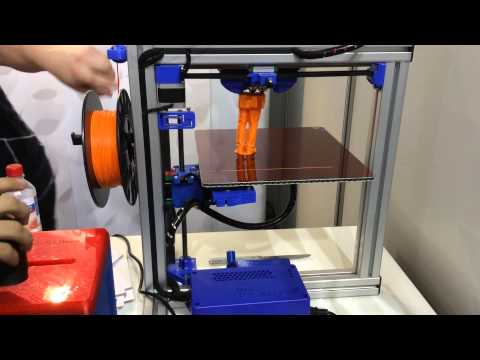

3D printing demo youtube

8 Helpful And Informative 3D Printing YouTube Channels

These 3D printing YouTube channels will help you expand your knowledge, fuel your imagination and inspire creativity.

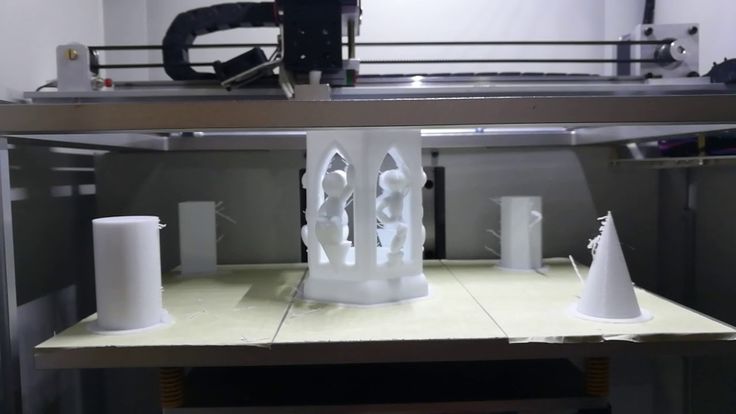

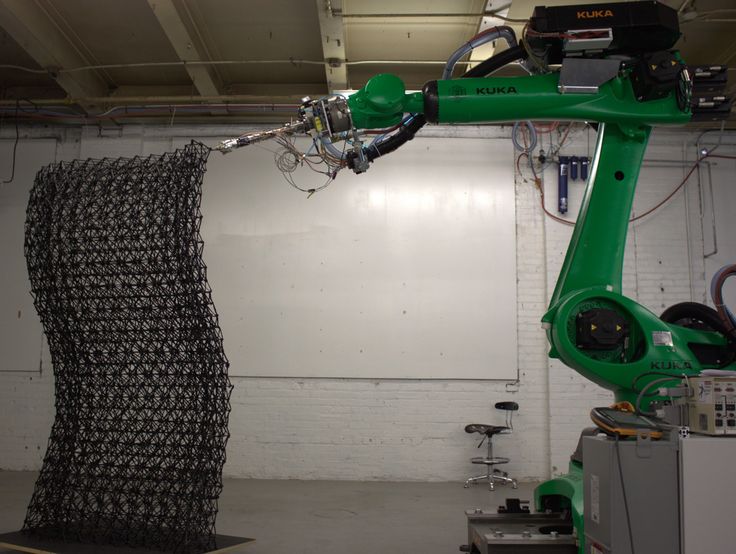

3D printing scene is vast and diverse almost like a universe with professional engineers creating spaceship prototypes to home DIY makers designing a cup holders for their cars. The same goes for 3D printing YouTube channels. You can easily find experienced makers who explain how the technology works as well as crazy nerds building their own Iron Man suits in a basement.

Source: 3D Printing NerdIt’s now easier to find your favorite channel with our list below. These picks aren’t in any particular order because we love and respect all of these guys!

The Maker’s Muse

Run by Angus, The Maker’s Muse offers a wide range of helpful videos. People starting their adventure with 3D printing should definitely check the 101 series in which Angus explains whether it’s better to print with ABS or PLA, how to choose infill settings, which slicing software to choose from and much more. He also records a lot of vlogs and does live streams in which he answers user questions, recommends various tech, shares his extensive knowledge, and talks about topics like how to make money with a 3D printer. Some of his videos are just fun to watch, like the one from his recent trip to the electronics market in Shenzhen, China.

3D Printing Nerd

Joel is a true 3D Printing Nerd from Seattle. His channel includes unboxing videos, reviews of various 3D printers, tips and tricks on how to print and post-produce your work, and many interesting videos about his own projects. He prints various items from party gadgets to mini nuke flower pots and huge video game gun replicas. In fact, his most popular video so far is a tutorial on how to assemble an awesome 3D printed gun from Destiny video game (with working parts but still a harmless cosplay prop).

[Tweet "7 helpful and informative #3Dprinting YouTube channels"]

3D Printing

Joe is calling himself a 3D printing professor and he really deserves this title. His 3D Printing channel is filled with very informative videos about the technology, its various applications, as well as tips and tricks on how to use it. He also records very interesting lectures (hence the professor) about market trends, things every 3D printer owner should have or cold, hard truths about owning a digital fabrication machine.

Thomas Sanladerer

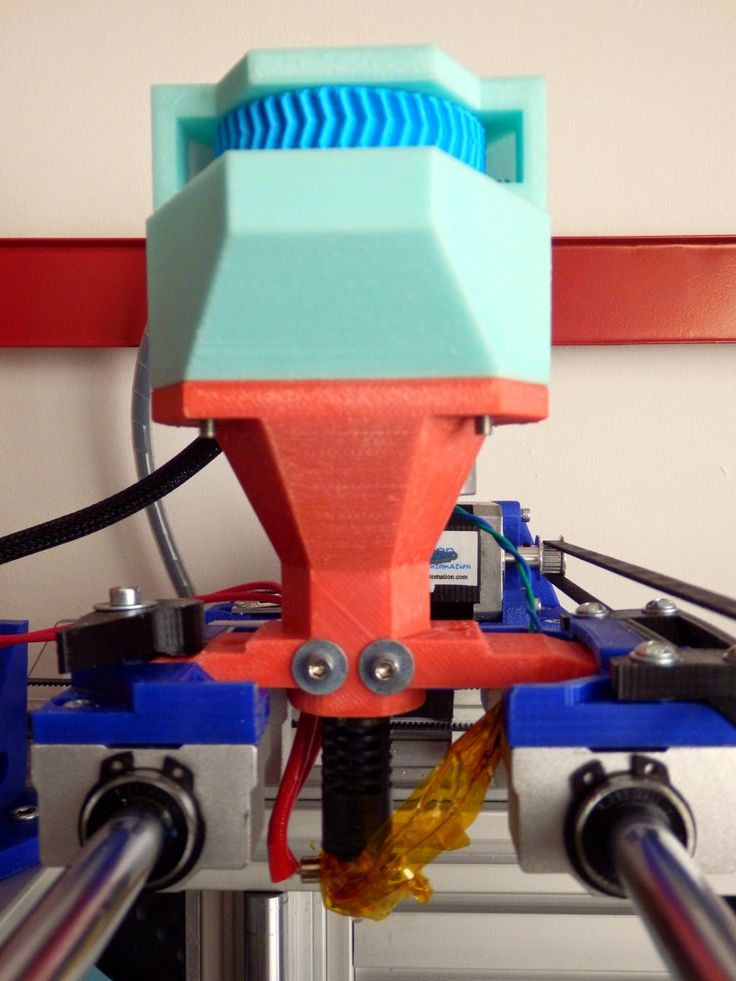

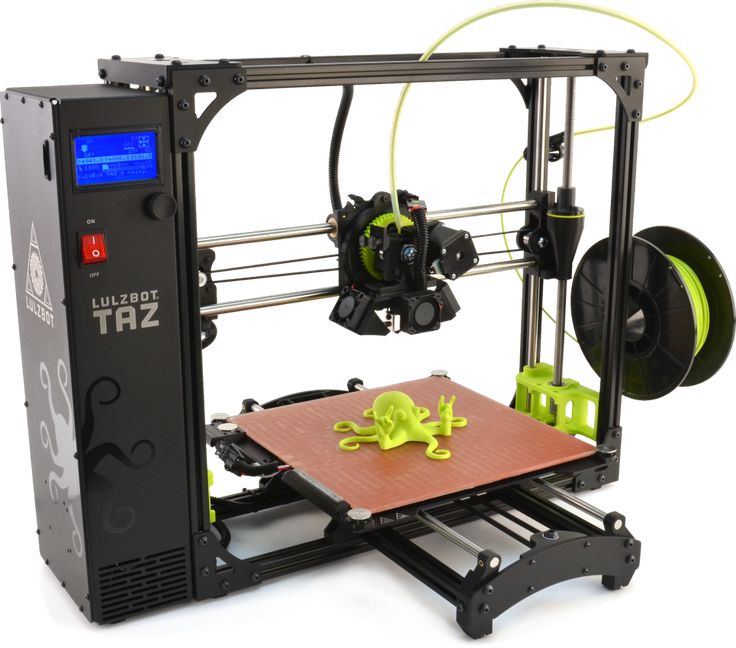

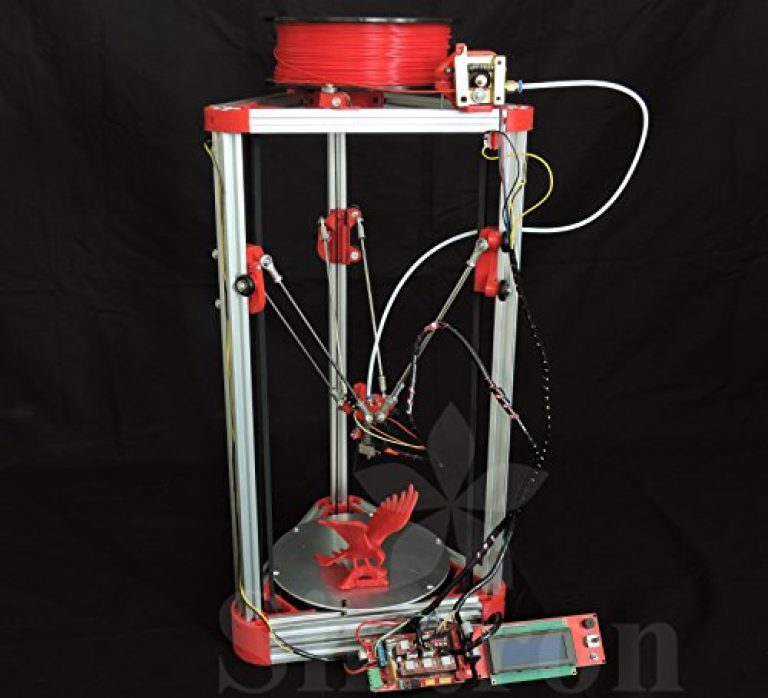

Thomas Sanladerer specializes in desktop and open-source RepRap-like 3D printers and shows his viewers what is possible with these machines and what’s not. His channel is the place to go when you search for tips about specific materials or comprehensive reviews of various 3D printers. Thomas also records guides for building your own 3D printer from scratch, which are one of the most comprehensive ones out there.

His channel is the place to go when you search for tips about specific materials or comprehensive reviews of various 3D printers. Thomas also records guides for building your own 3D printer from scratch, which are one of the most comprehensive ones out there.

Print That Thing

This is one of the most fun and optimistic from all 3D printing YouTube channels. At Print That Thing Jwall shares his designs and 3D prints requested by his friends and fans. He only needs a few minutes to design a cool gangsta necklace or a fantasy sword in Tinkercad 3D modeling software. But one of his most amazing projects is a set of cat armor that he later expanded with a special helmet, so his cat could stay safe in the urban jungle.

James Bruton - XRobots

The first time we mentioned James Bruton on this blog was in our 7 bizarre 3D printing applications piece to praise his outstanding work in designing real-life, human-sized robots and (almost) working Iron Man costume. Subscribe to his XRobots channel to follow every step of the manufacturing process. From him, you can learn not only about 3D printing but also molding, post-processing, applying working electronics, and much more.

Subscribe to his XRobots channel to follow every step of the manufacturing process. From him, you can learn not only about 3D printing but also molding, post-processing, applying working electronics, and much more.

Barnacules Nerdgasm

Before becoming a full-time nerd with hundreds of thousands of viewers, Barnacules worked as a software developer at Microsoft, so he knows a thing or two about programming and technology. No wonder then, that 3D printing is among his main interests on Barnacules Nerdgasm, right after video games of course. He often guest-stars at smaller 3D printing channels and recommends awesome designs he found around the web like he did recently with a Tracer Pistol model inspired by the Overwatch video game.

Simone | FNTSMN

Simone Fontana is a young 3D designer and 3D printing enthusiast from Italy who recently started his own business. On his Simone | FNTSMN YouTube channel he shares his extensive knowledge about the technology as well as shows his awesome projects. Awesome is the right word for literally all of them, like for example his custom 3D printed penny skateboard that was already tested by a few famous skaters. He also makes various stunning guns and video games props which are 3D printed and painted to look like the real deals.

On his Simone | FNTSMN YouTube channel he shares his extensive knowledge about the technology as well as shows his awesome projects. Awesome is the right word for literally all of them, like for example his custom 3D printed penny skateboard that was already tested by a few famous skaters. He also makes various stunning guns and video games props which are 3D printed and painted to look like the real deals.

Do you know other 3D printing YouTube channels?

Sure you do!

Let us know in the comments which other 3D printing YouTube channels do you consider worth watching and recommend them to others.

The best 3D printing YouTube channels in 2021

Many new 3D printing YouTubers run successful channels, and many 3D printing creators have grown tremendously – from a few subs to a few thousand in a few months, sometimes way more!

We spend a lot of time exploring YouTube and searching for great video content on additive manufacturing to create the most comprehensive list of 3D printing YouTube channels to date.

From 3D printer unboxing to filament reviews, 3D printing tutorials, how-to’s, live streams, and more, discover more on 3D printing with the channels below. We highlighted the super fast-growing channels with a little fire emoji (growth rate above 500% in terms of subscribers between March 2017 and September 2018).

List of the best 3D printing YouTube channels

| YouTube channel | Subs count (Sep’ 2018) | Growth rate** | Category | Country |

|---|---|---|---|---|

| I Like To Make Stuff | 2,033,244 | 70% | Maker | US |

| Barnacules Nerdgasm | 940,569 | 10% | Tech reviewer | US |

| James Bruton | 603,301 | 34% | Cosplay/props | UK |

| Naomi ‘SexyCyborg’ Wu 🔥 | 560,520 | 3119% | Maker | China |

| Punished Props | 363,008 | 114% | Cosplay/props | US |

| Maker’s Muse | 331,814 | 355% | 3D printing | Australia |

| Make Anything // 3D Printing Channel | 300,629 | 134% | 3D printing | US |

| RCLifeOn 🔥 | 285,293 | 591% | Tech reviewer | Sweden |

| 3D Printing Nerd | 258,855 | 225% | 3D printing | US |

| Thomas Sanladerer | 172,519 | 123% | 3D printing | Germany |

| 3D Print Guy | 131,052 | 374% | 3D printing | Canada |

| Uncle Jessy | 86,445 | 361% | Cosplay/props | US |

| Ivan Miranda | 77,732 | – | Maker | Spain |

| Gear Down For What | 65,043 | – | Maker | US |

| Tech3C | 47,557 | 99% | 3D printing | Australia |

| 3D Maker Noob 🔥 | 37,184 | 1254% | 3D printing | Malta |

| Jaidyn Edwards | 34,328 | 14% | Maker | Australia |

| Chaos Core Tech | 32,073 | 370% | 3D printing | US |

| CHEP 3D Printing | 25,410 | 69% | 3D printing | US |

| ModBot | 23,982 | 27% | Tech reviewer | US |

| 3D Printing Professor | 21,431 | 250% | 3D printing | US |

| Mold3D TV | 20,636 | 63% | 3D printing | US |

| The Hot End | 18,386 | 137% | 3D printing | Australia |

| PRINT THAT THING | 17,740 | 21% | 3D printing | US |

| DIY Engineering 🔥 | 14,943 | 514% | Maker | US |

| Hoffman Engineering | 13,295 | 91% | 3D printing | US |

| A Pyro Design | 13,091 | 224% | 3D printing | US |

| Richard Horne | 11,427 | 41% | 3D printing | UK |

| NeatherBot | 11,227 | 93% | Maker | US |

| Daniel Norée | 11,227 | 102% | Maker | Sweden |

| ProfDrafting | 10,637 | 130% | 3D printing | US |

| Kirby Downey | 10,609 | 7% | Cosplay/props | UK |

| 3D Print – Tech Design | 10,398 | 92% | 3D printing | Sweden |

| Nerdly | 9,991 | 340% | 3D printing | US |

| 3D Central | 9,716 | 55% | 3D printing | US |

| Joe Mike Terranella | 9,480 | 180% | 3D printing | US |

| FugaTech 3D Printing | 9,256 | 619% | 3D printing | US |

| Jimmy Shaw’s Tidbits 🔥 | 8,583 | 545% | 3D printing | US |

| Simone | FNTSMN | 7,952 | 6% | 3D printing | UK |

Mr. Crankyface Crankyface | 7,441 | 153% | Maker | Sweden |

| Zbysek Pilny | 7,214 | 333% | Maker | Czech Republic |

| The 3D Print General | 6,723 | – | 3D printing | US |

| Desktop Makes 🔥 | 6,719 | 977% | 3D printing | US |

| That 3D Print Guy | 6,201 | 258% | 3D printing | Australia |

| JAT.MN | 5,769 | 80% | 3D printing | US |

| 3DprintedLife | 5,511 | 26% | 3D printing | US |

| Make It And Fake It 🔥 | 5,422 | 271000% | 3D printing | US |

| Print 3D Channel 🔥 5,406 798% 3D printing US | 5,406 | 798% | 3D printing | US |

| TashTech | 5,190 | 71% | 3D printing | South Africa |

| Novice Expert | 4,662 | 68% | 3D printing | US |

| Think Making | 4,662 | 160% | 3D printing | Honduras |

| Nillabean | 4,588 | 80% | Tech reviewer | US |

| doodaddoes | 4,581 | 33% | 3D printing | US |

| Andreas Hölldorfer | 4,336 | 29% | Tech reviewer | Germany |

| XYZAidan | 4,284 | 252% | Tech reviewer | US |

| 3D Print Everything | 4,125 | 261% | 3D printing | US |

| 3d Print Creator | 3,629 | 147% | 3D printing | Netherlands |

| Abuzz Designs | 3,605 | 127% | 3D printing | US |

| BusyBotz | 3,406 | -1% | 3D printing | US |

| D-Tech | 3,314 | 297% | 3D printing | US |

| Model3D | 3,301 | 114% | 3D printing | UK |

| Practical Printing 🔥 | 3,270 | 4709% | 3D printing | US |

| Bobot’s Trains and Maker Zone | 2,990 | 36% | Maker | US |

| PatchBOTS | 2,928 | – | Cosplay/props | US |

| Dream 3D | 2,916 | 60% | 3D printing | UK |

| TGAW | 2,909 | 27% | 3D printing | US |

| SparkyFace5 | 2,721 | 9% | 3D printing | Australia |

| Dustin Corbin | 2,589 | 82% | 3D printing | US |

| 3DPrintingEverything | 2,224 | 90% | 3D printing | US |

| Afro3dprinter 🔥 | 2,136 | 979% | 3D printing | UK |

| Jeremy S Cook | 1,931 | – | Maker | US |

| Maker Hacks | 1,760 | 144% | Maker | US |

| NolanC 3DPrint Works | 1,589 | 109% | 3D printing | US |

| N Squared | 1,589 | 116% | 3D printing | US |

| Improper Engineering | 1,219 | 357% | 3D printing | US |

| 3D Printing Lab | 1,212 | 77% | 3D printing | US |

| How I Do It 🔥 | 1,054 | 1251% | Maker | US |

| Extruder Joe | 1,044 | 83% | 3D printing | US |

| 3DWithUs | 1,034 | 240% | 3D printing | UK |

| Agustin Flowalistik 🔥 | 1,029 | 586% | 3D printing | Spain |

| Potent Printables | 834 | – | Maker | US |

| Three-Dee Kid 🔥 | 801 | 685% | 3D printing | UK |

| Cat 🔥 | 581 | 976% | 3D printing | Liechtenstein |

| Disrupt It Yourself | 570 | 153% | 3D printing | US |

*Number of channel subscribers as of September 13, 2018

** Growth rate of the channel between March 2017 and September 2018

This list of 3D printing-related YouTube channels aims not to rank them by quality but to provide a comprehensive overview of the 3D printing landscape on YouTube. And also to give visibility to smaller 3D printing channels and help you find some great video content!

And also to give visibility to smaller 3D printing channels and help you find some great video content!

A selection of great 3D printing channels on YouTube

Make Anything // 3D Printing Channel

- Creator name: Devin Montes

- Country: United States

- Most popular video: Ambiguous Cylinder Illusion // How it Works

- Patreon: You can support Devin on Patreon by clicking here.

Make Anything is the biggest YouTube channel specialized in 3D printing. In his videos, Devin builds fun 3D printed objects and also gives useful 3D printing tips. Devin’s videos often have the potential to become viral and appeal to watchers way beyond the 3D printing community. Devin loves to use optical illusions and tricks to make visually striking 3D printing videos such as his famous Super Satisfying Twist Containers.

Thomas Sanladerer

- Country: Germany

- Most popular video: 3D printing guides: Setting up auto bed tramming leveling tilt compensation!

- Patreon: If you like his videos, you can support Thomas on Patreon by clicking here.

Tom is among the most popular 3D printing YouTube creators and there is a reason for that. His channel is a healthy mix of useful tips, in-depth tutorials, as well as balanced and thorough reviews. The German YouTube star also loves to test the limits of the 3D printers he reviews, for example by carrying out experiments such as in this awesome “Destructive testing: which 3D prints are bulletproof?” video. Tom’s channel is rather “serious”: you won’t find here clickbait/viral videos but researched, well-produced and insightful content. That’s actually what we love!

Thomas Sanladerer3D Printing Nerd

- Creator name: Joel Telling

- Country: United States

- Most popular video: 3D Printing and Testing the Makerbot Coin Sorter

- Patreon: You can support Joel on Patreon by clicking here.

In the span of a few years, Joel became a fixture of the 3D printing community. His outgoing personality, infectious good mood, and relentless social media presence enabled him to become a great ambassador of the 3D printing community. On his 3D Printing Nerd YouTube channel, you can find all kinds of 3D printing-related content: from unboxings to trade shows visits, outstanding prints, and more, everyone will find something they love. In March 2017, Joel’s coin sorter video went viral, which boosted his channel overall, setting him on track to break the 100k subscribers’ bar in the coming weeks. An amazing and well-deserved achievement for one of the hardest-working creators on this list. To top it all, Joel often uses his huge social media reach to promote less established Youtubers. This guy is the best friend any 3D printing addict wants! What else can we add? Just one thing: #HighFive!

3D Printing NerdMaker’s Muse

- Creator name: Angus Deveson

- Country: Australia

- Most popular video: Hacking Vase Mode – 3D Printing Experiments

- Patreon: if you like his videos, you can support Angus on Patreon by clicking here.

Maker’s Muse is one of the most established 3D printing creators on YouTube. On his channel, Angus carries out in-depth 3D printer reviews and provides lots of useful tips and educational videos. One thing you should know: Angus has a thing for torturing 3D printers, not for the sake of it (we think!) but rather to push the machines to their limits. For example, he loves designing insanely complex 3D models of objects super challenging to print! Angus recently started focusing on resin-based 3D printers, making his channel stand out as the vast majority of 3D printer videos focus on FFF/FDM 3D printers. He also often puts dirt-cheap 3D printers to the test and debunks any phony Marketing promises. All in all, a must-subscribe to channel if you’re into 3D printing!

Maker’s MuseNaomi ‘SexyCyborg’ Wu

- Creator name: Naomi Wu

- Country: China

- Most popular video: Infinity Skirt Build

Naomi is a maker and web developer based in Shenzen, China. Naomi is passionate about 3D printing technology among others she uses in her popular videos. She often visits maker fairs and trade shows in Asia, producing awesome and immersive 360° videos to show the rest of the world that Asia is also a hotbed with active local 3D printing/maker communities. Naomi is also one of the few voices defending minorities in the maker’s community. Be that the overwhelming domination of the white male demographic in 3D printing/maker media or the stereotypes attached to female makers, Naomi never lacks words to smartly bring people’s attention to these important topics – always respectfully and educationally. So don’t be fooled by her SexyCyborg moniker, Naomi is much more than that.

Naomi is passionate about 3D printing technology among others she uses in her popular videos. She often visits maker fairs and trade shows in Asia, producing awesome and immersive 360° videos to show the rest of the world that Asia is also a hotbed with active local 3D printing/maker communities. Naomi is also one of the few voices defending minorities in the maker’s community. Be that the overwhelming domination of the white male demographic in 3D printing/maker media or the stereotypes attached to female makers, Naomi never lacks words to smartly bring people’s attention to these important topics – always respectfully and educationally. So don’t be fooled by her SexyCyborg moniker, Naomi is much more than that.

JAT.MN

- Creator name: Dustin Phillips

- Country: United States

- Most popular video: Do not Pre Order the TIKO 3D printer until you watch this video

Dustin, aka the Jatman, is a very active and rising Youtuber and 3D printing evangelist. Despite being fairly recent, his channel is growing super fast, thanks to Dustin’s always thorough reviews and his overall 3D printing expertise. One thing that makes this channel stand out: the weekly live stream series “3D Printing Tonight”, a kind of late-night show where he discusses the week’s hot topics (check out the infamous Tiko videos!) and does Q/A sessions. Dustin is among the most involved members of the 3D printing community, with very active social media profiles and regular participation in events or guest videos. No doubt Dustin is on the right track to be a top 3D printing Youtuber, so get on board now and subscribe!

Despite being fairly recent, his channel is growing super fast, thanks to Dustin’s always thorough reviews and his overall 3D printing expertise. One thing that makes this channel stand out: the weekly live stream series “3D Printing Tonight”, a kind of late-night show where he discusses the week’s hot topics (check out the infamous Tiko videos!) and does Q/A sessions. Dustin is among the most involved members of the 3D printing community, with very active social media profiles and regular participation in events or guest videos. No doubt Dustin is on the right track to be a top 3D printing Youtuber, so get on board now and subscribe!

Chaos Core Tech

- Creator name: Garrett

- Country: United States

- Most popular video: 3D Printed Slimes [Slime Rancher] – Boom, Phosphor, Rad & Honey!

Garrett is a programmer passionate about 3D printing and making in general. On his channel, he shares his tips to design and 3D print characters from comics, movies, or video games. From South Park Christmas tree characters to sword design tutorials on Fusion360, Garrett is never short of inspiration to create new videos and share them with his audience!

On his channel, he shares his tips to design and 3D print characters from comics, movies, or video games. From South Park Christmas tree characters to sword design tutorials on Fusion360, Garrett is never short of inspiration to create new videos and share them with his audience!

A Pyro Design

- Creator name: Travis

- Country: United States

- Most popular video: 3d animated Family Guy cool whip scene

- Patreon: you can support Travis in his mission to bring logos to life by becoming one of his patrons by clicking here.

On his YouTube channel, Travis shares insights on his process to create three-dimensional logos from 2D images. You can watch the whole process from the designing part to the 3D printing part. Travis often collaborates with other 3D printing creators to bring their logos to life or create insanely cool objects such as this retro Sonic the Hedgehog logo, with Chaos Core Tech.

Abuzz Designs

- Creator name: Lauren Renee

- Country: United States

- Most popular video: DIY Wall Ombre Painted Canvas

- Patreon: Lauren needs patrons’ help to be able to keep making awesome videos. You can support her by clicking here and contribute to her Patreon.

Lauren is a passionate designer and maker, sharing her passion on her YouTube channel with original videos such as tutorials to create Halloween costumes, gift cards, and even yummy-looking recipes. Lauren is one of the few very active women of the 3D printing community. She quickly managed to connect with many other makers, her always positive attitude certainly played a part in the success of her channel.

Abuzz DesignsCHEP

- Creator name: Chuck Hellebuyck

- Country: United States

- Most popular video: Metal Inserts on a 3D Print – Video #020

Chuck is a seasoned maker and 3D printing user with extensive experience in electronics. On his YouTube channel, Chuck focuses on practical uses of 3D printing in his famous show called Filament Friday. You can, for instance, learn how to use 3D printing to repair a broken broom handle. Tired of printing useless plastic gadgets? Check out Chuck’s channel now!

On his YouTube channel, Chuck focuses on practical uses of 3D printing in his famous show called Filament Friday. You can, for instance, learn how to use 3D printing to repair a broken broom handle. Tired of printing useless plastic gadgets? Check out Chuck’s channel now!

Richard Horne

- Country : United Kingdom

- Most popular video: RepRap 3DR Delta 3D printer

Richard, also known online as RichRap, is a long-time maker and 3D printing user from the UK. On his channel, Richard focuses on quality over quantity: there are few but in-depth and highly instructive 3D printer reviews. As his nickname RichRap suggests, he is also very involved in the RepRap movement. A great no-frills 3D printing YouTube channel.

Richard HorneDaniel Norée

- Country: Sweden

- Most popular video: The OpenRC Truggy, A experimental 3D Printed R/C car

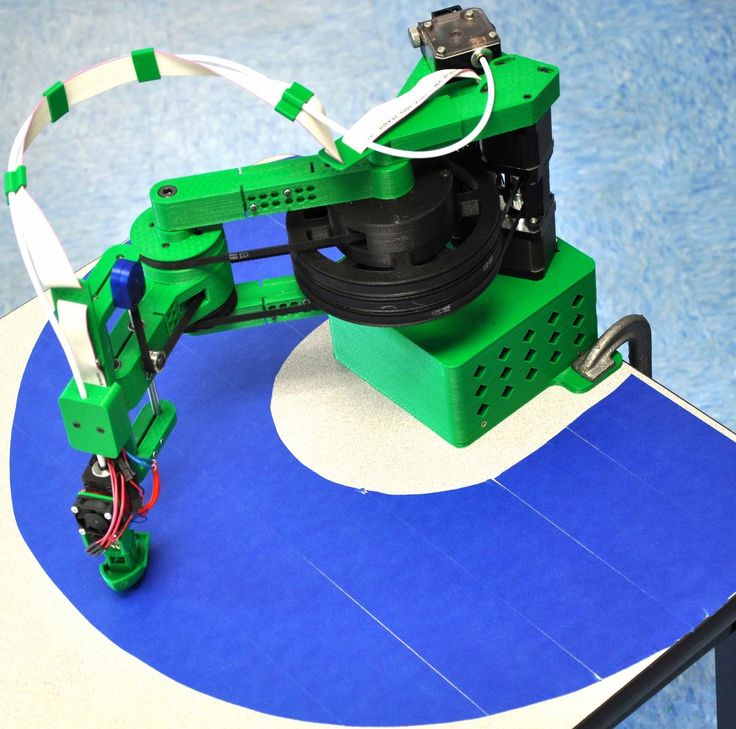

Daniel Norée is an award-winning Swedish 3D designer and 3D printing evangelist. He also is the author of The OpenR/C Project and The OpenRailway Project, and the inventor of the famous Benchy. In his videos, Daniel provides guidance on how to build remote-controlled cars or drones using 3D printing. He also showcases nice 3D printed objects such as a snowball maker or wrenches. A great channel from one of the pillars of the 3D printing community!

He also is the author of The OpenR/C Project and The OpenRailway Project, and the inventor of the famous Benchy. In his videos, Daniel provides guidance on how to build remote-controlled cars or drones using 3D printing. He also showcases nice 3D printed objects such as a snowball maker or wrenches. A great channel from one of the pillars of the 3D printing community!

3D printing on Youtube: trends and takeaways

There are MANY YouTube channels about 3D printing.

Since our last update, the number of 3D printing-related YT channels has grown sharply, showing how active the 3D printing community is. We now have 79 channels on this list, and many of them are growing really fast!

Live streaming is on the rise.

In 2016, YouTube added a live stream option and many 3D printing creators are making the most of it. Often longer than regular videos, YouTube live streams are used for live unboxing videos but also to make innovative formats such as the 3D Printing Tonight show by JAT.MN.

Often longer than regular videos, YouTube live streams are used for live unboxing videos but also to make innovative formats such as the 3D Printing Tonight show by JAT.MN.

The vast majority of 3D printing Youtubers are – surprise – white men. That’s a fact, and it’s becoming somewhat preoccupying, as diversity in media is always important (yes, YouTube is a media!). In terms of gender balance, we only list a handful of women with a 3D printing Youtube channel, and that’s not enough. Let’s not even get started on the overwhelming caucasian domination…

This hot topic is of course not limited to 3D printing and not easy to tackle but some voices are trying to make themselves heard, from Naomi Wu to the more controversial 3DPConfidential on Twitter. The diversity issue and lack of visibility for minorities in the makers’ community is definitely a hot topic that we hope will be addressed collectively in the future.

The brilliant @leahbuechley. @make then fixed "the problem"- by no longer releasing embarrassing demographic data. https://t.co/ljONAJ7DO7 pic.twitter.com/Wh5qrcmlkP

— Naomi Wu 机械妖姬 (@RealSexyCyborg) March 19, 2017

YouTube is a great (and free!) promotion channel for 3D printer brands.

3D printing companies are now using YouTubers to launch and promote their new products, by sending test units to prominent community members, sometimes flying them to events. Among the most successful 3D printer launches relying on heavy YouTube promotion were the Prusa i3 MK2, the Ultimaker 3, and the BCN3D Sigma R17.

Sending test units to 3D printing Youtubers can be a very efficient strategy when your machine is on point but can also backfire (ask the guys at Tiko or Tevo…). Best practices include building a friendly relationship with these Youtubers and the 3D printing community, ensure they have all they need to carry out the tests in optimal conditions, and address any issue or negative feedback which may arise. Also, make sure your 3D printer is a great product!

Also, make sure your 3D printer is a great product!

Looks like the @bcn3dtech Sigma R17 season has officially started!

— Aniwaa (@Aniwaa3d) March 6, 2017

Can't wait to see what these guys think about it 😊 pic.twitter.com/jBpUbWYTWY

How to make money with a Youtube channel?

Advertising

The easiest way to monetize a YouTube channel is advertising: YouTube being a part of Google, it is very easy to start showing ads on your videos through the AdSense program. To earn money from views on your videos, you can show banners or video ads in your videos and generate revenue every time a viewer will click on an ad.

Affiliate programs

Many YouTubers participate in affiliate programs, the most popular one being Amazon Associates. Thanks to these 3D printing affiliate marketing programs, creators can earn a commission via special links. If you make a purchase on the website (Amazon or others) using their custom link, the creator will receive a commission. If you want to support some of your favorites 3D printing creators while online shopping, just use their affiliate links usually found in the description fields below a video.

If you make a purchase on the website (Amazon or others) using their custom link, the creator will receive a commission. If you want to support some of your favorites 3D printing creators while online shopping, just use their affiliate links usually found in the description fields below a video.

Another way to earn $$$ revenue or get free products through YouTube is to get sponsored by a brand or establish a partnership with them. In the case of 3D printing, 3D printers and 3D scanners brands can send you 3D printers or 3D scanners for reviews.

Starting a Patreon

Patreon is a global crowdfunding platform where content creators of all kinds can get sustainable income from recurring donations from fans. Many 3D printing YouTube channels have a Patreon where you can contribute with a monthly donation, starting as low as a few dollars. Some of the most established YouTubers on our list can earn thousands of dollars each month thanks to their Patreon. Thomas Sanladerer, for instance, makes around $2k per month thanks to donations from his fans, thus providing more financial freedom to run his channel.

Some of the most established YouTubers on our list can earn thousands of dollars each month thanks to their Patreon. Thomas Sanladerer, for instance, makes around $2k per month thanks to donations from his fans, thus providing more financial freedom to run his channel.

Joining a multi-channel network (MCN)

According to Wikipedia, “a multi-channel network (MCN) is an organization that works with video platforms such as YouTube, to offer assistance to a channel owner in areas such as “product, programming, funding, cross-promotion, partner management, digital rights management, monetization/sales, and/or audience development” in exchange for a percentage of the ad revenue from the channel”. MCN is now common in the world of YouTubers looking to monetize their channel, and several makers from our list have already joined an MCN.

If you’re looking to take your 3D printing YouTube channel to the next step, this could be the way to go. No need to have tens of thousands of subscribers either, as MCN is not only focusing on reach but also on the engagement of the audience on high potential niches such as additive manufacturing.

No need to have tens of thousands of subscribers either, as MCN is not only focusing on reach but also on the engagement of the audience on high potential niches such as additive manufacturing.

Soooooo…. 5/10 of our top channels are #3Dprinting– Kill me? <3 U @joeltelling @THEJATMN @apyrodesign @pressreset @3DPProfessor @BINMedia

— Anthony Reyes (@BlindGaming) March 31, 2017

How to use our list of the 3D printing channels on YouTube

Subs count

Here is the number of subscribers as of September 13, 2018, 18 months after the last subs count we did in March 2017. This allowed us to calculate an 18-month growth rate for channels featured in this list.

Growth

This is the growth percentage of the channel, based on the evolution of the total number of subscribers over the past 18 months (from March 2017 to September 2018). This growth rate gives an indication of which channels are growing fast. We highlighted the super fast-growing channels with a little fire emoji (growth rate above 500%).

This growth rate gives an indication of which channels are growing fast. We highlighted the super fast-growing channels with a little fire emoji (growth rate above 500%).

Category

This time, we’ve decided to categorize 3D printing YouTubers to make the list easier to use:

- 3D printing: this is the main category, covering YouTube channels focusing solely on 3D printing and producing videos such as 3D printers unboxings, tests, tips, and general information about additive manufacturing.

- Maker: we regrouped here the channels of maker creators who regularly offer 3D printing-related content but whose channel is not fully dedicated to 3D printing. We thought it was interesting to expand a bit the scope of the list to see how established makers make the most of 3D printing for their projects.

- Tech reviewer: there are many tech reviewers with highly successful YouTube channels, and some of them have a knack for 3D printers! Why not include them here?

- Cosplay/props: this category covers creators and makers who use 3D printing to make cosplay, movie accessories, and props.

A very popular and active YouTube group with a nice overlap with the 3D printing community.

A very popular and active YouTube group with a nice overlap with the 3D printing community.

Country of origin

Pretty straightforward, because it’s cool to see how global the 3D printing movement has become (although most channels are still from the US).

Note:

For this list, we selected only 3D printing YouTube channels managed by independent creators. However, some 3D printing companies run great YouTube channels with instructive videos. For example, MatterHackers, a leading US reseller of 3D printers, produces lots of great content, from reviews to tutorials.

The different types of 3D printing YouTube videos

Tutorials

In tutorials, 3D printing Youtubers give step-by-step instructions on topics such as how to build a 3D printer in kit, how to improve your 3D printing techniques, and many more. You can also find 3D printing video tutorials on how to solve general 3D printer problems such as nozzle clogging.

Unboxings

Unboxing is a video where Youtubers unbox 3D printers, 3D scanners, or 3D filaments and share their first impressions with the viewers. 3D printers unboxing videos are quite popular and they usually cover every step, from opening the cardboard box to launching the first print. These videos are very popular on YouTube (not only for 3D printers!), as they allow viewers to share the thrill of unboxing a brand new machine and also provide unfiltered insights for potential buyers.

Reviews

For 3D printer reviews, manufacturers usually send a test unit to one or several Youtubers to get a video review and give exposure to their machine in the 3D printing community. Some creators also make reviews of 3D printers or filaments they purchased themselves, thus avoiding the potential conflict of interest.

Lately, a growing number of 3D printer and 3D filament brands have started to use YouTube reviews as a promotion channel, sending multiple 3D printer test units to influential channels and actively engaging with the community. Most YouTubers do not charge for a 3D printer review but they can sometimes keep the product for free.

Tips

In 3D printing tips videos, you will find ideas on how to solve a problem on your 3D printer or how to make some improvements to your 3D printer and your 3D prints.

How to become 3D printing Youtuber?

The beauty of YouTube is that anyone with basic video equipment can become a creator. To launch a 3D printing YouTube channel, you basically need a recording device, a 3D printer, and a good dose of motivation! Of course, if you intend to make tutorials or hands-on videos about 3D printing, having access to a 3D printer is a plus (some decent DIY 3D printers are available for less than $200). Note that the most popular YouTubers not only use top-notch video and audio gear, they also have great video production and editing skills, which take a lot of practice to acquire.

Note that the most popular YouTubers not only use top-notch video and audio gear, they also have great video production and editing skills, which take a lot of practice to acquire.

Once you’ve started your YouTube channel, you want to build a following and promote it on social media so people can discover your work. The 3D printing community is very active on Twitter, Facebook, and 3D printing forums. To find the best places to promote your channel, you can check our article on the best forums, communities, and discussion groups about 3D printing. If you’re planning to launch your channel, let us know about it, we will check it out and add it to our list of the best YouTube channels.

3D printing YoutubersConclusion on the best 3D printing YouTube channels

The 3D printing community is a fast-growing and very active group. The number of YouTube channels specialized in 3D printing keeps growing every month and some of them are now becoming established brands with a large following and professional approach to what started as a passion side project. It is great to see this branch of the 3D printing media landscape grow and structure itself!

It is great to see this branch of the 3D printing media landscape grow and structure itself!

We were the first website to provide a comprehensive overview and analysis of the 3D printing YouTube community and will continue to update our list of creators and publish updates. Stay tuned. And should you decide to open a YouTube channel, please contact us so we can add you to the list. You can give us your opinion on Facebook and Twitter.

Selective Laser Sintering (SLS) 3D Printing Guide

Selective Laser Sintering (SLS) 3D printing is a technology trusted by engineers and manufacturers across industries to create durable and functional models.

In this detailed guide, we'll explain selective laser sintering technology, the different systems and materials on the market, the workflow and different applications of SLS printers, and when to choose 3D printing with this technology over others. additive and traditional manufacturing methods.

White paper

Looking for a 3D printer to create durable, functional models? Download our white paper to learn how selective laser sintering (SLS) technology works and why it is popular in 3D printing for functional prototypes and end-use products.

Download white paper

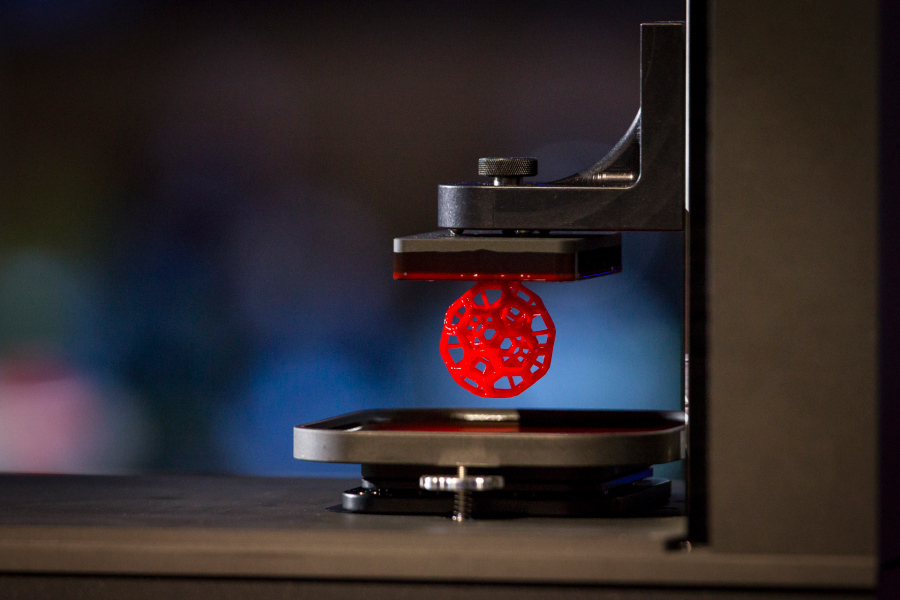

Selective laser sintering (SLS) is an additive manufacturing technology that uses a powerful laser to sinter fine polymer powder particles into a solid structure based on a 3D model.

SLS 3D printing has been popular with engineers and manufacturers for decades. With its low model cost, high productivity, and common materials, this technology is well suited for a wide range of applications, from rapid prototyping to low-volume production, limited trial runs, or custom-made products.

Recent advances in technology, materials and software have opened up the possibility of SLS printing to a wider range of companies. Previously, such tools were used only in a few high-tech industries.

Introducing the Fuse 1 high performance SLS 3D printer, finally available.

Webinar

Watch our product demo to learn about Fuse 1 and SLS 3D printing from Formlabs.

Watch webinar

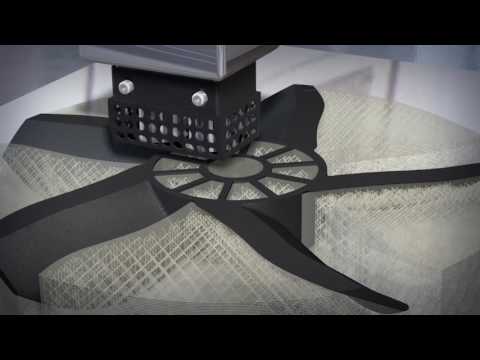

Schematic representation of the selective laser sintering process. The SLS method uses a powerful laser to sinter small particles of polymer powder into a solid structure based on a 3D model.

-

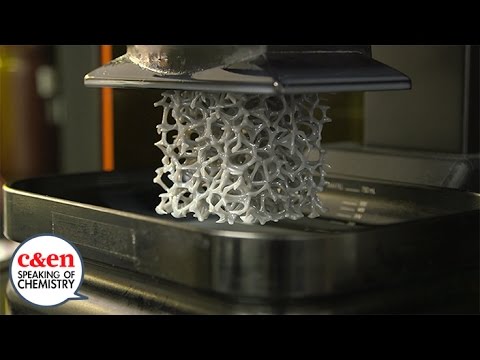

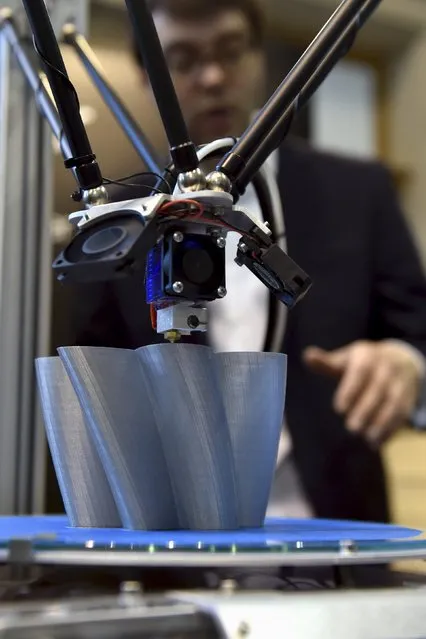

Print: A thin layer of powder is applied to the top of the platform inside the working chamber. The printer preheats the powder to just below the melting point of the feedstock. This allows the laser to more easily raise the temperature of certain areas of the powder bed and monitor the solidification of the model. The laser scans the cross section of the 3D model, heating the powder to the material's melting temperature or just below. Particles are mechanically joined together to form a single solid object. The unsprayed powder supports the model during printing and eliminates the need for special support structures. The platform is then lowered into the working chamber one layer, typically 50-200 µm thick, and the process is repeated for each layer until the models are complete.

-

Cooling down: after printing and before post-processing, the build chamber should cool down a little in the printer body and then outside the body to ensure optimal mechanical properties of the models and avoid their deformation.

-

Postprocessing: finished models must be removed from the working chamber, separated from each other and cleaned of excess powder. The powder can be recycled and printed models can be blasted or tumbled.

To learn more about the workflow, see the SLS 3D Printing Workflow section below.

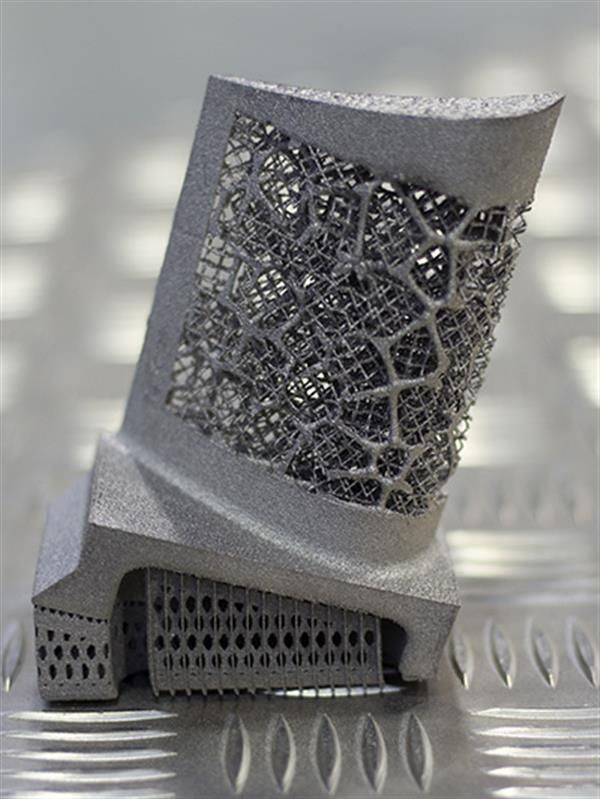

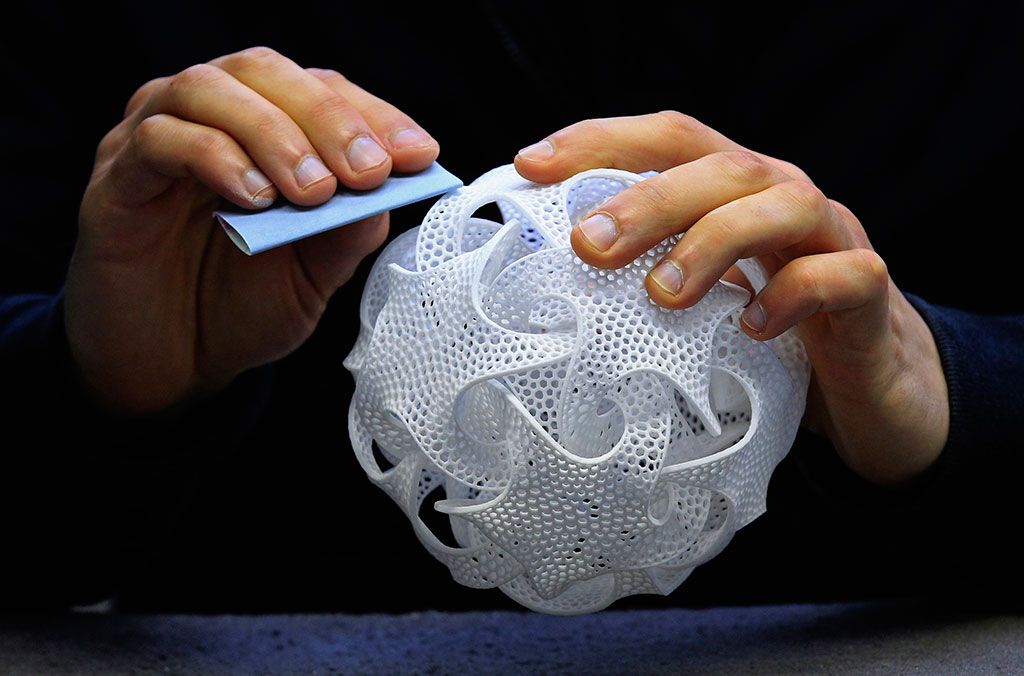

SLS models have a slightly grainy surface, but the layer lines are almost invisible. To achieve a smooth surface, SLS models are recommended to be blasted or tumbled. This sample was printed on a Fuse 1 industrial 3D printer with SLS technology for workshops from Formlabs.

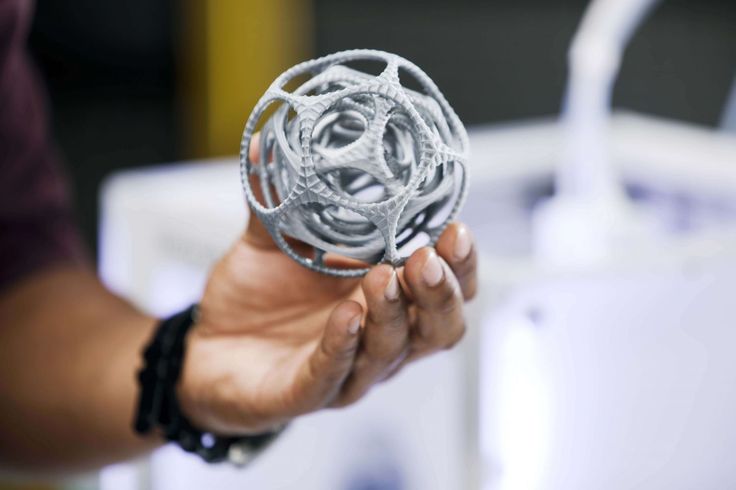

The green powder supports the model during printing and eliminates the need for special support structures. This makes SLS ideal for complex geometries, including internal features, undercuts, thin walls, and negative draft features.

This makes SLS ideal for complex geometries, including internal features, undercuts, thin walls, and negative draft features.

Models created using SLS 3D printing have excellent mechanical properties: their strength is comparable to that of injection molded models.

Compare Selective Laser Sintering (SLS) 3D printing with other common plastic modeling technologies: Fused Deposition Modeling (FDM) and Stereolithography (SLA).

Selective Laser Sintering (SLS) is one of the first additive manufacturing technologies developed in the mid-1980s by Dr. Carl Deckard and Dr. Joe Beeman at the University of Texas at Austin. Since then, the method has been adapted to work with a variety of materials, including plastics, metals, glass, ceramics, and various powdered composite materials. Today, all of these technologies are classified as wafer synthesis, additive manufacturing processes that selectively sinter regions of a powder layer under the influence of thermal energy.

The two most common substrate synthesis systems currently available are a plastic based method commonly referred to as Selective Laser Sintering (SLS) and a metal based method known as Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM). ). Until recently, both systems were very expensive and complex, which limited their use to the production of small batches of expensive models or custom-made products, such as aerospace components or medical devices.

Innovation in this area will make plastic-based SLS as affordable as other 3D printing technologies such as stereolithography (SLA) and Fused Deposition Modeling (FDM) and become widely available in affordable, compact systems.

All selective laser sintering 3D printers use the process described in the previous section. Basically, such printers differ in the type of laser, the volume of printing and the complexity of the system. Different solutions are used for temperature control, powder dosing and layering in different devices.

Selective laser sintering technology requires high precision and strict control during the printing process. The temperature of the powder and (incomplete) models must be controlled within 2°C during the three stages of production: preheating, sintering and storage before extraction, in order to minimize warping, stress and thermal deformation.

For decades, selective laser sintering has been one of the most popular professional 3D printing technologies, but due to its complexity, strict requirements and high price, only service bureaus and large enterprises could use it.

Conventional industrial SLS 3D printing systems have one or more powerful lasers. An inert atmosphere (nitrogen or other gases) is needed to prevent the powder from oxidizing and breaking down during the printing process, which requires specialized air handling equipment.

These installations also require special heating, ventilation and air conditioning (HVAC) systems and industrial power supplies. In addition, even the smallest industrial installations occupy an area of at least 10 square meters. m.

In addition, even the smallest industrial installations occupy an area of at least 10 square meters. m.

Due to the high initial cost of approximately $100,000 (and much more for complete solutions), traditional industrial systems with SLS technology were out of reach for many enterprises.

As with other 3D printing technologies such as Fused Deposition Modeling (FDM) and Stereolithography (SLA), more affordable, compact systems with SLS technology have recently begun to appear on the market. However, these solutions had significant drawbacks. These include low quality models and complex manual workflows due to a lack of post-processing solutions. This severely limited their use in industrial production.

The Formlabs Fuse 1 printer is in a new category with these deficiencies fixed . It is the first industrial SLS 3D printer for the workshop, delivering high quality, compact size, streamlined workflow, and cost far less than traditional industrial systems of the same type.

The Fuse 1 printer does not require any special infrastructure and will easily fit into your workplace.

The Fuse 1 uses a single laser and has a smaller working chamber that requires less heat. The powder is exposed to elevated temperatures for a shorter period of time, so there is no need for inert gases and specialized ventilation equipment. Thanks to its lower power consumption, it can run on a standard AC power supply without requiring special infrastructure.

The Fuse 1 features patent pending Surface Armor technology. This creates a semi-baked shell that heats evenly around the models as they are printed. This results in excellent surface quality, stable mechanical properties, high reliability and a high material renewal rate.

In addition to providing a compact, self-sustaining ecosystem and complete powder handling capability, Fuse 1 is complemented by the Fuse Sift Station, a stand-alone stand-alone device for model retrieval, recovery, storage and powder mixing.

Overall, the Fuse 1 industrial 3D printer with SLS for workshops has slightly less print volume than traditional entry-level SLS systems, but is smaller, easier to work with and less expensive.

| Fuse 1 Industrial SLS Workshop Printer | Traditional Industrial SLS 3D Printers | 5 Cost | from 18,500 US dollars | 100 000 - 500,000 US dollars and more than | ||||

|---|---|---|---|---|---|---|---|---|

| Press volume | to 165 x 165 x 300 mm | 9010 x 550 x 750 mm 750 mm 7509 Benefits | Availability High quality models High performance Simplified workflow Compact dimensions Low maintenance | High print volume High quality models High performance Many material options | ||||

| Disadvantages | Less print volume Limited material options | Expensive equipment Big sizes Infrastructure Requirements Large amount of maintenance Special Operator Required |

The most common selective laser sintering (SLS) material is nylon. It is a high performance engineering thermoplastic for both functional prototyping and end-use fabrication. Nylon is ideal for the production of complex knots and strong models with high environmental resistance.

It is a high performance engineering thermoplastic for both functional prototyping and end-use fabrication. Nylon is ideal for the production of complex knots and strong models with high environmental resistance.

3D printed SLS nylon for strength, rigidity and durability. The final models are impact-resistant and highly wear-resistant. Nylon is resistant to UV, light, heat, moisture, solvents, temperature and water. Nylon models printed on a 3D printer are also biocompatible and do not cause allergic reactions. This means that they can be worn and used safely in many situations.

Nylon is ideal for a range of functional applications, from consumer product design to healthcare applications.

Nylon is a synthetic thermoplastic polymer from the polyamide family. It is available in several versions, each designed to print different products. Nylon 12 Powder has a wide range of applications and is a general purpose, general purpose SLS 3D printing powder. Nylon 12 GF Powder is a composite material with a high fiber content, increased stiffness and heat resistance for difficult industrial conditions. Nylon 11 Powder helps fill a gap in prototyping and end-use applications where increased ductility, impact resistance and the ability to withstand wear without brittle fracture are required.

Nylon 11 Powder helps fill a gap in prototyping and end-use applications where increased ductility, impact resistance and the ability to withstand wear without brittle fracture are required.

- Impact proof prototypes, fixtures and fittings

- Thin-walled pipes and bodies

- Rivets, fasteners and latches

- Orthopedic products and prostheses*

- High Performance Prototyping

- Small batch production

- One-piece clamping and holding fixtures and tooling

- Conventional SLS models

- Heavy duty clamping and fastening fixtures and spare parts

- Continuous models

- Thread and sockets

- High temperature models

* Material properties may vary depending on model design and manufacturing method. It is the manufacturer's responsibility to confirm the suitability of printed models for their intended use.

109 40%

8 MPa (°C)

8 MPa (°C) Nylon 12 Powder and Nylon 11 Powder are one-component powders, but some SLS 3D printers can also use two-component powders, such as coated powders or powder blends.

Nylon 12 GF Powder is a composite material with a high fiberglass content, while other nylon composites with aluminide, carbon or glass are designed to increase the strength, stiffness or flexibility of models. In such two-component powders, only the component with the lower glass transition point is sintered, which binds both components.

SLS 3D printing accelerates innovation and helps businesses in a wide range of industries such as engineering, manufacturing and healthcare.

Manage the entire product development process, from iteration of first concept design to production of ready-to-use products:

- Rapid Prototyping

- Product mockups for user feedback

- Functional Prototyping

- Functional testing of products under severe conditions (e.

g. piping, brackets)

g. piping, brackets)

Manage your supply chain and respond quickly to changing needs:

- End-Use Manufacturing

- Small batch production

- Mass production of new customized consumer products

- Spare parts manufacturing, supply chain sustainability

- Durable, durable clamping and fastening devices (e.g. clamps and clamps) and accessories

- Custom manufacture of automotive, motorcycle and marine equipment parts, and restock military items on demand

Self-manufacturing of ready-to-use medical devices, taking into account the individual characteristics of patients:

- Medical device prototyping

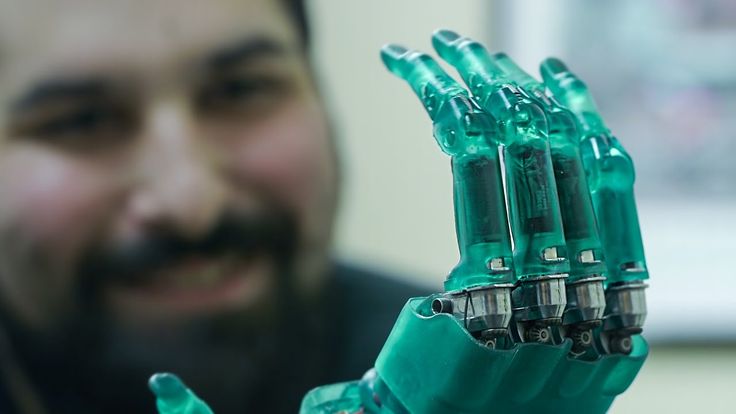

- Prostheses and orthotics (e.g. prosthetic limbs and orthoses)

- Surgical models and instruments

- End use products (nylon 12 biocompatible and sterilizable*)

* Material properties may vary depending on model design and production method. It is the manufacturer's responsibility to confirm the suitability of printed models for their intended use.

Use any CAD software or 3D scan data to design the model and export it to a 3D printable format (STL or OBJ) file. All printers with SLS technology use software that allows you to adjust settings, position models, estimate print times, and layer your digital model. Once set up, the model preparation software sends commands to the printer via a wireless or cable connection.

The Fuse 1 uses PreForm print preparation software (free to download). It allows you to easily duplicate and place multiple models on a 3D grid to maximize your print volume. PreForm automatically suggests the optimal orientation and position of models with the ability to make manual changes.

The workflow for preparing the printer varies from system to system. Most traditional SLS systems require extensive training, tools, and physical actions to prepare and maintain them.

Fuse 1 redefines the SLS workflow, making it simple and efficient, as well as providing trouble-free printing and complete powder handling thanks to modular components.

The Fuse 1 can be easily loaded with powder using a special cartridge.

The Fuse 1 uses a detachable build chamber so you can start a new print while the previous build chamber is still cooling.

Once all pre-checks have been completed, the machine is ready to print. Depending on the size and complexity of the 3D models, as well as their density, printing using SLS technology can take from several hours to several days.

When printing is complete, the build chamber in the housing should cool down a bit before proceeding with the next steps. To start the next print, you can remove the build chamber and insert a new one. Before post-processing, the working chamber must cool down to ensure optimal mechanical properties of the models and avoid their deformation. This can take up to half of the total print time.

Fuse 1 is equipped with a touch screen that allows you to see in real time how each new layer is formed during the printing process. This camera image can also be transferred to a computer using PreForm to monitor the print without leaving the workplace.

Compared to other 3D printing processes, post-processing of SLS-printed models requires a minimum of time and labor. With no supporting structures, it is easy to scale and provides consistent results across batches of models.

After printing is completed, remove the finished models from the build chamber, separate them and clean them of excess powder. As a rule, this is done manually at the cleaning station using compressed air or a jet apparatus.

The excess powder left after the creation of the model is filtered to remove large particles from it. After that, it can be recycled. Under the influence of high temperature, the properties of green powder deteriorate slightly, so for subsequent printing it must be mixed with new material. Due to the possibility of reusing materials, SLS technology produces a minimum amount of waste.

SLS technology typically uses separate devices for powder recovery, storage and mixing. The Fuse 1 workflow uses a single Fuse Sift to retrieve patterns and greens, store, dispense, and mix material streams.

Fuse Sift completes the Fuse 1 SLS print workflow. This system is used for safe and efficient model retrieval and powder recycling.

Fuse Sift automatically doses and mixes used and new powder, reducing waste and controlling powder delivery.

After the powder has been sieved, the 3D models printed using selective laser sintering technology are ready for use. However, there are a few more post-processing steps you can perform on these models.

By default, the surface of 3D models created using SLS technology remains grainy. To achieve a smooth surface, Formlabs recommends blasting or tumbling models made using this method. Models can be spray painted, lacquered, electroplated or otherwise to achieve the desired color, surface quality and properties such as water resistance (special coating) and electrical conductivity (electrolytic coating). Models created with SLS Formlabs are dark in color and therefore not well suited for staining.

Immersion printed SLS model from Partial Hand Solutions.

SLS models can be electroplated for a metal-like surface.

Selective laser sintering is preferred by engineers and manufacturers for its wide design options, high productivity, low model cost and proven end use materials.

Most additive manufacturing processes such as stereolithography (SLA) and Fused Deposition Modeling (FDM) require specialized support structures to fabricate overhang structures.

Selective laser sintering does not require support structures because the unsintered powder surrounds the model during printing. SLS printing makes it easy to create overhangs, intricate geometries, interconnecting parts, internal channels and other intricate details.

Intricately patterned arm splint for weight reduction.

Engineers typically design models in terms of the capabilities of the final manufacturing process, also known as design-for-technology (DFM). When additive manufacturing is only used for prototyping, it comes down to creating models and designs that can be replicated in the manufacturing process using traditional tools.

Selective laser sintering is emerging as a viable rapid production method and its application area continues to expand, so it can open up new possibilities in design and construction. 3D printers with SLS technology can create complex geometries that are impossible or incredibly expensive to manufacture using traditional processes. SLS technology also allows design professionals to combine complex assemblies into a single model that would normally require multiple models to be created. This helps avoid the problem of loose connections and saves assembly time.

Selective laser sintering can unleash the potential of generative design, as it allows the creation of lightweight models that use complex lattice structures that cannot be fabricated by traditional methods.

Selective laser sintering is the fastest additive manufacturing technology for making functional, durable prototypes and end-use products. Lasers used for powder sintering have much faster scanning speeds and are more accurate than the layering methods used in other processes such as Industrial Fused Deposition Modeling (FDM).

To maximize the available print volume in each printer, multiple models can be placed side by side. Operators can use the software to optimize print volume and maximize productivity by leaving only minimal clearance between models.

SLS technology allows operators to fill the build chamber with as many models as possible, as it allows them to be printed without supporting structures, saving time in post-processing.

SLS 3D printing requires the right materials for functionality and versatility. Nylon and its composites are proven, high quality thermoplastic materials. Laser-sintered nylon models have close to 100% density and mechanical properties that are comparable to products made using traditional manufacturing methods such as injection molding.

Screwdriver printed in Nylon 12 Powder. After a simple post-processing, nylon models have a smooth, professional quality surface.

SLS Printable Nylon is an excellent replacement for conventional injection molded plastics. The latches and other mechanical connections produced from it are superior to products created using any other additive manufacturing technology. It is ideal for making functional plastic parts that will work and not break down over time like products created through other additive manufacturing methods.

The latches and other mechanical connections produced from it are superior to products created using any other additive manufacturing technology. It is ideal for making functional plastic parts that will work and not break down over time like products created through other additive manufacturing methods.

When calculating the cost of one model, it is usually necessary to take into account the cost of ownership of equipment, material costs and labor costs:

-

Equipment cost of ownership: The more models a printer can produce over its lifetime, the lower the cost per model. Therefore, higher performance results in a lower cost of ownership per model. With high laser scanning speeds, the ability to produce multiple models at once to maximize the working volume, and a simple post-processing process, SLS 3D printing guarantees the highest productivity of any additive manufacturing method.

-

Material: Most 3D printing technologies use proprietary materials, while nylon is a common thermoplastic that is produced in large quantities for industrial applications.

This makes it one of the most inexpensive raw materials for additive manufacturing. SLS 3D printing requires no support structures and allows you to print with recycled powder with minimal waste.

This makes it one of the most inexpensive raw materials for additive manufacturing. SLS 3D printing requires no support structures and allows you to print with recycled powder with minimal waste. -

Labor: Labor is a disadvantage of many 3D printing solutions. Work processes in most technologies are quite laborious and difficult to automate, which can significantly affect the cost of one model. Easy post-processing with SLS printing reduces manual labor and allows for easy scalability.

A 3D printer with SLS technology is a significant investment initially, but this investment often pays off even faster than buying smaller devices. SLS for workshop technology significantly reduces initial acquisition costs and also reduces model costs in most applications.

If 3D printing is rarely used in your business, it is recommended to use the services of third-party service bureaus. But in this case, the cash costs will be higher and you will have to wait longer for the order to be completed. One of the main advantages of 3D printing is its speed compared to traditional production methods. But this advantage loses its value when it takes up to several weeks for a third-party company to deliver a model.

One of the main advantages of 3D printing is its speed compared to traditional production methods. But this advantage loses its value when it takes up to several weeks for a third-party company to deliver a model.

REEKON Tools

In many cases, for the production of limited or small trial runs, selective laser sintering is a cost-effective alternative to injection molding.

In many cases, for the production of limited or small trial runs, selective laser sintering is a cost-effective alternative to injection molding.  3% of the global additive manufacturing market. According to Market Research Future (MRFR), the cumulative annual growth rate of the global medical device 3D printing market in 2018-2023 is estimated at 18%.

3% of the global additive manufacturing market. According to Market Research Future (MRFR), the cumulative annual growth rate of the global medical device 3D printing market in 2018-2023 is estimated at 18%.

In the case of transplantation, 3D models help to develop detailed and individual plans for operations and select exactly the right organs.

In the case of transplantation, 3D models help to develop detailed and individual plans for operations and select exactly the right organs.  The first of them uses a thermoplastic thread or granules as a consumable, the second uses a photopolymer resin, the third uses polyamide or modified powders.

The first of them uses a thermoplastic thread or granules as a consumable, the second uses a photopolymer resin, the third uses polyamide or modified powders.  Topological optimization solves such important tasks for prosthetics as:

Topological optimization solves such important tasks for prosthetics as:

HP Jet Fusion technology was used to recreate the various components of the forearm. After manufacturing, all parts were finished and painted.

HP Jet Fusion technology was used to recreate the various components of the forearm. After manufacturing, all parts were finished and painted.  Then, after the doctors planned the operation on a mock-up, the prosthesis was 3D printed. The patient, whose hip joint was almost destroyed as a result of an injury, got to his feet.

Then, after the doctors planned the operation on a mock-up, the prosthesis was 3D printed. The patient, whose hip joint was almost destroyed as a result of an injury, got to his feet.  Using a 3D printer, models of a blood vessel and aneurysm can be printed, which will help the surgeon better understand the anatomical structure. A life-size 3D printed model can be used to visually demonstrate blood vessels and aneurysms.

Using a 3D printer, models of a blood vessel and aneurysm can be printed, which will help the surgeon better understand the anatomical structure. A life-size 3D printed model can be used to visually demonstrate blood vessels and aneurysms.

Leading scientific and medical centers are developing new technologies and conducting clinical research in this area.

Leading scientific and medical centers are developing new technologies and conducting clinical research in this area.