, you can select standard print settings.

The 2021 Guide to 3D Printing Materials

Learn about polymers, composites, and metals all available for 3D Printing!

Supplies Used:

3D printed mold box, 3D printed master, Cyanoacrylate glue, Mold release spray, Vents & Keys

A: Spray your mold box, master, vents, and keys with mold release.

B: Choose points across model to glue vents

C: With our 3D printed mold box we were able to glue our master directly onto the pour hole during preparation.

D: Spray again with mold release for good measure

You can suspend your master using popsicle sticks, skewers, or 3D printed rods glued to the surface of the master in an inconspicuous place. The holes left in their place after your mold has cured will aid in resin flow through the mold.

Step 5: Open Bottles of Silicone (Parts A and B) and Stir Thoroughly

Supplies Used: Silicone (Part A & B), Mixing Sticks

As silicone comes in two parts, it needs to be mixed both individually and once combined with its hardener.![]()

Mix slowly using separate mixing sticks.

Supplies Used: Measuring cups

A: Determine the volume of silicone needed to fill your mold

B: Measure desired amount of silicone and hardener separately in two measuring cups.

We calculated our mold volume by filling our 3D printed mold box with water and pouring the water into a measuring cup to find exact volume.

For two part molds like the one shown, you only need to mix enough silicone to fill half of the volume of your mold.

Once you have measured each part, combine the two parts into one mixing cup and stir slowly with a mixing tool.

Be cautious not to stir in air bubbles. Be sure to scrape the sides of the cup to mix in all material.

Once your parts are thoroughly mixed the curing process will begin.

TIP

Read instructions on your silicone for “pot-life”. This is how long you have to work with the silicone before it cures.

Supplies Used: Mixed silicone, prepared mold box and master

Pour silicone into the first half of your mold box.

When pouring, pour slowly into one corner of the mold box and allow the silicone to run to other parts of the mold box as it fills.

Stop when the silicone reaches the top of the first half of your mold box.

Once you have poured your silicone place small keys into the silicone. These will create negative spaces and allow the mold halves to fit together once poured. We will remove them before pouring the second half of our mold.

Depending on what type of silicone you are using it can take anywhere from 75 minutes to overnight to cure.

Temperature and humidity will affect curing times, so we recommend this process be done in a room temperature environment.

Step 10: Attach and Prepare Mold Part Two

Supplies Used: Mold box part two, hardware (nuts & bolts)

Once our mold has set, we will prepare to pour the second half of our mold.

A: Remove the keys you inserted in step 9.

B: Attach and secure second half of mold box.![]()

C: Spray with mold release

Next, repeat steps 5-9 and create the second half of your mold using the methods mentioned above.

Step 12: Let Cure

Supplies Used: Pliers or Ex-Acto knife

Once both halves of your mold have cured you are ready to remove them from the mold box and begin using them to recreate parts.

A. Remove the hardware

B: Remove the mold from the mold box and open.

C: Remove the master and vents.

Supplies Used: Cured mold, mold release spray, rubber bands

Next, you will need to reassemble your mold.

A: Ensure that all parts of your mold are correctly aligned, and plug any holes created by vents.

B: Secure mold pieces using rubber bands, straps, or tape.

Tip

Another great application for 3D printing would be to design and print a box to hold the mold together when pouring resin, or modify the mold box we used to serve the same purpose.

TIP:

If your vents leave holes in areas where resin can spill out during the pour, they will need to be plugged.

Supplies Used: Resin (Part A & B), measuring cups, measuring sticks, dye.

Just as with silicone you will need to measure each part of the mixture taking into account the volume needed to create a part.

If you have made several molds, you can mix a larger quantity of resin and pour several molds at once.

Add dye to the part of the resin mixture specified in the instructions.

Step 16: Mix Resin

Combine both parts of the resin mixture and mix thoroughly being sure not to stir in air bubbles.

TIP:

Resins typically have a shorter “pot-life” than silicone meaning they will cure faster.

Step 17: Pour Resin

Supplies: Funnel

Once mixed, pour immediately into the opening of your mold using a funnel.

Pour slowly as not to overfill and spill resin.

Any resin that remains in the mixing cup will harden, but can typically be removed afterwards.

Step 18: Let Cure

Once poured, allow the resin to cure for the appropriate amount of time.

Supplies Used: Pliers

Once your resin has cured, you can open the mold and remove your cast part.

Any resin that escaped through seams or voids and cured is called “flash”. Flash will need to be removed from the part through post processing.

Below, you can see that we were able to recreate our perfume bottle cap in several different colors and opacities using silicone molding.

Visit one of our other applications pages for tips on how to take your print even further.

We recommend that you visit our pages on:

Silicone Molding Part II

Vacuum Forming

Sanding

Last but not least, remember to share your work with us on Thingiverse and social media @MakerBot.

We can’t wait to see what you make!

Powered by MakerBot Learning.

How are 3D printed molds beneficial for your production?

3D Learning Hub

See all categories

Contents:

- Introduction

- Why should you use 3D printing to produce your molds?

- Let’s talk business: real live examples of 3D printed molds

- Create your 3D printed molds today!

Introduction

Why should you use 3D printing to produce your molds?

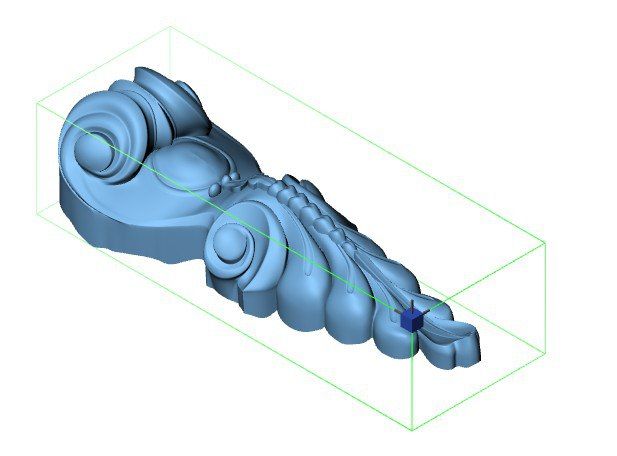

First of all, a 3D printer will provide you with a very high quality and highly detailed part. . Thanks to Additive Manufacturing technologies you can design complex geometries and achieve impossible before structures. For instance, Metal Casting uses a 3D printed masterpiece to create the molds, just have a look at this beautiful jewelry created via our online 3D printing service.

. Thanks to Additive Manufacturing technologies you can design complex geometries and achieve impossible before structures. For instance, Metal Casting uses a 3D printed masterpiece to create the molds, just have a look at this beautiful jewelry created via our online 3D printing service.

Our Brass 3D prints

Silver Metal Casting

But looks are not the only advantage of using 3D printed molds. Additive Manufacturing is also very time-effective. It is a much faster process compared to the traditional techniques. It is as simple as uploading STL files and just 3D printing them. Precise time depends on the size of your object, but small objects such as jewelry can come out of the 3D printer in just half an hour. And if you’re not happy with the masterpiece- all you need to do is just adjust the STL files and 3D print it again, keeping all the design rules in mind.

3D printing is an amazing tool to get perfect molds. It is fast and will speed up the creation of the masterpiece, and let you easily adjust it. To produce single pieces for molds, 3D printing is also cheaper at the same time providing you with the highest standards of quality, which is crucial when creating a mold.

To produce single pieces for molds, 3D printing is also cheaper at the same time providing you with the highest standards of quality, which is crucial when creating a mold.

Let’s talk business: real live examples of 3D printed molds

We can talk about using 3D printed molds and its benefits forever, but is anyone actually doing it? Yes! From 3D printed molds for cakes to metal creations, we gathered for you the best examples of what you can do with 3D printed molds. Check them out now.

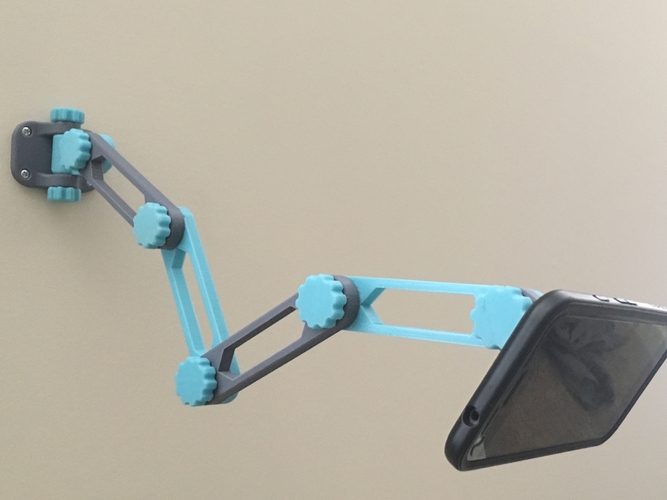

3D printed molds for silicone parts

If your end product is made out of silicone, then 3D printed molds will be ideal for you. Silicon will not interfere or react with Plastic molds, the only important thing to keep in mind is the melting point of the plastic. We provide you with the information about the melting point at dedicated pages of each material. Some materials are even heat-resistant which makes them perfect candidates for 3D printed molds.

Producing the mold will be quick and easy. Thanks to 3D printed molds, your silicone parts will be smooth and can have a great amount of detail. 3D printed molds are also robust and can easily be used multiple times. This is an amazing way to improve your manufacturing process.

Thanks to 3D printed molds, your silicone parts will be smooth and can have a great amount of detail. 3D printed molds are also robust and can easily be used multiple times. This is an amazing way to improve your manufacturing process.

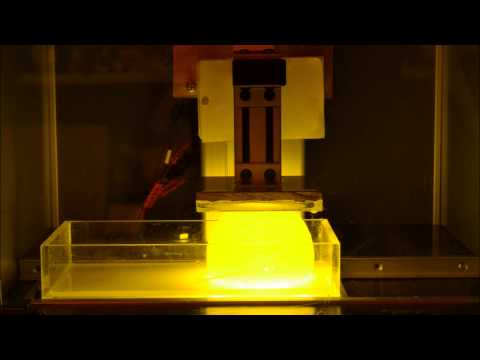

Metal parts with 3D printed molds

3D printing the mold itself is not the only way you can use Additive Manufacturing to produce molds. Casting is a popular method to create molds. In the video below it is explained how the mold and the metal parts were created. As you can see 3D printing was used at the very beginning for a silicone mold.

The 3D printed mold was very useful to manufacture a high standard silicone mold. There were no leaks or air bubbles. The 3D printed mold was precise and perfectly suitable to be used as the masterpiece for a silicone mold. The quality of the 3D printed mold was crucial, as it played a key role in producing the silicone mold. From the silicone mold, a final product was then produced.

Another example is using 3D printed parts to produce metal parts from a sand mold. With Additive Manufacturing the model will be very detailed and will leave the exact shape of your design in the sand to manufacture accurate metal products. You can find a great example of combining Metal Casting and 3D printing below.

As you can see it is possible to create 3D printed molds for projects as big as a hammer. But Additive Manufacturing can also be used for more delicate designs such as jewelry. 3D printing allows us to create an amazing architecture of the objects, impossible to achieve with traditional production methods.

Paula Szarejko is a designer who uses different 3D technologies for her unique jewelry collections. For one of them, her signature silver ornaments inspired by animals, she used wax 3D printing to create 3D printed molds. The technique is the same one as we use at Sculpteo to produce your Metal Casting parts. A wax model is first 3D printed, then a mold is created around it. When hot metal is poured into the mold, it pushes the wax out creating your final product.

http://blog.zmorph4d.com/silver-jewelry-3d-printed-molds/

Can we produce food with 3D printed molds?

Yes! And make sure you see all the projects as they are stunning. We eat with our eyes first, baking cakes and other delicacies is not only about the taste as we very often base our choice of food on how it looks. Thanks to 3D printing bakers have been able to reach a new level of beauty and creativity in producing cakes.

One of the sweet surprises is chocolate art, possible only thanks to 3D printing.![]() Lehrmitt Design Studio invested in Additive Manufacturing as a new way to produce chocolates. The CEO of the company, Bob Lehrmitt comments: ‘’Everybody is looking at the idea of printing chocolate as opposed to printing a mold. [With 3D printing] You can really extend the range of designs you can bring to chocolate. It allows you to do photographic representations. We haven’t come across anything yet that we haven’t been able to print’’.

Lehrmitt Design Studio invested in Additive Manufacturing as a new way to produce chocolates. The CEO of the company, Bob Lehrmitt comments: ‘’Everybody is looking at the idea of printing chocolate as opposed to printing a mold. [With 3D printing] You can really extend the range of designs you can bring to chocolate. It allows you to do photographic representations. We haven’t come across anything yet that we haven’t been able to print’’.

Their 3D printed molds are created of food-safe silicone, which can be created in just 5 days. They present high detail which is easily filled by chocolate, producing beautiful and customized designs, the final product sure looks tasty.

Another amazing example of using 3D printed molds is an architect Dinara Kasko who decided to change her career into pastry but kept her passion for architecture. Her cakes sometimes don’t even resemble what we usually picture when it comes to buying a birthday cake.

Thanks to 3D printed molds, she’s been able to create perfect designs consisting of perfectly straight lines, geometrical shapes and round structures. Dinara shared her secret, she uses 3Ds Max to create the models, then she 3D prints the master model and lastly she uses silicone to cast the molds. The final products are absolutely stunning cakes, bending the design rules of pastry, which would be impossible to achieve without 3D printing.

Dinara shared her secret, she uses 3Ds Max to create the models, then she 3D prints the master model and lastly she uses silicone to cast the molds. The final products are absolutely stunning cakes, bending the design rules of pastry, which would be impossible to achieve without 3D printing.

Create your 3D printed molds today!

As you can see people all around the world are already using 3D printed molds. From professional pastry chefs to jewelry designers and metal crafters- people from various industries already benefit from 3D printed molds. Using Additive Manufacturing to create your molds will bring your production costs down, speed up the manufacturing process and give you absolutely new design freedom.

Start using 3D printed molds today! It is as simple as uploading your 3D model to our 3D printing service and getting your parts delivered straight to your door. If you’re unsure about the process, don’t hesitate to contact us, we’re here for you to answer any questions. And if you want to make your own 3d printed molds, we also have a blog post about it!

And if you want to make your own 3d printed molds, we also have a blog post about it!

Related Topics

- Return to Top

Get the latest 3D printing news delivered right to your inbox

Subscribe to our newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

3d printer for silicone molds and products

With a 3D printer, you can create many complex and unusual products from various materials. In recent years, silicone 3D printing has become increasingly popular, which allows you to create implants, organ prototypes, and other useful products. Let's take a closer look at silicone printing, products that can be created with its help, the necessary equipment and the prospects for the development of new technology.

What is 3D printing silicone?

Silicone is a polymer that consists of chains of alternating silicon and oxygen atoms. This material is resistant to various temperature ranges and various chemicals.

This material is resistant to various temperature ranges and various chemicals.

In 2016, Wacker Chemie found the most efficient way to 3D print silicone products. Based on this technology, Fripp Design, Envisiontec, Carbon 3D developed and produced equipment and materials that made it possible to work with silicone on a 3D printer.

Silicone is most often used in the medical industry to create objects that are resistant to changing environmental conditions. Until 2016, it was possible to create medical objects from silicone only with the help of injection molding of thermoplastics (injection molding). However, the new technology of additive 3D printing allows you to create smaller parts at an acceptable cost compared to injection molded products.

3D silicone printing technology

3D printer, which can print silicone products, has the same principle of operation as an inkjet printer. Liquid molten silicone is fed through the extruder in small droplets that are superimposed on each other, forming layers. The printer software is responsible for the correct formation of lines and shapes as a whole.

The printer software is responsible for the correct formation of lines and shapes as a whole.

The curing process is required for the silicone to cure. It is performed using ultraviolet radiation, which forms cross-links between sections of the polymer chain. Due to this, the silicone is strengthened and becomes heat resistant.

3D printed silicone inside a microgel

Silicone 3D printed inside a microgel was developed at the University of Florida. This technology makes it possible to create more durable, but at the same time flexible and comfortable implants. At the same time, the cost of their production will be significantly lower, as well as the final cost for buyers. In the future, silicone printing inside the microgel will allow the creation of various therapeutic devices and very complex structures, such as human organs and tissues.

This 3D printing method allows you to create individual products of various shapes. The printing nozzle moves along a predetermined path and extrudes liquid silicone drop by drop onto the microorganic gel substrate. Depending on the complexity of the finished product, the printing process can take from several hours to several days.

Depending on the complexity of the finished product, the printing process can take from several hours to several days.

Application of silicone mold printer

3D silicone mold printer is applicable to the following industries:

- Medicine. Silicone is biologically compatible with the human body, does not have a toxic effect on it and is resistant to the influence of an aggressive environment. Thanks to this, the material is used for the production of:

- individual implants;

- respiratory masks;

- hearing aids;

- ear prostheses;

- training preoperative organ models;

- spectacle nose pads;

- contact lenses.

- Automotive industry. Due to the resistance of silicone to extreme temperatures and solar radiation, it is used for the production of automotive plugs, hose. The presence of waterproofing properties also allow the use of silicone for the manufacture of seals in hydraulic systems and materials for sealing automotive joints.

- Manufacture of everyday or sports articles. The elasticity of silicone and the safety of its use makes it possible to produce insoles for running shoes, ear plugs for headphones, and wristbands.

- Manufacture of souvenirs and jewelry.

Which 3D printer is suitable for silicone products?

What to look for when choosing?

When choosing a 3D printer for printing silicone products, you should pay attention to three main parameters of the device:

- Extruder. It must be inkjet, as liquid silicone is used for printing.

- Integrated heater and pump. To prevent liquid silicone from cooling down during printing and not clumping, the printer must have a heater that will constantly maintain the same temperature. It is also important to have a pump. It will help to evenly supply liquid filament to the work surface from the extruder.

- Closed print area. It is necessary for the vulcanization of the printed blank.

An ultraviolet emitter is located in the printed area, and the area itself is closed with a darkened glass dome.

An ultraviolet emitter is located in the printed area, and the area itself is closed with a darkened glass dome.

German RepRap LAM PRE-SERIES 3D printer

Ideal for printing silicone products. It adopts FDM technology, in which two-component liquid silicone rubber (LSR) is mixed by a pneumatic piston and extruded by an extruder. Then each layer of material is thermally cured under the action of an infrared rod.

The FDM technology used by the printer has increased print speed, reduced waste during production, completely eliminated post-processing of the product and accelerated its time to market.

The operation of the device is controlled using the touch screen. The printer uses Simplify3D software to process 3D models.

3D printer German RepRap LAM PRE-SERIES

- Base platform heated

- The weight 80

- Material LC-3335

- Seal FDM

- Working chamber area 390 x 400 x 330 mm

- Speed 6000 mm/m or 100 mm/s

- Number of print heads 1

- Layer thickness from 100 µm

- Nozzle diameter, mm 0.

4

4

Go to product

Top 9 Silicone 3D Printers0021

The following professional silicone 3D printers have proven themselves in the market:

- EnvisionTEC - printing medical and dental parts (Perfactory Micro, Vida HD CROWN & BRIDGE and Xede 3SP Ortho lines).

- Structo - creation of dental products (OrthoForm, DentaForm series).

- Total Z - printing of advertising, souvenir, layout and educational products (Anyform line).

- Stratasys - creation of parts for the automotive, aerospace, defense industries (Connex Objet series), printing of dental products (J720 Dental line).

- 3D Systems - printing of souvenirs, models, promotional items and educational products (sPro series).

- Sinterit Lisa Set is a system for creating advertising, souvenir, mock-up and educational products.

- Intamsys FUNMAT PRO 610 HT is an industrial printer for printing large items and testing functional parts under critical conditions.

3D printer Intamsys FUNMAT PRO 610 HT

- Software IntamSuit, Simplify 3D, Cura

- Control connection interfaces WiFi, Internet, USB

- Material PEEK, PEKK, PEI, PPSU, PC, Nylon, ABS, PLA, PVA, TPU, Carbonfiber Reinforcement

- Seal FDM

- Supported file formats STL, OBJ

- Z-axis resolution 0.0016 mm

- Resolution X and Y 0.016 mm

- Platen temperature 300°C

- Extruder temperature 500°C

- Working chamber area 610 x 508 x 508 mm

- Number of print heads 2

- Layer thickness from 50 µm

- Thread diameter 1.

75

75 - Nozzle diameter, mm 0.4 (0.25, 0.5, 0.6, 0.8, 1.2 mm)

- Display 7" color touch screen

Go to product

Sinterit Lisa Set

- Control connection interfaces WiFi

- Laser IR 5W

- Maximum Layer Height 0.15 mm

- Maximum consumer power 24 W

- Maximum build chamber temperature 105 °C

- Maximum platform temperature for printing 190 °C

- Max extruder temperature 275 °C

- Material PA12 smooth, flexa Black

- Minimum Layer Height 0.

06 mm

06 mm - Seal SLS

- Food 110/120 V or 220/230 V

- Supported Software Sinterit Studio 2016

- Dimensions (mm) Sinterit Lisa - 650x550x450; Sinterit Sieve - 600x340x330; Sinterit Sandblaster - 480x370x360

- Accuracy along X, Y axes, mm 0.1

- Speed 15 mm / hour

- Layer thickness from 75 µm

- Weight, kg Sinterit Lisa - 35;Sinterit Sieve - 22.

5;Sinterit Sandblaster-15

5;Sinterit Sandblaster-15

- Data output format STL, OBJ, 3DS, FBX, DAE, 3MF

- Max workpiece size PA12: 90x110x130 mm, flexa Black: 110x130x150 mm

- Print area Sinterit Lisa - 150x200x150 mm; Sinterit Sandblaster - 410x310x200 mm

- Operating system Microsoft Windows

Go to product

The future of silicone 3D printing

Silicone printing was originally developed for medical applications. Therefore, the most promising goal is the development and creation of silicone tissues and human organs that imitate real ones with great accuracy.

Help.

The first attempts to create a human organ from a silicone filament were made at the Federal Institute of Technology Zurich. The artificial heart in design and movement completely imitated the real one. However, the silicone model takes only 3,000 strokes to wear out, which is equivalent to a lifespan of less than one hour.

In 2021, only training and demonstration organs are printed from silicone, which help to study human physiology during training in medical specialties. The first experimental implants and prostheses also began to be developed.

Silicone 3D printing with silicone is a new, emerging technology. It is considered very promising due to the ease of use of the material, its high elasticity, wear resistance, resistance to radiation and aggressive chemical environments.

- March 14, 2021

- 6273

Get expert advice

3D printed silicone mold cover.

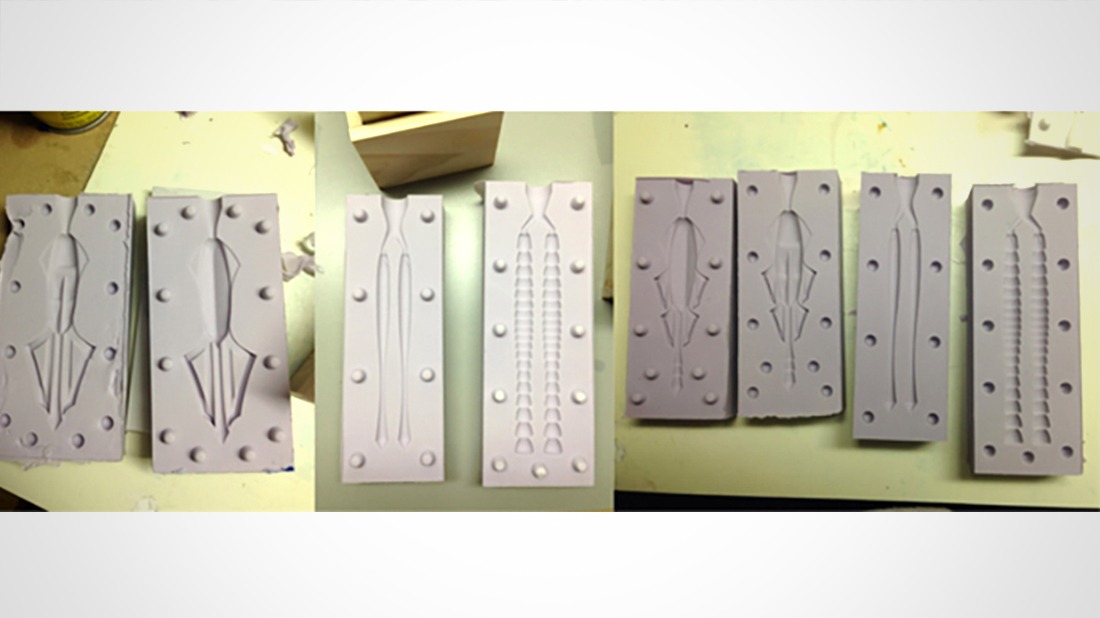

Many craftsmen involved in small-scale casting are familiar with the process of creating casings for matrix silicone molds, this is a very laborious and rather "dirty" process:

fiberglass cloth impregnated with epoxy or polyester resin. Below is a photo of the process of creating a matrix form for one of my masks using the classic method.

Matrix molds allow you to save silicone and repeat the silicone mold in a short time, since the casing is always the same, only the silicone part changes.

For several years I had the idea to try to print a casing on a 3D printer, but everything rested on the skill of 3D modeling, since it is quite difficult to explain the features of the process to a modeller, and I myself could only cut models in Netfabb. But time passed and I had to study 3D modeling more closely: Fusion 360, Blender, Netfabb.

As it turned out, modeling the casing is not that difficult, you don't need deep knowledge, just the basics.

First, I would like to say a big thank you to Greg for providing the filament for my experiments) the plastic is chic, not nearly inferior to the Moscow manufacturer. I have already printed several tens of kilograms and everything is in order. I recommend taking PLA or Petg plastic for casings, they have good sintering of the layers.

Let's get started!

All you need to model the casing is Blender, Netfabb and the model itself.

Blender is a fairly cheap program, I advise you to buy on Steam to receive updates.

Netfabb is already much more expensive, so I advise you to download from the torrent.

As an example, I took Smoke's mask from the Mortal Kombat game by bkzthunder

Open Blender and import the mask model. The first thing we need to do is to think over the place where the plastic is poured - the "sprue" and the places for the air to exit - the "bulges", also check that the protrusions are located wherever air pockets are possible.

In the case of the Smoke mask, I decided to place a sprue on the top of the nose and two sprues at the ends of the mask near the ears, the sprues do not have to be wide, about 2-3 mm is enough, the sprue is the larger the better, but we must remember that the plastic will harden in these channels and they will have to be cut and sanded. I made the sprue the same as the sprue - 3 mm and this was my mistake, then I had to cut the silicone, since the plastic did not have time to pass through such a small hole, it is better to make at least 6 mm.

Shift + A - add an object, select a cylinder, press the letter N it doesn’t work if specialists read it - I will be glad for advice, although I have already tried all the tutorials) and scale using the letter S (press X, Y or Z if you need to scale relative to a specific axis). We select the sprue and sprue through Shift , right click and select join .

Once the sprue and lugs are in place, you can begin to create a border between the two halves of the mold, here it is also very important to pay attention to the location of this border, because its location will determine how easy it will be to connect and separate the halves. In some cases, it is required to make a casing from 3-4 or more parts, in our case it was necessary to make three parts, but I arrogantly made it out of two, which is why I had to modify it later.

In some cases, it is required to make a casing from 3-4 or more parts, in our case it was necessary to make three parts, but I arrogantly made it out of two, which is why I had to modify it later.

Add through the same Shift + A model Plane , enter edit mode through TAB , in the upper left corner select selection Face , right click on the polygon and press Subdivide . Select two polygons on the same side of the Y axis and delete via the X key, selecting Face (depending on the axis along which your object is symmetrical). Next, in the panel on the right, select the icon wrench and press Add Modifier , select the modifier mirror and select your main model through the pipette. Now all actions with one half of the polygon will be repeated on the other. Also in the modifier, check the box Clipping . At this stage, you can delete the edge in the middle (select the edge, press X and select Dissolve edges ), it will be easier. With key G(move) and R(rotate) and X, Y, Z we move to the place where the border will be, it is important to position it so that one side enters the inside of the model, and the other departs from the model by 10 centimeters. Next, select the edge between the edge that enters the model and the opposite one and extrude it with the letter E. Important make sure that the border passes in the middle of the sprue and protrusions, as well as its lower part is always inside the model. Extrude this edge until it connects to itself. Then press Ctrl + R and place the yellow line about 1-1.5 cm from the mask, this will be the future length of the silicone bead. I recommend to exit edit mode, press Apply in modifier mirror and copy our border through Shift + D , but don't move it. Select the copy of the border, press TAB and delete all long polygons. We exit the edit mode and add the modifier Solidify, to both our sides, setting the parameter offset to 0.

With key G(move) and R(rotate) and X, Y, Z we move to the place where the border will be, it is important to position it so that one side enters the inside of the model, and the other departs from the model by 10 centimeters. Next, select the edge between the edge that enters the model and the opposite one and extrude it with the letter E. Important make sure that the border passes in the middle of the sprue and protrusions, as well as its lower part is always inside the model. Extrude this edge until it connects to itself. Then press Ctrl + R and place the yellow line about 1-1.5 cm from the mask, this will be the future length of the silicone bead. I recommend to exit edit mode, press Apply in modifier mirror and copy our border through Shift + D , but don't move it. Select the copy of the border, press TAB and delete all long polygons. We exit the edit mode and add the modifier Solidify, to both our sides, setting the parameter offset to 0.

When our auxiliary models are ready, we export them separately in the stl format to a separate folder via File - Export - stl (do not forget to press selection only in the save window on the right) and sign accordingly.

Open Netfabb and add all files except for the big border to the project.

Each imported object, including the mask, is "healed":

When everything is cured, select all models and perform a boolean operation (union). Yes, this can be done in Blender, but familiar modellers unanimously recommended doing it right away in Netfabb.

We have one object, now we need to make an imitation of a silicone mold. Select the mask and then right mouse button - Extras - Create Shell , in the window that opens in Shell thickness set 5 mm (the optimal thickness of silicone), on the right set Outer offset, below in Accuracy set 1 mm, I do not recommend put less, there will be a very heavy model.

We get this beauty:

Select - Right mouse button - Export Part - as STL , label "Silicone mold without locks and sprue"

Go back to Blender, import our silicone mold, hide everything in the upper right by clicking on the eye icon.

Now we need to make "locks" and a sprue on the silicone mold, the locks are needed to keep the mold in the same position during each casting cycle, and the sprue is clear, you need to fill in the silicone somehow.

The sprue needs to be made large, about 3-4 cm in diameter, it can be placed immediately on the border of the casing, or on each side separately, in my case it can be placed on the border. Check that the part that enters the silicone mold enters it completely and smoothly, without sharp corners, for this you can extrude the bottom circle in edit mode and place it inside the silicone mold, scaling and moving. You can also "pull" the silicone mold itself onto the sprue using the Sculpting tab, I recommend watching tutorial videos on YouTube, otherwise this long post will become even longer)

I advise you to make locks of a trapezoidal shape from cylinders: add a cylinder, scale to the desired size and scale the top cover in edit mode.![]() I also advise adding the modifier mirror - will be half as much work. We place the locks on the surface of the silicone mold so that they are a little buried in it (you need at least 2-3 pieces), but do not overdo it, distribute it evenly over the surface and do not forget about the back of the silicone mold.

I also advise adding the modifier mirror - will be half as much work. We place the locks on the surface of the silicone mold so that they are a little buried in it (you need at least 2-3 pieces), but do not overdo it, distribute it evenly over the surface and do not forget about the back of the silicone mold.

Select the locks, sprue, large rim and combine them into one file through right mouse button - Join, export them as a separate file and combine them with the silicone mold in Netfabb. We apply Create shell to the silicone mold, but set the thickness not 5 mm, but 3 mm: with this thickness, the casing will be strong and light, you can make it thicker, but as for me it is superfluous.

We get the casing itself, but it is still raw, we need to refine it.

Next, you need to cut off the excess, follow the instructions in the picture:

I just forgot to check the box at the bottom left opposite Only selected parts. Remove the cut piece.

Remove the cut piece.

Use a boolean operation and "subtract" the silicone mold with the large rim from the resulting casing. Using the arrows below the parts list, move the silicone mold file to the right column, the shape will turn red, which means it will be subtracted or green casing when we press minus.

Now you need to split the shell into two separate files, right mouse button - Extended - Shells to parts

No need to expand, I just did it for clarity.

Export models to Blender.

It remains to make holes for the screws that will tighten the two halves with each other and holes for the air outlet. I use M6 screws, so I made the holes 6.2mm. We model cylinders with a diameter of 6.2 mm and a length of several centimeters, set along the perimeter of the side using modifier mirror. Make sure the cylinders are perpendicular to the bead. We also make cylinders with a diameter of 2 mm and place them over the entire area of \u200b\u200bthe casing and in places where air can get stuck.