3D printing farming

3D Print Farm - Behind the Scenes

Learn Blog

3D printing is a hallmark manufacturing technique for rapid prototyping, however in more recent years it has taken on the role of a primary production method. A 3D print farm is a group of 3D printers that run simultaneously and as continuously as possible to increase production rates of printed parts. In order for a print farm to function at high efficiency, it is essential to minimize printer down time.

Two factors that limit print farm efficiency: lack of printer automation and printer reliability. The machines need to run for long periods of time without failure or depletion in part quality, and transitions between prints need to be as seamless as possible. Without these key automation and reliability factors, managing large quantities of printers can become tedious and time consuming. Markforged printers have several unique features that make them ideal for running a print farm.

In fact, Markforged houses its own 3D print farm, where 25 printers - a mix of Onyx Ones, Onyx Pros, Mark Twos, and Mark Xs - crank out thousands of sample parts each week. The print farm produced 10,500 sample parts just in the month of May, with a yield rate of about 92%.

System Features

The unique marriage of quality software, hardware, and materials across Markforged products makes this small factory not only effective, but straightforward to implement.

To start, Markforged employs streamlined communication across every component of the 3D printing experience. Liveprint monitoring in Eiger allows the freedom to leave many printers running unattended.

With live print monitoring, users can track their prints and receive notifications when jobs are completed or if any utilities require attention.

The newly updated print queue functionality for each printer allows large sequences of prints to be organized across many different printers and managed with ease. Additionally, out of material warnings keep track of filament supply to ensure that someone is readily available to replace the spools when they run out.

The Mark X has the capability to sense exactly when filament runs out. All other Markforged printers use the weight of the filament spool to estimate when it will run out so users can get the most out of their material.

On the hardware side, the kinematic coupling that secures the build plate of all Markforged printers allows the plate to be removed and re-installed with up to 10 micron accuracy. This minimizes the need for bed releveling so less time is spent calibrating and more time is spent printing. The hardware is designed for continuous use so all printers are prepared to run for long hours without risk of overheating or mechanical failure.

Our materials provide another advantage in print farming. The resolution of our printers and the quality of our filament ensure production caliber surface finish that requires minimal post processing. All materials and processes are office friendly, so no special facilities or disposal procedures are needed for operation.

3D Print Farm Operations

In the Markforged 3D print farm, one person is responsible for removing parts from print beds and setting up the printers for their next job. This person cleans the print beds daily and runs utilities twice a week. They also carry out maintenance jobs, such as nozzle replacements and calibration, when required.

The print farm mimics the nature of all Markforged products; user friendly, clean, and astonishingly quiet. Because the print farm setup is so easily implementable, it can be replicated even in an office environment. We have found that Trinity wire racks work great for our print farm because they can hold four printers and four dry boxes with additional space available on the bottom shelf for tools and bins to organize finished parts. Up to 8 printers can be powered on 120 volts and 20 amps, standardly provided by most building codes in the United States.

Up to 8 printers can be powered on 120 volts and 20 amps, standardly provided by most building codes in the United States.

Our print farm is a nearly fully autonomous factory, boasting 75% uptime over a 24 hour day running six days a week. No mess, no fuss, no sound, no smell. Just high quality parts made possible through the fully integrated Markforged ecosystem.

Experience a Markforged printer firsthand by requesting a demo!

All of the blogs and the information contained within those blogs are copyright by Markforged, Inc. and may not be copied, modified, or adopted in any way without our written permission. Our blogs may contain our service marks or trademarks, as well as of those our affiliates. Your use of our blogs does not constitute any right or license for you to use our service marks or trademarks without our prior permission. Markforged Information provided in our blogs should not be considered professional advice. We are under no obligation to update or revise blogs based on new information, subsequent events, or otherwise.

Your use of our blogs does not constitute any right or license for you to use our service marks or trademarks without our prior permission. Markforged Information provided in our blogs should not be considered professional advice. We are under no obligation to update or revise blogs based on new information, subsequent events, or otherwise.

Never miss an article

Subscribe to get new Markforged content in your inbox

required required requiredSubmit

Thanks!

Top 7 of the best projects

Posted By Lucie Gaget on Jul 4, 2018 |

Additive manufacturing is a great asset for many different industries and can be used for various applications. You may not know it, but agriculture is one of the industries starting to make the most of the cutting-edge technology that is 3D printing. You will see in this blog post what are the benefits of this technology for agriculture and what are the most innovative projects developed in this sector. From urban gardens to 3D printed tools, we will see how additive manufacturing is helping the development of agriculture. Follow the guide.

You will see in this blog post what are the benefits of this technology for agriculture and what are the most innovative projects developed in this sector. From urban gardens to 3D printed tools, we will see how additive manufacturing is helping the development of agriculture. Follow the guide.

The benefits of 3D printing for agriculture

Mass customization

Agriculture and technology have a lot to do together. For food production, farm equipment, farming products, 3D printing could be a great asset and simplify a lot of processes. 3D printing is the perfect tool for mass-customization. Indeed, you should know that this technology is perfect to create custom-made objects for many different sectors such as medical or automotive.

For agriculture, this mass-customization aspect is also a great advantage. Indeed, it is particularly convenient to get 3D printed tools, for example. This way, the tools can be adapted to the activity and their really specific use. Indeed, using digital manufacturing is a great way to manufacture objects that you have designed perfectly.

Indeed, using digital manufacturing is a great way to manufacture objects that you have designed perfectly.

Useful both for prototyping and production

Moreover, this technique can be used both for prototype and production. Indeed, 3D printing is a great asset for your prototyping process but is now becoming an amazing production technique for various projects, as new resistant 3D printing materials are now available on the market. Check out our 3D printing material page to get more information about the materials that we are offering on our online 3D printing service.

Moreover, 3D printing is really a great advantage as farmers can really print devices on demand. It is especially useful to print devices in remote areas.

Plastic and metal 3D printing can totally be used for agriculture projects. But for what applications can 3D printing can be used in agriculture? What has been made? Discover the best applications of this cutting-edge technology for agriculture now.

The best 3D printing projects in agriculture

Here is a selection of the most interesting and innovative projects for agriculture using the 3D printing technology. Get inspired!

Farmers in Myanmar using 3D printing to create tools

Additive manufacturing is a great technique to improve some processes that are already existing. It can help farmers to manufacture traditional equipment and tools. That is exactly the technique used by farmers in Myanmar.

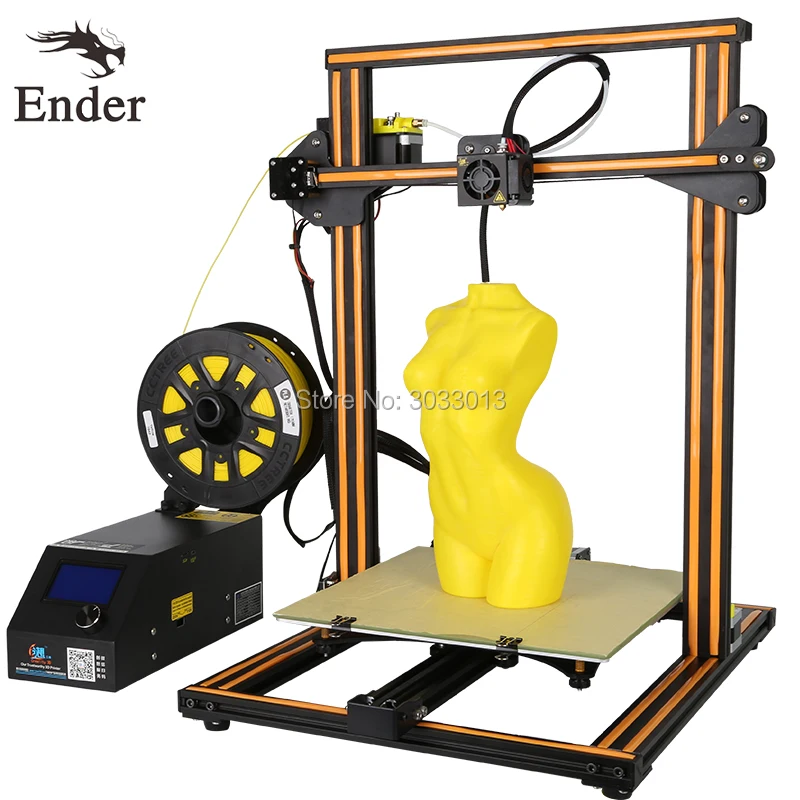

They were first using CNC machines to prototype their tools, but it was quite slow and expensive. Including the 3D printing technology in their production process helped them to create quality tools more quickly and improve their manufacturing process. This way, they can totally adapt the tools to their use and improve their farming activities. Moreover, for this kind of use, desktop 3D printer are great because they allow them to print directly on place.

https://3dprint.com/149881/myanmar-makerbot-farming/

3D printing, a great advantage for African agriculture

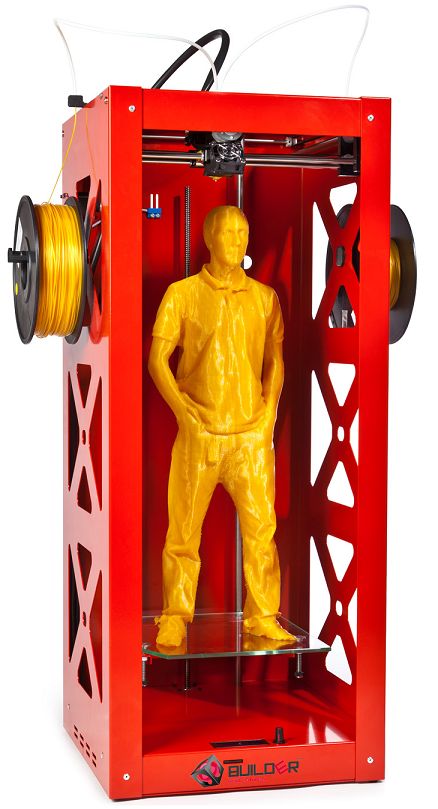

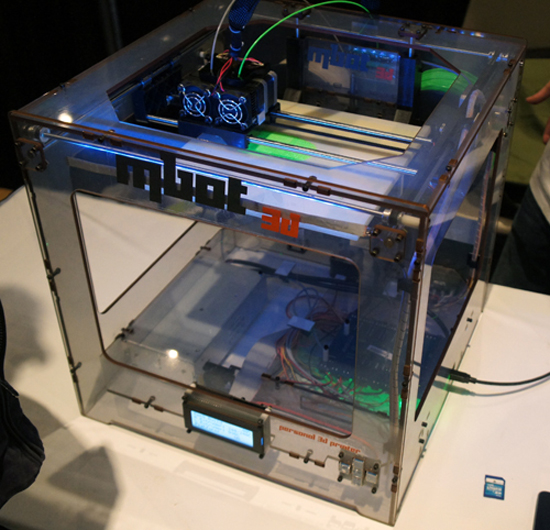

In some African countries such as Togo, farmers still have a difficult access to mechanized equipment. Sénamé Koffi Agbodjinou, founded an African digital fablab, he designed a 3D printer and built it only using waste and electronic components he found in the street. This 3D printer is working perfectly and helps local farmer to prototype their own tools. This additive manufacturing technology actually boosts their crop yields as they are free to produce all the tools that they need.

Sénamé Koffi Agbodjinou, founded an African digital fablab, he designed a 3D printer and built it only using waste and electronic components he found in the street. This 3D printer is working perfectly and helps local farmer to prototype their own tools. This additive manufacturing technology actually boosts their crop yields as they are free to produce all the tools that they need.

3D printed machine parts for agriculture

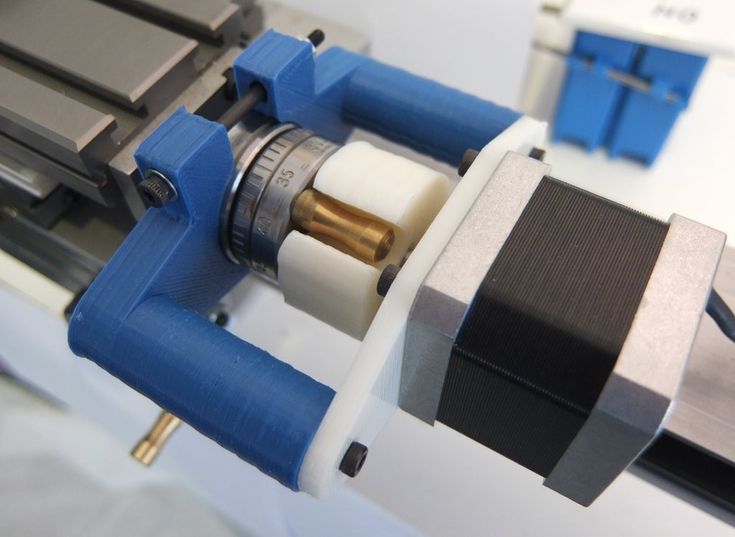

Most of the time, farmers are working with specialized machines. These are massive and expensive machines. Even to replace just one part, it can be quite expensive. Or the part that the farmer is searching for is maybe not on the market anymore. In this case, additive manufacturing is an amazing solution. Just like for the automotive industry, it is possible to print spare parts for farming machines. That is exactly the project of GVL Proto Poly. They are actually receiving a lot of 3D printing demands from farmers looking for new parts for their machines.

This project requires large 3D printers. With the quick evolutions made in the 3D printing industry, it will be soon more convenient to 3D print large parts like these in only one time.

https://www.3ders.org/articles/20141003-minnesota-company-bringing-3d-printing-services-to-individual-farms.html

3D printing for urban farming

The company Farmshelf has developed an autonomous system allowing anybody to start a smart indoor farm. Developing a new business is hard and quite expensive. Thanks to 3D printing some entrepreneurs are able to save time and money by using additive manufacturing to develop some parts of their project. And that is what the compan Farmshelf did.

3D printing allowed them to design the right parts for their project like mounting brackets and plant hangings. Then they were able to print custom parts quite quickly and test them. This would have been more expensive and would have taken more time with traditional manufacturing technique such as injection molding.

Custom 3D printed parts. credit: https://3dprint.com/198409/ultimaker-2-farmshelf-parts/

Small-scale organic farms in developing countries using 3D printing

Michigan Technological University’s Dr. Joshua Pearce made a whole study on how open source 3D printing could help small farms. Indeed, most of the world’s organically managed land is located in developing countries. And the thing is that farmers located in these countries are using labor-intensive tools. Thanks to additive manufacturing, it is possible to manufacture other efficient tools that could fit better the use of the local farmers. It could help organic farms, but also animal and water management!

Sustainable indoor garden using 3D printed connectors

Here is the project of an Italian start-up Hexagro Urban Farming. This company is trying to innovate with urban farming and hanging gardens. They choose to 3D print the little connectors of their Living Farming Tree:

https://www. hexagrourbanfarming.com/

hexagrourbanfarming.com/

Here is what a 3D printed connector look like:

https://www.hexagrourbanfarming.com/

These connectors can be adapted to any use of the tree and to the specific needs of the customers. The design can be customized to fit any place. This Living Farming Tree will be brought to the market quickly as the 3D printing technology is actually improving the whole product development, by making it really easier for Hexagro Urban Farming.

For more details about Hexagro Urban Farming, check out the video below:

3D printing to test agricultural devices

A Canada-based company has produced 3D printed parts in order help test a high-technological crop seeding system. Additive manufacturing is here really useful for the Research and Development department, allowing to test a whole device and create many iterations in order to develop the best product possible.

https://3dprint.com/48469/3d-printing-groundbreaking/

The ultimate part is made of cast iron and carbide because the parts need durability and strength. But for the test process, 3D printed parts can actually hold up the physical pressure. As it is really cheaper to test a 3D printed parts, and the process is also quite simple: they just have to modify their digital 3D model to get a different part. This way, they are able to make as many iterations as they need to develop their project. Thanks to this technique the company saved a lot of money!

But for the test process, 3D printed parts can actually hold up the physical pressure. As it is really cheaper to test a 3D printed parts, and the process is also quite simple: they just have to modify their digital 3D model to get a different part. This way, they are able to make as many iterations as they need to develop their project. Thanks to this technique the company saved a lot of money!

Metal is expensive, and metal 3D printing is expensive too. That is way using another resistant 3D printing material is perfect for these kinds of projects.

The future of 3D printing for agriculture

A lot of applications are already possible in the farming sector using 3D printing, but it will certainly evolve in the upcoming years and become even more integrated into agriculture. Indeed, this technology has many benefits to bring to the farming sector, from tools to more elaborated devices. We obviously need more 3D printers in agriculture, the use of the 3D printing technology needs to be developed.

The 3D printing industry still has a lot to offer to agriculture. 3D printing in agriculture will certainly become more common.

More and more projects are bringing together 3D printing and recycling. For example, 3D printing could be a great solution to recycle plastic or metal materials laying around a farm. These materials could totally be used to recreated new tools or any other useful 3D printable device.

Do you have a farming project that you would like to 3D print? Upload your 3D files right now on our online 3D printing service.

We hope that you can now see the benefits of 3D printing for agriculture.

If you want to read more blog post about different 3D printing application, don’t hesitate to subscribe to our weekly newsletter.

3D printing in agriculture. Agroindustry and 3D printing.

Agriculture has long ceased to be low-tech. On the contrary, this industry is becoming more and more optimized every year. Ordinary farmers are working to increase productivity and make work easier. Scientific institutions are developing new, more efficient methods of work. It is not surprising that 3D technologies have also found application in agriculture.

Ordinary farmers are working to increase productivity and make work easier. Scientific institutions are developing new, more efficient methods of work. It is not surprising that 3D technologies have also found application in agriculture.

Somewhere in America…

Minnesota is home to GVL Proto Poly, which has been involved in agriculture since 2012. The company motivated its decision by the fact that this industry uses a large number of highly specialized machines that need not only regular repair and service work, but also modernization. That is why the company decided to use 3D printing, since only these technologies can offer a huge number of settings and exclusivity, coupled with an adequate prototype cost, greater variability. For their work, the specialists organized a huge 3D printer that occupies an entire room. Printing sometimes takes a whole day, but this is also fast, because waiting for the delivery of a part, its development used to take months.

Special attention deserves close cooperation with farmers, who help to improve the existing equipment, modernize it. It is the farmers who have to work with the equipment every day and it is they who have practical skills, see what can be improved in order to get maximum performance.

It is the farmers who have to work with the equipment every day and it is they who have practical skills, see what can be improved in order to get maximum performance.

The demand for unique, customized solutions for farmers is growing steadily. And at the very beginning, no one believed in the success of GVL Proto Poly in this field.

In Russia, this case is still in its infancy, but even here there are certain advances.

And what about our agriculture?

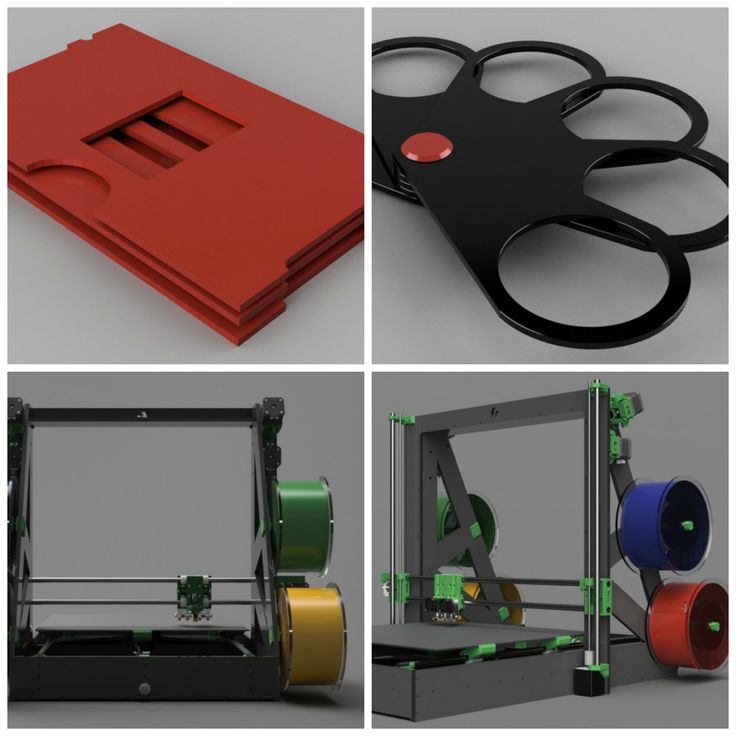

Federal Scientific Agroengineering Center "All-Russian Institute of Mechanization" is actively engaged in the development and implementation of various types of equipment in agriculture. This is a large center that has been actively using 3D printing and 3D scanning since 2018. It was this equipment that made it possible to reduce the time from development to the appearance of the first, including functional prototypes. At the moment, the fleet of VIM 3D printers includes several models:

- PICASO 3D printers

- Formlabs 3D printers

- Hercules 3D printers

Thus, printing is carried out using several technologies: FDM, SLA, SLS. Thus, it is possible to solve almost all tasks with maximum efficiency. Firstly, the devices have different working volumes, and secondly, they work with materials of different characteristics. This allows you to create not only functional prototypes of products, parts of mechanisms, but also experimental batches of cases, brackets, master models for casting.

Thus, it is possible to solve almost all tasks with maximum efficiency. Firstly, the devices have different working volumes, and secondly, they work with materials of different characteristics. This allows you to create not only functional prototypes of products, parts of mechanisms, but also experimental batches of cases, brackets, master models for casting.

With this equipment, it is possible to produce both prototypes of equipment and equipment for testing solutions, in particular milking machines, etc.

Possibilities of 3D printing in agriculture

We can confidently talk about the high efficiency of 3D printing in the field of agriculture. (More articles about various applications can be found HERE). But these opportunities are open not only to large scientific institutions and companies, but also to ordinary people and individual households. The main advantage of 3D technologies is their accessibility.

If you have any developments, drawings, you want to make a unique solution a reality, to upgrade existing equipment. Or maybe you just lost some detail, and it takes a very long time to wait for it from abroad, but in agriculture every hour counts, let alone a day, then in any of these cases 3D printing can come to the rescue .

Or maybe you just lost some detail, and it takes a very long time to wait for it from abroad, but in agriculture every hour counts, let alone a day, then in any of these cases 3D printing can come to the rescue .

3DServices makes 3D printing accessible to everyone. Do you have any questions? Contact our specialists through the form on the website, by phone +7(495) 134-56-42 or e-mail [email protected]

3D printing for creating light and spore traps for agriculture

Application

Subscribe to the author

Subscribe

Not want

10

Can 3D printing be used in agriculture? Of course! Today we will tell you about the use of the Designer X 3D printer in the Laboratory for Phytosanitary Monitoring of Agroecosystems of the Federal Scientific Center for Biological Plant Protection.

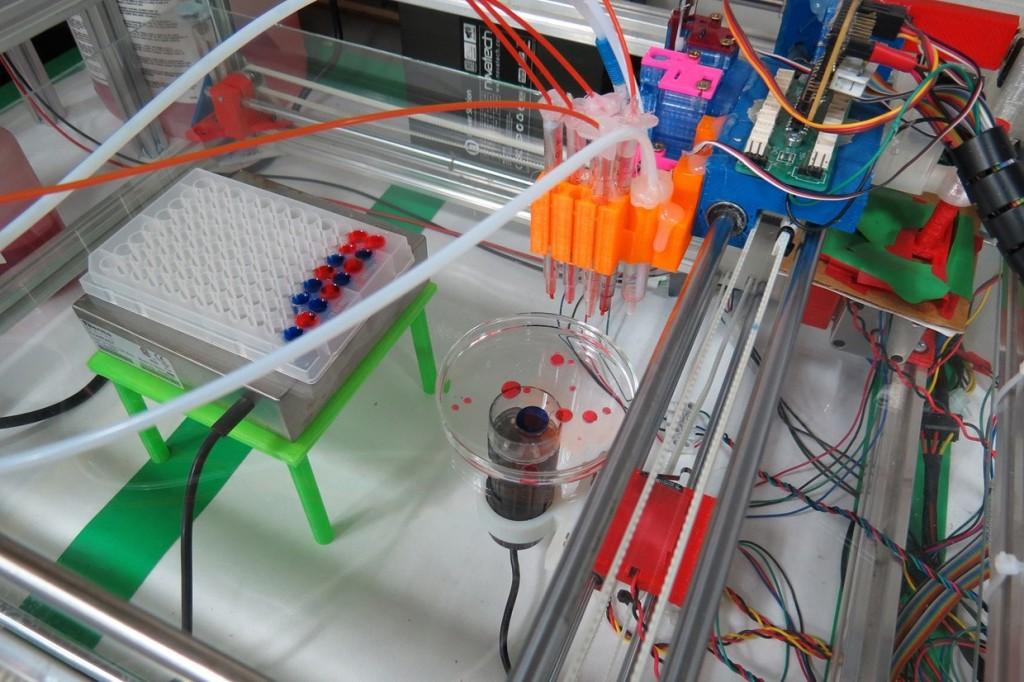

Using the printer, the laboratory develops devices that are used in the monitoring of plant diseases and pests, as well as in pest control.

Testing of devices is carried out in various organizations: Federal State Budgetary Educational Institution Rosselkhoztsentr, Syngenta LLC, large and small agricultural producers.

Aleksey Pachkin, Ph.D., Senior Researcher, Laboratory of Phytosanitary Monitoring.

Plant protection against diseases and pests is based on the so-called phytosanitary monitoring. Its essence is to assess the state of populations of diseases and pests by surveying crops. Visual counts and counts are carried out using various devices. The final result depends on the quality of the examinations - making decisions on the implementation of treatments, the timing of the implementation, the plant protection products used (chemicals, biological products), etc.

In our laboratory, 3D printers, including Designer X, are used for printing the cases of devices that we develop, as well as for various equipment. We work mainly with ABS and PETG.

We work mainly with ABS and PETG.

The first device I want to talk about is light traps for insects.

Light traps use the ability of insects to fly towards light (positive phototaxis) and selectivity in the light spectrum to attract insects. Those. devices have a specific combination of LED wavelengths. Today, pheromone traps are the most common pest monitoring tool. Their main advantage is species specificity. However, this feature is also a minus in the case when new species appear that have not previously been noted in a particular culture or in certain geographical latitudes. Pheromone traps only catch male insects. In addition, they are not able to catch insects for a long time without replacing special adhesive inserts and are not able to give an objective assessment of the amount of the pest at a very high number.

"Aspiration" trap before 3D printing, printed body and working version.

Our light traps are also highly effective for mass pest control. Tests show the capture of such dangerous pests as cotton bollworm (Helicoverpa armigera) and meadow moth (Loxostege sticticalis) up to 12 thousand specimens per week. At the same time, females and males of insects are caught. One female cotton bollworm, according to various sources, is capable of laying from 300 to 3000 eggs. And one caterpillar can damage, for example, several tomato fruits. Catching one female, we save a large number of agricultural products from damage and reduce the pest population. "Conical" light trap for insects. There are several options for light traps. Our light traps, unlike analogues, are completely autonomous, have minimal weight and power consumption, low price, are safe for warm-blooded and a large number of beneficial insects.

Tests show the capture of such dangerous pests as cotton bollworm (Helicoverpa armigera) and meadow moth (Loxostege sticticalis) up to 12 thousand specimens per week. At the same time, females and males of insects are caught. One female cotton bollworm, according to various sources, is capable of laying from 300 to 3000 eggs. And one caterpillar can damage, for example, several tomato fruits. Catching one female, we save a large number of agricultural products from damage and reduce the pest population. "Conical" light trap for insects. There are several options for light traps. Our light traps, unlike analogues, are completely autonomous, have minimal weight and power consumption, low price, are safe for warm-blooded and a large number of beneficial insects.

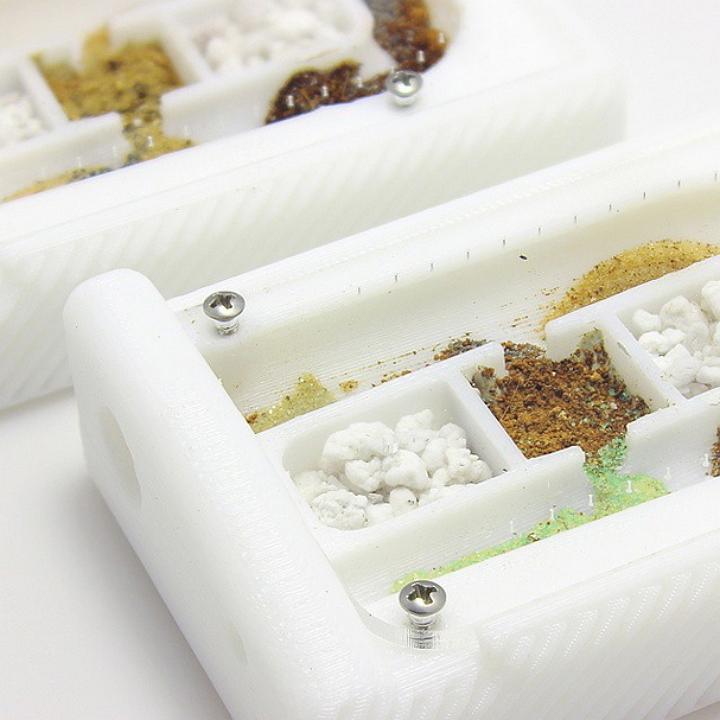

Another development example is spore traps.

Spore traps of various designs (vane, OZR, PSL) perform one function - trapping spores of fungal plant diseases. Vane - stationary trap capable of taking 1 sample. ORM is a mobile device used manually, taking up to 10 samples. PSL - used in conjunction with a UAV (drone) up to 10 samples. Those. remote monitoring takes place with the possibility of linking GPS coordinates and remote detection of disease foci, which is very typical for most plant diseases. GPS binding allows you to identify foci and treat only infected areas of agricultural crops.

Vane - stationary trap capable of taking 1 sample. ORM is a mobile device used manually, taking up to 10 samples. PSL - used in conjunction with a UAV (drone) up to 10 samples. Those. remote monitoring takes place with the possibility of linking GPS coordinates and remote detection of disease foci, which is very typical for most plant diseases. GPS binding allows you to identify foci and treat only infected areas of agricultural crops.

Vane spore trap before printing and 3D printed by Designer X.

Today, all treatments against diseases are carried out when the plant is already infected with a pathogen and sporulation and other signs of disease are visible on its surface. Those. the fungus has already invaded the plant, and only so-called systemic preparations (systemic fungicides) can destroy it there. These are harmful, including for humans, chemicals. In this case, the plant experiences stress from being infected with a disease, then it experiences stress when treated with chemicals.