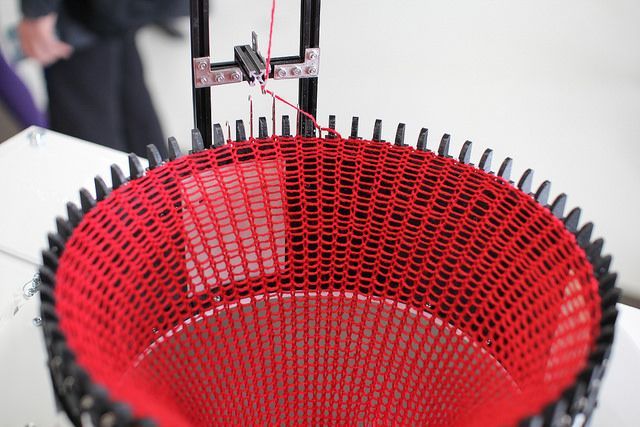

3D printed knitting needles

3D Printed Needle and Stitch Gauge

-

Item in the photo is in Primary color: Semi-Clear Purple

Option selected!

This option is sold out.

-

Item in the photo is in Primary color: Black

Option selected!

This option is sold out.

-

Item in the photo is in Primary color: Purple

Option selected!

This option is sold out.

Click to zoom

Star Seller

Star Sellers have an outstanding track record for providing a great customer experience—they consistently earned 5-star reviews, shipped orders on time, and replied quickly to any messages they received.

| 780 sales |

€14.13

Loading

Low in stock

VAT included (where applicable), plus shipping

Primary color

Select a color Black Blue Brown Gray Orange Red White Semi-Clear White Purple Semi-Clear Purple Glow in the Dark Gold

Please select a color

Quantity

1234567

Star Seller. This seller consistently earned 5-star reviews, shipped on time, and replied quickly to any messages they received.

This seller consistently earned 5-star reviews, shipped on time, and replied quickly to any messages they received.

Listed on Aug 21, 2022

23 favorites

Report this item to Etsy

Choose a reason…There’s a problem with my orderIt uses my intellectual property without permissionI don’t think it meets Etsy’s policiesChoose a reason…

The first thing you should do is contact the seller directly.

If you’ve already done that, your item hasn’t arrived, or it’s not as described, you can report that to Etsy by opening a case.

Report a problem with an order

We take intellectual property concerns very seriously, but many of these problems can be resolved directly by the parties involved. We suggest contacting the seller directly to respectfully share your concerns.

If you’d like to file an allegation of infringement, you’ll need to follow the process described in our Copyright and Intellectual Property Policy.

Review how we define handmade, vintage and supplies

See a list of prohibited items and materials

Read our mature content policy

The item for sale is…not handmade

not vintage (20+ years)

not craft supplies

prohibited or that use prohibited materials

not properly labeled as mature content

Please choose a reason

Tell us more about how this item violates our policies.Tell us more about how this item violates our policies.

All categories

Craft Supplies & Tools

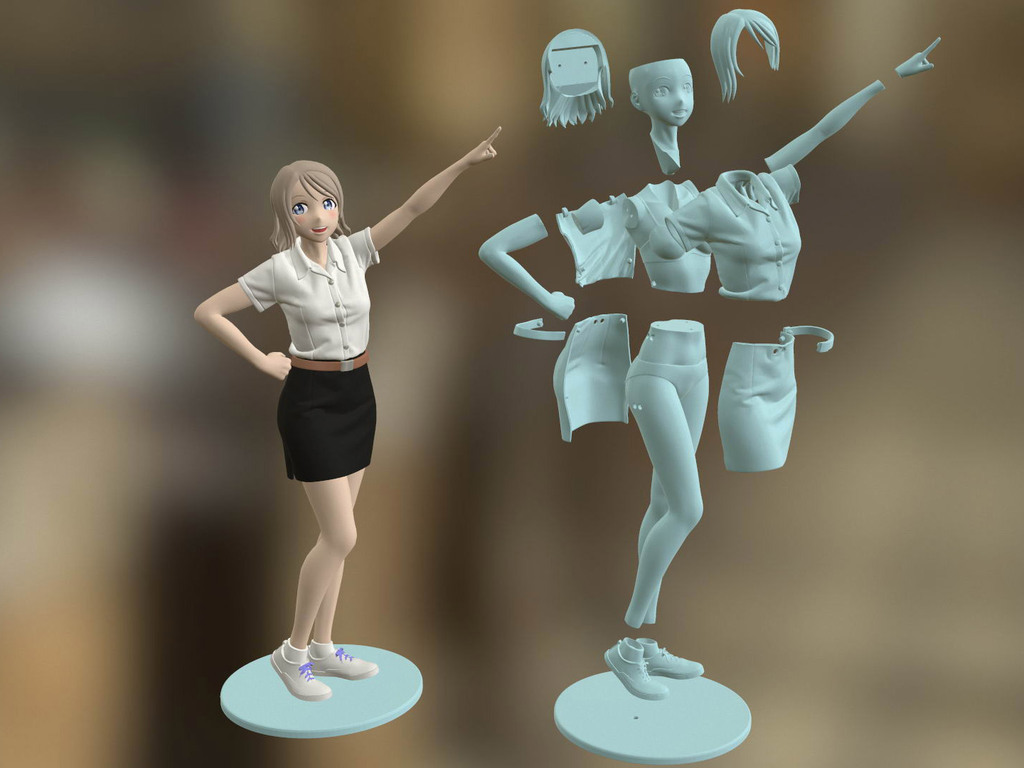

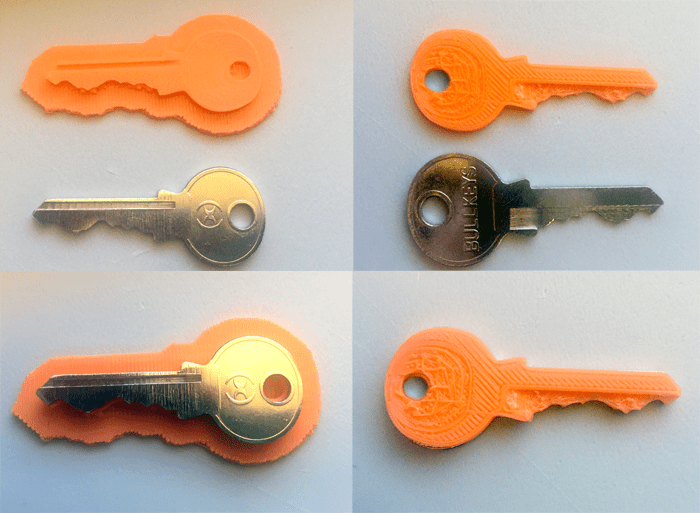

Products tagged: knitting needles - Shapeways 3D Printing

- All Categories

- Tech

- Airsoft & Paintball

- Camera & Video

- Cases

- Drone Parts

- Maker/DIY

- Mechanical Parts

- RC Cars

- Robotics

- Other

- Accessories

- Belts

- Keychains

- Music

- Other

- Jewelry

- Bracelets

- Cufflinks and Tie Clips

- Earrings

- Pendants and Necklaces

- Rings

- Other

- Art

- Mathematical Art

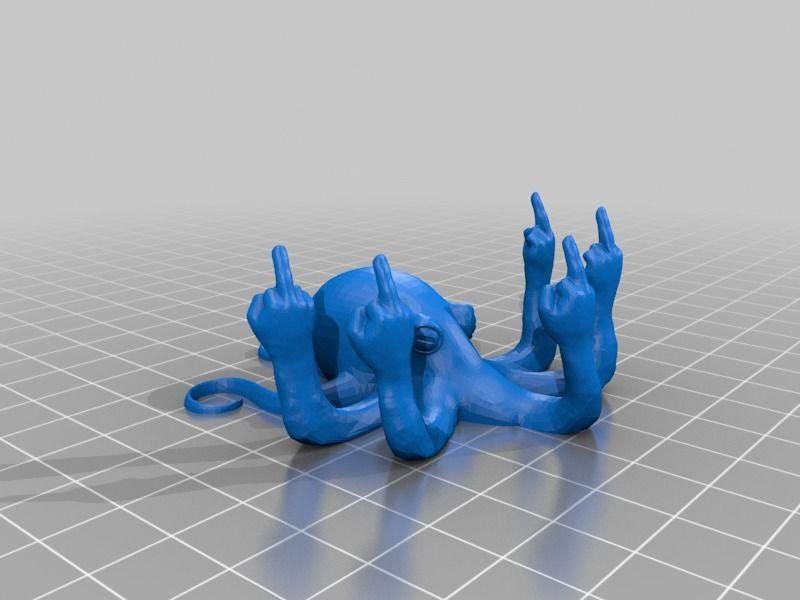

- Memes

- Sculptures

- Other

- For Your Home

- Accessories

- Dining

- Lighting

- Other

- Games

- Board Games

- Desk Toys

- Dice

- Puzzles

- Tabletop & Wargaming

- Toys

- Other

- Miniatures

- Aircraft

- Figurines

- Interior Models

- Scenery

- SciFi

- Ships

- Trains

- Vehicles

- Other

- Other

CATEGORIES

FILTER BY

Clear- Customizable

From $to $

- Any Material

- Versatile Plastic

- Steel

- Aluminum

- Multi Jet Fusion Plastic

- Silver

- Gold

- Gold Plated Brass

- Rhodium Plated Brass

- Platinum

- Brass

- Bronze

- Sandstone

- Fine Detail Plastic

- PA11 (SLS)

- Gray PA12 Glass Beads

- Dark Gray PA12 Glass Beads

- Accura Xtreme

- Accura 60

- Black Smooth PA12

- Standard High Definition Full Color

- Matte High Definition Full Color

- White Smooth Versatile Plastic

- Black Smooth Versatile Plastic

- Processed Stainless Steel 17-4PH (BJT)

- Processed Stainless Steel 316L (BJT)

- Natural Full Color Nylon 12 (MJF)

- Smooth Full Color Nylon 12 (MJF)

- Blue Smooth Versatile Plastic

- Red Smooth Versatile Plastic

- Yellow Smooth Versatile Plastic

- Orange Smooth Versatile Plastic

- Green Smooth Versatile Plastic

- Purple Smooth Versatile Plastic

- Pink Smooth Versatile Plastic

- White Natural TPE (SLS)

- Black Natural TPE (SLS)

- 9K Yellow Gold

- 9K Rose Gold

- Vermeil

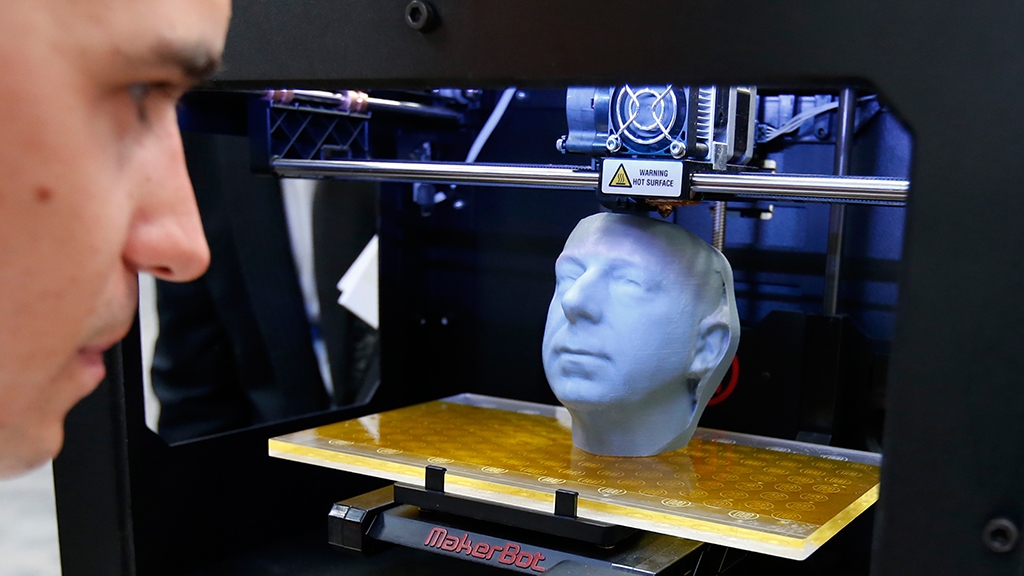

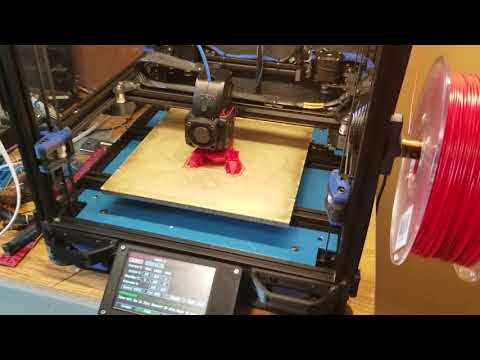

3d printing at home

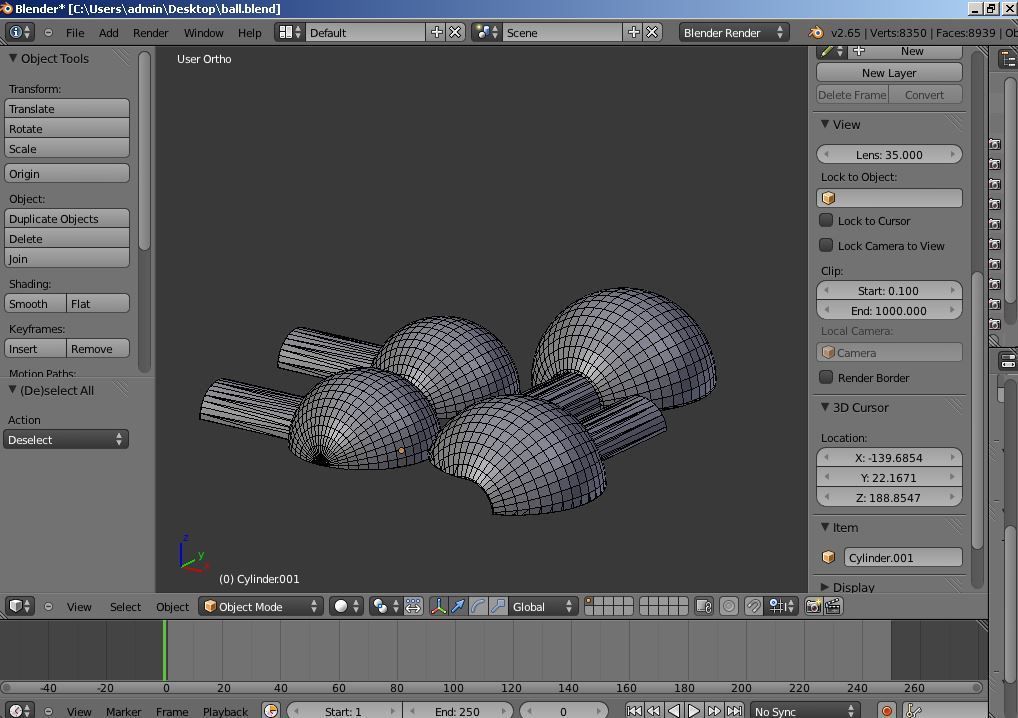

The hour is not far off when 3d printing will be applied everywhere, 3d printers will be in every house and there will be universal happiness and prosperity. So far, the user must have 3d modeling skills and be at least a little bit of an engineer. In order to pump this skill a little, I offer an example of household use of 3d printing.

So far, the user must have 3d modeling skills and be at least a little bit of an engineer. In order to pump this skill a little, I offer an example of household use of 3d printing.

It's time for a vacation, and such bad luck, the wheels of a beautiful summer stroller broke. They used it in the tail and mane and the wheels on the axle were flared. The Chinese did not provide any seals and bearings, wheels made of foamed plastic, tires made of foamed rubber, and that's it.

It would certainly be possible to buy a new stroller. Or collective farm wheels from another moving vehicle, a scooter there or something else. But our hands are not for boredom, the itch of rubbing haunts and a flock of 3D printers in the corner buzzes invitingly.

So given:

Excellent lightweight stroller that folds and unfolds with one wave of the hand. 2 broken-down wheels from the lazy uncle Liao to her, solid works and a 3D printer to load. Well, a little more free time and 200 grams of plastic. Here is a simple equation. There will be many pictures and little text.

Here is a simple equation. There will be many pictures and little text.

First, we disassemble the stroller and study the wheels, so that later we can use the reverse engineering method to chop our own, remove the rubber.

Everything is clear, nothing complicated. The rim also has grips for the rubber to keep it from slipping.

We take measurements, draw a dimensional drawing by hand, and move on.

Opening solid. And we start with the outer diameter. We create an elongated boss according to the sketch in our overall dimensions.

On one of the faces, draw a sketch for the outer cutout (where the wheel will be attached to the axle).

And cut out with an elongated cut according to the measurements to the desired depth (in our case 11.5 mm).

Now the inner structure needs to be sunk a little so that the cover is flush with the outside of the wheel. We simply form another sketch on the outer edge, matching the diameter of the cutout, and apply the cutout to the thickness of our lid, 3mm. Next, we make chamfers and roundings, as in the original.

We simply form another sketch on the outer edge, matching the diameter of the cutout, and apply the cutout to the thickness of our lid, 3mm. Next, we make chamfers and roundings, as in the original.

We form the grooves for the lid latches also with elongated cutouts through.

Making a groove on the rim. Draw a suitable ellipse on the frontal plane and apply “cut-rotate” to it.

Grooves for the cover latch

In the process of work, I thought, why should I make a solid wheel, I will make spokes with stiffeners. I didn’t want to bother with the alteration of what was done, I just created a profile, pulled out the boss to get the desired shape. Then I checked with an array.

Cut the spokes also on the outer edge

Then cut out the stiffeners also in an array

Round everything that is rounded

It's time for the brake sprocket. Draw a sketch on the edge.

Draw a sketch on the edge.

Pull out the boss. Roundings at the junction of the sprocket and the edge will give the structure additional fracture strength, and the sprocket will not come off under load. Cut out the axle.

So that the shaft does not break the wheel along the axis, as in the Chinese parent, I want to press the bearing. We make a cutout under it.

It can be seen that the diameter of the cutout for the bearing is larger than the embedded diameter for the axle. I tried on the wheel again, and found out that you can add thickness. I just increase the boss by 5 mm, and everything is ok.

The finishing touch. Tire hooks.

On the front view, draw a sketch to create a cone. According to my estimates, the cone should be enough for a confident hook.

Rotate the “rotated boss” sketch around the axial one to get a cone.

Next is the circular array of the resulting cone, and that's it. The layout of the product is ready.

All finished with modeling.

Printed the whole thing in white HIPS with 100% coverage. Of course, PETG would have been better, but I only had black left. HIPS is also suitable, it is quite rigid.

Printed product with pressed bearing.

Trying on

Everything is ok, I put on the printed boot.

Final assembly

Test drive)))

That's it, take me there, to the sea)))

Forty minutes of modeling with a tea break, 12 hours of printing and the new wheels are ready. Field tests showed that the wheels held up, only the bearing had to be pressed in on both sides. Wear on the inside takes place from rolling the stroller on the sand.

In summary, I would like to note that the pros, of course, will not surprise you with the described techniques, and for beginners one more applied lesson will be useful.

That's all, may the force be with you.

Yours sincerely, design-exp.com

What the first 3D printed village looks like

Trends

TV channel

Pro

Investments

Events

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating club

Research

Credit ratings

Franchises

Newspaper

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Politics

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

RBC Trends

Photo: New Story

Do you dream of cheap and beautiful housing? It can be created in just a day using a 3D printer. So, in Mexico, by the end of 2020, they plan to print an entire village. Two houses are ready, and tenants have moved in

3D printing of real estate is gaining popularity: it is cheap, fast and requires relatively little energy. Technology allows you to create housing in just 24 hours - who among us will refuse a village house, which can be entered in just a day after the start of construction?

Technology allows you to create housing in just 24 hours - who among us will refuse a village house, which can be entered in just a day after the start of construction?

Photo: New Story

But for now, technological know-how is serving the needs of the poorest, most vulnerable. For example, it may be the construction of temporary shelters for victims of military conflicts.

New Story, a non-profit organization with the support of local governments, 3D printed two houses in the Mexican village of Tobasco. This housing is intended for the poor and those who have lost their homes due to an earthquake or flood - in the area where the village is located, they occur quite often. By the end of 2020, New Story plans to build 50 one-story 3D houses with an area of about 47 square meters. m each.

The houses were printed using a Vulcan II printer. It works as follows: cement is squeezed out of the nozzle of the apparatus and applied layer by layer around the perimeter of the designed house.