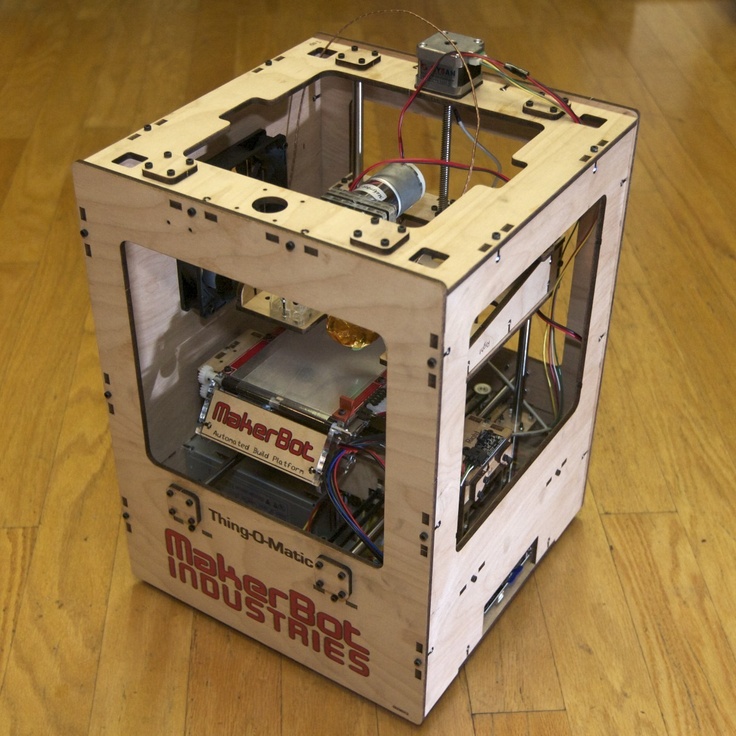

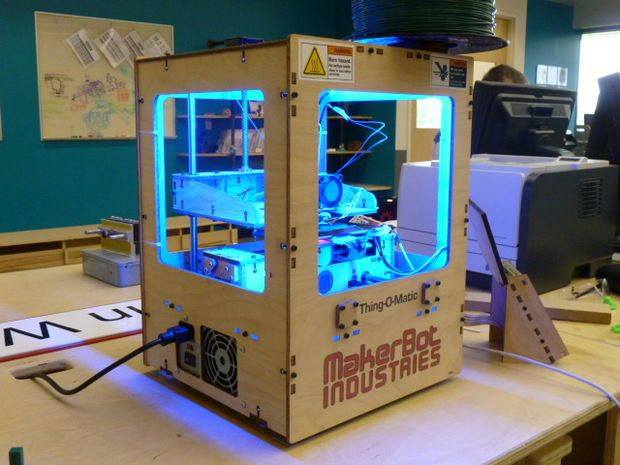

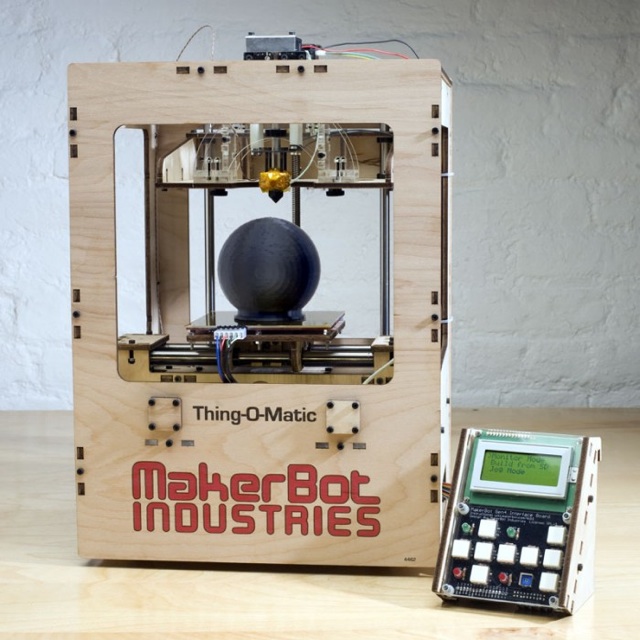

Makerbot industries thing o matic 3d printer

MakerWare 2.1.0 Now Available, With Thing-O-Matic Support

| by MakerBot

Version 2.1.0 of MakerWare is now available for download. This latest version of our 3D printing preparation software includes support for the MakerBot Thing-O-Matic, our second generation 3D printer released in 2010. We’re glad to offer this integration for some of our long-time customers, who have contributed significantly to the MakerBot community.

What’s New in MakerWare 2.1.0 Besides support for the Thing-O-Matic, there are some changes and a bunch of bug fixes for MakerBot Replicator, Replicator 2, and Replicator 2X users. In our testing and in your feedback, we’ve seen that some prints need extra help to stick to the build plate, so we’ve included an update to the rafts feature. Now when you choose to use a raft, the MakerBot Slicing Engine will code the first layer of the raft to print much slower than the rest of the layers. This really helps adhesion. Another feature requested by our customers is the ability to heat the build plate on the MakerBot Replicator and Replicator 2X when using PLA. This is now possible in MakerWare 2.1.0. We’ve tested this in-house and had some success. If you’ve been experimenting with using a heated build plate with PLA, tell us about your experience in the comments. In other news, the MakerWare interface got a nice design refresh that we think you’ll enjoy. Click below to see the full release notes and to learn more about using MakerWare for your Thing-O-Matic.

New features in MakerWare 2.1.0

-

Thing-O-Matic now supported in MakerWare.

-

The raft base prints at a slower speed when using MakerBot Slicing Engine (12 mm/second).

-

Users can now heat the build platform when printing with PLA on a MakerBot Replicator or Replicator 2X.

-

The Settings button has been removed from the upper right corner of the screen. The Settings option has been moved to the Edit menu.

-

The design of the buttons within main MakerWare user interface has been refreshed.

Bug Fixes in MakerWare 2.1.0

-

A Windows registry key fix for users unable to connect to a MakerBot over USB.

-

Changed the Mac installer to address installation issues on some Snow Leopard machines.

-

Users are warned if they attempt to save .x3g files with names too long for the firmware (>30 characters), and the filename is automatically truncated.

- MakerWare performs a more complete reset if user attempts to reset the motherboard.

-

Fixed dual extrusion long retract to reset the filament distance in order to reduce blobbing.

-

Fixed the example Chain_Linked file to print correctly at default settings.

-

Fixed the ‘Uniform scaling’ checkbox bug in Windows XP.

-

Fix for excessive memory usage during the verification stage.

-

Adjusted the Skeinforge custom profile defaults to print better on MakerBots (removed rafts and support as default during dual extrusion).

-

Exported gcode now has variables replaced with appropriate values.

Using MakerWare with a MakerBot Thing-O-Matic

Under the MakerBots menu in the MakerWare toolbar, set your Type of MakerBot to Thing-O-Matic. Then you will have the option to open a Control Panel. If your machine is connected to your computer via USB, it will show up as either “Arduino Mega” or “FTDI”. Highlight the entry and click “Connect”; this will change the name of the entry to “Thing-O-Matic” and allow you to operate your machine. Click “Direct Controls” to change filament and manage build plate settings. You can also run the calibration script from this dialog box. Once these steps are complete, you are ready to use MakerWare normally. Open files into the virtual build space and use the Make It menu to start printing. For more on MakerWare, click here. With the Thing-O-Matic setting in MakerWare, you can:

Highlight the entry and click “Connect”; this will change the name of the entry to “Thing-O-Matic” and allow you to operate your machine. Click “Direct Controls” to change filament and manage build plate settings. You can also run the calibration script from this dialog box. Once these steps are complete, you are ready to use MakerWare normally. Open files into the virtual build space and use the Make It menu to start printing. For more on MakerWare, click here. With the Thing-O-Matic setting in MakerWare, you can:

-

Work within the Thing-O-Matic build volume.

-

Place multiple separate files objects on the build plate at once.

-

Print from your Thing-O-Matic over USB.

-

Print from an SD card using a Gen4 LCD interface.

-

Adjust onboard preferences.

-

Load/Unload filament.

-

Run the Thing-O-Matic calibration script.

-

Export to s3g, x3g, and gcode files.

-

Work with Thing-O-Matic running Sailfish 4.1, 4.2, or 4.3 Firmware.

- Update Firmware to Sailfish 4.1.

Congrats! You read to the end. If you have more technical questions about using MakerWare with a MakerBot Thing-O-Matic, check out the documentation page here. Otherwise, head over to Thingiverse and find your favorite Collection of things to make with your new MakerWare download.

Thing-O-Matic Makerbot – University of Toronto Scientific Instruments Collection

IHPST

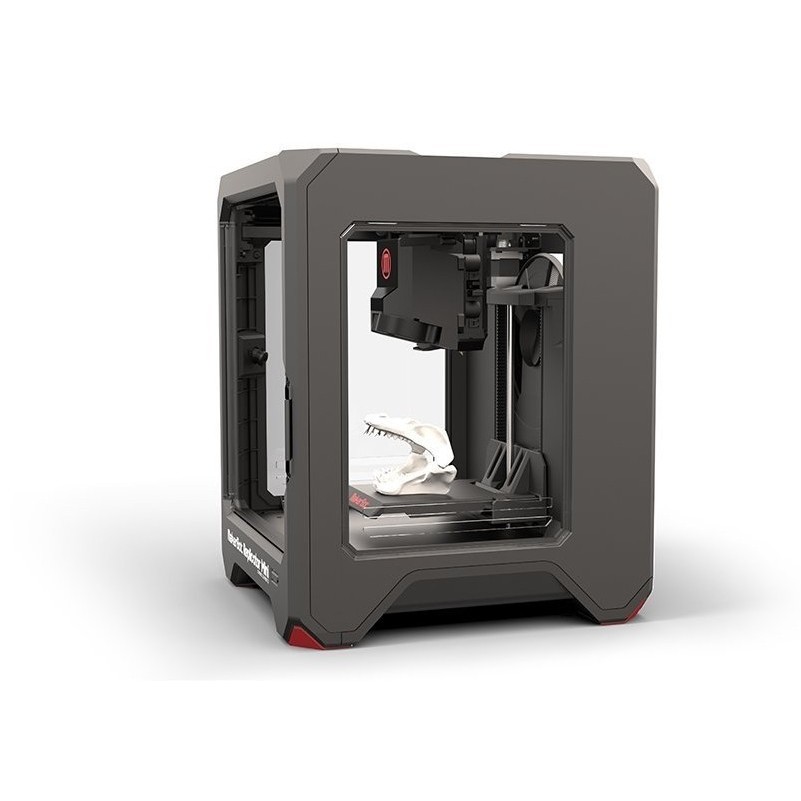

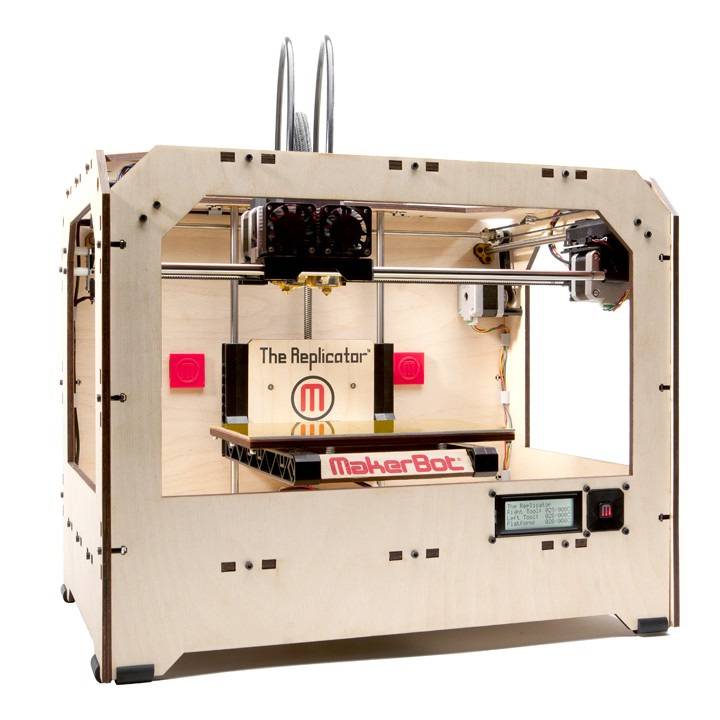

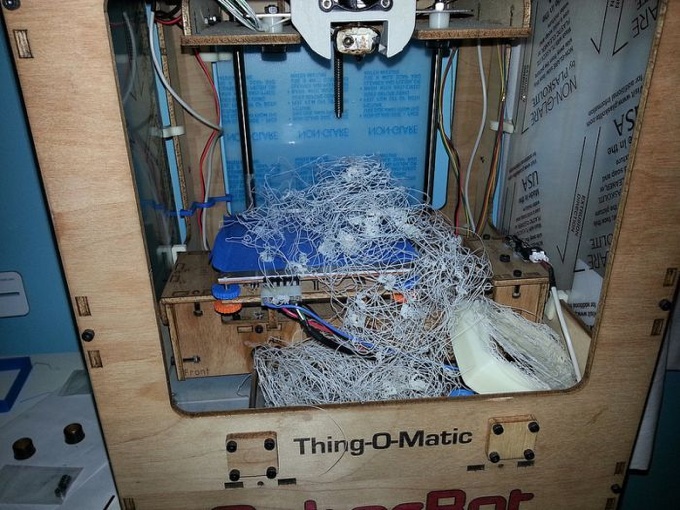

The Thing-O-Matic is a 3D printer which was released by Makerbot in 2010.

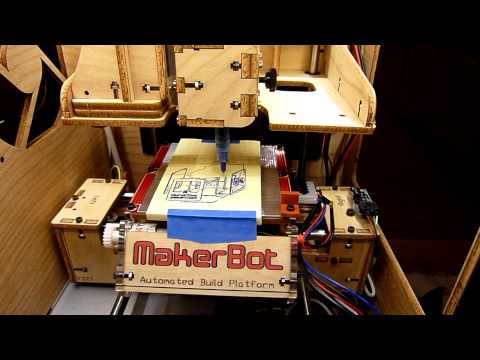

This model includes the supplemental “automated build platform,” a movable belt system incorporated into the build platform that was meant to automatically release a finished print in order to permit serial printing.

The original model was designed to have all electronics secured inside the bottom of the device, but this custom assembly includes a separate detached compartment with the electronics, allowing for easier troubleshooting. It was assembled by Gabby Resch, a PhD candidate at the Semaphore research cluster at the University of Toronto Faculty of Information.

Gabby Resch describes 3D printing, and his experience assembling and using the Thing-O-Matic in this video.

Accession Number: 2016.ihpst.32

Alternative Name: 3D Printer

Primary Materials:

Plyood, steel, plastic, electronic components

Markings:

Factory labelling reading “ThingOMatic” and “Makerbot Industries” has been painted on various surfaces. An additional sticker reading “Children’s own media museum” has been fixed to one side.

Dimensions (cm):

Width = 30, Length = 60, Height = 40 (with external case placed beside the printer, lid closed)

Function:

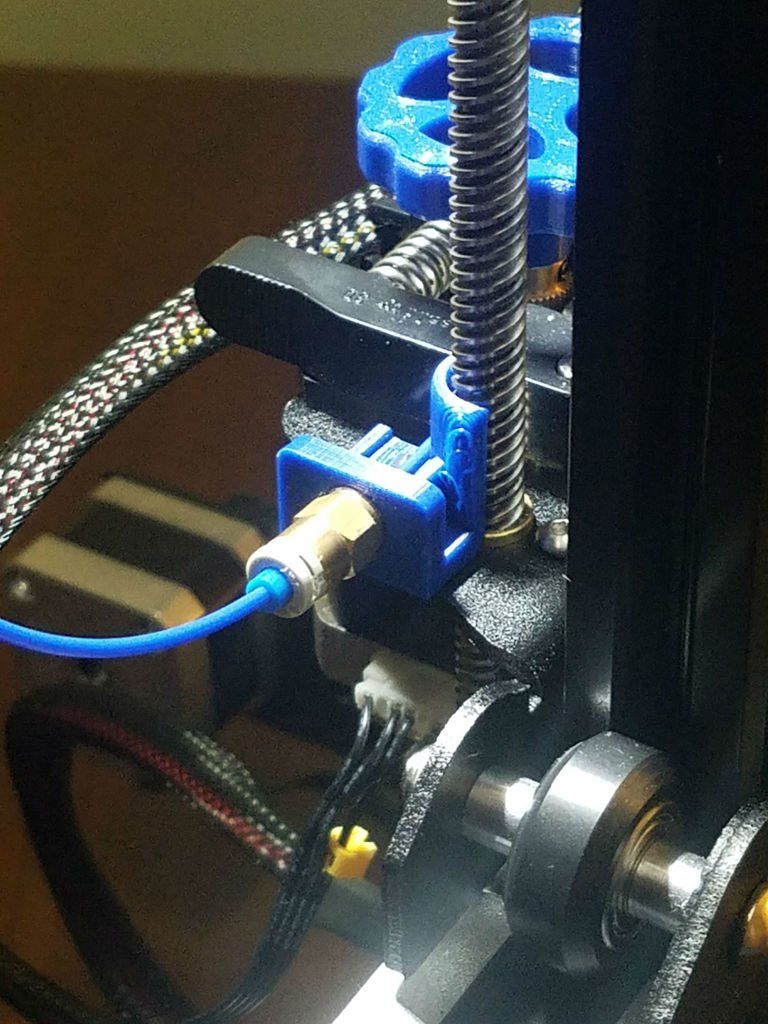

A printer, based on the fused deposition modelling (FDM) principle, that creates objects by extruding layers of plastic onto a platform through a heated nozzle. In this instrument, the build platform moves along the x and y axes relative to a print head. The print head is raised and lowered along the z axis.

In this instrument, the build platform moves along the x and y axes relative to a print head. The print head is raised and lowered along the z axis.

Condition:

This machine is well-used and has many visible signs of wear and tear, repair, and customization.

Associated Instruments:

3D printed medical models (on display for Made in Toronto Exhibit)

Manufacturer: Makerbot Industries

Date of Manufacture: 2010

Provenance:

This machine was used at the Semaphore Critical Making Lab of the University of Toronto’s Faculty of Information, and was used primarily for demonstrative purposes.

It was the first 3D printer used at the Semaphore Critical Making Lab and served as an introductory device to the practice of 3D printing for researchers at the lab.

This object was acquired by UTSIC in 2016.

Additional Information and References:

This object was part of the “Made in Toronto” exhibit April 2016-April 2017. Gabby Resch also ran a 3D printing demonstration at the opening reception, and was interviewed on his research and work with 3D printing, within the context of a series of interviews on the makers of scientific materials at the University of Toronto.

The videos from this interview can be found here: <a href=”https://utsic.org/2016/03/08/critical-making-gabby-resch/”>https://utsic.org/2016/03/08/critical-making-gabby-resch/</a>

For more information on the Makerbot company: <a href=”https://www.makerbot.com/”>https://www.makerbot.com/</a>

For more information on the Critical Making Lab: <a href=”http://criticalmaking.com/”>http://criticalmaking.com/</a>

Historical Notes:

The Thing-O-Matic by Makerbot was the first 3D printer to be widely manufactured and sold at a price that was generally affordable to consumers. The FDM technology on which it was based was much cheaper and simpler than the technologies used in existing commercial printers. Its lower quality prints, with the characteristic visible striations produced by early FDM printers, were acceptable to hobbyists excited at the possibilities of 3D printing.

The Thing-O-Matic was open source technology. It was designed to be assembled and modified by its users–a principle embodied in the considerable modifications made to this unit.

The 2013 acquisition of the Makerbot company by market incumbent Stratasys Incorporated, led to Makerbot’s move away from open source technology. This shift caused controversy both within the company and among Makerbot owners and fans.

Themes:

Flags:

- Donated to UTSIC

MakerBot Industries, LLC 3D Printers

For

For

Professional

Industrial

Personal

Commercial

3D printer type

3D printer type

Tabletop

Food

Professional

For home

Chocolate

Jewelry

Russian

Reprap

Dental

Full color

Industrial

Not expensive

Medical

For training

Material type

Material type

Plastic

606

Metal

50

Photopolymer

245

Other

144

Manufacturer

Manufacturer

3D Systems

84

PICASO 3D

8

Stratasys Ltd

38

Leapfrog BV

6

EnvisionTEC

51

Myriwell

4

3D-Experts

3

PrintBox3D

4

FELIXrobotics

11

Solidoodle

8

WANHAO

32

ROKIT

5

SeeMeCNC

4

mUVe 3D LLC

1

RepRapPro

5

Formlabs

9

Afinia

1

Airwolf 3D

6

Type A Machines

2

iRapid

1

RoBo 3D Printer

3

Mixshop Inc

4

IonCoreLtd

1

Old World Laboratories

1

XYZprinting

13

Panowin Technologies Co. , Ltd.

, Ltd.

2

MiiCraft

7

Portabee 3D Printer

2

Zeepro

1

Pirate 3D

1

Qualup SAS

2

BEETHEFIRST

3

Heacent

2

Robot Factory

2

Kuhling&Kuhling

1

3Dfactories

3

Tangible Engineering USA Corporation

1

DWS Lab

1

Sedgwick

2

3DJoy

4

Futura Elettronica

1

Makible Ltd

2

ALT Design

1

Active 3D

2

Trinitylabs

1

Sumpod Ltd.

4

Brahma3

1

Hyrel 3D

5

Omni3D

4

BCN3D Technologies

7

Boots Industries

2

ORD Solutions

2

Ironvault

1

2PrintBeta

3

Unique Design

3

Hot Proceed

1

3DD Plas

2

York3dPrinters

1

Code-P

4

Deezmaker

3

Ruian Maitian Network Technology Co

2

CB-Printer

1

Print Technologies Pty Ltd.

5

MaukCC

1

Choc Edge Ltd

2

Shenzhen WeisTek Co.,Ltd

5

Delta Tower

2

Tegelbeckers Ltd

1

Deltaprinter

1

MindKits

1

Robot Co, Ltd

1

Romscraj

2

Fabmaker

1

Peerbhai Robotic

1

Sintermask GmbH

1

KL Services Group Inc

1

Fochif Mechatronics Technology Co. , Ltd

, Ltd

4

Teil3

1

Maker's Tool Works, LLC.

2

Gaminu

1

re:3D

1

inDimension3

4

Acuity Design

1

Essential Dynamics

1

Isis3D

1

Velleman

1

Kentstrapper

4

Blue Eagle Labs

1

Gubbels Engineering

2

Zortrax

8

3dBotic

1

MakerGear, LLC

1

Jelwek

1

it is 3D

2

Cablysa Systems, S. L.

L.

3

Ac123Dc

1

E3D Online

1

Hydraraptor

1

MakerBot Industries, LLC

8

Delta Micro Factory Corporation

3

Ultimaker B.V.

11

Solidscape Inc.

8

MBot3D

4

B9Creations

4

Jinhua Flashforge Technology Co., Ltd

26

Tinkerine Studio Ltd

3

Aleph Objects Inc.

4

DeltaMaker

1

Reprap Austria

3

IC3D LLC.

1

Ultibots, LLC.

2

Intelligent Machine Inc.

1

Metamaquina

1

Shenzhen Mootooh Engineering Co., Ltd.

1

Multitec GmbH

3

German RepRap GmbH

3

Sharebot

17

Nova 3D

1

QU-BD Inc.

4

RDMCU

1

Full Spectrum Laser LLC

1

PieceMaker Technologies

1

Printbot, Inc.

7

Terawatt Industries

1

botObjects

1

Lunavast

2

Maker Farm

3

NWRepRap

1

eMotion Tech

1

Printed Worlds

1

Reprapsource

1

Twelvepro Co

1

Replicator Warehouse

1

Stellamove Inc.

1

Make Mendel

6

Rapide 3D

2

Makealo

1

Crew Ltd.

1

Open cube

1

3D Kits

1

Coombes Solutions Ltd.

1

SHARK Limited Partnership

1

Smartfriendz

1

3D Monster

1

Kikai Labs

2

THY3D

1

Tantillus

1

RepRap Diffusion

1

QSQM International Co.

1

Tumaker

1

Makism 3D Corp.

3

3dBotZ

1

ZMorph 3d

1

Eckertech Inc.

1

Imec Proto

6

miniFactory Oy Ltd

1

printMATE 3D

1

CMET Inc.

5

Arcam AB

6

3Geometry Manufacturing Systems Pvt Ltd

8

Electro Optical Systems

15

Trump Precision Machinery Co. , Ltd

, Ltd

4

Wuhan Binhu Mechanical & Electrical Co., Ltd.

11

Optomec Inc.

1

Shaanxi Hengtong Intelligent Machine Co., Ltd.

9

Matsuura Machinery Corporation

1

ExOne Company, LLC

6

Concept Laser GmbH

9

Instrument Tech Co, Ltd

7

UnionTech

8

Renishaw plc

2

D-MEC Ltd.

3

Realizer GmbH

5

SLM Solutions GmbH

5

Fabriconic LLC

3

Mark Forged

8

Keyence Corporation

2

SYS + ENG

1

Lithoz GmbH

1

DWS s.r.l.

12

Beijing TierTime Technology Co. Ltd

17

Carima

3

Mcor Technologies Ltd.

3

Asiga

11

Rapid Shape GmbH

14

solido ltd.

1

Blueprinter ApS

1

Kevvox Pte Ltd.

2

JER Education Technology Co., Ltd

1

Azuma Engineering Machinery Inc.

2

Space Monkey

1

Trimaker

1

Most Fun

1

Iniciativas 3D

1

IdeaLab 3d

1

MendBot Labs

Bonsai Lab

2

MakerDreams

1

i3Dbot Co. , Ltd

, Ltd

2

Natural Machines

1

Cyrus3D

ITALYmaker

Something3D

Cagelli Distribution

E Crew Vis

BigRep GmbH

2

Voxeljet Technology GmbH

5

Sciaky Inc.

Mankati

4

F&B rapid production

3

3DQuality

17

Workshop Churyumov

2

Unimix

2

Center for Additive Technologies

3

ENNOVA

1

Exclusive Solutions

2

Magnum

5

SHEKLA

1

D-Force

3

BigRep

4

Roland

1

Alphabet 3D

2

MAKEX

1

3D Master Kit

7

Shining 3D

25

3NOVATICA

3

AVS Robotics

1

IMPRINTA

11

Createbot

5

AIO Robotics

1

RK-3D

1

SPETSAVIA

3

3DiY

14

Wonwall

1

Apium Additive Technologies

3

3DSUN

1

Cheap3D

1

3rd

1

EGL3D

1

Creality 3D

42

UNIMATECH

2

VolgoBot

3

ZVER 3D

3

Zenith

2

MicroFactory

1

Hewlett Packard

2

Shenzhen Anet Technology Co Ltd

15

MASS PORTAL SIA

11

Cyberon

2

PHOTOCENTRIC

2

TotalZ

11

3dcon

2

Raise3D

6

OOO RUSSIAN ENGINEER

1

Vortex-3D

5

Flying bear

11

Print3D

5

ROBOINO

1

SoloPrint

1

Fun Distribution

1

Alekmaker

2

Cronos

2

TEVO 3D

9

3D printers from China

2

ZAV 3D printer

4

Epo3d

1

FLSUN 3D

3

WINBO

19

PROTOTYPE

1

UNIZ TECHNOLOGY

2

W2P Engineering GmbH

4

MAESTRO

1

Pi 3D printer

1

Shenzhen Tronxy Technology Co

23

Kelandi

1

Geeetech

21

3DCeram

2

Omaker

1

Builder 3D Printers

6

Creatable Labs

1

ROBOZE

3

Desktop Metal

1

Sintratec

2

CreatBot

10

ANYCUBIC

29

3dlaboratorio

2

OOO SPC "Lasers and Equipment"

2

Prusa Research

6

Prismlab

3

ivilol

2

Geralkom-3D

7

EqMex

1

Tsar3D

2

Zhuhai CTC Electronic Co. , Ltd

, Ltd

3

Shenzhen Aurora Technology Co., Ltd

6

Monoprice

1

Shenzhen Salon Technologies Co., Ltd.

1

Shenzhen Sundystar Technology Co., Ltd

2

Shenzhen Easythreed Technology Co., Ltd

1

WOW Innovation Technology Co., Ltd.

2

Jinhua Xingzhe 3D Technology Co., Ltd

1

Shenzhen Zhongxin Microscience Software Co., Ltd.

1

Shenzhen Yaying Trading Co. , Ltd

, Ltd

5

Z Bolt Co.

2

Anisoprint

1

Shanghai 3D ARTEL Science and Technology Co.

3

FABERANT 3D printers

1

Self-assembly 3D printers

4

Z Rapid Tech

21

Zonestar

13

3DGence

3

BLB Industries

1

Hard Light

1

Stereotech

2

TPM3D

7

Artillery

4

Phrozen Tech Co. , Ltd.

, Ltd.

8

INDIGO 3D

1

Aconity3d

6

OR Laser

3

Farsoon Technologies

5

QIDI Technology

11

Shenzhen Twotrees Technology Co., Ltd.

7

Mingda

18

Elegoo

14

Longer

9

Sunhockey

2

DUPAS3D

1

Kelant

5

Voxelab

3

DIYMARIA

1

VSHAPER

CREASEE

CNC Barcenas

5

Vistar

11

Kingroon

1

IdeaFormer

3

F2 Innovations

3

Sindoh

8

Eplus3D

8

Print Technology

Print Technology

Plastic Jet Printing (PJP)

8

MultiJet Modeling (MJM) Technology

1

SLA printing technology

Sterolithography (SLA) technology

2

Film Transfer Imaging (FTI)

MultiJet Printing (MJP)

20

Multi-Jet Modeling (MJM) Technology

2

Stereolithography (SLA)

115

Selective Laser Sintering (SLS)

65

Direct Metal Sintering (DMS)

6

Granular

5

Fused deposition modeling (FDM/FFF)

962

DoD/SCP Technology

6

PolyJet 3D printing Technology

19

The EnvisionTEC 3D-Bioplotter 3D printing technique

2

Direct Light Projection (DLP)

31

Photopolymerization

Digital Light Projection (DLP)

5

Digital Light Processing (DLP)

64

Additive Layer Manufacturing (ALM)

2

Laser Stereolithography (LSLA)

1

Direct Light Processing (DLP)

1

Electron Beam Melting (EBM)

6

Laser welding CLAD

6

Laser sintering (LS)

4

Layer by layer manufacturing (LOM)

5

Selective laser melting (SLM)

31

Laser Engineered Net Shaping (LENS)

1

Direct Metal Laser Sintering (DMLS)

11

Laser metal melting (LC)

10

Direct Metal Tooling (DMT)

7

Solid Creation System (SCS)

3

Ultrasonic Additive Manufacturing (UAM)

3

Composite Filament Fabrication (CFF)

1

Drop on Demand (DOD)

1

Lithography Ceramic Manufacturing

1

Melted and Extruded Modeling (MEM)

7

Drop-On-Demand (DOD)

Sliding Separation Process (SSP)

9

Smooth Curvature Printing (SCP)

2

Plastic Sheet Lamination (PSL)

1

Selective Heat Sintering (SHS)

1

ColorJet Printing (CJP)

7

Micro-SLA

1

DLP-SLA

3

WDM (Layer Waxing)

2

SLA-sla

Direct Metal Printing (DMP)

7

HP Multi Jet Fusion technology

2

3D Daylight Polymer Printing (DPP)

2

Smart-Positioning-System Technology (SPS)

2

LCD Stereolithography

62

UV LED DLP

4

Single Pass Jetting (SPJ)

1

Atomic Diffusion Additive Manufacturing (ADAM)

1

bioprinting

3

Powder Binder Jetting (PBJ)

10

Reset Filters

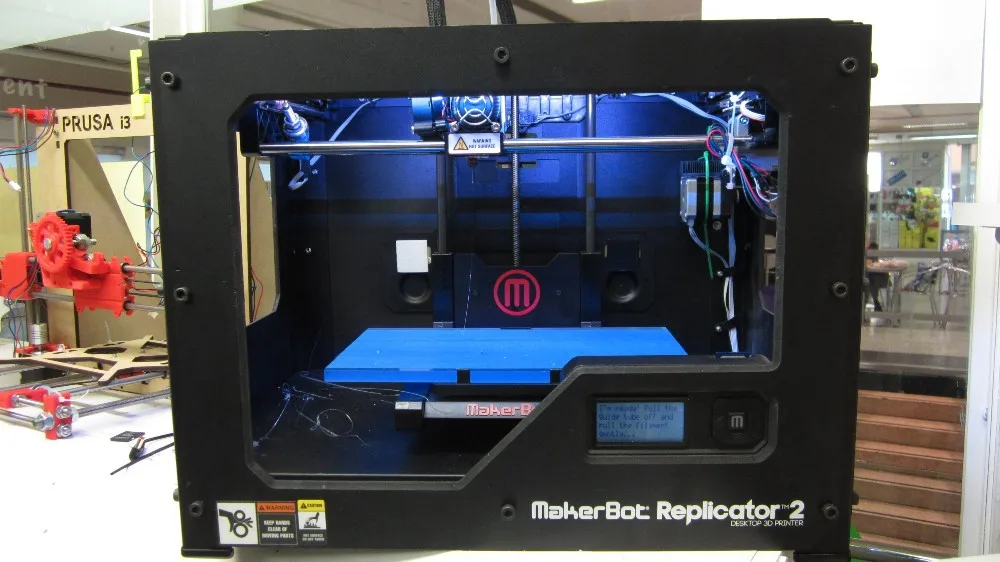

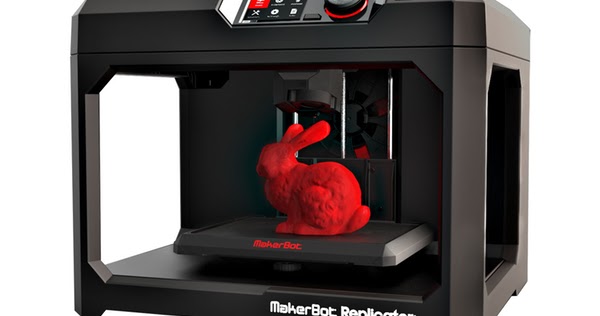

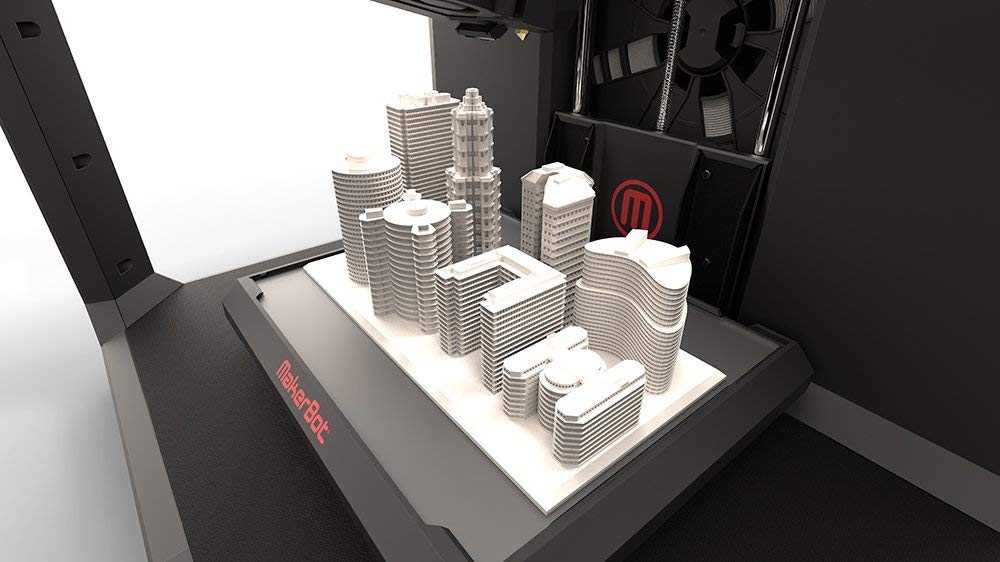

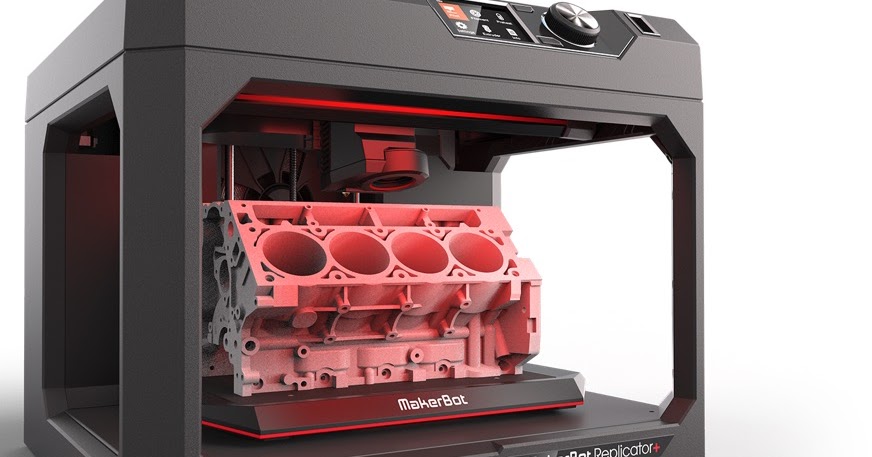

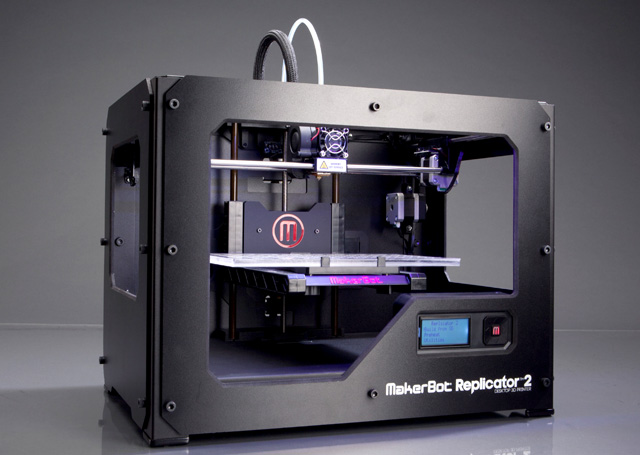

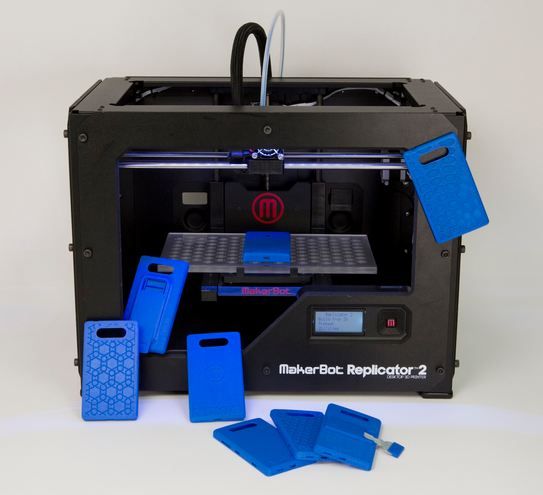

MakerBot Replicator 3D Printer by MakerBot Industries, LLC The Makerbot Replicator is one of the most popular desktop 3D printers and has spawned many imitations around the world.

Since its inception, the design of the printer has been constantly improved: the fifth generation of the popular device is currently being released. The printer is designed to print with polylactide (PLA) using a single extruder. The maximum size of manufactured models reaches 252x199x150mm with a minimum applied layer thickness of 100µm. The printer is equipped with a control module with LCD screen, USB port, wireless connection (Wi-Fi) and Ethernet interface.

Since its inception, the design of the printer has been constantly improved: the fifth generation of the popular device is currently being released. The printer is designed to print with polylactide (PLA) using a single extruder. The maximum size of manufactured models reaches 252x199x150mm with a minimum applied layer thickness of 100µm. The printer is equipped with a control module with LCD screen, USB port, wireless connection (Wi-Fi) and Ethernet interface. About the MakerBot Replicator

MakerBot welcomed 2014 with a new range officially classified as "5th Generation". This includes the new compact MakerBot Mini printer, its exact opposite of the MakerBot Z18 (the name directly refers to the height of the working area of 18 inches, i.e. 455mm) for printing large objects and, of course, the updated flagship and golden mean - MakerBot Replicator.

Here it is, handsome

Don't be confused by the name of the model - the new Replicator is the development of the Replicator 2 printer. The company deliberately did not call it Replicator 3, but instead introduced the concept of generations. Thus, the Replicator 2 belongs to the fourth generation, and the new printer - to the fifth.

The company deliberately did not call it Replicator 3, but instead introduced the concept of generations. Thus, the Replicator 2 belongs to the fourth generation, and the new printer - to the fifth.

This option has a lot of interesting and quite rational ideas, although the result can hardly be called ideal. So:

Design

The appearance of the printer gives the impression of a high-tech gadget, which is what the Replicator is. While maintaining the black, matte severity of the Replicator 2, the new device was “licked” - the panels disappeared, the supporting steel frame was hidden in a smoothed plastic lining. The first optimization is visible to the naked eye: the control module has moved from its usual place in the lower right corner to the top, which makes its use much more convenient. Despite rumors about the touch screen, the display remained just liquid crystal, but color. But the large rotary knob is very convenient, reminiscent of the smoothness of the volume controls on expensive stereos.

Magnetically mounted smart extruder

The new version of the extruder is smart: built-in electronics allow the printer to detect when a consumable is running low and alert the user. This moment alone deserves huge praise for the designers. No printing "over the air" and decommissioned semi-finished models - received a warning, changed the coil, continued printing. Wonderful.

The “jumping nozzle” is also interesting: when changing the horizontal position without printing (for example, when layering individual fragments on the same level), the platform movement is no longer required to distance the layer from the nozzle and prevent smearing of freshly applied plastic. Instead of a platform, the nozzle itself comes into motion. The extrusion stops, the nozzle rises, separating from the applied plastic, the print head moves to a new position, the nozzle lowers and printing continues. This approach theoretically allows for higher Z-axis accuracy and higher print speeds. As for the mechanism of movement of the nozzle, it is extremely simple: the feed mechanism simply turns on the “reverse speed”, and the plastic thread pulls the nozzle up with it.

As for the mechanism of movement of the nozzle, it is extremely simple: the feed mechanism simply turns on the “reverse speed”, and the plastic thread pulls the nozzle up with it.

The third interesting element was the Hall sensor built into the print head. The platform calibration procedure has become much easier. Now tilt adjustment is carried out using two large, comfortable handles. The sensor in the head tells you when one or another edge of the platform reaches the optimal position. The light came on - it means that the slope is eliminated. The same for the perpendicular axis, and the calibration is complete. But why not put two servomotors instead of handles and make the process fully automatic?

The disadvantage of the new extruder is its relative complexity. In fact, it is not designed to be repaired on its own. If the nozzle becomes clogged, then the entire extruder will most likely have to be replaced with a new one or the old one should be sent to a service center, which is a problem in Russia. The good news is that detaching the assembly is exceptionally simple: the extruder is held in place with fairly powerful magnets. You just need to apply enough force, and the whole assembly separates. I stuck a new extruder in its place, threaded the thread, continued working.

The good news is that detaching the assembly is exceptionally simple: the extruder is held in place with fairly powerful magnets. You just need to apply enough force, and the whole assembly separates. I stuck a new extruder in its place, threaded the thread, continued working.

Glass platform covered with blue masking tape. An illuminated light near the nozzle indicates that the stage is properly calibrated. MakerBot deliberately sticks to the flagship concept of printing with one filament and one extruder. On the one hand, this allows you to slightly increase the size of the working area while maintaining the dimensions of the printer - after all, the more extruders, the larger the printed assembly. On the other hand, polylactide is one of the easiest materials to print, does not suffer from high shrinkage and does not emit harmful fumes due to its organic origin. Since PLA plastic is almost not subject to deformation during curing, the Replicator is not equipped with a heated platform. On the other hand, fans of "replicators" often misuse these printers, printing with ABS plastic, polystyrene, nylon and other alternative materials. Many of them require platform heating. Fortunately, purchasing such an upgrade from a third-party manufacturer is quite simple. The previous model used an acrylic worktop, but on the new version, the designers decided to use glass. In principle, both options are excellent for printing with polylactide.

On the other hand, fans of "replicators" often misuse these printers, printing with ABS plastic, polystyrene, nylon and other alternative materials. Many of them require platform heating. Fortunately, purchasing such an upgrade from a third-party manufacturer is quite simple. The previous model used an acrylic worktop, but on the new version, the designers decided to use glass. In principle, both options are excellent for printing with polylactide.

Built-in camera allows you to transfer images of the printing process to remote computers and mobile devices

Finally, for the first time, the "replicator" was equipped with a camera. The idea is to be able to control the printing process remotely. What if there's a crash? To receive images and control using a mobile device, you will have to connect the printer to the network, for which an Ethernet interface was provided. The USB port remained in place and became multifunctional, as the developers abandoned the use of memory cards in favor of flash drives. By the way, branded flash drives, as in the case of CubeX, are not required. Any drive with standard formatting will do. True, the drive is not supplied in the kit. Remote control is carried out using the MakerBot Mobile mobile application or the standard MakerBot Desktop software, and within the office, you can also use a Wi-Fi connection.

By the way, branded flash drives, as in the case of CubeX, are not required. Any drive with standard formatting will do. True, the drive is not supplied in the kit. Remote control is carried out using the MakerBot Mobile mobile application or the standard MakerBot Desktop software, and within the office, you can also use a Wi-Fi connection.

Plastic thread spools have been resized. All fifth generation MakerBot printers use thinner, larger diameter spools. This was done so that the coils fit more ergonomically into the dimensions of the devices themselves, because they are stored inside. You don't have to turn the entire printer around to change the spool: the spool slides into a drawer at the back of the printer with the mount facing forward. After installing the spool, the section drops down and the printer looks neat.

Thread spools are inserted into the drawer

Of course, no one else produces such spools except MakerBot. But! The company does not break the hands of users by forcing them to use branded cartridges, as 3D Systems did. Those who wish can use standard coils, they just have to be installed outside the printer. And the drawer section, with the guide tube attached, has a latch that holds it in the raised position. It will not look particularly attractive, but the functionality is provided. Branded thread is sold at a price of about $40 per kilogram, which is about 20% more expensive than consumer goods. But the quality is guaranteed - no dust or oval profile. Unfortunately, a rather complicated filament feed path, coupled with a narrow nozzle, creates an additional load on the pulling mechanism of the extruder. Although the designers have spring-loaded the roller, there are times when the printer simply cannot grab onto the filament. As a rule, such problems do not appear immediately.

Those who wish can use standard coils, they just have to be installed outside the printer. And the drawer section, with the guide tube attached, has a latch that holds it in the raised position. It will not look particularly attractive, but the functionality is provided. Branded thread is sold at a price of about $40 per kilogram, which is about 20% more expensive than consumer goods. But the quality is guaranteed - no dust or oval profile. Unfortunately, a rather complicated filament feed path, coupled with a narrow nozzle, creates an additional load on the pulling mechanism of the extruder. Although the designers have spring-loaded the roller, there are times when the printer simply cannot grab onto the filament. As a rule, such problems do not appear immediately.

Despite all the tricks, such as optimization of algorithms, the use of an ARM9 processor and a jumping nozzle, the new printer is noticeably slower than the Replicator 2. In one of the comparative tests, the task was to print a Lego brick. The Replicator 2 completed the task in 18 minutes, while the 5th generation "replicator" took 25! Even the inclusion process is quite long - the download takes about three minutes.

The Replicator 2 completed the task in 18 minutes, while the 5th generation "replicator" took 25! Even the inclusion process is quite long - the download takes about three minutes.

Not practical, but glamorous!

And yet, if everything works as expected, the Replicator is pleased with the good quality of the models. The printer allows you to print with a resolution of 100 microns vertically, although the thickness of the applied layer can be increased to speed up the process. Back at the office, the MakerBot team prints mostly in 200-micron layers, which is enough for most tasks, according to CEO Bree Pettis. Positioning accuracy has remained at the level of the fourth generation printers, which is good in itself: 11 microns in the X and Y axes, 2.5 microns in the Z axis.

And yes, the new Replicator informs you about the progress of the print and estimates the remaining time. This feature has been enabled due to persistent user requests. As Pettis explained, there was simply no room for it on the old hardware.

The platform has undergone significant changes. The dimensions have changed: the area of the table has slightly increased and become “square”: 252x199mm versus 285x153mm for the Replicator 2. The material of the table has been replaced with more and more popular glass, and the table itself is now attached to the platform using skids instead of clips. So it's safer and more convenient. For better adhesion of plastic to the table, a time-tested solution is used - masking tape.

Software

MakerBot Desktop software. The status bar at the bottom indicates that the printable model is 98 percent complete.

The software used is the MakerBot Desktop software package. This includes MakerWare, which made its debut on the Replicator 2 and is responsible for model processing, slicing, and other functions and settings related directly to printing. In addition, networking features have been added, including access to the Thingiverse website, which features many digital models, including free ones, uploading your own digital designs for the benefit of the community, the ability to order additional consumables, and more and more. With it, you can also receive pictures from the built-in camera or remotely control the printer. To use the software, you will have to open an account on Thingiverse, but it is not at all difficult and completely free.

With it, you can also receive pictures from the built-in camera or remotely control the printer. To use the software, you will have to open an account on Thingiverse, but it is not at all difficult and completely free.

The MakerBot Digitizer Desktop 3D Scanner and MakerBot Replicator Printer is a Chinese engineer's dream. Copy, copy!

It's worth noting that MakerBot is seriously aiming to create a 3D "ecosystem" tested by 3D Systems. This means the integration of hardware, software and networking into a single whole. If in the case of 3D Systems the ecosystem consists of Cube 3D printers, Sense 3D scanner and Cubify online service, then in the case of MakerBot we have Replicator, Digitizer and Thingiverse, respectively. Adding to the intrigue is the fact that MakerBot is actually an independent division of 3D Systems' main competitor, Stratasys.

Summary

The new "replicator" has become friendlier due to an optimized design and user-friendly software.