Byui 3d printing

Mac Lab | McKay Library

The purpose of the Mac Lab is to offer students a creative space to help them in their academic pursuits by providing trained lab assistants. Computers are equiped with course-related software such as Adobe Creative Cloud and Microsoft Office. The lab also provides 3D printing and equipment checkout.

MAC LAB

- One computer per person

- No food or drink

- Must have BYU-I username and password

- Abandoned belongings will be taken to lost & found after 30 minutes

- Keep noise to a minimum, take phone calls to the Commons

SOFTWARE

(This list is constantly changing to adapt to Faculty requirements.)CREATIVE CLOUD

Illustrator, Photoshop, InDesign, Premiere Pro, Acrobat, XD, and more

MICROSOFT OFFICE

Word, Power Point, Excel

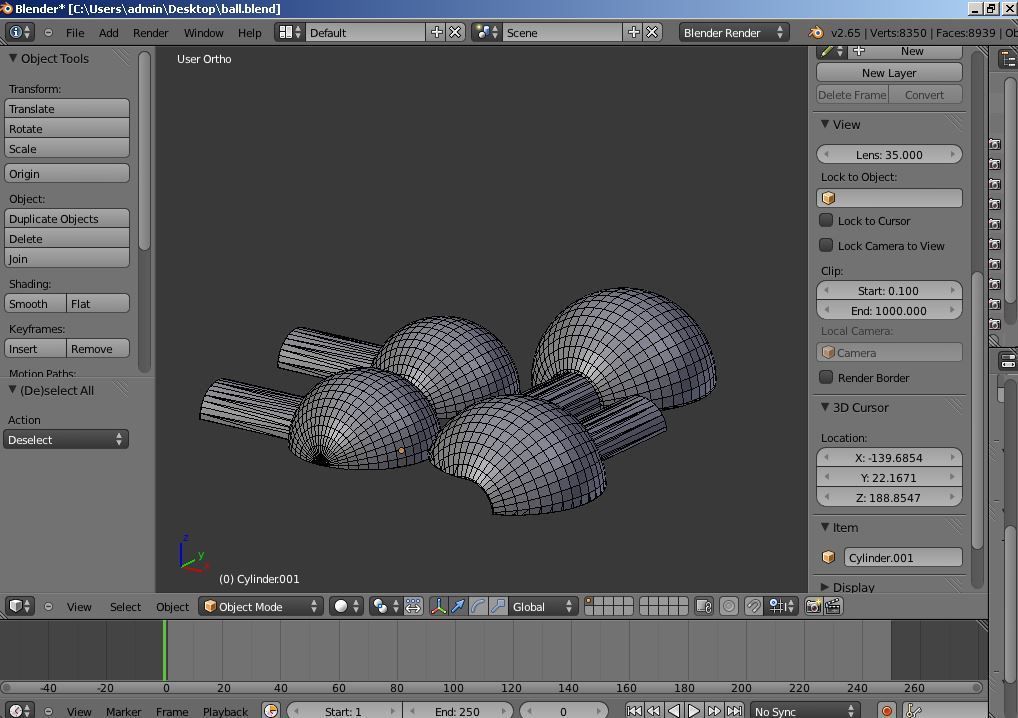

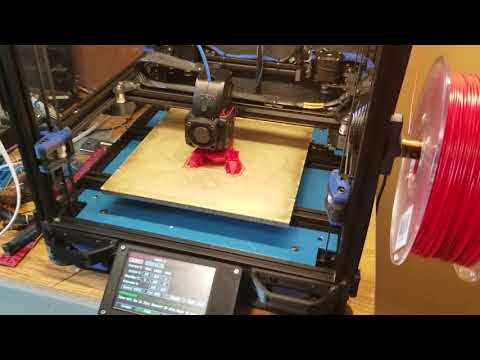

3D PRINTING

Cura, Slic3r, Maya, Inventor

SOFTWARE DEVELOPMENT

XCode, BBEdit, RStudio, NetBeans, Cyberduck

3D PRINTING

This policy establishes how and under what circumstances the BYU-Idaho community may use the Library’s 3D printer.

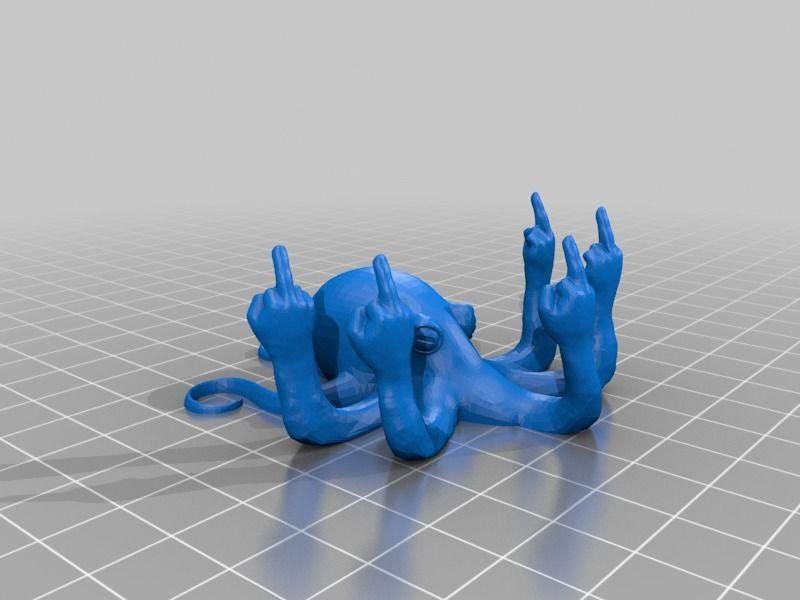

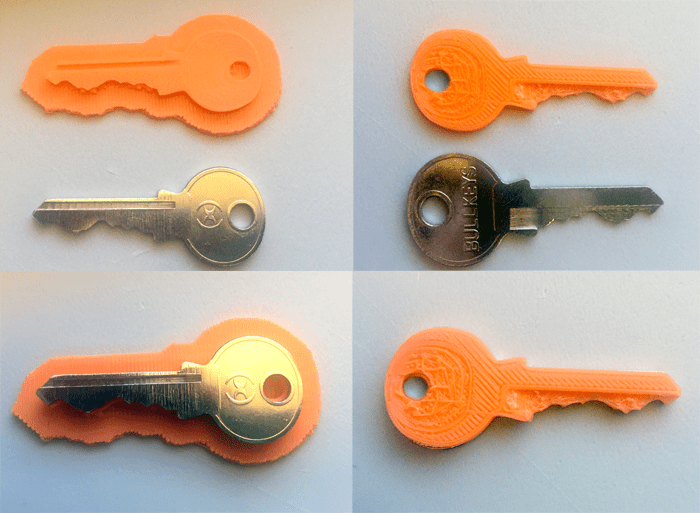

- The Library’s 3D printer may be used only for lawful purposes. No one will be permitted to use the Library’s 3D printer to create material that:

- Is not in compliance with BYU-Idaho’s Acceptable Use of Information Technology;

- Violates the CES or BYU-I Honor Code;

- In regard to printing firearms or other weapons, see Housing & Student Living and Student Life (Firearms). In summary, the Mac Lab will not print firearms, facsimiles, or any related parts/ accessories.

- Is obscene or otherwise inapporpriate for the Library environment;

- Is in violation of another’s intellectual property rights including copyright, patent, and/ or trademark protections with respect to fair use and other legal expectations

- BYU-Idaho students, staff, and faculty are able to use the 3D printers by submitting their files online to be printed by Mac Lab employees.

- Patrons are not permitted to keep failed or unsatisfied prints unless paid for individually. Mac Lab employees are directed to consult with a supervisor before making exceptions.

- Not complying with the policy or repeated attempts to print restricted models can cause you to lose access to the 3D printers.

- The copyright law of the United States (Title 17, United States Code) governs the making of photocopies or other reproductions of copyrighted material.

Under certain conditions specified in the law, libraries and archives are authorized to furnish a photocopy or other reproduction. One of these specific conditions is that the photocopy or reproduction is not to be "used for any purpose other than private study, scholarship, or research." If a user makes a request for, or later uses, a photocopy or reproduction for purposes in excess of "fair use," that user may be liable for copyright infringement.

This institution reserves the right to refuse to accept a copying order/scanning or printing services if, in its judgment, fulfillment of the order would involve violation of copyright or other intellectual property laws.

CAMERA EQUIPMENT

- Camera equipment is for academic use only.

- You are responsible for any repair / replacement of any items that are damaged while checked out to you.

- You can only check out and return equipment for yourself.

- A fee of $10 per day will be charged to your account for any late items.

OTHER EQUIPMENT

- You are responsible for any repair / replacement of any items that are damaged while checked out to you.

- Chargers are provided as a courtesy and should be used at your own risk. The McKay Library is not responsible for any damages caused to personal equipment they are used with.

- Tablets and tablet pens must remain in the Mac Lab.

- Headphones should remain in the McKay Library.

- A fee of $10 per day will be charged to your account for any late items.

Blog Archives - BYU-Idaho Pre-Arrival Mentoring

5/5/2021

New Student Information

Heard from your Pre-Arrival Mentor lately?

If you have questions about the New Student Checklist, registration, housing, campus life or anything else, get in touch with us!

Connect via Facebook, Instagram, Email, or Phone[email protected] | (208) 496-1424

Move-In Day |

September 10th| Complexes open at 8:00 a.m. for you to start moving in; Get Connected events begin as early as 1:00 p. |

Get Connected

Don’t miss out on Get Connected! This is BYU-Idaho's new student orientation!

Fri-Sat | September 10-11, 2021

This is a great opportunity to make new friends, learn more about your Academic Program, and become familiar with the unique atmosphere of BYU-Idaho.

*Look for more details closer to the start of the semester. There is a possibility this will be held online due to COVID precautions.

| Please download the “BYUI I-Belong” app. It includes important deadlines and reminders, a calendar of events, tickets to your purchased events, access to your email and canvas, your I-card, the job board, a place to reserve a study room, etc. | There is a Career and Networking Center on campus that will help you build & update a resume or cover letter, create a LinkedIn account, learn how to network, practice interviews, and explore different majors. |

| The David O. McKay library houses the tutoring center, a Mac Lab & 3D Printing studio, study rooms for group study sessions, special collections, an iron acorn press, and great places to do research! |

The Spirit of Ricks

President Clark said,

“The Spirit of Ricks is the defining characteristic of BYU-Idaho. It is something we share as a university community. We experience the Spirit of Ricks because individual students and individual employees receive spiritual light and use spiritual gifts. ”

”

Watch President Kim B. Clark’s full address in the link below.

The spirit of ricks

Forward>>

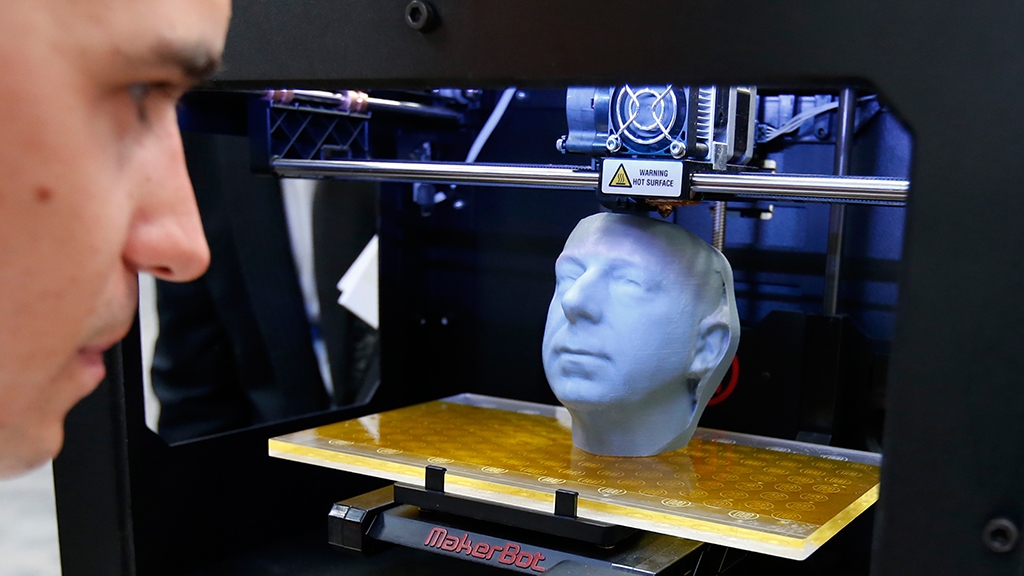

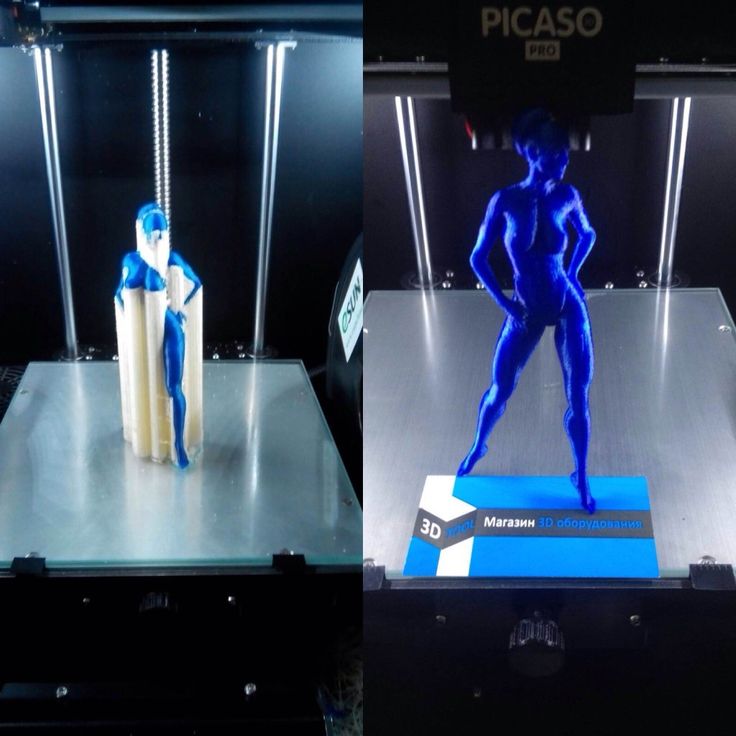

How to order 3D printing of a bust

It is this phrase that is usually entered into the search box if you need to "make a bust on a 3D printer", for example, from a photograph. In this article, we will try to tell you how to build the process and what you need to make your bust high quality and inexpensive.

3D bust modeling

At the forefront, as always with 3D printing, is a properly made and prepared digital 3D model exported to STL format.

In this case, the model is of decisive importance and often costs more than the production itself, since the modeling of the head is a serious task, often in the "artistic" plane. We put this word in quotation marks, because, in fact, even when modeling a person's face or body, only engineering, technical principles are used.

In order for the model to cost less and be as similar to the original as possible, you need to provide the "3D artist" with the following source material: Photos of the head "rotating" in a circle: the camera is fixed at 1 point and the head rotates so that all photos are on the same axis with the neutral and the same facial expression (or whatever expression you need) + photo above and below, ideally it should look something like this:

At least 3-5 photos are required for successful modeling. In this case, we can guarantee "similarity" of 75% or higher, since the task is in the technical plane (not "artistic")

Sometimes we can model from 2 photos, or photos from different angles, different times, low quality and so on. Working with such source materials is always more expensive, and the bar of guaranteed “similarity” is always lower, since, in this case, a lot of things need to be thought out and the task turns from a technical one into an artistic one.

In addition to the photo, you also need to select a frame for cropping (bust outline), it looks something like this:

"Full" and "Cropped"

Finally, you need to indicate the size, 1 overall height is enough.

Optionally, you can also add a nameplate or anything else to the composition.

After the materials are provided, modeling begins, which necessarily includes at least 2 stages of approval. After the model is ready and agreed upon, the production begins.

Bust 3D printing

Here everything happens the same way as in conventional 3D printing - the model is "grown" from plastic, assembled and processed if necessary. If necessary, paint (by default, we only paint in 1 color - we recommend white). If necessary, we can make the bust heavier by mounting the load inside, but this must be taken into account at the modeling stage.

At the output we get a three-dimensional portrait:

It is better to lay at least 2-3 weeks for the whole process (modeling + coordination + manufacturing).

Journal of International Life - Scientists have created a universal nanosyringe for injecting DNA into living cells them to expand the pores in their shell with the help of a current.

Today, scientists are creating transgenic animals and trying to cure congenital diseases using several relatively unsafe ways to introduce new DNA into cells - either by using ultra-fine needles that "pierce" the egg, or by using retroviruses, whose "combat" part is replaced with useful genetic code.

Such operations, according to Cullen Buie of the Massachusetts Institute of Technology (USA), can lead to fatal consequences as a result of banal damage to the cell membrane when the needle is inserted incorrectly, or as a result of the development of an immunological reaction to the virus.

Both are not an obstacle to experiments in laboratories, but this makes it extremely difficult to transfer the results of experiments into medical practice. For this reason, biologists, engineers and biotechnologists are now actively looking for methods of "direct" introduction of DNA into a cell that would not lead to its death or damage.

In recent years, according to Buey, these two technologies have a real alternative - the introduction of DNA into cells using electric fields and special molecular "guns" that disperse fragments of the genetic code before inserting them into a bacterium or egg.

The electrochemical principles of this technology have been known to scientists since the mid-1980s. In 1982, the German biologist Eberhard Neumann found that when exposed to a strong electric field, small pores begin to appear in the cell membrane, capable of passing foreign molecules.

In 2011, one of the first versions of such "nano-syringes" appeared, but their use revealed a new problem - it turned out that for successful DNA injection, it is necessary to individually select the field strength for each new cell type, which is an extremely long and laborious process. Buey and his colleagues found a way to simplify and speed it up by adding to the "nanosyringe" a set of protein molecules that begin to glow when they attach to DNA.

The "syringe" itself is a miniature converging channel machined into a semiconductor wafer using an electron beam. Due to its shape, the electrical potential in it gradually increases as it narrows. If a bacterium floats along it, then as it moves, it will experience more and more electric fields until the moment when its pores open and pigment molecules penetrate into the microbe through them.

This allows, as the scientist says, to very quickly and accurately select the minimum field strength at which DNA can penetrate inside the cells, and the current will not damage the membrane and cause the contents of the bacterium to literally "leak" out of it.

As a demonstration of this technology, scientists inserted DNA into the cells of one of the tuberculosis bacillus relatives, which gave these microbes the ability to resist one of the antibiotics. The bacteria successfully "read" the new DNA and used it to protect themselves from the drug, confirming that these "syringes" work in practice.

m. Plan to move into your complexes early that morning so everything is set up and ready to go for Get Connected that afternoon!

m. Plan to move into your complexes early that morning so everything is set up and ready to go for Get Connected that afternoon!