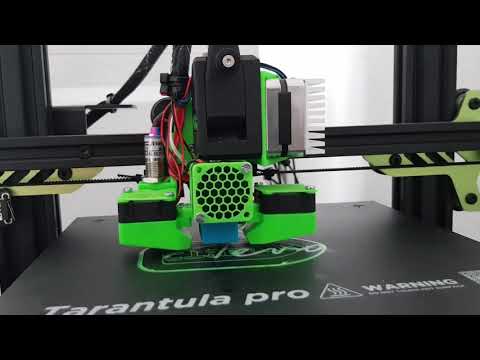

Tarantula pro 3d printer

TEVO Tarantula Review 2022 - Is This 3D Printer Worth The Money?

3.4

See Price

Choosing a budget 3D printer is tough. If you’re new to the hobby, you might not know which specifications are important, and which are only mentioned to draw your attention away from other things. The good news is that you don’t have to spend hours on research: we’ve done it for you.

Today, we’re looking at a popular entry-level printer, the TEVO Tarantula. We’ll be highlighting this model’s strengths and weaknesses in the hopes of giving you all the information you’ll need to decide if the Tarantula is right for you. Without further ado, let’s begin.

| Filament Diameter | 1.75mm |

| Extruders | 1 |

| Supported Materials | PLA, ABS, PETG, PVA, Exotics |

| Connectivity | USB, SD Card |

| Printing Speed | 150mm/s |

| Build Volume | 7. |

Table of ContentsShow

Design

First of all, you should know that this printer has to be assembled from parts. Still, the construction is fairly straightforward, if a little time-consuming. When it’s complete, you’ll notice that the build area is pretty big for a printer in this price range. Simply, that’s never a bad thing.

On the other hand, there are a few structural complaints. The frame is a little flimsy and prone to wobbling during prints, the print bed is absurdly sticky, and the bed-leveling mechanism isn’t as stable as we’d like. Still, these issues can be solved with a bit of preparation, so they’re not total deal-breakers.

Because the entire unit is so open and accessible, there’s a lot of scope for modifications. Some of these (like additional support brackets) can actually help offset some of the issues we discussed earlier, although really, you shouldn’t have to. You can even add WiFi support to complement the USB and SD card interfaces if you’d like.

Printing

Due to the lack of a cooling fan, it’s hard to print with anything other than PLA at first. The temperature is just too inconsistent. However, once you add a fan, it’s possible to create decent models at reasonable speeds. Make no mistake: this is not a pro-level printer, but it’ll do fine for around the home or office.

The Tarantula does have layer integration going for it though. You can print as finely as 50 microns, at which point the layers are barely perceptible, assuming you’ve set the printer up properly. However, it can be difficult to achieve a perfect print since the Tarantula is prone to spool tangles, heating issues, and sticking.

Initially, we were impressed by the range of materials that this printer could handle. That said, there are just too many variables to look after, at least initially. We’d recommend sticking with the basic filaments until you get a feel for this model’s quirks.

Features

As far as functionality goes, this is a pretty bare-bones printer. There’s a small screen so you can control prints when not connected to a PC, but that’s about it. Indeed, the features that get people excited online seem to be the ones they’ve added personally.

There’s a small screen so you can control prints when not connected to a PC, but that’s about it. Indeed, the features that get people excited online seem to be the ones they’ve added personally.

At the very least, there is a heated print bed. In theory, this should help keep your prints in place, but in practice, it can be extremely difficult to remove them once completed. If you like to tinker, this may be a good long-term project, but if you just want something that works consistently, the Tarantula probably won’t cut it.

There is one saving grace: the build volume is larger than you’d usually find on an entry-level printer. That said, whether you’ll get any advantage from this is unclear, given how often the Tarantula encounters problems.

Cost

It’s true that the TEVO Tarantula is one of the least expensive 3D printers on the market. You can pick one up for around $200, and its running costs are fairly low too, thanks to its ability to use third-party materials. However, what you save in cash, you pay for with your time.

However, what you save in cash, you pay for with your time.

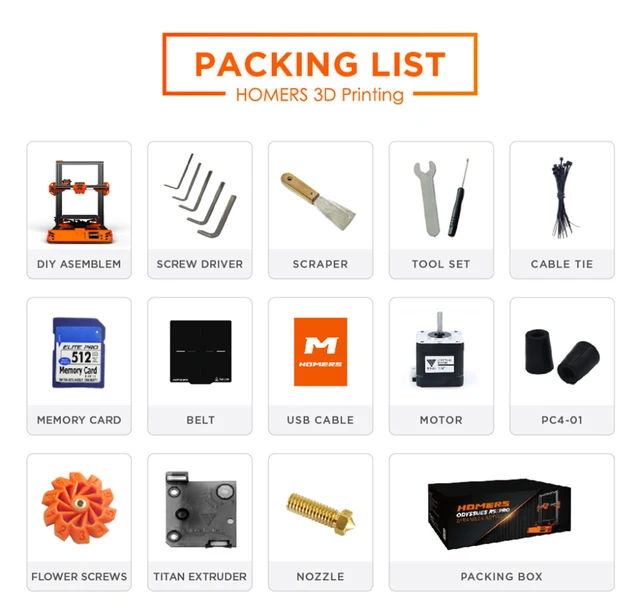

Remember that you’ll have to build this printer from a kit, a process that can take days if you’re inexperienced. Additionally, some users have reported their kits to arrive without essential components, or with parts that don’t fit. As such, be prepared to spend a couple more days waiting for replacements to arrive.

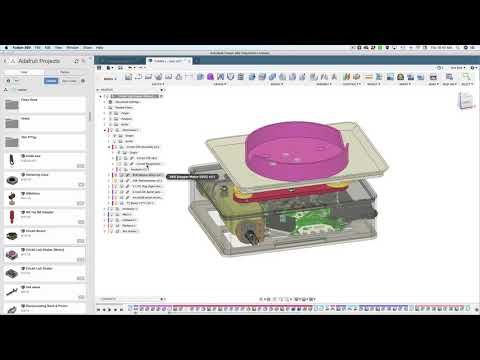

It’s also worth noting that this isn’t a simple product to make. Its design is deceptively simple, but take a look at the image above. That’s a blown-up diagram of how the extruder fits onto the arm and we count no less than 15 components, all of which have to be quality checked and attached.

Support

The Tarantula support page can be described as basic, at best. It consists entirely of a ridiculously complex construction guide for the printer. There are firmware updates (hosted on Dropbox, of all places) on a separate page, but no troubleshooting guides, tutorials, or anything approaching a professional-level support system.

If you’re completely stuck, you can contact TEVO via email, a support form, or (sigh) Facebook Messenger. The site is primarily written in broken English, so you’ll probably have to resort to forums or YouTube videos to better understand how to fix a given problem.

This is quite simply one of the least professional websites we’ve ever seen. It’s a real shame since $200 is still a lot of money, and customers deserve to be given some kind of after-purchase support. TEVO’s iterative design practices mean that much of the helpful information out there becomes more outdated each time they release an upgrade, too, so you might well end up having to fix problems on your own.

Tevo Tarantula PRO Review 3D Printer - Homers Odyssues

Table of Contents

The TEVO Tarantula is the 1ST DIY kit 3D printer from the Chinese manufacturer TEVO. It has a construction volume of 200x 200x 200 mm and can be used with a variety of different filaments ranging from PLA, TPU, PETG, ABS and many more.

To make the Tarantula print good there had to be a lot of upgrades, but of course, it is a DIY Machine. Once you got the machine dialled in, after many hours of print time and upgraded the 3D printer printed great quality prints. There are a lot of printable modifications for STL, OBJ repositories. These can be found on Thingiverse, Cults, Cgtrader and other downloadable 3D model websites.

After three years of Tevo designing and selling their 3D printers and a lot of user comments and reviews. They must have thought we need to go back to the Tarantula and make the machine better and they did! Calling it the Tarantula Pro.

In this article of the Tevo tarantula Pro review we will be going over features looks how we compare it to the original Tevo tarantula, and much more.

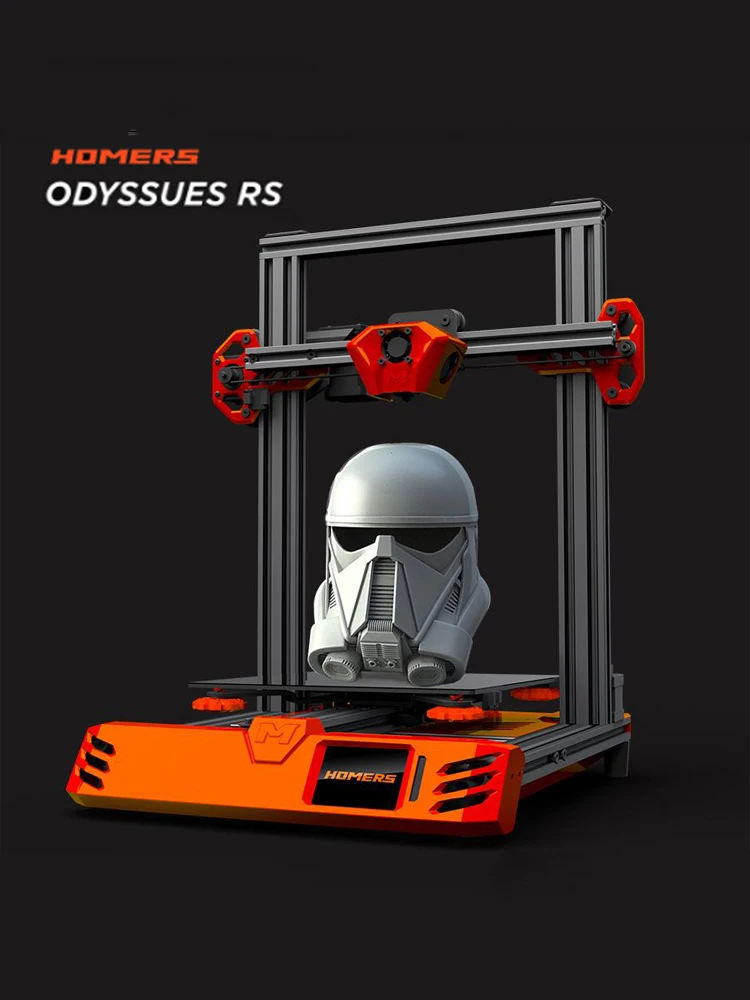

Tevo Tarantula Tevo Tarantula Pro Tevo Tarantula RS Homers Odyssues RSHomers Odyssues And Homers Odyssues RS

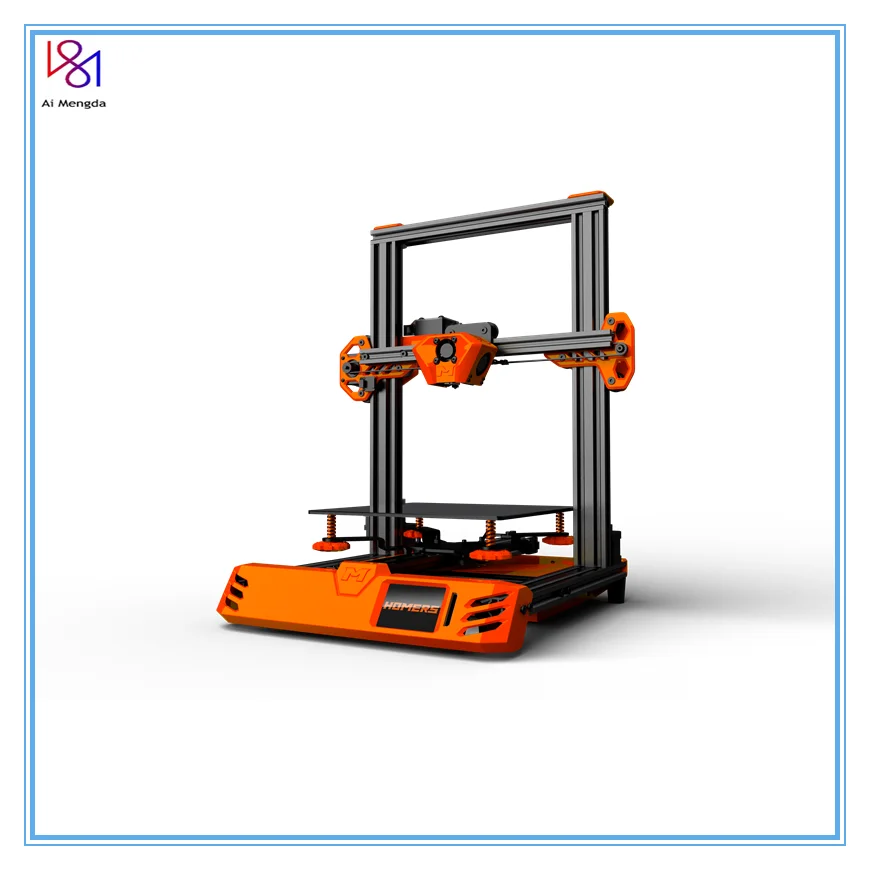

The new Homers Odyssues Pro and Odyssues RS look identical there are differences between them. Tevo has now re-branded to Homers. I can’t understand the reason behind this move because the company in my eyes were doing a good job, and now this will more than likely be a set back for them, lets get on to the Tevo tarantula Pro review.

Tevo has now re-branded to Homers. I can’t understand the reason behind this move because the company in my eyes were doing a good job, and now this will more than likely be a set back for them, lets get on to the Tevo tarantula Pro review.

About The ProTo find out more information about these two 3D printers have a look at the articles bellow

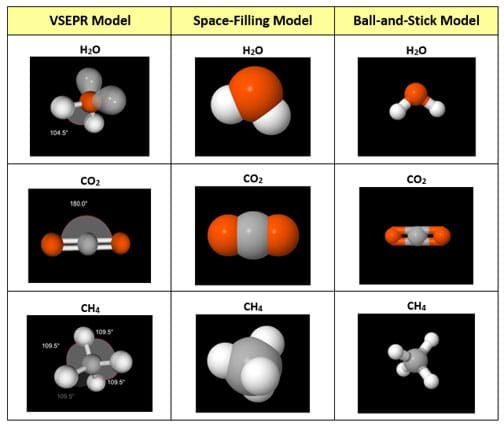

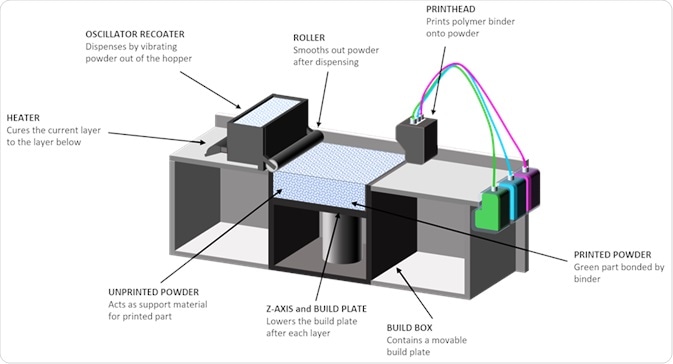

The Tarantula Pro is an FDM (Fused Deposition Modelling) 3D Printing technology. This is the standard format for most home desktop and consumer-grade 3D Printers. FDM printers like the Tarantula Pro have become the norm for most hobbyists and small businesses looking to take advantage of prototyping and even end-use products. FDM 3D Printers produce physical objects by interpreting the information from a CAD file and a slicing application like Cura or Simplify3D then laying down plastic layer by layer until your virtual concept becomes a physical object in the real world.

The Tarantula Pro, like many similar i3 based FDM printers, is an open-source 3D printer and can, therefore, take advantage of the current slicers available. Slic3r, CURA, Simplify3D, CraftWare, MatterControl – to name a few.

Why Is The Tarantula Pro Better?In our opion we prefair the PRO better for the following reasons, but we aren’t going to go into every little detail just the sections we found that had been improved alot more, please read on.

Tarantula (PROS)

- Good Print Quality (once modded)

- Highly Moddable

- Inexpensive

- Active User Community

Tarantula (CONS)

- Frame Isn’t Rigid Enough

- Poor Quality Control

- Infuriating Instructions

- Missing Essential Parts

Tarantula PRO (PROS)

- Unique Aesthetic

- Highly Versatile

- Inexpensive

- Great Packaging

- Heats Quickly

- Great Print Quality

Tarantula PRO (CONS)

- Takes a Couple Of Hours To Build

- One Part Was Counter Sunk The Wrong Way

- Bolts Go Through The Bed

Athstetics And Frame

The Tevo Tarantula came with aluminium extrusions for the frame, plastic pulleys running in the extrusions’ grooves and XY axes are belt-driven. Z is driven with a leadscrew. With the structure being so weak and unstable, it needed to be modified quite a bit by printing new brackets.

Z is driven with a leadscrew. With the structure being so weak and unstable, it needed to be modified quite a bit by printing new brackets.

Acrylic parts ranging from the LCD screen, motherboard and base of the print bed, the acrylic parts break easily if under stress. I have experienced this before, and it is very time consuming having to re-print parts to replace the broken brackets. The layout, you say? I don’t see a design just a mess of randomly placed pieces. It was not a very appealing 3D printer to look at.

For the Tarantula PRO, the frame comes with the standard black colour scheme. There are two Z extrusions that are 40mm x 20mm x 424mm, the X extrusion is 20mm x 20mm x 345mm and last of all the Y extrusion is 40mm x 20mm x 394mm. The only acrylic part is for the z limit switch which is not a structural part, so it won’t matter if this is made out of plastic but if it does break it won’t take long to design and re-print. The rest of the brackets are aluminium with a beautiful sparkly anodised green. The part that struck my eyes is the front screen face cover.

The part that struck my eyes is the front screen face cover.

That has slots for the LCD screen and memory card. It also helps hide the cables, MKS Genl V1.0 Control Board, MKS MINI12864 LCD screen and of course the power supply keeping everything all neat and clean. I’m loving the fact that Tevo is now re-designing their 3D printers to have a nice design with a touch of colour. I like having a colour theme for my 3D printers instead of dull old black. The machines that have colour seem to attract people more.

Tarantula Pro Review – Technical

- Cable management

The Tarantula had virtually no cable management at all to make the cables look a bit better and neater you had to think out of the box. The wires are all over the place you needed to use zip ties and cable sleaves. There was no quick and easy way to take the cables out of the control box you had to unscrew the top cover on the mks board to get to the wires.

The wires are all over the place you needed to use zip ties and cable sleaves. There was no quick and easy way to take the cables out of the control box you had to unscrew the top cover on the mks board to get to the wires.

For the Tarantula PRO, on the other hand, comes with the cables in a braided sleeve and with a quick way to disconnect the cables from the mainboard the wires are more hidden and looks more appealing to the eye.

- Power Supply

On to the messy power supply for the Tarantula, this was a nightmare sitting on the table right next to the printer is this box with a lot of cables coming out of it maybe about six roughly that all went to the control board that was a hazard.

The Pros power supply is under the frame; this makes it all hidden; there is not much more to say about it.

Features

- Extruder – Hotend

It was a long time ago since I had the Tarantula I can’t remember precisely what the hotend was I did try and do some research but couldn’t find much information regarding the extruder. I’m not 100% sure but I think it was the Tevo clone E3D Chimera.

I’m not 100% sure but I think it was the Tevo clone E3D Chimera.

Now on to the pro, this has an E3D Volcano Hotend clone. The advantages of this are faster printing speeds. I do have a genuine E3D Volcano on one of my other printers; this is an all-metal hotend, the clone, on the other hand, I’m not sure, also we cant leave out the extrude which is the titan.

- Layer Cooling

Tarantula comes with no layer cooling what so ever so you do need to print one.

I’m glad Tevo took out the Tarantula PRO with dual fan layer cooling. Besides helping with overhangs, you can print a lot faster due to the layers bellow cooling quicker.

- Print Bed

The Tarantula has good adhesion but could be better. Comes with no insulation under the heatbed this can make the bed temperature fluctuate more. The aluminium beds have been known to be warped.

Excellent adhesion on the Tarantula Pro print surface but please do not squish the filament too much or you won’t get your 3D print off. You do not need any products to keep your print stuck to the bed lets rule out what you don’t need, the popular one’s glue stick, hairspray, 3dlac, filaprint. This 3D printer comes with insulation under the heat bed a cosey evenly heated print surface with no warpage.

You do not need any products to keep your print stuck to the bed lets rule out what you don’t need, the popular one’s glue stick, hairspray, 3dlac, filaprint. This 3D printer comes with insulation under the heat bed a cosey evenly heated print surface with no warpage.

General Specification

- Technology: FDM

- Year: 2019

- Assembly: DIY kit

- Mechanical arrangement: Cartesian-XZ-Head

- Manufacturer: Tevo 3D

- Filameter diameter: 1.75 mm

- Third-party filaments: Yes

- Materials: PLA, ABS, Flexible PLA, Wood, PVA, HIPS

- Build volume: 235 x 235 x 250 mm

- Outer dimensions: 434 x 333 x 504 mm

- Recommended Slicer: Repetier (provided)

- Operating systems: Windows, Mac OSX, Linux

3D Printing Properties

- Accuracy: X/Y-axes +/-50 micron, Z-axis +/- 10 micron

- Layer height: 50– 350 microns

- Feeder system: Bowden drive

- Extruder type: Single

- Nozzle size: 0.

4 mm

4 mm - extruder temperature: 240°C

- heated bed temperature: 70°C

- print speed: 150 mm/s

- Frame: Aluminum

- Print chamber: No

- Temperature controlled print chamber: No

- Bed leveling: Manual

- Print bed: Heated

- Display: LCD Screen

- Firmware: Marlin

- Connectivity: SD, USB cable

- Built-in camera: No

- Print recovery: No

- Filament sensor: No

This slideshow requires JavaScript.

3D PrintingModels:

- Frozen / Tigger/ Owl / Joker / Benchy / Test / Shao Khan / Venom Pool / Freddy Kruger / Cloud Strife

This slideshow requires JavaScript.

The Tarantula Pro is a fantastic, friendly beginner 3D printer that comes as a DIY kit but is very easy to assemble. There are several YouTube video tutorials online that make this a reasonably straight-forward build. Most people should be able to assemble the Tarantula Pro between 45 minutes to 90 minutes, depending on your skill level. I enjoyed the build process and have since been using my Tarantula Pro for many hours every day. The quality of the prints out of the box is excellent, and with a few tweaks to your slicer’s profile for the Tarantula Pro, you will print superior quality models, comes with additional accessories.

But in the meantime, if you are unaware who Tevo are or what other products they have read on.

- Who Are Tevo All About them

- Tarantula RS 3D Printer – 32Bit?

- Nereus 2019

- Tevo Pulsar DLP Reaching New Heights

- Tarantula Pro Community Questions And Answers

- Tevo Flash Review

- Tevo Tornado Gold Edition

FDM 3d printertevotevo tarantula pro 2020-05-28

Tags FDM 3d printer tevo tevo tarantula pro

3D printer Tevo Tarantula I3 — Shop-kit

Specifications

| Attention!!! | Unassembled model !!! |

| Layer resolution | 50 µm |

| Maximum print speed | 150 mm / s |

| Assembly size | 200x200x200 mm. Large print area 200 x 280 x 200 mm (optional) Large print area 200 x 280 x 200 mm (optional) |

| Instrument material | Full Metal E3D Bowden Extruder |

| Material | PLA, ABS, PETG, PVA and flexible filaments (With Pro Metal Extruder) |

| Specification material | 1.75mm in diameter |

| Positioning accuracy | Z 0.004mm, XY 0.012mm |

| Print Color | Single color (two colors optional) |

| Nozzle diameter | 0.4mm (adjustable 0.3mm / 0.2mm) |

| Recommended extruder temperature | 210°C (maximum can be set to 260°C). |

| Heating plate temperature | 60-120 ° C (actual warming in winter and summer corresponding cooling). |

| Recommended ambient temperature | ≥25°C. |

| Power Requirements | 220V, 250W, 50Hz, 0.89A |

| Connection | TF card or USB |

| Print file format | STL, G-code |

| Compatible | Windows, Linux, Mac |

| Features | CE, FCC: CE, FC, ROHS |

| Unit weight | 7.5 kg |

| Equipment size | 430x440x400 mm |

| Package size | 440x340x190mm |

| Package Automatic platform | This is a standard package (print area 200x200x200, heated bed, one extruder (bowden). No auto-leveling (mechanical Z-limits and wing nuts for table leveling) + automatic platform. Adds inductive sensor for Z-axis. Includes 2 rolls of filament as a gift |

A little sweat with the assembly, you get a pretty good 3D printer made of aluminum profile and V-rollers, with a square heated table and Cartesian coordinate system, and auto-calibration in the Z axis. Extruder type: bowden with mechanism placed on the profile.

Extruder type: bowden with mechanism placed on the profile.

Profile 2020(2040) from which the frame is made is an extruded X-shaped structural profile with side dimensions of 20 mm. or 40mm. This profile is light and strong, which allows you to make a rigid frame for the printer, while the design is light and not bulky. Shafts or rails are not used, therefore, the design is simplified due to the absence of bearings, shaft holders and other things. That is, the profile also replaces the guide rails. To connect the profile, use internal L-connectors for the profile (and not just corners) and external L-corners.

In addition to the profile, the printer has a number of other advantages - this is the presence of a heated table, and the size of the print area is about 220x270x260. The heated table allows you to get high-quality models when printing with ABS plastic (not all printers are capable of producing high-quality printing with this material),

Facebook user group. There are many upgrades, both mechanical and software, which gives you the opportunity to completely customize the printer to your needs.

There are many upgrades, both mechanical and software, which gives you the opportunity to completely customize the printer to your needs.

Tevo Tarantula 3D Printer Enhancers

It's no secret that stable 3D printing requires a lovingly tuned rigid frame 3D printer. Tevo Tarantula has "children's" sores, which are very desirable to eliminate during assembly. Namely, to increase the rigidity of its aluminum frame.

Buy Tevo Tarantula

Initially, Tevo Tarantula comes with a frame made of plastic (acrylic) connectors, which are replaced with metal parts when finalized: laser-cut corners, brackets, holders and carriages.

I recommend the profile group Aluminum parts 3D printer TEVO Tarantula

The list of improvements is not very large, but it is desirable to complete it completely.

This is the replacement of the acrylic table holder (sore spot), the replacement of motor and roller brackets, the replacement of carriages, and the installation of a second motor on the Z axis.

Standard and retrofit kits available.

This kit is made of durable aluminum to replace the original acrylic bottom brackets and connectors. Aluminum parts ensure the rigidity of the frame connection and the strength of the structure as a whole. As a result, the printer will not require frequent calibration and will delight owners with stable and accurate printing for a long time. The modernized kit differs from the standard one by the presence of X and Y belt tensioners, as well as the ability to install all axles both on rollers and on rails.

Lucky - if the kit is purchased before starting to assemble the printer.

If the printer is already assembled, then to replace the plastic carriages, it will be necessary to sort out the corresponding units according to the instructions. It won't take much time, but the result will be simply stunning.

This carriage replaced the plastic table holder, which was broken several times in my version. Acrylic is not the best choice for a 3D printer, I recommend replacing all such “weak” points with aluminum parts.

All parts are made of aluminum alloy AMG3 with corrosion protection (thickness - 4 mm) by laser cutting.

Kit before assembly.

The photo shows the roller holder with tensioner from the upgraded kit. Provides accurate adjustment of the GT2-6 belt tension, which was sorely lacking in the original version.

In addition, all acrylic corners on the frame are replaced with aluminum ones from the kit.

Aluminum motor holders

An aluminum T8 nut holder is installed along the Z axis (similarly, a weak point in the printer).

The choice of a kit with one or two extruders is worth paying attention to. This is a good opportunity to add a second extruder to your printer.

Photo shows carriage X with one extruder.

The photo shows a 3D printer with a second extruder carriage installed.

Aluminum table carriage. The photo uses insulation for the table MK3

Appearance of the assembled 3D printer.