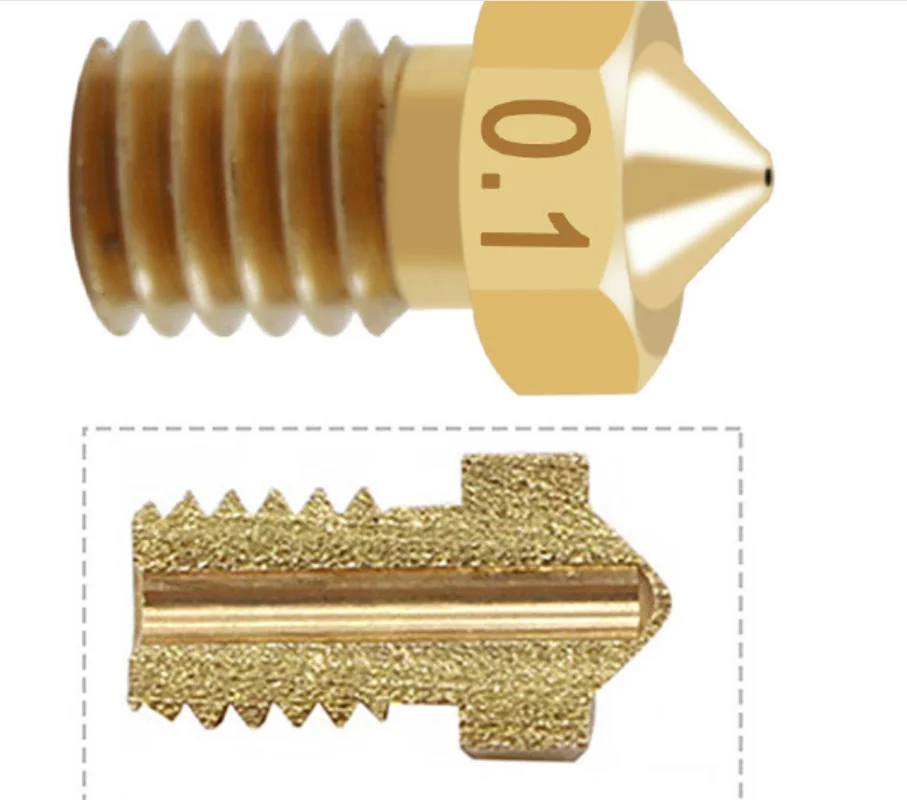

Tungsten carbide 3d printer nozzle

Tungsten carbide nozzle - Durability and performance

Our warehouse will be closed from December 24th to January 1st. All orders made after December 20th could only get processed on and after January 2nd.

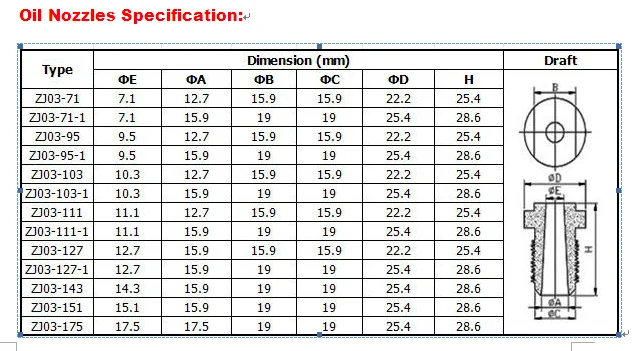

Refer to the nozzle body compatibility chart below to select the correct nozzle for your hotend

✕

Rated 4.50 out of 5 based on 10 customer ratings

(10 customer reviews)

CA$75.00

3D printer nozzle in tungsten carbide for the ultimate balance between wear resistance and high performance.

| Range | Discount |

|---|---|

| 3 + | 10% CA$67.50 |

Share

0

- Description

- Features

- Technical Information

- 1

- Reviews 10

Tungsten Carbide: High flow with abrasion resistance

Tungsten carbide, not to be confounded with tungsten alloy, which is metal, is the ceramic of choice when it comes to wear and abrasion resistance. Cutting tools for steel and tool steel are made from tungsten carbide. It is also used extensively in the mining industry as a button insert for crushing rocks.

The high thermal performance of the tungsten carbide keeps the nozzle tip hot, thus allowing faster printing speed without sacrificing the quality.

Tungsten carbide has exceptional wear resistance due to its high hardness. Both the nozzle hole size and height will always stay the same, no matter how long or how hard you use it.

Compared to a reference brass nozzle, the tungsten carbide nozzle is much easier to extrude. In fact, the output flow can be increased by around 80% while having the same results.

For more information: https://dyzedesign.com/tungsten-carbide-nozzle/

Ultra wear resistant

The high hardness of tungsten carbide will provide a carefree extrusion experience. Its unparalleled wear resistance will ensure that both the nozzle diameter and flat will keep the same dimension, and so will your printed parts.

Low pushing force

The high thermal conductivity of both the nozzle tip and body will pump all the required heat to maintain an even temperature while extruding. Viscosity highly depends on the plastic temperature for a constant shear rate. The flow pressure will be constant resulting in excellent results and stability. The ease of pushing the filament will give an extra margin for your extruder safety.

Faster speed

Due to the high thermal performance of the nozzle in general, the printing speed can be pushed even further without sacrificing the quality. The special shape inside the nozzle allowed by the manufacturing technique improves the flow where the diameter gets reduced, thus allowing a faster flow rate.

Low friction

The whole nozzle is electroless nickel plated for enhanced slippery properties. Plastic will slide on the nozzle instead of sticking to it. This result is cleaner parts and less dragging problems.

Any material

From printing PLA to carbon fiber reinforced plastics, this nozzle can handle anything. The low friction coating greatly helps with flexible filaments allowing, them to slide through the nozzle. A single nozzle will offer quality prints, wear resistance, and high flow, so there is no need to get a ton of different nozzles when a single one can offer the best of all worlds.

The low friction coating greatly helps with flexible filaments allowing, them to slide through the nozzle. A single nozzle will offer quality prints, wear resistance, and high flow, so there is no need to get a ton of different nozzles when a single one can offer the best of all worlds.

Unbeatable price/performance

Tungsten carbide is easier to produce than corundum (Sapphire, Ruby, etc) and the performance is very similar for abrasion and much more performant for thermal conductivity. The use of steel makes it very easy to manufacture and offers amazing thermal performance. The whole package is a win-win situation in terms of performance and price.

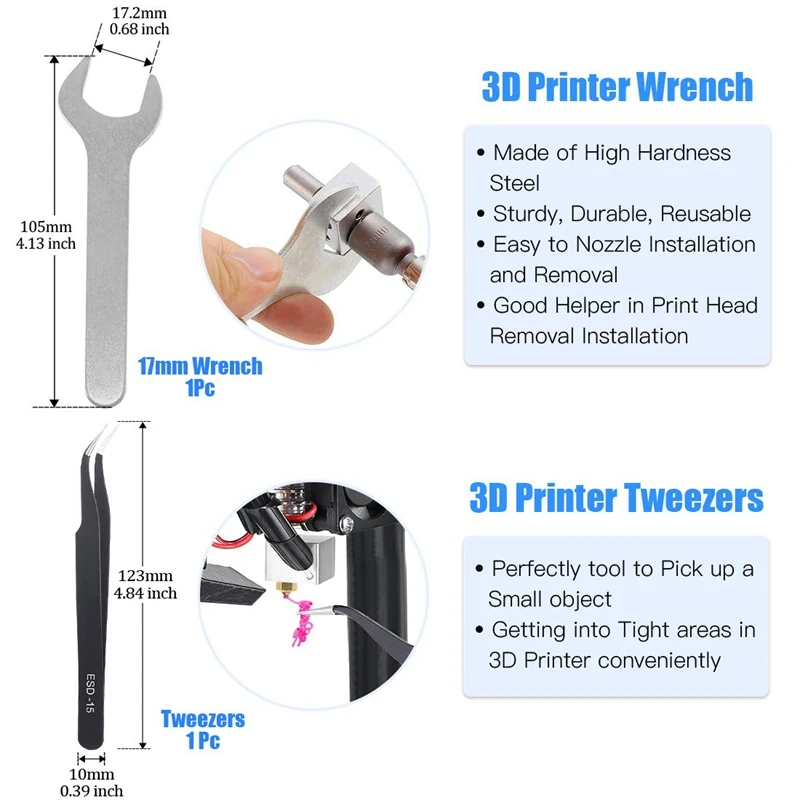

Refer for the following table for absolute maximum torque. Make sure your hotend specification are within these limits.

✕

| T (°C) | Maximum torque (Nm) | |||||

| M6-1.75mm | M6-3.00mm | M6-3. 00mm HF 00mm HF | M7 MK10 | M10 | UM3 | |

| 25 | 1.9 | 1.7 | 1.7 | 2.7 | 10.1 | 1.9 |

| 200 | 1.6 | 1.4 | 1.4 | 2.2 | 8.2 | 1.5 |

| 300 | 1.3 | 1.2 | 1.2 | 1.9 | 7.1 | 1.3 |

| 400 | 1.1 | 1.0 | 1.0 | 1.6 | 5.9 | 1.1 |

| General specifications | |

|---|---|

| Housing material | High thermal conductivity steel |

| Tip material | Tungsten carbide, Fine Grade |

| Is electrical conductive | Yes |

| Maximum working temperature | 500 °C |

| Maximum working pressure | 25 MPa |

| 3D Printer | |||

| Tungsten Carbide UM3 | Tungsten Carbide M7 MK10 | Tungsten Carbide M6 1. 75mm 75mm | Tungsten Carbide M6 High Flow 3.00mm |

| Ultimaker 3 | FlashForge Creator Pro | Raise3D N1 | 3D Platform |

| FlashForge Creator X | Raise 3D N2 | LulzBot Taz 5 MoarStruder | |

| FlashForge Dreamer | Raise 3D N2 Plus | LulzBot Taz 6 MoarStruder | |

| FlashForge Finder | Prusa i3 MK2 | ||

| Qidi Tech X-One | Prusa i3 MK3 | ||

| Qidi Tech I | E3D BigBox | ||

| PowerSpec 3D X | gCreate gMax 15XT+ | ||

| Wanhao i3 V2.1 | Makerbot Replicator 2 | ||

| Wanhao i3 Plus | Makerbot Replicator 2X | ||

| Wanhao Duplicator 6 | Felix Pro 2 | ||

| Wanhao Duplicator 6 Plus | Creality CR-10 | ||

| Wanhao Duplicator 9 | MakerBot Replicator 5th Gen | ||

| Monoprice Maker Select 3D Printer v2 | MakerBot Replicator Mini | ||

| Monoprice Maker Select Plus | MakerBot Replicator z18 | ||

| Cocoon Create 3D Printer | CraftBot 2 | ||

| CraftBot Plus | |||

| Ender 3 | |||

| BQ Witbox | |||

| BQ Prusa I3 Hephestos | |||

| Robo R1 | |||

| Robo R1 +PLUS | |||

| RoboC2 | |||

| RoboR2 | |||

| Wanhao i3 Mini | |||

| Wanhao Duplicator 4S | |||

| FlashForge Creator Original | |||

| 3D Printer Hotends | ||||

| Tungsten Carbide UM3 | Tungsten Carbide M6 3. 00mm 00mm | Tungsten Carbide M6 High Flow 3.00mm | Tungsten Carbide M6 1.75mm | Tungsten Carbide M7 MK10 |

| Ultimaker Heatcore | Hexagon | e3D Volcano | Hexagon | MK10 |

| e3D | LulzBot | e3D | ||

| Olson Block | ||||

| Not Compatible | |||

| M6 3.50mm nozzles | Fine Thread | Female Thread | Fixed Heatbreak |

| Afinia h579 | WANHAO duplicator 5 | Printrbot Ubis | Phaetus Dragon Hotend |

| Afinia h580 | WANHAO Duplicator 5S | ||

| Up Plus | WANHAO Duplicator 5S MINI | ||

| Up Plus 2 | |||

| Up mini | |||

| Zortrax M200 | |||

M6 Tungsten Carbide M6 Nozzle | Canada

While the idea of this nozzle is fantastic, and the nozzle itself seems great, it just will not stay tight on my stock aluminum E3D heater block on a stock Prusa i3. It'll be great for maybe 5-10 prints but then it will have loosened itself enough that filament starts leaking up the top of the heating block and burnt filament dribbles down in blobs randomly into your print, making things a mess. (It also doesn't help that, having loosened itself, it will have messed up your carefully calibrated base Z layer offset).

I can go back and re-tighten it to 3Nm (and recalibrate the base layer), and it'll work for a while again, but after a few days the dreaded blobs of burnt gunk start showing up to ruin my prints again.

There are lots of reports of this happening with tungsten carbide nozzles, unfortunately (in general: not just this one): the leading hypothesis seems to be that the thermal expansion properties of tungsten carbide and aluminum are too dissimilar for it to stay tight. People with copper blocks (like the E3D plated copper block, also sold here) seem to have much less trouble.

So if you have a stock E3D heat block (which is what a Prusa i3 comes with) either stay away from this nozzle, or also upgrade your heater block at the same time.

It'll be great for maybe 5-10 prints but then it will have loosened itself enough that filament starts leaking up the top of the heating block and burnt filament dribbles down in blobs randomly into your print, making things a mess. (It also doesn't help that, having loosened itself, it will have messed up your carefully calibrated base Z layer offset).

I can go back and re-tighten it to 3Nm (and recalibrate the base layer), and it'll work for a while again, but after a few days the dreaded blobs of burnt gunk start showing up to ruin my prints again.

There are lots of reports of this happening with tungsten carbide nozzles, unfortunately (in general: not just this one): the leading hypothesis seems to be that the thermal expansion properties of tungsten carbide and aluminum are too dissimilar for it to stay tight. People with copper blocks (like the E3D plated copper block, also sold here) seem to have much less trouble.

So if you have a stock E3D heat block (which is what a Prusa i3 comes with) either stay away from this nozzle, or also upgrade your heater block at the same time.

Posted by Jason, December 11, 2022

I use tungsten carbide nozzles on all my Prusa printers and haven't had any problems with the Spool3D brand. Unlike other brands, it's solid tungsten carbide, not an alloy, and not just the tip. And unlike hardened steel I never had to change any of my print profiles, the thermal properties are very close to brass or coated copper. Spool3D seems to be the only manufacturer covering a broad spectrum of TC nozzle sizes. The nozzles are not cheap, especially if you factor in shipping to the U.S., but (I hope) they'll last forever.

Posted by Rainer Fuchs, August 16, 2022

The thermal specs of this nozzle were worse than hardened steel. It is supposed to be similar to brass. Carbon fibre prints failed so I ran some tests with PLA. Brass nozzle 210C had great layer adhesion and printing. Hardened steel nozzle 215C had good prints. Tungsten carbide nozzle: 210C extruder grinds filament after a couple layers, 215C no layer adhesion, 220C layers adhering but still weaker than normal, 225C good print. Put the brass nozzle back on and 210C had perfect prints again. This TC nozzle did not live up to its specifications.

Put the brass nozzle back on and 210C had perfect prints again. This TC nozzle did not live up to its specifications.

Posted by Tom Dakin, May 21, 2022

Solid product, prints at temps same as brass nozzles. Inside is not as polished but that’s because carbide is though to work with. For such price it should have come in nice metal box in foam like Phaetus recently introduced carbide nozzles (they only have a carbide tip like Dyzedesign), not in a plastic bag. Shipping to europe is crazy expensive, coming in bubble envelope. Guys, you should really work more on presentation of a product and do something with shipping as it definitely doesn’t cost that much via regular post.

Posted by Jozef Remen, January 20, 2022

Perfect with spool3d carbon fiber

Posted by Bruno, January 10, 2022

I've only had it for a week (after being held up by Fedex at the Canadian/US Border for two weeks...). But so far it's performing great. Excellent prints with my Prusa Mk3S+ using standard profiles, no need for adjustments.

Excellent prints with my Prusa Mk3S+ using standard profiles, no need for adjustments.

Posted by fuchsr, December 23, 2021

I've got around 50-100 hours of use with abrasive filaments on this nozzle and it has performed wonderfully, and consistently. Brass nozzles would require swapping every 20-40 hours or so on the same filament. Having used both this and the Dyze design tungsten carbide nozzle, this one is superior, because it is made of tungsten carbide all the way through, whereas the Dyze design version has a steel housing with just a tungsten carbide tip. This means the Spool3D tungsten carbide nozzle has better thermal conductivity performance which rivals brass and wont require you to change print temps to compensate for a steel or steel-core nozzle. Of course the shipping price stinks, hopefully they can do something about that! Excellent product.

Posted by Jaanisar, September 23, 2021

20$ shipping and VAT appearently was not included so had to pay an additional 20$ to receive it (TOTAL SCAM, 40$ for a 3g package, costs 3$ with a simple tracked letter). I make thousands of orders and taxes are always covered by the seller

Do not buy if you don't want to get ripped off, just get the olson ruby from prusa website.

I make thousands of orders and taxes are always covered by the seller

Do not buy if you don't want to get ripped off, just get the olson ruby from prusa website.

Posted by Giorgio Ballestin, July 01, 2021

Prusa I3 Mk3S, swapped with stock nozzle, Same Z calibration setting. Did not need to change anything. Printing 3DXTech CarbonX Carbon Fiber PETG Filament without any problems. Using PrusaSlicer Prusament PETG settings.

Posted by Ed Moy, June 04, 2021

I bought this nozzle to use with abrasive filaments, and plan to use it full time in my Prusa i3 MK3s. The product appeared well made, decent surface finish for tungsten carbide. All profiles used with my 0.4mm brass nozzle work great with this, and the print quality is equal if not better. Shipping to the US was fast and easy. I would not hesitate to shop with Spool3D again.

Posted by Ian, October 05, 2020

The idea is great and the M6 nozzle perform like a champ. The only problem is it loosen after a couple of prints. No matter how hard I tighten this thing at a temperature of 280C. I bought cheap brass nozzle and now everything is working perfectly. The thread on my tungsten nozzle is .005" smaller than other nozzles. By the way it is not even in the tolerance range of a M6 x 1 thread major diameter.

I also bought the MK8 version and this one was even more terrible, There was a problem of under extruding. I also went back to a brass nozzle, and everything is working back to normal.

UPDATE: After reaching out the spool3D customer support, they asked me to send back the faulty item and sent me a new one. I have been using the new nozzle since. I am printing glow in the dark and carbon fiber PETG without worrying about the wear. It is printing flawlessly. Thank you very much for the replacement and the fast response.

No matter how hard I tighten this thing at a temperature of 280C. I bought cheap brass nozzle and now everything is working perfectly. The thread on my tungsten nozzle is .005" smaller than other nozzles. By the way it is not even in the tolerance range of a M6 x 1 thread major diameter.

I also bought the MK8 version and this one was even more terrible, There was a problem of under extruding. I also went back to a brass nozzle, and everything is working back to normal.

UPDATE: After reaching out the spool3D customer support, they asked me to send back the faulty item and sent me a new one. I have been using the new nozzle since. I am printing glow in the dark and carbon fiber PETG without worrying about the wear. It is printing flawlessly. Thank you very much for the replacement and the fast response.

Posted by Gabriel, March 29, 2020

Really happy with this. After a lot of printing I can say it prints very well. No need to retune profiles, it works just as well as brass. Handles carbon fiber infused filament. Machining on the inside of the nozzle looked really good, couple really tiny burrs but nothing that would be a problem.

I had to re-tighten mine 3 times before it stopped leaking, might just need more torque versus a brass nozzle. Has been working well since then.

Handles carbon fiber infused filament. Machining on the inside of the nozzle looked really good, couple really tiny burrs but nothing that would be a problem.

I had to re-tighten mine 3 times before it stopped leaking, might just need more torque versus a brass nozzle. Has been working well since then.

Posted by Screwyluie, November 07, 2019

Finally! A robust* nozzle that I can seamlessly use to switch between abrasive and non abrasive filament, without having to worry about which print profile I am using. I love that all my brass profiles work perfectly without changing anything and I still get the same layer adhesion as I would with using the brass nozzle. This was not the case with using a couple of the other more popular hardened steel nozzles. So far I couldn't be more happy with the results. *I only have put a few CF-PETG parts through it so far but given its material should be very robust.

Posted by Cole , October 24, 2019

This is the nozzle of my dreams, good thermal conductivity (good as brass), extreme hardness (as hard as ruby), features one-piece-construction, all with a fair price tag. It looks really good too, the photos do not do this nozzle justice.

The only (non)-issue is that the threads are a very slightly looser fit. However, that does not impact performance in any way.

This is the only nozzle you will ever need.

It looks really good too, the photos do not do this nozzle justice.

The only (non)-issue is that the threads are a very slightly looser fit. However, that does not impact performance in any way.

This is the only nozzle you will ever need.

Posted by Tom Hsia, October 17, 2019

I recommend this tungsten carbide highly. It mechanically matches an E3D brass nozzle close enough that only Live-Z needs to be adjusted. No PINDA repositioning necessary as opposed to a nozzle that is too long or short. Its filament inlet has a small chamfer similar to a E3D brass nozzle. One piece construction means I don't worry about it coming apart or having any portion of it composed of lower conductance steel.

Thermal conductivity is excellent. On the print-fan finicky Mosquito hotend, a hardened vanadium steel nozzle would require a 20 to 30C boost in nozzle temperature to achieve almost brass equivalent filament melt. The Spool3D tungsten carbide nozzle solves that issue completely. I can use my normal brass nozzle print profiles once more.

This nozzle provides both abrasion resistance AND good thermal conductance making it both durable AND capable of printing well. I will not go back to a low conductance, hardened steel nozzle after using tungsten carbide.

I can use my normal brass nozzle print profiles once more.

This nozzle provides both abrasion resistance AND good thermal conductance making it both durable AND capable of printing well. I will not go back to a low conductance, hardened steel nozzle after using tungsten carbide.

Posted by Guy Kuo, August 07, 2019

Early days yet, but nozzle installed easily on my Prusa Mk3S. I’ve printed a few models with carbon fibre reinforced nylon with excellent results. Bodes well for the future. Fast delivery from Spool 3D from Canada to Australia.

Posted by Rick , July 31, 2019

I personally believe this is the best nozzle available anywhere. The flow is super consistent, it heats like a brass nozzle and it will literally last forever. It is the last nozzle you will ever have to buy. Buy this and an E3D pro silicone sock and you'll be set until you need another one for your next printer.

Posted by Donovan Bisharat, March 27, 2019

Works great, Had to turn down temps (normally have hardened steel). I hope to see a .25 nozzle in Tungsten Carbide too.

I hope to see a .25 nozzle in Tungsten Carbide too.

Posted by undefined, January 02, 2019

NOZZLE FOR 3D PRINTER

Popular goods

-

Bearing 604UU U604ZZ

U-bearing U604ZZ 604UU 4*13*4

35.00 UAH

-

Thermokilim for 3D druk 200 x 200 mm

Thermokilim for 3D Druku

150.00 UAH

-

Buy epo3d+ 3D printer

Epo3d+ Ukrainian FDM 3D printer on HIWIN rails. Zavdyaki nadіinіy...

UAH 35,000.00

-

ABS granules

ABS pellets for extrusion

400.

00 UAH

00 UAH -

PLA

PLA environmental plastic from Plexiwire. 100% advance payment....

UAH 375.00

-

Buy ABS plastic (ABS)

ABS plastic from Plexiwire. 100% prepayment. Free shipping...

UAH 220.00

-

Mini motor reducer 12v 100 rpm

high torque mini electric motor. Its size...

150.00 UAH

-

Nozzle for 3D printer 1.

75 mm, for hotends E3D and MK8

75 mm, for hotends E3D and MK8 3D printer nozzle 1.75 mm 0.2/0.3/0.4/0.5

35.00 UAH

-

PETG plastic for 3D printer

PETG plastic from Plexiwire. 100% prepayment. Free...

UAH 360.00

-

SHF-20 shaft support

SHF-20 shaft support is used for CNC

60.00 UAH

-

A4988 crocodile driver

35.00 UAH

-

Buy epo3d 3D printer

Ukrainian 3D printer epo3d based on modern kinematics.

..

.. UAH 18,000.00

All popular items

Catalog

Information

NOZZLE FOR 3D PRINTER

The nozzle is an indispensable component of a 3D printer. There are many different types of nozzles for 3D printers. Standard brass filaments are great for general purpose 3D printing, but abrasive filament like NylonX requires a high performance filament. Copper and specialty CleanTips are designed to stay clean and prevent filament from sticking to them. Read this article and learn about the different nozzle styles and contents.

One of the great things about 3D printing is the ability to change nozzles to suit the application and the plastics being used.

What is a nozzle?

In a nutshell, a nozzle is a 3D printer nozzle that screws into the extruder heater block and has a small chamber inside.

When it comes to 3D printer nozzles, there are two main points: the diameter of the hole and the material it is made from.

Materials

On a typical desktop 3D printer, you will find a 0.4 mm nozzle, most likely made of brass. This material is suitable for printing PLA and ABS, but when it comes to materials such as glowing PLA or metal-enriched filaments, the softness of brass becomes a problem.

Plastics that contain solid particles will gradually destroy the 3D printer nozzle. Over time, this also distorts the internal dimensions of the nozzle, reducing the uniformity of what is extruded and at some point affecting the quality of the print. It is for this reason that some 3D printer nozzles made from more than

hard materials.

Here is a summary of some of the 3D printer nozzle materials that are coming to market these days:

Brass 3D Printer Nozzle

The most commonly used but effective nozzle for desktop 3D printers. Of all the materials used, it is the softest. Easily machined brass nozzles are cheap and widely available, making them easy to replace.

Features:

• High thermal conductivity

• Corrosion resistant

• Relatively soft

• Low abrasion resistance

Best use: "soft" plastic filaments such as PLA, ABS and PETG. Threads that do not contain particles of additives such as metal and carbon fiber.

Stainless / hardened steel printer head

Mk6 steel head in all its shiny gray glory.

Various types of steel that are harder than brass can now be used as nozzles for 3D printers. Typically stainless or hardened steel, these materials provide long-term printing with particulate-enriched materials such as carbon fiber and metal without the risk of breakage and reduced print performance.

The disadvantage of steel is its low thermal conductivity compared to brass. This can mean inconsistent flow characteristics, especially with large nozzle sizes.

Characteristics:

• Low thermal conductivity

• Resistant to corrosion

• Relatively heavy

• High abrasion resistance

Best use : filaments with additives such as metal, glass fiber and carbon.

Ruby nozzle 3d printer

Anders Olsson's Olders Ruby nozzle is a brass nozzle with an aluminum oxide (ruby) tip.

There are many other materials used for 3D printer nozzles, some more exotic than others.

Olsson Rubin is one such nozzle. Developed by Anders Olsson, a research engineer at Uppsala University in Sweden, it is the result of a requirement for a specific 3D printing experiment to produce a mixture of filaments containing boron carbide. After only 1 kg of filament, standard brass and steel nozzles wear out beyond repair.

And so Olsson created Olsson Rubin. The ruby tipped brass nozzle retains the thermal conductivity of brass and mates with excellent abrasion resistance (especially aluminum oxide).

It could be argued that the ruby element itself in the Olsson Ruby nozzle has low thermal conductivity, making it less reliable in some cases, but there is little to be found on the internet about this.

Characteristics

• Low thermal conductivity

• Corrosion resistant

• High abrasion resistance

Best Application: As with steel, high abrasion threads are the main use case. The only difference is that it has been specifically designed to be printed as the third heaviest material in the world.

The only difference is that it has been specifically designed to be printed as the third heaviest material in the world.

Tungsten Carbide

Dyze Design Tungsten Carbide Nozzle

New to the 3D printer nozzle market. Manufactured by Canadian manufacturer DyzeDesign, it is partly inspired by heavy mining and the use of ceramics for metal cutting and rock drilling. Tungsten carbide provides a balance of hardness, wear resistance and thermal conductivity.

However, real-life testing of the injectors is sparse as they currently only completed a Kickstarter campaign with production in late 2018.

0

Characteristics :

• High thermal conductivity

• High resistance to abrasion

• Hard

• The best use is resistant to corrosion : accompanying 3D-driving of tungsten carbide, which is considered the best universal machine, it will be more than comfortable, more and more comfortable work. with abrasive threads requiring a hard nozzle.

with abrasive threads requiring a hard nozzle.

Sizes

Nozzle diameter affects how fine the level of detail you can achieve when printing, affecting not only the line width but also the recommended layer height.

For beginners, the advantage of using a diameter of 0.15 mm over the standard 0.4 mm is obvious, it can achieve higher resolution in the X and Y axes. Finer lines can give sharper angles, however this is only possible on a well maintained and tuned 3D printer.

As a rule of thumb, the diameter of the 3D printer's nozzle should determine the layer height you're aiming for. Try to keep the print layer height approximately 25-50% of the nozzle diameter.

This (together with a properly calibrated layer) provides better adhesion between lines. For example, with a standard 0.4mm 3D printer nozzle, you should aim to print with a layer height of 0.1 - 0.2mm.

To have a better chance of successfully printing ultra-thin layers less than 0. 05mm high, you'd better choose a 0.2mm nozzle.

05mm high, you'd better choose a 0.2mm nozzle.

The downside of using smaller nozzles is that they tend to clog, so be prepared for regular cleaning.

The possible disadvantages of using smaller nozzles include a significant increase in print time, since more printhead passes are required to cover the same distance that a larger nozzle will reach in fewer strokes.

Wider diameters can cut print times exponentially - for example, one 0.8mm wall takes half the time of a 0.4mm wall.

In addition, larger extrusion lines bond better, resulting in stronger prints. These advantages make large nozzles for 3D printers a boon for rapid prototyping where small details are of low priority.

It can be argued that the benefits of using smaller nozzles are limited to hobby and models that require fine detail, most of which are jewelry design models.

Choose and experiment and you will definitely succeed.

Factory Stock 3D Tungsten Carbide Nozzle Tungsten Carbide Nozzle China Manufacturers

-

Lead Time:

-

Payment Items:

-

Ship Methods:

-

Price:

-

How to order:

- Online request

- detail

Factory stock 3D tungsten carbide nozzle tungsten carbide nozzle

(1) High hardness and wear resistance

(2) Heat resistance and corrosion resistance

(3) High quality, preferential price 9009 nozzles are widely used 9008 in the oil industry for exploration of oil wells. Many oil companies have adopted this type of product for use in this industry.

Many oil companies have adopted this type of product for use in this industry.

Due to its good hardness, wear resistance and abrasion resistance, it is widely used in many other industries.

A nozzle is a device designed to control the direction or characteristics of a flow (especially to increase speed) as it exits (or enters) a closed chamber or pipe through an orifice. For nozzles, the tungsten carbide nozzle is the strongest and most durable and provides the best value for money.

The tungsten carbide nozzle is precision machined with tungsten carbide (superhard alloy). The hardness has reached the level of HRA90, and the degree of anti-bending is more than 2300N/mm. The tungsten carbide nozzle is produced by hot pressing with a straight bore and a Ven or orifice. Due to its hardness, low density and excellent wear resistance and anti-corrosion. The tungsten carbide nozzle is widely used in sandblasting and shot blasting equipment, providing long life with optimal use of air and abrasives.

| Level. | Basic chemical composition. | Flexural strength. | Hardness. | Virtue. | Linear. | Suitable medium. | ||||

| (≥N/mm2). | (≥HRA). | (g/cm²) | Drums. | |||||||

| WC. | Company. | Ni. | Convulsions. | Others. | | | | Module. | ||

| YWN6. | 94. | \. | 6. | \. | \. | 1500. | 89. | 14.5-14.9. | 5.2. | Oil, waste water, acids, alkalis, fats, fluids. |

| YWN8. | 92. | \. | 8. | \. | \. | 1650 | 88. | 14.4-14.8. | 5.3. | Hydrocarbons, strong bases with particles. |

| YWN10. | 90. | \. | 10. | \. | \. | 2100. | 87. | 14.5-14.9. | 5.3. | |

| YG6. | 94. | 6. | \. | \. | \. | 1550 | 89.5. | 14.7-15.1. | 5. | Oil, sewage, mild acids or alkalis, grease. |

| Fluid. | ||||||||||

| YG8. | 92. | 8. | \. | \. | \. | 1700. | 89. | 14.6-14.9. | 5.1. | Hydrocarbons, medium, particulate. |

| YG13. | 87. | 13. | \. | \. | \. | 2400. | 88. | 13.9-14.2. | 6. | Compressor gas seal. |

| YG15. | 85. | 15. | \. | \. | \. | 2500. | 87. | 13.9-14.2. | 6.3. | |

| YT10. | 80. | 10. | ||||||||